Multi-Factor Analysis of Cutting Parameters for Bamboo Milling

Abstract

1. Introduction

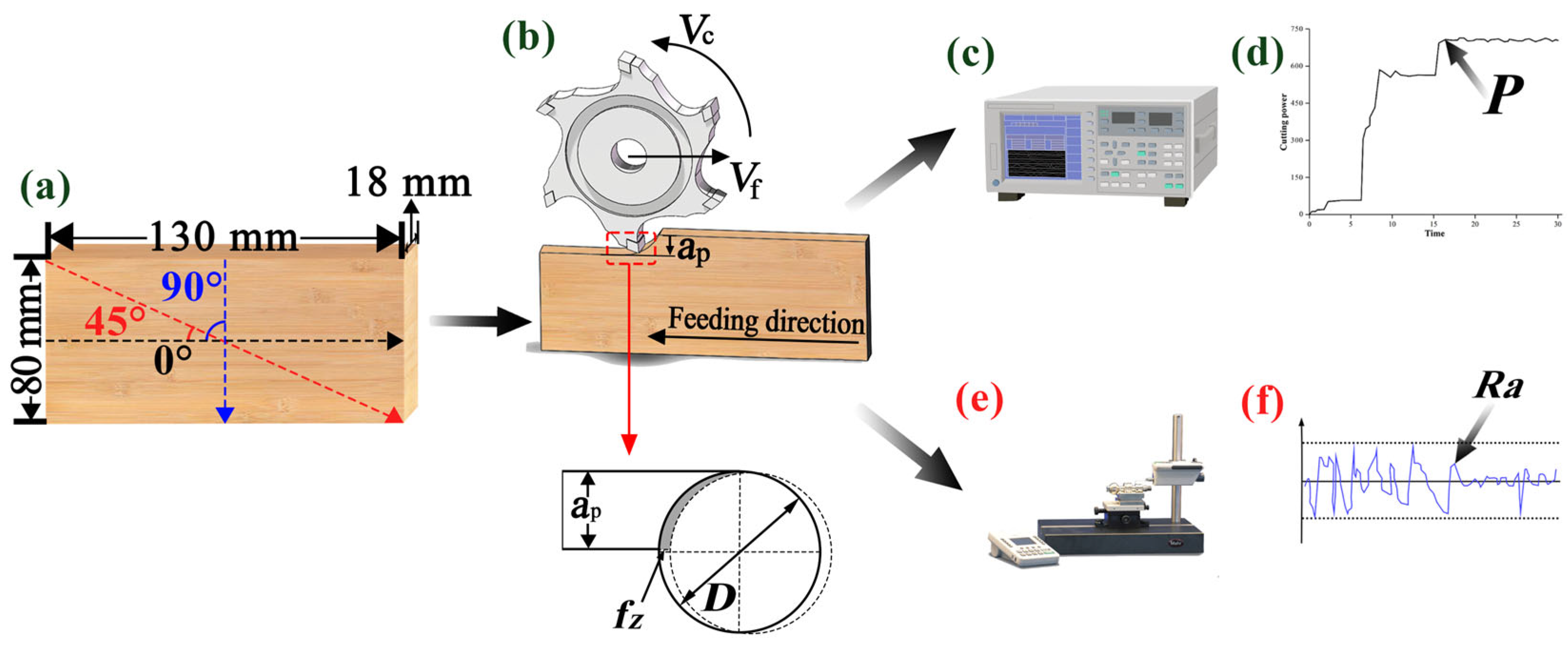

2. Materials and Methods

2.1. Experimental Materials

2.2. Test Equipment

2.3. Experimental Methods

3. Results and Analysis

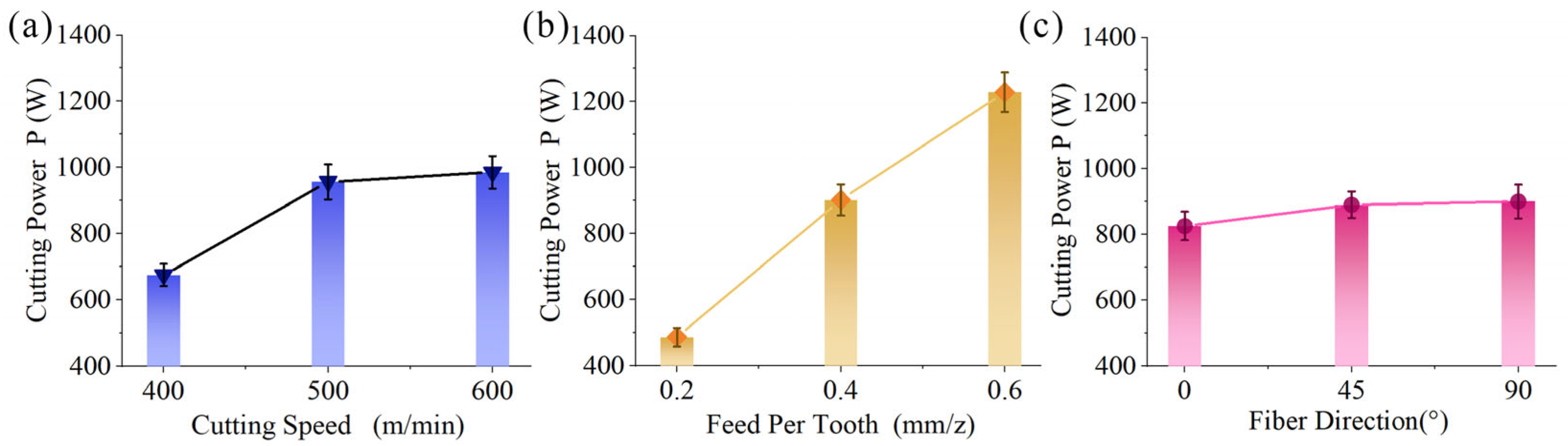

3.1. Cutting Power Analysis

3.2. Surface Roughness Analysis

3.3. Optimization and Verification of Cutting Parameters

4. Conclusions

- (1)

- As the fiber direction increased from 0° to 90°, the cutting power increased by 9.08% and the surface roughness rose by 143.85%. When the feed per tooth increased from 0.2 mm/z to 0.6 mm/z, the cutting power increased by 152.55% while the surface roughness went up by 32.46%. As the cutting speed increased from 400 m/min to 600 m/min, the cutting power increased by 41.67% and the surface roughness increased by only 13.35%.

- (2)

- According to the result of ANOVA, feed per tooth (76.7%) had the greatest contribution to the cutting power, followed by cutting speed (16.3%) and fiber direction (9.0%). While, fiber direction (78.6%) had the greatest impact on the surface roughness, followed by feed per tooth (9.1%) and cutting speed (2.2%).

- (3)

- The optimal combination of cutting parameters was determined to achieve lowest cutting power and surface roughness, where fiber direction was 0°, feed per tooth was 0.2 mm/z, and cutting speed was 400 m/min, this combination of parameters is hoped to offer guidance for the machining of bamboo.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shi, J.J.; Li, Z.Z.; Chen, H.; Wu, Z.H.; Ji, J.G.; Xia, C.L.; Wang, H.K.; Zhong, T.H. Optimizing processing strategies for eco-friendly bamboo curved components: Insights from bamboo internode and node differences. Ind. Crop. Prod. 2024, 216, 118823. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Y.J.; Wu, Y.; Zhao, W.Y. A multilayer transparent bamboo with good optical properties and uv shielding prepared by different lamination methods. ACS Sustain. Chem. Eng. 2022, 10, 6106–6116. [Google Scholar] [CrossRef]

- Lian, C.P.; Wang, X.H.; Chen, H.; Fei, B.H.; Pang, X.R.; Lian, J.C.; Wu, Z.H. Using statistical methods to comparatively analyze the visual characteristics of flattened bamboo boards in different bamboo culms. Polymers 2022, 14, 4327. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Zhou, J.C.; Yang, F.; Wang, Y.J.; Wang, J.; Zhang, J.L. A strong multilayered transparent wood with natural wood color and texture. J. Mater. Sci. 2021, 56, 8000–8013. [Google Scholar] [CrossRef]

- Zheng, Y.W.; Zhu, J.G. The application of bamboo weaving in modern furniture. Bioresources 2021, 16, 5024–5035. [Google Scholar] [CrossRef]

- Shi, J.J.; Li, Z.Z.; Chen, H.; Wu, Z.H.; Ji, J.G.; Xia, C.L.; Wang, H.K.; Zhong, T.H. Facile fabrication of curved furniture by bamboo restructuring plasticizing for green furniture manufacturing. Constr. Build. Mater. 2024, 456, 139312. [Google Scholar] [CrossRef]

- Li, R.R.; Yao, Q.; Xu, W.; Li, J.Y.; Wang, X.D. Study of cutting power and power efficiency during straight-tooth cylindrical milling process of particle boards. Materials 2022, 15, 879. [Google Scholar] [CrossRef]

- Liu, J.; Zheng, J.; Li, R. Molecular dynamics simulation and experimental analysis of laser-induced graphene on moso bamboo. Wood Sci. Technol. 2025, 59, 99. [Google Scholar] [CrossRef]

- Hu, W.G.; Yu, R.Z.; Yang, P. Characterizing roughness of wooden mortise and tenon considering effects of measured position and assembly condition. Forests 2024, 15, 1584. [Google Scholar] [CrossRef]

- Pinkowski, G.; Piernik, M.; Wolpiuk, M.; Krauss, A. Effect of chip thickness and tool wear on surface roughness and cutting power during up-milling wood of different density. Bioresources 2024, 19, 9234–9248. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, J.; Xu, W. Surface roughness of wood substrates after grinding and its influence on the modification effect of structural color layers. Forests 2023, 14, 2213. [Google Scholar] [CrossRef]

- Li, R.R.; He, C.J.; Wang, X.D. Evaluation and modeling of processability of laser removal technique for bamboo outer layer. JOM 2021, 73, 2423–2430. [Google Scholar] [CrossRef]

- Chen, Y.; Li, H.T.; Gao, L.; Xu, W.; Lorenzo, R.; Gaff, M. A review of experimental research on the mode i fracture behavior of bamboo. J. Renew. Mater. 2023, 11, 2787–2808. [Google Scholar] [CrossRef]

- Li, R.R.; Guo, X.L.; Cao, P.X.; Wang, X.D. Optimization of laser cutting parameters for recombinant bamboo based on response surface methodology. Wood Res.-Slovak. 2016, 61, 275–285. [Google Scholar]

- Guo, X.L.; Li, R.R.; Cao, P.X.; Ekevad, M.; Cristóvao, L.; Marklund, B.; Grönlund, A. Effect of average chip thickness and cutting speed on cutting forces and surface roughness during peripheral up milling of wood flour/polyvinyl chloride composite. Wood Res. 2015, 60, 147–156. [Google Scholar]

- Xiong, X.Q.; Ma, Q.R.; Yuan, Y.Y.; Wu, Z.H.; Zhang, M. Current situation and key manufacturing considerations of green furniture in china: A review. J. Clean. Prod. 2020, 267, 121957. [Google Scholar] [CrossRef]

- Li, R.; Yang, F.; Wang, X. Modeling and predicting the machined surface roughness and milling power in scot’s pine helical milling process. Machines 2022, 10, 331. [Google Scholar] [CrossRef]

- Li, R.R.; He, C.J.; Xu, W.; Wang, X.D.A. Prediction of surface roughness of CO2 laser modified poplar wood via response surface methodology. Maderas-Cienc. Tecnol. 2022, 24, 1–12. [Google Scholar] [CrossRef]

- Yang, F.; Yang, B.; Li, R. Surface defect detection technology of wood-based panel based on image segmentation and deep learning. J. Zhejiang Univ-Sca. 2024, 41, 176–182. [Google Scholar]

- Li, R.R.; Ekevad, M.; Guo, X.L.; Ding, J.W.; Cao, P.X. Effect of pressure, feed rate, and abrasive mass flow rate on water jet cutting efficiency when cutting recombinant bamboo. Bioresources 2015, 10, 499–509. [Google Scholar] [CrossRef]

- Li, R.R.; He, C.J.; Xu, W.; Wang, X.D. Modeling and optimizing the specific cutting energy of medium density fiberboard during the helical up-milling process. Wood Mater. Sci. Eng 2023, 18, 464–471. [Google Scholar] [CrossRef]

- Song, M.; Guan, J.; Tang, Q.; Du, X.; Yu, Y.; Guo, X. Analysis of axial forcein drilling of melamine impregnated paper veneer particleboards. J. For. Eng. 2025, 10, 39–45. [Google Scholar]

- Zhou, X.; Li, R.; Wu, Z. Scheduling optimization for laminated door machining shop based on improved genetic algorithm. Comput. Oper. Res. 2025, 180, 107078. [Google Scholar] [CrossRef]

- Yu, Y.; Buck, D.; Yang, H.; Du, X.; Song, M.; Wang, J.; Zhu, Z. Cutting power, temperature, and surface roughness: A multiple target assessment of beech during diamond milling. Forests 2023, 14, 1163. [Google Scholar] [CrossRef]

- Piernik, M.; Pinkowski, G.; Krauss, A. Effect of chip thickness, wood cross-sections, and cutting speed on surface roughness and cutting power during up-milling of beech wood. Bioresources 2023, 18, 6784–6801. [Google Scholar] [CrossRef]

- Liu, Y.H.; Zhou, J.B.; Fu, W.S.; Zhang, B.; Chang, F.H.; Jiang, P.F. Study on the effect of cutting parameters on bamboo surface quality using response surface methodology. Measurement 2021, 174, 109002. [Google Scholar] [CrossRef]

- Radmanovic, K.; Dukic, I.; Merhar, M.; Safran, B.; Jug, M.; Lucic, R.B. Longitudinal and tangential coefficients of chip compression in orthogonal wood cutting. Bioresources 2018, 13, 7998–8011. [Google Scholar] [CrossRef]

- Bao, X.; Guo, X.L.; Cao, P.X.; Xie, L.L.; Deng, M.S. Technical note: Research on cutting forces and cutting temperature in orthogonal cutting softwood and hardwood parallel to grain. Wood Fiber. Sci. 2018, 50, 458–464. [Google Scholar] [CrossRef]

- Guo, X.L.; Ekevad, M.; Marklund, B.; Li, R.R.; Cao, P.X.; Grönlund, A. Cutting forces and chip morphology during wood plastic composites orthogonal cutting. Bioresources 2014, 9, 2090–2106. [Google Scholar] [CrossRef]

- Cao, P.X.; Zhu, Z.L.; Buck, D.; Guo, X.L.; Ekevad, M.; Wang, X. Effect of rake angle on cutting performance during machining of stone-plastic composite material with polycrystalline diamond cutters. J. Mech. Sci. Technol. 2019, 33, 351–356. [Google Scholar] [CrossRef]

- Wu, Z.W.; Wang, J.X.; Zhang, F.; Zhu, Z.L.; Guo, X.L.; Cao, P.X. Investigation of the orthogonal cutting of wood-plastic composites for obtaining better stability and quality. Eur. J. Wood Wood Prod. 2023, 81, 399–410. [Google Scholar] [CrossRef]

- EN ISO 21920-1:2022; Geometrical product specifications (GPS)-Surface texture. European Committee for Standarization: Brussels, Belgium, 2022.

- Yang, B.K.; Li, R.R.; Meng, Y.; Xu, Z.Y. Research on texture features classification of multilayered wood flooring using global image structure method. Wood Mater. Sci. Eng. 2025, 1–13. [Google Scholar] [CrossRef]

- Guan, Y.Y.; Li, S.Z.; Jiang, X.; Xu, B.H.; Liu, P.Y.; Li, H.T. Design of bamboo cutting mechanism based on crack propagation principle. Bioresources 2021, 16, 5890–5900. [Google Scholar] [CrossRef]

| Density (g/cm3) | Elastic Modulus (GPa) | Poisson Ratio | Thermal Conductivity (W/(m K)) | Heat Capacity (J/(kg K) | Melting Point (°C) |

|---|---|---|---|---|---|

| 14 | 6000 | 0.22 | 4.5 | 220 | 2870 |

| Number | Cutting Speed V (m/min) | Feed per Tooth fz (mm/z) | Fiber Direction θ (°) |

|---|---|---|---|

| 1 | 400 | 0.2 | 0 |

| 2 | 400 | 0.4 | 45 |

| 3 | 400 | 0.6 | 90 |

| 4 | 500 | 0.2 | 90 |

| 5 | 500 | 0.4 | 0 |

| 6 | 500 | 0.6 | 45 |

| 7 | 600 | 0.2 | 45 |

| 8 | 600 | 0.4 | 90 |

| 9 | 600 | 0.6 | 0 |

| No. | Cutting Power P (W) | Tolerance of P | Surface Roughness Ra (μm) | Tolerance of Ra |

|---|---|---|---|---|

| 1 | 264.10 | ±10.26 | 1.35 | ±0.03 |

| 2 | 815.76 | ±24.10 | 4.61 | ±0.12 |

| 3 | 945.36 | ±36.44 | 8.06 | ±0.18 |

| 4 | 691.92 | ±32.73 | 5.55 | ±0.09 |

| 5 | 824.80 | ±35.22 | 3.65 | ±0.07 |

| 6 | 1352.04 | ±44.81 | 4.66 | ±0.15 |

| 7 | 503.60 | ±17.35 | 5.30 | ±0.13 |

| 8 | 1064.70 | ±40.35 | 6.97 | ±0.19 |

| 9 | 1388.20 | ±46.59 | 3.44 | ±0.06 |

| Factors | Degree of Freedom | Sum of Square | Mean Square | Contribution Percentage | F Value | Prominence |

|---|---|---|---|---|---|---|

| V (m/min) | 2 | 176,282.275 | 88,141.138 | 16.300 | 0.521 | Insignificant |

| fz (mm/z) | 2 | 829,741.387 | 414,870.694 | 76.700 | 2.450 | Insignificant |

| θ (°) | 2 | 9917.627 | 4958.813 | 9.000 | 0.029 | Insignificant |

| Error | 2 | 66,554.402 | 33,277.201 | — | — | — |

| Corrected total | 8 | 1,082,495.692 | — | — | — | — |

| Factors | Cutting Speed V (m/min) | Feed per Tooth fz (mm/z) | Fiber Direction θ (°) |

|---|---|---|---|

| K1 | 675.073 | 486.540 | 825.700 |

| K2 | 956.373 | 901.753 | 890.467 |

| K3 | 985.500 | 1228.653 | 900.660 |

| RP | 310.427 | 742.113 | 74.960 |

| Factors | Cutting Speed V (m/min) | Feed per Tooth fz (mm/z) | Fiber Direction θ (°) |

|---|---|---|---|

| K1 | 4.673 | 4.067 | 2.813 |

| K2 | 4.620 | 5.077 | 4.857 |

| K3 | 5.237 | 5.387 | 6.860 |

| RRa | 0.617 | 1.320 | 4.047 |

| Factors | Degree of Freedom | Sum of Square | Mean Square | Contribution Percentage | F Value | Prominence |

|---|---|---|---|---|---|---|

| V (m/min) | 2 | 0.700 | 0.35 | 2.2 | 0.075 | Insignificant |

| fz (mm/z) | 2 | 2.859 | 1.429 | 9.1 | 0.305 | Insignificant |

| θ (°) | 2 | 24.564 | 12.282 | 78.6 | 2.620 | Insignificant |

| Error | 2 | 3.139 | 1.570 | — | — | — |

| Corrected total | 8 | 31.262 | — | — | — | — |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, M.; Buck, D.; Yuan, Z.; Xu, C.; Zhu, Z. Multi-Factor Analysis of Cutting Parameters for Bamboo Milling. Coatings 2025, 15, 1148. https://doi.org/10.3390/coatings15101148

Hong M, Buck D, Yuan Z, Xu C, Zhu Z. Multi-Factor Analysis of Cutting Parameters for Bamboo Milling. Coatings. 2025; 15(10):1148. https://doi.org/10.3390/coatings15101148

Chicago/Turabian StyleHong, Mengqi, Dietrich Buck, Ziyi Yuan, Changshun Xu, and Zhaolong Zhu. 2025. "Multi-Factor Analysis of Cutting Parameters for Bamboo Milling" Coatings 15, no. 10: 1148. https://doi.org/10.3390/coatings15101148

APA StyleHong, M., Buck, D., Yuan, Z., Xu, C., & Zhu, Z. (2025). Multi-Factor Analysis of Cutting Parameters for Bamboo Milling. Coatings, 15(10), 1148. https://doi.org/10.3390/coatings15101148