Microstructure and Wear Resistance of Plasma-Sprayed Al2O3-TiO2-CeO2/YSZ Composite Coatings

Abstract

1. Introduction

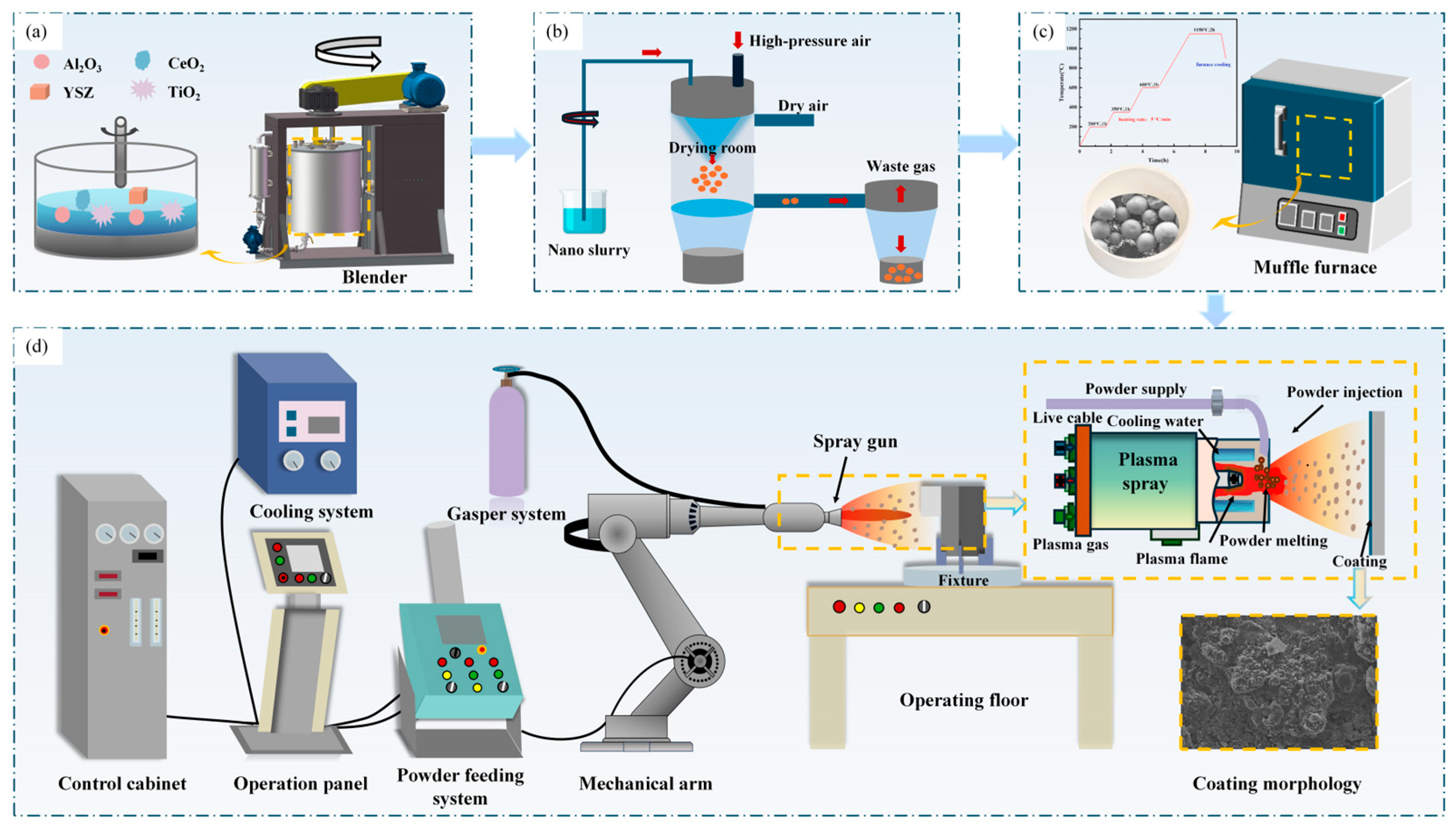

2. Experimental Procedures

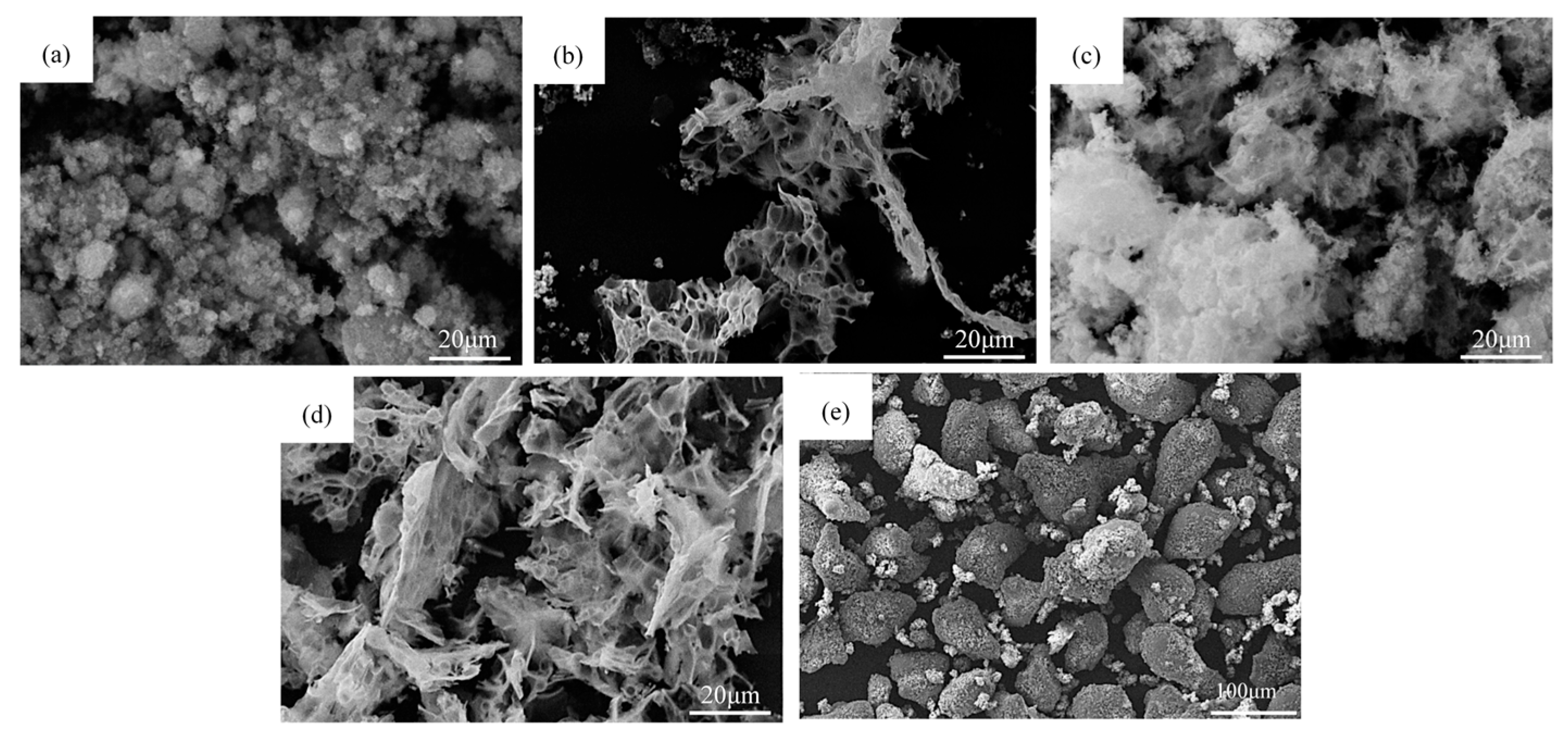

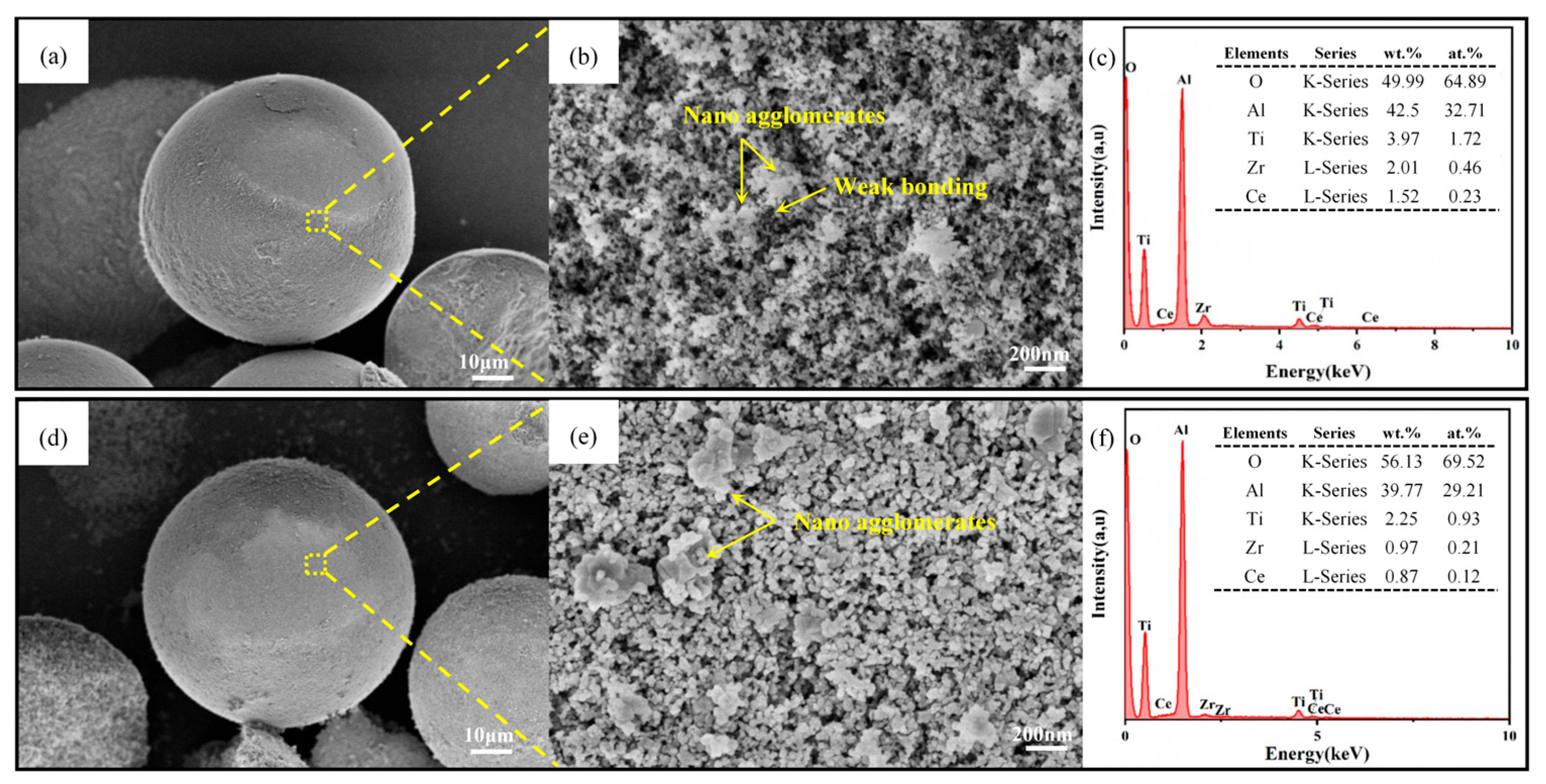

2.1. Powder Preparation and Coating Preparation

2.2. Microstructure Observation and Performance Testing

3. Results

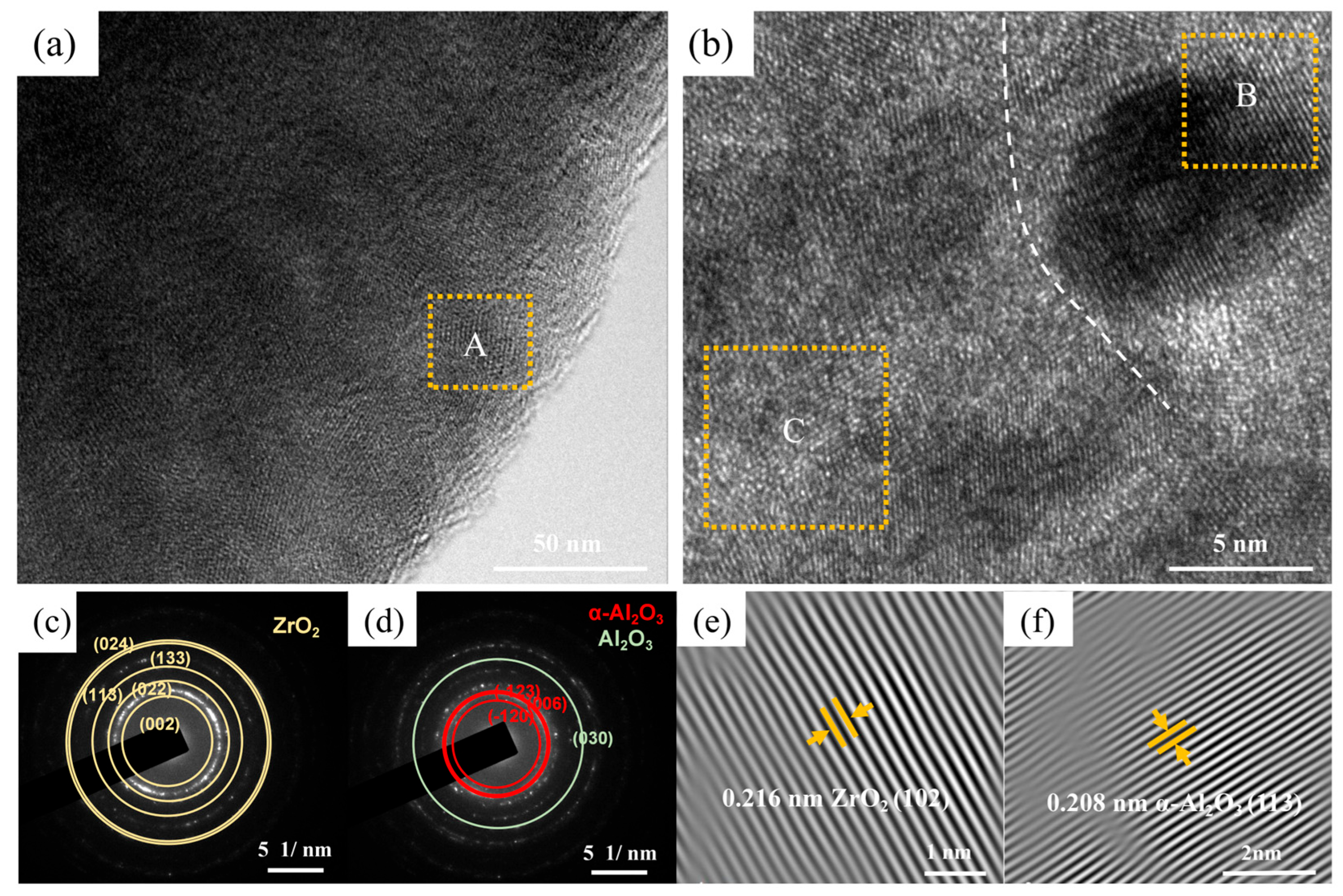

3.1. Microstructure

3.2. Mechanical Properties

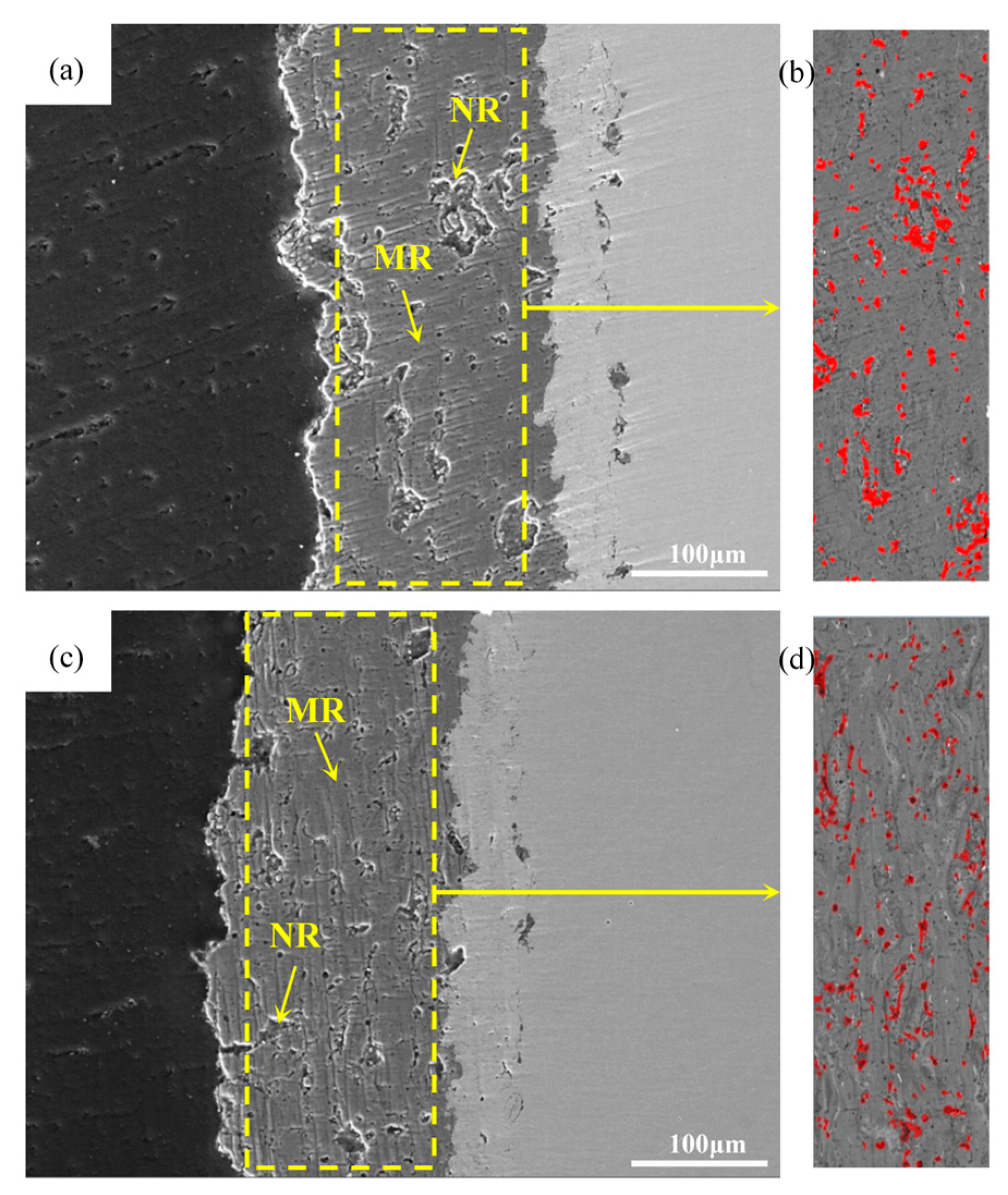

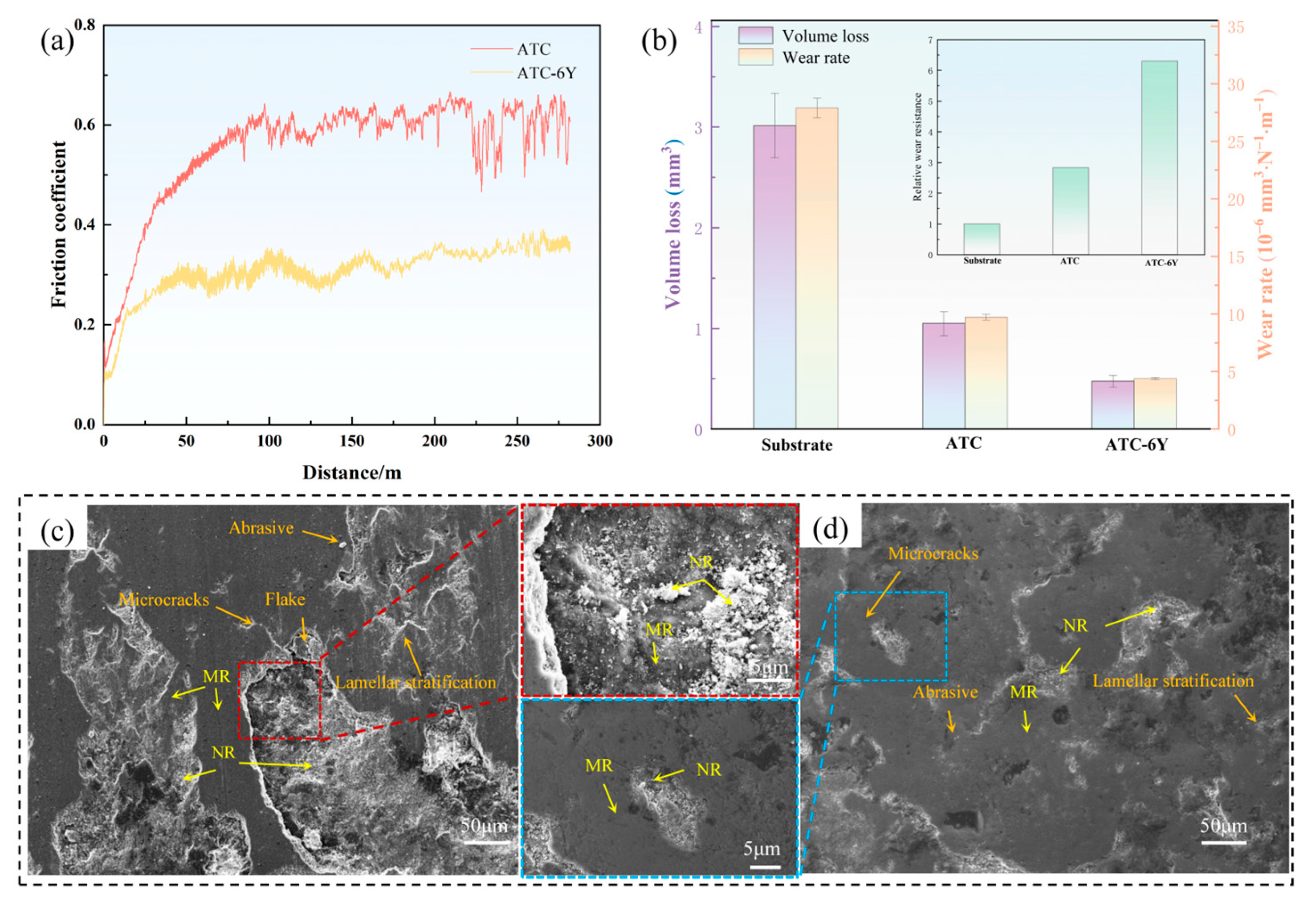

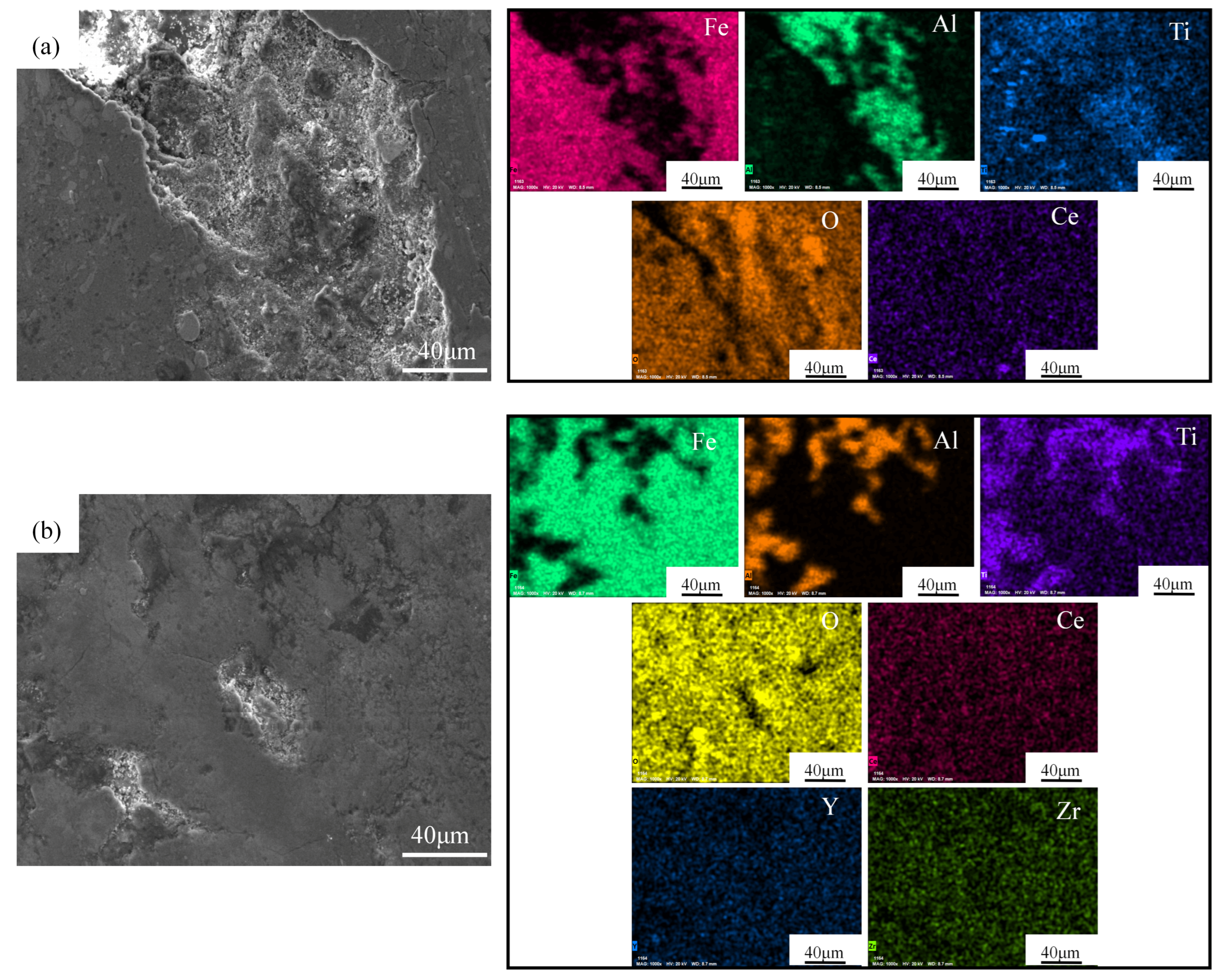

3.3. Wear Behavior

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bolelli, G.; Steduto, D.; Kiilakoski, J.; Varis, T.; Lusvarghi, L.; Vuoristo, P. Tribological properties of plasma sprayed Cr2O3, Cr2O3-TiO2, Cr2O3-Al2O3 and Cr2O3-ZrO2 coatings. Wear 2021, 480, 203931. [Google Scholar] [CrossRef]

- Testa, V.; Morelli, S.; Bolelli, G.; Usvarghi, L.; Björklund, S.; Joshi, S. Micromechanical behaviour and wear resistance of hybrid plasma-sprayed TiC reinforced Tribaloy-400. Surf. Coat. Technol. 2021, 425, 127682. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Y.W.; Sun, W.W.; Yang, Y.; Zhang, C.; Ma, Y.D.; Cui, Y.H.; Zhao, C.C.; Wang, L.; Dong, Y.C.; et al. Microstructure and properties of Al2O3-ZrO2-Y2O3 composite coatings prepared by plasma spraying. J. Therm. Spray Technol. 2020, 29, 967–978. [Google Scholar] [CrossRef]

- Mao, J.Y.; Liu, M.; Deng, C.M.; Mao, J.; Zeng, D.C. A comparative study of spray-dried and mechanically-mixed ZrB2-MoSi2 composite coatings fabricated by low pressure plasma spray. Rare Met. Mat. Eng. 2016, 45, 1386–1390. [Google Scholar] [CrossRef]

- Wang, H.B.; Lu, H.; Song, X.Y.; Yan, X.F.; Liu, X.M.; Nie, Z.R. Corrosion resistance enhancement of WC cermet coating by carbides alloying. Corros. Sci. 2019, 147, 372–383. [Google Scholar] [CrossRef]

- Matikainen, V.; Bolelli, G.; Koivuluoto, H.; Sassatelli, P.; Lusvarghi, L.; Vuoristo, P. Sliding wear behaviour of HVOF and HVAF sprayed Cr3C2-based coatings. Wear 2017, 388, 57–71. [Google Scholar] [CrossRef]

- Zhang, Y.G.; Gao, X.F.; Liang, X.B.; Chong, K.; Wu, D.T.; Zou, Y. Effect of laser remelting on the microstructure and corrosion property of the arc-sprayed AlFeNbNi coatings. Surf. Coat. Technol. 2020, 398, 126099. [Google Scholar] [CrossRef]

- Nayak, S.K.; Kumar, A.; Pathak, A.; Banerjee, A.; Laha, T. Multi-scale mechanical properties of Fe-based amorphous/nanocrystalline composite coating synthesized by HVOF spraying. J. Alloys Compd. 2020, 825, 154120. [Google Scholar] [CrossRef]

- Senthilkumar, N.; Perumal, G.; Palanikumar, K.; Deepanraj, B.; Shameer Basha, M. Wear and mechanical characteristics of coated Ti-6Al-4 V alloy with an alumina-13 wt.% titania -40 wt.% yitrium stabilized zirconia ceramic composite via plasma spraying technique. Results Eng. 2025, 25, 103777. [Google Scholar] [CrossRef]

- Karagedov, G.R.; Lyakhov, N.Z. Preparation and sintering of nanosized α-Al2O3 powder. Nanostructured Mater. 1999, 11, 559–572. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, Y.G.; Zhang, Q. Study on tribological properties and process optimization of Al2O3-xTiO2 composite coatings prepared by plasma spraying. Mater. Today Commun. 2025, 44, 112182. [Google Scholar] [CrossRef]

- Xue, Z.L.; Zhu, Y.; Yu, H.Y.; Shi, M.C.; Liu, X.; Zhang, S.H. Nano-agglomerated powder and thermal shock cycling property of 8YSZ nano-structured thermal barrier coating. Surf. Coat. Technol. 2022, 433, 128173. [Google Scholar] [CrossRef]

- Li, G.R.; Yang, G.J. Understanding of degradation-resistant behavior of nanostructured thermal barrier coatings with bimodal structure. J. Mater. Sci. Technol. 2019, 35, 231–238. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Y.; Sun, X.G.; He, J.Q.; Pan, Z.Y.; Wang, C.H. Microstructure and indentation mechanical properties of plasma sprayed nano-bimodal and conventional ZrO2–8wt% Y2O3 thermal barrier coatings. Vacuum 2012, 86, 1174–1185. [Google Scholar] [CrossRef]

- Masanta, M.; Ganesh, P.; Kaul, R.; Nath, A.K.; Choudhury, A.R. Development of a hard nano-structured multi-component ceramic coating by laser cladding. Mater. Sci. Eng. A 2009, 508, 134–140. [Google Scholar] [CrossRef]

- Li, W.Z.; Zhu, Y.P.; Wang, X.Y.; Zhao, L.L.; Chu, Y.; Chen, F.H.; Chang, G.; Fang, S.G. Preparation and thermophysical properties of new multi-component entropy-stabilized oxide ceramics for thermal barrier coatings. Coatings 2023, 13, 937. [Google Scholar] [CrossRef]

- Carnicer, V.; Orts, M.J.; Moreno, R.; Sánchez, E. Microstructure assessment of suspension plasma spraying coatings from multicomponent submicronic Y-TZP/Al2O3/SiC particles. Ceram. Int. 2018, 44, 12014–12020. [Google Scholar] [CrossRef]

- Jia, S.K.; Yong, Z.; Xu, J.Y.; Wang, J.; Yu, L. Effect of TiO2 content on properties of Al2O3 thermal barrier coatings by plasma spraying. Trans. Nonferrous Met. Soc. China 2015, 25, 175–183. [Google Scholar] [CrossRef]

- Brar, S.S.; Brar, G.S.; Chawla, V. Characterization of D-gun sprayed Al2O3-13% TiO2 and Al2O3-40% TiO2 coatings on ASTM 316 boiler steel and their microstructure. Mater. Today Proc. 2022, 50, 2299–2306. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, S.L.; Zhao, L.; Yang, C.D.; Wu, L.P.; Guo, Y.J.; Ang, S.M. Corrosion Behavior of Plasma-Sprayed Al2O3-3% TiO2 Coatings Doped with CeO2. J. Therm. Spray Technol. 2023, 32, 290–305. [Google Scholar] [CrossRef]

- Yang, C.D. Study on Microstructure and Properties of Plasma Sprayed Al2O3/TiO2-CeO2 Composite Coating. Master’s Thesis, Shenyang University, Shenyang, China, 2021. [Google Scholar] [CrossRef]

- Hebbale, A.; Ramesh, M.R.; Petru, J.; Chandramouli, T.V.; Srinath, M.S.; Shetty, R.K. A microstructural study and high-temperature oxidation behaviour of plasma sprayed NiCrAlY based composite coatings. Results Eng. 2025, 25, 103926. [Google Scholar] [CrossRef]

- Shi, T.J.; Bai, B.T.; Peng, H.R.; Yuan, K.; Han, R.F.; Zhou, Q.; Pang, X.X.; Zhang, X.; Yan, Z. Improved thermal shock resistance of GYYZO-YSZ double ceramic layer TBCs induced by induction plasma spheroidization. Surf. Coat. Technol. 2024, 77, 130372. [Google Scholar] [CrossRef]

- Luțcanu, M.; Cimpoeșu, R.; Abrudeanu, M.; Munteanu, C.; Moga, S.G.; Coteata, M.; Zegan, G.; Benchea, M.; Cimpoeșu, N.; Murariu, A.M. Mechanical Properties and Thermal Shock Behavior of Al2O3-YSZ Ceramic Layers Obtained by Atmospheric Plasma Spraying. Crystals 2023, 13, 614. [Google Scholar] [CrossRef]

- Mehar, S.; Sapate, S.G. Contact severity maps for plasma sprayed YSZ modified Al2O3-3% TiO2 coatings. Ceram. Int. 2024, 50, 13003–13013. [Google Scholar] [CrossRef]

- Wang, C.; Pang, X.J.; Gao, Z.H.; Liu, J.N.; Fang, Y.C.; Cui, X.F.; Liu, E.B.; Jin, G. Wear Resistance of YSZ Fibers Reinforced Al2O3/8YSZ Coatings Prepared by Atmosphere Plasma Spraying. J. Mater. Rep. 2018, 32, 563–568. [Google Scholar] [CrossRef]

- Zeng, Y.B.; Liu, Y.Z.; Zhang, Y.X.; Zhou, Z.G.; Liu, X.H. Ferroelastic domain switching toughening in Ce-Y-La co-stabilized zirconia ceramics obtained from coated starting powders. J. Alloys Compd. 2020, 820, 153177. [Google Scholar] [CrossRef]

- Guan, H.; Gong, X.J.; Liu, R.; Liu, Y. Preparation of Stable Nanosized ZrO2 Particles with Different Crystallographic Structures. Chin. J. Mater. Res. 2014, 28, 139–143. [Google Scholar] [CrossRef]

- Kumar, R.; Goyal, K.; Bhandari, D. Slurry Erosion Behavior of Thermally Sprayed Nano YSZ Reinforced WC-10Co-4Cr Ceramic Nanocomposite Coatings. Tribol. Trans. 2023, 66, 47–58. [Google Scholar] [CrossRef]

- Zhao, X.L.; Liu, W.; Li, C.; Yan, G.; Wang, Q.W.; Li, Y.; Zhou, Y.C. Solid particle erosion behavior of La2Ce2O7/YSZ double-ceramic-layer and traditional YSZ thermal barrier coatings at high temperature. Coatings 2022, 12, 1638. [Google Scholar] [CrossRef]

- An, G.S.; Li, W.S.; Li, F.; Cheng, B.; Wang, Z.P.; Li, Z.Y.; Zhang, Y. Isothermal oxidation and TGO growth behaviors of YAG/YSZ double-ceramic-layer thermal barrier coatings. Ceram. Int. 2021, 47, 24320–24330. [Google Scholar] [CrossRef]

- Liu, L.; Maeda, K.; Onda, T.; Chen, Z.C. Effect of YSZ with different Y2O3 contents on toughening behavior of Al2O3/Ba-β-Al2O3/ZrO2 composites. Ceram. Int. 2019, 45, 18037–18043. [Google Scholar] [CrossRef]

- Meng, Z.C.; Qian, W.F.; Ning, B.K.; Wang, S.; Chen, Y.N.; Zhang, Y.; Wang, N.; Li, Y.C.; Zhang, W.; Gao, G.R. High-temperature crack resistance of yttria-stabilized zirconia coatings enhanced by interfacial stress transfer. J. Appl. Surf. Sci. 2025, 682, 161688. [Google Scholar] [CrossRef]

- Sanjai, S.G.; Srideep, S.; Krishna, B.A.; Sumanth, M.S.; Ramaswamy, P. Synthesis of yttria-stabilized zirconia nano powders for plasmasprayed nano coatings. Mater. Today Proc. 2019, 22, 1253–1263. [Google Scholar] [CrossRef]

- Padture, N.P.; Gell, M.; Jordan, E.H. Thermal barrier coatings for gas-turbine engine applications. Science 2002, 296, 280–284. [Google Scholar] [CrossRef]

- Carpio, P.; Borrell, A.; Salvador, M.D.; Gómez, A.; Martínez, E.; Sánchez, E. Microstructure and mechanical properties of plasma spraying coatings from YSZ feedstocks comprising nano- and submicron-sized particles. Ceram. Int. 2015, 41, 4108–4117. [Google Scholar] [CrossRef]

- Vicent, M.; Bannier, E.; Moreno, R.; Salvador, M.D.; Sánchez, E. Atmospheric plasma spraying coatings from alumina–titania feedstock comprising bimodal particle size distributions. J. Eur. Ceram. Soc. 2013, 33, 3313–3324. [Google Scholar] [CrossRef]

- Loghman-Estarki, M.R.; Edris, H.; Jamali, H.; Ghasemi, R.; Pourbafrany, M.; Erfanmanesh, M.; Ramezani, M. Spray drying of nanometric SYSZ powders to obtain plasma sprayable nanostructured granules. Ceram. Int. 2013, 39, 9447–9457. [Google Scholar] [CrossRef]

- Gao, Y. Study of the Microstructure and Properties of Plasma-Sprayed Al2O3-TiO2-ZrO2 Coating. Master’s Thesis, Tianjin Hebei University of Technology, Tianjin, China, 2009. [Google Scholar]

- GB/T 8642-2002; Thermal Spraying—Determination of Tensile Adhesive Strength. China Standards Press: Beijing, China, 2002.

- Mcpherson, R. Formation of Metastable Phase in Flame and Plasma Prepared Alumina. J. Mater. Sci. 1973, 8, 851–858. [Google Scholar] [CrossRef]

- Lu, F.Z.; Liu, H.T.; Huang, W.Z. A Review of 8YSZ-Al2O3Composite Thermal Barrier Coatings. J. Mater. Rep. 2021, 35, 7042–7047+7070. [Google Scholar] [CrossRef]

- Rong, J.; Yang, K.; Zhao, H.Y.; Liu, C.G.; Zhuang, Y.; Tao, S.Y. Tribological performance of plasma sprayed Al2O3–Y2O3 composite coatings. Surf. Coat. Technol. 2016, 302, 487–494. [Google Scholar] [CrossRef]

- Mehar, S.; Sapate, S.G.; Vashishtha, N.; Rathod, A.; Bagde, P. Tribological performance of plasma sprayed Al2O3-TiO2-ZrO2 ceramic coating. Mater. Today Proc. 2021, 45, 4737–4741. [Google Scholar] [CrossRef]

- Yang, S.Y.; Xing, X.G.; Zhang, J.J.; Wang, H.; Si, M.L.; Wang, H.F. Influence of rare earth oxide (REO) additives on mechanical and friction and wear properties of aluminum oxide ceramics. J. Funct. Mater. 2018, 49, 6190–6195+6200. [Google Scholar] [CrossRef]

- Liu, J.L.; Wu, R.; Zu, Y.D.; Xiao, J.S.; Zhang, B.; Zou, H.J. Crystalline Size of TiO2 at Calcination Temperature with by RietveldRef inement, Debye-Scherrer and Williamson-Hall Method. Chem. Eng. Manag. 2023, 13, 151–155. [Google Scholar] [CrossRef]

- Sui, Y.D.; Han, L.N.; Jiang, Y.H. Effect of Ta2O5 addition on the microstructure and mechanical properties of TiO2-added yttria-stabilized zirconia-toughened alumina (ZTA) composites. Ceram. Int. 2018, 44, 14811–14816. [Google Scholar] [CrossRef]

- Li, R.B.; Xing, Y.; Zhang, Z.X.; He, F. Plasma Spraying Process of YSZ Thermal Barrier Coatings. J. Surf. Technol. 2024, 53, 217–229. [Google Scholar] [CrossRef]

- Kushwaha, S.; Bhadauria, A.; Bajpai, S.; Tiwari, A.; Pandey, K.K.; Keshri, A.K.; Balani, K. Mechanical, microstructural, and fretting wear behaviour of Al2O3–ZrO2-CNT based bimodal composite coatings. Wear 2023, 532, 205127. [Google Scholar] [CrossRef]

- Bogicevic, A.; Wolverton, C.; Crosbie, G.M.; Stechel, E.B. Defect ordering in aliovalently doped cubic zirconia from first principles. Phys. Rev. B 2001, 64, 014106. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Severo, F.D.S.; Scheuer, C.J.; Cardoso, R.P.; Brunatto, S.F. Cavitation erosion resistance enhancement of martensitic stainless steel via low-temperature plasma carburizing. Wear 2019, 428, 162–166. [Google Scholar] [CrossRef]

- Zhao, X.; An, Y.; Chen, J.; Zhou, H.; Yin, B. Properties of Al2O3–40 wt.% ZrO2 composite coatings from ultra-fine feedstocks by atmospheric plasma spraying. Wear 2008, 265, 1642–1648. [Google Scholar] [CrossRef]

- Gasson, P.C. Materials Sciences and Engineering–Eighth edition. WD Callister and DG Rethwisch John Wiley and Sons, The Atrium, Southern Gate, Chichester, West Sussex, PO19 8SQ, UK. 2010. 968pp. Illustrated.£ 47.99. ISBN 978-0-470-50586-1. Aeronaut. J. 2011, 115, 388–389. [Google Scholar] [CrossRef]

| Parameters | NiCrAlY Bond Coating | ATC/ATC-6Y Composite Coating |

|---|---|---|

| Spraying current (A) | 450 | 600 |

| Spraying voltage (V) | 60 | 70 |

| Main gas Ar flow rate (L/min) | 42 | 42 |

| Secondary gas H2 flow rate (L/min) | 10 | 10 |

| Gun moving speed (mm/s) | 400 | 400 |

| Spraying distance (mm) | 110 | 110 |

| Powder feed rate (g/min) | 35 | 11 |

| Coating | 2θ (°) | FWHM | β (rad) | D (nm) |

|---|---|---|---|---|

| ATC | 45.668 | 0.329 | 0.00574 | 26.200 ± 1.2 |

| ATC-6Y | 45.879 | 0.414 | 0.00723 | 20.833 ± 1.0 |

| Samples | H (GPa) | E (GPa) | H/E | H3/E2 |

|---|---|---|---|---|

| ATC | 6.46 | 113.8 | 0.0568 | 0.021 |

| ATC-6Y | 9.96 | 169.1 | 0.0589 | 0.035 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Meng, J.; Chen, B.; Xu, Z.; Jiang, B.; Shi, X. Microstructure and Wear Resistance of Plasma-Sprayed Al2O3-TiO2-CeO2/YSZ Composite Coatings. Coatings 2025, 15, 1164. https://doi.org/10.3390/coatings15101164

Li S, Meng J, Chen B, Xu Z, Jiang B, Shi X. Microstructure and Wear Resistance of Plasma-Sprayed Al2O3-TiO2-CeO2/YSZ Composite Coatings. Coatings. 2025; 15(10):1164. https://doi.org/10.3390/coatings15101164

Chicago/Turabian StyleLi, Sijie, Junsheng Meng, Baisen Chen, Zhifu Xu, Bei Jiang, and Xiaoping Shi. 2025. "Microstructure and Wear Resistance of Plasma-Sprayed Al2O3-TiO2-CeO2/YSZ Composite Coatings" Coatings 15, no. 10: 1164. https://doi.org/10.3390/coatings15101164

APA StyleLi, S., Meng, J., Chen, B., Xu, Z., Jiang, B., & Shi, X. (2025). Microstructure and Wear Resistance of Plasma-Sprayed Al2O3-TiO2-CeO2/YSZ Composite Coatings. Coatings, 15(10), 1164. https://doi.org/10.3390/coatings15101164