Study on the Effects of Micro-Groove Tools on Surface Quality and Chip Characteristics When Machining AISI 201

Abstract

1. Introduction

2. Experimental Principles and Methods

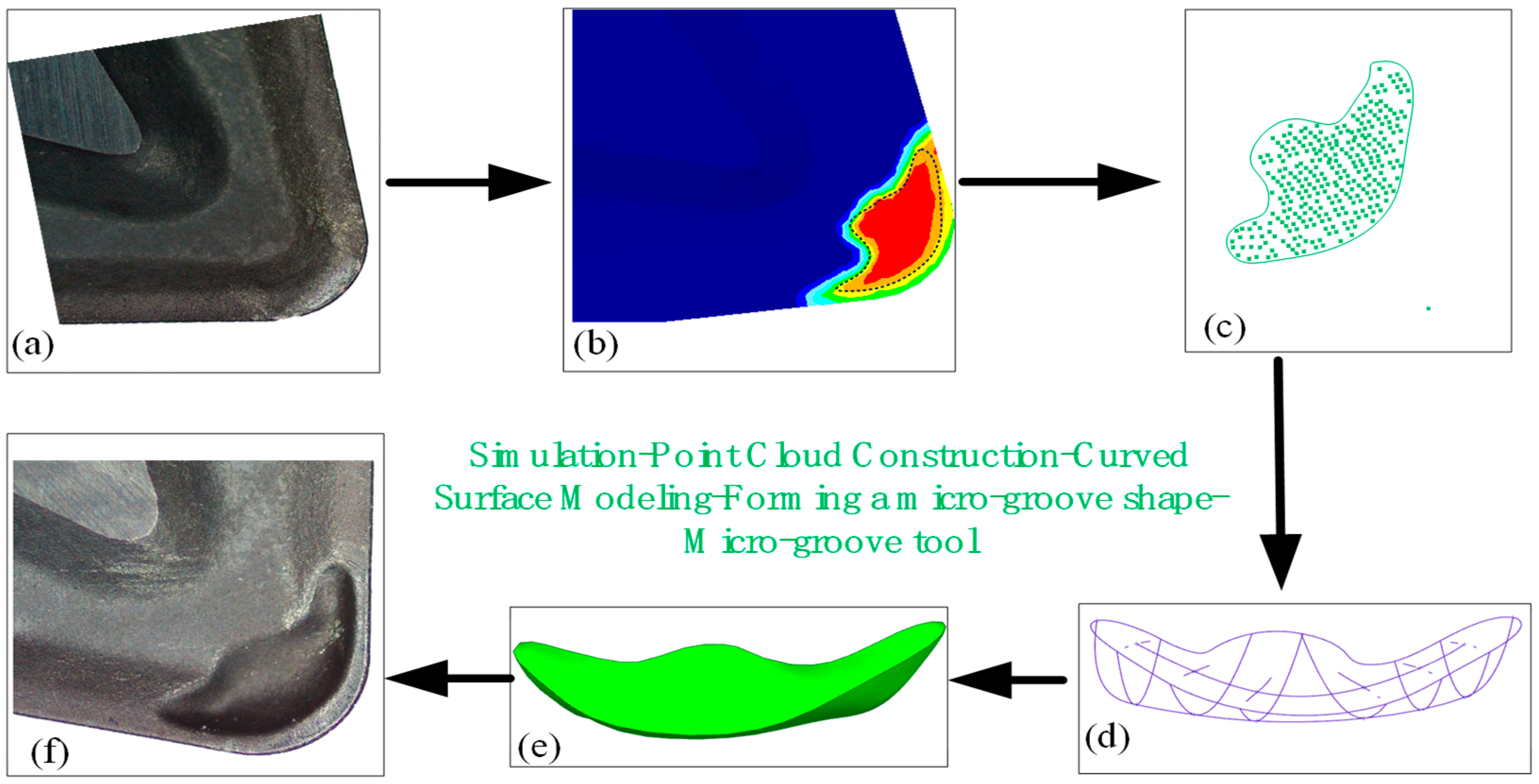

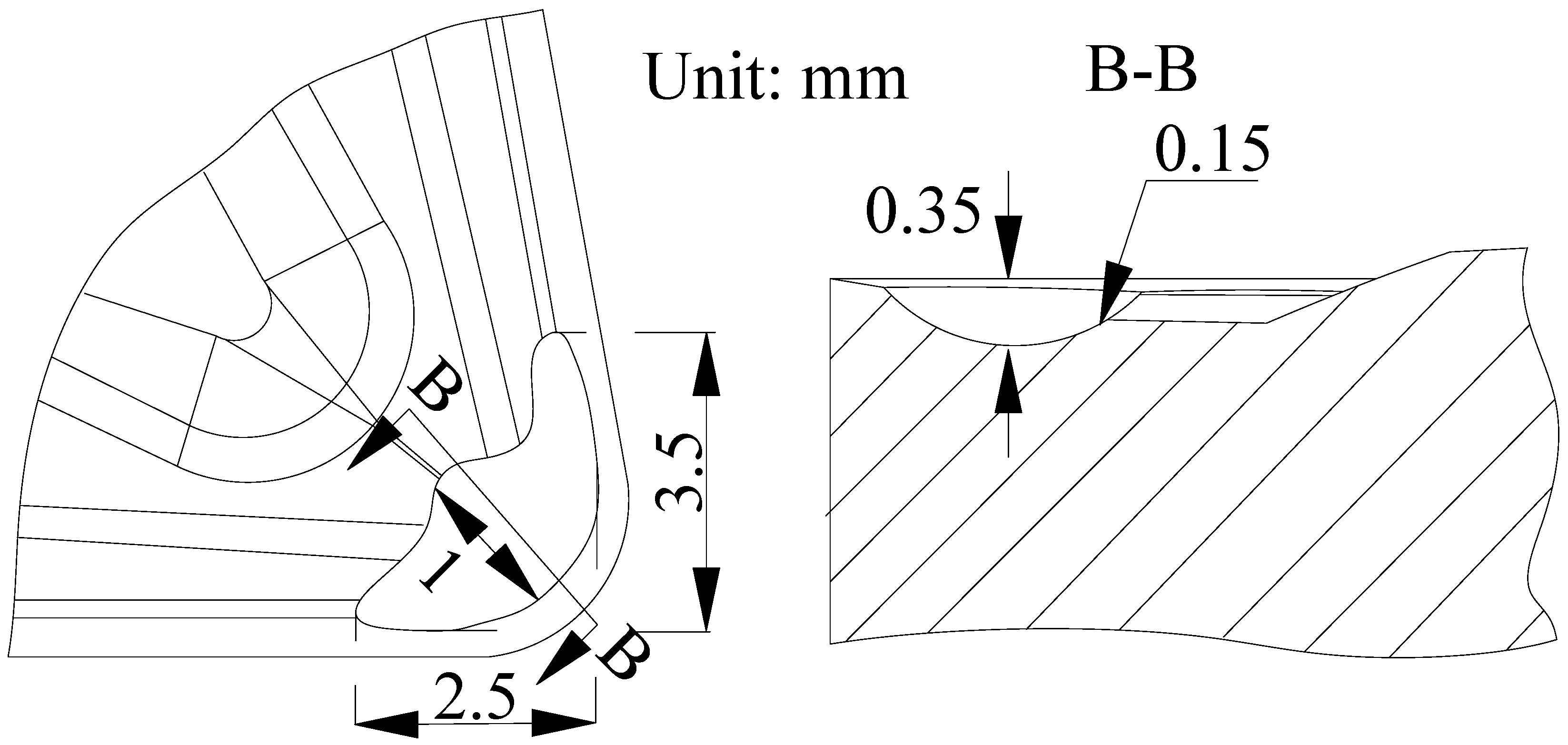

2.1. Design of Micro-Groove Cutting Tool

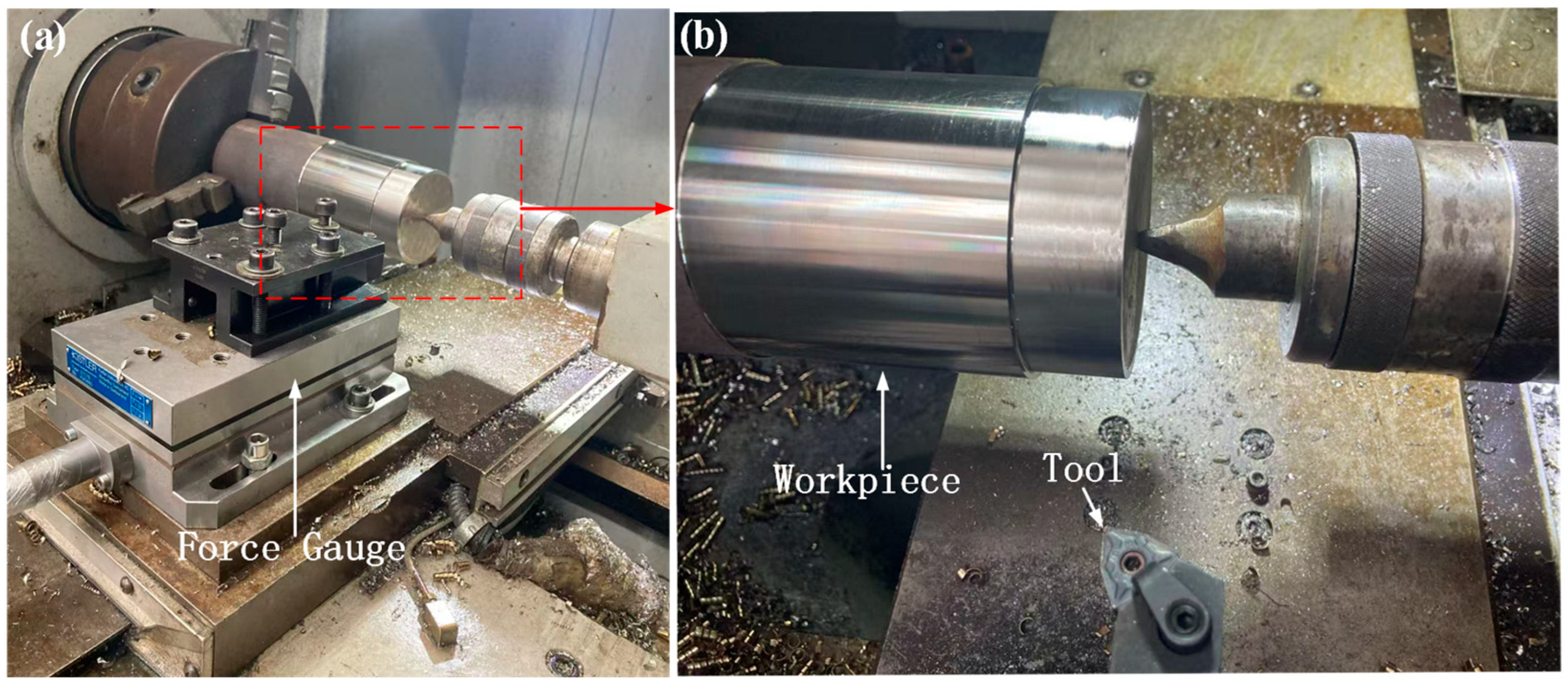

2.2. Research on Tool Cutting Experiments and Workpiece Surface Quality

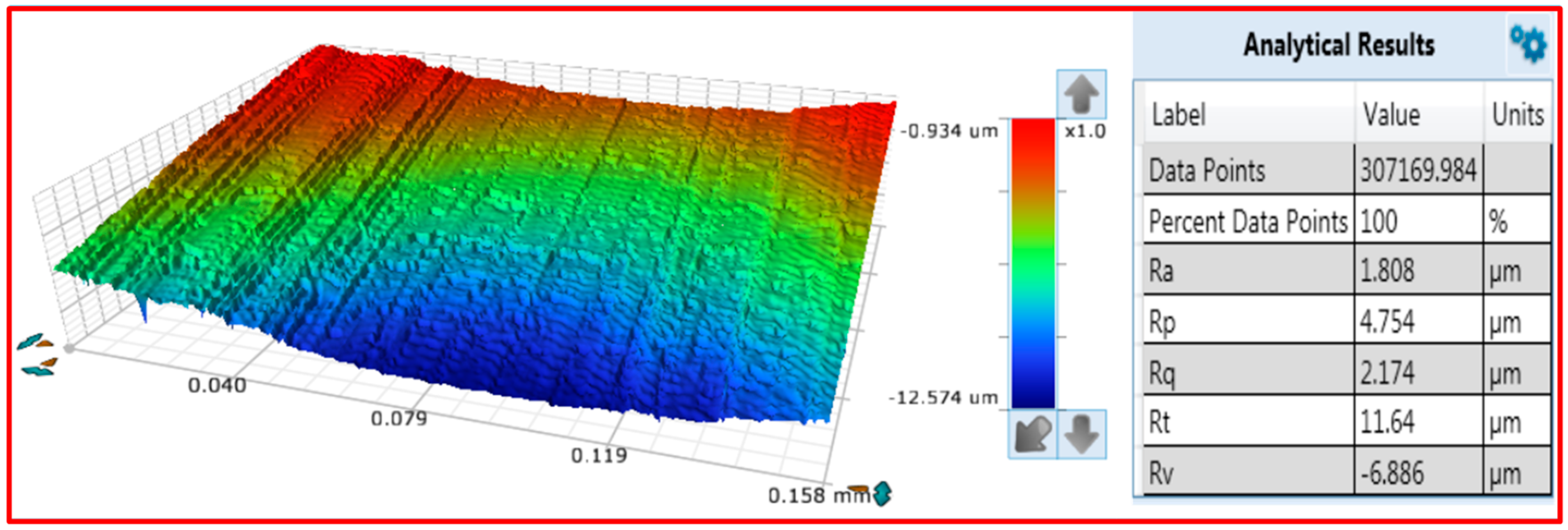

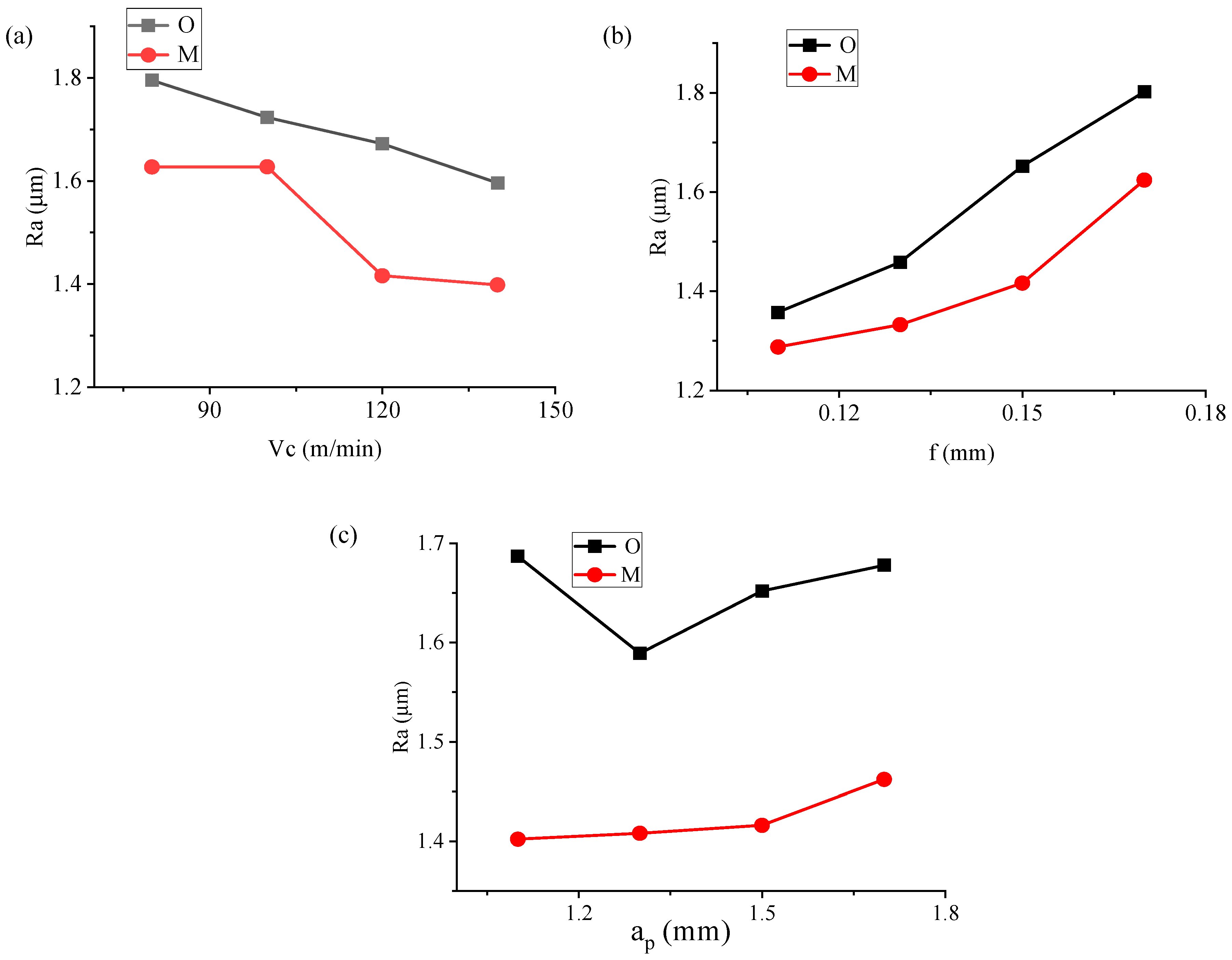

2.2.1. Comparison of Workpiece Surface Roughness

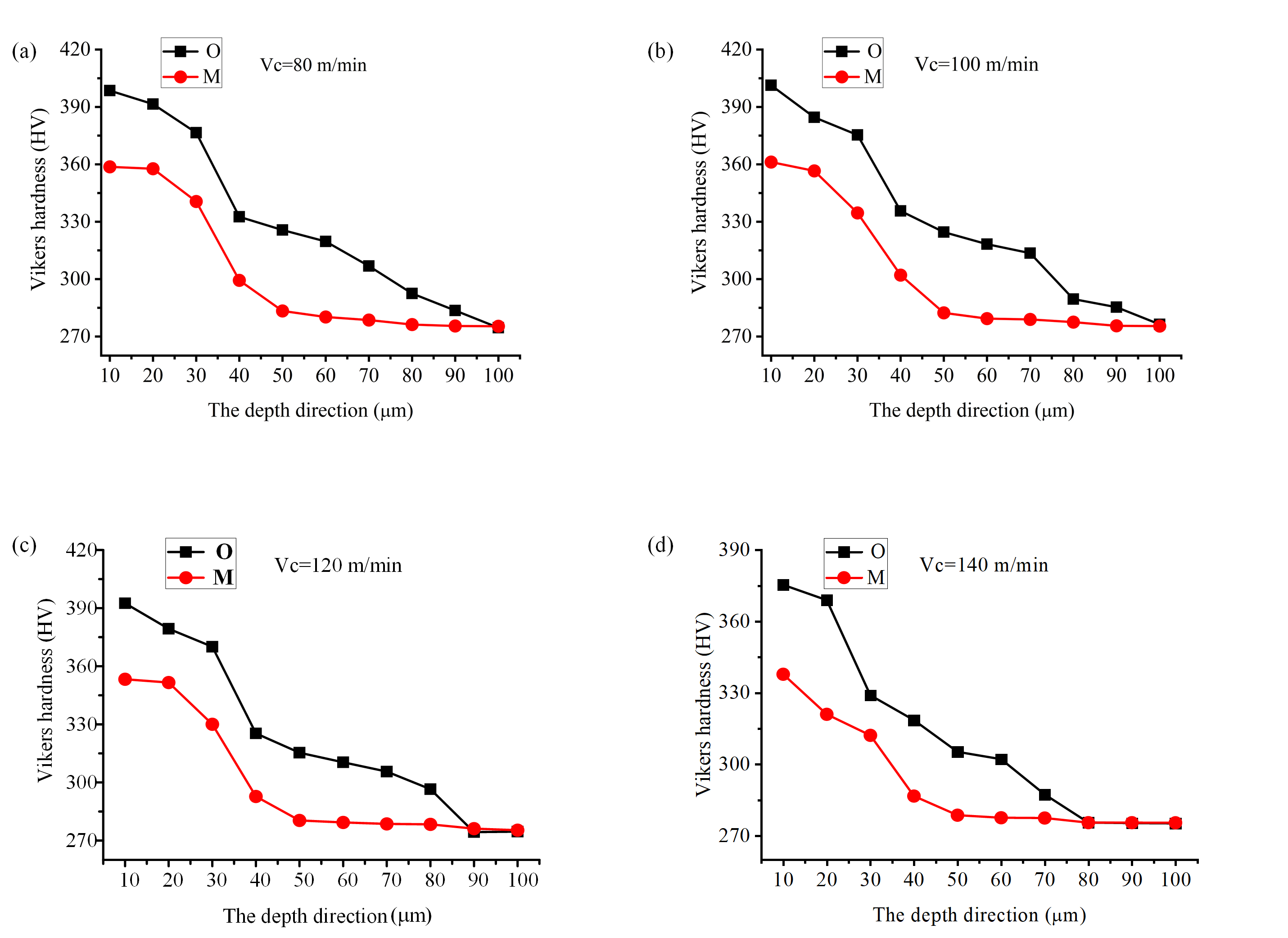

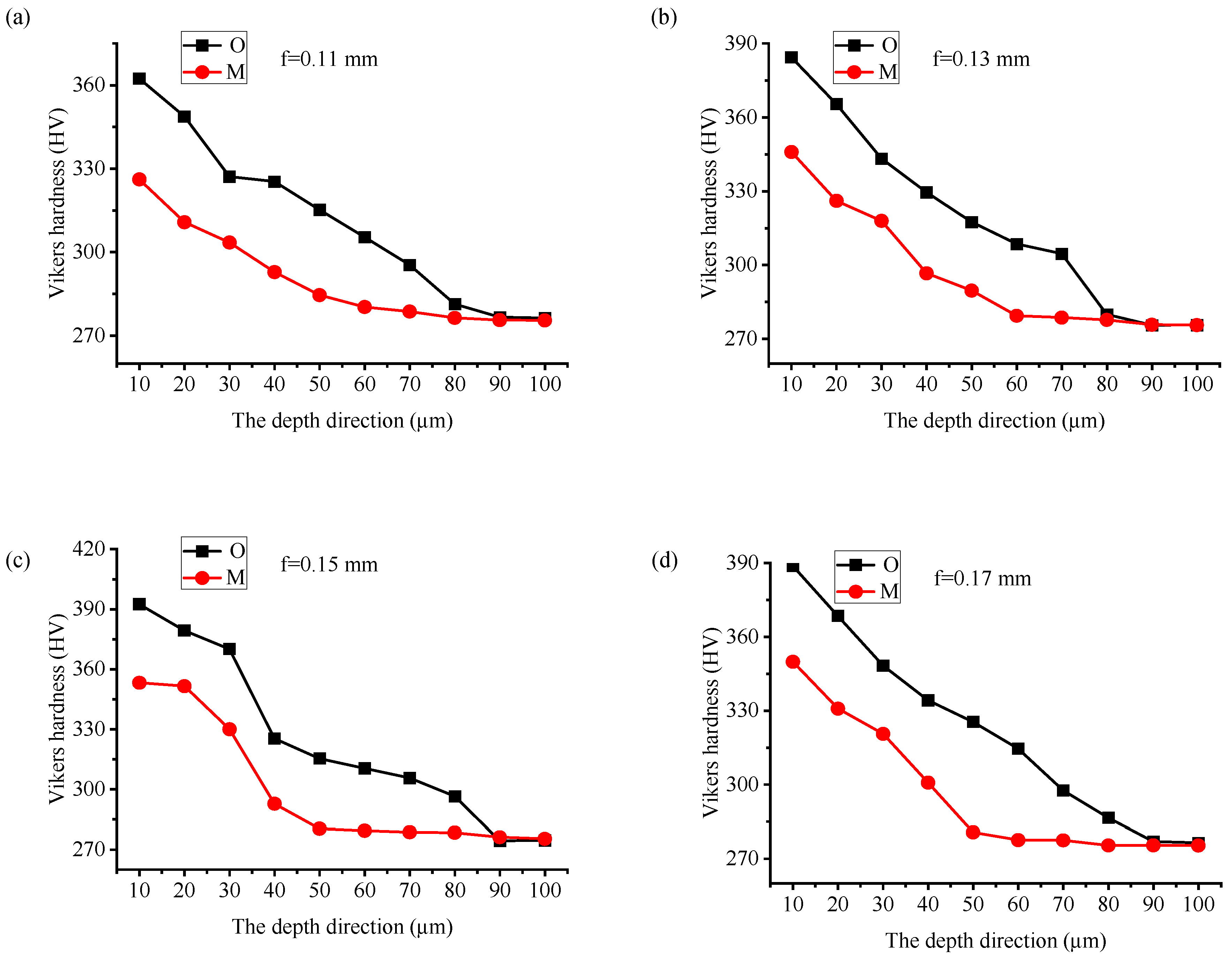

2.2.2. Analysis of Surface Hardening of Workpieces

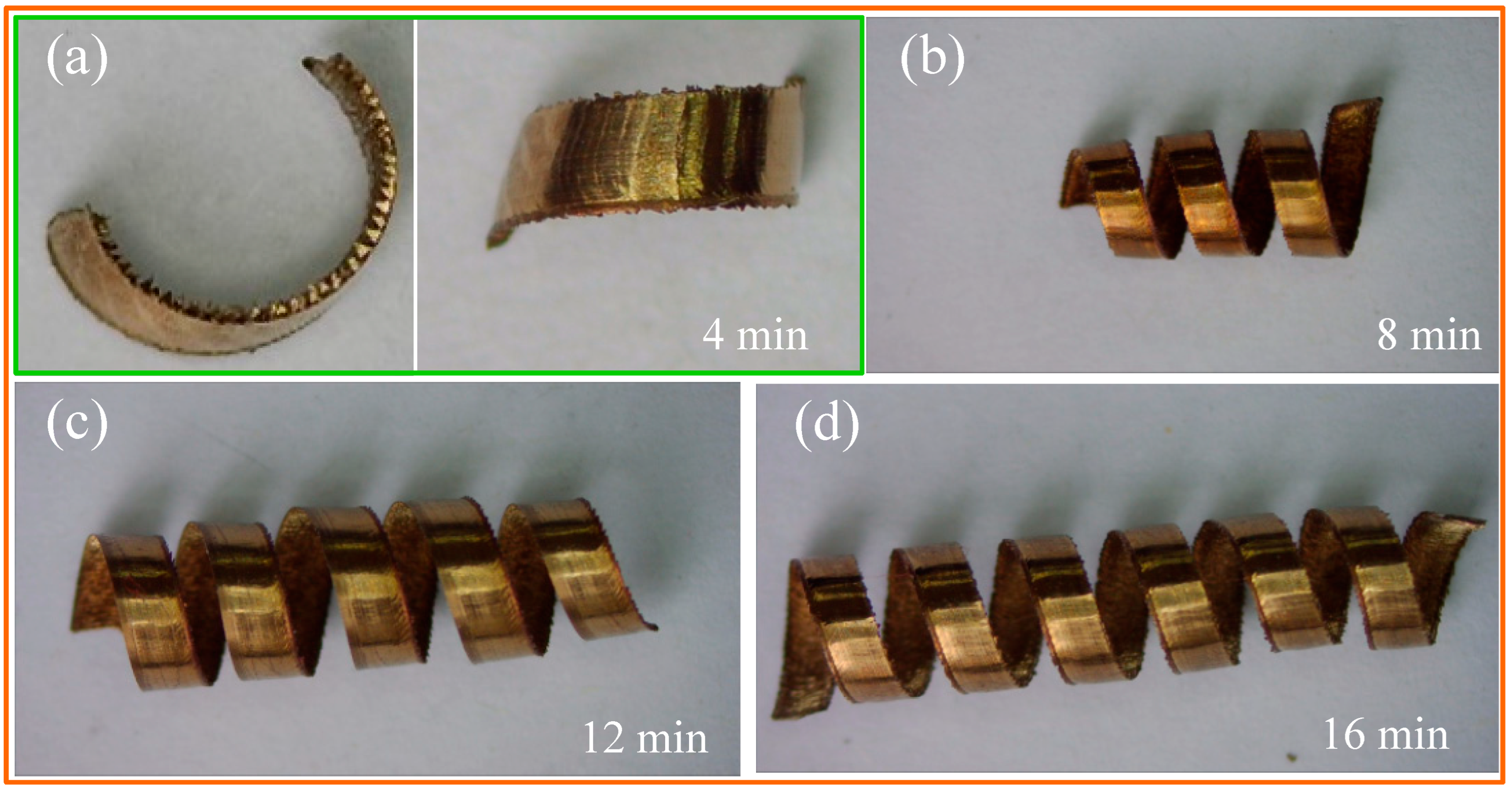

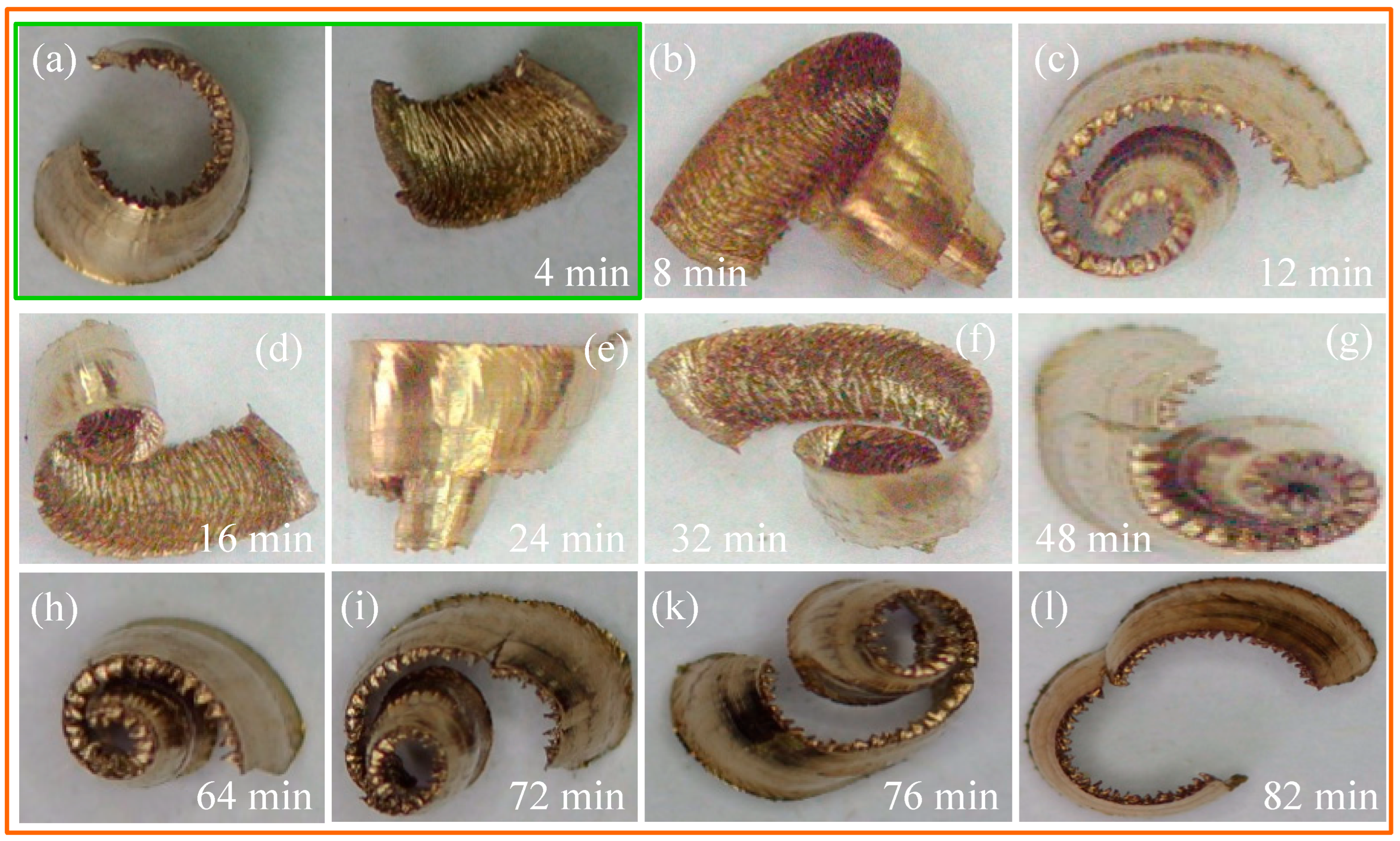

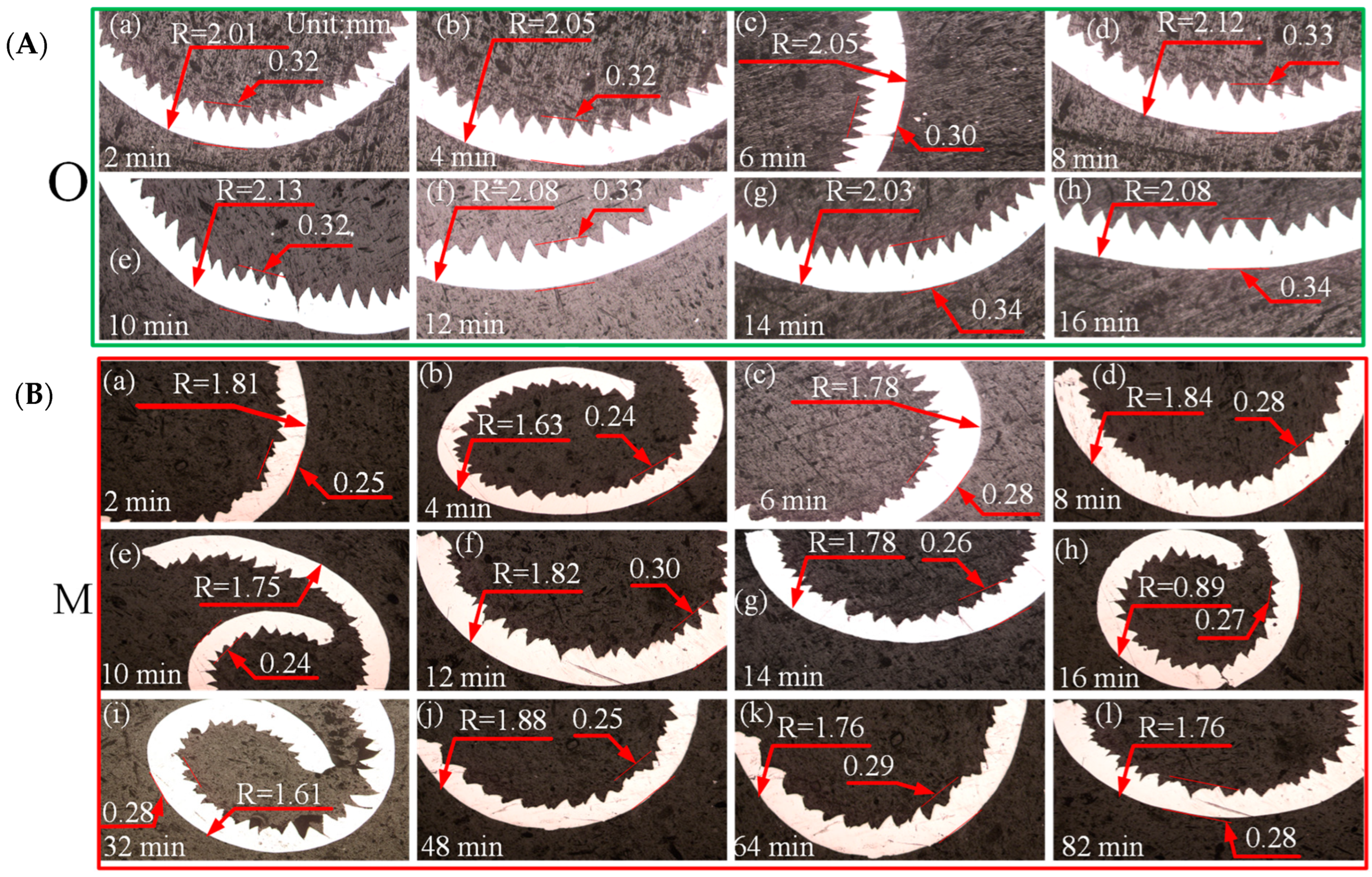

2.2.3. Analysis of Changes in the Macroscopic Morphology of Tool Chips

3. Results and Discussion

4. Conclusions

- Measurements of surface roughness and workpiece surface hardness revealed that the workpieces machined with tool M exhibited lower surface roughness and reduced hardening compared to those machined with the original tool, with a shallower hardened layer depth.

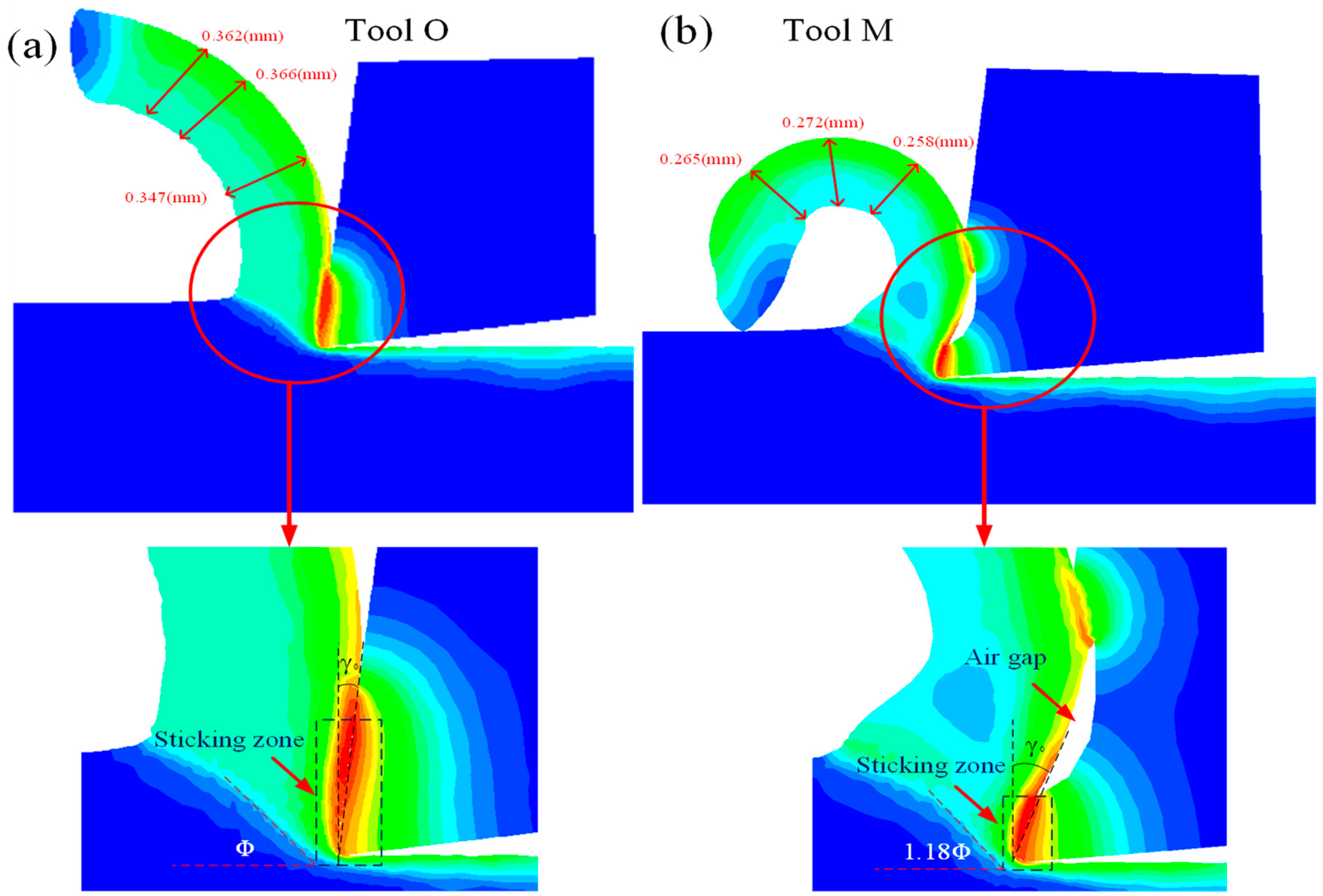

- During cutting, the micro-grooves increase the deformation space for chips on the rake face, causing chips to elongate along the micro-grooves. This effectively increases the actual cutting rake angle γ0, thereby enlarging the tool’s shear angle φ. Consequently, the tool becomes sharper, cutting forces decrease, cutting temperatures drop, chip thickness reduces, and chip deformation energy diminishes.

- Establishing a correlation analysis method between cutting energy and workpiece surface quality reveals that achieving equivalent surface quality requires lower cutting energy with new tools compared to original ones. To attain superior surface quality, cutting parameters must be selected at lower cutting energy levels.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Giudice, F.; Missori, S.; Scolaro, C.; Sili, A. A review on fusion welding of dissimilar ferritic/austenitic steels: Processing and weld zone metallurgy. J. Manuf. Mater. Process. 2024, 8, 96. [Google Scholar] [CrossRef]

- Fouad, R.A.; Habba, M.I.; Elshaghoul, Y.G.; El-Sayed Seleman, M.M.; Hafez, K.M.; El-Fahhar, H.H.; Barakat, W.S. Comparative analysis of filler metals on microstructure and mechanical performance of TIG-welded AISI 201 austenitic stainless steel joints. Sci. Technol. Weld. Join. 2024, 29, 356–367. [Google Scholar] [CrossRef]

- Kumar, N.; Choubey, V.K. Recent trends in coating processes on various AISI steel substrates: A review. J. Mater. Sci. 2024, 59, 395–422. [Google Scholar] [CrossRef]

- Sana, M.; Asad, M.; Farooq, M.U.; Anwar, S.; Talha, M. Machine learning for multi-dimensional performance optimization and predictive modelling of nanopowder-mixed electric discharge machining (EDM). Int. J. Adv. Manuf. Technol. 2024, 130, 5641–5664. [Google Scholar] [CrossRef]

- Masoumi, M.; de Oliveira, S.E.; Paredes, M. Influence of Cold Drawing on Phase Transformation and Tensile Properties of FeCrMn Austenitic Stainless Steel 201. Steel Res. Int. 2025, 96, 2400469. [Google Scholar] [CrossRef]

- Vetter, J.; Beneder, S.; Kandler, M.; Feyer, F.; Körner, C.; Schmidt, M. Impact of particle size distribution in the preform on thermal conductivity, Vickers hardness and tensile strength of copper-infiltrated AISI H11 tool steel. Materials 2023, 16, 2659. [Google Scholar] [CrossRef]

- Pelissari, G.H.; Braga, D.P.; Oliveira, P.H.F.; Magalhães, D.C.C.; Ferrante, M.; Rovere, C.A.D.; Sordi, V.L. Creep and Hot Tensile Behavior of AISI 201LN Austenitic Stainless Steel. Metall. Mater. Trans. A 2021, 52, 4413–4423. [Google Scholar] [CrossRef]

- Zeng, K.; Wu, X.; Jiang, F.; Shen, J.; Zhu, L.; Wen, Q.; Li, H. The non-traditional and multi-energy field hybrid machining processes of cemented carbide: A comprehensive review. Int. J. Adv. Manuf. Technol. 2024, 133, 2049–2082. [Google Scholar] [CrossRef]

- Zabon, A.H.; Abbas, T.F.; Bedan, A.S. Enhancing laser cutting quality of stainless steel 201 by controlling dross formation and surface roughness using multi-factor experimental design. Adv. Sci. Technol. Res. J. 2025, 19, 458–470. [Google Scholar] [CrossRef] [PubMed]

- Vornberger, A.; Picker, T.; Pötschke, J.; Herrmann, M.; Denkena, B.; Krödel, A.; Michaelis, A. Influence of cemented carbide composition on cutting temperatures and corresponding hot hardnesses. Materials 2020, 13, 4571. [Google Scholar] [CrossRef] [PubMed]

- Tang, X.; Wang, Z.; Huang, L.; Wang, X.; Chang, T.; Huang, P.; Zhu, Z. Preparation, properties and microstructure of high hardness WC-Co cemented carbide tool materials for ultra-precision machining. Int. J. Refract. Met. Hard Mater. 2023, 116, 106356. [Google Scholar] [CrossRef]

- You, Q.; Xiong, J.; Li, H.; Guo, Z.; Huo, Y. Study on the microstructure and high temperature friction and wear characteristics of three CVD coated cermets. Int. J. Refract. Met. Hard Mater. 2021, 96, 105495. [Google Scholar] [CrossRef]

- You, Q.; Xiong, J.; Guo, Z.; Huo, Y.; Liang, L.; Yang, L. Study on coating performance of CVD coated cermet tools for 4340 steel cutting. Int. J. Refract. Met. Hard Mater. 2021, 98, 105554. [Google Scholar] [CrossRef]

- Bhushan, R.K. Minimising tool wear by optimisation (ANOVA) of cutting parameters in machining of 7075Al Alloy SiC particle composite. Aust. J. Mech. Eng. 2023, 21, 499–517. [Google Scholar] [CrossRef]

- Abbed, K.; Kribes, N.; Yallese, M.A.; Chihaoui, S.; Boutabba, S. Effects of tool materials and cutting conditions in turning of Ti-6Al-4V alloy: Statistical analysis, modeling and optimization using CoCoSo, MABAC, ARAS and CODAS methods. Int. J. Adv. Manuf. Technol. 2023, 128, 1535–1557. [Google Scholar] [CrossRef]

- Pang, S.; Zhao, W.; Qiu, T.; Liu, W.; Yan, P.; Jiao, L.; Wang, X. Effect of cutting fluid on milled surface quality and tool life of aluminum alloy. Materials 2023, 16, 2198. [Google Scholar] [CrossRef]

- Saraf, G.; Nirala, C.K. Experimental investigation of micro-pillar textured WC inserts during turning of Ti6Al4V under various cutting fluid strategies. J. Manuf. Process. 2024, 113, 61–75. [Google Scholar] [CrossRef]

- Alves, U.C.; Ricci, V.P.; Mota, I.G.; Koga, G.Y.; Hassui, A.; Ventura, C.E. Mechanical and tribological characterization of TiAlN/TiN and TiSiN/AlTiN coating systems for cutting tools. J. Manuf. Process. 2025, 145, 522–535. [Google Scholar] [CrossRef]

- Bakar, H.A.; Ghani, J.A.; Haron, C.C.; Ghazali, M.J.; Kasim, M.S.; Al-Zubaidi, S.; Jouini, N. Wear mechanisms of solid carbide cutting tools in dry and cryogenic machining of AISI H13 steel with varying cutting-edge radius. Wear 2023, 523, 204758. [Google Scholar] [CrossRef]

- Chen, T.; Liu, J.; Liu, G.; Xiao, H.; Li, C.; Liu, X. Experimental study on titanium alloy cutting property and wear mechanism with circular-arc milling cutters. Chin. J. Mech. Eng. 2023, 36, 57. [Google Scholar] [CrossRef]

- Liu, C.; Ren, J.; Zhang, Y.; Shi, K. The effect of tool structure and milling parameters on the milling quality of CFRP based on 3D surface roughness. Int. J. Precis. Eng. Manuf. 2023, 24, 931–944. [Google Scholar] [CrossRef]

- Zhang, S.; Shi, H.; Wang, B.; Ma, C.; Li, Q. Research on the milling performance of micro-groove ball end mills for titanium alloys. Lubricants 2024, 12, 204. [Google Scholar] [CrossRef]

- Zou, Z.; He, L.; Jiang, H.; Zhan, G.; Wu, J. Development and analysis of a low-wear micro-groove tool for turning Inconel 718. Wear 2019, 420, 163–175. [Google Scholar] [CrossRef]

- Zou, P.; Zhou, L.; Yang, Z.; Ren, B.; Wang, X. Effect of texture location in tool-chip friction region on cutting performance in turning AISI 304. Int. J. Adv. Manuf. Technol. 2024, 132, 2787–2805. [Google Scholar] [CrossRef]

- Miao, X.; Zhang, X.; Liu, X.; Yu, Q.; Zhang, L. Numerical analysis of performance of different micro-grooved tools for cutting titanium alloy Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2020, 111, 1037–1054. [Google Scholar] [CrossRef]

- Yu, Z.; Chen, G.; Xuan, W.; Wei, H. Machining performance of micro-pit and micro-groove composite textured tools in tungsten alloy turning. Proc. Inst. Mecha. Eng. Part B J. Eng. Manuf. 2025, 239, 418–427. [Google Scholar] [CrossRef]

- Jiang, J.; Luo, T.; Zhang, G.; Dai, Y. Novel tool offset fly cutting straight-groove-type micro structure arrays. J. Mater. Process. Technol. 2021, 288, 116900. [Google Scholar] [CrossRef]

- Wang, X.; Popov, V.L.; Yu, Z.; Li, Y.; Xu, J.; Li, Q.; Yu, H. Evaluation of the cutting performance of micro-groove-textured PCD tool on SiCp/Al composites. Ceram. Int. 2022, 48, 32389–32398. [Google Scholar] [CrossRef]

- Jin, L.; Gong, Y.; Sun, Y.; Wen, Q.; Sun, J. Research on surface quality and tool wear of micro-groove array machined by a novel micro-milling cutter. Int. J. Adv. Manuf. Technol. 2022, 121, 2383–2397. [Google Scholar] [CrossRef]

- Deng, J.; Wang, F.; Lin, Y.; Sun, L. An unequal pitch ball-end milling cutter with micro-groove structure for suppressing CFRP milling chatter based on coordinated regulation of time delay effect and milling force. Int. J. Adv. Manuf. Technol. 2025, 137, 1437–1456. [Google Scholar] [CrossRef]

- Ahmed, T.; Mollick, N.; Mahmud, S.; Ahmad, T. Analysis of Effects of Machining Parameters on Cutting Force Components in Turning AISI 201 Stainless Steel Using Cemented Carbide Cutting Tool Insert. Mater. Today Proc. 2021, 44, 4151–4156. [Google Scholar] [CrossRef]

- Elmunafi, M.H.S.; Yusof, M.S.M. Effect of cutting speed and feed in turning hardened stainless steel using coated carbide tool under Minimum Quantity Lubrication. Adv. Mech. Eng. 2015, 7, 1–9. [Google Scholar] [CrossRef]

- Zou, Z.; He, L.; Jiang, H. Influence of microgroove structure on cutting performance and chip morphology during the turning of superalloy Inconel 718. Materials 2021, 14, 4142. [Google Scholar] [CrossRef]

- Chen, S.H.; Luo, Z.R. Study of using cutting chip color to the tool wear prediction. Int. J. Adv. Manuf. Technol. 2020, 109, 823–839. [Google Scholar] [CrossRef]

- Abdalrahman, R.M.; Rostam, S.; Deboucha, A. Effect of Cutting Tool Rake and Inclination Angles and Feeding Method on Cutting Force and Surface Quality in Single-point Threading. Kurd. J. Appl. Res. 2025, 10, 55–67. [Google Scholar] [CrossRef]

- Li, P.; Chang, Z. Accurate modeling of working normal rake angles and working inclination angles of active cutting edges and application in cutting force prediction. Micromachines 2021, 12, 1207. [Google Scholar] [CrossRef] [PubMed]

| Performance Parameters | ρ (g/cm3) | Tensile Strength | Bending Strength (GPa) | Hardness | Poisson’s Ratio | Elastic Modulus (GPa) |

|---|---|---|---|---|---|---|

| Tool(M30) | 14.6 | 4.7 Gpa | 1.4 | 91 HRA | 0.23 | 630–640 |

| Workpiece-AISI201 | 7.93 | 543 Ma | / | 274.56 HV | 0.249 | 201 |

| Geometric Angle | Tool Angle | Rake Angle | Clearance Angle | Main Cutting Edge Angle | End Cutting Edge Angle | Inclination Angle |

|---|---|---|---|---|---|---|

| Value (°) | 80 | 8 | 5 | 95 | −5 | 7 |

| No. | vc (m/min) | f (mm/r) | ap (mm) | Number of Tests | Simulation Fc (N) | Actual Fc (N) | p-Value (Simulation) | p-Value (Measured) | Significance (α = 0.05) |

|---|---|---|---|---|---|---|---|---|---|

| A1 | 80 | 0.15 | 1.5 | 3 | 1194.9 | 919.2 | 0.00029 | <0.00001 | Significant |

| A2 | 100 | 0.15 | 1.5 | 3 | 1098.6 | 865.8 | |||

| A3 | 120 | 0.15 | 1.5 | 3 | 1102.4 | 863.4 | |||

| A4 | 140 | 0.15 | 1.5 | 3 | 1085.9 | 855.3 | |||

| B1 | 120 | 0.11 | 1.5 | 3 | 1020.8 | 785.3 | <0.00001 | 0.000070 | Significant |

| B2 | 120 | 0.13 | 1.5 | 3 | 1036.9 | 843.8 | |||

| B3 | 120 | 0.15 | 1.5 | 3 | 1122.4 | 863.4 | |||

| B4 | 120 | 0.17 | 1.5 | 3 | 1378.5 | 1060.4 | |||

| C1 | 120 | 0.15 | 1.1 | 3 | 1004.8 | 772.9 | 0.000022 | 0.000023 | Significant |

| C2 | 120 | 0.15 | 1.3 | 3 | 1086.6 | 835.8 | |||

| C3 | 120 | 0.15 | 1.5 | 3 | 1112.4 | 863.4 | |||

| C4 | 120 | 0.15 | 1.7 | 3 | 1246.1 | 1066.3 |

| Cutting Time (min) | Chip Thickness Ratio ξO | Chip Thickness Ratio ξM | Front Corner γ0 (°) | Shear Angle φO (°) | Shear Angle φM (°) |

|---|---|---|---|---|---|

| 2 | 2.13 | 1.67 | 8 | 26.7 | 34.8 |

| 4 | 2.13 | 1.60 | 8 | 26.7 | 36.9 |

| 6 | 2.00 | 1.87 | 8 | 29.0 | 31.2 |

| 8 | 2.20 | 1.87 | 8 | 25.3 | 31.2 |

| 10 | 2.13 | 1.60 | 8 | 26.7 | 36.9 |

| 12 | 2.20 | 2.00 | 8 | 25.3 | 29.0 |

| 14 | 2.27 | 1.73 | 8 | 24.5 | 33.7 |

| 16 | 2.27 | 1.80 | 8 | 24.5 | 32.3 |

| 32 | / | 1.87 | 8 | / | 31.2 |

| 48 | / | 1.67 | 8 | / | 34.8 |

| 64 | / | 1.93 | 8 | / | 30.2 |

| 82 | / | 1.87 | 8 | / | 31.2 |

| Number of Experiments | Simulation Fc (N) | Actual Fc (N) | Cutting Simulation Temperature t (°C) | |

|---|---|---|---|---|

| Tool O | 3 | 1102.4 | 863.4 | 674.5 |

| Tool M | 3 | 887.5 | 657.3 | 534.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Hu, W.; Zhang, Y.; Wu, C.; Yang, Z. Study on the Effects of Micro-Groove Tools on Surface Quality and Chip Characteristics When Machining AISI 201. Coatings 2025, 15, 1124. https://doi.org/10.3390/coatings15101124

Wu J, Hu W, Zhang Y, Wu C, Yang Z. Study on the Effects of Micro-Groove Tools on Surface Quality and Chip Characteristics When Machining AISI 201. Coatings. 2025; 15(10):1124. https://doi.org/10.3390/coatings15101124

Chicago/Turabian StyleWu, Jinxing, Wenhao Hu, Yi Zhang, Changcheng Wu, and Zuode Yang. 2025. "Study on the Effects of Micro-Groove Tools on Surface Quality and Chip Characteristics When Machining AISI 201" Coatings 15, no. 10: 1124. https://doi.org/10.3390/coatings15101124

APA StyleWu, J., Hu, W., Zhang, Y., Wu, C., & Yang, Z. (2025). Study on the Effects of Micro-Groove Tools on Surface Quality and Chip Characteristics When Machining AISI 201. Coatings, 15(10), 1124. https://doi.org/10.3390/coatings15101124