Controlled Nanopore Fabrication on Silicon via Surface Plasmon Polariton-Induced Laser Irradiation of Metal–Insulator–Metal Structured Films

Abstract

1. Introduction

2. Theoretical Analysis

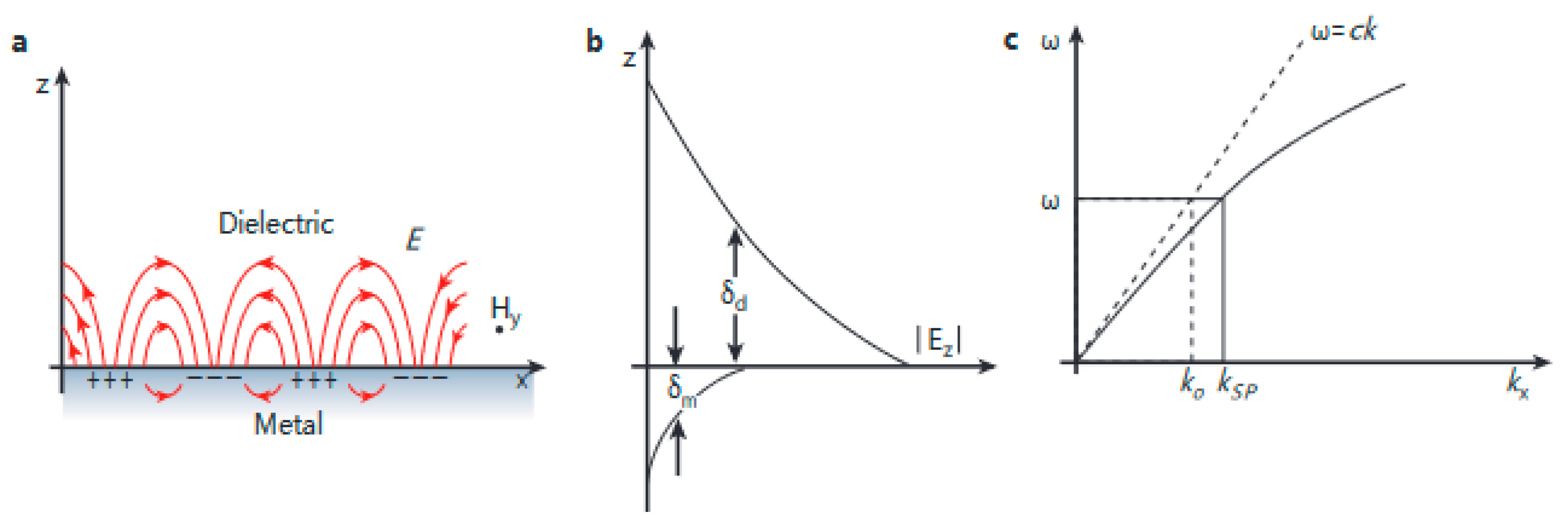

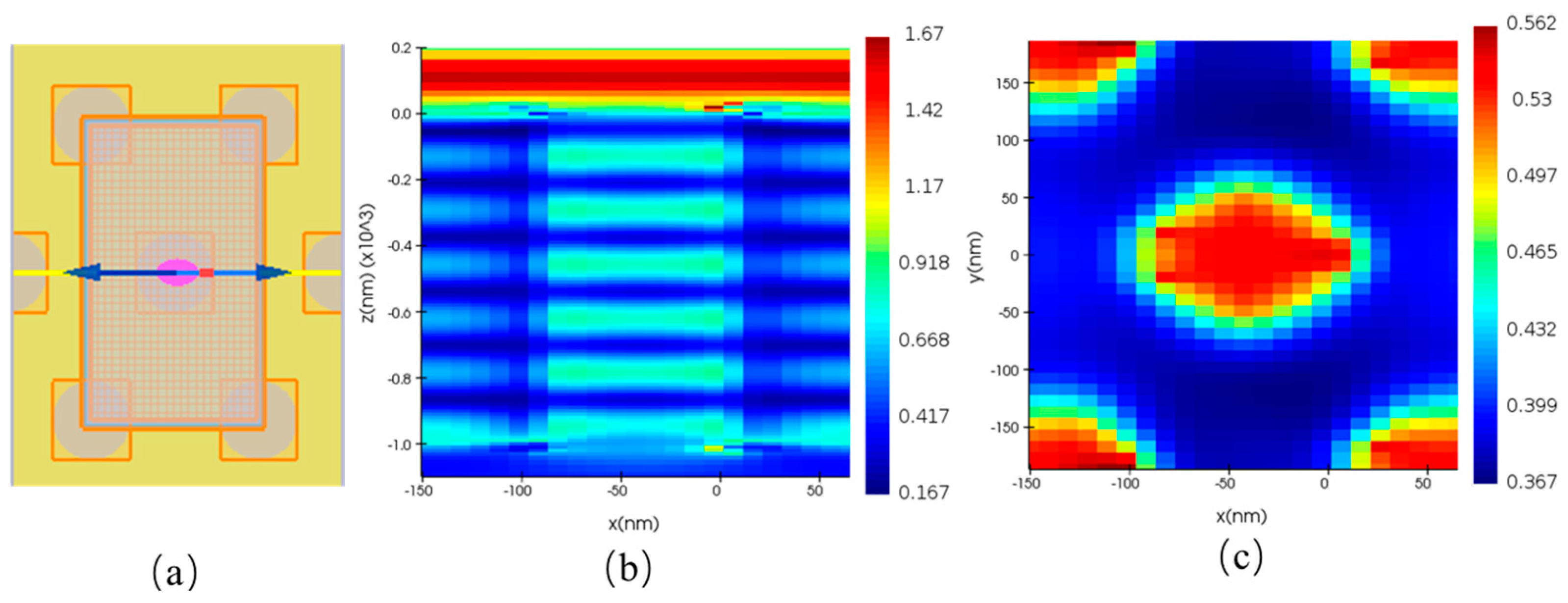

2.1. Theoretical Calculations Related to Surface Plasmas

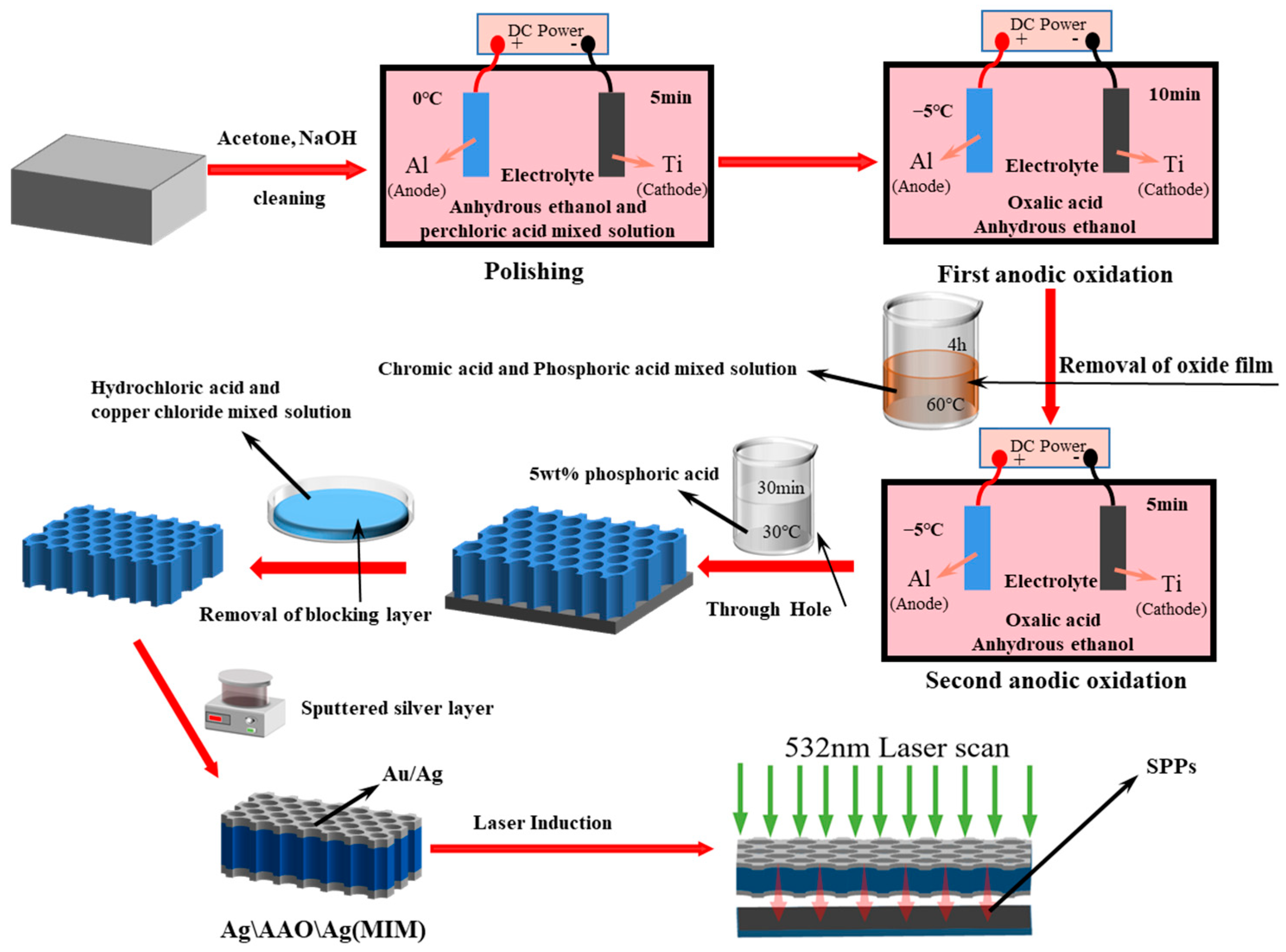

2.2. Theoretical Analysis of Porous Anodized Aluminum Oxide Preparation

2.3. Theoretical Analysis of Laser Induction

3. Experimental Procedure

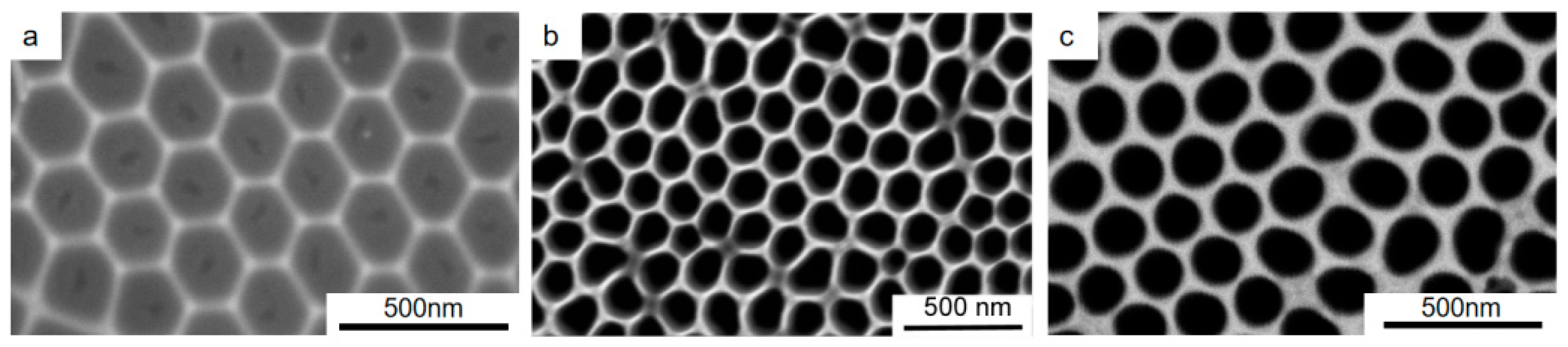

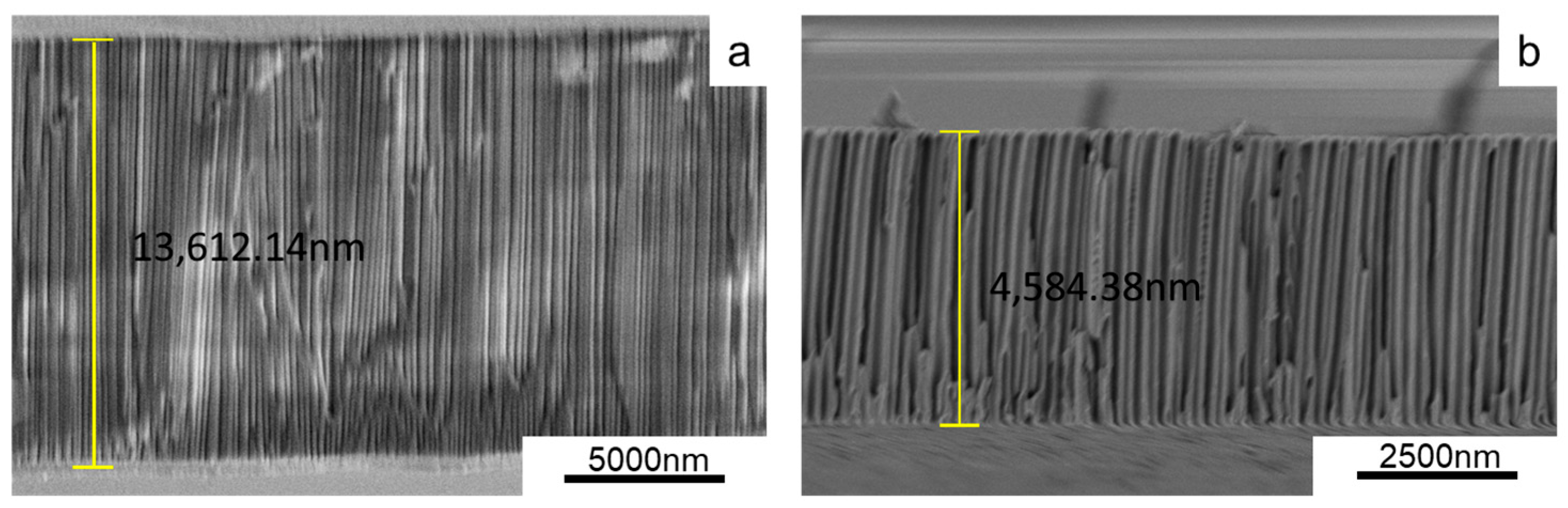

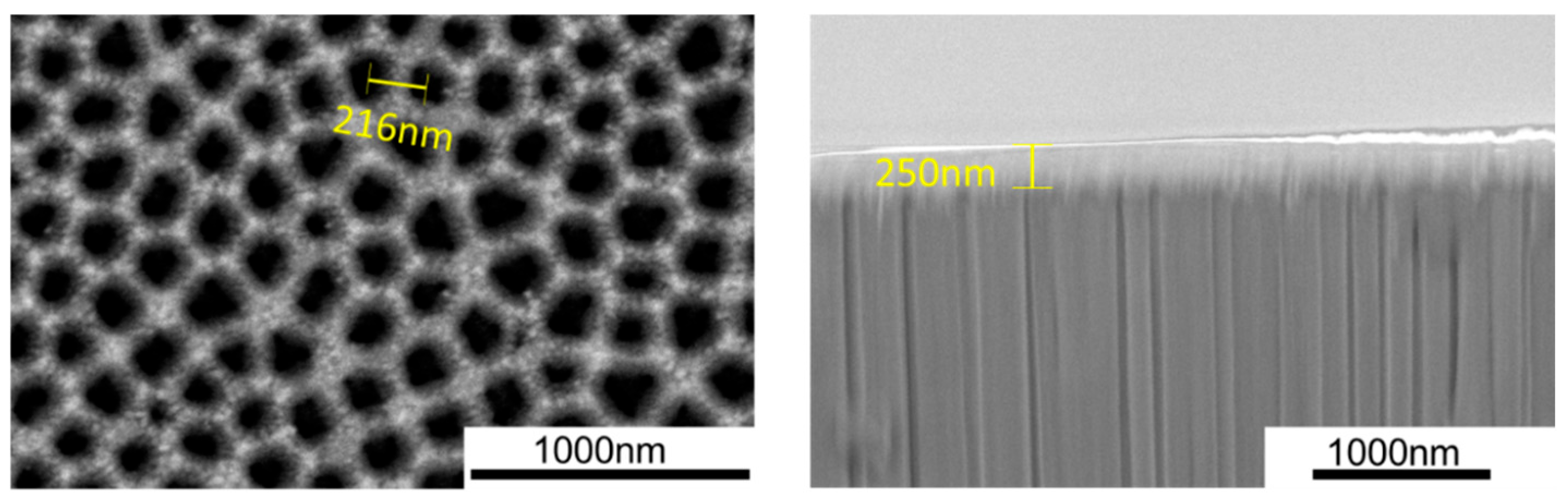

3.1. Preparation of 216 nm MIM-Type Hole Array Cycles

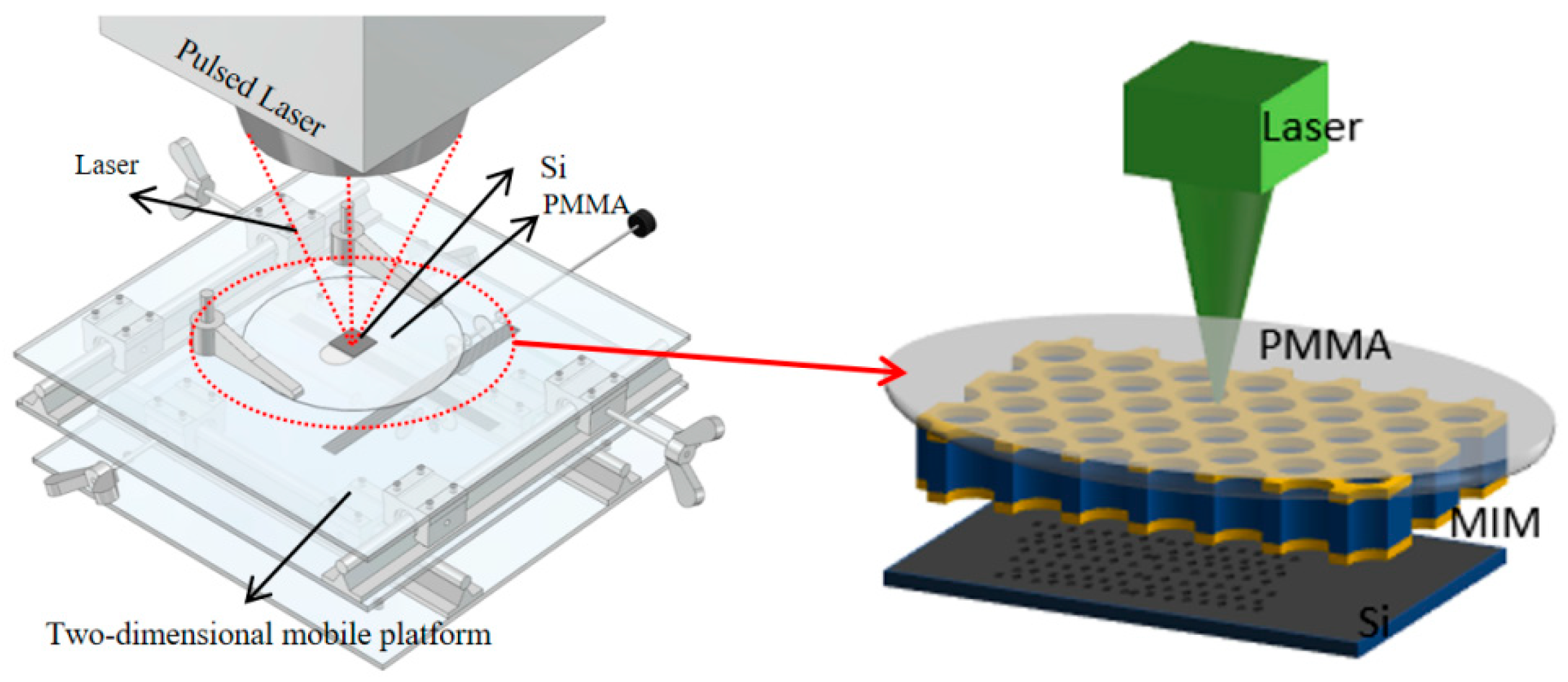

3.2. Laser-Induced Surface Plasmas for Nanopore Etching of Single Crystal Silicon

4. Results

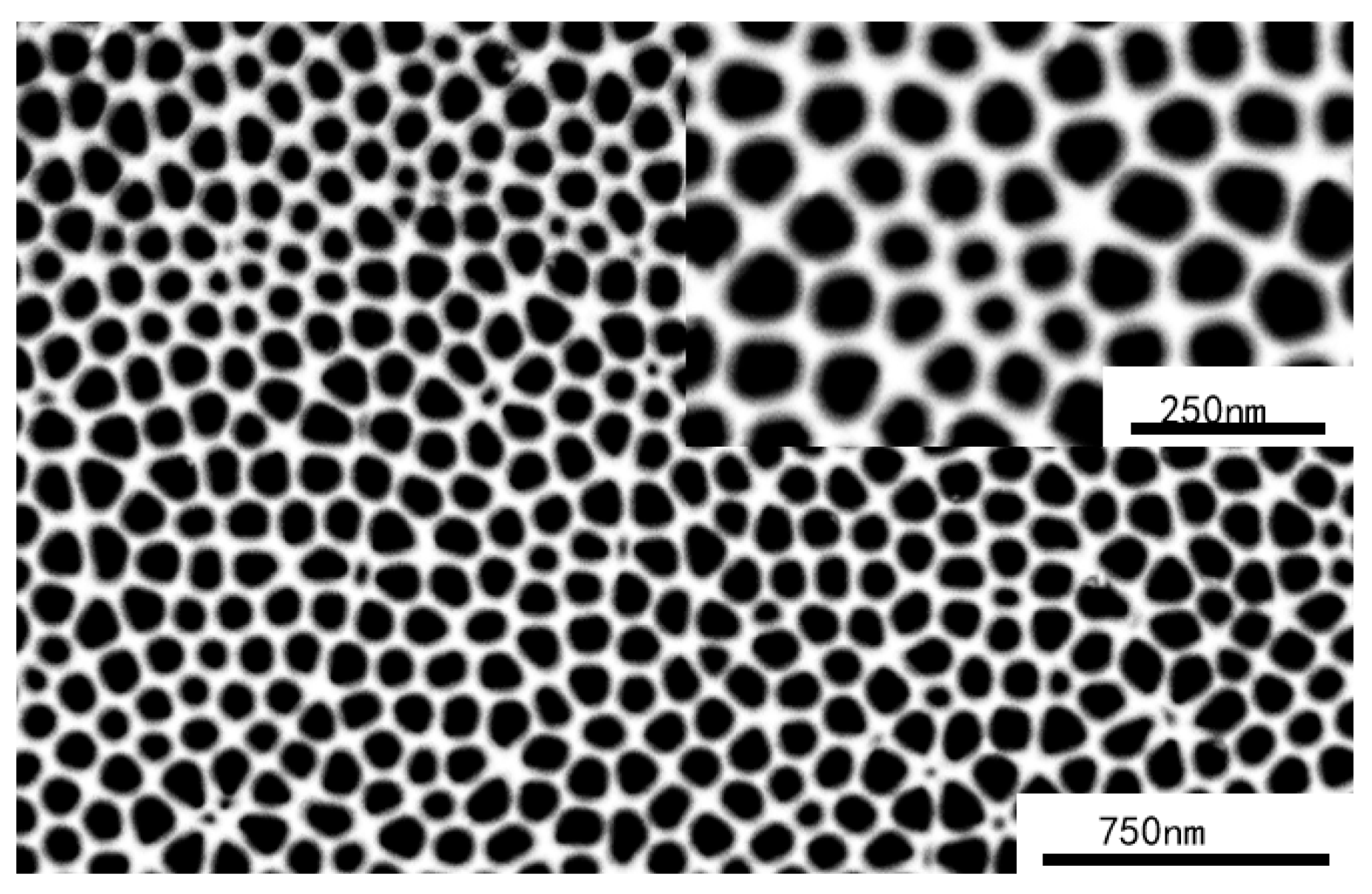

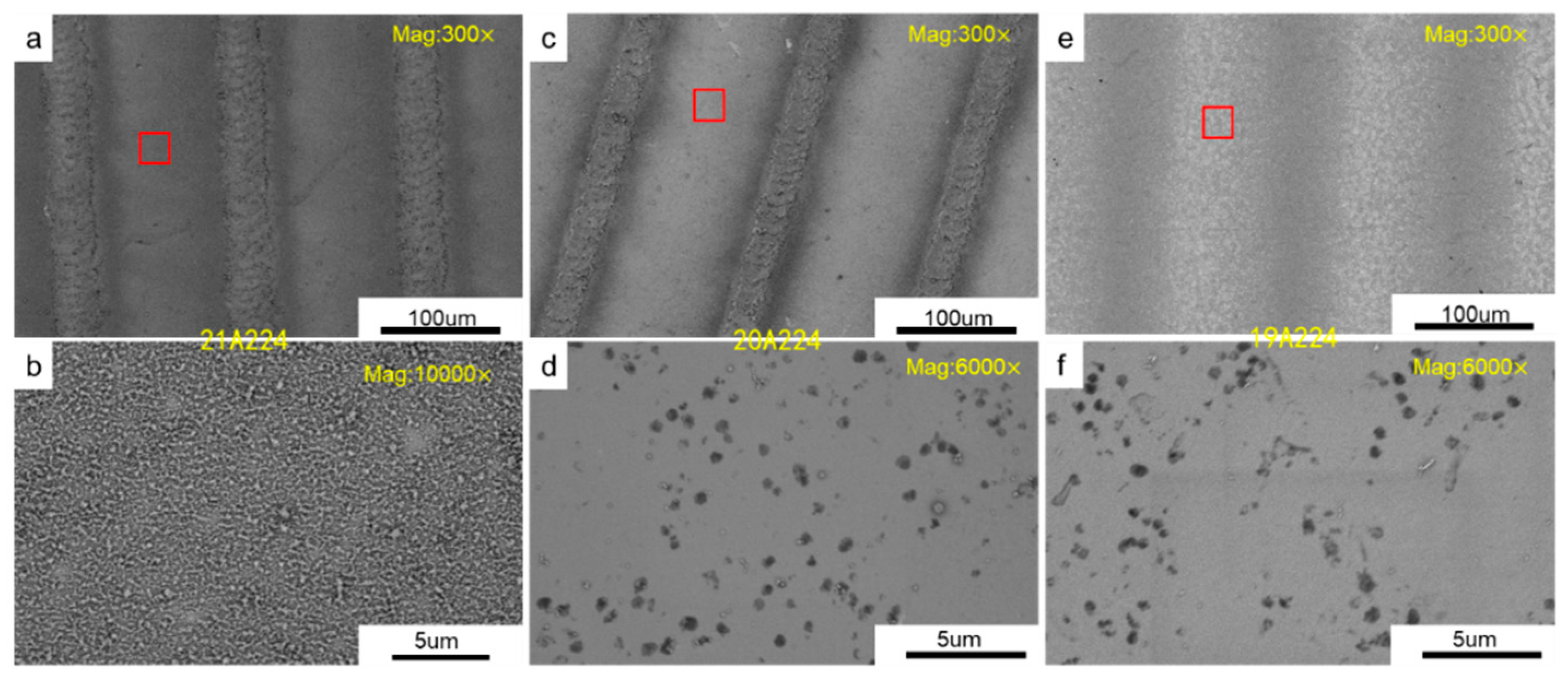

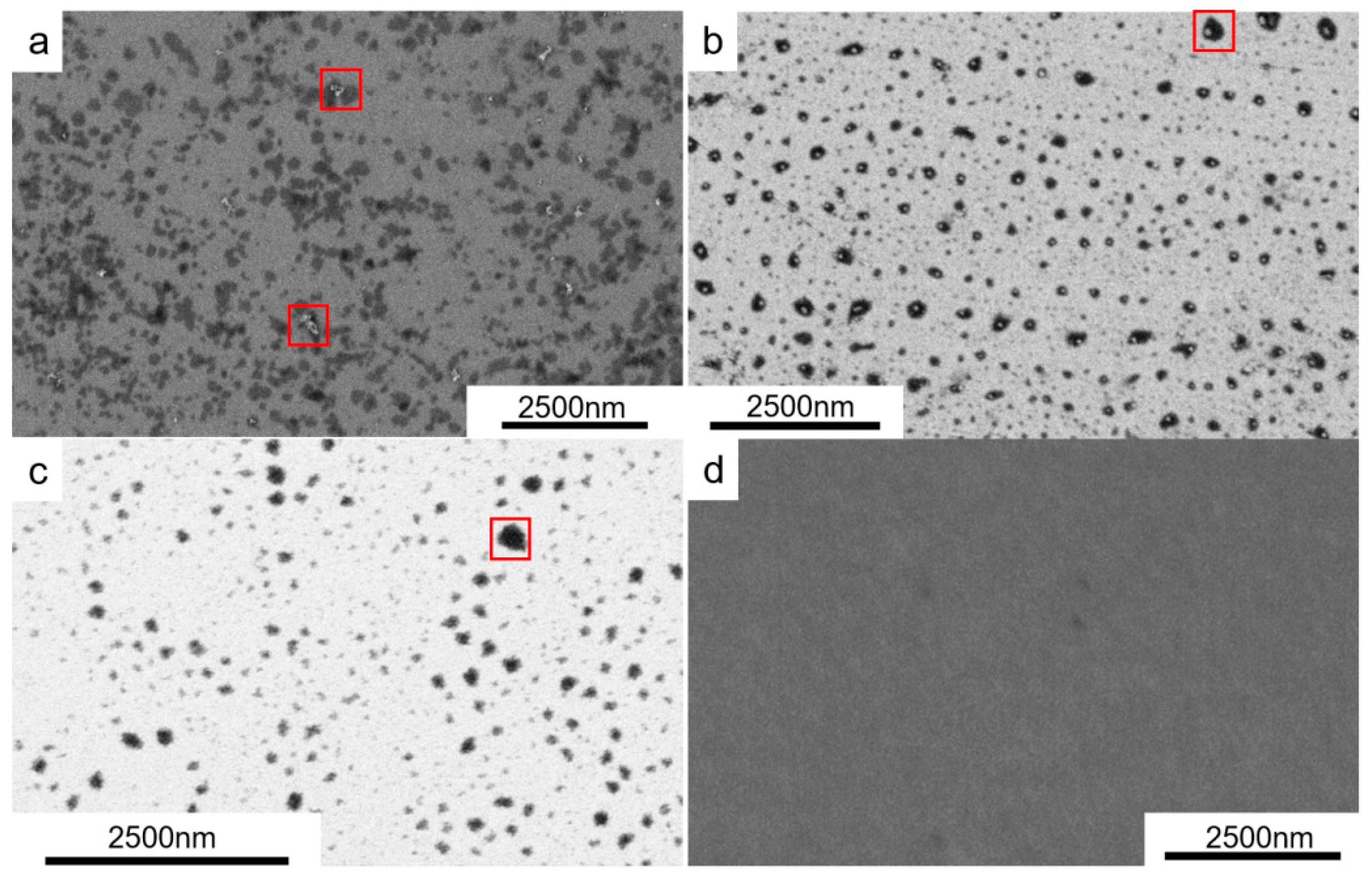

4.1. Preparation of AAO Thin Films and MIM Structure Characterization and Analysis

4.2. Results and Analysis of Micro- and Nanopore Preparation by Laser Irradiation of Ag/AAO/Ag Periodic Pore Arrays for Excitation of SPPs

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AAO | Anodic aluminum oxide |

| Ag/AAO/Ag | Silver–alumina–silver |

| Au/AAO/Au | Gold–alumina–gold |

| MIM | Metal–insulator–metal |

| SPPs | Surface plasmon polaritons |

| SPs | Surface plasmons |

References

- Wang, K.; Liu, C.; Meng, T.; Yi, C.; Gong, X. Inverted organic photovoltaic cells. Chem. Soc. Rev. 2016, 45, 2937–2975. [Google Scholar] [CrossRef]

- Duan, C.; Wang, W.; Xie, Q. Fabrication of nanofluidic devices. Biomicrofluidics 2013, 7, 026501. [Google Scholar] [CrossRef]

- Gilboa, T.; Zvuloni, E.; Zrehen, A.; Squires, A.H.; Meller, A. Automated, ultra-fast laser-drilling of nanometer scale pores and nanopore arrays in aqueous solutions. Adv. Funct. Mater. 2020, 30, 1900642. [Google Scholar] [CrossRef]

- Lillo, M.; Losic, D. Ion-beam pore opening of porous anodic alumina: The formation of single nanopore and nanopore arrays. Mater. Lett. 2009, 63, 457–460. [Google Scholar] [CrossRef]

- Knapp, J.A.; de Boer, M.P. Mechanics of microcantilever beams subject to combined electrostatic and adhesive forces. J. Microelectromech. Syst. 2002, 11, 754–764. [Google Scholar] [CrossRef]

- Biapo, U.; Ghisolfi, A.; Gerer, G.; Spitzer, D.; Keller, V.; Cottineau, T. Functionalized TiO2 Nanorods on a Microcantilever for the Detection of Organophosphorus Chemical Agents in Air. ACS Appl. Mater. Interfaces 2019, 11, 35122–35131. [Google Scholar] [CrossRef]

- Liu, N.W.; Liu, C.Y.; Wang, H.H.; Hsu, C.F.; Lai, M.Y.; Chuang, T.H.; Wang, Y.L. Focused-Ion-Beam-Based Selective Closing and Opening of Anodic Alumina Nanochannels for the Growth of Nanowire Arrays Comprising Multiple Elements. Adv. Mater. 2008, 20, 2547–2551. [Google Scholar] [CrossRef]

- Chen, B.; Lu, K.; Tian, Z. Novel patterns by focused ion beam guided anodization. Langmuir 2011, 27, 800–808. [Google Scholar] [CrossRef] [PubMed]

- Howitt, D.G.; Chen, S.J.; Gierhart, B.C.; Smith, R.L.; Collins, S.D. The electron beam hole drilling of silicon nitride thin films. J. Appl. Phys. 2008, 103, 024310. [Google Scholar] [CrossRef]

- Ammann, A.A. Inductively coupled plasma mass spectrometry (ICP MS): A versatile tool. J. Mass Spectrom. 2007, 42, 419–427. [Google Scholar] [CrossRef] [PubMed]

- Henzie, J.; Lee, M.H.; Odom, T.W. Multiscale patterning of plasmonic metamaterials. Nat. Nanotechnol. 2007, 2, 549–554. [Google Scholar] [CrossRef]

- Ritchie, R.H. Plasma. losses by fast electrons in thin films. Phys. Rec. 1957, 106, 874–875. [Google Scholar] [CrossRef]

- Stem, E.A.; Ferrel, R.A. Surface Plasma oseillations of degenerate electron gas. Phys. Rev. B 1960, 120, 130–131. [Google Scholar]

- Barnes, W.L.; Dereux, A.; Ebbesen, T.W. Surface plasmon subwavelength optics. Nature 2003, 424, 824–830. [Google Scholar] [CrossRef]

- Ozbay, E. Plasmonics: Merging photonics and electronics at nanoscale dimensions. Science 2006, 311, 189–193. [Google Scholar] [CrossRef] [PubMed]

- Tong, L.; Wei, H.; Zhang, S.; Xu, H. Recent advances in plasmonic sensors. Sensors 2014, 14, 7959–7973. [Google Scholar] [CrossRef] [PubMed]

- Piliarik, M.; Homola, J.; Manikova, Z.; Ctyroky, J. Surface plasmon resonance sensor based on a single-mode polarization-maintaining optical fiber. Sens. Actuators B Chem. 2003, 90, 236–242. [Google Scholar] [CrossRef]

- Hajshahvaladi, L.; Kaatuzian, H.; Danaie, M. A high-sensitivity refractive index biosensor based on Si nanorings coupled to plasmonic nanohole arrays for glucose detection in water solution. Opt. Commun. 2021, 502, 127421. [Google Scholar] [CrossRef]

- Alipour, A.; Farmani, A.; Mir, A. High Sensitivity and Tunable Nanoscale Sensor Based on Plasmon-Induced Transparency in Plasmonic Metasurface. IEEE Sens. J. 2018, 18, 7047–7054. [Google Scholar] [CrossRef]

- Liu, L.; Luo, Y.; Zhao, Z.; Zhang, W.; Gao, G.; Zeng, B.; Wang, C.; Luo, X. Large area and deep sub-wavelength interference lithography employing odd surface plasmon modes. Sci. Rep. 2016, 6, 30450. [Google Scholar] [CrossRef]

- Fang, N.; Lee, H.; Sun, C.; Zhang, X. Sub-Diffraction-Limited Optical Imaging with a Silver Superlens. Science 2005, 308, 534–537. [Google Scholar] [CrossRef]

- Liu, Z.; Lee, H.; Xiong, Y.; Sun, C.; Zhang, X. Far-Field Optical Hyperlens Magnifying Sub-Diffraction-Limited Objects. Science 2007, 315, 1686. [Google Scholar] [CrossRef]

- Schilling, A.; Schilling, J.; Reinhardt, C.; Chichkov, B. A superlens for the deep ultraviolet. Appl. Phys. Lett. 2009, 95, 121909. [Google Scholar] [CrossRef]

- Kletchillann, E. The determination of the optical constants of metals by exciation of surface plasmons. Z. Phys. A Hadron. Nucl. 1971, 241, 313–315. [Google Scholar]

- Wang, C.; Du, C.; Lv, Y.; Luo, X. Surface electromagnetic wave excitation and diffraction by subwavelength slit with periodically patterned metallic grooves. Opt. Express 2006, 14, 5671–5681. [Google Scholar] [CrossRef]

- Otto, A. Excitation of Nonradiative surface Plasmon wave in sliver by the method of frustrated total reflection. Z. Phys. A Hadron. Nucl. 1968, 205, 398–399. [Google Scholar] [CrossRef]

- Yan, S.; Zhang, M.; Zhao, X.; Zhang, Y.; Wang, J.; Jin, W. Refractive Index Sensor Based on a Metal–Insulator–Metal Waveguide Coupled with a Symmetric Structure. Sensors 2017, 17, 2879. [Google Scholar] [CrossRef] [PubMed]

- Jani, A.M.M.; Losic, D.; Voelcker, N.H. Nanoporous anodic aluminium oxide: Advances in surface engineering and emerging applications. Prog. Mater. Sci. 2013, 58, 636–704. [Google Scholar] [CrossRef]

- Lee, W.; Ji, R.; Gösele, U.; Nielsch, K. Fast fabrication of long-range ordered porous alumina membranes by hard anodization. Nat. Mater. 2006, 5, 741–747. [Google Scholar] [CrossRef]

- Miao, W.; Yang, Y.; Zhao, J.; Zhang, H.; Guo, Z.; Cui, Y.; Wang, R.; Zhu, Y. Fabrication of Au/AAO/Au nanopore arrays based on induced excitation SPPs for the fabrication of nanopores on silicon surfaces. Mater. Today Commun. 2023, 35, 105953. [Google Scholar] [CrossRef]

- Huang, Z.; Geyer, N.; Werner, P.; De Boor, J.; Gösele, U. Metal-assisted chemical etching of silicon: A review: In memory of Prof. Ulrich Gösele. Adv. Mater. 2011, 23, 285–308. [Google Scholar] [CrossRef]

- Majumdar, P.; Ray, A. Maxwell electrodynamics in terms of physical potentials. Symmetry 2019, 11, 915. [Google Scholar] [CrossRef]

- Tarigan, H.J. Study of Surface Plasmon Polaritons (SPPs) Propagation Through Plasmonic Crystals. Master’s Thesis, Texas Tech University, Lubbock, TX, USA, May 2012. [Google Scholar]

- Wang, G.; Lu, H.; Liu, X. Dispersionless slow light in MIM waveguide based on a plasmonic analogue of electromagnetically induced transparency. Opt. Express 2012, 20, 20902–20907. [Google Scholar] [CrossRef]

- Dong, J.; Liu, J.; Kang, G.; Xie, J.; Wang, Y. Pushing the resolution of photolithography down to 15nm by surface plasmon interference. Sci. Rep. 2014, 4, 5618. [Google Scholar] [CrossRef] [PubMed]

- Xie, H.; Kong, F.M.; Li, K. The Electric Field Enhancement and Resonance in Optical Antenna Composed of AU Nanoparicles. J. Electromagn. Waves Appl. 2009, 23, 534–547. [Google Scholar] [CrossRef]

- Belwalkar, A.; Grasing, E.; Vangeertruyden, W.; Huang, Z.; Misiolek, W. Effect of processing parameters on pore structure and thickness of anodic aluminum oxide (AAO) tubular membranes. J. Membr. Sci. 2008, 319, 192–198. [Google Scholar] [CrossRef] [PubMed]

- Lee, W.; Park, S.J. Porous anodic aluminum oxide: Anodization and templated synthesis of functional nanostructures. Chem. Rev. 2014, 114, 7487–7556. [Google Scholar] [CrossRef]

- Sulka, G.D.; Stępniowski, W.J. Structural features of self-organized nanopore arrays formed by anodization of aluminum in oxalic acid at relatively high temperatures. Electrochim. Acta 2009, 54, 3683–3691. [Google Scholar] [CrossRef]

- Reddy, P.R.; Ajith, K.M.; Udayashankar, N.K. Optical and mechanical studies on free standing amorphous anodic porous alumina formed in oxalic and sulphuric acid. Appl. Phys. A 2018, 124, 765. [Google Scholar] [CrossRef]

- Yuan, J.H.; He, F.Y.; Sun, D.C.; Xia, X.H. A Simple Method for Preparation of Through-Hole Porous Anodic Alumina Membrane. Chem. Mater. 2004, 16, 1841–1844. [Google Scholar] [CrossRef]

- Rieger, G.; Taschuk, M.; Tsui, Y.; Fedosejevs, R. Comparative study of laser-induced plasma emission from microjoule picosecond and nanosecond KrF-laser pulses. Spectrochim. Acta Part B At. Spectrosc. 2003, 58, 497–510. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, J.; Liang, F.; Yin, M.; He, M. Investigation of magnetron sputtered nano-silver coating on titanium surface with micro-nanostructure. Surfaces Interfaces 2023, 38, 102770. [Google Scholar] [CrossRef]

- Yue, Y.; Yan, X.; Zhang, Y. Nano-fiber-structured Cantor alloy films prepared by sputtering. J. Mater. Res. Technol. 2022, 21, 1120–1127. [Google Scholar] [CrossRef]

- Tran, T.; Wang, X.; Shrestha, M.; Wang, K.; Fan, Q.H. Ultra-thin silver films grown by sputtering with a soft ion beam-treated intermediate layer. J. Phys. D Appl. Phys. 2023, 56, 365501. [Google Scholar] [CrossRef]

- Vilkevičius, K.; Ignatjev, I.; Selskis, A.; Niaura, G.; Stankevičius, E. Tuning SERS performance through the laser-induced morphology changes of gold nanostructures. Appl. Surf. Sci. 2024, 660, 160003. [Google Scholar] [CrossRef]

- Molian, P.A. Laser-Energized Plasmonics for Nanopatterning Medical Devices. J. Micro Nano-Manuf. 2015, 3, 031003. [Google Scholar] [CrossRef]

| Voltage (V) | Primary Oxidation Time (min) | Secondary Oxidation Time (min) | Hole Spacing (nm) | Nanopore (nm) |

|---|---|---|---|---|

| 95 | 10 | 10 | 189 (±3) | 150 (±3) |

| 100 | 10 | 10 | 203 (±3) | 147 (±3) |

| 105 | 10 | 10 | 217 (±5) | 117 (±5) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huo, S.; Luo, S.; Wang, R.; Zhao, J.; Miao, W.; Guo, Z.; Cui, Y. Controlled Nanopore Fabrication on Silicon via Surface Plasmon Polariton-Induced Laser Irradiation of Metal–Insulator–Metal Structured Films. Coatings 2025, 15, 1187. https://doi.org/10.3390/coatings15101187

Huo S, Luo S, Wang R, Zhao J, Miao W, Guo Z, Cui Y. Controlled Nanopore Fabrication on Silicon via Surface Plasmon Polariton-Induced Laser Irradiation of Metal–Insulator–Metal Structured Films. Coatings. 2025; 15(10):1187. https://doi.org/10.3390/coatings15101187

Chicago/Turabian StyleHuo, Sifan, Sipeng Luo, Ruishen Wang, Jingnan Zhao, Wenfeng Miao, Zhiquan Guo, and Yuanchen Cui. 2025. "Controlled Nanopore Fabrication on Silicon via Surface Plasmon Polariton-Induced Laser Irradiation of Metal–Insulator–Metal Structured Films" Coatings 15, no. 10: 1187. https://doi.org/10.3390/coatings15101187

APA StyleHuo, S., Luo, S., Wang, R., Zhao, J., Miao, W., Guo, Z., & Cui, Y. (2025). Controlled Nanopore Fabrication on Silicon via Surface Plasmon Polariton-Induced Laser Irradiation of Metal–Insulator–Metal Structured Films. Coatings, 15(10), 1187. https://doi.org/10.3390/coatings15101187