Understanding the Correlations Between the Formation of Columnar Structures and Suspension Properties for Suspension Plasma-Sprayed Thermal Barrier Coatings

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Coating Deposition Process

2.3. Characterization of Suspensions and Coatings

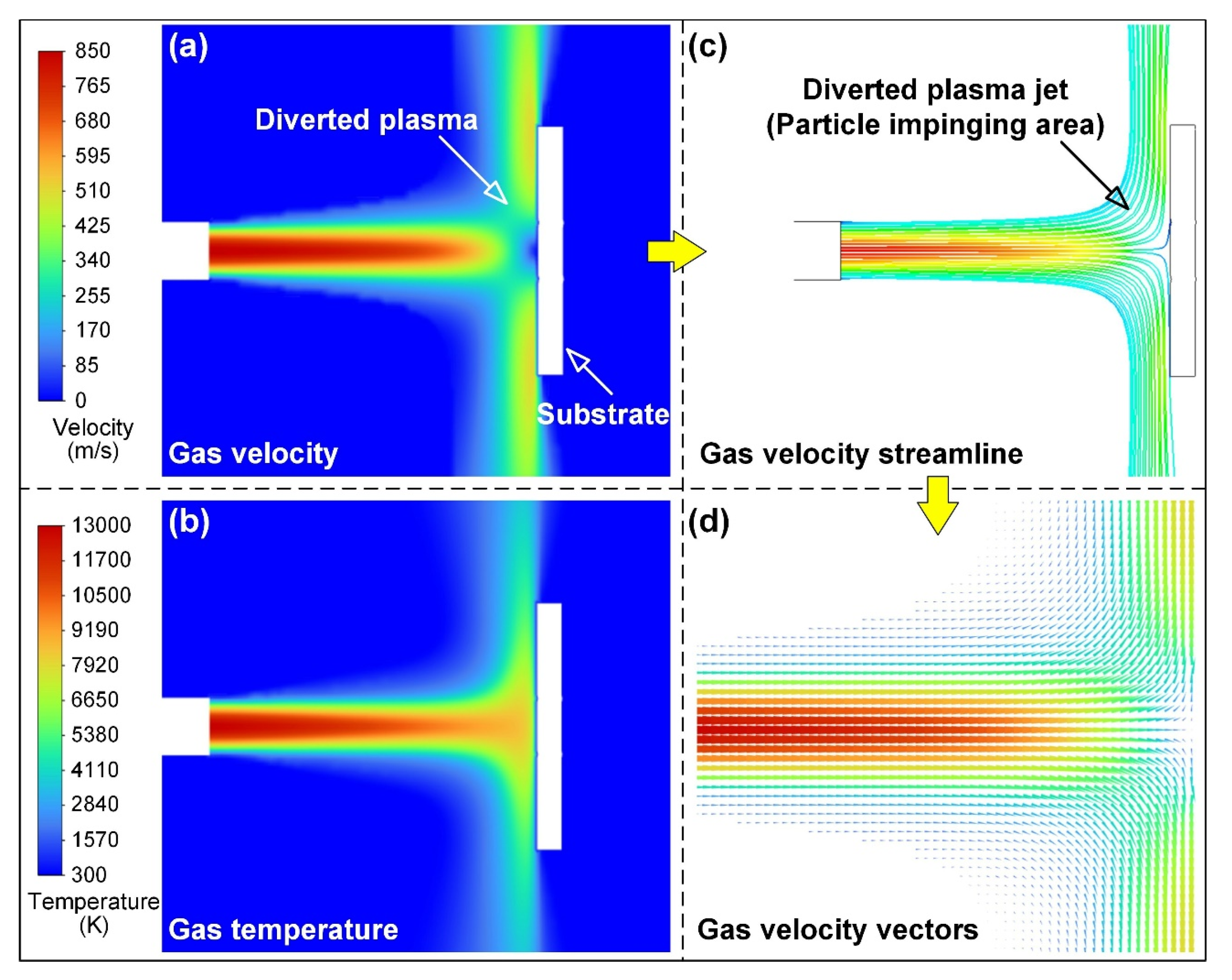

2.4. Modelling of Particle Movement

3. Results and Discussion

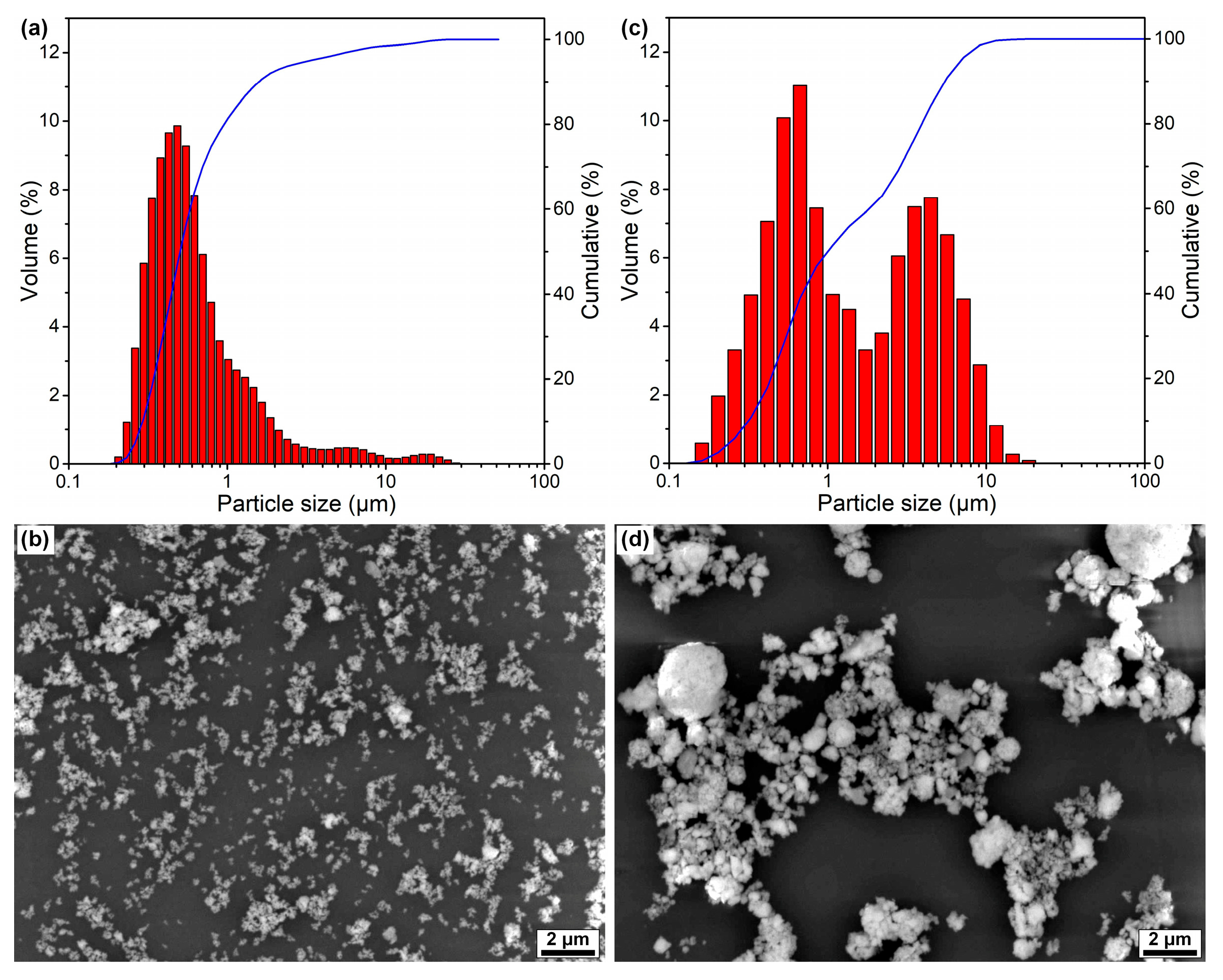

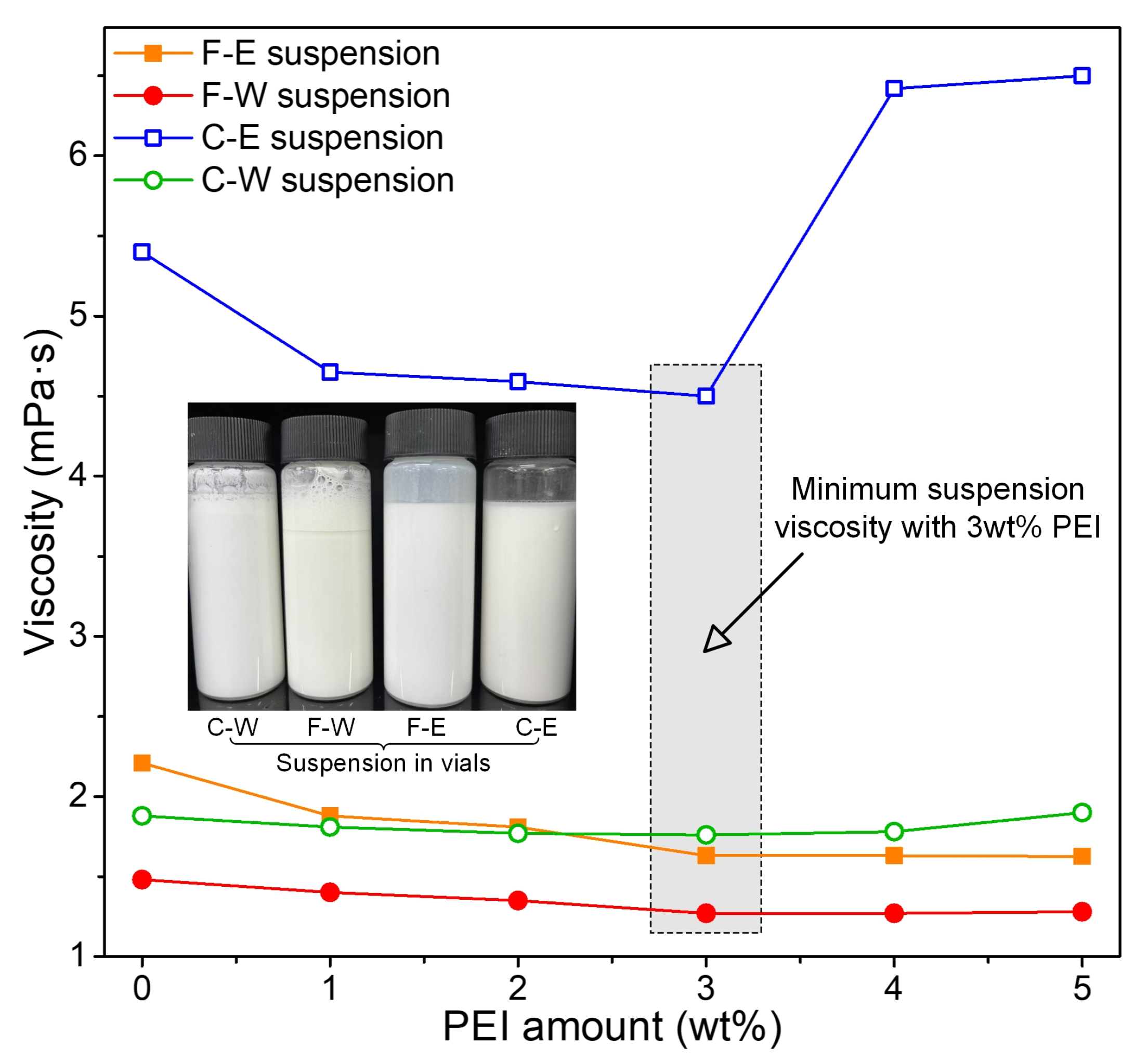

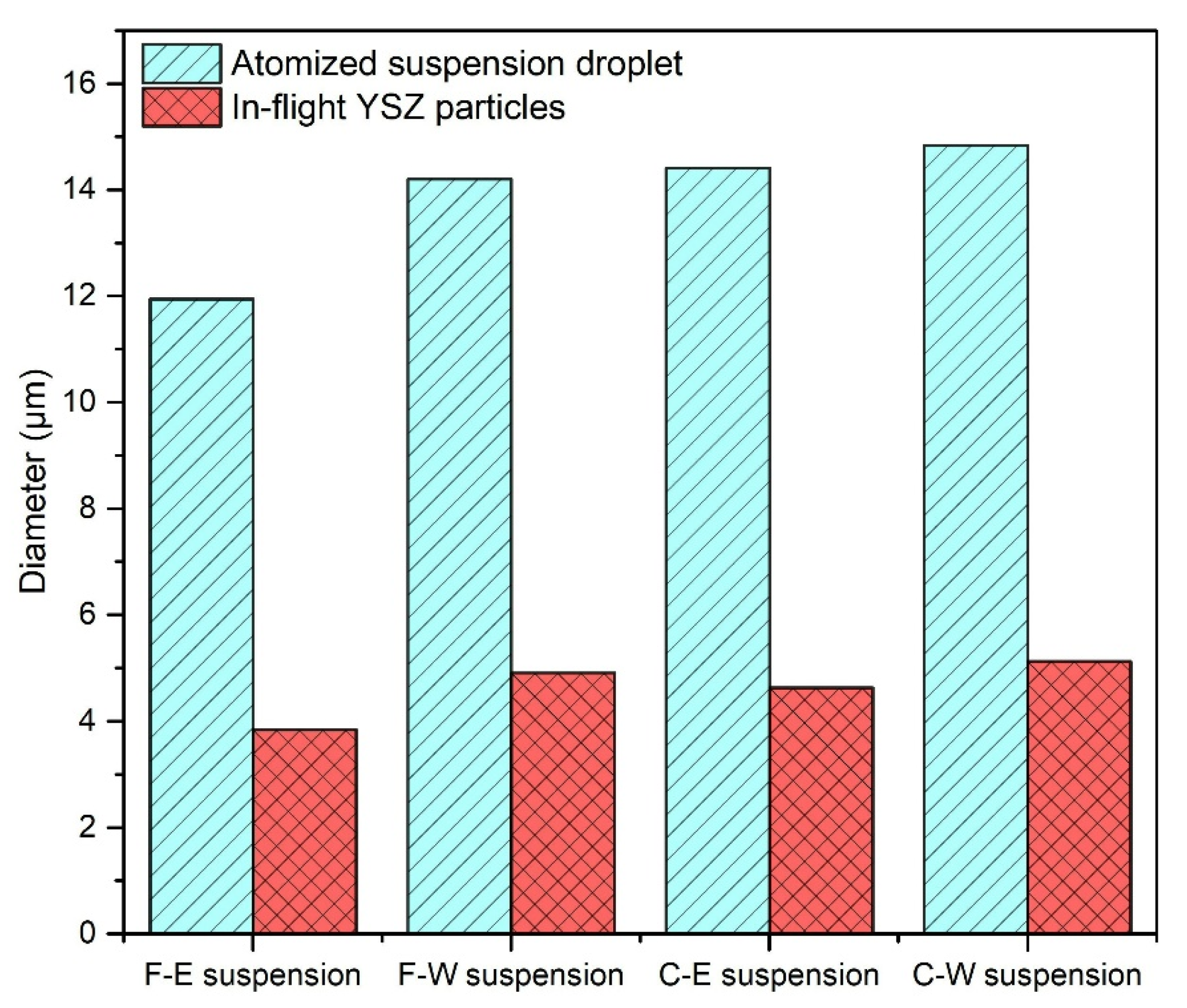

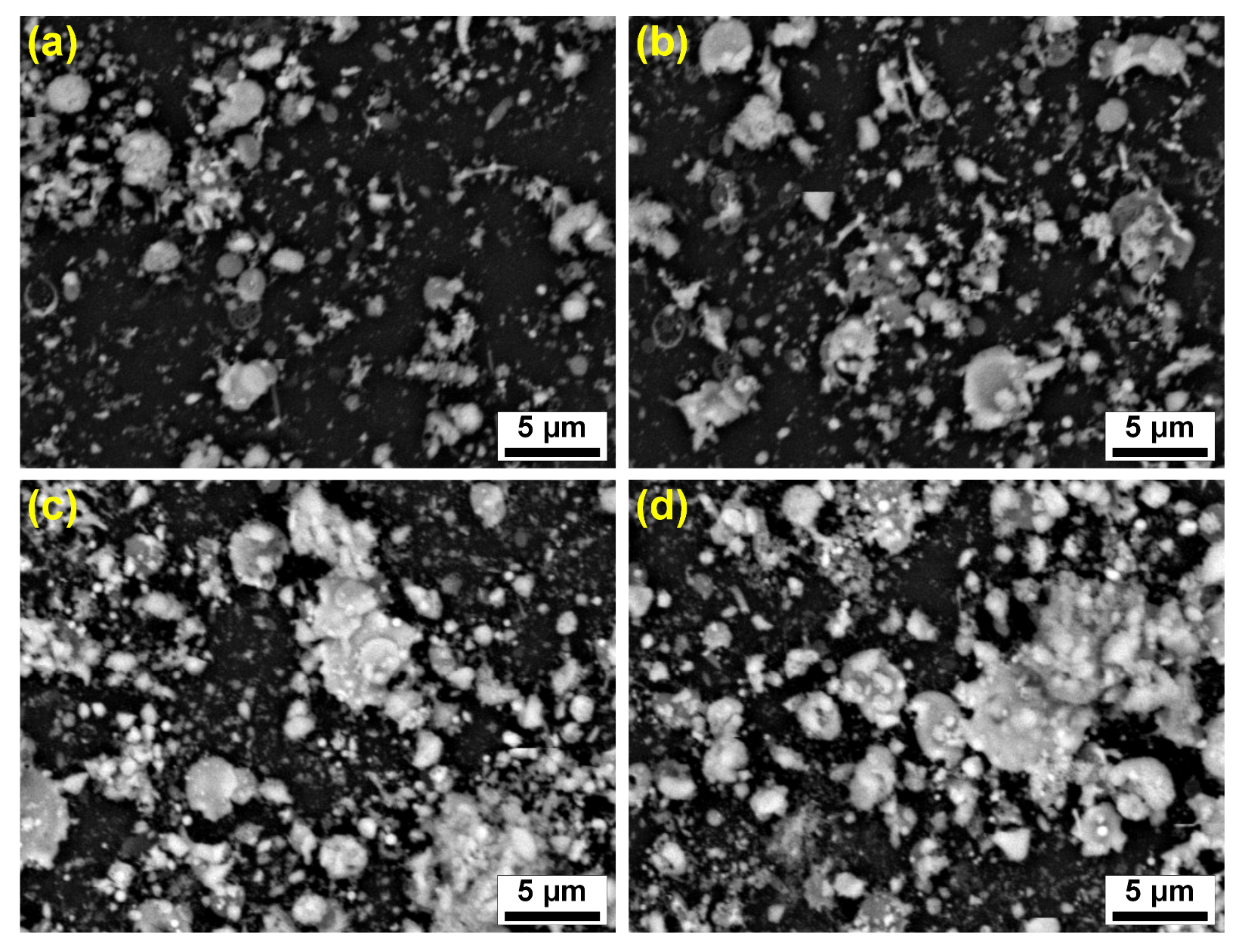

3.1. Suspension Properties

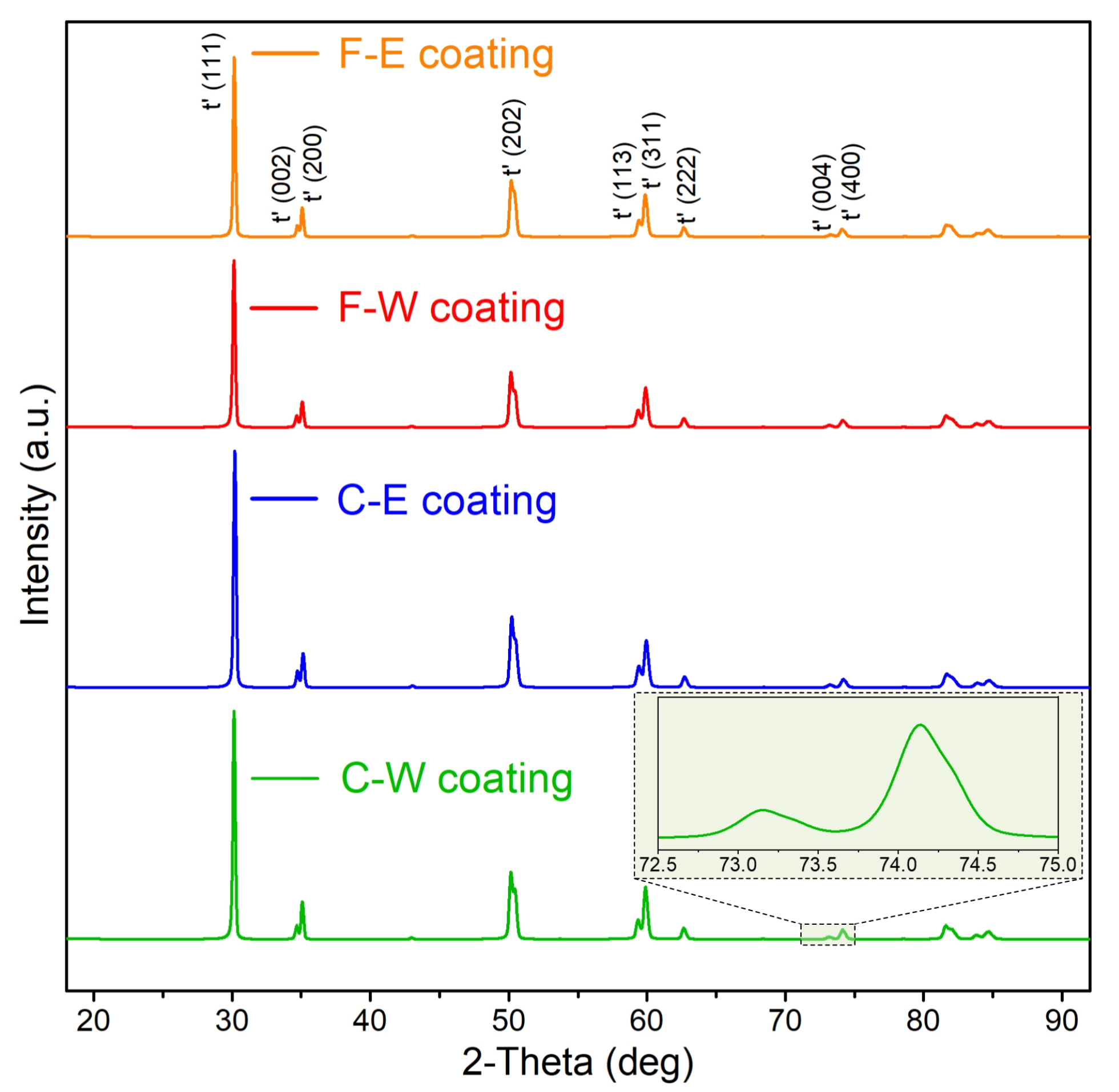

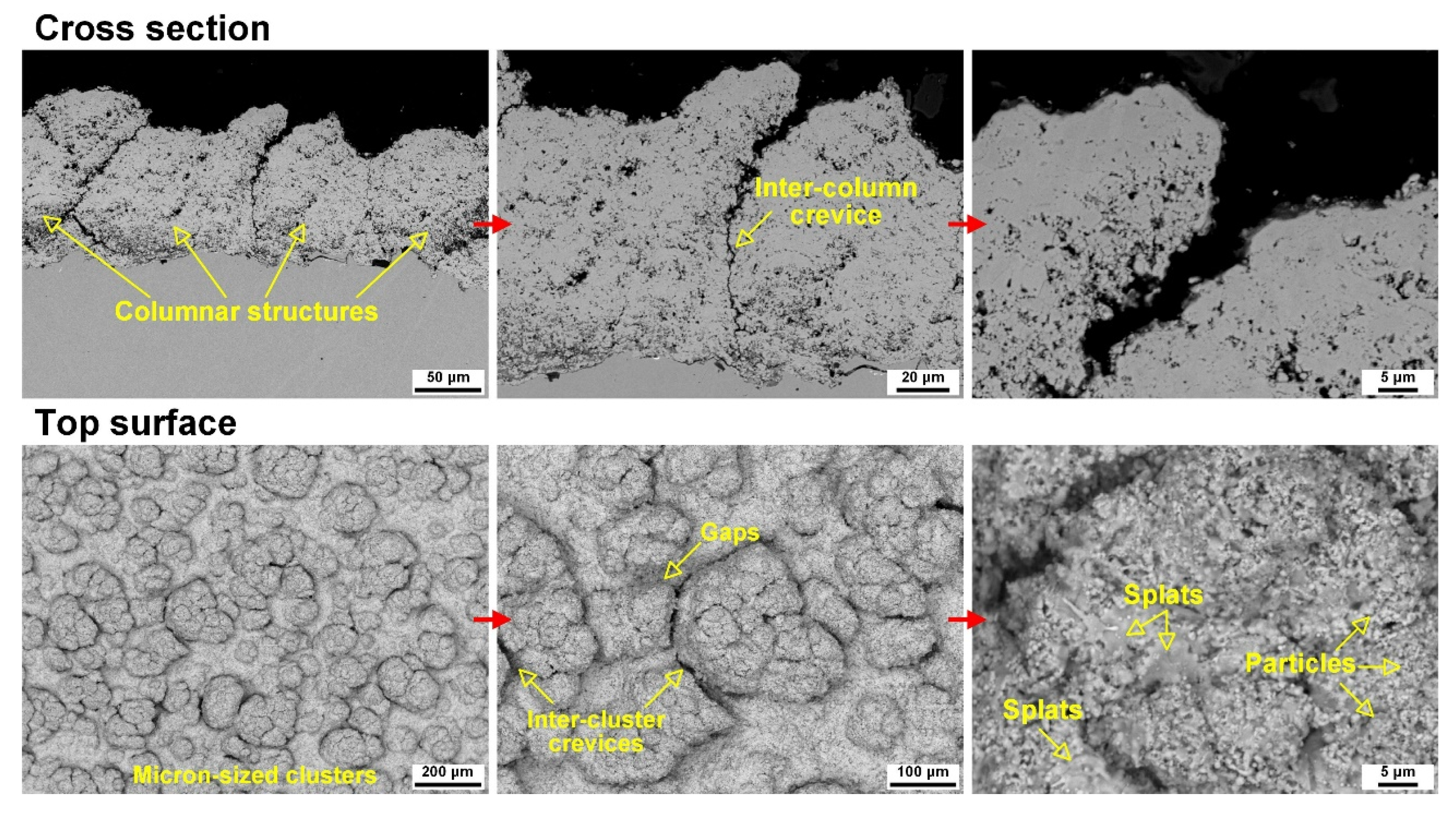

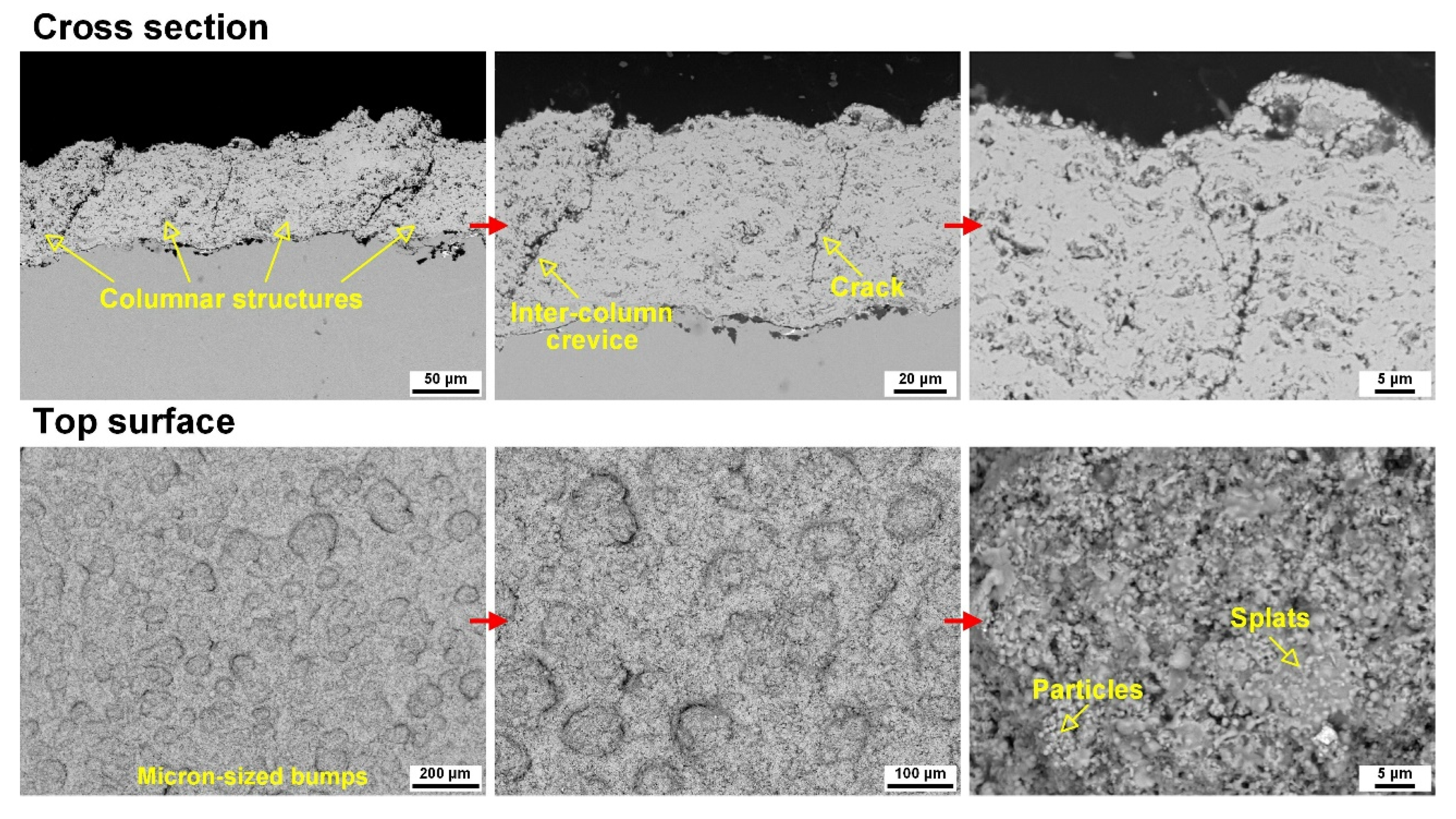

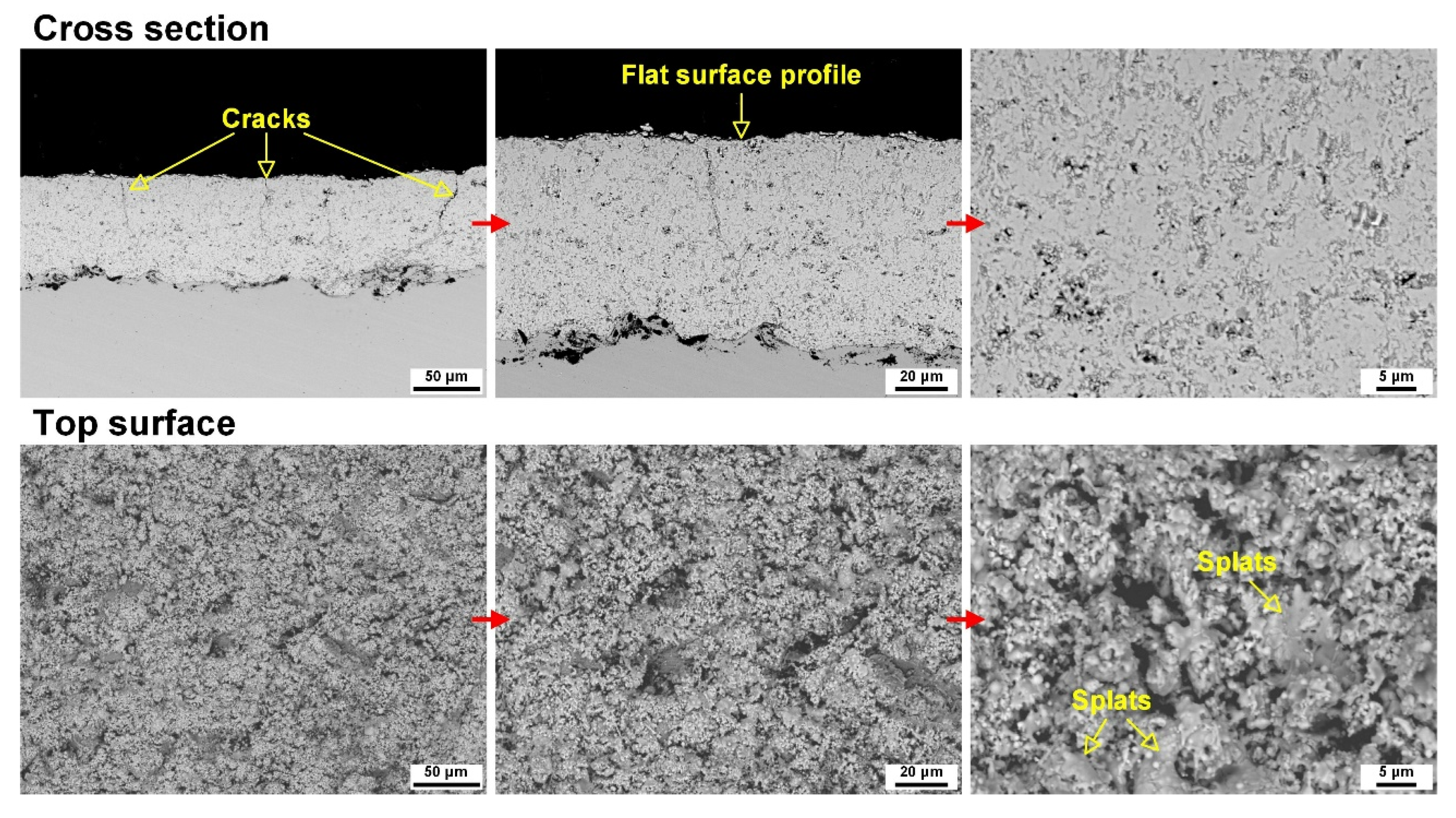

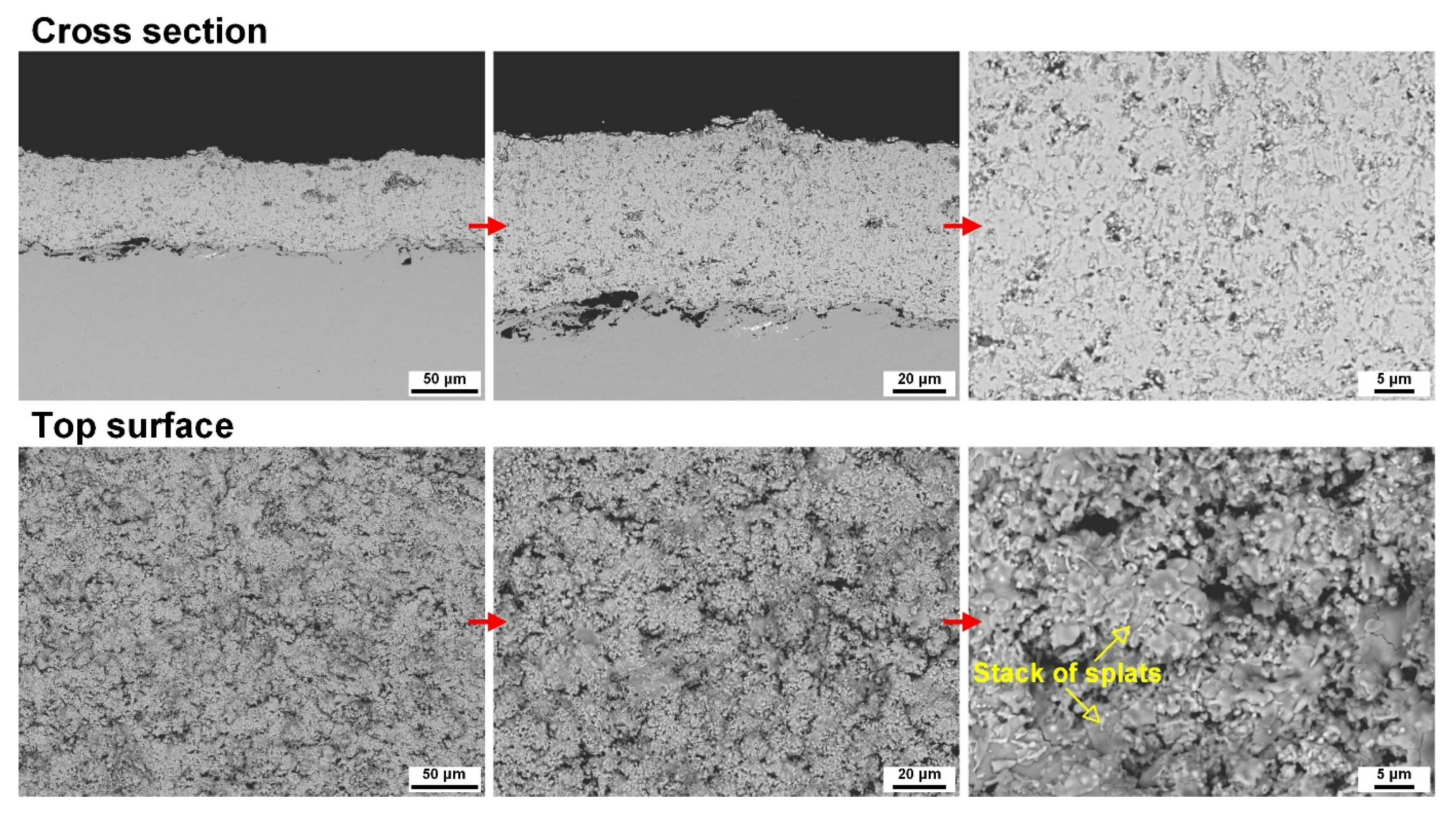

3.2. Crystalline Phases and Microstructures of Coatings

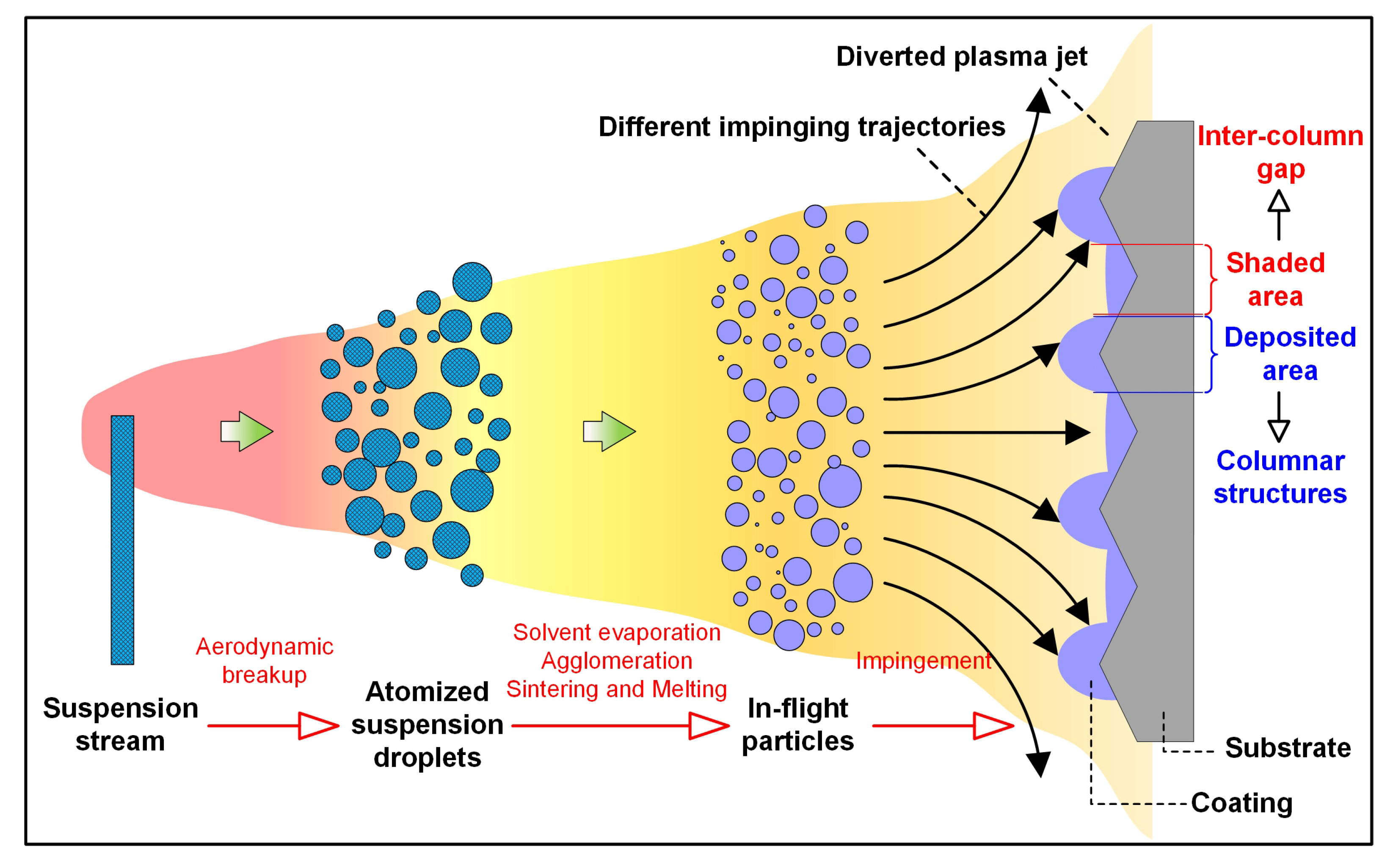

3.3. Formation Mechanism of Different Microstructures

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Song, J.B.; Wang, L.S.; Dong, H.; Yao, J.T. Long lifespan thermal barrier coatings overview: Materials, manufacturing, failure mechanisms, and multiscale structural design. Ceram. Int. 2023, 49, 1–23. [Google Scholar] [CrossRef]

- Mehta, A.; Vasudev, H.; Singh, S.; Prakash, C.; Saxena, K.K.; Linul, E.; Buddhi, D.; Xu, J. Processing and advancements in the development of thermal barrier coatings: A review. Coatings 2022, 12, 1318. [Google Scholar] [CrossRef]

- Lashmi, P.; Ananthapadmanabhan, P.; Unnikrishnan, G.; Aruna, S. Present status and future prospects of plasma sprayed multilayered thermal barrier coating systems. J. Eur. Ceram. Soc. 2020, 40, 2731–2745. [Google Scholar] [CrossRef]

- Sampath, S. Durability of plasma sprayed thermal barrier coatings with controlled properties part I: For planar disk substrates. Surf. Coat. Technol. 2021, 424, 127678. [Google Scholar]

- Mittal, G.; Paul, S. Suspension and solution precursor plasma and HVOF spray: A review. J. Therm. Spray Technol. 2022, 31, 1443–1475. [Google Scholar] [CrossRef]

- Li, C.J.; Zhang, Q.L.; Yao, S.W.; Yang, G.J.; Li, C.X. Plasma spraying of dense ceramic coating with fully bonded lamellae through materials design based on the critical bonding temperature concept. J. Therm. Spray Technol. 2019, 28, 53–62. [Google Scholar] [CrossRef]

- Mauer, G.; Vaßen, R. Coatings with columnar microstructures for thermal barrier applications. Adv. Eng. Mater. 2019, 22, 1900988. [Google Scholar] [CrossRef]

- Lima, R.S.; Guerreiro, B.M.; Aghasibeig, M. Microstructural Characterization and Room-Temperature Erosion Behavior of As-Deposited SPS, EB-PVD and APS YSZ-Based TBCs. J. Therm. Spray Technol. 2019, 28, 223–232. [Google Scholar] [CrossRef]

- Bernard, B.; Quet, A.; Bianchi, L.; Joulia, A.; Malié, A.; Schick, V.; Rémy, B. Thermal insulation properties of YSZ coatings: Suspension plasma spraying (SPS) versus electron beam physical vapor deposition (EB-PVD) and atmospheric plasma spraying (APS). Surf. Coat. Technol. 2017, 318, 122–128. [Google Scholar] [CrossRef]

- Dalir, E.; Dolatabadi, A.; Mostaghimi, J. Investigating the in-flight droplets’ atomization in suspension plasma-sprayed coating. Int. J. Heat Mass Transf. 2022, 182, 121969. [Google Scholar] [CrossRef]

- Gulyaev, I. Phenomenological model of the suspension droplets evaporation in a plasma flow considering different mass transfer mechanisms. Surf. Coat. Technol. 2020, 404, 126454. [Google Scholar] [CrossRef]

- Li, D.; Feng, J.; Zhao, H.; Liu, C.; Zhang, L.; Shao, F.; Zhao, Y.; Tao, S. Microstructure formed by suspension plasma spraying: From YSZ splat to coating. Ceram. Int. 2017, 43, 7488–7496. [Google Scholar] [CrossRef]

- Guignard, A.; Mauer, G.; Vaßen, R.; Stöver, D. Deposition and characteristics of submicrometer-structured thermal barrier coatings by suspension plasma spraying. J. Therm. Spray Technol. 2012, 21, 416–424. [Google Scholar] [CrossRef]

- Curry, N.; Mahade, S.; Venkat, A.; Joshi, S. Erosion performance of suspension plasma spray thermal barrier coatings-A comparison with state of art coatings. Surf. Coat. Technol. 2022, 437, 128311. [Google Scholar] [CrossRef]

- Lokachari, S.; Leng, K.; Rincon Romero, A.; Curry, N.; Brewster, G.; Norton, A.; Hussain, T. Processing-microstructure–properties of columns in thermal barrier coatings: A study of thermo-chemico-mechanical durability. ACS Appl. Mater. Interfaces 2024, 16, 10646–10660. [Google Scholar] [CrossRef] [PubMed]

- Joeris, J.; Scheld, W.S.; Uhlenbruck, S.; Sohn, Y.J.; Sebold, D.; Guillon, O.; Vaßen, R. Preparation of highly durable columnar suspension plasma spray (SPS) coatings by pre-oxidation of the conicraly bondcoat. Coatings 2023, 13, 1575. [Google Scholar] [CrossRef]

- Leng, K.; Romero, A.R.; Curry, N.; Hussain, T. Multilayer GZ/YSZ thermal barrier coating from suspension and solution precursor plasma spray. Ceram. Int. 2024, 50, 631–649. [Google Scholar] [CrossRef]

- Amer, M.; Curry, N.; Hayat, Q.; Sharma, R.; Janik, V.; Zhang, X.; Nottingham, J.; Bai, M. Cracking behavior of Gd2Zr2O7/YSZ multi-layered thermal barrier coatings deposited by suspension plasma spray. Coatings 2023, 13, 107. [Google Scholar] [CrossRef]

- Mahade, S.; Zhou, D.; Curry, N.; Markocsan, N.; Nylén, P.; Vaßen, R. Tailored microstructures of gadolinium zirconate/YSZ multi-layered thermal barrier coatings produced by suspension plasma spray: Durability and erosion testing. J. Mater. Process. Technol. 2019, 264, 283–294. [Google Scholar] [CrossRef]

- Ganvir, A.; Joshi, S.; Markocsan, N.; Vassen, R. Tailoring columnar microstructure of axial suspension plasma sprayed TBCs for superior thermal shock performance. Mater. Des. 2018, 144, 192–208. [Google Scholar] [CrossRef]

- Joeris, J.; Tiwari, A.; Brinckmann, S.; Kurze, F.; Guillon, O.; Vaßen, R. Evaluation of major factors influencing the TBC topcoat formation in axial suspension plasma spraying (SPS). Int. J. Appl. Ceram. Technol. 2023, 20, 884–895. [Google Scholar] [CrossRef]

- Kiełczawa, T.; Sokołowski, P.; Małachowska, A. The influence of substrate topography on the plasma jet flow in the substrate boundary layer under suspension plasma spray conditions: A numerical approach. J. Therm. Spray Technol. 2022, 31, 84–101. [Google Scholar] [CrossRef] [PubMed]

- Seshadri, R.C.; Dwivedi, G.; Viswanathan, V.; Sampath, S. Characterizing suspension plasma spray coating formation dynamics through curvature measurements. J. Therm. Spray Technol. 2016, 25, 1666–1683. [Google Scholar] [CrossRef]

- Ganvir, A.; Curry, N.; Björklund, S.; Markocsan, N.; Nylén, P. Characterization of microstructure and thermal properties of YSZ coatings obtained by axial suspension plasma spraying (ASPS). J. Therm. Spray Technol. 2015, 24, 1195–1204. [Google Scholar] [CrossRef]

- Bernard, B.; Bianchi, L.; Malie, A.; Joulia, A.; Remy, B. Columnar suspension plasma sprayed coating microstructural control for thermal barrier coating application. J. Eur. Ceram. Soc. 2016, 36, 1081–1089. [Google Scholar] [CrossRef]

- Ganvir, A.; Calinas, R.F.; Markocsan, N.; Curry, N.; Joshi, S. Experimental visualization of microstructure evolution during suspension plasma spraying of thermal barrier coatings. J. Eur. Ceram. Soc. 2019, 39, 470–481. [Google Scholar] [CrossRef]

- Xu, P.; Meng, G.; Liu, G.; Coyle, T.; Pershin, L.; Mostaghimi, J. Columnar-structured thermal barrier coatings deposited via the water-based suspension plasma spray process. J. Phys. D Appl. Phys. 2022, 55, 204001. [Google Scholar] [CrossRef]

- Curry, N.; VanEvery, K.; Snyder, T.; Susnjar, J.; Bjorklund, S. Performance testing of suspension plasma sprayed thermal barrier coatings produced with varied suspension parameters. Coatings 2015, 5, 338–356. [Google Scholar] [CrossRef]

- VanEvery, K.; Krane, M.J.; Trice, R.W.; Wang, H.; Porter, W.; Besser, M.; Sordelet, D.; Ilavsky, J.; Almer, J. Column formation in suspension plasma-sprayed coatings and resultant thermal properties. J. Therm. Spray Technol. 2011, 20, 817–828. [Google Scholar] [CrossRef]

- Chen, X.; Kuroda, S.; Ohnuki, T.; Araki, H.; Watanabe, M.; Sakka, Y. Effects of processing parameters on the deposition of yttria partially stabilized zirconia coating during suspension plasma spray. J. Am. Ceram. Soc. 2016, 99, 3546–3555. [Google Scholar] [CrossRef]

- Jadidi, M.; Mousavi, M.; Moghtadernejad, S.; Dolatabadi, A. A three-dimensional analysis of the suspension plasma spray impinging on a flat substrate. J. Therm. Spray Technol. 2015, 24, 11–23. [Google Scholar] [CrossRef]

- Berghaus, J.O.; Bouaricha, S.; Legoux, J.; Moreau, C. Injection Conditions and In-Flight Particle States in Suspension Plasma Spraying of Alumina and Zirconia Nano-Ceramics. In Proceedings of the International Thermal Spray Conference, Basel, Switzerland, 2–4 May 2005; ASM International: Basel, Switzerland, 2005; pp. 512–518. [Google Scholar]

- Mauer, G. Numerical study on particle-gas interaction close to the substrates in thermal spray processes with high-kinetic and low-pressure conditions. J. Therm. Spray Technol. 2019, 28, 27–39. [Google Scholar] [CrossRef]

- Hansen, F.; Rødsrud, G. Surface tension by pendant drop: I. A fast standard instrument using computer image analysis. J. Colloid Interface Sci. 1991, 141, 1–9. [Google Scholar] [CrossRef]

- Berry, J.D.; Neeson, M.J.; Dagastine, R.R.; Chan, D.Y.; Tabor, R.F. Measurement of surface and interfacial tension using pendant drop tensiometry. J. Colloid Interface Sci. 2015, 454, 226–237. [Google Scholar] [CrossRef]

- Boulos, M.I.; Fauchais, P.; Pfender, E. Thermal Plasmas: Fundamentals and Applications; Springer Science & Business Media: New York, NY, USA, 1994. [Google Scholar]

- Zhao, Y.; Grant, P.; Cantor, B. Modelling and experimental analysis of vacuum plasma spraying. Part I: Prediction of initial plasma properties at plasma gun exit. Modell. Simul. Mater. Sci. Eng. 2000, 8, 497. [Google Scholar] [CrossRef]

- Rat, V.; Chazelas, C.; Goutier, S.; Keromnes, A.; Mariaux, G.; Vardelle, A. In-flight mechanisms in suspension plasma spraying: Issues and perspectives. J. Therm. Spray Technol. 2022, 31, 699–715. [Google Scholar] [CrossRef]

- Jadidi, M.; Moghtadernejad, S.; Hanson, J. Numerical study of the effects of twin-fluid atomization on the suspension plasma spraying process. Fluids 2020, 5, 224. [Google Scholar] [CrossRef]

- Saha, A.; Seal, S.; Cetegen, B.; Jordan, E.; Ozturk, A.; Basu, S. Thermo-physical processes in cerium nitrate precursor droplets injected into high temperature plasma. Surf. Coat. Technol. 2009, 203, 2081–2091. [Google Scholar] [CrossRef]

- Kebriyaei, A.; Rahimipour, M.R.; Razavi, M. Solution medium suspension plasma spray (SMSPS): A microstructure and high-temperature properties analysis of YSZ thermal barrier coating. J. Therm. Spray Technol. 2024, 33, 2395–2407. [Google Scholar] [CrossRef]

- Mahade, S.; Curry, N.; Björklund, S.; Markocsan, N.; Nylén, P.; Vaßen, R. Erosion performance of gadolinium zirconate-based thermal barrier coatings processed by suspension plasma spray. J. Therm. Spray Technol. 2017, 26, 108–115. [Google Scholar] [CrossRef]

- Karger, M.; Vaßen, R.; Stöver, D. Atmospheric plasma sprayed thermal barrier coatings with high segmentation crack densities: Spraying process, microstructure and thermal cycling behavior. Surf. Coat. Technol. 2011, 206, 16–23. [Google Scholar] [CrossRef]

- Shinde, S.V.; Johnson, C.A.; Sampath, S. Segmentation crack formation dynamics during air plasma spraying of zirconia. Acta Mater. 2020, 183, 196–206. [Google Scholar] [CrossRef]

- Abubakar, A.A.; Arif, A.F.M.; Akhtar, S.S. Evolution of internal cracks and residual stress during deposition of TBC. Ceram. Int. 2020, 46, 26731–26753. [Google Scholar] [CrossRef]

- Xu, P.; Sui, X.; Wang, S.; Liu, G.; Ge, A.; Coyle, T.W.; Mostaghimi, J. Superhydrophobic ceramic coatings with lotus leaf-like hierarchical surface structures deposited via suspension plasma spray process. Surf. Interfaces 2023, 38, 102780. [Google Scholar] [CrossRef]

- Xu, P.; Coyle, T.W.; Pershin, L.; Mostaghimi, J. Superhydrophobic ceramic coating: Fabrication by solution precursor plasma spray and investigation of wetting behavior. J. Colloid Interface Sci. 2018, 523, 35–44. [Google Scholar] [CrossRef]

- Delbos, C.; Fazilleau, J.; Rat, V.; Coudert, J.-F.; Fauchais, P.; Pateyron, B. Phenomena involved in suspension plasma spraying part 2: Zirconia particle treatment and coating formation. Plasma Chem. Plasma Process. 2006, 26, 393–414. [Google Scholar] [CrossRef]

- Joulia, A.; Bolelli, G.; Gualtieri, E.; Lusvarghi, L.; Valeri, S.; Vardelle, M.; Rossignol, S.; Vardelle, A. Comparing the deposition mechanisms in suspension plasma spray (SPS) and solution precursor plasma spray (SPPS) deposition of yttria-stabilised zirconia (YSZ). J. Eur. Ceram. Soc. 2014, 34, 3925–3940. [Google Scholar] [CrossRef]

| Particle | Solvent | Dispersant | Suspension | Coatings |

|---|---|---|---|---|

| Fine particles | Ethanol | PEI | F-E suspension | F-E coating |

| Fine particles | Water | PEI | F-W suspension | F-W coating |

| Coarse particles | Ethanol | PEI | C-E suspension | C-E coating |

| Coarse particles | Water | PEI | C-W suspension | C-W coating |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, Y.; Jiao, W.; Xu, P.; Sui, X.; Liu, G.; Zhan, X.; Fan, C.; Lv, M. Understanding the Correlations Between the Formation of Columnar Structures and Suspension Properties for Suspension Plasma-Sprayed Thermal Barrier Coatings. Coatings 2025, 15, 1132. https://doi.org/10.3390/coatings15101132

Feng Y, Jiao W, Xu P, Sui X, Liu G, Zhan X, Fan C, Lv M. Understanding the Correlations Between the Formation of Columnar Structures and Suspension Properties for Suspension Plasma-Sprayed Thermal Barrier Coatings. Coatings. 2025; 15(10):1132. https://doi.org/10.3390/coatings15101132

Chicago/Turabian StyleFeng, Yachen, Wenhan Jiao, Pengyun Xu, Xiaomu Sui, Guijie Liu, Xianghua Zhan, Changfeng Fan, and Mingli Lv. 2025. "Understanding the Correlations Between the Formation of Columnar Structures and Suspension Properties for Suspension Plasma-Sprayed Thermal Barrier Coatings" Coatings 15, no. 10: 1132. https://doi.org/10.3390/coatings15101132

APA StyleFeng, Y., Jiao, W., Xu, P., Sui, X., Liu, G., Zhan, X., Fan, C., & Lv, M. (2025). Understanding the Correlations Between the Formation of Columnar Structures and Suspension Properties for Suspension Plasma-Sprayed Thermal Barrier Coatings. Coatings, 15(10), 1132. https://doi.org/10.3390/coatings15101132