Heat-Stored Engineered Cementitious Composite Containing Microencapsulated n-Octadecane with Cenosphere Shell

Abstract

1. Introduction

2. Materials and Methods

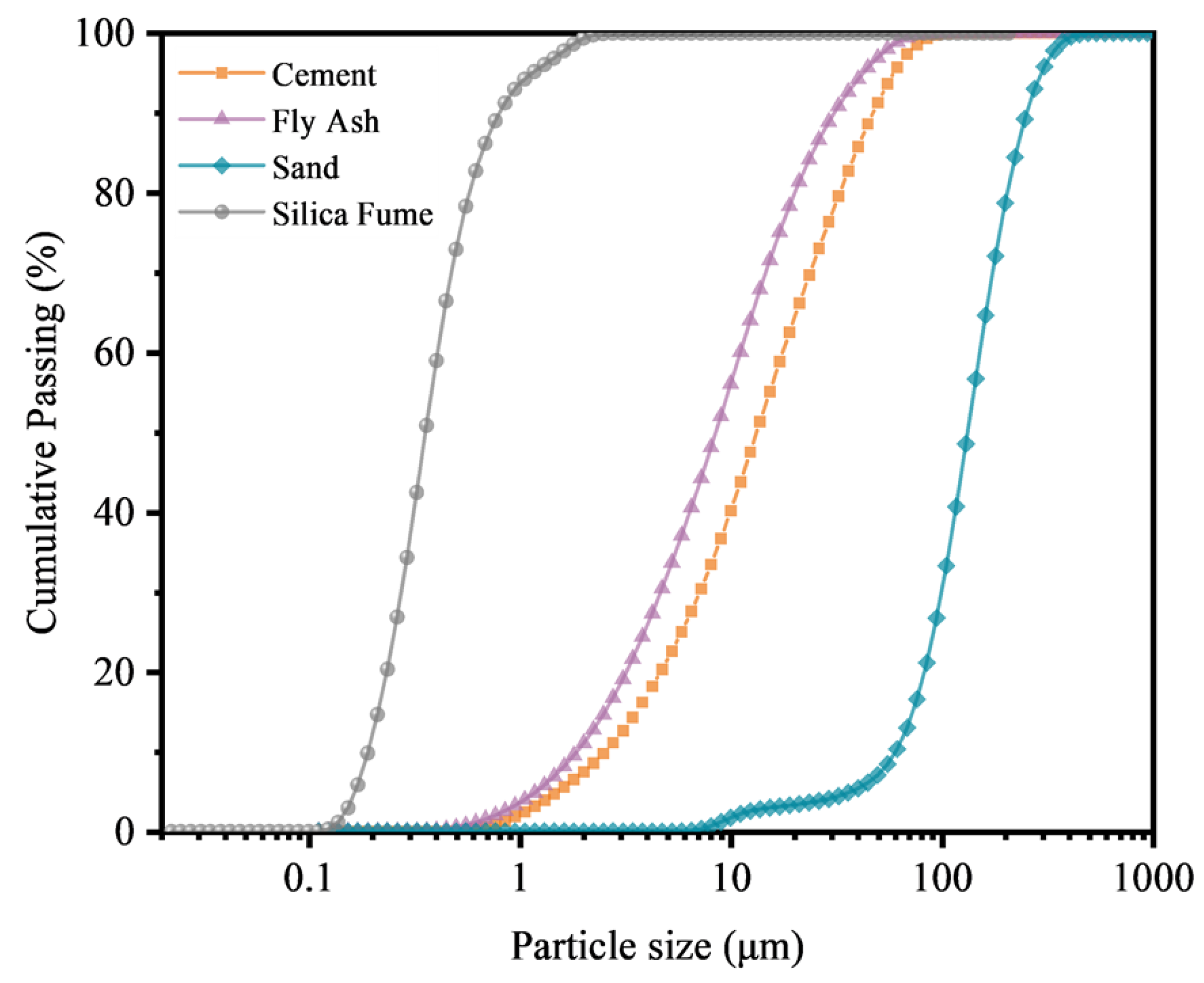

2.1. Raw Materials

2.2. Preparation of ODE/FAC Composite PCM

2.3. Mixed Proportion of Heat-Stored ECC

2.4. Testing Methods

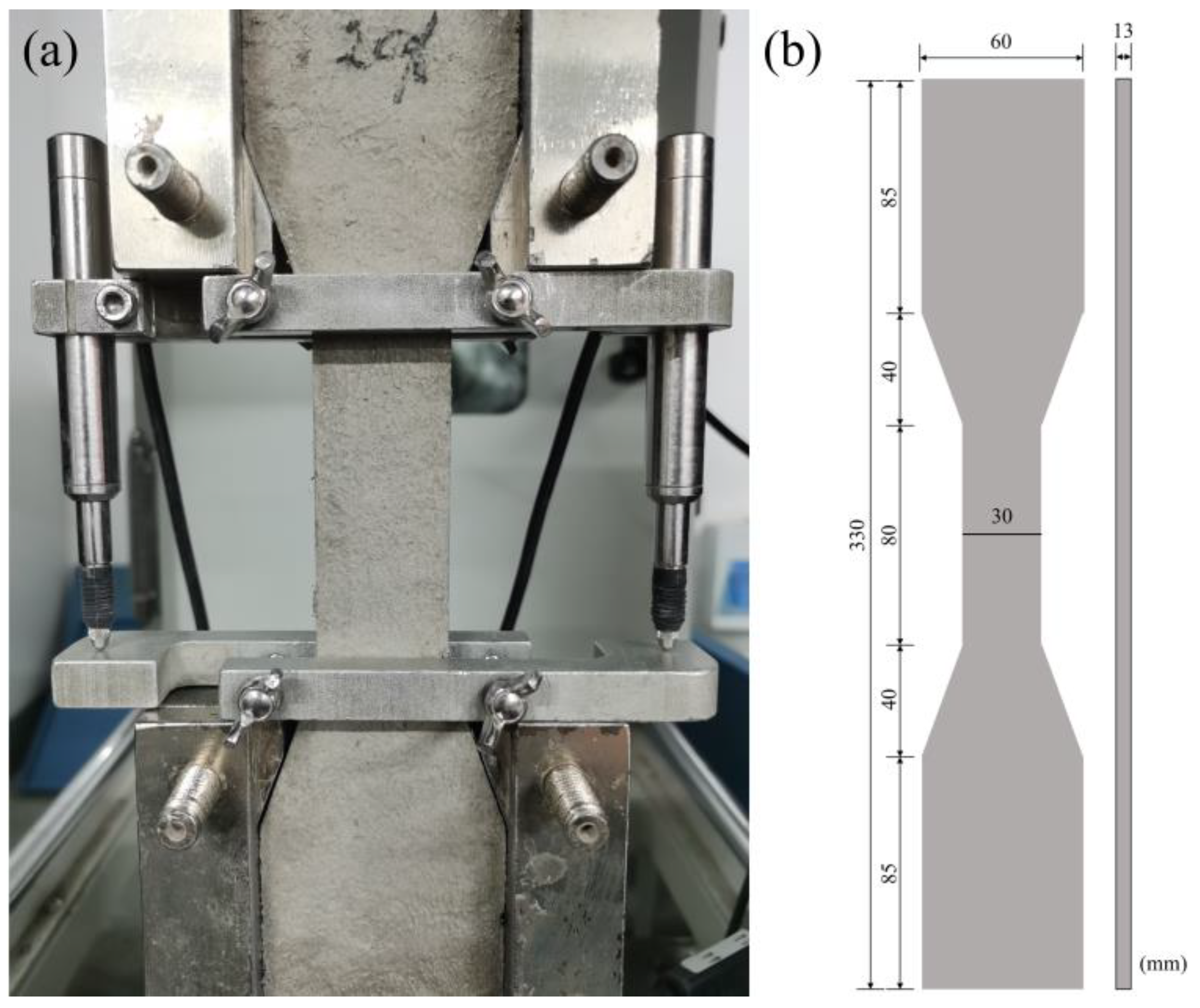

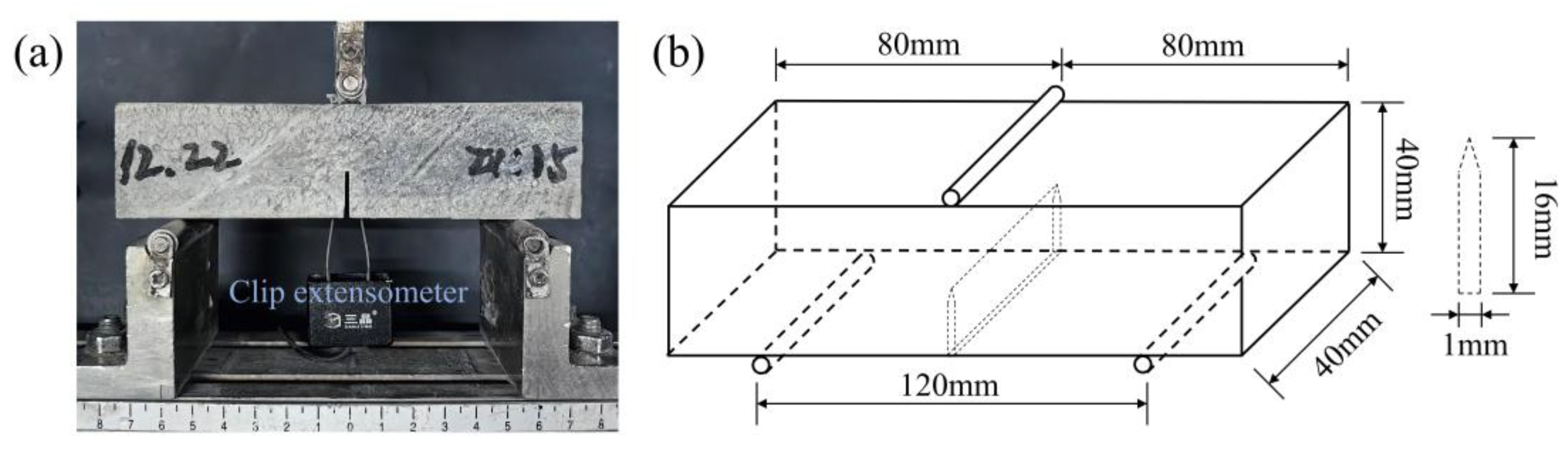

2.4.1. Mechanical Tests

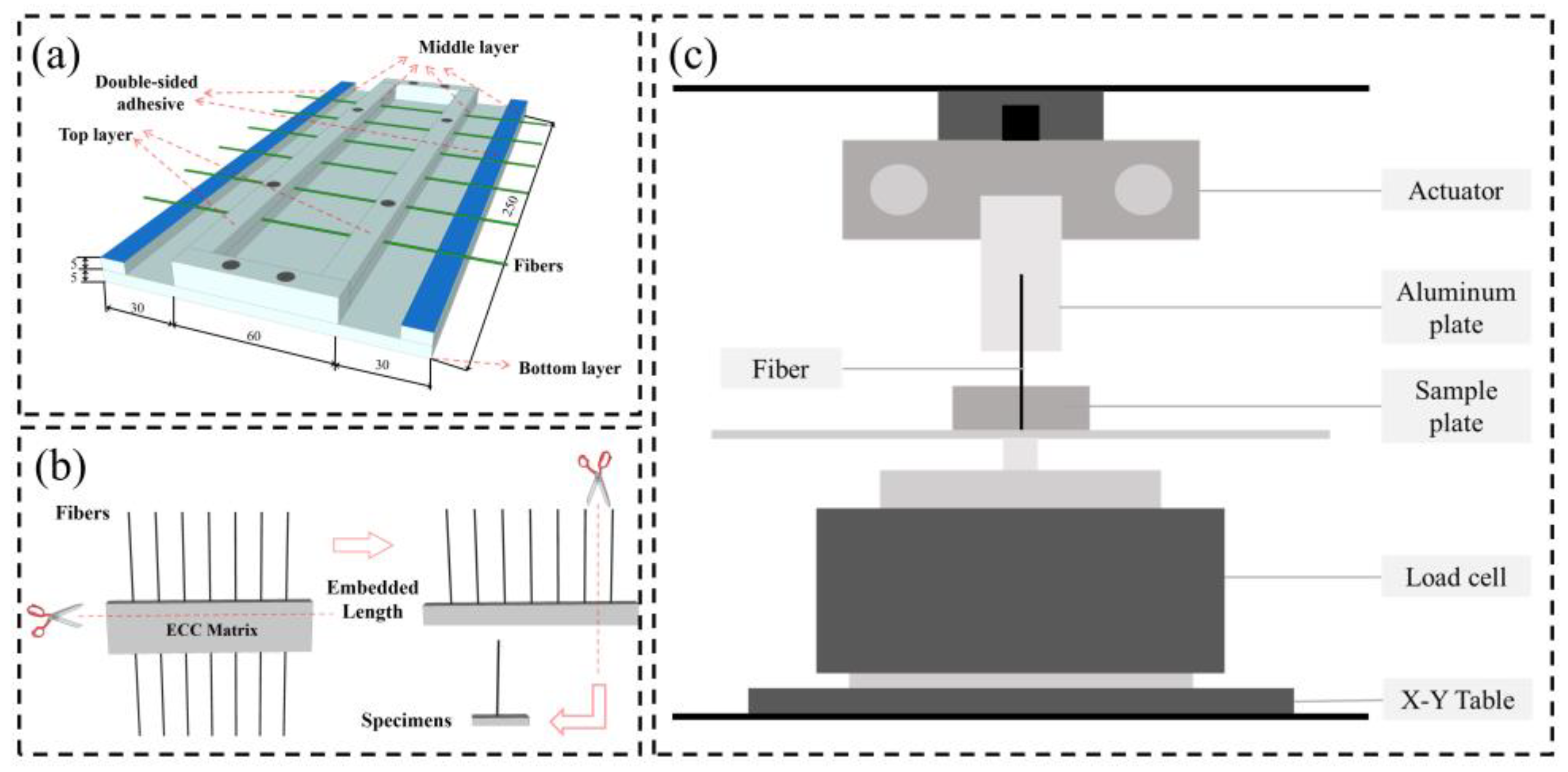

2.4.2. Single-Fiber Pullout Test

2.4.3. Characterization Methods

3. Results and Discussion

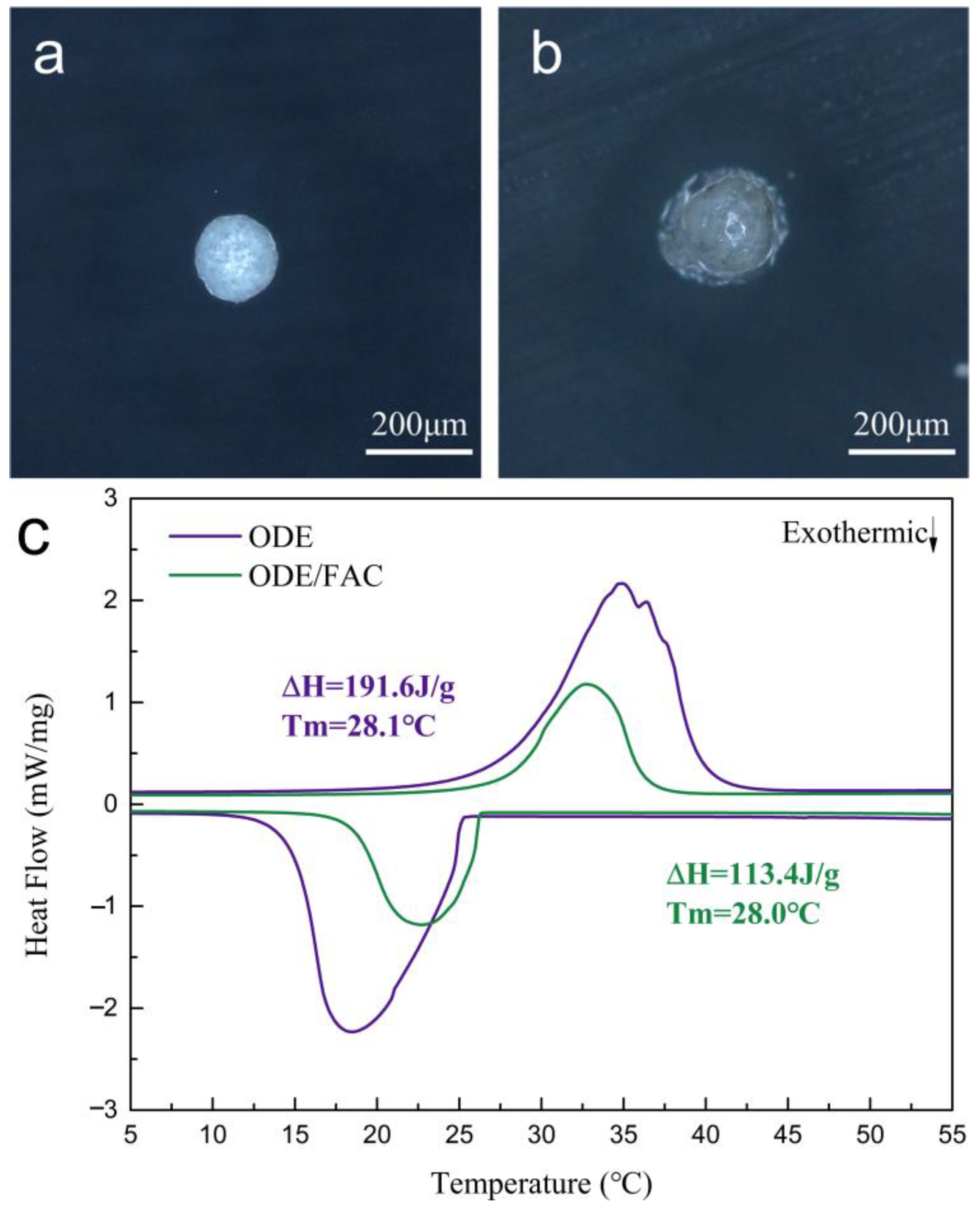

3.1. Micromorphology and Phase Transition Properties of ODE/FAC

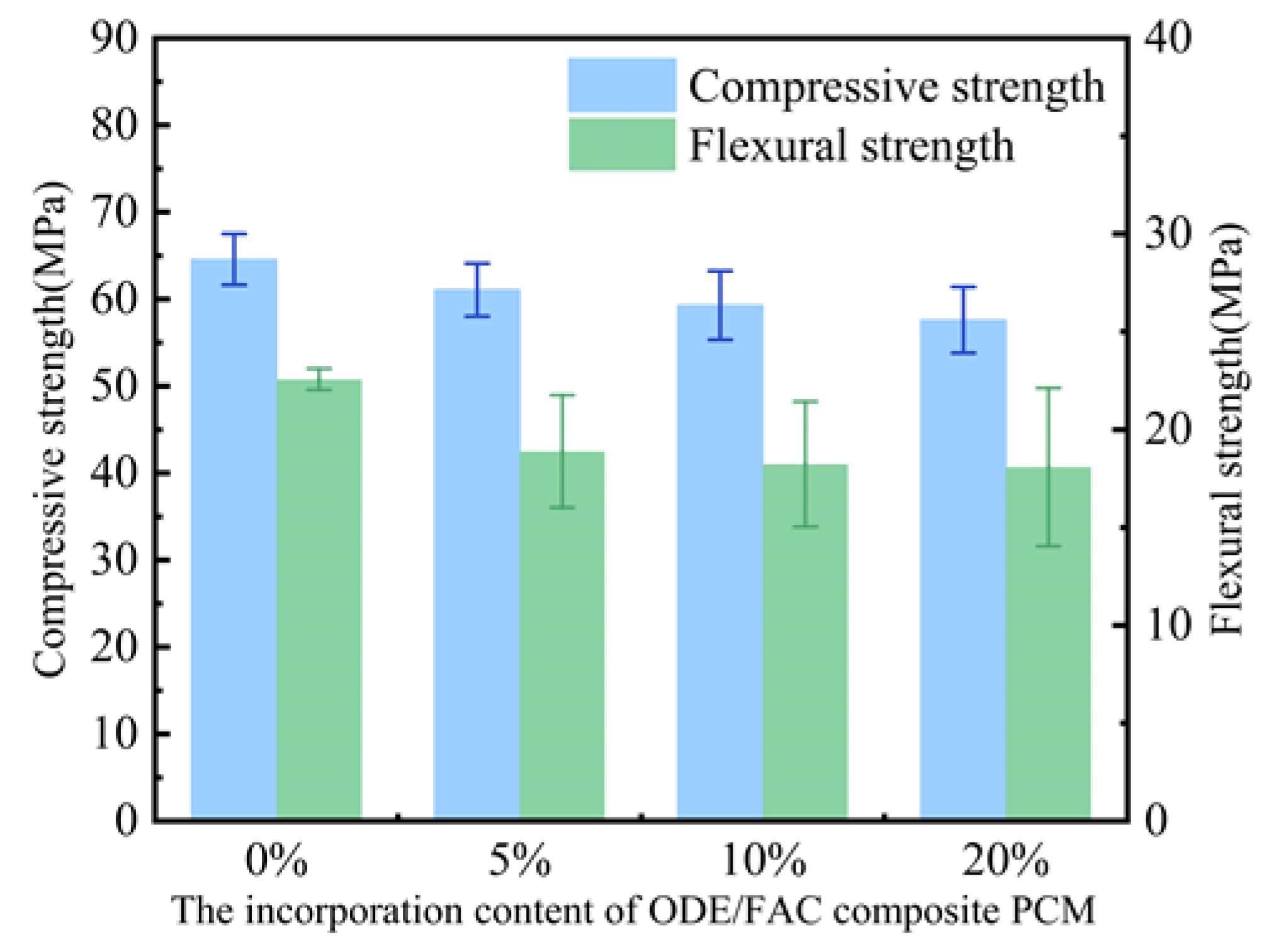

3.2. Flexural Strength and Compressive Strength of Heat-Stored ECC

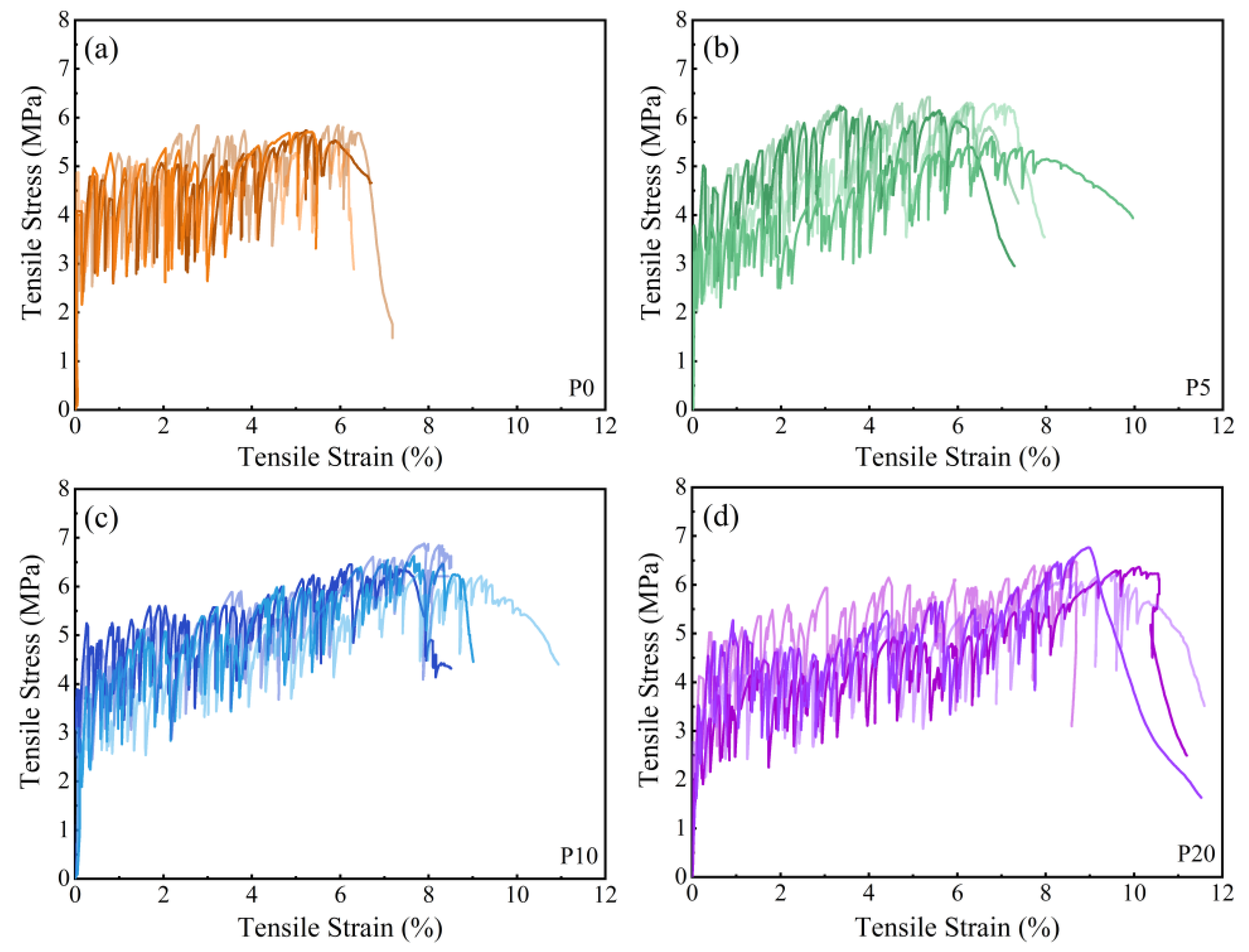

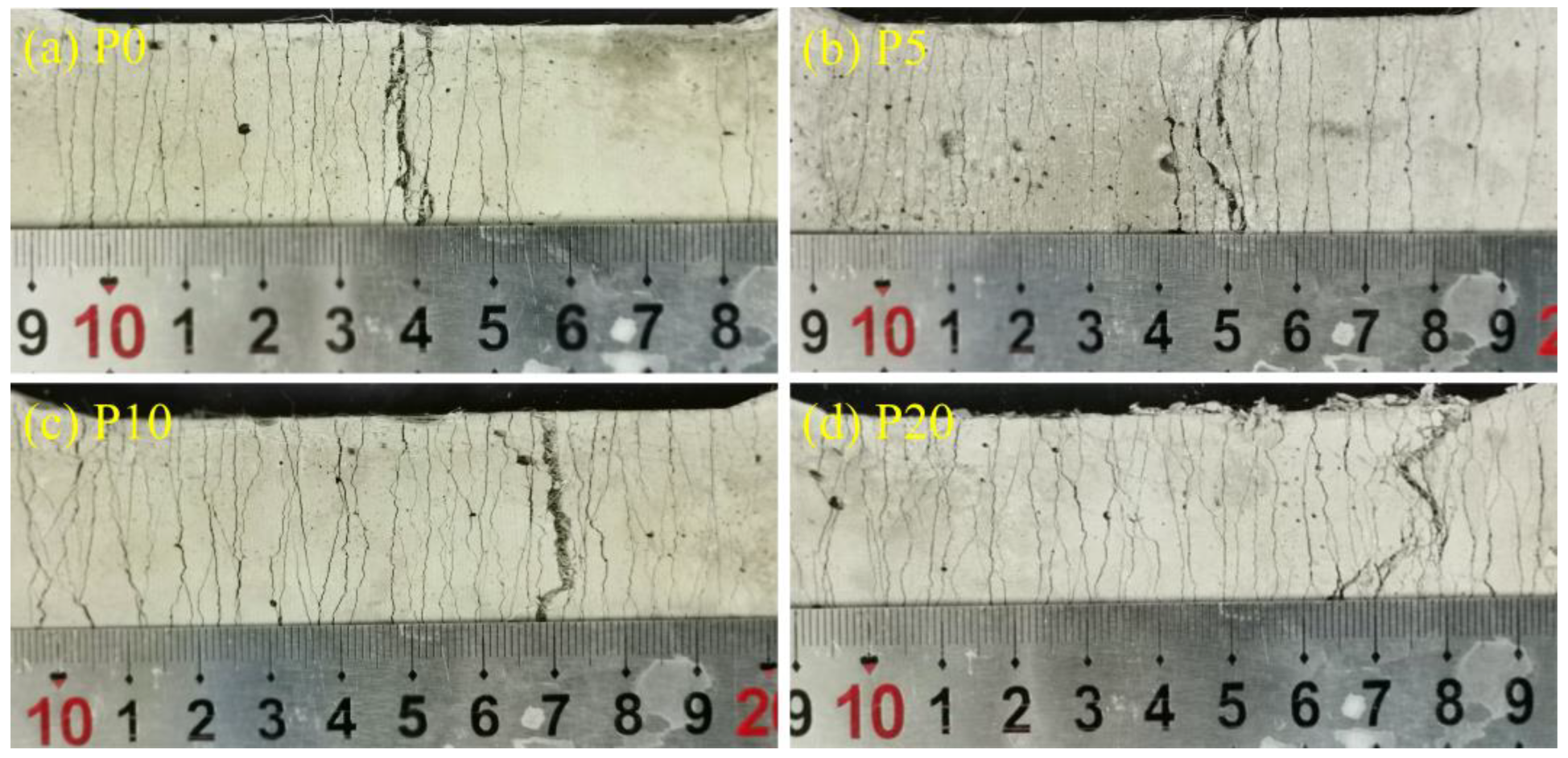

3.3. Uniaxial Tensile Properties

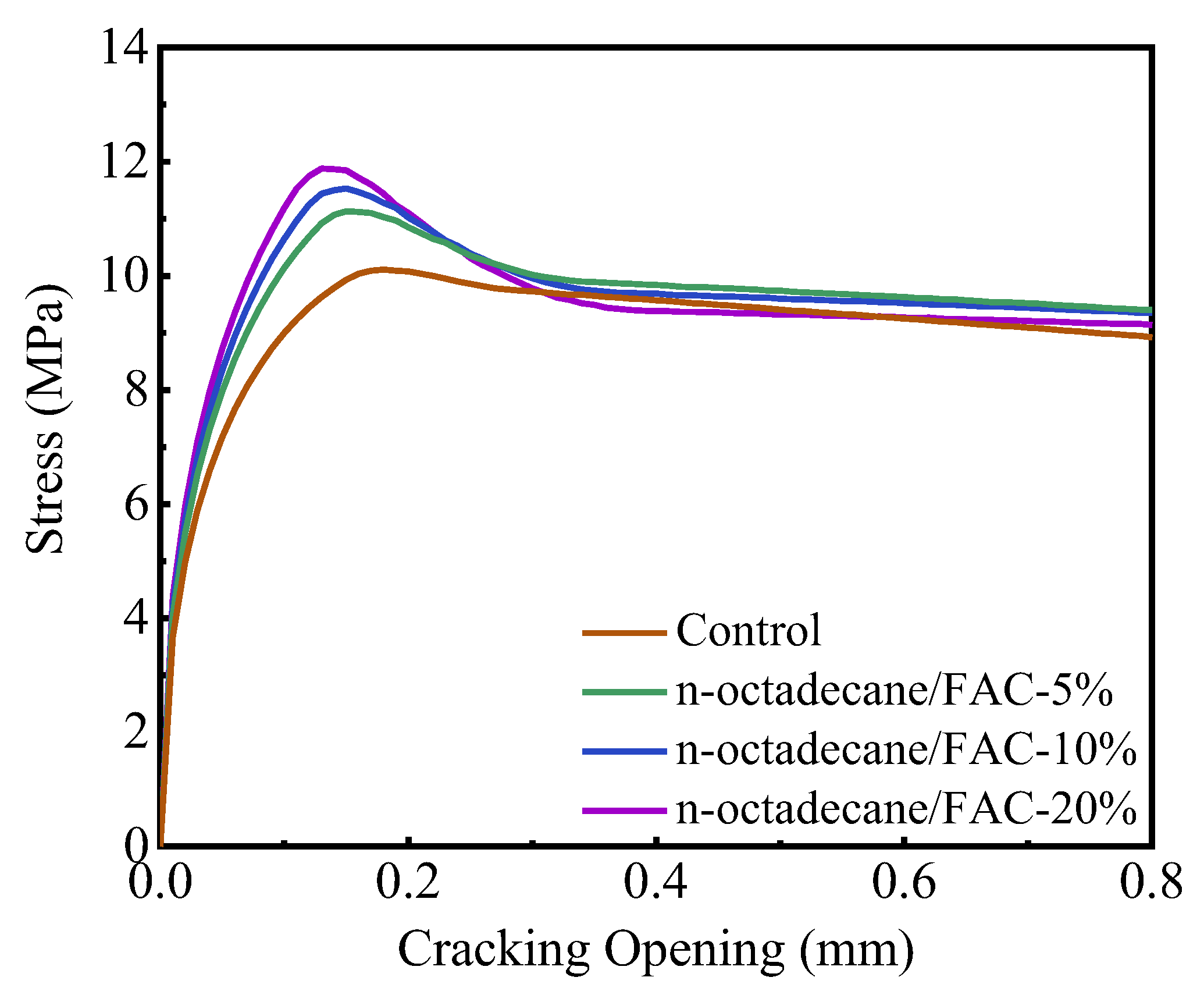

3.4. Micromechanical Analysis

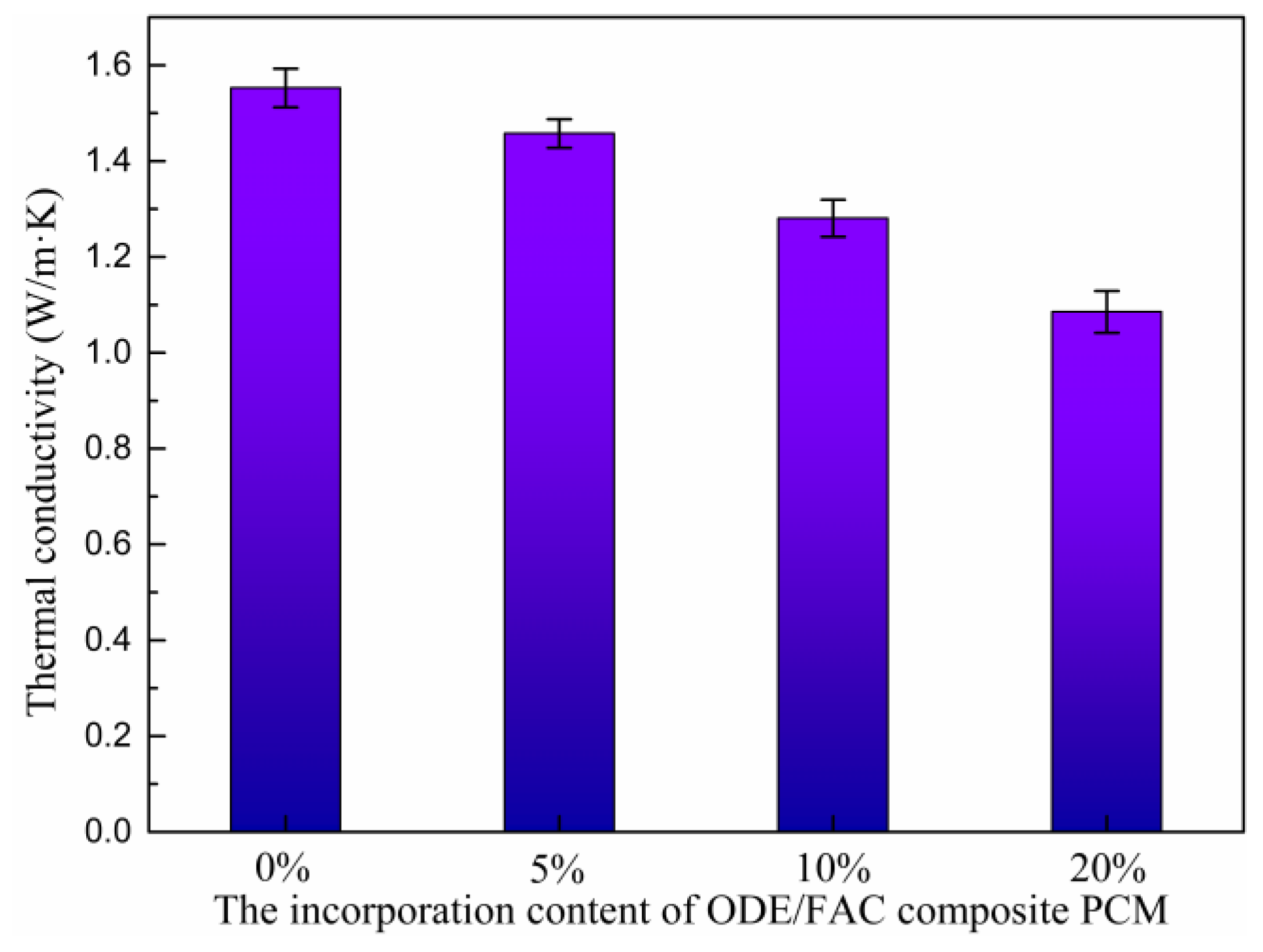

3.5. Thermal Conductivity of Heat-Stored ECC

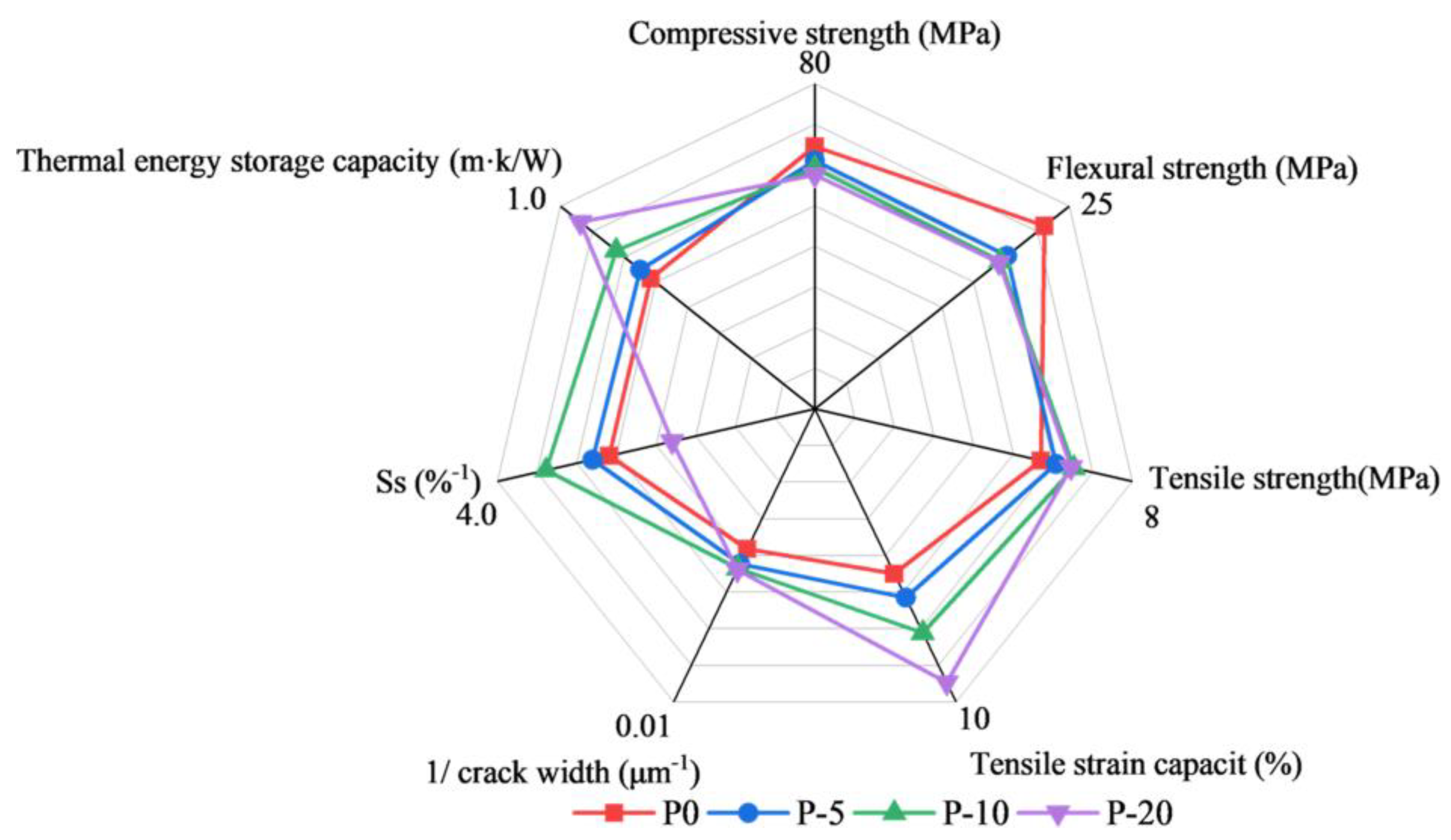

3.6. Evaluating the Effect of ODE/FAC Composite PCM on the Performance of Heat-Stored ECC

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ma, M.; Ma, X.; Cai, W.; Cai, W. Carbon-dioxide mitigation in the residential building sector: A household scale-based assessment. Energy Convers. Manag. 2019, 198, 111915. [Google Scholar] [CrossRef]

- Yu, K.; Jia, M.; Tian, W.; Yang, Y.; Liu, Y. Enhanced thermo-mechanical properties of cementitious composites via red mud-based microencapsulated phase change material: Towards energy conservation in building. Energy 2024, 290, 130301. [Google Scholar] [CrossRef]

- Xu, B.; Li, Z. Performance of novel thermal energy storage engineered cementitious composites incorporating a paraffin/diatomite composite phase change material. Appl. Energy 2014, 121, 114–122. [Google Scholar] [CrossRef]

- Yu, K.; Jia, M.; Liu, Y.; Yang, Y. Binary decanoic acid/polyethylene glycol as a novel phase change material for thermal energy storage: Eutectic behaviors and energy conservation evaluation. J. Energy Storage 2023, 68, 107663. [Google Scholar] [CrossRef]

- Mohtasim, M.S.; Das, B.K. MXene based composite phase change materials for thermal energy storage applications: Featuring bio-mimic approaches. Renew. Sustain. Energy Rev. 2025, 207, 114952. [Google Scholar] [CrossRef]

- Yu, K.; Liu, C.; Li, L.; Tian, W.; Yang, Y.; Liu, Y. Carbon-negative heat-stored limestone calcined clay cement mortar containing form-stable phase change materials. J. Clean. Prod. 2024, 437, 140703. [Google Scholar] [CrossRef]

- Yu, K.; Liu, Y.; Jia, M.; Wang, C.; Yang, Y. Thermal energy storage cement mortar containing encapsulated hydrated salt/fly ash cenosphere phase change material: Thermo-mechanical properties and energy saving analysis. J. Energy Storage 2022, 51, 104388. [Google Scholar] [CrossRef]

- Wong, W.P.; Kagalkar, A.; Patel, R.; Patel, P.; Dharaskar, S.; Walvekar, R.; Khalid, M.; Gedam, V.V. Nano-enhanced phase change materials for thermal energy storage: A comprehensive review of recent advancements, applications, and future challenges. J. Energy Storage 2023, 74, 109265. [Google Scholar] [CrossRef]

- Junaid, M.F.; Rehman, Z.U.; Ijaz, N.; Farooq, R.; Khalid, U.; Ijaz, Z. Performance evaluation of cement-based composites containing phase change materials from energy management and construction standpoints. Constr. Build. Mater. 2024, 416, 135108. [Google Scholar] [CrossRef]

- Li, M.; Shi, J. Review on micropore grade inorganic porous medium based form stable composite phase change materials: Preparation, performance improvement and effects on the properties of cement mortar. Constr. Build. Mater. 2019, 194, 287–310. [Google Scholar] [CrossRef]

- Lee, J.; Wi, S.; Yun, B.Y.; Yang, S.; Park, J.H.; Kim, S. Development and evaluation of gypsum/shape-stabilization phase change materials using large-capacity vacuum impregnator for thermal energy storage. Appl. Energy 2019, 241, 278–290. [Google Scholar] [CrossRef]

- Drissi, S.; Mo, K.H.; Falchetto, A.C.; Ling, T.-C. Understanding the compressive strength degradation mechanism of cement-paste incorporating phase change material. Cem. Concr. Compos. 2021, 124, 104249. [Google Scholar] [CrossRef]

- Jia, M.; Yu, K.; Liu, Y.; Yang, Y. Enabling superior thermo-mechanical performance of hydrated salt-based phase change energy storage cementitious composite using graphene oxide reinforced micro-interface. J. Build. Eng. 2023, 76, 107166. [Google Scholar] [CrossRef]

- Zhang, D.; Yu, J.; Wu, H.; Jaworska, B.; Ellis, B.R.; Li, V.C. Discontinuous micro-fibers as intrinsic reinforcement for ductile Engineered Cementitious Composites (ECC). Compos. Part B Eng. 2020, 184, 107741. [Google Scholar] [CrossRef]

- Yu, J.; Yao, J.; Lin, X.; Li, H.; Lam, J.Y.K.; Leung, C.K.Y.; Sham, I.M.L.; Shih, K. Tensile performance of sustainable Strain-Hardening Cementitious Composites with hybrid PVA and recycled PET fibers. Cem. Concr. Res. 2018, 107, 110–123. [Google Scholar] [CrossRef]

- Yu, J.; Chen, Y.; Leung, C.K.Y. Mechanical performance of Strain-Hardening Cementitious Composites (SHCC) with hybrid polyvinyl alcohol and steel fibers. Compos. Struct. 2019, 226, 111198. [Google Scholar] [CrossRef]

- Huang, B.-T.; Li, Q.-H.; Xu, S.-L.; Zhou, B.-M. Tensile fatigue behavior of fiber-reinforced cementitious material with high ductility: Experimental study and novel P-S-N model. Constr. Build. Mater. 2018, 178, 349–359. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Millon, O.; Butler, M.; Thoma, K. Mechanical behaviour of strain hardening cement-based composites under impact loading. Cem. Concr. Compos. 2011, 33, 1–11. [Google Scholar] [CrossRef]

- Zhang, H.; Liang, Q.; Shao, M.; Jiang, N.; Ma, W.; Ge, Z.; Šavija, B. Optimization of low-carbon lightweight foamed concrete using ground circulating fluidized bed fly ash. J. Clean. Prod. 2025, 489, 144697. [Google Scholar] [CrossRef]

- Yokota, H.; Rokugo, K.; Sakata, N. JSCE recommendations for design and construction of high performance fiber reinforced cement composite with multiple fine cracks. In High Performance Fiber Reinforced Cement Composites; Springer: Tokyo, Japan, 2008. [Google Scholar]

- ASTM E399-19; Standard Test Method for Plane-Strain Fracture Toughness KIc of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2019.

- Huang, B.-T.; Wu, J.-Q.; Yu, J.; Dai, J.-G.; Leung, C.K. High-Strength Seawater Sea-Sand Engineered Cementitious Composites (SS-ECC): Mechanical Performance and Probabilistic Modeling. Cem. Concr. Compos. 2020, 114, 103740. [Google Scholar] [CrossRef]

- Huang, Z.; Liang, T.; Huang, B.; Zhou, Y.; Ye, J. Ultra-lightweight high ductility cement composite incorporated with low PE fiber and rubber powder. Constr. Build. Mater. 2021, 312, 125430. [Google Scholar] [CrossRef]

- Curosu, I.; Muja, E.; Ismailov, M.; Ahmed, A.H.; Liebscher, M.; Mechtcherine, V. An Experimental-Analytical Scale-Linking Study on the Crack-Bridging Mechanisms in Different Types of SHCC in Dependence on Fiber Orientation. Cem. Concr. Res. 2022, 152, 106650. [Google Scholar] [CrossRef]

- Cheng, F.; Zhang, X.; Wen, R.; Huang, Z.; Fang, M.; Liu, Y.; Wu, X.; Min, X. Thermal Conductivity Enhancement of Form-Stable Tetradecanol/Expanded Perlite Composite Phase Change Materials by Adding Cu Powder and Carbon Fiber for Thermal Energy Storage. Appl. Therm. Eng. 2019, 156, 653–659. [Google Scholar] [CrossRef]

- Yousefi, A.; Tang, W.; Khavarian, M.; Fang, C. Development of Novel Form-Stable Phase Change Material (PCM) Composite Using Recycled Expanded Glass for Thermal Energy Storage in Cementitious Composite. Renew. Energy 2021, 175, 14–28. [Google Scholar] [CrossRef]

- Zhu, N.; Li, S.; Hu, P.; Wei, S.; Deng, R.; Lei, F. A Review on Applications of Shape-Stabilized Phase Change Materials Embedded in Building Enclosure in Recent Ten Years. Sustain. Cities Soc. 2018, 43, 251–264. [Google Scholar] [CrossRef]

- Lin, C.; Kanstad, T.; Jacobsen, S.; Ji, G. Bonding Property between Fiber and Cementitious Matrix: A Critical Review. Constr. Build. Mater. 2023, 378, 131169. [Google Scholar] [CrossRef]

- Gürbüz, E.; Erdem, S. Development and Thermo-Mechanical Analysis of High-Performance Hybrid Fibre Engineered Cementitious Composites with Microencapsulated Phase Change Materials. Constr. Build. Mater. 2020, 263, 120139. [Google Scholar] [CrossRef]

- Erdem, S.; Gürbüz, E. Influence of Microencapsulated Phase Change Materials on the Flexural Behavior and Micromechanical Impact Damage of Hybrid Fibre Reinforced Engineered Cementitious Composites. Compos. Part B Eng. 2019, 166, 633–644. [Google Scholar] [CrossRef]

- Zhang, Z.; Shen, Q.; Qin, F.; Abdalla, J.A.; Hawileh, R.A.; Xiong, Y. Expanded Vermiculite Acting as Artificial Flaws to Enhance the Tensile Properties of High-Strength Engineered Cementitious Composites. Constr. Build. Mater. 2024, 447, 138081. [Google Scholar] [CrossRef]

- Hou, M.; Xu, K.; Monteiro, P.J.M.; Li, V.C. Rubber Particle Bridging Effect on Crack Width Control of Low Carbon Engineered Cementitious Composites (ECC). Cem. Concr. Compos. 2023, 140, 105106. [Google Scholar] [CrossRef]

- Li, J.; Qiu, J.; Weng, J.; Yang, E.-H. Micromechanics of Engineered Cementitious Composites (ECC): A Critical Review and New Insights. Constr. Build. Mater. 2023, 362, 129765. [Google Scholar] [CrossRef]

- Lu, C.; Leung, C.K.Y. A New Model for the Cracking Process and Tensile Ductility of Strain Hardening Cementitious Composites (SHCC). Cem. Concr. Res. 2016, 79, 353–365. [Google Scholar] [CrossRef]

- Yang, E.-H.; Wang, S.; Yang, Y.; Li, V.C. Fiber-bridging constitutive law of engineered cementitious composites. J. Adv. Concr. Technol. 2008, 6, 181–193. [Google Scholar] [CrossRef]

- Ranade, R.; Li, V.C.; Stults, M.D.; Rushing, T.S.; Roth, J.; Heard, W.F. Micromechanics of high-strength, high-ductility concrete. ACI Mater. J. 2013, 110, 375. [Google Scholar]

- Li, V.C.; Leung, C. Steady-State and Multiple Cracking of Short Random Fiber Composites. J. Eng. Mech. 1992, 118, 2246–2264. [Google Scholar] [CrossRef]

- Kanda, T.; Li, V.C. Multiple Cracking Sequence and Saturation in Fiber Reinforced Cementitious Composites. Concr. Res. Technol. 1998, 9, 19–33. [Google Scholar] [CrossRef]

- Drissi, S.; Ling, T.-C.; Mo, K.H.; Eddhahak, A. A review of microencapsulated and composite phase change materials: Alteration of strength and thermal properties of cement-based materials. Renew. Sustain. Energy Rev. 2019, 110, 467–484. [Google Scholar] [CrossRef]

- Huang, B.-T.; Wu, J.-Q.; Yu, J.; Dai, J.-G.; Leung, C.K.Y.; Li, V.C. Seawater Sea-Sand Engineered/Strain-Hardening Cementitious Composites (ECC/SHCC): Assessment and Modeling of Crack Characteristics. Cem. Concr. Res. 2021, 140, 106292. [Google Scholar] [CrossRef]

| Ingredients | SiO2 | Al2O3 | CaO | Fe2O3 | K2O | MgO | Na2O | SO3 |

|---|---|---|---|---|---|---|---|---|

| SAC | 21.4 | 5.45 | 64.48 | 3.5 | 0.23 | 1.46 | 0.22 | 2.64 |

| FA | 49.22 | 27.8 | 3.14 | 1.29 | 1.06 | 0.86 | 0.92 | 0.16 |

| SF | 95.1 | 0.5 | 0.6 | 0.45 | 4.12 | 0.7 | 1.31 | 0.50 |

| Type of Fiber | Diameter (μm) | Length (mm) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Density (g/cm3) |

|---|---|---|---|---|---|

| PE | 20 | 18 | 3800 | 113 | 0.97 |

| Mix ID | Cement | Fly Ash | Silica Fume | Water | Aggregate | SP | ODE/FAC | PE Fiber (1.5 vol.%) |

|---|---|---|---|---|---|---|---|---|

| P0 | 533.2 | 733.15 | 66.65 | 359.91 | 479.88 | 5 | 0 | 14.7 |

| P5 | 533.2 | 733.15 | 66.65 | 359.91 | 455.89 | 5 | 8.81 | 14.7 |

| P10 | 533.2 | 733.15 | 66.65 | 359.91 | 431.59 | 5 | 17.63 | 14.7 |

| P20 | 533.2 | 733.15 | 66.65 | 359.91 | 383.90 | 5 | 35.25 | 14.7 |

| Mixture ID | First Cracking Strength (MPa) | Tensile Strength (MPa) | Ultimate Strain (%) | Crack Numbers | Average Crack Spacing (mm) | Residual Crack Width (μm) |

|---|---|---|---|---|---|---|

| P0 | 4.24 ± 0.63 | 5.70 ± 0.21 | 5.62 ± 0.48 | 21.50 ± 4.50 | 3.72 | 209.12 |

| P5 | 3.28 ± 0.50 | 6.08 ± 0.48 | 6.44 ± 0.86 | 27.25 ± 4.25 | 2.94 | 189.06 |

| P10 | 3.23 ± 0.47 | 6.53 ± 0.35 | 7.64 ± 0.49 | 33.25 ± 3.25 | 2.48 | 183.82 |

| P20 | 2.69 ± 0.84 | 6.46 ± 0.32 | 9.34 ± 1.03 | 41.00 ± 5.00 | 1.95 | 182.24 |

| Specimen | P0 | P5 | P10 | P20 |

|---|---|---|---|---|

| (MPa) | 1.098 ± 0.212 | 1.199 ± 0.115 | 1.289 ± 0.162 | 1.385 ± 0.291 |

| Micromechanical Parameters | P0 | P5 | P10 | P20 | |

|---|---|---|---|---|---|

| Fiber | Fiber length, Lf (mm) | 18 a | 18 a | 18 a | 18 a |

| Fiber diameter, df (μm) | 20 a | 20 a | 20 a | 20 a | |

| Fiber elastic modulus, Ef (GPa) | 113 a | 113 a | 113 a | 113 a | |

| Fiber strength, σfu (MPa) | 3800 a | 3800 a | 3800 a | 3800 a | |

| Fiber strength reduction factor, f’ | 0.33 b | 0.33 b | 0.33 b | 0.33 b | |

| Interface | Interfacial chemical bond, Gd (J/m2) | 0 b | 0 b | 0 b | 0 b |

| Interfacial frictional bond, τ0 (MPa) | 1.098 c | 1.199 c | 1.289 c | 1.385 c | |

| Slip-hardening coefficient, β | 0 b | 0 b | 0 b | 0 b | |

| Subbing coefficient, f | 0.59 b | 0.59 b | 0.59 b | 0.59 b | |

| Matrix | Elastic modulus, Em (MPa) | 33.39 c | 29.77 c | 27.99 c | 26.47 c |

| Cracking strength, σfc (MPa) | 4.24 c | 3.28 c | 3.23 c | 2.69 c | |

| Mixture ID | σfc (MPa) | σ0 (MPa) | PSHstrength | Jb’ (J/m2) | Jtip (J/m2) | PSHenergy |

|---|---|---|---|---|---|---|

| P0 | 4.24 | 10.11 | 2.38 | 385.10 | 17.15 | 22.46 |

| P5 | 3.28 | 11.13 | 3.39 | 432.89 | 14.86 | 29.13 |

| P10 | 3.23 | 11.53 | 3.57 | 446.47 | 14.54 | 30.71 |

| P20 | 2.69 | 11.88 | 4.42 | 453.70 | 14.31 | 31.71 |

| Specimen | P0 | P5 | P10 | P20 |

| Normalized areas | 1.217 | 1.347 | 1.570 | 1.467 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, H.; Yu, K.; Jia, M.; Wang, Z.; Yang, Y.; Liu, Y. Heat-Stored Engineered Cementitious Composite Containing Microencapsulated n-Octadecane with Cenosphere Shell. Coatings 2025, 15, 135. https://doi.org/10.3390/coatings15020135

Sun H, Yu K, Jia M, Wang Z, Yang Y, Liu Y. Heat-Stored Engineered Cementitious Composite Containing Microencapsulated n-Octadecane with Cenosphere Shell. Coatings. 2025; 15(2):135. https://doi.org/10.3390/coatings15020135

Chicago/Turabian StyleSun, Huayang, Kunyang Yu, Minjie Jia, Zilong Wang, Yingzi Yang, and Yushi Liu. 2025. "Heat-Stored Engineered Cementitious Composite Containing Microencapsulated n-Octadecane with Cenosphere Shell" Coatings 15, no. 2: 135. https://doi.org/10.3390/coatings15020135

APA StyleSun, H., Yu, K., Jia, M., Wang, Z., Yang, Y., & Liu, Y. (2025). Heat-Stored Engineered Cementitious Composite Containing Microencapsulated n-Octadecane with Cenosphere Shell. Coatings, 15(2), 135. https://doi.org/10.3390/coatings15020135