Effect of Mid-Frequency and Inductively Coupled Plasma on the Properties of Molybdenum Nitride Thin Films

Abstract

1. Introduction

2. Materials and Methods

3. Results

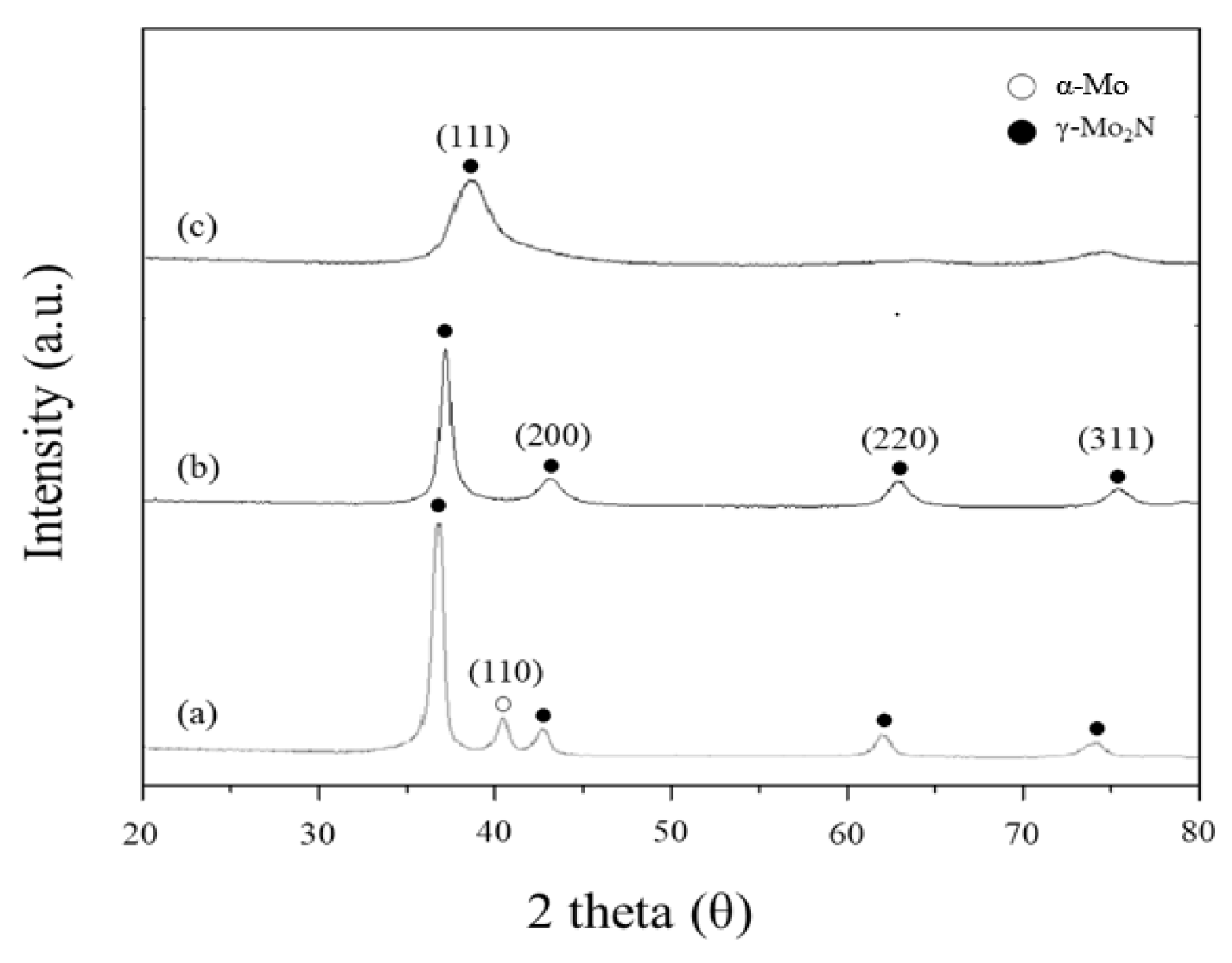

3.1. Crystal Structure

3.2. Residual Stress

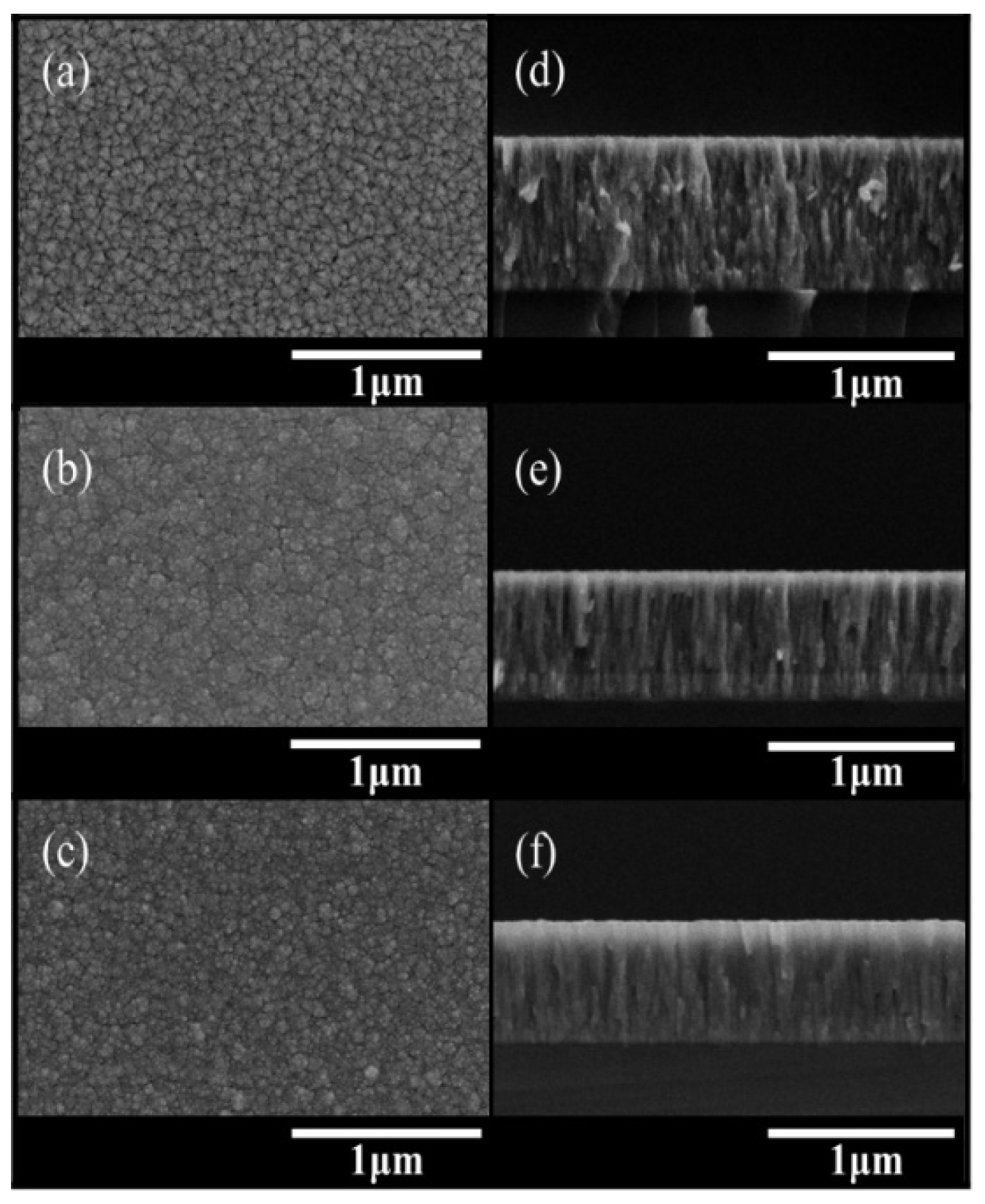

3.3. Microstructure

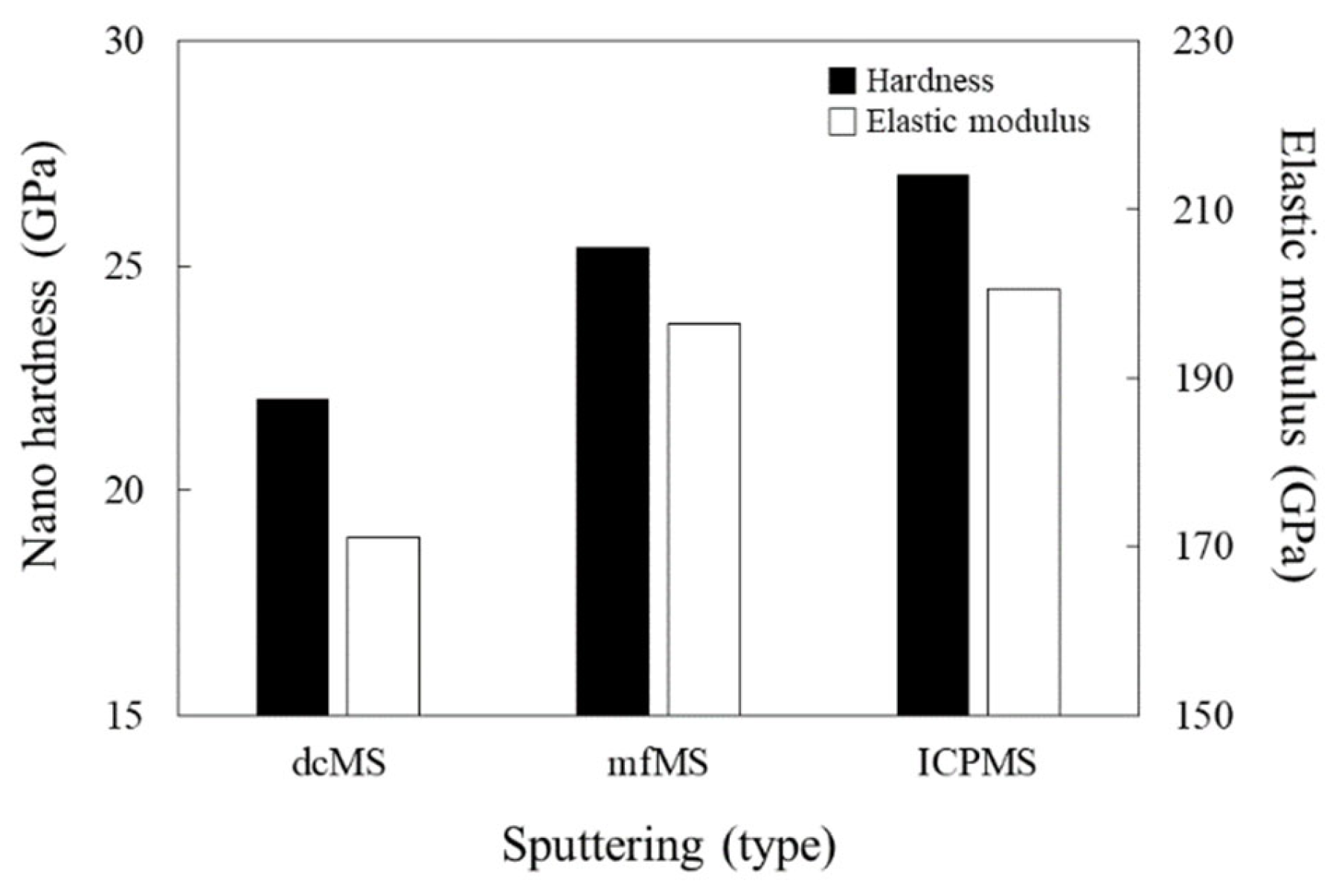

3.4. Nanoindentation Hardness and Elastic Modulus

3.5. Electrical Resistivity

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, S.; Antonio, D.; Yu, X.; Zhang, J.; Cornelius, A.L.; He, D.; Zhao, Y. The hardest superconducting metal nitride. Sci. Rep. 2015, 5, 13733. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Zhang, G.; Ren, S.; Jiang, B. Effect of nitrogen flow rate on structure and properties of MoNx coatings deposited by facing target sputtering. J. Alloys Compd. 2017, 701, 1–8. [Google Scholar] [CrossRef]

- Jauberteau, I.; Bessaudou, A.; Mayet, R.; Cornette, J.; Jauberteau, J.L.; Carles, P.; Merle-Méjean, T. Merle-Mejean, Molybdenum nitride films: Crystal structures, synthesis, mechanical, electrical and some other properties. Coatings 2015, 5, 656–687. [Google Scholar] [CrossRef]

- Sube, T.; Kommer, M.; Fenker, M.; Hader, B.; Albrecht, J. Reduced friction on γ-Mo2N coatings deposited by high power impulse magnetron sputtering on microstructured surfaces. Tribol. Int. 2017, 106, 41–45. [Google Scholar] [CrossRef]

- Mueller, B.J.; Fotler, A.; Haug, V.; Hergert, F.; Zweigart, S.; Herr, U. Influence of Mo-N as diffusion barrier in Mo back contacts for Cu (In,Ga) Se2 solar cells. Thin Solid Film. 2016, 612, 186–193. [Google Scholar] [CrossRef]

- Drayton, J.A.; Williams, D.D.; Geisthardt, R.M.; Cramer, C.L.; Williams, J.D.; Sites, J.R. Molybdenum oxide and molybdenum oxide-nitride back contacts for CdTe solar cells. J. Vac. Sci. Technol. A 2015, 33, 041201. [Google Scholar] [CrossRef]

- Xie, J.; Li, S.; Zhang, X.; Zhang, J.; Wang, R.; Zhang, H.; Pan, B.; Xie, Y. Atomically-thin molybdenum nitride nanosheets with exposed active surface sites for efficient hydrogen evolution. Chem. Sci. 2014, 5, 4615–4620. [Google Scholar] [CrossRef]

- Nandi, D.K.; Sen, U.K.; Choudhury, D.; Mitra, S.; Sarkar, S.K. Atomic layer deposited molybdenum nitride thin film: A promising anode material for Li ion batteries. ACS Appl. Mater. Interfaces 2014, 6, 6606–6615. [Google Scholar] [CrossRef]

- Krysina, O.V.; Shugurov, V.V.; Koval, N.; Prokopenko, N. Influence of Plasma Assistance on Arc Deposited MoN Coatings. Key Eng. Mater. 2016, 712, 9–14. [Google Scholar] [CrossRef]

- Stöber, L.; Konrath, J.P.; Krivec, S.; Patocka, F.; Schwarz, S.; Bittner, A.; Schneider, M.; Schmid, U. Impact of sputter deposition parameters on molybdenum nitride thin film properties. J. Micromech. Microeng. 2015, 25, 074001. [Google Scholar] [CrossRef]

- Roberson, S.; Finello, D.; Davis, R. Phase control of MoxN films via chemical vapor deposition. Thin Solid Film. 1998, 324, 30–36. [Google Scholar] [CrossRef]

- Sellers, J. Asymmetric Bipolar Pulsed DC: The Enabling Technology for Reactive PVD. Surf. Coat. Technol. 1998, 98, 1245–1250. [Google Scholar] [CrossRef]

- Chun, S.Y. Mechanical and Structural Behaviors of HfN Thin Films Fabricated by Direct Current and Mid-frequency Magnetron Sputtering. Corr. Sci. Technol. 2023, 22, 30–35. [Google Scholar]

- Chun, S.Y. Microstructures and Mechanical Properties of HfN Coatings Deposited by DC, Mid-Frequency, and ICP Magnetron Sputtering. Corr. Sci. Technol. 2023, 22, 393–398. [Google Scholar]

- Qiu, Y.; Zhang, S.; Li, B.; Lee, J.-W.; Zhao, D. Influence of Nitrogen Partial Pressure and Substrate Bias on the Mechanical Properties of VN Coatings. Procedia Eng. 2012, 36, 217–225. [Google Scholar] [CrossRef]

- Muniz, F.T.L.; Miranda, M.A.R.; dos Santos, C.M.; Sasaki, J.M. The Scherrer equation and the dynamical theory of X-ray diffraction. Acta Crystallogr. Sect. A Found. Adv. 2016, 72, 385–390. [Google Scholar] [CrossRef]

- Umar, Z.A.; Rawat, R.S.; Tan, K.S.; Kumar, A.K.; Ahmad, R.; Hussain, T.; Kloc, C.; Chen, Z.; Shen, L.; Zhang, Z. Hard TiCx/SiC/a-C: H nanocomposite thin films using pulsed high energy density plasma focus device. Nucl. Instrum. Methods Phys. Res. B 2013, 301, 53–61. [Google Scholar] [CrossRef]

- Gurarie, V.; Otsuka, P.; Jamieson, D.; Prawer, S. Crack-arresting compression layers produced by ion implantation. Nucl. Instrum. Methods Phys. Res. B 2006, 242, 421–423. [Google Scholar] [CrossRef]

- EerNisse, E.P. Stress in ion-implanted CVD Si3N4 films. J. Appl. Phys. 1977, 48, 3337–3341. [Google Scholar] [CrossRef]

- Shen, Y. Effect of deposition conditions on mechanical stresses and microstructure of sputter-deposited molybdenum and reactively sputter-deposited molybdenum nitride films. Mater. Sci. Eng. A 2003, 359, 158–167. [Google Scholar] [CrossRef]

- Hosseinnejad, M.T.; Shirazi, M.; Ghorannevis, Z.; Ghoranneviss, M.; Shahgoli, F. Using Mather-type plasma focus device for fabrication of tungsten thin films. J. Fusion Energy 2012, 31, 426–431. [Google Scholar] [CrossRef]

- A Umar, Z.; Ahmad, R.; Rawat, R.S.; A Baig, M.; Siddiqui, J.; Hussain, T. Structural and mechanical properties of Al–C–N films deposited at room temperature by plasma focus device. Chin. Phys. B 2016, 25, 075201. [Google Scholar] [CrossRef]

- Anitha, V.; Bhattacharya, A.; Patil, N.G.; Major, S. Study of sputtered molybdenum nitride as a diffusion barrier. Thin Solid Film. 1993, 236, 306–310. [Google Scholar] [CrossRef]

| MoN | Sputtering (Mode) | ||

|---|---|---|---|

| dcMS | mfMS | ICPMS | |

| Sputtering Power (W) | 300 | 300 | 300 |

| ICP Power (W) | - | - | 200 |

| Pulse frequency (kHz) | - | 15 | - |

| Duty cycle (%) | - | 85 | - |

| Substrate bias voltage (V) | −100 | −100 | −100 |

| Substrate temperature (℃) | 400 | 400 | 400 |

| MoN Phase | Structure | Lattice Plane Spacing (nm) | Lattice Constants (nm) |

|---|---|---|---|

| Υ-Mo2N(dcMS) | FCC | d = 0.2442 | a = 0.4229 |

| Υ-Mo2N(mfMS) | FCC | d = 0.2401 | a = 0.4159 |

| Υ-Mo2N(ICPMS) | FCC | d = 0.2334 | a = 0.4043 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chun, S.-Y. Effect of Mid-Frequency and Inductively Coupled Plasma on the Properties of Molybdenum Nitride Thin Films. Coatings 2025, 15, 1155. https://doi.org/10.3390/coatings15101155

Chun S-Y. Effect of Mid-Frequency and Inductively Coupled Plasma on the Properties of Molybdenum Nitride Thin Films. Coatings. 2025; 15(10):1155. https://doi.org/10.3390/coatings15101155

Chicago/Turabian StyleChun, Sung-Yong. 2025. "Effect of Mid-Frequency and Inductively Coupled Plasma on the Properties of Molybdenum Nitride Thin Films" Coatings 15, no. 10: 1155. https://doi.org/10.3390/coatings15101155

APA StyleChun, S.-Y. (2025). Effect of Mid-Frequency and Inductively Coupled Plasma on the Properties of Molybdenum Nitride Thin Films. Coatings, 15(10), 1155. https://doi.org/10.3390/coatings15101155