Abstract

This study evaluates the thermal comfort and energy performance of Qiang Zhuangfang manor houses in high-altitude regions, using Mao County’s Heihuzhai settlement as a representative case. Field surveys, tabulated data analysis, and computer simulations were conducted to measure wall surface temperature, ambient radiation temperature, air temperature, and relative humidity, comparing Zhuangfang buildings with brick Qiang houses. Results show that Zhuangfang walls have minor surface temperature differences, lower thermal conductivity, and superior insulation—retaining heat in winter, blocking heat in summer, and reducing solar gain. Optimization measures were tested through a model, revealing that lowering the main structure by 0.1 m and adding a surface material layer improved insulation while maintaining load-bearing capacity. The findings confirm that Zhuangfang houses are better suited to the local climate, offering ecological benefits in energy saving and heat preservation.

1. Introduction

There is more research about Qiang architecture in China. The book Sichuan Folk Habitat (China Building Industry Press, 2009) [1] by Li Xiankui discusses in detail the traditional dwellings in various places in Sichuan, introducing the morphology and structural characteristics of the Qiang dwellings, the architectural space and floor plan layout, and the materials, etc., respectively. In the research on modern Qiang architecture, the book Modern Transformation Design Research on Qiang Folk Houses (Cheng Bin, China Architecture Industry Press, 2018) [2] has achieved results. The book systematically explores the characteristics of Qiang dwellings in various historical periods from the perspectives of architectural space, appropriate technology, and Qiang regional culture. It summarizes the architectural model of modern Qiang dwellings. In recent years, Liu Wei wrote the book “Qiang Traditional Village Environment and Architectural Forms under the Influence of Place Microclimate” (China Building Materials Industry Press, 2024) [3], which systematically analyzes the Qiang village environment and its architecture under the influence of place climate, giving research from all aspects of climatic factors, and analyzes the village environment and architectural layout, as well as the formation of architectural forms. In international academic research, studies on architectural envelope materials primarily focus on modern industrial materials. In Seismic Behavior of Two Monumental Buildings in the Historical Cappadocia Region of Turkey [4], Baki Ozturk illustrates the responsiveness of building envelope material design to environmental conditions. Although there are articles that study the surface of heritage buildings—for example, Comparative Life Cycle Assessment of Traditional and Modern Materials in Heritage Building Restoration: A Case Study from Ushaiger Village [5] by Silvia Mazzetto compares mud, limestone, decorative plaster, blended hydraulic cement, and ready-mix concrete in heritage restoration—most still focus on renovation and replacement, lacking an in-depth exploration of the properties and merits or drawbacks of traditional surface materials, not to mention the surface materials on Qiang Zhuangfang.

Internationally, it is almost impossible to find research papers on the thermal comfort of the Qiang ethnic group’s farmhouses. The only relevant paper currently available is “Human thermal comfort and architectural volume” [6], co-authored by de Oliveira, EAS; Xavier, AAD; and Pizybski, EM. This paper explicitly studies the correlation between the thermal comfort of workers and the architectural volume of the workspace, providing evidence to support the claim that architectural space volume is correlated with workers’ thermal comfort. Similarly, it is difficult to find such research results in the field of passive design. However, we can learn about the research status of passive design in traditional Chinese architecture from the paper “The Open and Adaptive Tradition: Applying the Concepts of Open Building and Multi-Purpose Design in Traditional Chinese Vernacular Architecture” [7] by Tan, GY. Through extensive research on the surviving ancestral halls in Chinese villages and analysis of their functional plans and configuration desires, this paper attempts to prove that these passive designs already exist in traditional Chinese vernacular architecture. Although there is a lack of research results on the Qiang ethnic group’s farmhouse architecture, these articles and books by international researchers serve as the basis for citation and discussion in this paper.

There are fewer Qiang village-related treatises based on physical comfort, and even fewer architectural theories that quantitatively and comparatively analyze physical comfort. In Web of Science™, selecting the SCI, SSCI, and A&HCI databases and searching for “Qiang Zhuangfang” yields only one paper on Zhuangfang. That study concerns geological Zhuangfang structures rather than architectural aspects. In the Engineering Village database, searching for the keyword “Qiang Zhuangfang” (the research subject) for the years 1884–2026 yielded no relevant results; searching for the keyword “Qiang ethnic architecture” produced five studies, but none of them addressed the topic of architectural surface materials.

Therefore, from the above domestic and foreign literature, it seems that there are fewer and fewer studies on the physical properties of surface materials and their optimization and transformation of Qiang traditional village buildings in the direction of bodily comfort. Due to the lack of direction, this study will analyze the academic problem of designing and constructing wall surface materials and optimizing measures for Qiang traditional Zhuang houses based on physical comfort.

2. Problems

2.1. Overview of the Qiang Traditional Zhuang House

The Zhuang house is a Qiang people’s dwelling that has withstood the long-term climate impact, and to avoid the danger that their ancestors faced, it was built with a thick, defensive form. As early as in the “Book of the Later Han Dynasty—South Barbarians and Southwestern Barbarians biography”, records have said that the Qiang ancestors “are living on the mountain, the base stone for the room, and the height of more than ten zhang for Qiongcang” [8]; the Warring States period, “Qionglou”, is the Eastern Han Dynasty’s “Qiong cage” of harmonization. This is reflected in the traditional architecture of Heihuzhai in Mao County. The “Qiong cage” [9] is now known as the Qiang stone masonry Zhuang house, a characteristic building of the Qiang people. It gradually becomes smaller from the bottom to the top, reaching a height of 7 m~10 m, and has stood for many years. The house is made of stone, with small doors and smaller windows on the walls.

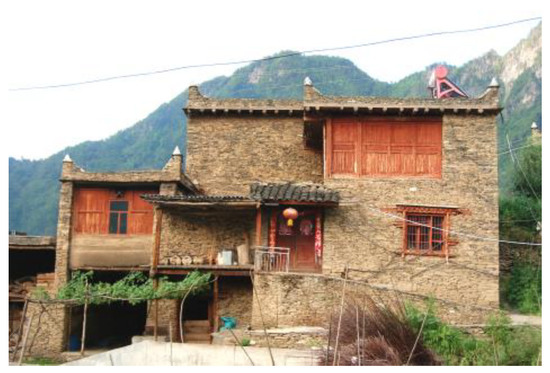

Zhuang houses are the most common houses inhabited by the Qiang people for generations, mainly two to three stories (Figure 1). Most of the buildings are made of stone masonry, with individual combinations of wooden elements, as well as rammed earth, in the form of trapezoidal and slightly varied rectangular shapes, which are closely integrated with the topography of the hillside. The Zhuangzi houses are usually laid out according to the contour lines, and their construction artistry is highly demanding. The building is characterized by durability and good earthquake resistance. The Qiang people would raise domestic animals and set up storage rooms on the first floor of the manor house, with an area of 60 m2, a face width of about 8 m, and a depth of more than 5 m. On the second floor, the “fire pit” [10] was set up as a living place for all family members, with an area of about 20 m2, and the opening and depth were usually 5 m by 6 m. The bedrooms were approximately 10 m2 in area, featuring different openings and depths of 3 m × 3 m and 3 m × 4 m. The third floor served as the auxiliary space for living, featuring the photo building and the sun deck, which was known as the “god’s platform” for the “god of the gods”. The third floor is an auxiliary space for living, featuring a lighthouse and a sun terrace, where the “god” resides. The floors of the building functionally reflect the Qiang people’s cultural concept of “people on animals and gods on people”. All of these plan layouts and space separations reflect the practical value and have the significance of construction engineering research of human beings adapting to the local natural environment.

Figure 1.

Qiang Zhuangfang house. Photographed by the author (2023).

2.2. Research Problems

In recent years, the Qiang villages and buildings in Aba Tibetan and Qiang Autonomous Prefecture in Sichuan Province, China, have been significantly impacted by natural disasters, resulting in substantial damage to traditional houses and other structures. To rescue and protect the people’s production and life, as well as their habitat, there is an urgent need to design and construct such buildings promptly. Currently, some new buildings modeled on the traditional houses have appeared in the area, thus creating a dilemma that is not in harmony with the local environment.

In the current social context of the global carbon-neutral movement and China’s vigorous promotion of ecological civilization, it is of practical significance and guiding value to study and explore the wisdom of the use of wall surface materials in traditional Qiang architecture from the perspective of physical comfort. Therefore, for design researchers, these issues need to be urgently explored using special topics in the convergence of information technology for the current cultural exchange.

According to the investigation of the situation in Wenchuan, Mao County, and Li County in Aba Prefecture, Sichuan Province, China, it is found that the Zhuang houses in these areas are the main buildings currently inhabited by the Qiang people, which are characterized by a long time ago, a rough surface, natural simplicity, a large number, and a large scale. Therefore, the research problem of this paper is precisely to analyze the issues arising from the wall insulation and the surface of the Qiang manor houses from the perspective of physical comfort, to reveal the root of the comfort of the Qiang manor houses, and to analyze and confirm the performance of their wall surface materials after they have been optimized.

3. Research Theory and Methodology

3.1. Research Theory

Frequent natural disasters in the Qiang region, the need for protective measures, the pressures of rapid urbanization and global integration, and the inherent sustainability of the manor house form the background of this study. Against this context, the principle of physical comfort is applied to investigate the comfort performance of Qiang manor houses, aiming to reveal the underlying sources of that comfort.

This study conducts a quantitative analysis of Qiang Zhuangfang buildings by measuring and calculating specific physical comfort indicators for selected representative cases. The resulting data are compared to derive the comfort factor parameters of traditional Zhuangfang, which are then evaluated in terms of the building’s actual utility, highlighting both strengths and weaknesses.

In this framework, physical comfort is understood as a component of the thermal environment, encompassing:

Temperature and humidity—determined by the combined effects of air temperature and relative humidity.

Ambient radiant temperature—influenced by air temperature, radiant temperature, and other environmental factors.

Thermal comfort—a synthesis of multiple thermal environment variables, organized into a comfort index for evaluation.

Key measurable factors include air temperature, relative humidity, surface temperature, and radiation intensity. By selecting relevant factors according to on-site building conditions and linking them to performance outcomes, this study assesses the building’s role in energy conservation and environmental protection—this constitutes the theoretical basis for applying the principle of physical comfort.

3.2. Research Ideas

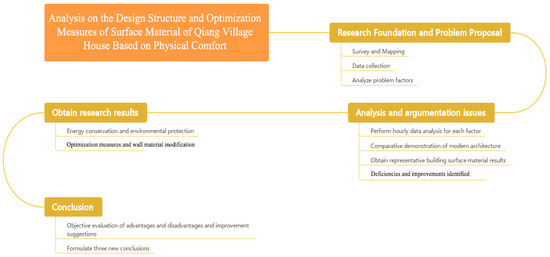

To reveal the comfort performance of the Qiang manor house, this paper will analyze in depth according to the objective environment of the Qiang architecture and analyze the comfort factor [11] where the Qiang manor house is located, mainly from the temperature and humidity, ambient radiant temperature, and the wall surface temperature, to analyze the constraints on the manor house by the thermal environment factor, which makes the building have a performance of passive adaptation and ultimately become one of the traditional buildings that are found to have the ecological scale of one of the conventional buildings seen today. The following will briefly introduce the basic idea of the argumentation of this paper (Figure 2):

Figure 2.

The basic idea diagram of this paper’s argument. Photo source: Author’s production.

First, the research basis and problem statement: Drawing on the environmental conditions of local natural settings, this study employs literature review, field survey, and on-site measurement methods to investigate the objective conditions of Qiang Zhuangfang. The analysis considers the historical development of Qiang manor houses, their architectural ontology, and measured data, identifying key issues through systematic discussion. To address these issues, tabular and graphical illustration methods—such as statistical tables, bar charts, and other visual diagrams—are applied to analyze the constraints affecting the local architectural environment. Geographic Information Systems (GIS) are used to present topography and terrain and to categorize and organize all data and information collected on both the Qiang Zhuang house and the brick Qiang house. These are presented in tabular form to convey the actual measurement results, followed by comparative bar charts to visually and systematically display the relative merits of the two building types.

Second, quantitative analysis and argumentation: The representative case of the Heihuzhai manor house was selected for detailed study. Physical thermal comfort parameters were measured during a freezing period, with data collected at regular intervals. For comparison, a modern brick–concrete Qiang house—constructed with new materials in the exact location and under identical conditions—was also measured over the same period, yielding a corresponding dataset. The measured data were then imported into the ECOTECT system to generate a three-dimensional analytical model, enabling simulation of the thermal environment under objective parameters. This allowed for comparison of wall surface temperatures and other thermal comfort indicators between the Zhuangfang and the modern Qiang house, thereby revealing the performance characteristics of their respective materials. The results were further visualized using tabular and graphical methods to illustrate the comfort levels of the Zhuangfang.

Third, research results: Based on the physical comfort diagrams and parameter comparisons, a systematic approach was applied to progressively analyze the energy-saving and environmental benefits associated with the main influencing factors of the manor house, as well as the deficiencies of its wall surfaces. Following the design of new materials, construction layering, and index establishment, optimization measures were proposed. The computer simulation method was then used to verify the model of a typical manor house. Thermal calculations of the enclosure structure—formed with the newly designed materials—were conducted to determine energy consumption levels. Thermal environment indices were calculated to assess indoor comfort, demonstrating that the renovated manor house and its wall surfaces outperform the original. These findings confirm that the proposed methods and optimization measures are feasible, reasonable, and practical. This study applies computer simulation as a means of examining the material properties of the wall surfaces of both the manor house and the brick–concrete Qiang house, using physical comfort factor analysis based on collected data. Software tools, including AutoCAD 2014, SketchUp 2016, and AutoCAD ECOTECT 2011, were employed to conduct systematic experiments and validations, enabling objective analysis of virtual models and confirming this study’s anticipated conclusions.

Fourth, conclusion: This study objectively evaluates the strengths and weaknesses of the physical comfort performance of the Zhuangfang and offers recommendations for improvement, identifying areas requiring further enhancement. It concludes that conservation and environmental protection principles should be integrated into the preservation of Zhuangfang and the revitalization of local traditional architecture, ensuring the inheritance and sustainable development of these buildings.

4. Mapping Data and System Argumentation

4.1. Determination of Measurement Locations and Architectural Representatives

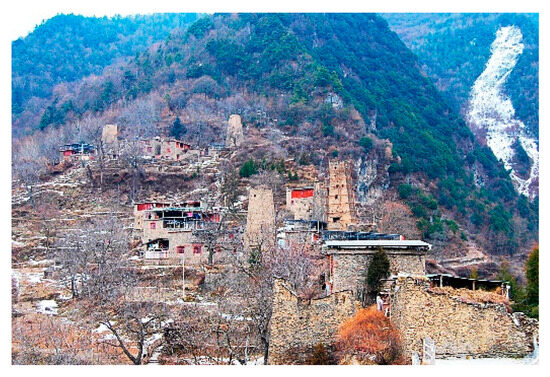

To know the adaptability, thermal comfort, and conservation value of traditional Qiang buildings, the representative Zhuang house of the Qiang people is used as an example to explore and reflect the response of this type of building in terms of comfort and its wall surface materials, and through the understanding of the energy consumption of the Qiang Zhuang house, to reveal its energy consumption and its indoor surface heat preservation performance, which is used for judging the conservation value of the building. Here, we compare modern buildings in the same region but with different materials, construction times, and methods. We use instruments to measure and obtain corresponding data to assess the impact of the Zhuangfang surface layer on environmental radiation. After comparison and selection, this paper will choose Heihuzhai in Mao County, Aba Tibetan and Qiang Autonomous Prefecture, where the Qiang people live, as the measurement site. Its elevation is 2479 m above sea level, and the terrain is treacherous, with high mountains and cliffs (Figure 3).

Figure 3.

Black Tiger Stronghold in Mao County. Photographed by the author (2023).

Heihuzhai in Mao County is composed of 11 households on the ridge, with five households on the high mountain and 12 households on the side of the hill, totaling 28 households [10]. According to the observation in the research at the beginning of 2023, the traditional buildings are mainly on the ridge and high mountains, where the Zhuang houses are dominated, all of which are more than 100 years old, totaling 9, and the brick Qiang houses are 4, all of which were built after 2008. On the side of the mountain, there are also a large number of Zhuang houses, but they are mostly remodeled; according to the locals, “they were all built after the earthquake…, in fact, people in the village are still willing to live in the past” [12]. Here, a larger number of Zhuang houses on the ridge and new Qiang houses (brick Qiang houses) are chosen to compare to obtain physical comfort (Figure 4).

Figure 4.

Location of two samples in Heihu Stronghold. Photographed by the author (2023).

Zhuangfang houses are the most preserved local dwellings in Heihuzhai now, and they are also one of the characteristic buildings of the village. The Zhuangfang houses in Heihuzhai represent the traditional Qiang village building technology and construction techniques. Common construction materials are stone, soil, and trees in the vicinity. The construction is based on the location, focusing on distance and convenience, with family relatives and villagers of the village mainly helping each other to build. For this reason, the Zhuang house has become the central dwelling place of the Qiang people, and especially it has become an important building built in the high mountains and halfway up the hillside. The comparison of ambient radiant temperature data for physical comfort [13] with brick Qiang houses can effectively reflect the indoor surface energy consumption and thermal insulation of the Zhuang house and further understand the comfort performance of the Zhuang house.

Brick–concrete Qiang houses are the new Qiang houses currently built in the Qiang area, which is developing fast, especially after the Wenchuan earthquake in 2008, and can be seen in towns and villages, high mountains, and river valleys. Several brick–concrete Qiang houses have appeared in Heihuzhai, forming a trend of spreading from the side of the hill to the ridge. These brick Qiang houses were remodeled, added to, and newly built after the earthquake. The materials used in the brick–concrete Qiang houses are concrete, steel, masonry, river sand, and glass. The high price, long transportation time, and lengthy construction process are factors that local villagers have never encountered before. The construction requires professional workers and technicians from outside the area, the use of modern mechanical facilities, and building templates for regularized construction, which in turn increases the cost of transportation.

4.2. Building Selection and Paths for Specific Measurement Samples

The selected samples of Heihuzhai used AutoCAD to draw the floor plan, followed by importing into SKETCHUP software to draw a three-dimensional building model, which shows the basic appearance of the two representative buildings through the corresponding body shapes. One of the choices is the Li’s Zhuangfang here, which is a Qiang residence of more than one hundred years (Figure 5), oriented east–west and located at the north end of the walled village with stone masonry. The house is a two-story house with a height of 7.6 m. The first floor is used for placing sundries, and the house is also load-bearing by a stone wall with a thickness of 0.4 m, which divides the indoor space into two parts in the east and west directions. There are two small windows on the west wall of this floor, which are high above the ground, about 3.0 m, and the whole interior is dimly lit. The interior of the second floor consists of a hall and a bedroom, featuring two to three windows on the south wall with large openings, positioned low from the floor surface at a distance of 0.8 m, and divided by wooden boards into two rooms. The east room is large enough to be a hall, and the narrower west one is a smaller bedroom. The third floor features a flat roof, with the east-facing side covered and the west part serving as a sunbathing area.

Figure 5.

Sample model of a Qiang village house. Produced by the author.

The brick Qiang house is another sample (Figure 6), which was rebuilt by the Yu Qiang people after the disaster and is oriented east–west. The building is constructed of brick, stone, and concrete, a masonry structure, with two floors and an outdoor balcony. The height of the building is 6.5 m, and the wall is about 0.3 m thick, according to the author’s visual estimation. The first floor is home to the living room, bedroom, and a service room for dining. The second floor features multiple bedrooms and storage rooms. The plan of the building is rectangular, but the addition of two low-level rooms in the northwest, which serve as a kitchen and a washroom, has slightly altered the building’s shape, with the first floor becoming L-shaped and the second floor square. The building is about 10 m away from Li’s Zhuangfang.

Figure 6.

Sample model of a brick–concrete Qiang house. Produced by the author.

Given the Qiang manor house’s location, the climate is cold in winter and mild in summer. For the local people, the primary concern is keeping warm and preventing cold in winter, which involves protecting against cold wind, ice, and snow. Therefore, according to the needs of the theme study, only the physical comfort of the two buildings in winter is considered for analysis. The author chose four days of freezing winter in the area, 3 January 2023 to 6 January 2023, and took measurements uninterruptedly from 8:00 to 18:00, recording data every 15 min. Measurement tools include a black sphere thermometer, a thermohygrometer, and a solar radiation self-logger; the measurement locations are the small black squares in the floor plan of each level, which are the bedrooms of Li’s Zhuangfang hall house (CRTCH) and Yu’s brick Qiangfang house, the ground-floor house, as well as the internal and external walls of the building (Figure 7a,b). By comparing the indoor and outdoor data at the same time and judging the measured surface temperature and ambient radiation temperature of the Qiang manor house and the brick–concrete Qiang house, we can not only analyze the advantages and disadvantages of their comfort but also find out the main points of the materials for wall insulation and energy consumption of the two.

Figure 7.

The layout of instrumented measurement points situated at various levels within the Qiang manor house. (a) A plan of instrument measurement points on the first floor. (b) Plan of instrument measurement points on the second floor. Produced by the author.

4.3. Comparative Analysis of Physical Comfort Factors and Wall Surface Material Properties

Four basic factors of physical comfort were used as parameters, specifically, indoor ambient radiant temperature, wall surface temperature, air temperature, and relative humidity [14]. Through the actual measurements of the selected manor house and the brick–concrete Qiang house, the cumulative daily average of each measurement point was obtained (Table 1). The comparison between them, in conjunction with each of the comfort factors, revealed the following situations and deficiencies.

Table 1.

The cumulative daily means of physical comfort across four factors at each measurement point for the Zhuangfang and brick Qiang houses.

4.3.1. Material Properties of Internal and External Surfaces of Two Types of Building Walls Under the Comparison of Surface Temperature and Ambient Radiant Temperature Data

Two representative building models were imported into the AutoCAD ECOTECT software tool, respectively. After the data of the measured factors were simulated for the preset time in winter, the results under field conditions were obtained, which were used to intuitively determine the radiant heat produced by the surface of the wall of the two types of buildings and to analyze the strong and weak performances of the surface materials of the wall.

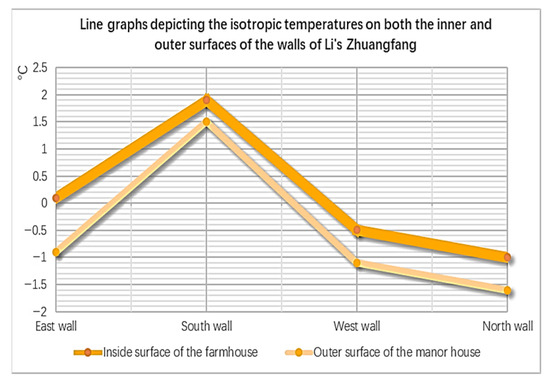

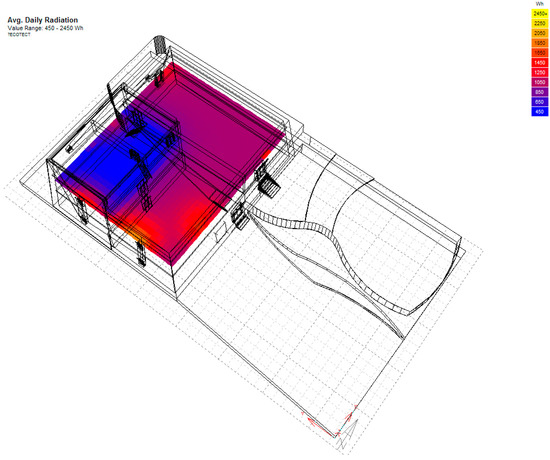

Through the field measurement of the freezing wintertime, Li’s Zhuangfang wall surface temperature in all directions is inconsistent; the most heat is on the south wall surface at 1.9 °C, followed by the east wall surface at 0.1 °C, then the west wall surface at −0.5 °C, and the north wall surface at −1.0 °C (at least), which can be judged that the south wall surface temperature is the highest and receives the most heat. The temperature of the outer surface of the wall is still different in each direction; the south wall is 1.5 °C, the east wall is −0.9 °C, the west wall is −1.1 °C, and the north wall is −1.6 °C. It can be observed that the south wall of the outdoor area is the most affected by external sunlight irradiation. The north wall is the smallest, which results in the heat gain of the wall of the manor house outside the face of the larger gap between the characteristics of the overall changes in the outdoor temperature (Figure 8). After the simulation of the surface temperature and ambient radiation temperature of the manor house model in Figure 7, it can be seen that the energy of the wall surface is between 650 and 1050 Wh, especially the highest radiation temperature around the surfaces of the south wall and the east wall, which is 1250~1650 Wh, and the individual windows can reach an extreme situation of 1960 Wh (Figure 9). This radiant energy originates from the direct action of solar radiation, which, when compared, proves that the thermal gap between the inner wall surfaces is small and the insulation performance is good. However, the materials used for the internal and external surfaces of the Zhuangfang wall are identical, reflecting the fact that the external surface of its wall will be affected by outdoor radiation. The average daily solar radiation and its transformed surface temperature are lower, resulting in reduced overall energy and a lower surface temperature compared to indoors, which necessitates a higher-performance wall material junction. Accordingly, since the stone walls have the same internal and external surfaces and the indoor temperatures are more suitable for local people to live in, it shows that the surface materials of the walls of the Zhuangfang were adapted to the requirements of the local natural environment in terms of heat preservation and insulation and have the properties associated with solar radiation. It also further shows that Zhuangfang has a thermal environment for living. Nevertheless, it is more necessary to optimize the construction of the special structure of the surface material according to the orientation of the wall so that the Zhuangfang is more suitable for the comfortable living requirements of the modern Qiang people.

Figure 8.

Line graphs depicting the isotropic temperatures on both the inner and outer surfaces of the walls of Li’s Zhuangfang. Photo credit: Produced by the author.

Figure 9.

Line graph depicting the isotropic temperature on the inner and outer surfaces of the walls of a brick–concrete Qiangfang. Photo credit: Produced by the author.

The average radiant temperature in the indoor environment is 4.3 °C for the first floor and 4.7 °C for the second floor, primarily due to heat transfer from the indoor walls radiating into the air, which brings the temperature into the environment. The second floor is higher than the ground floor because it is not directly affected by the harmful radiation from the ground. This results in a higher floor level, which also has a greater impact on the temperature. As a result, the indoor temperature will be higher than the outdoor temperature.

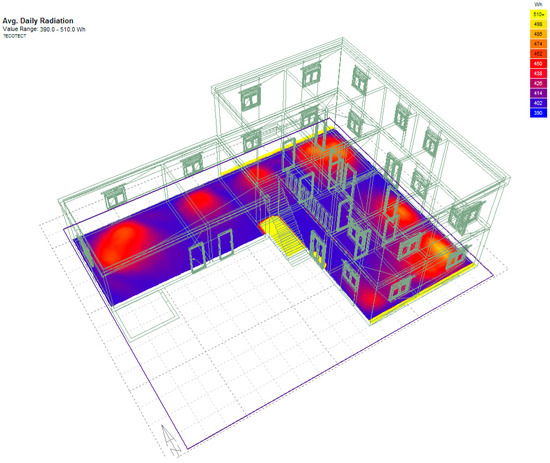

The internal surface temperatures of the walls of the brick–concrete Qiang houses measured at the same time were the same as those of the Zhuang houses, with the most heat gained on the south wall at −1.1 °C, followed by the east wall at −1.6 °C, the west wall at −1.9 °C, and the north wall at −2.3 °C. The radiant temperatures of the external surfaces of the walls were −1.5 °C on the south wall, −1.8 °C on the east wall, −2.1 °C on the west wall, and −2.6 °C on the north wall (Figure 10). The order of solar radiation to each wall surface is the same as that of the stately home, except that each building receives a different amount of radiant energy and thus converts a different amount of heat (Figure 11). This figure shows the surface temperature and ambient radiation temperature simulation of the brick Qiang room model at the same time as the Zhuang house. The difference between the radiant energy of the wall surface in each direction is significant, all between 390 and 414 Wh, especially around the surface of the south and east walls, where the radiant temperature is high, at 438~486 Wh. The highest energy at the individual window is 510 Wh, and the difference in the radiant energy produced compared to the surface material of the wall of the Zhuang house is large. This indicates that the two buildings exhibit inconsistencies in materials and construction processes, leading to significant differences in heat storage energy and thermal insulation energy. As for the indoor ambient radiant temperatures, the mean values of the first floor at 2.7 °C and the second floor at 3.5 °C are lower than those of the manor house, which further also suggests that the brick–concrete Qiang house loses more heat and dissipates it faster, resulting in lower indoor temperatures.

Figure 10.

A simulation model illustrating the effects of radiation on the surface of the wall of the sample Zhuangfang located in Heihuzhai. Photo credit: Produced by the author.

Figure 11.

A simulation model depicting the radiation effects on the surface of the brick wall of the Qiangfang house sample in Heihuzhai. Photo credit: Produced by the author.

Simply from the two buildings’ wall internal and external surface temperature values of the two buildings comparison, it can be found that the average value of the internal and external surfaces of the walls of the brick–concrete Qiang room is lower than the value of the internal and external surfaces of the walls of the Zhuangfang, which is very unfavorable to the people in the cold winter. Comparison of the internal and external surface temperature values of the walls of each building itself, but it is not difficult to find that the difference between the cumulative daily average values of the internal and external surface temperatures of the walls of the Zhuangfang houses is significant, between 0.1 °C and 0.5 °C, with a difference of 0.6 °C. In comparison, the cumulative daily average values of the internal and external surface temperatures of the walls of the brick Qiangfang houses range from −1.7 °C to −2.1 °C, with a difference of 0.4 °C, which means that the difference between the internal and external surface temperatures of the walls of the brick Qiangfang houses is small, with a difference of 0.6 °C. This comparison between the two is as follows: 0.6 °C > 0.4 °C. The smaller difference value indicates that the wall heat conduction is fast, resulting in similar temperatures on the inner and outer surfaces. Conversely, a larger difference value indicates slow wall heat conduction, leading to different temperatures on the inner and outer surfaces. It further reveals that the thermal insulation and cold protection performance of the manor house’s wall is better than that of the brick–concrete Qiang house’s wall.

Based on the surface temperature and ambient radiation temperature factor, through the comparative analysis of the material performance of the internal and external surfaces of the walls of Zhuangfang and brick–concrete Qiangfang, in the two types of buildings, due to the performance of different wall materials and their thicknesses, the internal and external surfaces of the stone wall of Zhuangfang are the body of Gingaoka stone blocks. The internal and external surfaces of the brick–concrete Qiangfang walls are made of cement. The performance of the greenoka stone heat storage is characterized by strong heat retention, slow heat transfer, and low heat radiation. In contrast, cement heat storage exhibits weak heat retention, fast heat transfer, and high heat radiation.

4.3.2. Indoor Temperature and Relative Humidity Data: Performance of the Two Types of Building Wall Surface Materials Embodied in the Comparison

By comparing the temperature and humidity of Zhuangfang and brick–concrete Qiangfang, the cumulative daily average temperature value of Zhuangfang is higher than that of brick–concrete Qiangfang by 1.1 °C (bottom layer) and 0.5 °C (second layer) in each layer, but comparing the values of two layers of a single building, the difference between the first layer of Zhuangfang and the second layer is 0.4 °C, and the difference between the two layers of the brick–concrete Qiangfang is 1.0 °C, which indicates that the difference between two layers of the Zhuangfang’s temperature is slight and that it has a temperature equalization performance. On the contrary, the temperature difference between the two layers of the brick–concrete Qiang house is larger, indicating that it is more affected by the outdoor air temperature, reflecting the weaker thermal effect of the building envelope, the higher heat transfer coefficient of the wall surface materials, the more obvious indoor and outdoor heat conduction, and the relatively poor thermal insulation performance. It is inferred that the building energy efficiency of the brick–concrete Qiang houses is also inadequate, which in turn indicates that the energy efficiency of the Zhuang houses is better than that of the brick–concrete Qiang houses (Figure 12).

Figure 12.

A column chart representing a comparison of daily average temperatures between the Zhuang house and the brick–concrete Qiang house. Photo credit: Produced by the author.

A comparison of humidity in the two buildings is as follows: The first floor of the manor house is more humid (Figure 13), with an average value of 72.5%, which is greater than the average value of the second floor of the house, 66.3%, and greater than the average value of the living room on the ground floor of the brick–concrete Qiang house, 71.9%. It is analyzed to be related to the rammed earth of the floor. The second floor is constructed from wooden boards and features a thick layer of soil underneath. The humidity difference between this layer and the ground floor is 6.2%, resulting in a lower humidity level in the second-floor space. This serves as a heat preservation and humidity insulation function. The two floors of the brick–concrete Qiang house are of mixed soil floor with low humidity, and its interior presents an overall humidity slightly smaller than that of the Zhuang house.

Figure 13.

Comparison area chart of indoor daily average humidity between the Zhuang houses and brick–concrete Qiang houses. Photo credit: Produced by the author.

After controlling the indoor temperature and relative humidity of the two buildings, a comparative analysis of the measured data reveals that, despite the use of the same measuring tools and conditions, the difference in indoor physical comfort between the two buildings is evident. From the data, it can be judged that the temperature and humidity of the farmhouse are better than those of the brick–concrete Qiang house, and the heat preservation performance is also better than that of the latter. Based on the comparison of indoor temperature and relative humidity data, it is considered here that under the condition of not changing the surface materials of the building walls, both buildings reflect that stone has the properties of heat storage and thermal inertness, and cement has the properties of heat transfer and thermal conductivity faster. To solve such problems and prevent energy consumption, insufficient radiation of wall surface materials, and a lack of thermal insulation and heat preservation layer of the stately home, and to improve the building’s stronger thermal comfort, optimization measures for the performance of the stately home’s wall surface materials are proposed here and proved by simulation experiments with typical samples.

4.4. Optimization Measures of Wall Surface Material Performance of Zhuangfang and Simulation Verification

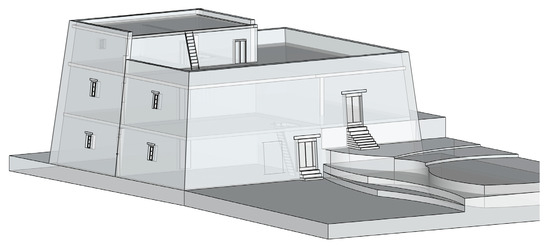

Comparison of the Zhuang and brick–concrete Qiang houses based on the series of data on the surface temperature of the building and the ambient radiant temperature, from which the advantages and disadvantages of the respective properties of the materials of the internal and external surfaces of the walls of the two types of buildings are reflected. Comparison of the measured data of the two buildings confirms that the thermal environment effect and comfort of Zhuangfang houses are better, the physical properties of the internal and external surfaces of their walls are better adapted to the local climatic environment, and the performance of the internal and external materials of their walls is also better. Therefore, the surface temperature of the materials inside and outside the walls of both buildings determines the physical comfort of the building. Here, we take the Zhuang house as the main one (Figure 14a,b) and apply AutoCAD ECOTECT software to construct a typical model of a Qiang Zhuang house with an opening of 8.0M, a depth of 6.0M, and a height of 7.5M; a two-story stone masonry building with load-bearing walls, facing north and south, with four windows on the south wall of 0.5 × 0.5 m and only one flue opening (vent) on the north wall of 0.2 × 0.2 m. On the east wall there are two windows, one on the first floor and one on the second floor, and one window on the second floor of the west wall, with the same size as the window on the south wall, all of which are double wooden glass windows. A door is opened on the first floor of the west wall against the south position, which is made of single-layer solid wood, and the size of it is 0.8 × 1.7 m. There is a door open on the roof, which is also made of solid wood. The form practice is the same as that of the door on the west wall, but the size of it is different, measuring 0.8 × 0.8 m. Overall, the structure, construction, material, space, and function of this typical manor house are the same as those in the west wall. The overall structure, material, space, function, doors, and windows of this typical manor house are all traditional forms.

Figure 14.

Typical Qiang manor house model. (a) Southwest perspective of the manor house with door. (b) Southeastern view of the manor house with windows. Photo credit: Produced by the author.

After the modification and addition of the internal and external materials of the wall of the typical Zhuangfang house, the thermal engineering of the wall materials and the indoor thermal environment are used to verify the energy-saving performance of the optimized wall surface, as well as the feasibility of the protection of the local traditional architecture. Moreover, the optimization measures will be proposed and summarized for it and the related brick–concrete Qiangfang houses.

4.4.1. Optimization Measures of Wall Surface Material Performance of Zhuangfang Walls Due to Building Surface Temperature and Ambient Radiant Temperature Data

(1) Apply stone on the outer surface of the wall of the Zhuangfang and cement on its inner surface and modify different physical comfort structures on the north, west, east, and south walls, according to their respective surface temperatures.

(2) A heat-insulating layer of polystyrene foam (EPS), known as benzene board, can be glued between the wall and the increased outer layer. The inner layer of the wall, similar to the outer layer of the construction, consists of a layer of hay, bark, and dry branches, serving as a thermal insulation layer. The wall of the manor house formed a surface layer, the role of the layer (adhesive layer), and the combination of the load-bearing wall layer. The outer layer of the wall consists of stone and styrene boards, and its inner layer consists of cement, bark, dried branches, clay, and straw, all of which work together for thermal insulation and heat preservation (Figure 15).

Figure 15.

Materials and construction layers of a typical manor house wall. Photo credit: Produced by the author.

The principle of increasing the internal and external surface materials of the wall: it is to maintain the traditional material texture and texture, color tone, but also to ensure architectural integrity and authenticity; to enhance the neat and beautiful visual effect of the building, but also to improve the ornamental properties of its indoor space, to the original authenticity of the architectural structure, construction and materials to express the organic beauty of the traditional architecture; to increase the thermal insulation of the wall of the building against the cold and sunlight insulation properties, the increase and decrease of the internal and external surface materials of the wall. The way of construction should improve the thermal properties of the wall and the comfort of the indoor thermal environment. Considering the ecological requirements of saving resources at present, the optimized internal and external surface materials of the wall body of the manor house are based on the minimum thickness, and the parameters of the specific thickness of each layer from the inside to the outside are as follows: the cement surface layer of 10 mm; the role of the hay (branch) bark layer of 10 mm; the addition of the grass clay bonding layer of 10 mm; the masonry stone block load-bearing wall of 300 mm; the EPS heat preservation and thermal insulation layer of 30 mm; and the stone facing layer of 40 mm. The total thickness of the wall is 0.4 m. Among them, the hay (branch) bark and EPS materials are layers that have the role of heat preservation and insulation.

(3) The outer surface of the wall of the brick–concrete Qiang house still needs to be applied with thermal insulation polystyrene board material. Its inner surface should be used with cement, and all the wall surfaces are also consistent with the method of the reconstruction of the manor house. All of these wall constructions are designed to be enhanced by the thermal storage and insulation aspects of the surface materials to achieve energy conservation and physical comfort and, thus, ecological [15] effects.

(4) In addition to this, factors such as indoor temperature and relative humidity, which are affected by radiation from the walls and their windows and doors, are also considered, and together they constitute an impact situation on building comfort.

4.4.2. Optimization Measures for the Performance of Wall Surface Materials of a Manor House Due to Indoor Temperature and Relative Humidity Data of the Building

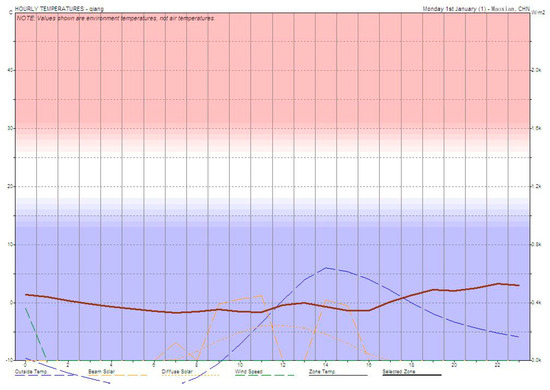

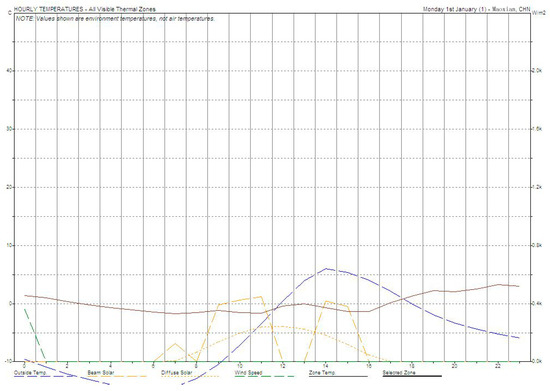

(1) The combination of the wall surface materials of the Zhuangfang building, respectively, makes it inevitable that the inner surface of its wall needs to transfer more heat, faster cement materials, to facilitate the improvement of the indoor environment radiation temperature so that the physical comfort of the Zhuangfang house will be better, for in the winter the inner surface of the wall needs to increase this structure (Figure 16). This figure shows that on 1 January (winter), the wall of the manor house is affected by the indoor people and their life and labor, cooking and boiling water, and other activities; the indoor surface of the ambient radiant temperature of the building; and on the whole, the internal air temperature simulation presentation.

Figure 16.

The relationship between ambient radiant temperature and indoor and outdoor air temperatures in a standard manor house. Photo credit: Produced by the author.

The thin blue dotted line in this figure represents the average outdoor temperature. The outdoor temperature on the day before 9:00 is below −10 °C. As the sun rises, the temperature increases rapidly. At 11:30, the temperature reaches 0 °C, and by 14:00, it peaks at about 6 °C. Then, the temperature gradually declines, reaching 16:00 and returning to 0 °C or below. This is because temperatures rise during the day as the sun comes out and shines and then fall rapidly in the afternoon as the sunlight diminishes. The whole-day temperature average line also reflects the high temperature variation in the high-altitude Qiang area, the cold winter, and the harsh natural climate. The thick red solid line represents the indoor temperature average, which shows that the indoor temperature is balanced. From 3:00 p.m. to 12:00 p.m., the temperature is around −1 °C, and from 13:00 to 14:00, it is 0 °C. After 17:00, the temperature gradually rises, especially at 10:00 p.m., when it reaches the highest value of the day, which is about 4 °C. The analysis of the reason for the change is that these are the times when there are people in the house, and their cooking fires and labor make the environment cold. The reason for this is that these are the times when there are people in the house and they are cooking and working, which increases the ambient radiation temperature and raises the indoor temperature; on the other hand, in the morning and afternoon, most people go out to work, and the indoor ambient radiation temperature decreases. In contrast, in the morning and afternoon, when most people go out to work, the indoor ambient radiation temperature decreases.

Comparison of indoor and outdoor temperatures reveals a small direct effect, indicating that the renovated building’s wall materials offer better thermal insulation and heat preservation. Outdoor temperatures are primarily influenced by solar radiation and wind speed. In contrast, indoor temperatures are influenced by the ambient radiation temperatures of the factors that have a greater impact.

(2) For the summer season, the construction relationships of manor house wall materials from the inside and outside, respectively, are cement, bark, dry branches, clay, stone masonry load-bearing wall, benzene board, and stone. The construction composition is the same as the optimization measures of the performance of the manor house wall surface materials for the influence of the building surface temperature and the ambient radiation temperature.

4.4.3. Simulation Validation After Optimization of Surface Material Performance of Zhuangfang Wall Body

To verify the performance of the internal and external surface materials of the wall of the renovated Qiang Zhuang house, the thermal engineering heat transfer coefficient of the wall is taken as the criterion, and the four factors of the thermal environment are taken as the research basis here. Calculations and inferences are made in terms of the indoor comfort analysis and the energy consumption of the surface materials of the wall. By comparing the energy-saving parameter standards in China’s Thermal Design Code for Civil Buildings (GB50176-93) [16], it is revealed that the surface temperature of the wall and the ambient radiant temperature of the Qiang manor house increase the thermal insulation of its indoor space and enhance the heat insulation, thus providing a reference for the indoor comfort in the worst climatic periods of the year in the winter and the summer seasons. Specific manor house model wall thermal calculation parameters are listed below (Table 2).

Table 2.

Thermal data statistics for wall optimization of a typical manor house model.

Using the AutoCAD ECOTECT software, we simulated the transformed Zhuangfang building to verify its indoor comfort. The algorithmic function provided by the software enabled us to obtain the thermal calculation results for its wall materials, with a heat transfer coefficient of 0.820 (w/(m2·k)). The basic equation is as follows:

K = 1/(R0 × δ)

where R0 = 1/λ

λ is the coefficient of thermal conductivity, reflecting the thermal conductivity of the material itself (unit w/(m·K)).

δ is the thickness of the material layer (unit m).

K is the heat transfer coefficient, indicating the overall heat transfer performance of the enclosure (unit w/(m2·K)).

The value of the heat transfer coefficient obtained by the calculation tool is less than the heat transfer coefficient of 0.850–1.100 (w/(m2·K)) in Aba Tibetan and Qiang Autonomous Prefecture, Sichuan Province, in China’s “Standard for Energy Saving Design of Civil Buildings (Part of Heating Residential Buildings)” (JGJ26-95) [17]. Therefore, it shows that the new design scheme with optimized wall surface materials is feasible and applicable. After simulating the indoor thermal environment with this tool, the time-by-time temperature map performance aligns with the indoor comfort reflected by the ambient radiant temperature on the wall surface (Figure 17), which remains averaged at 0.5 °C. For the cold winter season, indoor comfort is better compared to the average outdoor temperature of −8 °C.

Figure 17.

The hourly temperature variations within a standard manor house in relation to the radiant temperature emitted by its walls. Photo credit: Produced by the author.

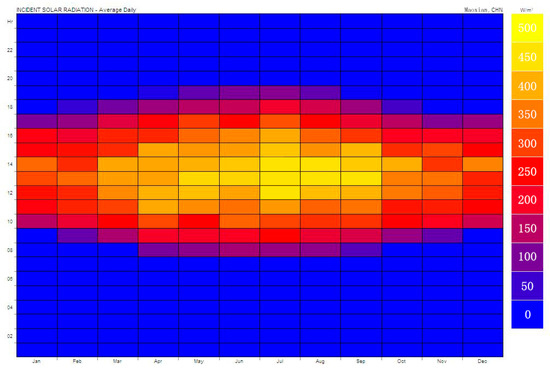

By calculating the four factors of thermal comfort for the Zhuangfang building, including solar radiation temperature action, wall surface ambient radiance, and environmental irradiance (Figure 18), we verify the feasibility and reasonableness of the wall surface construction and the material used. Here, the air temperature is determined by the parameters of environmental radiance, and the heat transfer performance of wall materials, as well as the indoor thermal environment and comfort, can also be judged. The Stefan–Boltzmann law can calculate the relationship between environmental radiance and temperature, and the formula is as follows:

where T represents the absolute temperature (Celsius plus 273.15 K).

W/m2 = 5.67 × 10−8 × T4

Figure 18.

The environmental irradiance distribution of a typical manor house wall in relation to its indoor temperature. Produced by the author.

According to Formula (3), calculations were conducted for the range of 0 W/m2–500 W/m2 in Figure 18, which illustrates the environmental irradiance distribution of a typical manor house wall in relation to its indoor temperature, and the indoor air temperature and absolute air temperature of the manor house were obtained. The results are organized as shown in Table 3. It was found that the temperature transferred by the environmental irradiance between 200 and350 W/m2 through radiation, convection, and other means is relatively comfortable.

Table 3.

Statistical table of environmental radiance, air temperature, and absolute temperature parameters.

The surface radiance diagram represents the development of the thermal environment inside the manor house room throughout the year, with the horizontal axis representing the month and the vertical axis representing the 24 h of the day. From left to right, the period spans from January to December. From January to March, the indoor environment is less affected by the outdoor effect, with the highest ambient environmental radiance reaching 200 W/m2. From April to June, the indoor ambient environmental radiance increases, reaching a high of 350 W/m2. In July, it peaks at the highest radiancy of the year, with ecological irradiance reaching 450 W/m2. From August to September, the environmental radiance is slightly lower, reaching a maximum of 400 W/m2. From October to December, the environmental radiance decreases to 250 W/m2. All day long, the indoor environment is affected by solar radiation from the outside, resulting in the radiation of the wall at 8:00 p.m. The indoor radiation from outdoor solar radiation is significant throughout the day, peaking from 8:00 to 18:00. The ambient radiation ranges from 200 to 400 W/m2, with the highest environmental radiance lasting only about 1 h, primarily impacting from April to September. Between January and March and October and December, the period is concentrated from 10:00 to 16:00, with temperatures ranging from approximately −2.2183534 °C to 26.6691524 °C. The other periods are influenced by sunlight and ambient radiation. Following the renovation of the manor house’s wall, it was found that the thermal conductivity decreased due to solar radiation, leading to reduced heat transfer. However, the environmental radiation performance improved. Thus, it is shown that in summer the walls of the manor house are strongly insulated, and the indoor temperature is lower, cooler, and more thermostatic than on the outside, for better comfort; in winter, the walls are well insulated, and the indoor temperature is higher, warmer, and more thermostatic. The result of this optimization is twofold: to increase the comfort of residents and to protect the continuation of the architectural structure and development of traditional houses in the area, thereby reflecting the role and value of additive surface materials.

Based on the analysis of the thermal and physical comfort measurement data of the typical Zhuangzhai model, it can be obtained that the use of new optimization measures and structural design has a strong feasibility for the energy saving and comfort of the Qiang Zhuangzhai, the protection of the traditional landscape, and the retention of the local villagers to continue to live in the house, as well as the revitalization of the traditional architecture. It provides a reference for the renovation, improvement, and protection of Heihuzhai Zhuangfang. These optimization measures can also be applied in the revitalization of traditional buildings in other Qiang areas.

5. Review of Multiple Possibilities

Through the analysis of the thermal comfort of the Qiang ethnic group’s farmhouses in Heihuzhai and the radiation amounts on the inner and outer surfaces of their walls, and the comparison with the radiation data of the inner and outer surfaces of the walls of brick–concrete Qiang houses, it is shown that the farmhouses are superior to the brick–concrete Qiang houses in terms of heat preservation, sun protection, and heat insulation. After analysis, it was found that this advantage stems from the performance of the stone materials of the farmhouse walls, indicating that stone materials have substantial benefits in heat storage, heat preservation, and energy saving. This proves that the Qiang people have consistently used stones to build buildings adapted to the climate environment throughout history. Although they have the advantages mentioned above, there are also deficiencies in the farmhouses, their wall surfaces, and materials, which are mainly reflected in the following three points:

(1) Under the condition of uniformly adopting the passive technology method, although the Qiang manor house is more comfortable than the brick Qiang house and better adapted to the local climate environment, the whole still cannot completely enhance the indoor space for better physical comfort. It cannot reach the comfortable temperature of 18 °C~24 °C and relative humidity of 30%–60% as required by China’s “Heating, Ventilating and Air Conditioning Design Code” (GB50019-2003) [18]. Suppose active technical equipment is used in brick–concrete houses—in that case, the indoor thermal environment will reach the physical comfort value, making it more comfortable, and at the same time, the problem of discomfort will be solved. The only shortcoming of this method is that the building consumes more energy and is ecologically poor, which can damage the local natural environment. Therefore, to maintain the manor house’s comfortable advantages and ecological benefits under passive technology conditions, it is necessary to renovate and optimize its wall materials and structure.

(2) Through the optimization and transformation of the wall materials of the manor house, it not only has better thermal engineering, increased energy saving and thermal insulation, and heat preservation performance but also retains the traditional architectural form and appearance and further improves the comfort of the indoor thermal environment to meet the microclimate of the local people living there, leaving the villagers to continue to live, to achieve the role of revitalization of traditional architecture, and to play a role in the protection of architectural cultural heritage purposes. However, the increase in wall materials for traditional Zhuangfang houses has led to a complex structure, necessitating the local artisans’ expertise. This has elevated their construction and masonry skills, requiring them to dedicate time to thoughtful consideration and training. The addition of wall coverings and materials, such as purchased EPS insulation boards and cement, inevitably increases the cost of construction. The cost of these materials and add-ons is higher than the price of a traditional Shoji house, estimated to be more than double the cost of the house. At the same time, the increase in construction costs will place higher economic demands on the Qiang villagers and increase their capital investment.

(3) Based on the stone masonry wall at the structural level, two to three layers of its inner and outer surfaces were added, which, although it resulted in a more suitable thermal performance and thermal comfort of the building, would also affect the solidity and safety of the building itself. Here, according to the saving and ecological requirements, in terms of ensuring low cost and occupying the least structural land area, the optimization measures adopt a 0.3 m thick stone masonry load-bearing structural wall, which is lower than the 0.4 m thickness of the wall of the traditional Zhuangfang house, and the heat preservation and insulation layer of the wall’s inner and outer surfaces has been achieved to be 0.1 m thick. The thickness of the wall remains the same before and after the renovation, but this also introduces higher difficulties in meeting the construction standards and the material requirements of the masonry. Especially in the seismic aspect, the Qiang region belongs to the high-altitude earthquake-frequent belt, where the transformed Zhuangfang building, in the thinning of the main load-bearing structure, needs other surface materials together to form a better integrity, together to enhance the building of earthquake-proof, earthquake-resistant, and strong performance, and then to meet the local people’s safe life, comfort, and health needs. These higher requirements are the challenges that the optimization measures are proposed to face.

6. Conclusions

The Qiang Zhuangfang has long been central to the cultural identity and daily life of the Qiang people and remains a source of pride as a primary form of habitation. This study introduces a novel, quantitative framework for evaluating the thermal comfort performance of traditional Zhuangfang in comparison with modern brick–concrete Qiang houses. By integrating field measurements, directional wall-surface analysis, tabular and graphical data representation, and computer simulation, it critically examines the relationship between wall material properties, thermal comfort, and environmental adaptability.

The following three key findings emerge:

- (1)

- Thermal performance superiority—Zhuangfang walls show greater variation in heat gain by orientation but minor internal surface temperature differences, indicating superior insulation and overall comfort. In contrast, brick–concrete Qiang houses display the opposite pattern, with lower energy efficiency and weaker environmental adaptability.

- (2)

- Directional optimization potential—South-facing walls achieve the highest temperatures, followed by east and west, with the north side performing worst. This directional pattern provides a basis for targeted retrofitting strategies to improve winter comfort.

- (3)

- Material and structural innovation—Six optimization measures for wall materials and layering significantly improve insulation, reduce heat transfer coefficients, and enhance thermal comfort, while preserving the architectural style and structural integrity of traditional Qiang buildings.

This research demonstrates that wall-surface optimization is a decisive factor in the sustainable preservation and revitalization of Qiang village houses. It challenges the assumption that modern brick–concrete construction inherently outperforms traditional forms, showing instead that Zhuangfang—when strategically upgraded—can surpass modern alternatives in energy efficiency, environmental protection, and cultural continuity.

Author Contributions

Z.L. was responsible for conceptualizing and writing articles and drawing pictures. P.T. was accountable for thesis guidance, revision, and control. All authors have read and agreed to the published version of the manuscript.

Funding

National Natural Science Foundation of China (NSFC): A data-driven approach to the multi-scale hierarchical conservation and renewal method of historic area.

Data Availability Statement

The data used to support the findings of this study are included within this article.

Acknowledgments

Southeast University, 2023, “Tibetan and Qiang Customs, Ethnic Watch”.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Li, X. Sichuan Folk Houses; China Architecture Industry Press: Beijing, China, 2009. [Google Scholar]

- Cheng, B. Research on Modern Transformation Design of Qiang Folk Houses; China Architecture Industry Press: Beijing, China, 2018. [Google Scholar]

- Liu, W. Qiang Traditional Village Environment and Architectural Forms under the Influence of Place Microclimate; China Building Materials Industry Press: Beijing, China, 2024. [Google Scholar]

- Ozturk, B. Seismic behavior of two monumental buildings in historical Cappadocia region of Turkey. Bull. Earthquake Eng. 2017, 15, 3103–3123. [Google Scholar] [CrossRef]

- Mazzetto, S. Comparative life cycle assessment of traditional and modern materials in heritage building restoration: A case study from Ushaiger Village. Sustainability 2025, 17, 25. [Google Scholar] [CrossRef]

- De Oliveira, E.A.S.; Xavier, A.A.D.; Pizybski, E.M. Human thermal comfort and architectural volume. Acta Sci. Technol. 2016, 38, 129. [Google Scholar] [CrossRef][Green Version]

- Tan, G.Y. The open and adaptive tradition: Applying the concepts of open building and multi-purpose design in traditional Chinese vernacular architecture. J. Asian Archit. Build. Eng. 2011, 10, 7–14. [Google Scholar] [CrossRef]

- Ji, F. Qiang Architecture in China; Southwest Jiaotong University Press: Chengdu, China, 2000. [Google Scholar]

- Geng, S. General History of the Qiang; Shanghai People’s Publishing House: Shanghai, China, 2010. [Google Scholar]

- Maowen Qiang Autonomous County, Aba Tibetan and Qiang Autonomous Prefecture, Sichuan Province, Local Records Compilation Committee. Maowen Qiang Autonomous County Records; Sichuan Dictionary Press: Chengdu, China, 1997. [Google Scholar]

- Liu, W. An analysis of the ecological sustainable design of Qiang Diaolou based on bioclimatology. Archit. Creat. 2020, 3, 230–236. [Google Scholar]

- Li, M.; (second group of Heihuzhai Village, Aba Tibetan and Qiang Autonomous Prefecture, China). Personal communication, 2023.

- Guo, F. Theory and Technology of Sustainable Building; Dalian University of Technology Press: Dalian, China, 2017. [Google Scholar]

- Liu, N.; Qin, Y. Thermal Environment of Buildings; Tsinghua University Press: Beijing, China, 2005. [Google Scholar]

- Zhou, H. Theory of Sustainable Indoor Environmental Design; China Building Industry Press: Beijing, China, 2011. [Google Scholar]

- State Bureau of Technical Supervision; Ministry of Construction of the People’s Republic of China. Thermal Design Code for Civil Buildings (GB50176-93); China Construction Industry Press: Beijing, China, 2005. [Google Scholar]

- China Academy of Building Research. Energy-Saving Design Standards for Civil Buildings—Heating Residential Buildings Part (JGJ26-95); China Building Industry Press: Beijing, China, 2007. [Google Scholar]

- Ministry of Construction of the People’s Republic of China; General Administration of Quality Supervision, Inspection and Quarantine. Heating Ventilation and Air Conditioning Design Code (GB50019-2003); China Planning Press: Beijing, China, 2004. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).