Improving the Corrosion Resistance and Blood Compatibility of Magnesium Alloy via Fe-Based Amorphous Composite Coating Prepared by Magnetron Sputtering

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of the Coating

2.2. Characterization

2.3. Corrosion Resistance Experiments

2.4. Blood Compatibility Evaluation

3. Results and Discussion

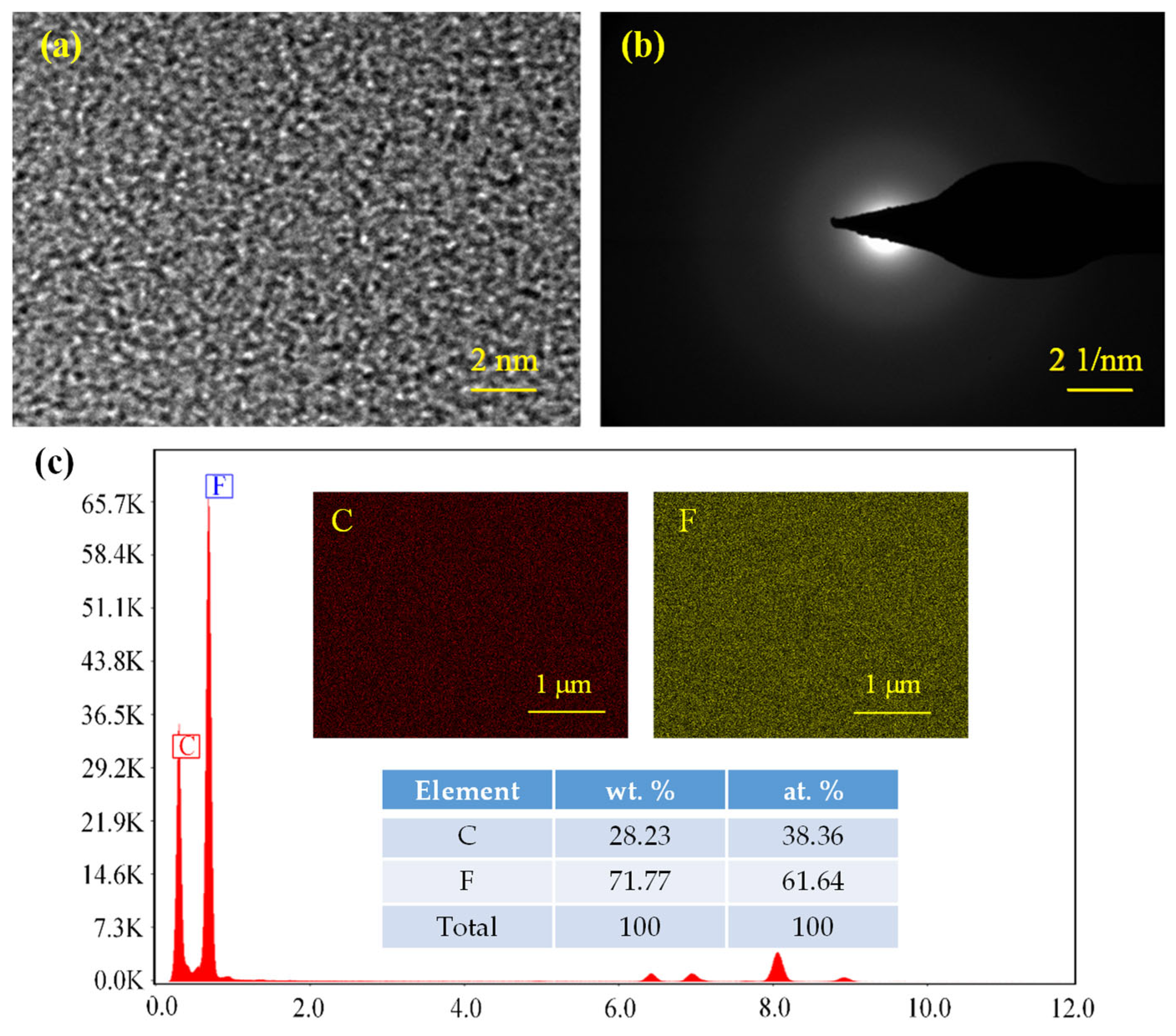

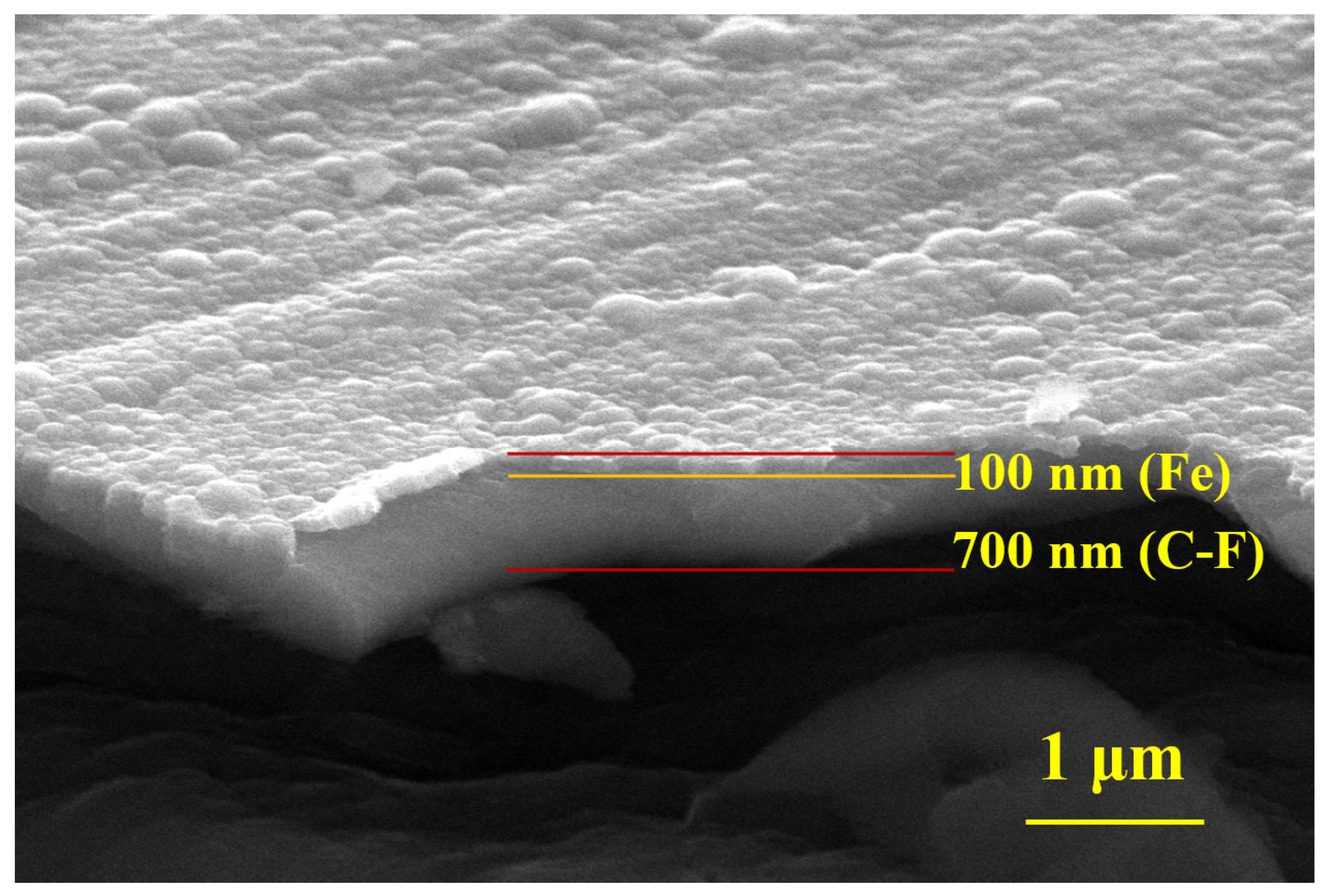

3.1. Characteristics of the Coating

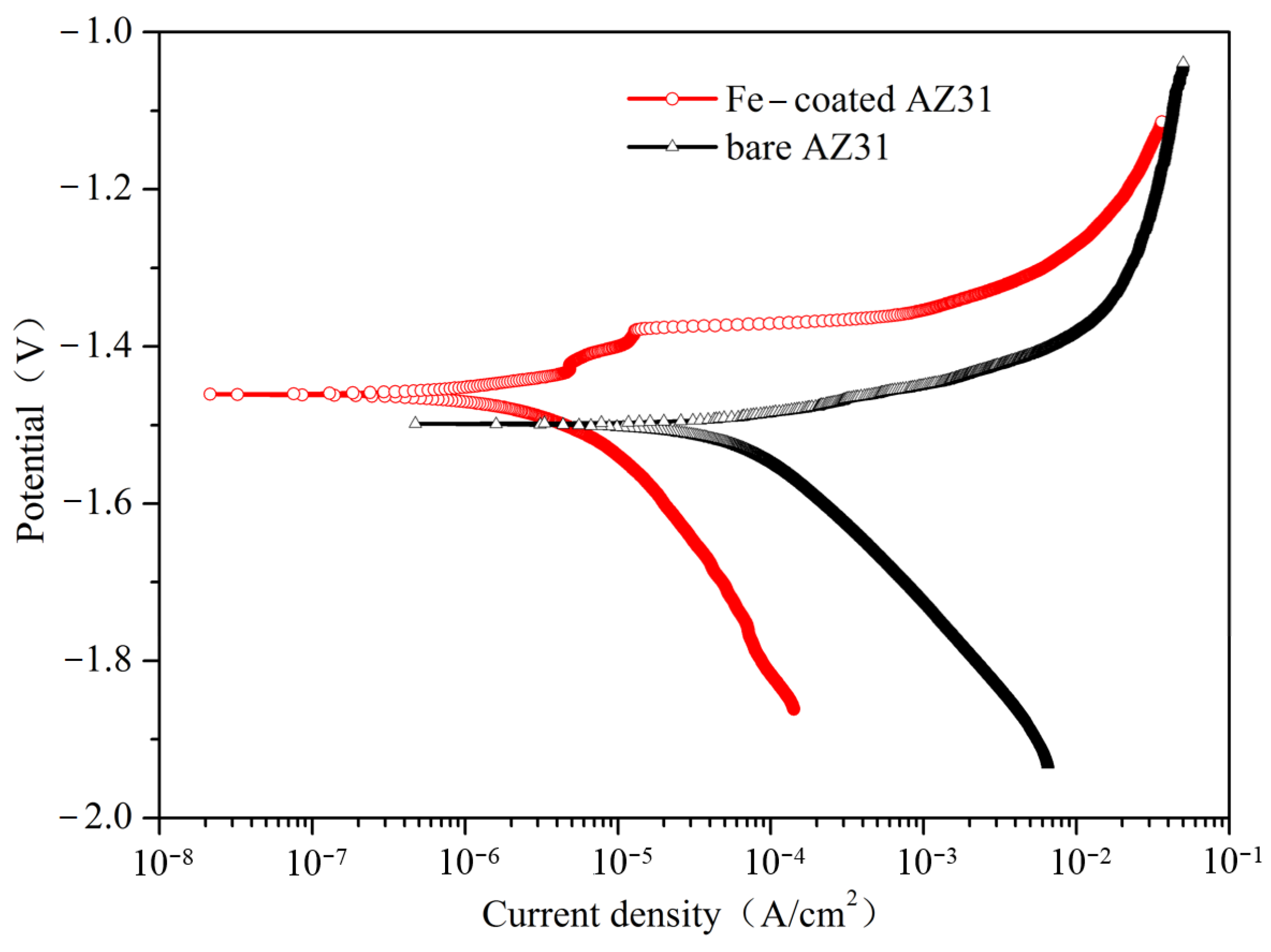

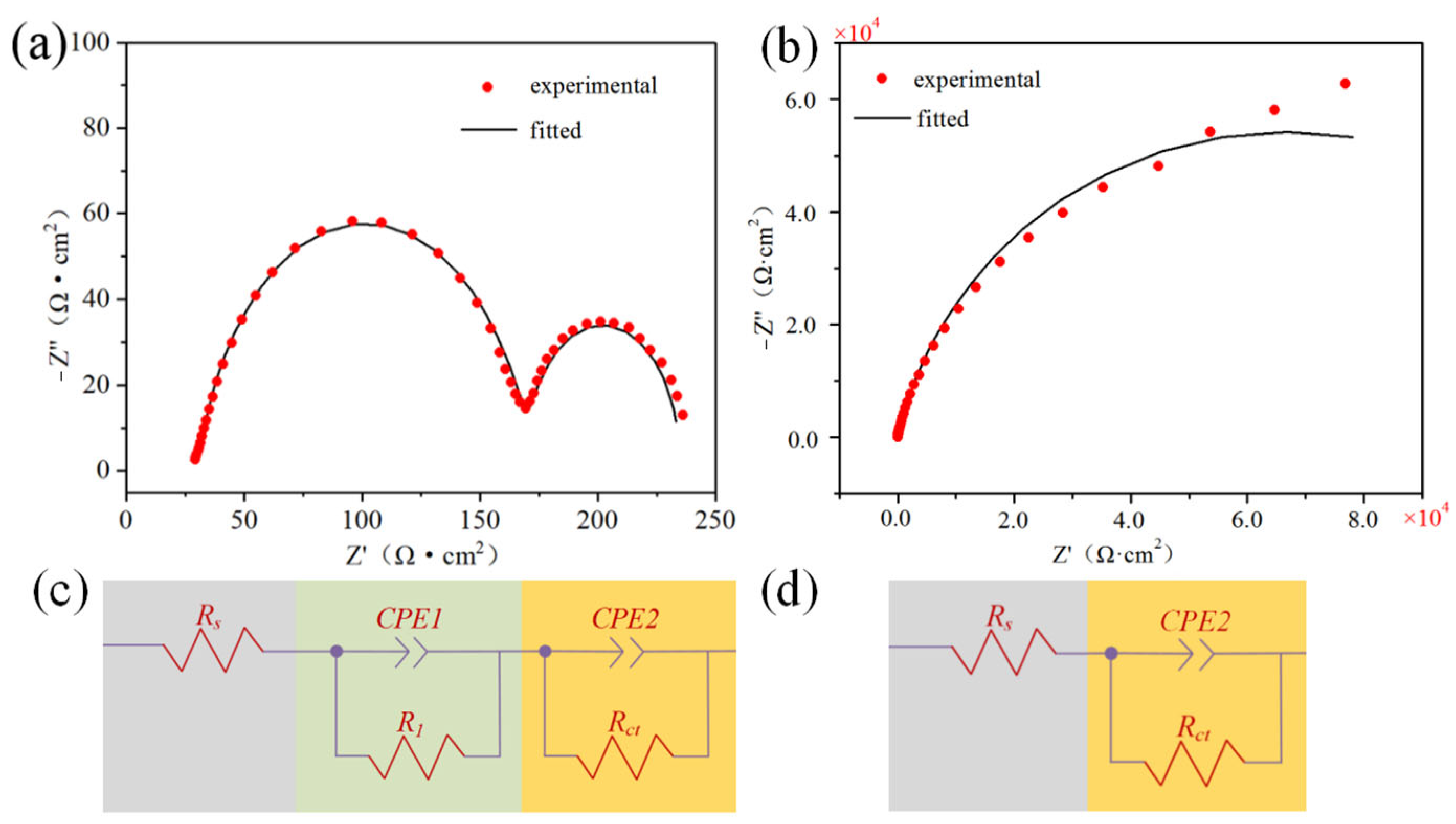

3.2. Corrosion Behavior

3.3. Blood Compatibility

4. Conclusions

- After 20 min of deposition at room temperature, a continuous, dense Fe-based coating with an amorphous structure was obtained, with a thickness of approximately 100 nanometers. The microstructure of the Fe-based coating is granular, comprising nanoscale particles.

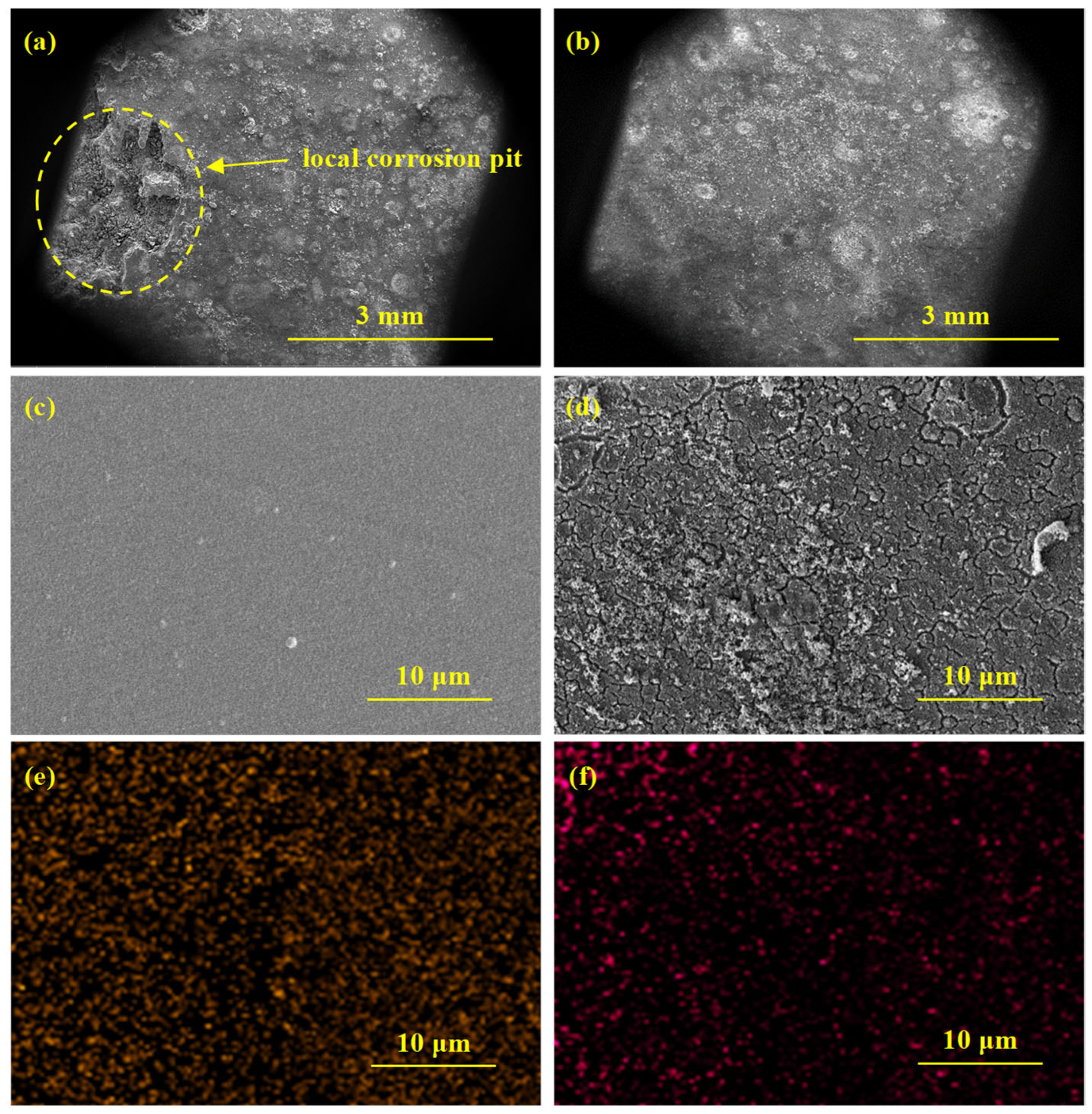

- After the Fe-based coating treatment, the corrosion resistance of the AZ31 magnesium alloy substrate is significantly improved. The corrosion current density decreases from 1.38 × 10−4 A/cm2 to 3.41 × 10−6 A/cm2 in SBF and the charge transfer resistance increases remarkably. Compared with the uncoated substrate, the coated AZ31 magnesium alloy exhibits an extremely low hydrogen evolution rate during the 28-day immersion test, and its surface morphology remains intact after corrosion.

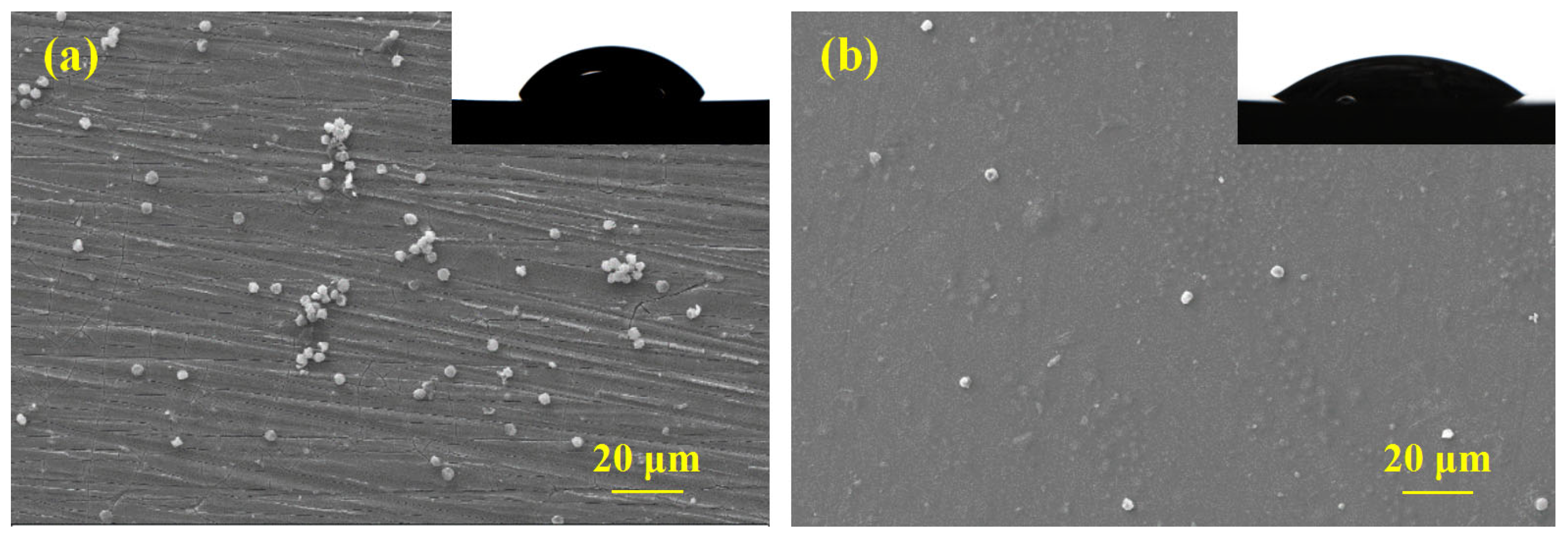

- The uncoated magnesium alloy induced severe hemolysis and platelet aggregation, whereas the Fe-based composite coating exhibited a hemolysis rate of merely 0.1% and superior anti-platelet adhesion capability—indicating excellent hemocompatibility.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Santos, V.; Uddin, M.; Hall, C. Mechanical surface treatments for controlling surface integrity and corrosion resistance of Mg alloy implants: A Review. J. Funct. Biomater. 2023, 14, 242. [Google Scholar] [CrossRef]

- Mahto, V.K.; Singh, A.K.; Malik, A. Surface modification techniques of magnesium-based alloys for implant applications. J. Coat. Technol. Res. 2022, 20, 433–455. [Google Scholar] [CrossRef]

- Sezer, N.; Evis, Z.; Kayhan, S.M.; Tahmasebifar, A.; Koc, M. Review of magnesium-based biomaterials and their applications. J. Magnes. Alloys 2018, 6, 23–43. [Google Scholar] [CrossRef]

- Chagnon, M.; Guy, L.G.; Jackson, N. Evaluation of magnesium-based medical devices in preclinical studies: Challenges and points to consider. Toxicol. Pathol. 2019, 47, 390–400. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Cao, J.; Liu, H.; Wang, C.; Chu, C.; Xue, F.; Willumeit-Rmer, R.; Hort, N.; Huang, Y.; Bai, J. Exploring the degradation behavior of biodegradable metals (Mg, Zn, and Fe) in human duodenal fluid. J. Magnes. Alloys 2025, 13, 2103–2119. [Google Scholar] [CrossRef]

- Qin, H.; Zhao, Y.C.; An, Z.Q.; Cheng, M.Q.; Wang, Q.; Cheng, T.; Wang, Q.J.; Wang, J.X.; Jiang, Y.; Zhang, X.L.; et al. Enhanced antibacterial properties, biocompatibility, and corrosion resistance of degradable Mg-Nd-Zn-Zr alloy. Biomaterials 2015, 53, 211–220. [Google Scholar] [CrossRef] [PubMed]

- Gao, Z.; Song, M.; Liu, R.L.; Shen, Y.; Ward, L.; Cole, I.; Chen, X.B.; Liu, X. Improving in vitro and in vivo antibacterial functionality of Mg alloys through micro-alloying with Sr and Ga. Mater. Sci. Eng. C 2019, 104, 109926. [Google Scholar] [CrossRef]

- Utyaganova, V.; Semin, V.; Savchenko, N.; Zotov, B.; Bazhenov, V.; Ershov, N.; Kavousi Sisi, A.; Egorov, V.; Bashmakova, O.; Irtegov, A.; et al. The effect of heat treatment of a biodegradable magnesium-based alloy produced by additive manufacturing on the product performance. Mater. Charact. 2025, 229, 115457. [Google Scholar] [CrossRef]

- Minarik, P.; Landa, M.; Lesna, I.K.; Zemkova, M.; Jablonska, E.; Hadzima, B.; Janecek, M.; Kral, R. Interrelation of microstructure and corrosion resistance in biodegradable magnesium alloys with aluminum, lithium and rare earth additions. Acta Phys. Pol. A 2015, 128, 491–496. [Google Scholar] [CrossRef]

- Li, J.; Li, J.; Li, Q.; Zhou, H.; Wang, G.; Peng, X.; Jin, W.; Yu, Z.; Chu, P.K.; Li, W. Titania-zinc phosphate/nanocrystalline zinc composite coatings for corrosion protection of biomedical WE43 magnesium alloy. Surf. Coat. Technol. 2021, 410, 126940. [Google Scholar] [CrossRef]

- Liu, J.; Yin, B.; Song, F.; Liu, B.; Peng, B.; Wen, P.; Tian, Y.; Zheng, Y.; Ma, X.; Wang, C. Improving corrosion resistance of additively manufactured WE43 magnesium alloy by high temperature oxidation for biodegradable applications. J. Magnes. Alloys 2024, 12, 940–953. [Google Scholar] [CrossRef]

- Ye, T.; Wang, L.; Hu, X.; Bu, Z. Studies on the coating formation and structure property for plasma electrolytic oxidation of AZ31 magnesium alloy. Coatings 2025, 15, 846. [Google Scholar] [CrossRef]

- Cui, L.Y.; Wei, G.B.; Han, Z.Z.; Zeng, R.C.; Wang, L.; Zou, Y.H.; Li, S.Q.; Xu, D.K.; Guan, S.K. In vitro corrosion resistance and antibacterial performance of novel tin dioxide-doped calcium phosphate coating on degradable Mg-1Li-1Ca alloy. J. Mater. Sci. Technol. 2019, 35, 254–265. [Google Scholar] [CrossRef]

- Diaz-Ramos, M.; Roche, V.; Song, R.; Fan, H.; Bureau, C.; Lepretre, J.C. Electrochemical impedance spectroscopy (EIS) of parylene coated magnesium stents in organic solvent to study early corrosion control. Corros. Sci. 2023, 213, 110932. [Google Scholar] [CrossRef]

- Cao, X.R.; Chen, Y.N.; Zhang, C.; Mao, Z.; Zhang, J.; Ma, T.; Tian, W.; Kong, X.; Li, H.; Rao, S. Heterogeneous nucleation induced A. pernyi/B. mori silk fibroin coatings on AZ31 biometals with enhanced corrosion resistance, adhesion and biocompatibility. Int. J. Biol. Macromol. 2024, 264, 130524. [Google Scholar] [CrossRef] [PubMed]

- Hou, S.; Yang, T.; Li, Y.; Lian, L.; Yu, W.; Yang, L. Topography control of micro-nanosized anatase coating on magnesium alloy. Coatings 2022, 12, 1063. [Google Scholar] [CrossRef]

- Rahimi, R.N.; Hassannejad, H.; Nouri, A. Corrosion and mechanical behaviour of biodegradable PLA-cellulose nanocomposite coating on AZ31 magnesium alloy. Surf. Eng. 2020, 37, 236–245. [Google Scholar] [CrossRef]

- Kim, K.J.; Hwang, M.J.; Choe, S.W. Drug release profile of phenytoin-loaded starch-based biomaterials incorporating hierarchical microparticles with photothermal effects. Int. J. Biol. Macromol. 2024, 282, 136803. [Google Scholar] [CrossRef]

- Haude, M.; Wlodarczak, A.; van der Schaaf, R.J.; Torzewski, J.; Ferdinande, B.; Escaned, J.; Iglesias, J.F.; Bennett, J.; Toth, G.G.; Joner, M.; et al. A new resorbable magnesium scaffold for de novo coronary lesions (DREAMS 3): One-year results of the BIOMAG-I first-in-human study. EuroIntervention 2023, 19, E414–E422. [Google Scholar] [CrossRef]

- Zhai, H.; Yuan, H.; Li, W.; Zhang, X.; Li, X.; Cai, A. Corrosion resistance mechanisms of detonation sprayed Fe-based amorphous coating on AZ31B magnesium alloy. J. Non-Cryst. Solids 2022, 576, 121276. [Google Scholar] [CrossRef]

- Li, S.; Ren, J.Z.; Wang, X.D.; Ding, Y.J.; Li, P.W.; Hu, Y.F.; Yang, Y.W. Dilemmas and countermeasures of Fe-based biomaterials for next-generation bone implants. J. Mater. Res. Technol. 2022, 20, 2034–2050. [Google Scholar] [CrossRef]

- Xu, C.; Zhang, H.; Yu, S.; Wu, W.; Zhang, L.; Liu, Q.; Ren, L. Direct ink writing of porous Fe scaffolds for bone implants: Pore size evolution and effect on degradation and mechanical properties. J. Mater. Res. Technol. 2023, 25, 4901–4912. [Google Scholar] [CrossRef]

- Yusop, A.H.M.; Bahrudin, M.T.A.H.; Ali, W.F.F.W.; Sarian, M.N.; Arafat, A.; Nur, H. Biocorrosion of Fe-based implants in protein-containing simulated body fluid: Importance, mechanism, and development. Mater. Today Chem. 2024, 42, 102355. [Google Scholar] [CrossRef]

- Putra, N.; Youf, R.; Moosabeiki, V.; Leeflang, M.; Klimopoulou, M.; Mirzaali, M.; Mol, A.; Riool, M.; Fratila-Apachitei, L.; Zhou, J. Direct ink writing of sustainable multifunctional biodegradable porous Fe-eggshell scaffolds. Acta Biomater. 2025, 202, 622–640. [Google Scholar] [CrossRef]

- Kartikasari, R.; Effendy, M. Surface characterization of Fe-10Al-25Mn alloy for biomaterial applications. J. Mater. Res. Technol. 2021, 15, 409–415. [Google Scholar] [CrossRef]

- Zhang, E.; Chen, H.; Shen, F. Biocorrosion properties and blood and cell compatibility of pure iron as biodegradable biomaterial. J. Mater. Sci. Mater. Med. 2010, 21, 2151–2163. [Google Scholar] [CrossRef]

- Rabeeh, V.P.M.; Hanas, T. Progress in manufacturing and processing of degradable Fe-based implants: A review. Prog. Progress. Biomater. 2022, 11, 163–191. [Google Scholar] [CrossRef]

- Liu, B.; Zheng, Y.F. Effects of alloying elements (Mn, Co, Al, W, Sn, B, C and S) on biodegradability and in vitro biocompatibility of pure iron. Acta Biomater. 2011, 7, 1407–1420. [Google Scholar] [CrossRef]

- Bencina, M.; Rawat, N.; Paul, D.; Kovac, J.; Lakota, K.; Zigon, P.; Kralj-Iglic, V.; Iglic, A.; Junkar, I. Enhanced hemocompatibility and cytocompatibility of stainless steel. ACS Omega 2024, 9, 19566–19577. [Google Scholar] [CrossRef]

- Petroušek, P.; Kvačkaj, T.; Bidulská, J.; Bidulský, R.; Grande, M.A.; Manfredi, D.; Weiss, K.P.; Kočiško, R.; Lupták, M.; Pokorný, I. Investigation of the properties of 316L stainless steel after AM and heat treatment. Materials 2023, 16, 3935. [Google Scholar] [CrossRef]

- Esmaeili, A.; Ghaffari, S.A.; Nikkhah, M.; Malek Ghaini, F.; Farzan, F.; Mohammadi, S. Biocompatibility assessments of 316L stainless steel substrates coated by Fe-based bulk metallic glass through electro-spark deposition method. Colloids Surf. B Biointerfaces 2021, 198, 111469. [Google Scholar] [CrossRef]

- Kokubo, T.; Takadama, H. How useful is SBF in predicting in vivo bone bioactivity? Biomaterials 2006, 27, 2907–2915. [Google Scholar] [CrossRef]

- Guo, Z.; Ye, Y.; Zhou, Z.; Wang, Q.; Zhang, B.; Shen, B. Novel FeNiCrMoCBPNb high-entropy amorphous coatings prepared by atmospheric plasma spraying with excellent corrosion and wear properties. J. Therm. Spray Technol. 2025, 34, 394–408. [Google Scholar] [CrossRef]

- Xie, L.; Wang, Y. High temperature wear and corrosion behavior of detonation sprayed Fe-based amorphous coatings. Sci. Rep. 2024, 14, 29410. [Google Scholar] [CrossRef]

- Hou, S.S.; Yu, W.X.; Yang, Z.J.; Li, Y.; Yang, L.; Lang, S.T. Properties of titanium oxide coating on Mg-Zn alloy by magnetron sputtering for stent application. Coatings 2020, 10, 999. [Google Scholar] [CrossRef]

| Al | Zn | Mn | Si | Fe | Ni | Cu | Mg |

|---|---|---|---|---|---|---|---|

| 3.120 | 0.930 | 0.300 | 0.018 | 0.003 | 0.001 | 0.001 | balance |

| Cr | Ni | Mo | Mn | Si | C | P | Fe |

|---|---|---|---|---|---|---|---|

| 16–18 | 10–14 | 2–3 | 0.2–2 | <1 | <0.03 | <0.045 | balance |

| Target | Temperature (°C) | Power (W) | Pressure (Pa) | Argon Flow (sccm) | Time |

|---|---|---|---|---|---|

| PTFE | 25 | 120 | 0.6 | 30 | 5 h |

| 316L | 25 | 120 | 0.6 | 30 | 20 min |

| Sample | Bare AZ31 | Coated AZ31 |

|---|---|---|

| Rs/(Ω·cm2) | 30.17 | 18.36 |

| R1/(Ω·cm2) | 63.31 | - |

| CPE1-T/(F·cm2) | 2.15 × 10−3 | - |

| CPE1-P/(F·cm2) | 1.023 | - |

| Rct/(Ω·cm2) | 141.40 | 134,770 |

| CPE2-T/(F·cm2) | 1.10 × 10−5 | 6.71 × 10−5 |

| CPE2-P/(F·cm2) | 0.86 | 0.95 |

| Samples | Hemolysis Rate (%) |

|---|---|

| Bare AZ31 | 42.2 ± 2.5 |

| Fe-coated AZ31 | 0.1 ± 0.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, G.; Hou, S.; Liu, B.; Du, X.; Zuo, D. Improving the Corrosion Resistance and Blood Compatibility of Magnesium Alloy via Fe-Based Amorphous Composite Coating Prepared by Magnetron Sputtering. Coatings 2025, 15, 1167. https://doi.org/10.3390/coatings15101167

Guo G, Hou S, Liu B, Du X, Zuo D. Improving the Corrosion Resistance and Blood Compatibility of Magnesium Alloy via Fe-Based Amorphous Composite Coating Prepared by Magnetron Sputtering. Coatings. 2025; 15(10):1167. https://doi.org/10.3390/coatings15101167

Chicago/Turabian StyleGuo, Guizhong, Shusen Hou, Bing Liu, Xingzhu Du, and Dunwen Zuo. 2025. "Improving the Corrosion Resistance and Blood Compatibility of Magnesium Alloy via Fe-Based Amorphous Composite Coating Prepared by Magnetron Sputtering" Coatings 15, no. 10: 1167. https://doi.org/10.3390/coatings15101167

APA StyleGuo, G., Hou, S., Liu, B., Du, X., & Zuo, D. (2025). Improving the Corrosion Resistance and Blood Compatibility of Magnesium Alloy via Fe-Based Amorphous Composite Coating Prepared by Magnetron Sputtering. Coatings, 15(10), 1167. https://doi.org/10.3390/coatings15101167