3.2. Freeze–Thaw Damage Model

Owing to the changes in positive and negative temperatures, the aqueous solution alternates back and forth between the liquid phase and the solid phase; as a result, cracks inside the concrete are gradually generated and developed, and the performance of the concrete is gradually reduced. The degree of damage is a variable that represents the internal damage state of the material and can be used to describe the damage evolution process of concrete during the FTC [

22,

47]. On the basis of damage mechanics theory, concrete before FTCs is considered a nondestructive material composed of countless microelements, and the degree of damage is defined as the ratio of the number of microelements damaged after FTCs to the number of microelements damaged before FTCs [

48]. In this study, the RDEM of the concrete was used to represent the change in the number of microelements in the concrete before and after freeze–thawing [

26,

49]. On the basis of the strain equivalence assumption proposed by Lematire [

50], the degree of damage

DN is defined as follows:

where

DN represents the freeze–thaw damage value of the concrete sample,

EN represents the dynamic elastic modulus of the concrete sample after

N cycles of freeze–thaw,

E0 represents the dynamic modulus of elasticity of the concrete sample without freeze–thaw, and

N represents the number of FTCs of the test sample.

3.2.1. Construction of GM(1, 1) Model

Various prediction models for freeze–thaw damage in RAC have been developed by researchers, including models based on the Weibull distribution [

51], the GM method [

20,

21], models developed from the Aas-Jakobsen fatigue theory [

52], and classical damage evolution models such as the Chaboche model [

53]. Among these, the Weibull distribution model effectively captures performance variability caused by the uneven distribution of internal defects in concrete; however, its prediction accuracy is highly sensitive to the number of test samples [

54]. Freeze–thaw damage is inherently a complex process involving coupled physical and chemical interactions, which differ significantly from the mechanical fatigue damage mechanisms observed in metallic materials. Consequently, directly applying the Aas-Jakobsen fatigue theory struggles to accurately capture specific damage mechanisms prevalent in freeze–thaw processes, such as salt crystallization and moisture migration [

51,

55]. Although the Chaboche damage evolution model can meticulously describe the nonlinear accumulation of damage, it involves numerous material parameters, making practical calibration challenging [

51,

55]. In contrast, the GM offers distinct advantages in handling data characterized by “small sample sizes and limited information.” It enables effective prediction of long-term material durability based on limited initial experimental data, providing an efficient and economical approach for rapidly assessing the frost resistance of RAC. Therefore, the GM was selected in this study to establish the freeze–thaw damage prediction model for RAC.

The first-order, one-variable grey model, GM(1, 1), is effective for modeling systems with limited data [

56]. It processes original, non-negative, discrete data sequences through accumulation to reveal underlying patterns [

57]. GM(1, 1) is more accurate at modeling monotonic data, can retain the characteristics of the original system, and better reflects the real situation of the system [

58]. Therefore, in this experiment, GM(1, 1) is used to establish a prediction model for the degree of damage

DN. For the detailed modeling steps, see the literature [

33,

59].

The freeze–thaw damage data of the RAC are shown in

Table 6. The freeze–thaw damage data of the RAC were brought into the GM (1, 1), where

n (

n = 10

k) represents the number of FTCs and

X(0) represents the freeze–thaw damage value of the RAC.

3.2.2. Validation and Analysis of GM(1, 1) Model

The accuracy of the GM(1, 1) model was further tested on the calculation results via the posterior difference test method [

18]. The specific formula is as follows:

where

represents the mean of the residuals,

εk denotes the residual of the k-th sample, and

m indicates the total number of samples.

where

S12 represents the variance of the residuals,

represents the mean of the residuals,

εk denotes the residual of the k-th sample, and

m indicates the total number of samples.

where

represents the mean of the original sequence,

X(0)k denotes the k-th sample in the original sequence, and

m indicates the total number of samples.

where

S22 represents the variance of the original sequence,

represents the mean of the original sequence,

Xk(0) denotes the k-th sample in the original sequence, and

m indicates the total number of samples.

where

c denotes the posteriori error ratio,

S1 represents the standard deviation of the residuals, and

S2 signifies the standard deviation of the original sequence.

In the equation, both u and P denote probability values, where p signifies the small error probability, represents the mean of the residuals, εk denotes the residual of the k-th sample, m indicates the total number of samples, and S2 signifies the standard deviation of the original sequence.

The accuracy test results and accuracy level comparison tables for the G(1, 1) model are shown in

Table 7 and

Table 8, respectively. Both the posteriori error ratio (

c) and the small error probability (

p) attained Grade I, indicating that the GM(1, 1) model exhibits high accuracy and provides reliable predictions for the freeze–thaw damage of RAC.

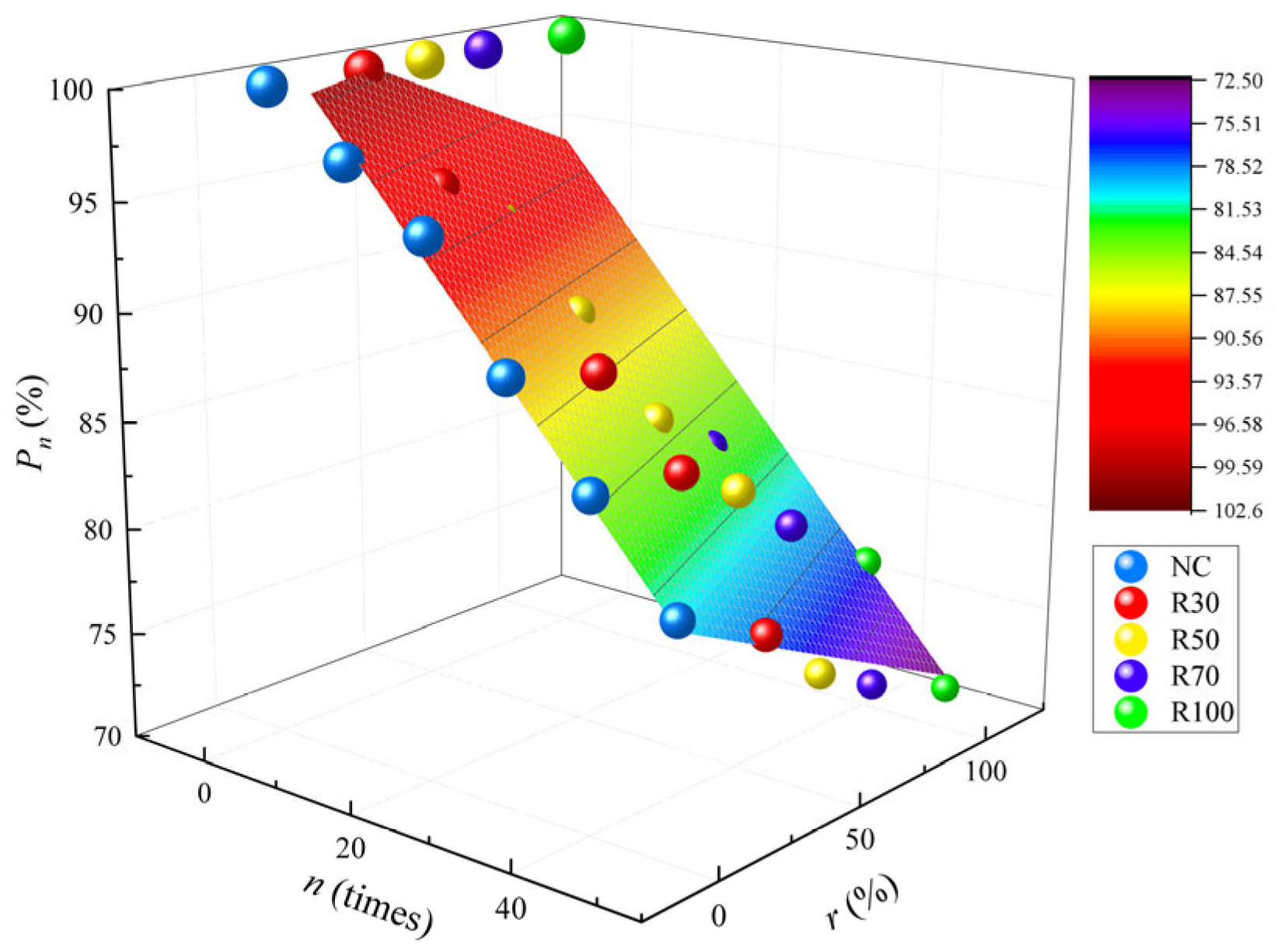

The damage data of the RAC before 50 FTCs were brought into the GM(1, 1) model for fitting, and the fitting results are shown in

Table 9. When

R2 > 0.92, the fitting accuracy of the GM(1, 1) model is high.

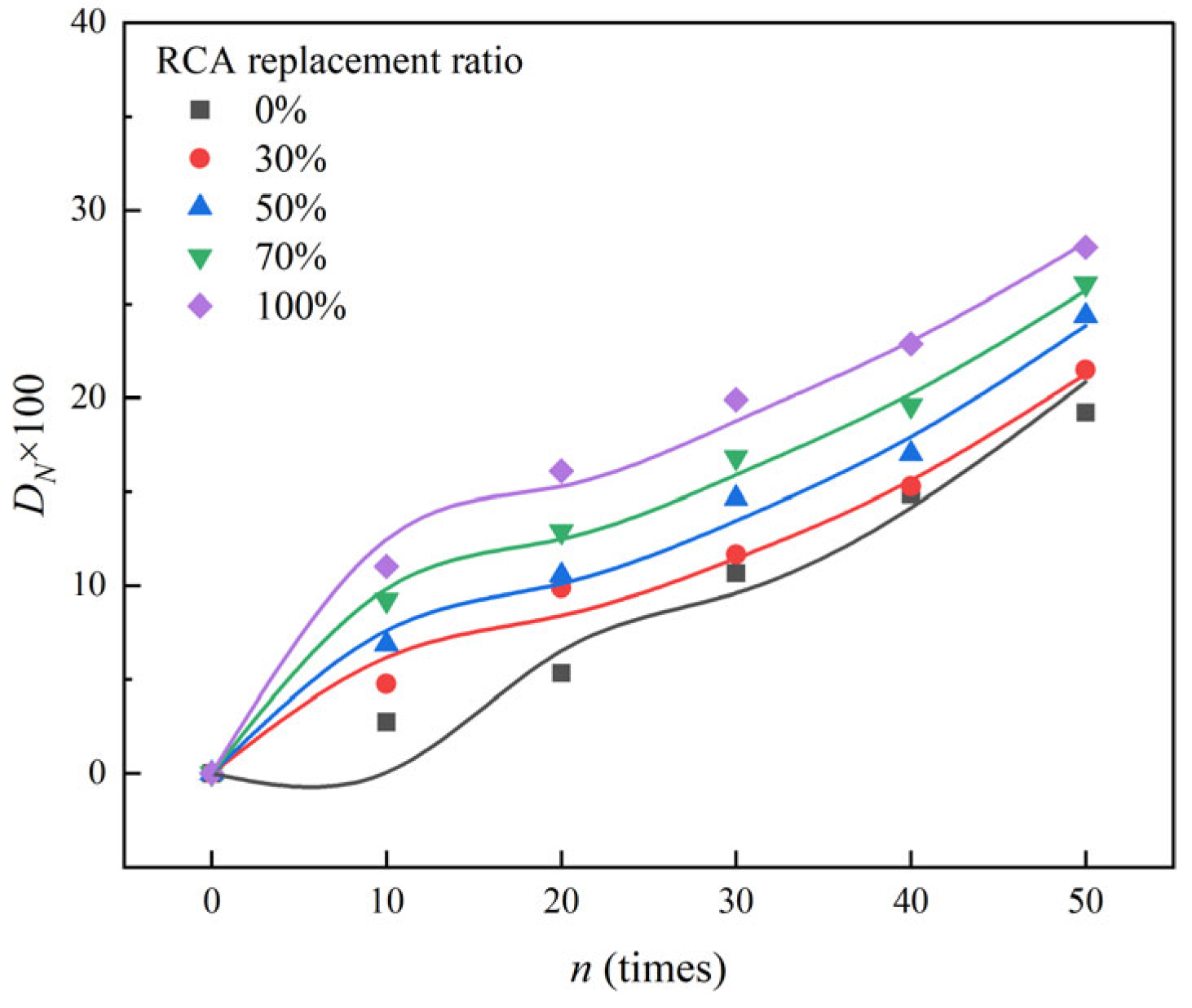

The freeze–thaw damage value

DN of the RAC is shown in

Figure 10. According to GB/T 50082-2009 [

37],

DN = 40% is the critical value for the freeze–thaw damage of a test sample. After 50 RAC FTCs, the

DN ranged from 20.84% to 28.26%. Through the

R2 and posterior difference tests, the G(1, 1) prediction model had higher accuracy and could better predict the RAC frost resistance.

3.3. Freeze–Thaw Damage Mechanism

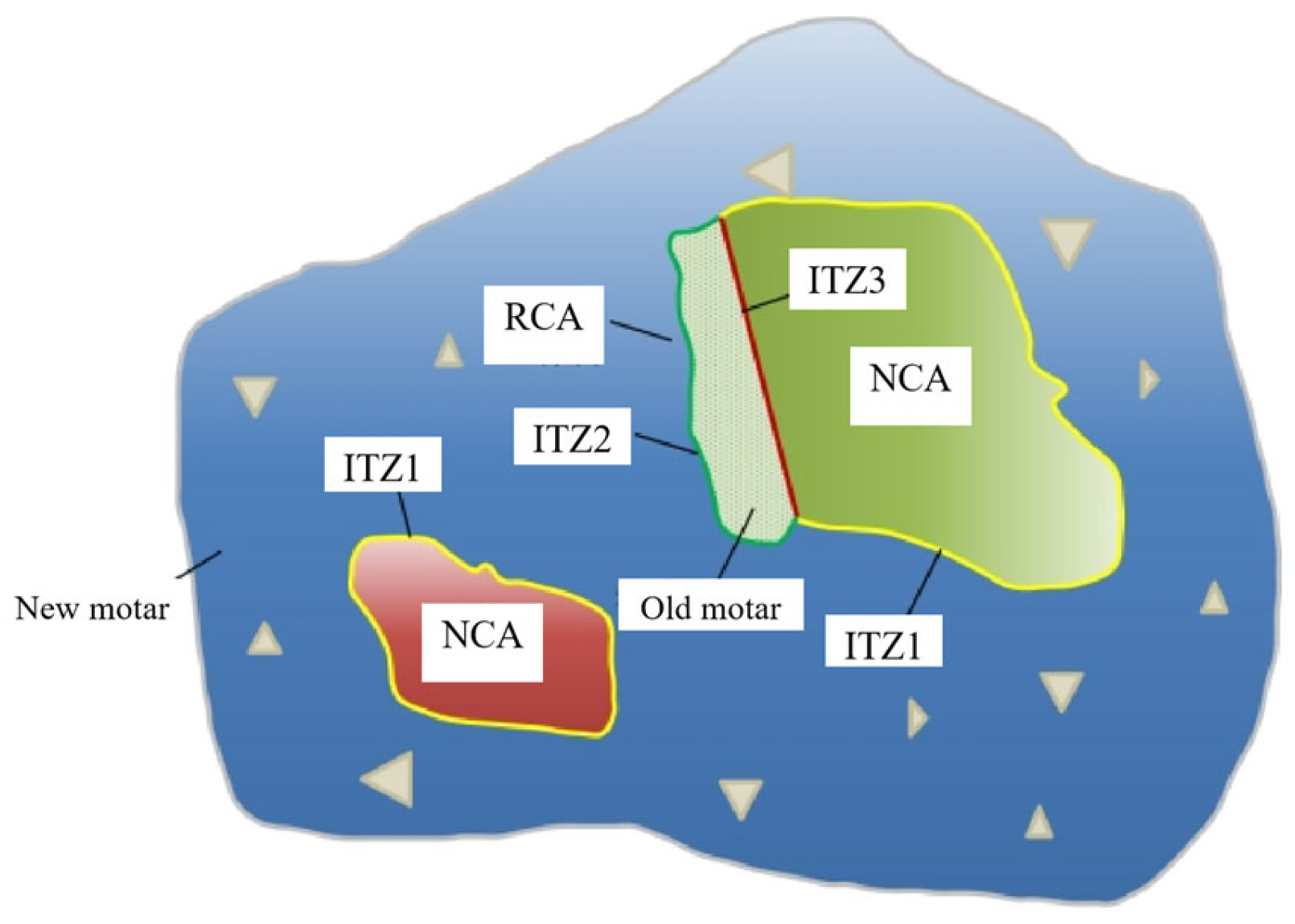

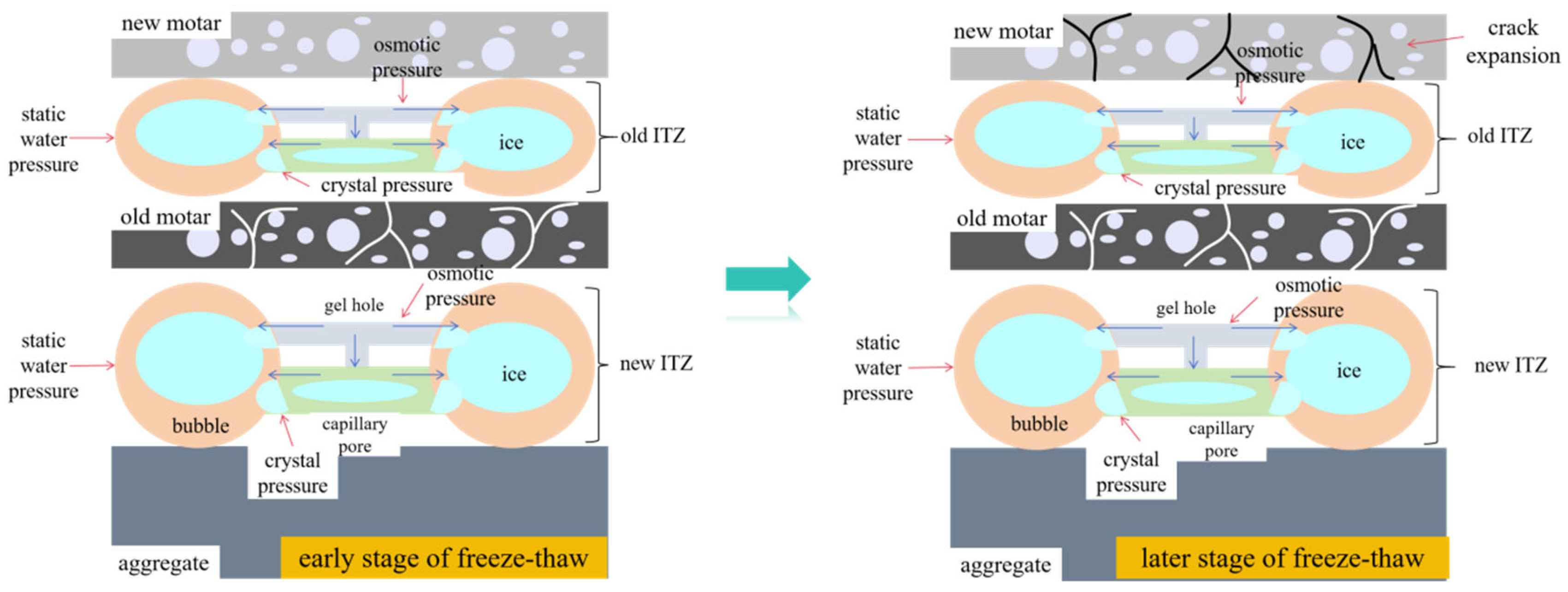

To thoroughly elucidate the freeze–thaw damage mechanism of RAC in depth, a systematic analysis of the ITZ structures of NCA and RCA is necessary. A schematic diagram comparing the ITZ structures of NCA and RCA is presented in

Figure 11. It can be observed that the ITZ structure of RCA is relatively simple, consisting only of the transition zone formed between the NCA and the new mortar (ITZ1). In contrast, the ITZ structure of RAC is more complex. In addition to ITZ1, it includes the transition zone between the new mortar and the old adhered mortar (ITZ2), as well as the transition zone between the original aggregate (within the RCA) and the old adhered mortar (ITZ3). This multi-layered ITZ system in RAC contributes to its higher susceptibility to freeze–thaw damage.

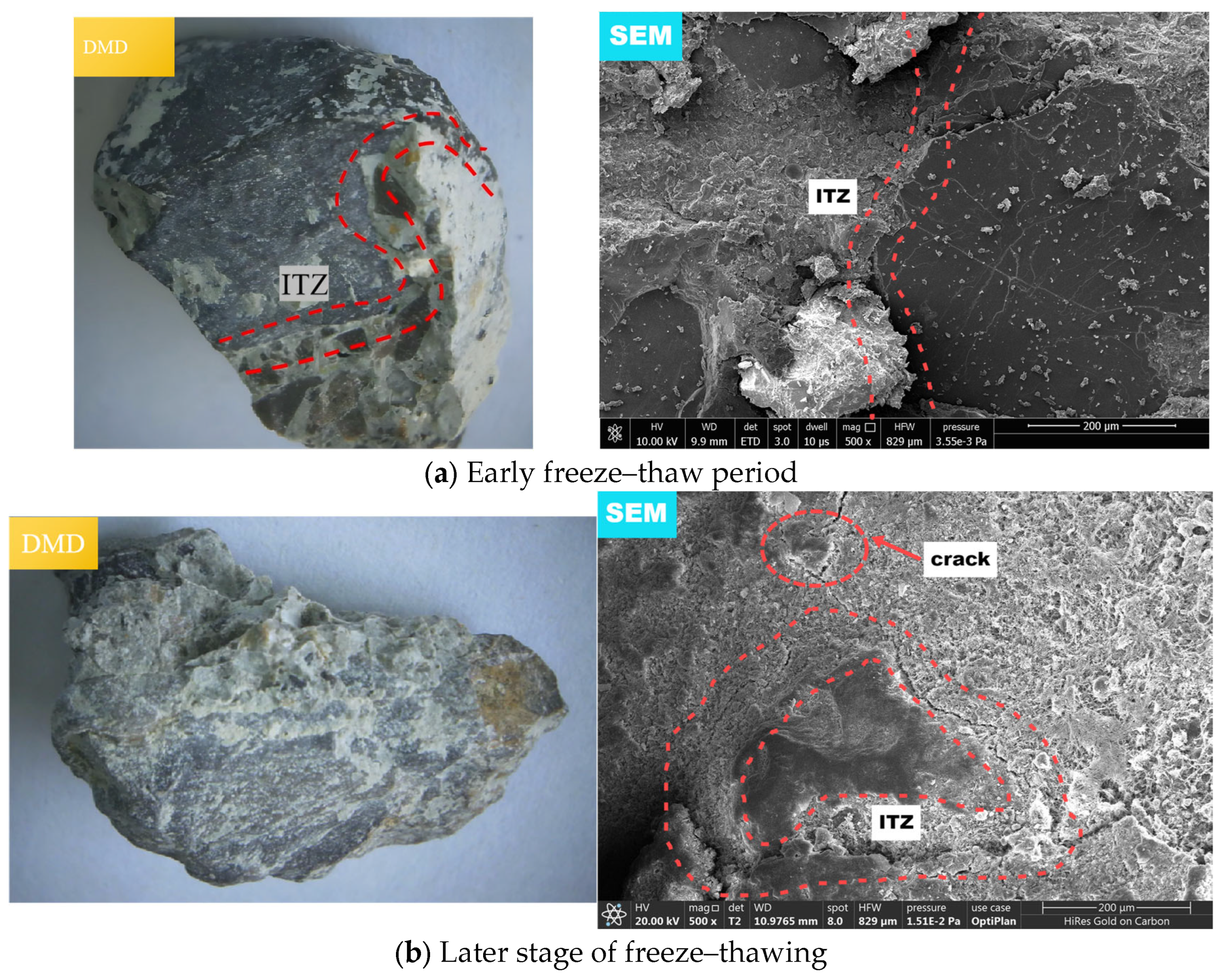

The DMD and SEM images of the NCA before and after freeze–thaw cycling are shown in

Figure 12. As shown in

Figure 12a, in the early stage of FTCs (after 10 FTCs), the NCA cement stone had no cracks, and the main cracks appeared in the mortar and ITZ [

60]. The interior of the NCA is very dense with almost no cracks; therefore, its deformation (contraction and expansion) during the freeze–thaw process is relatively small. When the NCA cement mortar region freezes, the aqueous solution in the gel pores is absorbed by the capillary pores and air bubbles, and the volume decreases; the gel pores absorb the aqueous solution from the outside when melting, and the volume expands. During the freeze–thaw process, the mortar region experienced large deformation, which caused the cracks in the ITZ region to propagate continuously. In addition, owing to the high water–cement ratio in the ITZ region during the condensation and hardening process, the NCA concrete has more pores in the ITZ region, and its strength is lower; thus, the ITZ region of the test piece is the most prone to stress concentration.

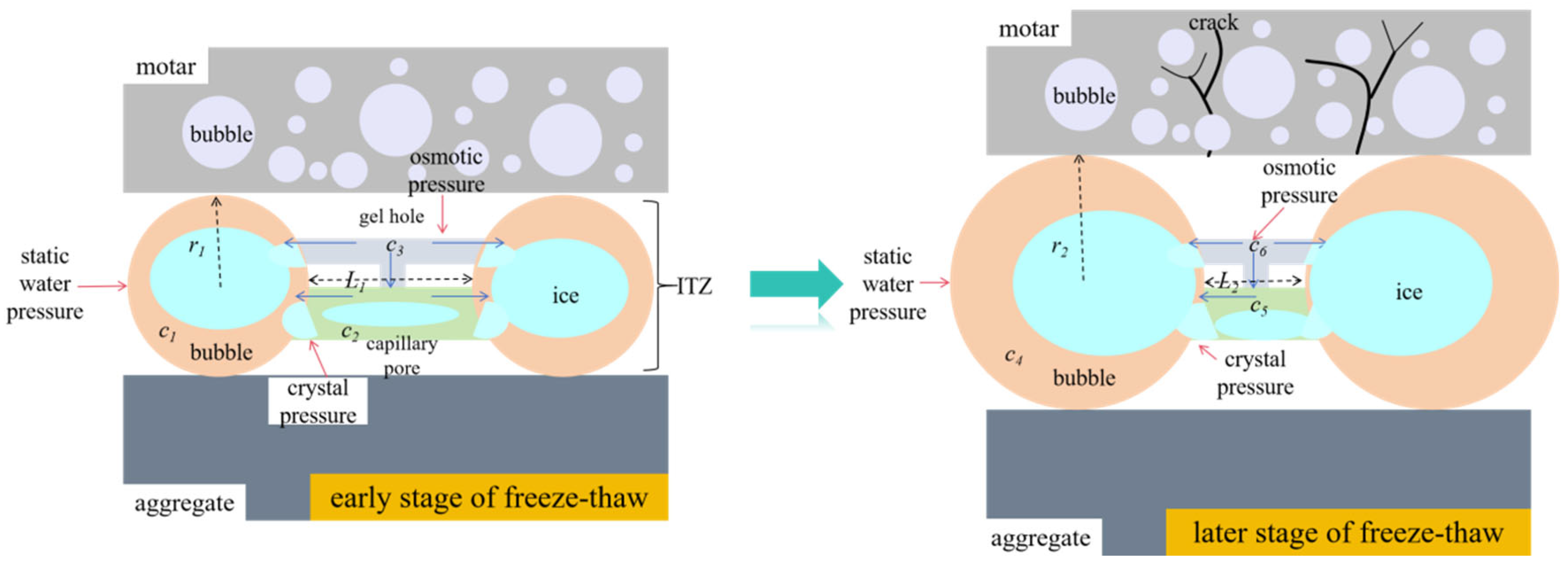

As shown in

Figure 12b, at the later stage of the FTC (after 50 FTCs), the ITZ of the NCA cement was severely damaged. As the number of FTCs increases, the cracks in the ITZ continue to develop, the diameter of the bubbles increases, the number of fractures in the ITZ increases, and the pore spacing decreases, as shown in

Figure 13. Scherer et al. [

61] and Powers et al. [

62] reported that the diameter

r2 of the bubbles in the ITZ at the later stage of freeze–thawing is greater than the diameter

r1 of the early stage of freeze–thawing, and the spacing

L2 of the air bubbles in the ITZ is smaller than the number of bubbles

L1 at the early stage of freeze–thawing; therefore, in the NCA, the hydrostatic pressure and crystallization pressure in the cement ITZ decrease as the cracks on the pore wall propagate. On the other hand, in the early stage of freeze–thawing,

c1 (the concentration of the aqueous solution in the air bubbles in the early stage of freeze–thawing) >

c2 (the concentration of the aqueous solution in the capillary pores in the early stage of freeze–thawing) >

c3 (the concentration of the aqueous solution in the gel pores in the early stage of freeze–thawing); therefore, in terms of the difference in concentration, the aqueous solution in the gel pores continuously flows to the capillary pores and air bubbles, and during this process, osmotic pressure is generated on the pore walls. During the later stage of freeze–thawing, the diameters of the air bubbles and capillary pores in the ITZ expand, and the volume of the ice crystals increases; as a result, the concentrations of

c4 (the concentration of the aqueous solution in the bubbles during the later stage of freeze–thawing) and

c5 (the concentration of the aqueous solution in the capillary pores during the later stage of freeze–thawing) increase,

c5,

c4 and

c6 (the concentration of the aqueous solution in the gel pores during the later stage of freeze–thawing) further increase, resulting in an increase in the osmotic pressure in the ITZ region.

During the initial stage of freeze–thawing, the crystallization pressure and hydrostatic pressure inside the bubbles increased. As the number of FTCs increases, the bubbles experience fatigue failure, the pore wall is damaged, the size expands, and the internal pressure (hydrostatic pressure and crystallization pressure) of the bubbles decreases, whereas the pressure (osmotic pressure) on the capillary pores and gel pores increases, which is referred to as the “pressure shift down” phenomenon. As the number of FTCs increases, the pressure of the larger air bubbles shifts to smaller capillary pores and gel pores. Therefore, as the number of FTCs increased, the internal stress of the test sample tended to increase overall. In addition, when the test piece melts, the air bubbles and ice in the capillary pores melt, the aqueous solution flows back into the gel pores, and the tensile stress in the test piece decreases. As the number of FTCs increases, the pores will suffer fatigue breakage. When the pore size reaches a certain stage, the test piece will suffer from global failure.

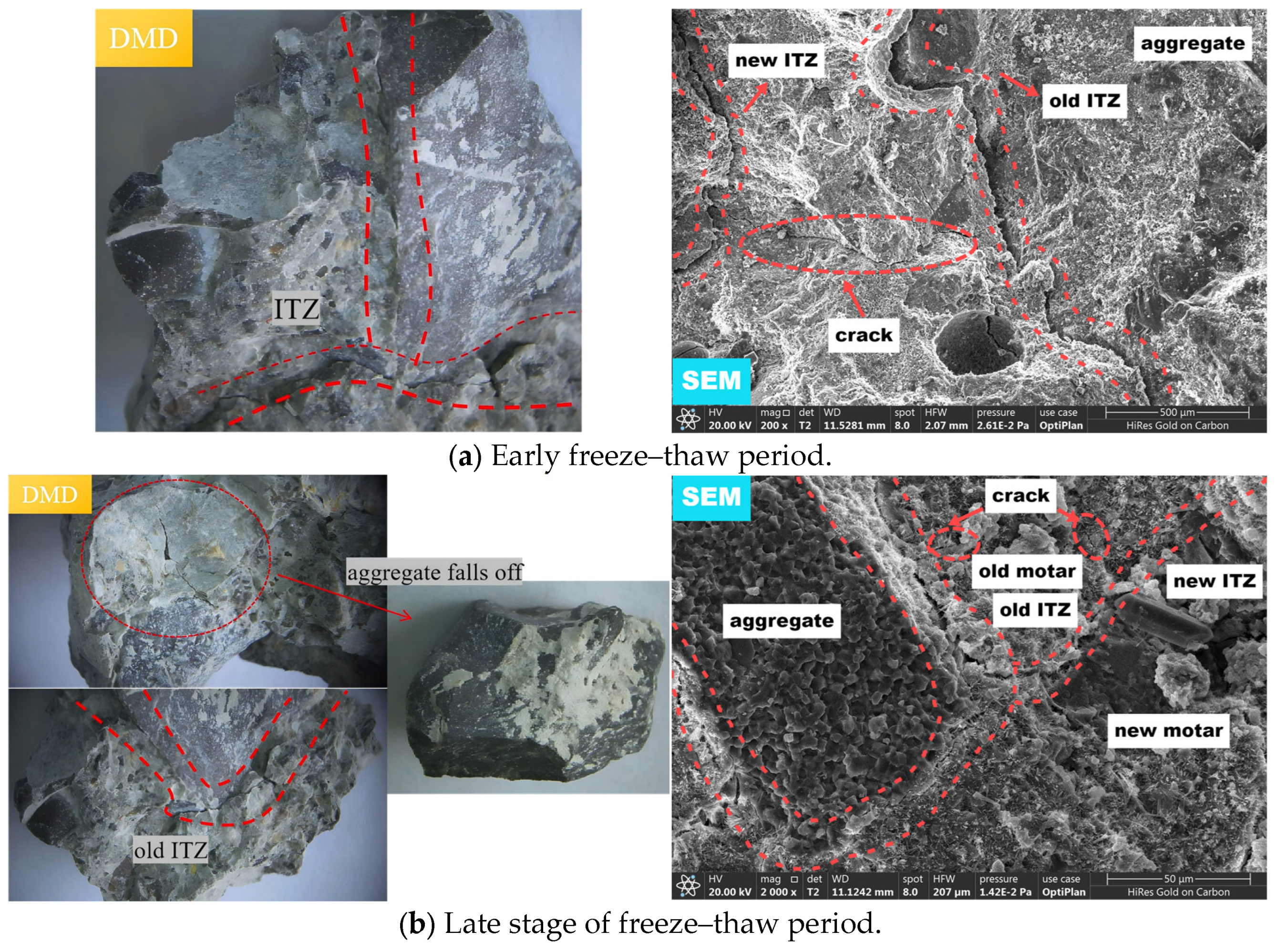

The DMD and SEM images of RCA before and after freeze–thaw cycles are shown in

Figure 14.

Figure 14a reveals that during the initial freeze–thaw stages, the aggregate particles within the RCA cement paste remain relatively dense and suffer minor damage, whereas the old mortar, along with the old and new ITZs, exhibits a porous and microcracked structure, becoming the primary zones of damage concentration [

63,

64]. The propagation and interconnection of these microcracks manifest macroscopically as initial surface roughening and localized minor spalling, leading to the observed mass loss in the concrete specimens. Furthermore, the differential thermal expansion coefficients between the aggregate and the mortar result in more initial microcracks within the old ITZ, exacerbating its freeze–thaw damage [

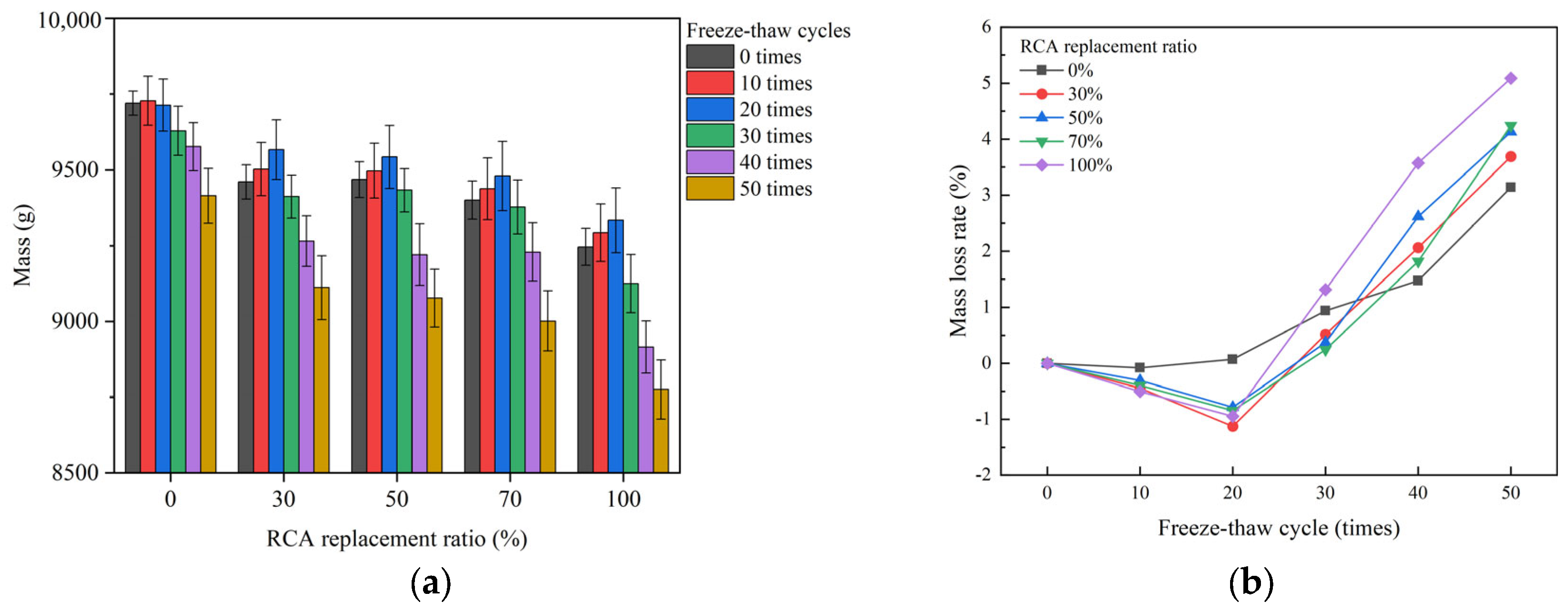

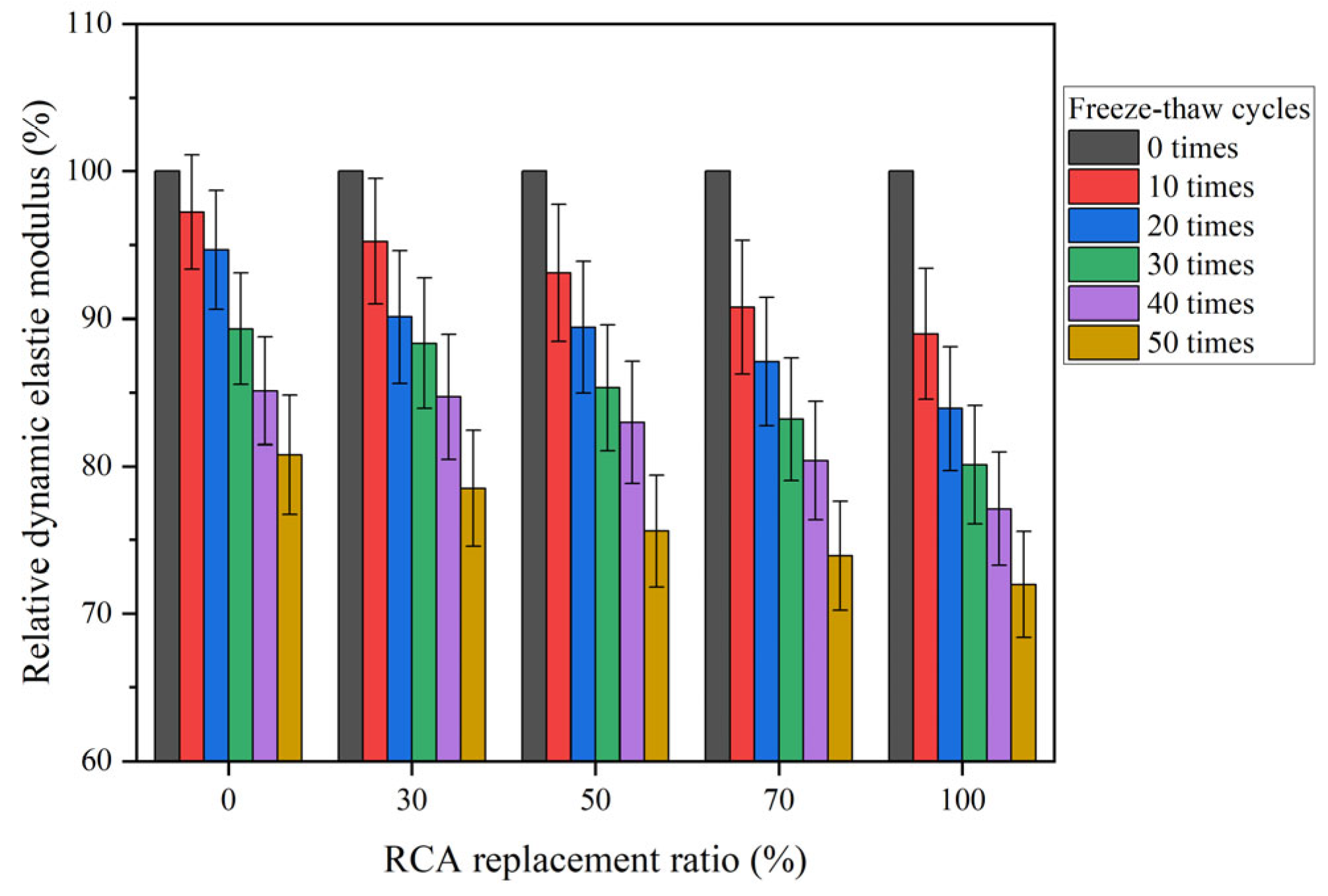

65]. Consequently, damage in RAC typically initiates at the internal old mortar interfaces and is more severe than in conventional concrete, macroscopically evidenced by greater mass loss and a more significant reduction in the RDEM for RAC.

Figure 14b demonstrates that in the later freeze–thaw stages, the old ITZ experiences the most severe damage, culminating in paste-aggregate separation and ultimately leading to specimen failure. This key microstructural failure directly corresponds to the macroscopic phenomena of extensive mortar and aggregate spalling and a sharp decline in mass.

As freeze–thaw cycling progresses, a “stress shift” phenomenon also occurs within the RCA cement paste. However, due to the pre-existing abundance of microcracks and larger defect zones in RCA, cracks within the ITZ propagate rapidly, as illustrated in

Figure 15. This allows water and ice crystallization pressures to penetrate deeper into the material. Macroscopically, this is reflected by damage progression not being limited to the surface but extending inwards, leading to a continuous decline in the RDEM with increasing FTCs. Moreover, under the same number of cycles, RCA cement paste suffers greater damage than NCA cement paste [

66], specifically manifested as a much larger reduction in the relative dynamic modulus for RAC. This is attributed to the higher number of microcracks in RCA, which severely impair the material’s ability to transmit elastic waves, indicating a rapid loss of load-bearing stiffness. Additionally, the significant difference in the thermal expansion coefficients between the aggregate and the mortar causes the old and new ITZs to endure the most severe damage, leading to paste-aggregate separation [

67]. In summary, the macroscopic spalling, mass loss, and deterioration of the dynamic modulus of elasticity in RAC are the direct external manifestations of the initiation, propagation, and ultimate failure of its internal weak interfaces under freeze–thaw action.