Experimental Study on Tool Performance in the Machining of AISI 4130 Alloy Steel with Variations in Tool Angle and Cutting Parameters

Abstract

1. Introduction

2. Experimental Principles and Methods

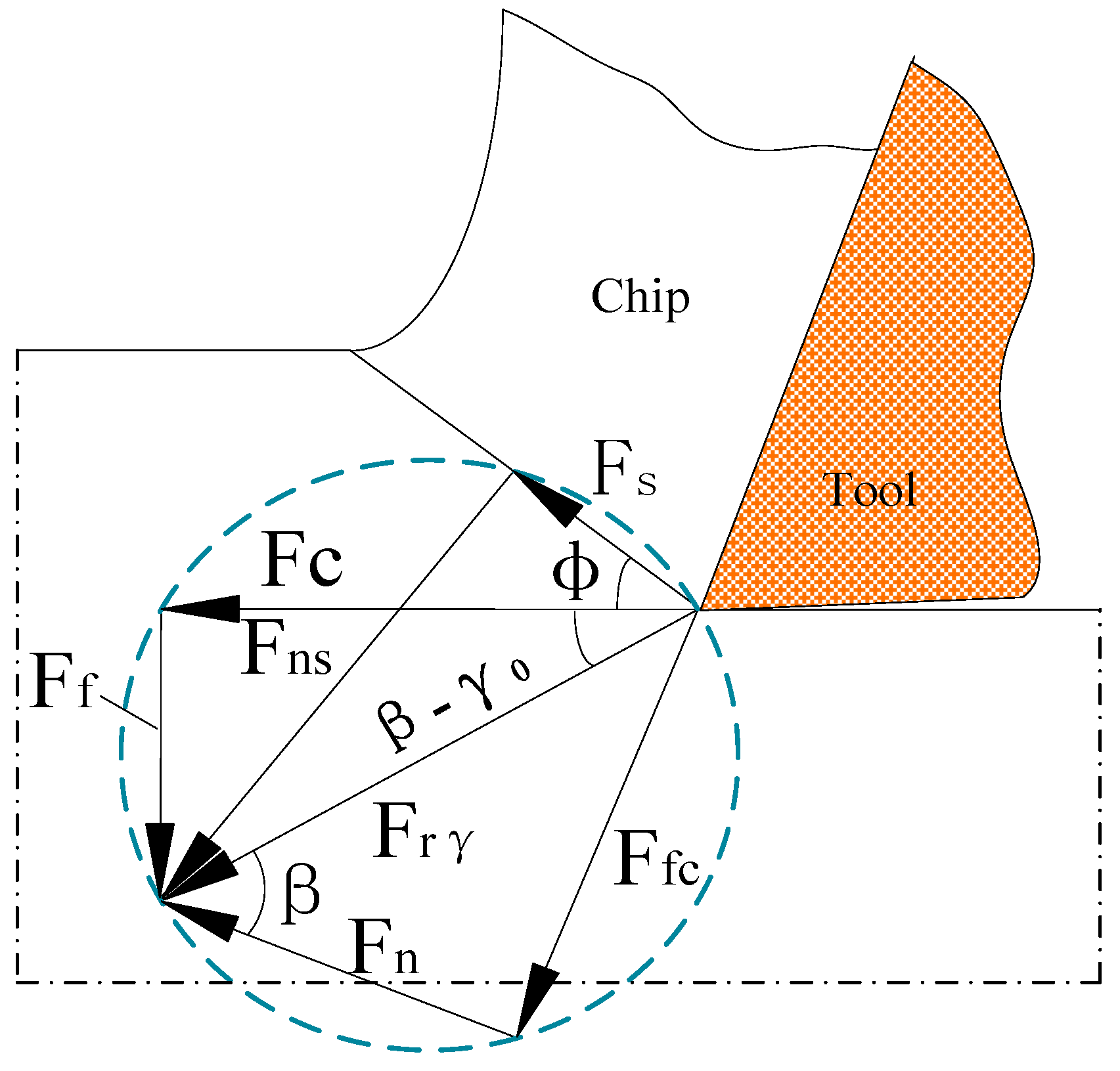

2.1. Theoretical Analysis of the Cutting Process

2.2. Analysis of the Influence of Tool Angles on the Cutting Process

2.3. Experimental Study on the Effect of Tool Angle on the Cutting Process

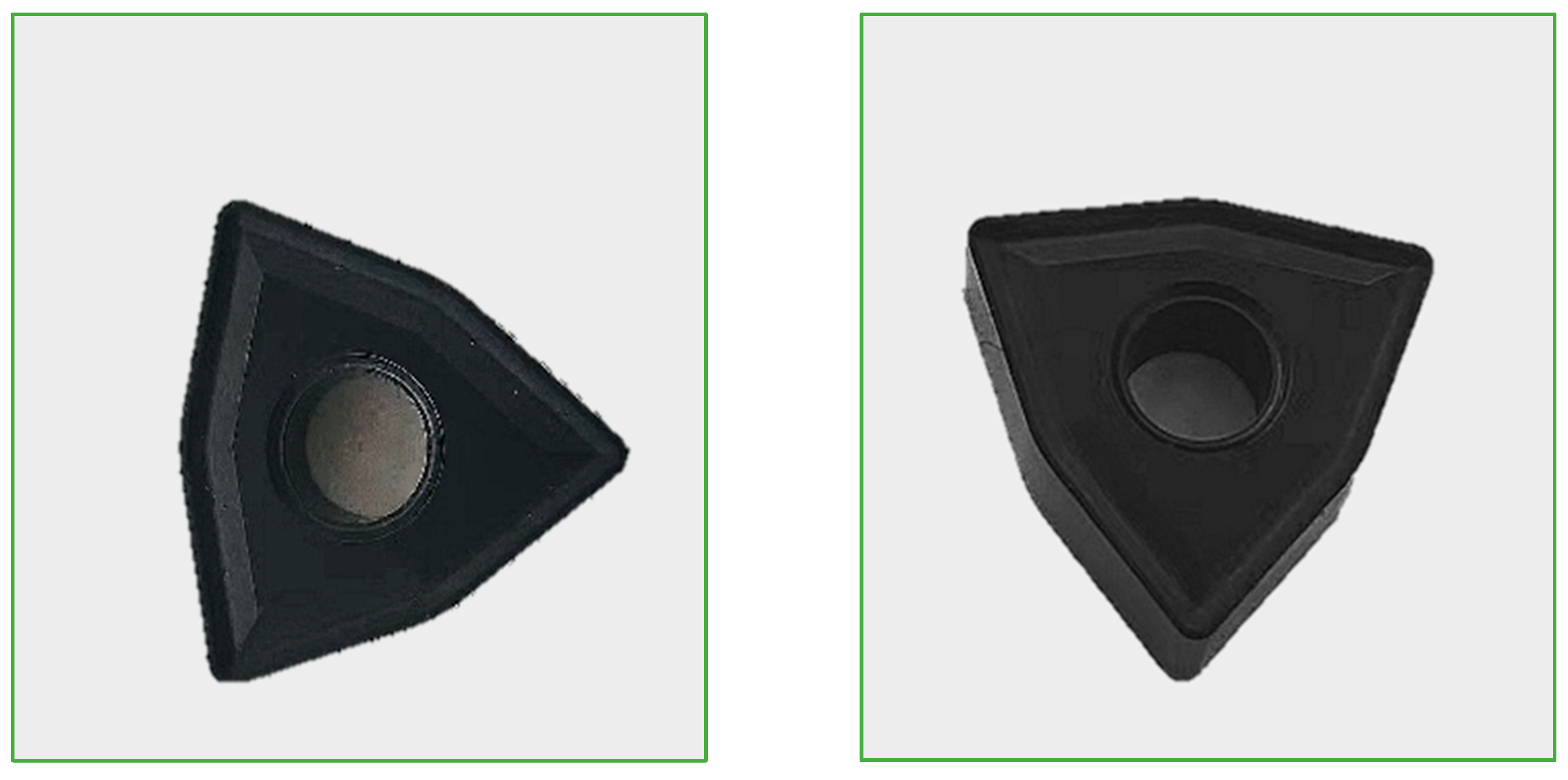

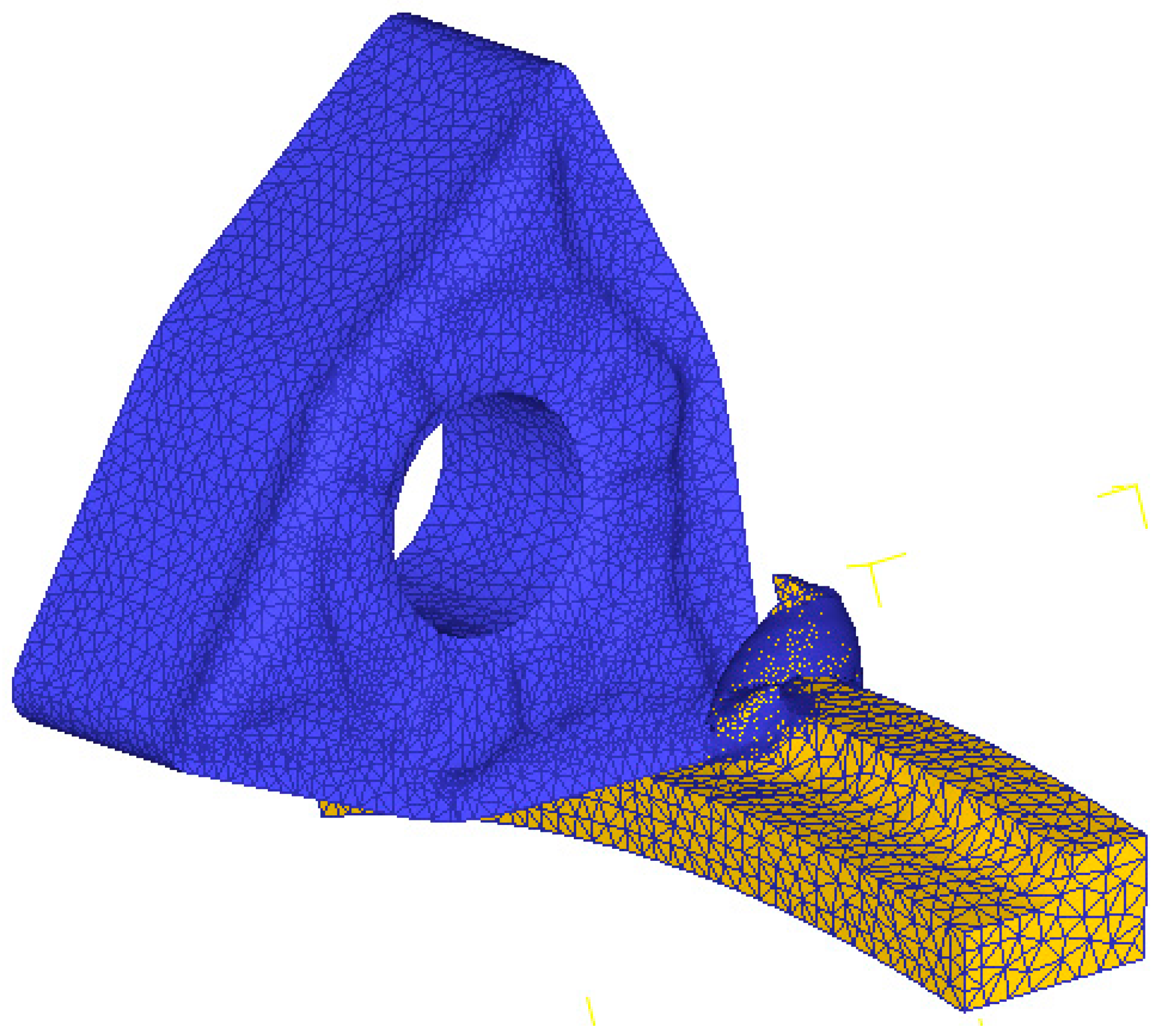

2.3.1. Cutting Simulation Model Establishment

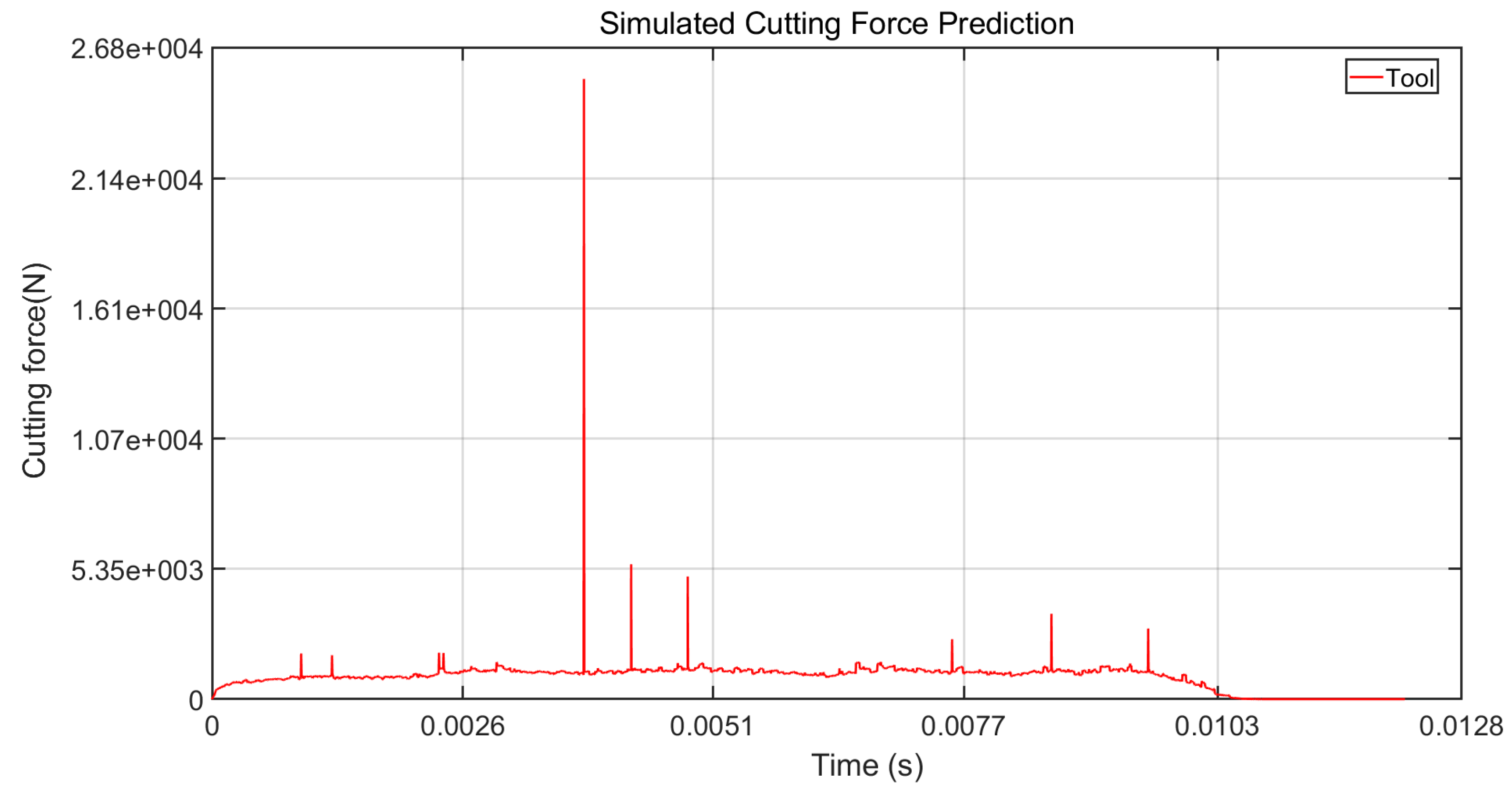

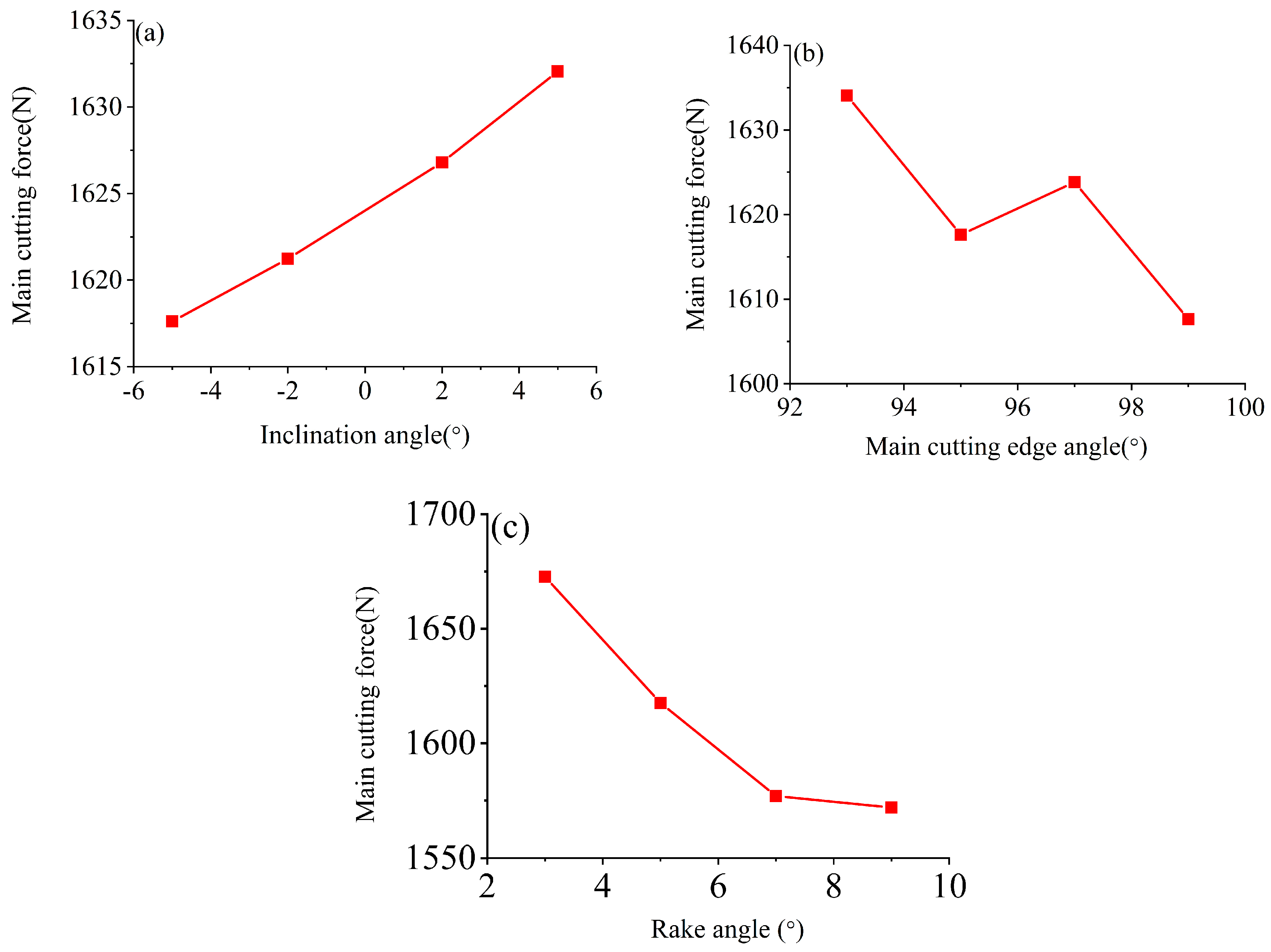

2.3.2. Study on the Influence of Tool Angles on Cutting Force and Cutting Temperature

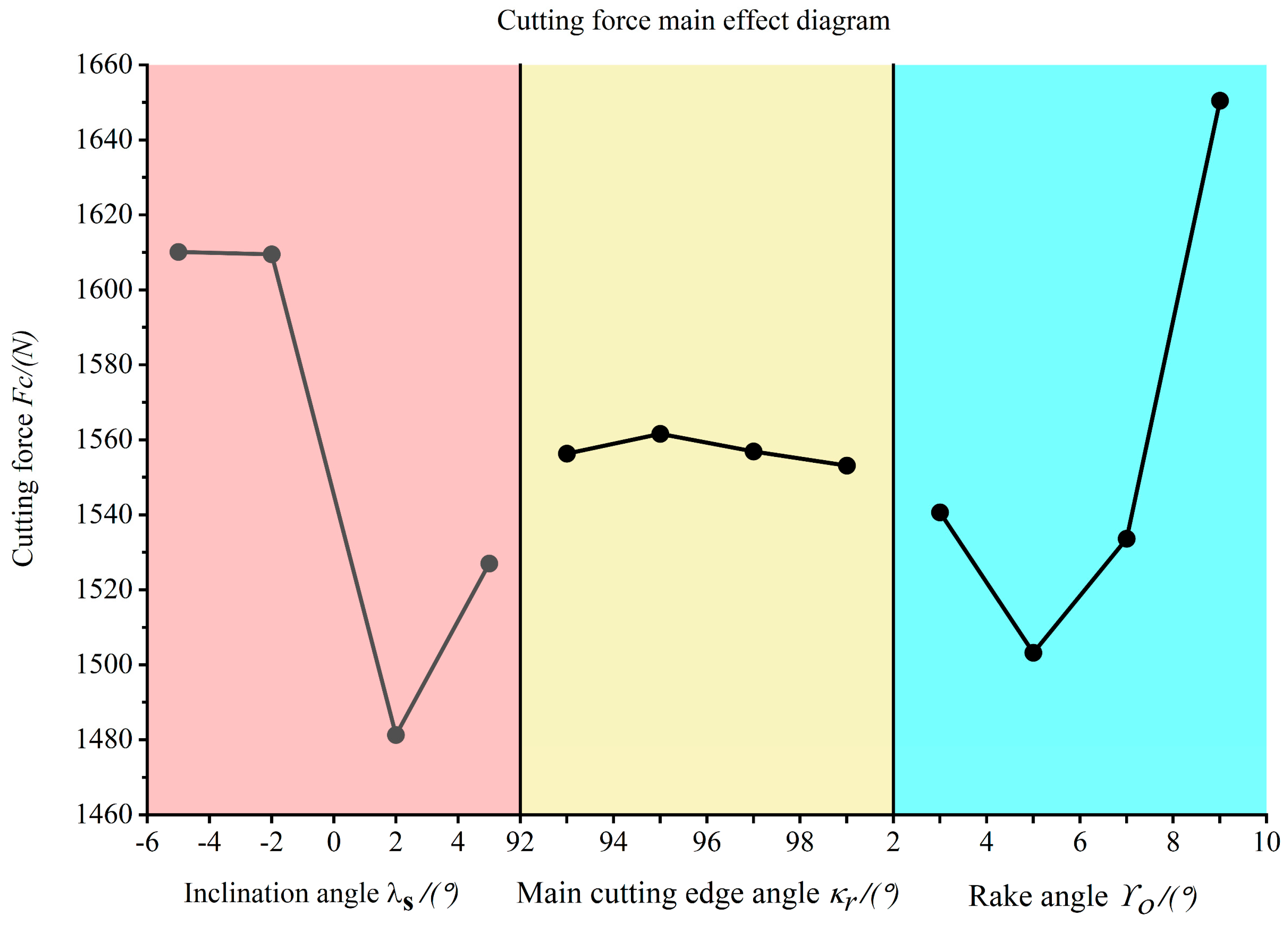

2.3.3. Tool Angle Optimization Based on Orthogonal Experiments

- Meaning and principles of calculation of M1, M2, M3, M4:

- In the polar analysis of orthogonal experiments, M1, M2, M3, and M4 represent the average of all the results of the main cutting force (Fc) corresponding to a certain geometric angle factor at each level, respectively.

- Calculation principle: For a certain level of a factor, all rows appearing at that level were screened from all 16 sets of experiments, and the main cutting force (Fc) values corresponding to these rows were arithmetically averaged to obtain the mean value M at that level.

- 2.

- The way in which the polar R-value is formed:

- The extreme variance R is the difference between the maximum and minimum values of the four water means (M1, M2, M3, M4) for the same factor, i.e., R = max (M1, M2, M3, M4) − min (M1, M2, M3, M4).

- Significance of R-value: This reflects the magnitude of the effect of the change in the level of the factor on the outcome. The larger the R-value, the more significant the change in the level of the factor is in influencing the results.

2.4. Study on the Influence of Cutting Parameters on the Cutting Process

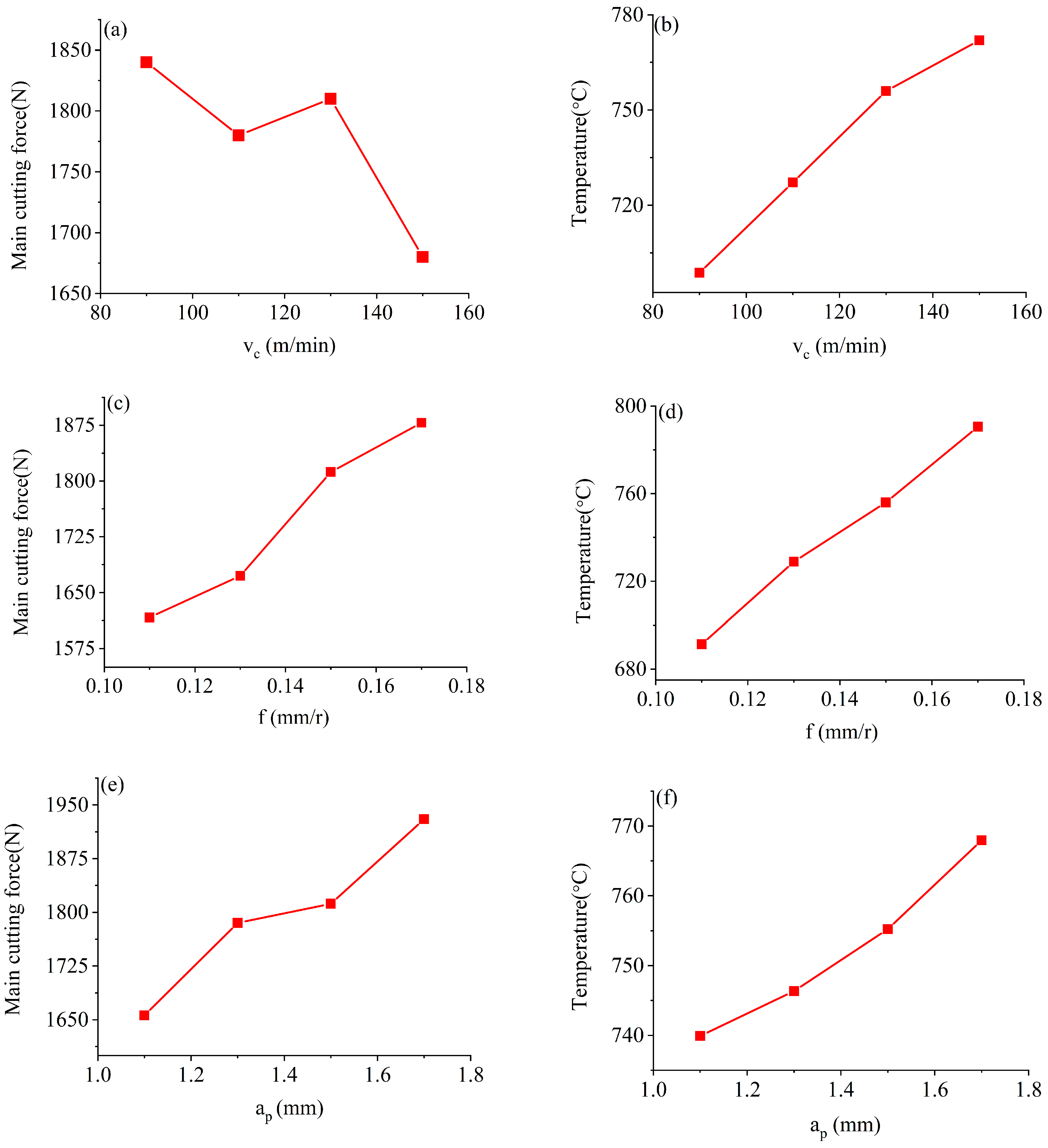

2.4.1. Simulation Analysis of the Influence of Cutting Parameters on Cutting Force and Cutting Temperature

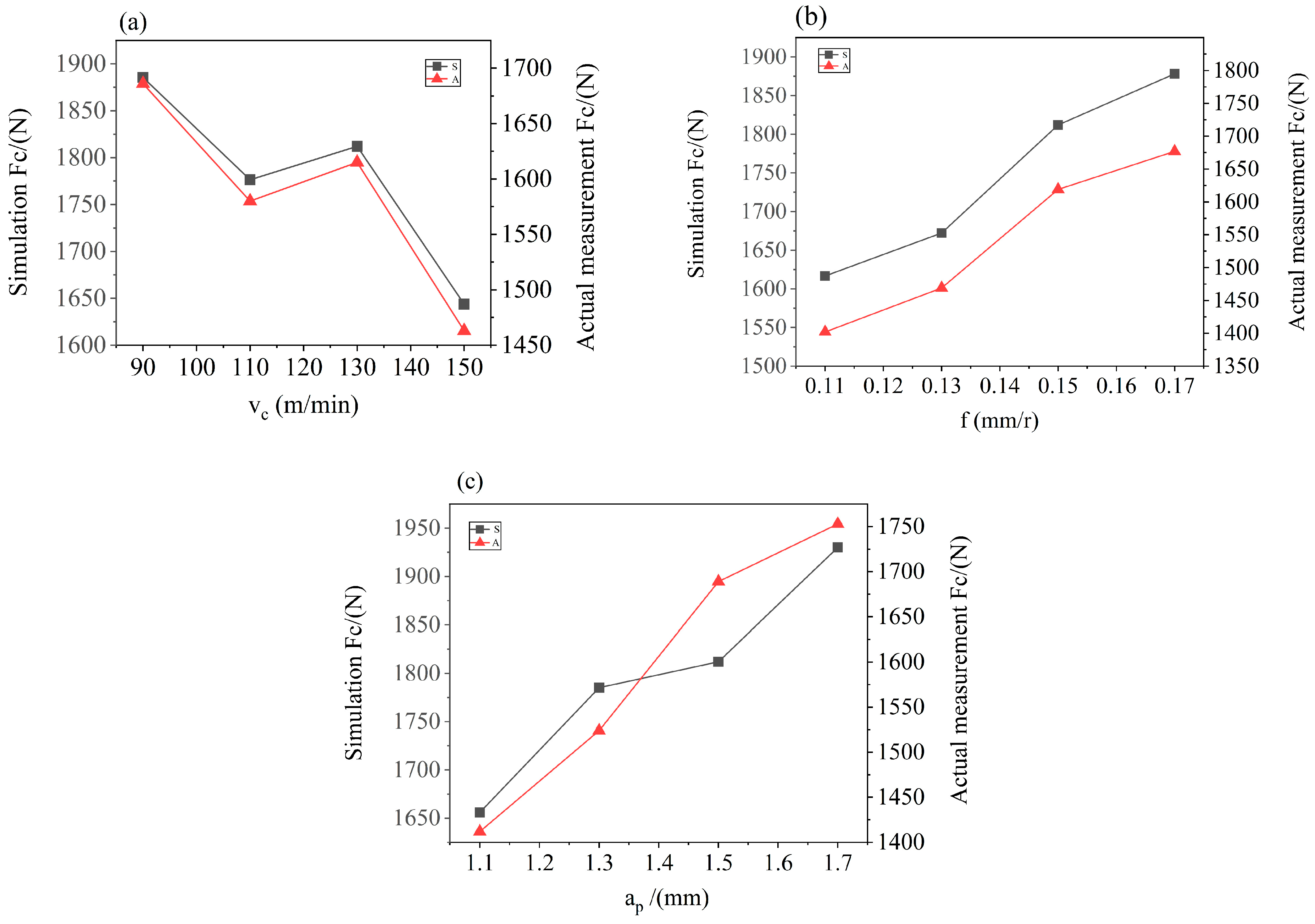

2.4.2. Turning Experiment Verification

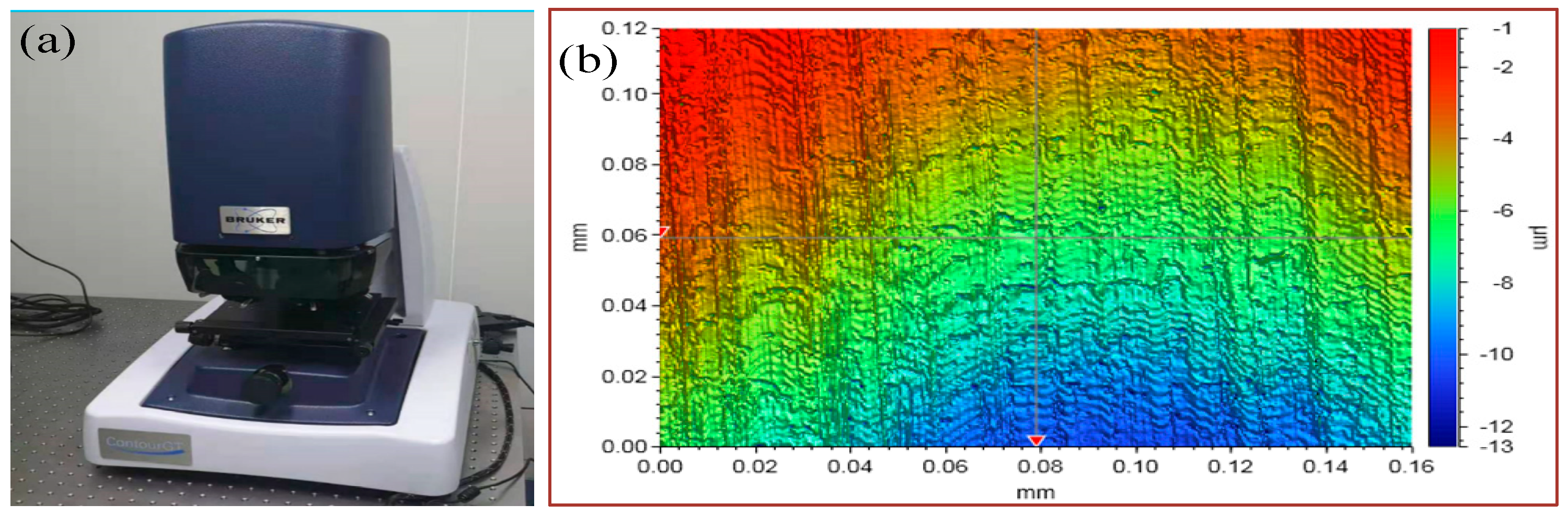

2.4.3. Study on the Effect of Cutting Parameters on Surface Roughness

3. Results and Discussion

3.1. Discussion on the Effect of Tool Angle on Cutting Force and Cutting Temperature

3.2. Discussion on the Influence of Cutting Parameters on Cutting Force and Cutting Temperature

4. Conclusions

- Through cutting simulation, it was found that as the inclination angle increases, the cutting force increases and the cutting temperature decreases; as the main cutting edge angle increases, the cutting force decreases and the cutting temperature rises; and as the rake angle increases, both the cutting force and cutting temperature decrease.

- Orthogonal experiments revealed that the tool angle combination with the smallest principal cutting force was the inclination angle λs = 2°, the main cutting edge angle kr = 99°, and the rake angle γ0 = 5°.

- As the cutting speed increases, the cutting force decreases and the cutting temperature rises; as the feed rate increases, both the cutting force and cutting temperature increase; and as the cutting depth increases, both the cutting force and cutting temperature increase. Through actual cutting experiments, it has been verified that cutting simulation and actual cutting exhibit consistent trends.

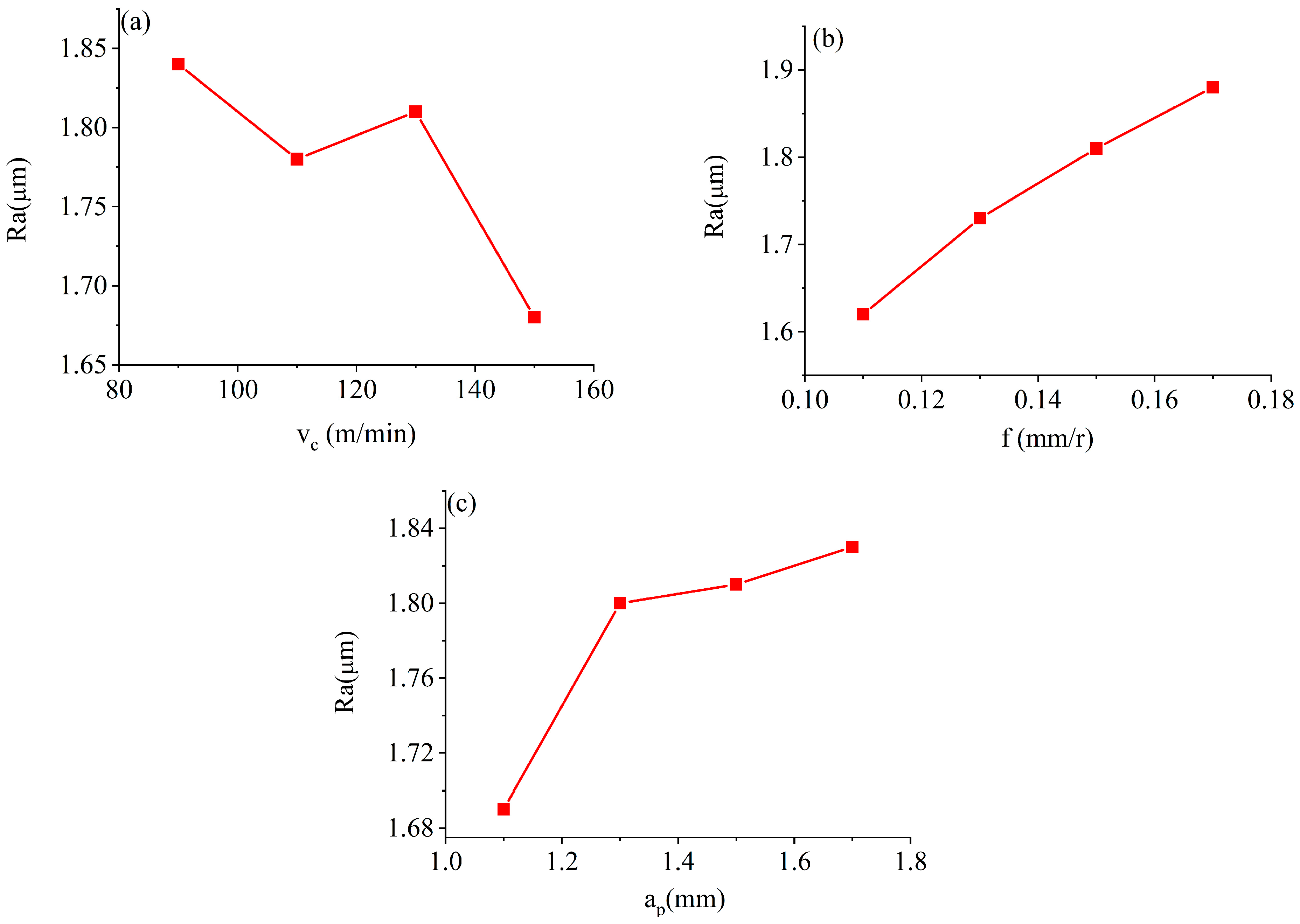

- By measuring the surface quality of the workpiece, it was found that the surface roughness of the workpiece decreases with an increasing cutting speed, increases with an increasing feed rate, and increases with an increasing cutting depth.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, J.; Xia, J.; Liu, Z.; Xu, L.; Liu, J.; Xiao, Y.; Jiao, J. A comprehensive review of metal laser hardening: Mechanism, process, and applications. Int. J. Adv. Manuf. Technol. 2024, 134, 5087–5115. [Google Scholar] [CrossRef]

- Kanovic, Z.; Vukelic, D.; Simunovic, K.; Prica, M.; Saric, T.; Tadic, B.; Simunovic, G. The modelling of surface roughness after the ball burnishing process with a high-stiffness tool by using regression analysis, artificial neural networks, and support vector regression. Metals 2022, 12, 320. [Google Scholar] [CrossRef]

- Moghanian, A.; Mohammadi, M.A.; Ansari, J.; Asadi, P.; Akbari, M.; Yazdi, M.S.; Safaee, S. Enhancing corrosion resistance of AISI 4130 steel through optimized HVOF tungsten carbide coatings. Results Surf. Interfaces 2025, 18, 100450. [Google Scholar] [CrossRef]

- Khatir, F.A.; Sadeghi, M.H.; Akar, S. Investigation of surface integrity in laser-assisted turning of AISI 4340 hardened steel: Finite element simulation with experimental verification. Opt. Laser Technol. 2022, 147, 107623. [Google Scholar] [CrossRef]

- Bakhtiari, M.; Fayazi Khanigi, A.; Farnia, A. Improving the wear properties of AISI4130 steel using laser surface hardening treatment. Arab. J. Sci. Eng. 2023, 48, 11801–11818. [Google Scholar] [CrossRef]

- Arsene, B.; Gheorghe, C.; Sarbu, F.A.; Barbu, M.; Cioca, L.I.; Calefariu, G. MQL-assisted hard turning of AISI D2 steel with corn oil: Analysis of surface roughness, tool wear, and manufacturing costs. Metals 2021, 11, 2058. [Google Scholar] [CrossRef]

- Kuo, C.; Liu, J.; Chang, T.; Ko, S. The effects of cutting conditions and tool geometry on mechanics, tool wear and machined surface integrity when routing CFRP composites. J. Manuf. Process. 2021, 64, 113–129. [Google Scholar] [CrossRef]

- Ashworth, S.; Fairclough, J.P.A.; Meredith, J.; Takikawa, Y.; Kerrigan, K. Effects of tool coating and tool wear on the surface quality and flexural strength of slotted CFRP. Wear 2022, 498, 204340. [Google Scholar] [CrossRef]

- Zhou, X.; He, L.; Zhou, T.; Yuan, S.; Tian, P.; Zou, Z. A comprehensive review of tool surface texturing in the cutting process. Int. J. Adv. Manuf. Technol. 2022, 123, 2427–2467. [Google Scholar] [CrossRef]

- Rahman, H.A.; Ghani, J.A.; Rasani, M.R.M.; Mahmood, W.M.F.W.; Yaaqob, S.; Abd Aziz, M.S. Application of finite element analysis and computational fluid dynamics in machining AISI 4340 steel. Tribol. Int. 2025, 207, 110616. [Google Scholar] [CrossRef]

- Aslantas, K.; Ucun, I.; Cicek, A. Tool life and wear mechanism of coated and uncoated Al2O3/TiCN mixed ceramic tools in turning hardened alloy steel. Wear 2012, 274, 442–451. [Google Scholar] [CrossRef]

- Deng, L.C.; Li, X.Z.; Chen, Y.W.; Zhuang, Q.W.; Zhu, L.H.; Zhang, C. Investigations on cutting force and temperature field of pick cutter based on single factor and orthogonal test methods. Rock Mech. Rock Eng. 2023, 56, 619–645. [Google Scholar] [CrossRef]

- Özel, T.; Zeren, E. Finite element method simulation of machining of AISI 1045 steel with a round edge cutting tool. In Proceedings of the 8th CIRP International Workshop on Modeling of Machining Operations, Chemnitz, Germany, 10–11 May 2005; pp. 533–542. [Google Scholar]

- Usca, Ü.A.; Uzun, M.; Şap, S.; Kuntoğlu, M.; Giasin, K.; Pimenov, D.Y.; Wojciechowski, S. Tool wear, surface roughness, cutting temperature and chips morphology evaluation of Al/TiN coated carbide cutting tools in milling of Cu–B–CrC based ceramic matrix composites. J. Mater. Res. Technol. 2022, 16, 1243–1259. [Google Scholar] [CrossRef]

- Şap, E.; Usca, U.A.; Gupta, M.K.; Kuntoğlu, M. Tool wear and machinability investigations in dry turning of Cu/Mo-SiCp hybrid composites. Int. J. Adv. Manuf. Technol. 2021, 114, 379–396. [Google Scholar] [CrossRef]

- Demirpolat, H.; Binali, R.; Patange, A.D.; Pardeshi, S.S.; Gnanasekaran, S. Comparison of tool wear, surface roughness, cutting forces, tool tip temperature, and chip shape during sustainable turning of bearing steel. Materials 2023, 16, 4408. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Yue, C.; Li, X.; Liu, X.; Liang, S.Y.; Wang, L. Research on tool wear based on 3D FEM simulation for milling process. J. Manuf. Mater. Process. 2020, 4, 121. [Google Scholar] [CrossRef]

- Shi, Z.Y.; Li, X.; Duan, N.M.; Yang, Q.B. Evaluation of tool wear and cutting performance considering effects of dynamic nodes movement based on FEM simulation. Chin. J. Aeronaut. 2021, 34, 140–152. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, D.; Agmell, M.; M’Saoubi, R.; Ahadi, A.; Stahl, J.E.; Zhou, J. Numerical and experimental investigation of tool geometry effect on residual stresses in orthogonal machining of Inconel 718. Simul. Model. Pract. Theory 2021, 106, 102187. [Google Scholar] [CrossRef]

- Shaw, M.C.; Cookson, J.O. Metal Cutting Principles; Oxford University Press: New York, NY, USA, 2005. [Google Scholar]

- Trent, E.M. Some factors affecting wear on cemented carbide tools. Proc. Inst. Mech. Eng. 1952, 166, 64–74. [Google Scholar] [CrossRef]

- Li, C.; Huang, L.; Xu, M.; Chen, Y.; Chen, J.; Li, S.; Ko, T.J. Processing mechanism of electrical discharge-assisted milling titanium alloy based on 3D thermal-mechanical coupling cutting model. J. Manuf. Process. 2022, 78, 107–119. [Google Scholar] [CrossRef]

- Zhang, Y.; Bai, Q.; Qing, L.; Chen, S. 3D coupled thermo-mechanical simulation of surface roughness and residual stress in end milling aluminum alloy. Int. J. Adv. Manuf. Technol. 2022, 123, 4489–4504. [Google Scholar] [CrossRef]

- Miller, L.; Zhou, K.; Tang, J.; Frame, L.D.; Hebert, R.J.; Narayan, L.R.; Kim, J. Thermomechanical finite element simulation and correlation analysis for orthogonal cutting of normalized AISI 9310 steels. Int. J. Adv. Manuf. Technol. 2021, 114, 3337–3356. [Google Scholar] [CrossRef]

- Klocke, F.; Kratz, H. Advanced tool edge geometry for high precision hard turning. CIRP Ann. 2005, 54, 47–50. [Google Scholar] [CrossRef]

- Singh, D.; Venkateswara Rao, P. Optimization of tool geometry and cutting parameters for hard turning. Mater. Manuf. Process. 2007, 22, 15–21. [Google Scholar] [CrossRef]

- Sivalingam, V.; Zhao, Y.; Thulasiram, R.; Sun, J.; Nagamalai, T. Machining behaviour, surface integrity and tool wear analysis in environment friendly turning of Inconel 718 alloy. Measurement 2021, 174, 109028. [Google Scholar] [CrossRef]

- Peng, Z.; Zhang, X.; Liu, L.; Xu, G.; Wang, G.; Zhao, M. Effect of high-speed ultrasonic vibration cutting on the microstructure, surface integrity, and wear behavior of titanium alloy. J. Mater. Res. Technol. 2023, 24, 3870–3888. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B. The effects of coolant on the cutting temperature, surface roughness and tool wear in turning operations of Ti6Al4V alloy. Mech. Based Des. Struct. Mach. 2024, 52, 3277–3299. [Google Scholar] [CrossRef]

- Bhandarkar, L.R.; Behera, M.; Mohanty, P.P.; Sarangi, S.K. Experimental investigation and multi-objective optimization of process parameters during machining of AISI 52100 using high performance coated tools. Measurement 2021, 172, 108842. [Google Scholar] [CrossRef]

- Özbek, O.; Saruhan, H. The effect of vibration and cutting zone temperature on surface roughness and tool wear in eco-friendly MQL turning of AISI D2. J. Mater. Res. Technol. 2020, 9, 2762–2772. [Google Scholar] [CrossRef]

- Salur, E.; Kuntoğlu, M.; Aslan, A.; Pimenov, D.Y. The effects of MQL and dry environments on tool wear, cutting temperature, and power consumption during end milling of AISI 1040 steel. Metals 2021, 11, 1674. [Google Scholar] [CrossRef]

- Deepanraj, B.; Senthilkumar, N.; Hariharan, G.; Tamizharasan, T.; Tefera Bezabih, T. Numerical Modelling, Simulation, and Analysis of the End-Milling Process Using DEFORM-3D with Experimental Validation. Adv. Mater. Sci. Eng. 2022, 2022, 5692298. [Google Scholar] [CrossRef]

- Gupta, M.K.; Korkmaz, M.E.; Sarıkaya, M.; Krolczyk, G.M.; Günay, M.; Wojciechowski, S. Cutting forces and temperature measurements in cryogenic assisted turning of AA2024-T351 alloy: An experimentally validated simulation approach. Measurement 2022, 188, 110594. [Google Scholar] [CrossRef]

- Paturi, U.M.R.; Methuku, S.; Siripragada, S.S.; Sangishetty, Y.; Gunda, R.K. Finite element simulations of machinability parameters in turning of Inconel 718. Mater. Today Proc. 2021, 38, 2658–2663. [Google Scholar] [CrossRef]

- Muhammad, A.; Kumar Gupta, M.; Mikołajczyk, T.; Pimenov, D.Y.; Giasin, K. Effect of tool coating and cutting parameters on surface roughness and burr formation during micromilling of inconel 718. Metals 2021, 11, 167. [Google Scholar] [CrossRef]

- Szczotkarz, N.; Maruda, R.W.; Dębowski, D.; Leksycki, K.; Wojciechowski, S.; Khanna, N.; Królczyk, G.M. Formation of surface topography during turning of AISI 1045 steel considering the type of cutting edge coating. Adv. Sci. Technol. Res. J. 2021, 15, 253–266. [Google Scholar] [CrossRef]

- Hashmi, A.W.; Mali, H.S.; Meena, A.; Khilji, I.A.; Hashmi, M.F. Machine vision for the measurement of machining parameters: A review. Mater. Today Proc. 2022, 56, 1939–1946. [Google Scholar] [CrossRef]

- Merchant, M.E. Mechanics of the metal cutting process. orthogonal cutting. J. Appl. Phys. 1945, 16, 318–324. [Google Scholar] [CrossRef]

- Sousa, V.F.; Da Silva, F.J.G.; Pinto, G.F.; Baptista, A.; Alexandre, R. Characteristics and wear mechanisms of TiAlN-based coatings for machining applications: A comprehensive review. Metals 2021, 11, 260. [Google Scholar] [CrossRef]

- Abdalrahman, R.M.; Rostam, S.; Deboucha, A. Effect of Cutting Tool Rake and Inclination Angles and Feeding Method on Cutting Force and Surface Quality in Single-point Threading. Kurd. J. Appl. Res. 2025, 10, 55–67. [Google Scholar] [CrossRef]

- Li, P.; Chang, Z. Accurate modeling of working normal rake angles and working inclination angles of active cutting edges and application in cutting force prediction. Micromachines 2021, 12, 1207. [Google Scholar] [CrossRef] [PubMed]

- Mikołajczyk, T.; Latos, H.; Pimenov, D.Y.; Paczkowski, T.; Gupta, M.K.; Krolczyk, G. Influence of the main cutting edge angle value on minimum uncut chip thickness during turning of C45 steel. J. Manuf. Process. 2020, 57, 354–362. [Google Scholar] [CrossRef]

- Shah, D.R.; Pancholi, N.; Gajera, H.; Patel, B. Investigation of cutting temperature, cutting force and surface roughness using multi-objective optimization for turning of Ti-6Al-4 V (ELI). Mater. Today Proc. 2022, 50, 1379–1388. [Google Scholar] [CrossRef]

- Srivastava, V.S.; Gupta, T.K.; Srivastava, A.K.; Chauhan, S.; Chauhan, P.K. Effects of cutting parameters on aluminium alloys-A review. Mater. Today Proc. 2021, 47, 3823–3827. [Google Scholar] [CrossRef]

| Chemical Composition | C | Cr | Mo | Mn | Si | Ni |

|---|---|---|---|---|---|---|

| Mass fraction ratio (wt%) | 0.28–0.33 | 0.80–1.1 | 0.15–0.25 | 0.4–0.6 | 0.15–0.35 | ≤0.25 |

| Performance Parameters | Density (g/cm3) | Modulus of Elasticity (GPa) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Poisson Ratio | Hardness |

|---|---|---|---|---|---|---|

| AISI 4130 | 7.85 | 190–210 | ≥930 | 42.7 | 0.28 | ≤229 HB |

| Tool (WC) | 13.6 | 650 | 2000 | 72 | 0.23 | 89–94 HRA |

| Tool Angle | Angle Change (°) |

|---|---|

| Inclination angle | −5, −2, 2, 5 |

| Main cutting edge angle | 93, 95, 97, 99 |

| Rake angle | 3, 5, 7, 9 |

| Simulated Experiment | Inclination Angle λs/(°) | Main Cutting Edge Angle κr/(°) | Rake Angle γ0/(°) | Principal Cutting Force Fc/(N) | Cutting Temperature t/(°C) |

|---|---|---|---|---|---|

| 1 | −5 | 95 | 5 | 1617.61 | 700.1 |

| 2 | −2 | 95 | 5 | 1619.23 | 714.71 |

| 3 | 2 | 95 | 5 | 1642.8 | 807.89 |

| 4 | 5 | 95 | 5 | 1657.05 | 750.03 |

| 5 | −5 | 93 | 5 | 1668.06 | 685.61 |

| 6 | −5 | 95 | 5 | 1617.61 | 700.1 |

| 7 | −5 | 97 | 5 | 1642.82 | 711.35 |

| 8 | −5 | 99 | 5 | 1639.63 | 721.45 |

| 9 | −5 | 95 | 3 | 1672.65 | 712.81 |

| 10 | −5 | 95 | 5 | 1617.61 | 700.1 |

| 11 | −5 | 95 | 7 | 1576.96 | 707.44 |

| 12 | −5 | 95 | 9 | 1571.94 | 692.25 |

| Simulated Experiment | Inclination Angle λs/(°) | Main Cutting Edge Angle κr/(°) | Rake Angle γ0/(°) | Principal Cutting Force Fc/(N) |

|---|---|---|---|---|

| 1 | −5 | 93 | 3 | 1539.09 |

| 2 | −5 | 95 | 5 | 1598.69 |

| 3 | −5 | 97 | 7 | 1619.71 |

| 4 | −5 | 99 | 9 | 1776.11 |

| 5 | −2 | 93 | 5 | 1520.22 |

| 6 | −2 | 95 | 7 | 1610.11 |

| 7 | −2 | 97 | 9 | 1631.84 |

| 8 | −2 | 99 | 3 | 1670.43 |

| 9 | 2 | 93 | 7 | 1473.72 |

| 10 | 2 | 95 | 9 | 1564.96 |

| 11 | 2 | 97 | 5 | 1445.3 |

| 12 | 2 | 99 | 3 | 1311.23 |

| 13 | 5 | 93 | 9 | 1679.73 |

| 14 | 5 | 95 | 3 | 1449.03 |

| 15 | 5 | 97 | 5 | 1489.33 |

| 16 | 5 | 99 | 7 | 1432.93 |

| Analysis Data | Inclination Angle λs/(°) | Main Cutting Edge Angle κr/(°) | Rake Angle γ0/(°) |

|---|---|---|---|

| A | B | C | |

| M1 | 1610.173 | 1556.345 | 1540.66 |

| M2 | 1609.523 | 1561.598 | 1503.23 |

| M3 | 1481.308 | 1556.913 | 1533.648 |

| M4 | 1527.013 | 1553.17 | 1650.478 |

| R | 128.865 | 8.4275 | 147.2475 |

| Primary–Secondary Factors | C-A-B | ||

| Best level | C2A3B4 | ||

| Simulation Experiments | Cutting Speed vc/(m/min) | Feed Rate f/(mm/r) | Cutting Depth ap/(mm) |

|---|---|---|---|

| 1 | 90 | 0.15 | 1.5 |

| 2 | 110 | 0.15 | 1.5 |

| 3 | 130 | 0.15 | 1.5 |

| 4 | 150 | 0.15 | 1.5 |

| 5 | 130 | 0.11 | 1.5 |

| 6 | 130 | 0.13 | 1.5 |

| 7 | 130 | 0.15 | 1.5 |

| 8 | 130 | 0.17 | 1.5 |

| 9 | 130 | 0.15 | 1.1 |

| 10 | 130 | 0.15 | 1.3 |

| 11 | 130 | 0.15 | 1.5 |

| 12 | 130 | 0.15 | 1.7 |

| Number | Variation in Cutting Parameters | Simulation Fc/(N) | Actual Measurement Fc/(N) | |

|---|---|---|---|---|

| 1 | cutting speed vc/(m/min) | 90 | 1885.48 | 1686 |

| 2 | 110 | 1776.39 | 1580 | |

| 3 | 130 | 1812.03 | 1615 | |

| 4 | 150 | 1643.77 | 1463 | |

| 5 | feed rate f/(mm/r) | 0.11 | 1616.68 | 1402 |

| 6 | 0.13 | 1672.33 | 1469 | |

| 7 | 0.15 | 1812.03 | 1619 | |

| 8 | 0.17 | 1878.27 | 1677 | |

| 9 | cutting depth ap/(mm) | 1.1 | 1656.02 | 1412 |

| 10 | 1.3 | 1785.23 | 1524 | |

| 11 | 1.5 | 1812.03 | 1689 | |

| 12 | 1.7 | 1930.04 | 1753 | |

| Evaluation Indicator | Cutting Speed vc/(m/min) | Feed Rate f/(mm/r) | Cutting Depth ap/(mm) |

|---|---|---|---|

| RMSE | 193.56 | 203.22 | 208.73 |

| MAPE | 12.20% | 13.27% | 12.95% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Zhang, Y.; Hu, W.; Wu, C.; Yang, Z.; Yang, R. Experimental Study on Tool Performance in the Machining of AISI 4130 Alloy Steel with Variations in Tool Angle and Cutting Parameters. Coatings 2025, 15, 1115. https://doi.org/10.3390/coatings15101115

Wu J, Zhang Y, Hu W, Wu C, Yang Z, Yang R. Experimental Study on Tool Performance in the Machining of AISI 4130 Alloy Steel with Variations in Tool Angle and Cutting Parameters. Coatings. 2025; 15(10):1115. https://doi.org/10.3390/coatings15101115

Chicago/Turabian StyleWu, Jinxing, Yi Zhang, Wenhao Hu, Changcheng Wu, Zuode Yang, and Ruobing Yang. 2025. "Experimental Study on Tool Performance in the Machining of AISI 4130 Alloy Steel with Variations in Tool Angle and Cutting Parameters" Coatings 15, no. 10: 1115. https://doi.org/10.3390/coatings15101115

APA StyleWu, J., Zhang, Y., Hu, W., Wu, C., Yang, Z., & Yang, R. (2025). Experimental Study on Tool Performance in the Machining of AISI 4130 Alloy Steel with Variations in Tool Angle and Cutting Parameters. Coatings, 15(10), 1115. https://doi.org/10.3390/coatings15101115