1. Introduction

China’s karst geological area is widely distributed and diverse, involving 23 provinces (municipalities and autonomous regions), with an overall area of 3.44 million square dry meters [

1,

2], and the total number of karst subsidence exceeds 40,000 [

3]. Ground collapse, mud and water surge, seepage and waterlogging and other geological disasters occur very easily in the construction of karst areas, which seriously threaten the safety of engineering construction, ecological environment and people’s lives and properties, and become an important bottleneck restricting the rapid development of karst areas.

Karst formations are generally reinforced through grouting [

4]. Grouting technology can effectively prevent groundwater infiltration while filling and reinforcing fractured rock masses. In practical grouting operations, issues such as slurry bubbling and cascading frequently occur due to factors including topography, stratigraphic structure, geological features, sealing performance, and grouting pressure [

5]. A slight degree of slurry bubbling has little impact on grouting effectiveness; however, severe bubbling not only impedes the formation of the grouting curtain but also increases project costs and exacerbates environmental impacts.

As a crucial material for foundation treatment and structural reinforcement, grouting materials have been extensively researched and applied both domestically and internationally [

6]. The development history of grouting materials spans over two centuries [

7]; as early as 1802, the French engineer Charles Berigny [

8] successfully injected clay slurry into the ground using a hammering method, marking the inception of humanity’s use of grouting technology to address engineering challenges such as foundation reinforcement. In 1826, Portland cement was invented in the United Kingdom [

9]. Owing to its high strength, excellent durability, and wide applicability, it quickly emerged as an ideal option for grouting projects [

10]. Currently, there exists a diverse range of grouting materials. For instance, the acrylamide-based slurry (AM-9) [

11] developed in the United States, as a pioneering organic polymer grouting material, has effectively overcome the limitations of traditional slurries in terms of strength and durability, thanks to its exceptional fluidity and adjustable curing time. This has propelled rapid advancements in the field of organic grouting materials [

12,

13,

14]. Nevertheless, when dealing with complex geological conditions and large-scale engineering projects, grouting materials still exhibit limitations in their performance [

15].

Many researchers have investigated geophysical methods to evaluate the effectiveness of grouting, and these studies have provided important results [

16]. The high-density resistivity method has been widely employed in fields such as resource exploration, hydrogeological surveys, and engineering geological evaluation, owing to its cost-effectiveness, efficiency, and non-destructive nature [

17,

18,

19]. Li et al. [

20] elaborated on the application of the high-density resistivity method in slope management: using a Wenner array to map resistivity profiles, they effectively assessed landslide stability and proposed targeted management strategies. Li CZ et al. [

21] utilized clay as a conductive medium to enhance electrode grounding performance, successfully applying high-density electrical technology to detect subgrade faults. However, current traditional cement-based grouting materials lack conductivity, which means the high-density resistivity method cannot reflect the internal conditions of grouting through electrical properties [

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24,

25]. When addressing issues like structural damage (e.g., cracks, deformation, and strength degradation), it remains necessary to embed additional sensors (such as strain gauges). This approach not only incurs high costs but may also compromise the structural integrity. Therefore, the development of new conductive cement-based grouting materials is imperative.

In this study, based on traditional cement grouting materials, functional components such as chopped carbon fibers and polymer water-absorbent resin were incorporated to modify the material properties. The optimal formulation of the novel conductive cement-based grouting material was determined by evaluating three key factors: initial setting time, fluidity, and compressive strength. Additionally, investigations were conducted on resistivity variations under different conditions, including chopped carbon fiber dosage, curing duration, temperature changes, and working pressure, alongside on-site testing. It was verified that this conductive cement grouting material enables the detection of grouting effectiveness through the “continuity of conductive paths.” A uniform resistivity distribution indicates sufficient slurry diffusion and complete filling; localized changes in resistivity may suggest hollow or unfilled zones, which can be promptly addressed through supplementary grouting. The development of this new conductive cement-based grouting material significantly enhances the controllability of grouting quality. Compared to traditional cement grouting materials, its advantages are primarily manifested in aspects such as ease of detection and improved performance.

3. Study on Conductivity of Conductive Cement-Based Grouting Materials

3.1. Effect of Curing Age on Electrical Conductivity

Carbon fiber is widely used in composites as a material with good electrical conductivity. The materials used in the test include ordinary silicate cement, short-cut carbon fibers (0.2 wt%, 0.8 wt% and 1.2 wt%), high water-absorbent resin (0.4 wt%), high-efficiency water-reducing agent (0.25 wt%), and water. The water–cement ratio was 0.8. According to the above materials and ratios, conductive cementitious grouting material specimens were made to test the effect of age on the electrical properties, and the conductivity test was carried out by curing to the age of 1d, 3d, 7d, 14d, 21d and 28d.

Figure 6 shows the variation in volume resistivity of the specimens at different ages (1d, 3d, 7d, 14d, 21d, 28d) in the conservation process.

Figure 6 shows the variation in volume resistivity of the specimens at different curing ages (1, 3, 7, 14, 21, and 28 days). Overall, the resistivity of the conductive cementitious grouting material exhibits a clear time-dependent trend: it gradually increases with curing age. Before 7 days, resistivity rises rapidly, after which the growth slows down and tends to stabilize.

This behavior can be attributed to the progressive hydration of cement clinker, which alters the distribution of water molecules, promotes gel formation, and gradually reduces the continuity of conductive pathways. As hydration proceeds, pores and capillaries become increasingly filled, reducing available conduction channels and thus increasing resistivity. Once hydration reaches a steady state, the internal microstructure stabilizes, leading to smaller resistivity changes.

Although this mechanism can be reasonably inferred from hydration chemistry, direct microstructural observation was not conducted in this study. Future work will incorporate scanning electron microscopy (SEM) to visualize fiber distribution and conductive pathway evolution, providing further validation of the proposed explanation.

3.2. Effect of Temperature on Electrical Conductivity

The electrical conductivity of carbon fibers is temperature-dependent: while it remains relatively stable at room temperature, it increases as temperature rises.

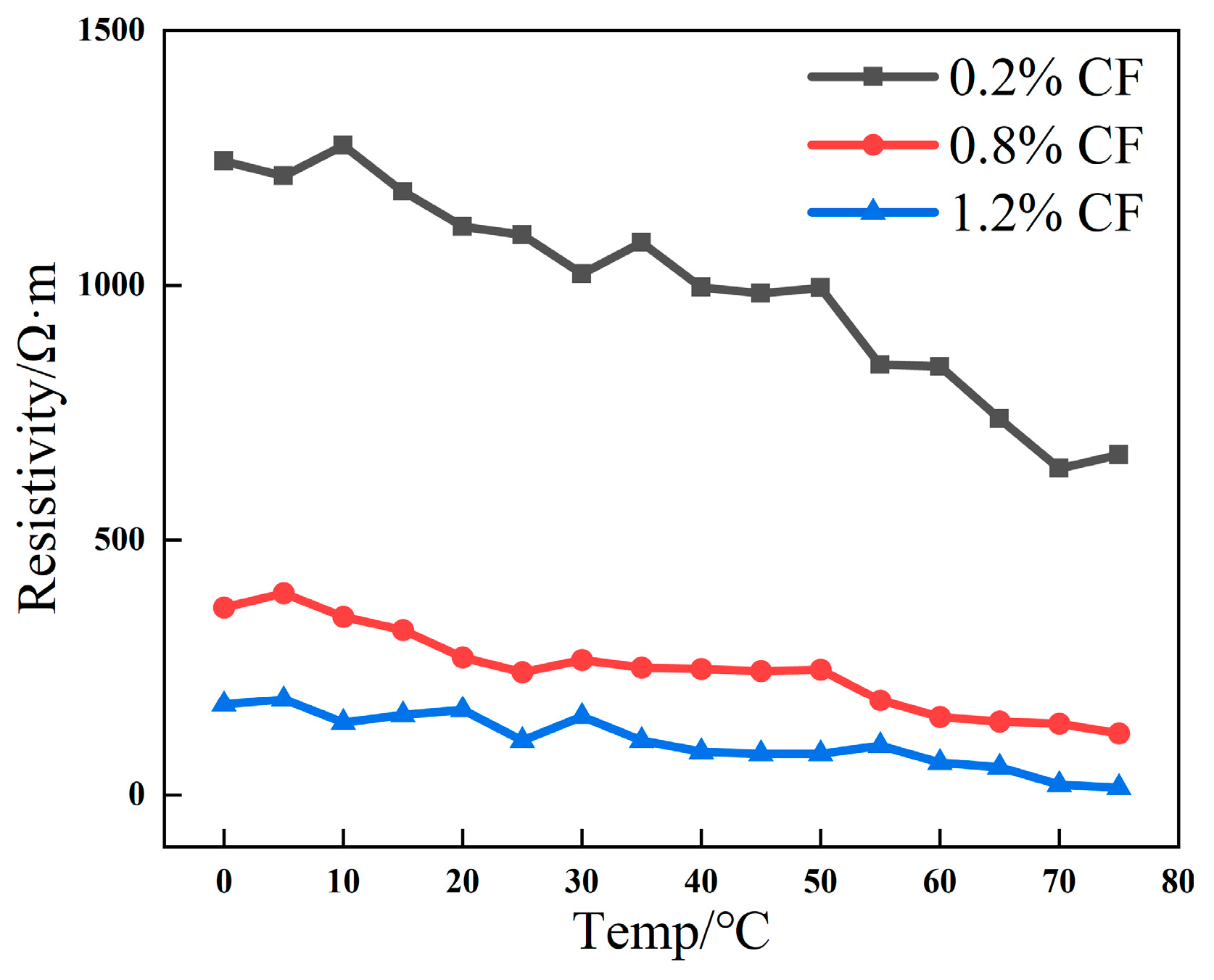

As illustrated in

Figure 7, in this test, the conductive cementitious grouting material specimens were connected to a preset circuit with a stable 12-volt direct current (12VDC) power supply. A DW-40 low-temperature test chamber (Weike Technology, Beijing, China) was used as the temperature control device to precisely regulate the ambient temperature. The temperature was increased incrementally by 5 °C each time until reaching 75 °C, at which point the test was terminated. For each set temperature, the specimen was held at that temperature for 5 min to ensure uniform and stable internal temperature distribution before recording the ammeter and voltmeter data.

The resistivity variation in the conductive cementitious specimens with temperature is presented in

Figure 8. The results show that resistivity decreases with rising temperature, demonstrating a negative temperature coefficient effect. The decrease is more pronounced in specimens with lower fiber content (0.2 wt%), where the initial conductive network is sparse. As temperature increases, electron mobility is enhanced, and thermal energy promotes more effective contact between dispersed fibers, thereby improving conductivity.

This phenomenon can be explained by electron migration and the progressive formation of new conductive paths under elevated temperatures. The voltage field further accelerates electron motion, linking previously isolated conductive particles and strengthening the overall conductive network. This phenomenon arises not only from the intrinsic conductivity of carbon fibers but also from the combined influence of the cement matrix and the fiber–matrix interface. As temperature increases, electron mobility in carbon fibers improves, while ionic conduction in the cementitious pore solution also becomes more active. Furthermore, electrochemical interactions at the fiber–matrix interface promote better charge transfer and enhance the continuity of conductive pathways. Therefore, the observed negative temperature coefficient effect results from the coupled action of fiber conductivity, matrix ionic transport, and interfacial electrochemical processes, rather than from fiber properties alone.

However, in this study, no SEM data were collected to directly observe fiber distribution or conductive pathway changes with temperature. The explanation is therefore limited to a phenomenological level. Future work will incorporate SEM imaging to provide direct evidence of fiber connectivity and microstructural changes that underlie the observed resistivity–temperature relationship.

3.3. Changes in Electrical Conductivity Under the Working Condition

As a key functional property of conductive cementitious grouting materials, pressure sensitivity reflects the dynamic changes in the electrical resistivity of specimens during loading. In this study, pressure sensitivity tests were conducted on such specimens under uniaxial compression.

During the pressure sensitivity test, core data including the stress distribution and compression duration of the cementitious specimens were output and collected using an EHC-3100 press (Hangzhou Xingao Technology Co., Ltd., Hangzhou, China). The raw data were further converted into more intuitive stress–strain values. Additionally, the readings from the voltmeter and ammeter were recorded; the resistivity of the specimens was calculated using Equations (1) and (2), and the relative rate of change in resistivity (

FCR) was derived via Equation (3).

where

R—Test resistance of the specimen; (Ω)

U—Test voltage of the specimen; (V)

I—Test current of the specimen. (A)

where

ρ-volume resistivity of the specimen (Ω·m);

R—test resistance of the specimen (Ω);

S—cross-sectional area of the surface of the specimen (m2);

L1—spacing between the two electrodes of the specimen (m).

where

ρ0—resistivity of the specimen when no load is applied (Ω·m);

ρm—resistivity of the specimen when load is applied (Ω·m).

The sensitivity of conductive cementitious grouting material specimens is specifically characterized by calculating the ratio of the strain change in the specimen during loading to the corresponding resistivity change. This ratio intuitively reflects the dynamic correlation degree between the electrical and mechanical properties of the specimen under stress, and it is calculated using Equation (4).

where

ε is the uniaxial compressive strain value of the specimen.

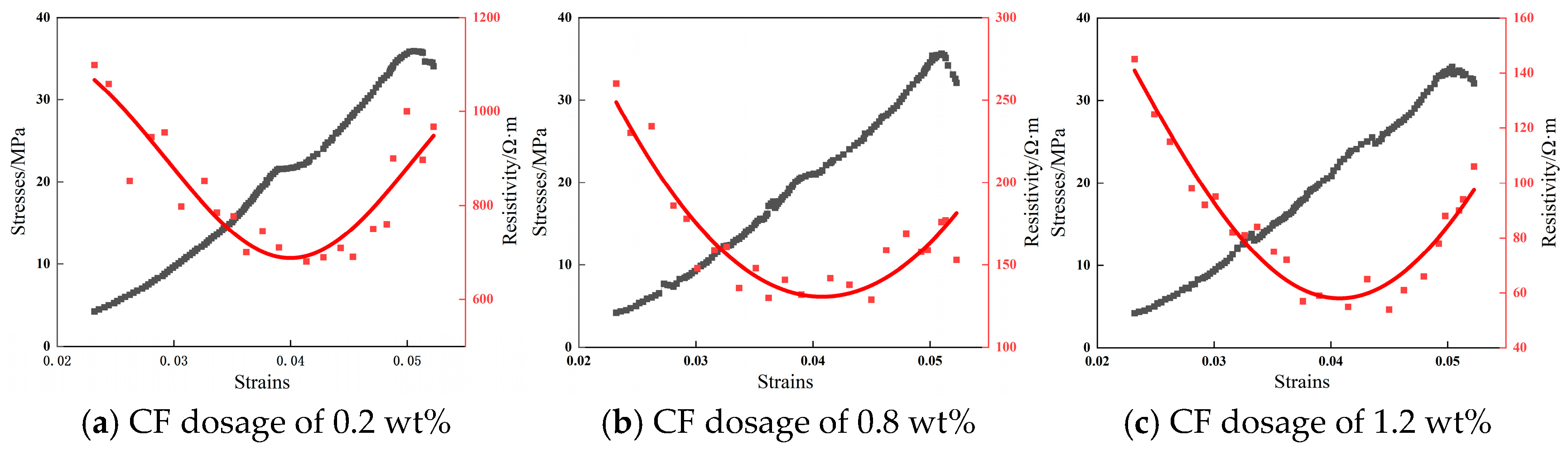

Figure 9 shows the graph of the effect of the deformation of the internal structure of the specimen on the electrical conductivity of the material under three kinds of CF doping:

As shown in

Figure 9, the resistivity of the conductive cementitious specimens first decreases with increasing applied stress and then increases once damage and crack propagation occur. To provide a quantitative evaluation of this pressure-sensitive behavior, the gauge factor (

GF) was introduced as a sensitivity index.

GF is defined as follows:

where

ρ0 is the initial resistivity at zero strain,

ρ(ε) is the resistivity at strain

ε, and Δ

ρ =

ρ(

ε) −

ρ0. Pointwise

GF values were calculated from the GaussAmp-fitted resistivity–strain data for each specimen. The results demonstrate distinct sensitivity levels: specimen 9a shows relatively low sensitivity with

GF values between −0.6 and +1.2, reflecting the transition from compaction-induced resistivity reduction to crack-induced resistivity growth. Specimen 9b exhibits the highest sensitivity, with

GF values around −16 to −17, indicating a pronounced resistivity decrease with strain due to enhanced conductive fiber network contacts. Specimen 9c shows an intermediate response, with

GF ranging from approximately ×13 to −15 in the early stage, and gradually approaching −5 at larger strains, corresponding to the transition from network densification to crack formation.

These results confirm that the conductive cement-based grout not only demonstrates qualitative pressure-sensitive characteristics but also achieves quantifiable self-sensing performance. Compared with traditional cementitious materials (typically exhibiting negligible sensitivity, GF ≈ 0), the obtained GF values highlight the potential of the developed conductive grout for accurate stress monitoring and structural health sensing applications.

Verification showed that specimens with 0.8 wt% and 1.2 wt% chopped carbon fiber (CF) doping exhibited better conductivity, while those with 0.2 wt% CF had poorer conductivity. As discussed in

Section 2, the grouting material performs optimally when CF doping is 0.8 wt%. Therefore, the CF doping amount for the cement grout in this study was set at 0.8 wt%.

4. Field Test for Detecting the Effect of Grouting Based on High-Density Electrical Method

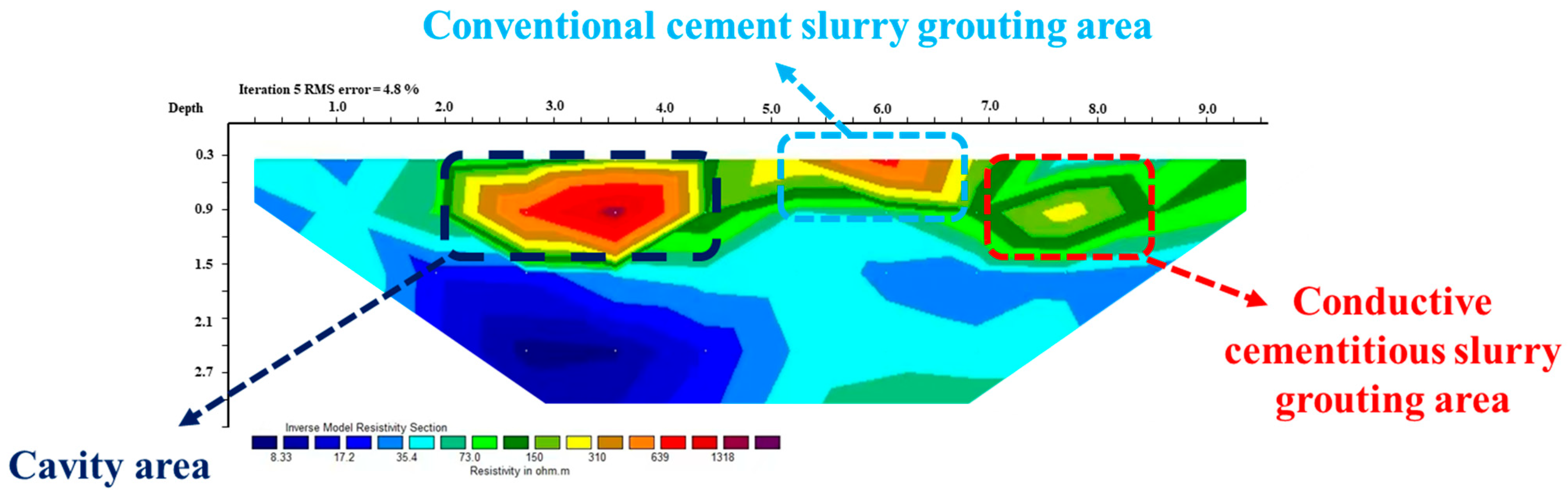

Based on the high-density electrical method detection, a field test for detecting the grouting effect of the caverns was carried out to simulate the field grouting conditions, and the three caverns were treated with no grouting, ordinary cement slurry grouting and conductive cement-based slurry grouting, and then the grouting effect of each cavern was detected by the high-density electrical method.

The test site of this study is located in an open area in Changqing District, Jinan City, Shandong Province, China, where the geological conditions are dominated by sandy clay, with a natural water content of 11.4% and a resistivity of 100 Ω-cm. Three cavern zones were constructed within the test site, labeled as 1# empty cavern zone, 2# conventional grouting zone, and 3# conductive grouting zone, and the specific geometrical parameters of each cavern are shown in

Figure 10. The 1# void area did not implement a grouting treatment, simulating the original cave state without filler, as a baseline control group, used to quantitatively assess the reinforcement effect of other grouting treatment areas; 2# conventional grouting area used conventional cement-based slurry grouting operations, as a control experimental group for 3# conductive grouting area and as a comparison; 3# conductive grouting area is injected with self-developed conductive cement-based slurry, as a core experimental group. The research team used the high-density electrical method to carry out non-destructive testing of the grouting effect in the three test areas. By determining the resistivity distribution inside the caverns in different areas, the research team compared and analyzed the differences in resistivity characteristics between unfilled caverns, conventional cement-based grouting bodies, and conductive cement-based grouting bodies, and then assessed the quality of the grouting.

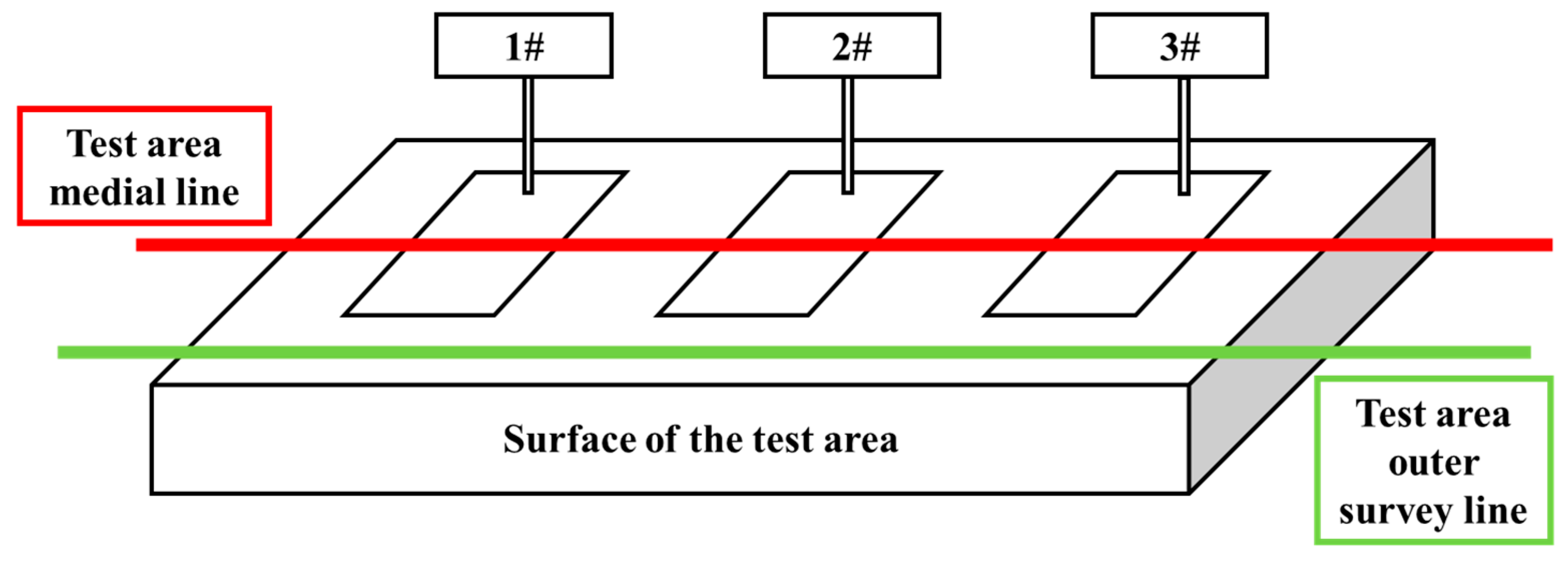

The test line on the outside of the test area, with a length of 60 m, is arranged on the outside of the test area, and the test line on the inside of the test area, with a length of 36 m, is arranged through the test area, and the layout of the test line is shown in

Figure 11.

Figure 12 displays the outer measurement line of the test area. At locations close to the test area, the apparent resistivity shows no obvious abnormalities and changes relatively uniformly. In contrast, the section in

Figure 13 exhibits two distinct high-resistance anomalous responses within the test area.

In

Figure 13, the cavity area contains air, a non-conductive high-resistance medium. Because the interior is air or water, it shows very poor conductivity and appears as a high-resistivity anomaly in the resistivity profile. Within the depth range of approximately 0.85–1.4 m in the cross-section map, the apparent resistivity shows an obvious high-resistance reaction, with contour lines presenting closed circular changes. This is analyzed to be due to a relatively large degree of voids.

The conventional cement slurry grouting area is filled with conventional cement slurry. Conventional cement, together with the surrounding soil layer, forms a high-resistance reaction. Ordinary cement slurry has no conductivity, so its resistivity is relatively high and close to that of the surrounding soil. Therefore, it appears as a medium-to-high resistivity zone, making it difficult to distinguish whether the cavity is fully filled.

The conductive cementitious slurry material exhibits obvious resistivity differences not only from conventional cement slurry but also from ordinary soil layers. With the addition of chopped carbon fibers and other conductive components, the material exhibits low resistivity, which is significantly different from both the cavity area and conventional cement grout. This distinct electrical property verifies the feasibility of using conductive cementitious grouting material as a precise grouting material—its unique resistivity signature allows for clear identification and differentiation in practical applications, laying a foundation for accurate monitoring and evaluation of grouting effects.

5. Conclusions

In this paper, conductive cement-based grouting materials were developed and tested, with the construction process optimized based on material characteristics. The high-density electrical method was applied to achieve precise control of grouting and evaluation of filling effects. The main findings are as follows:

- (1)

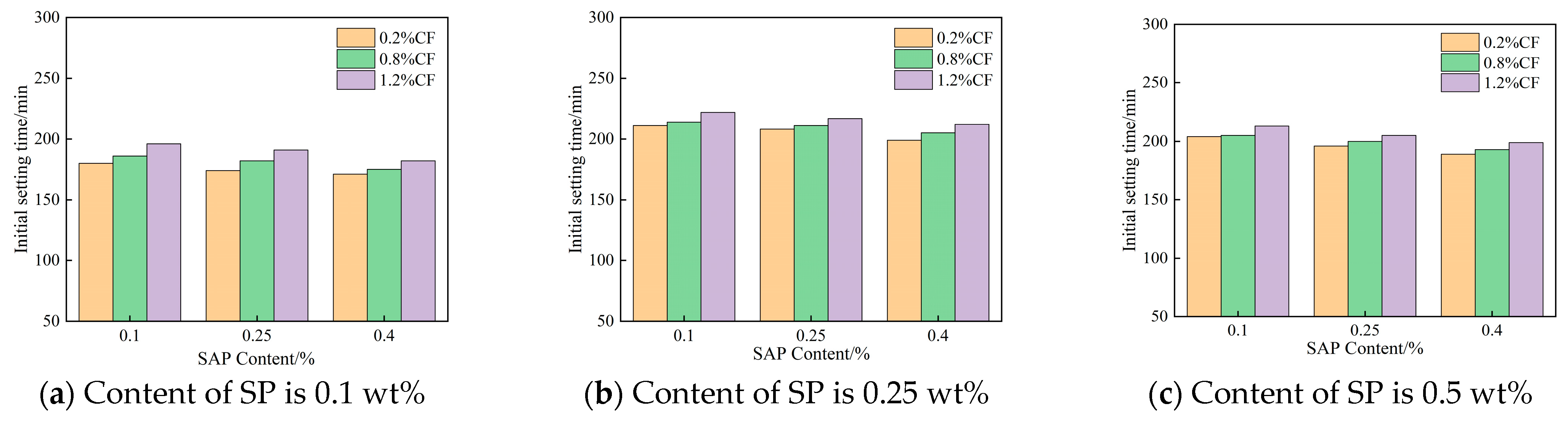

Multi-factor analysis clarified the influences of polymer admixture components on the setting time, fluidity, bleeding rate, and compressive strength of fresh cement slurry. The optimal mix ratio was determined as: 0.4 wt% superabsorbent resin, 0.25 wt% high-range water-reducing agent, 0.8 wt% short-cut carbon fibers, and a water–cement ratio of 0.8.

- (2)

With curing age, the volume resistivity of the specimens gradually increased. The resistivity decreased with rising temperature, showing a negative temperature coefficient effect. The incorporation of carbon fibers enhanced conductivity, with diminishing returns when the fiber content exceeded a certain threshold.

- (3)

Conductive grouting specimens exhibited pressure-sensitive properties: resistivity decreased with stress in the initial compaction stage and increased after crack initiation. Quantitative analysis using the gauge factor (GF) confirmed that the material demonstrates measurable sensitivity, with specimens showing different levels of response depending on fiber distribution and structural condition.

- (4)

Field tests using high-density electrical detection confirmed that the conductive grout can be effectively applied for assessing grouting integrity and identifying potential damage, thus enabling self-sensing capability without the need for embedded sensors.

In practical engineering applications, several issues require further attention. First, the uniform distribution of conductive fibers at large volumes must be ensured through optimized mixing and construction techniques. Second, the long-term durability of electrical conductivity under aggressive environmental conditions, including potential corrosion, should be systematically evaluated. Third, calibration procedures for different geological settings should be developed to ensure reliable monitoring. These aspects were beyond the scope of the present study but will be the focus of future work.