Modelling on How Topcoat/Bond Coat Micro-Rough Interface and Nearby Voids Affect the Stress Distribution in Thermal Barrier Coating Systems in Quenching Process

Abstract

1. Introduction

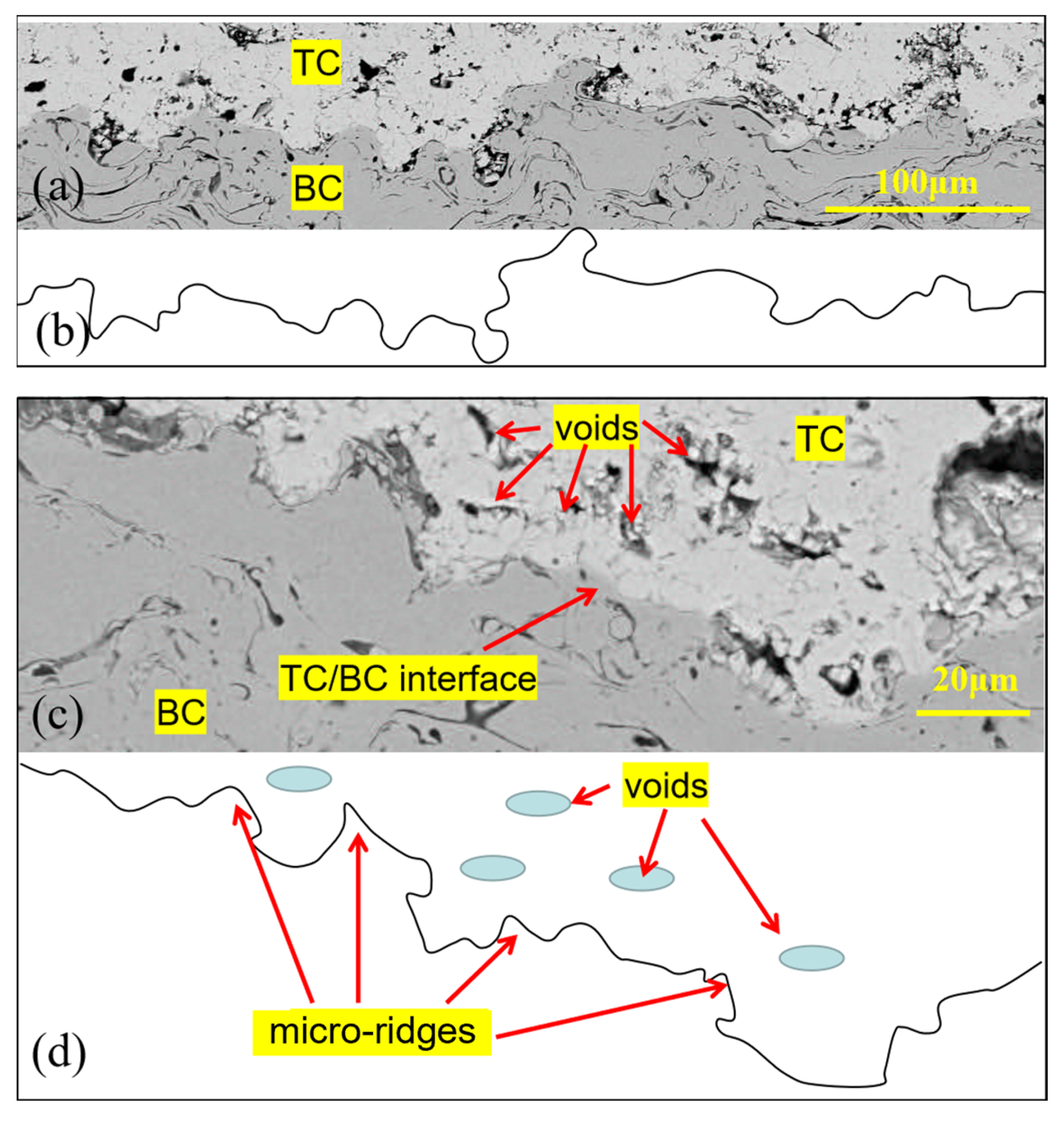

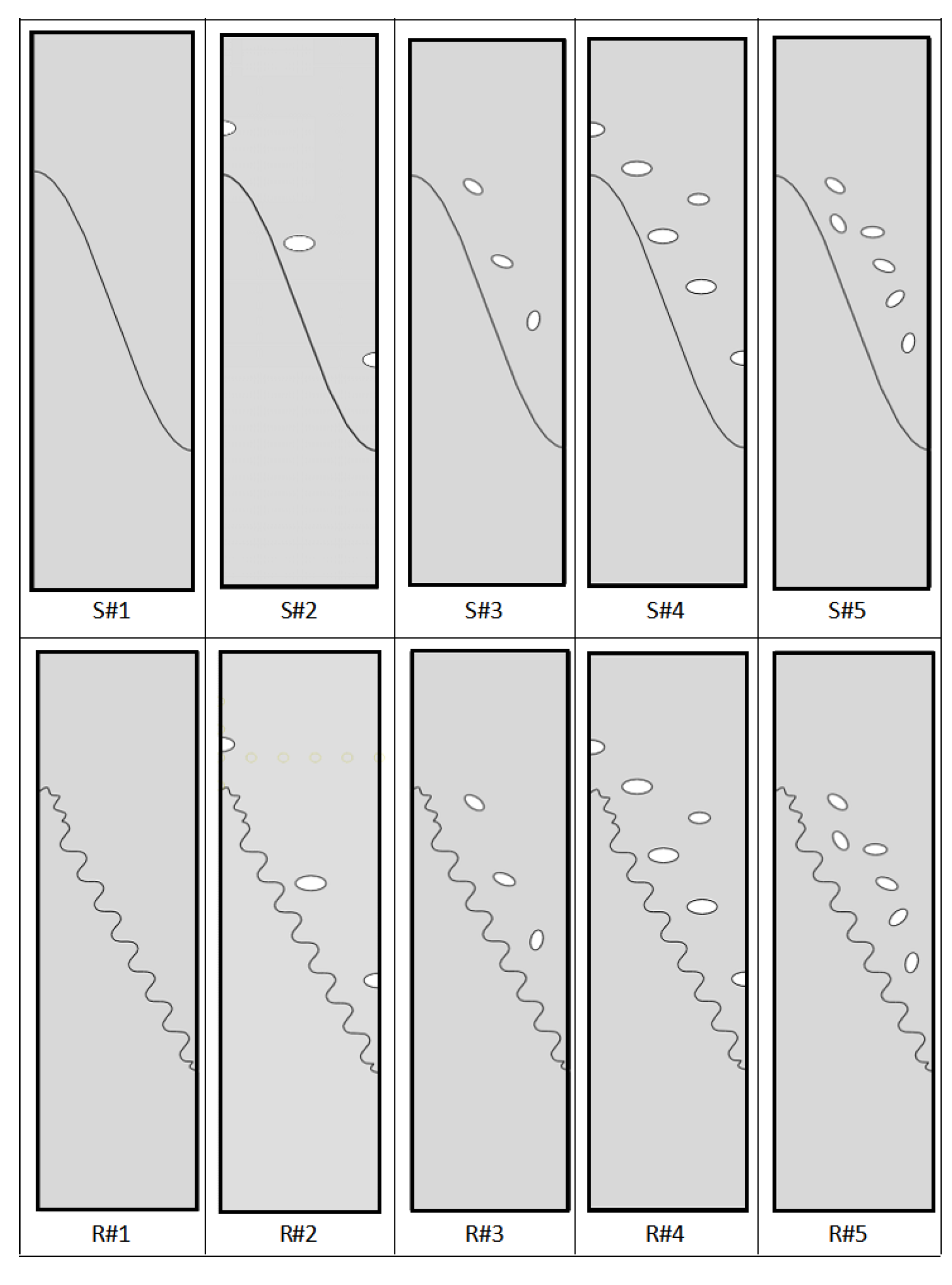

2. Model Set-Up and Experiments

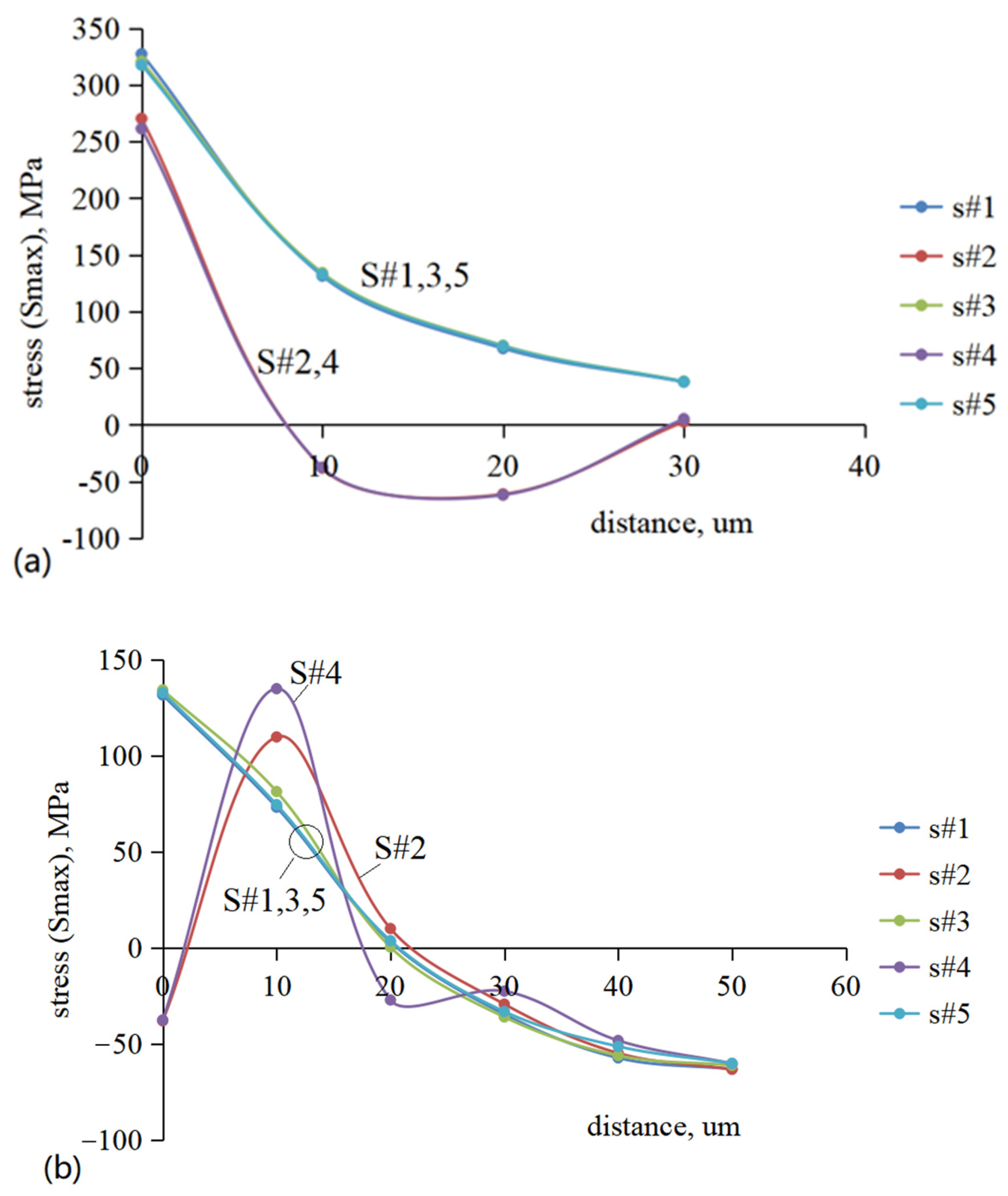

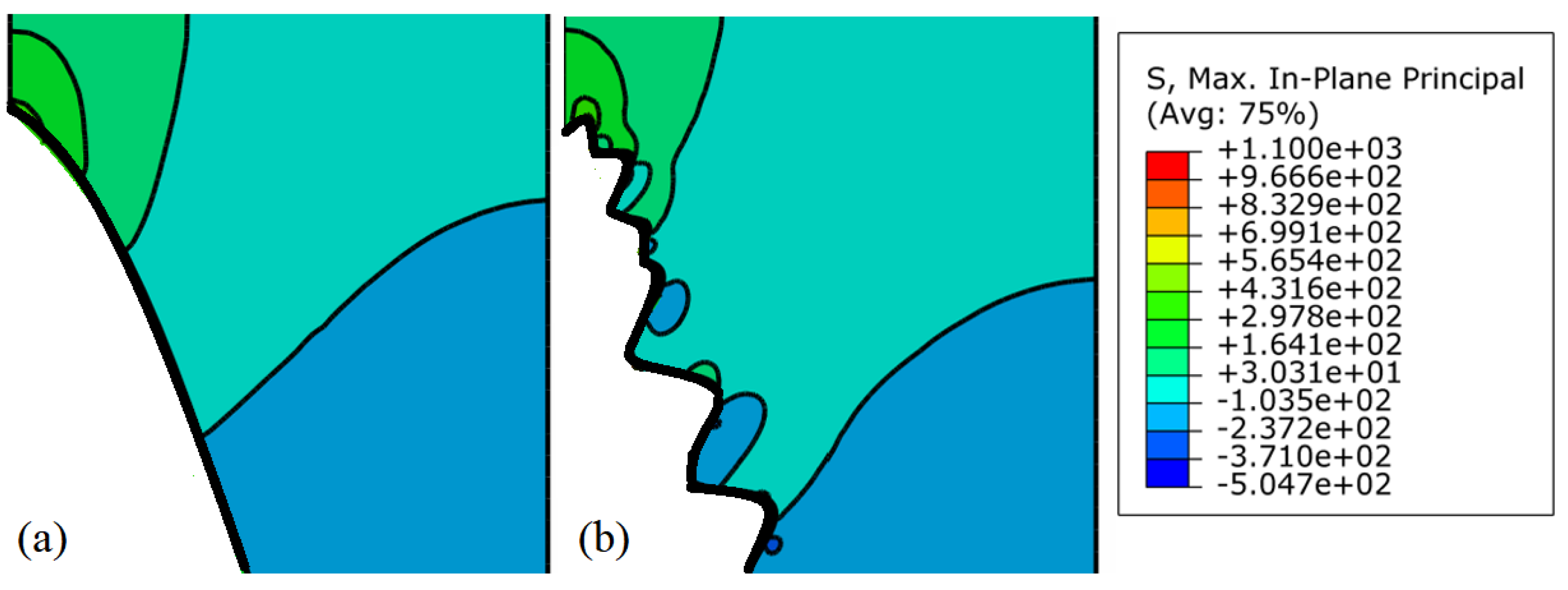

3. Results and Analyses

Characterization of the Agglomerated YSZ Powders

4. Conclusions

- 1.

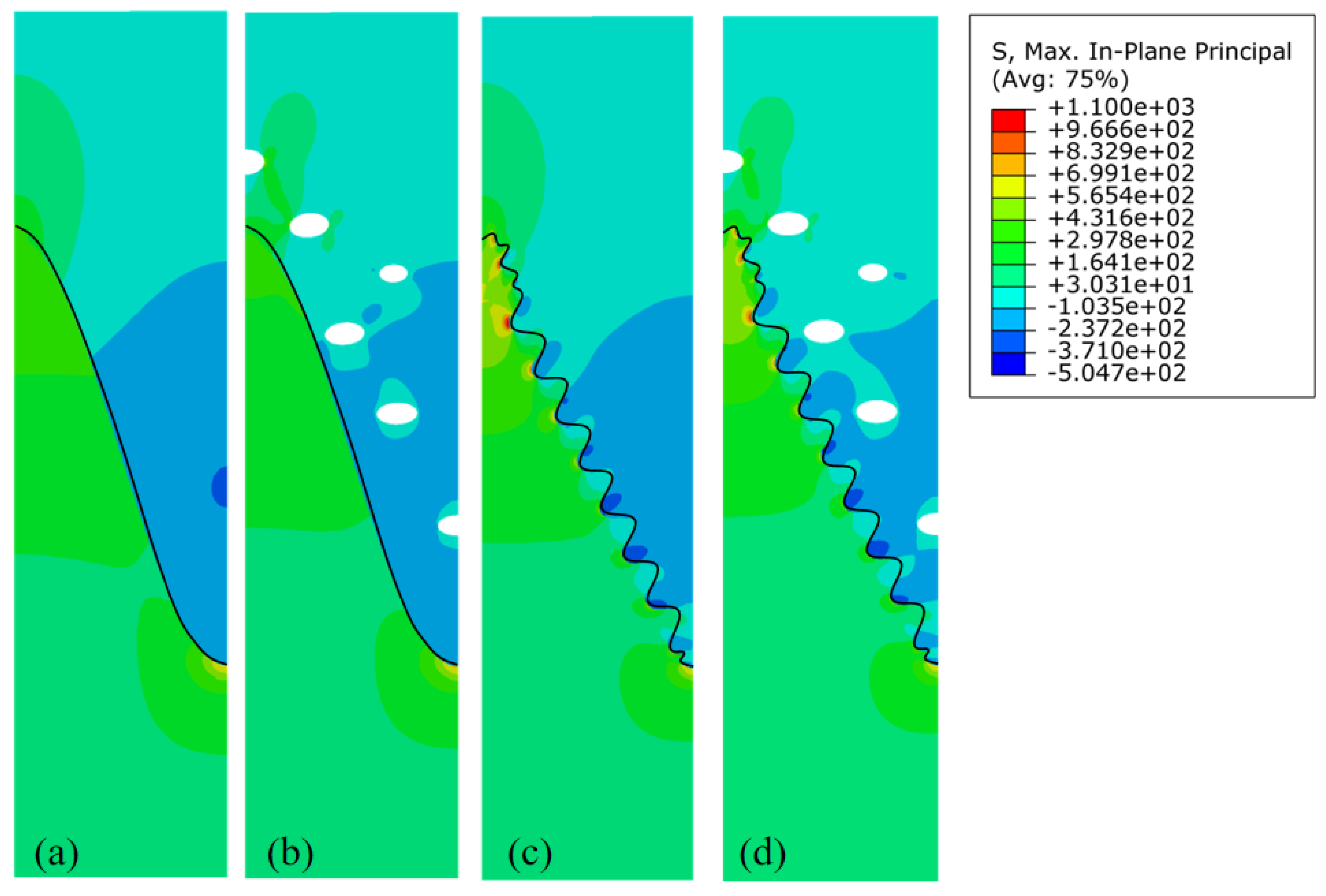

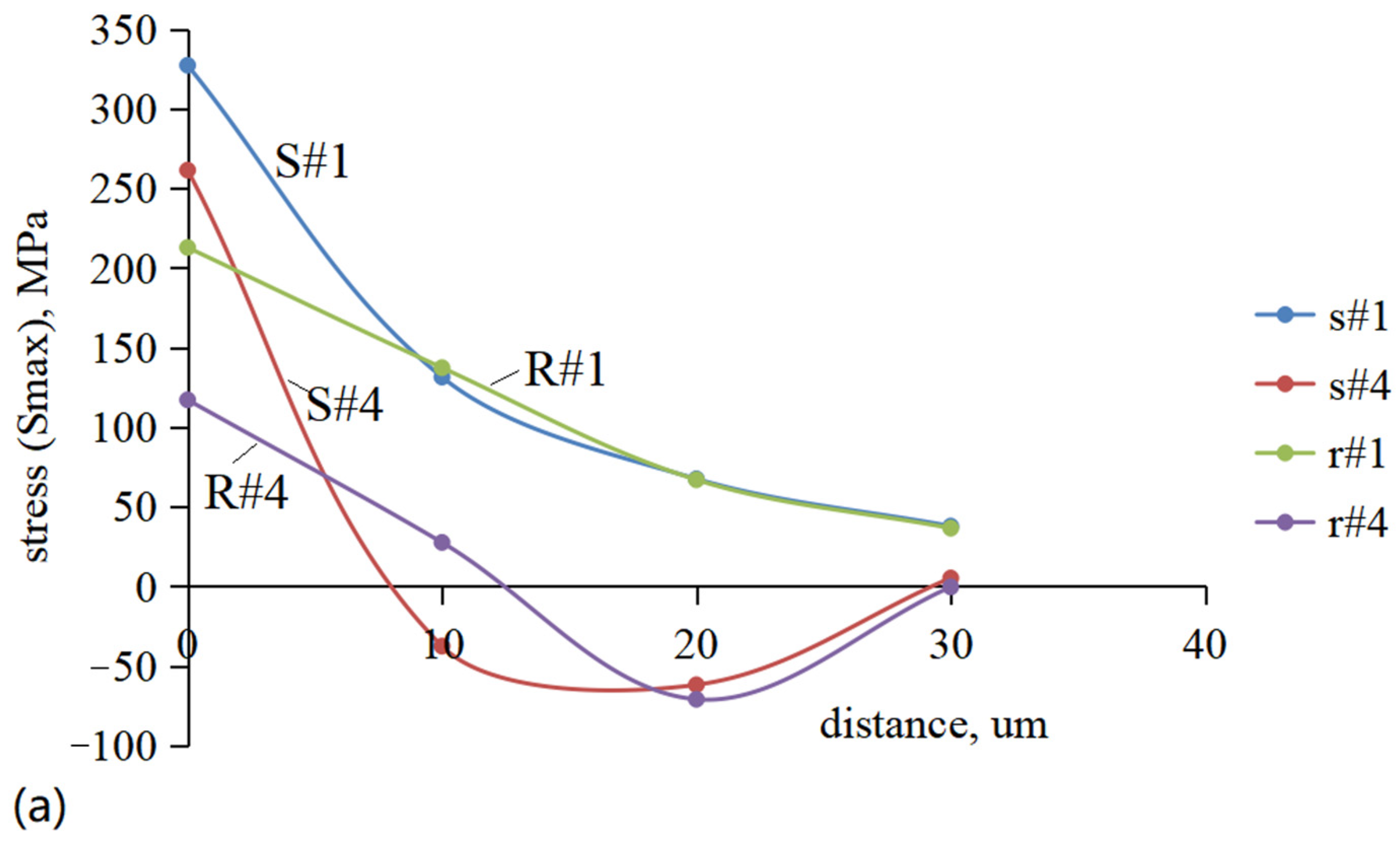

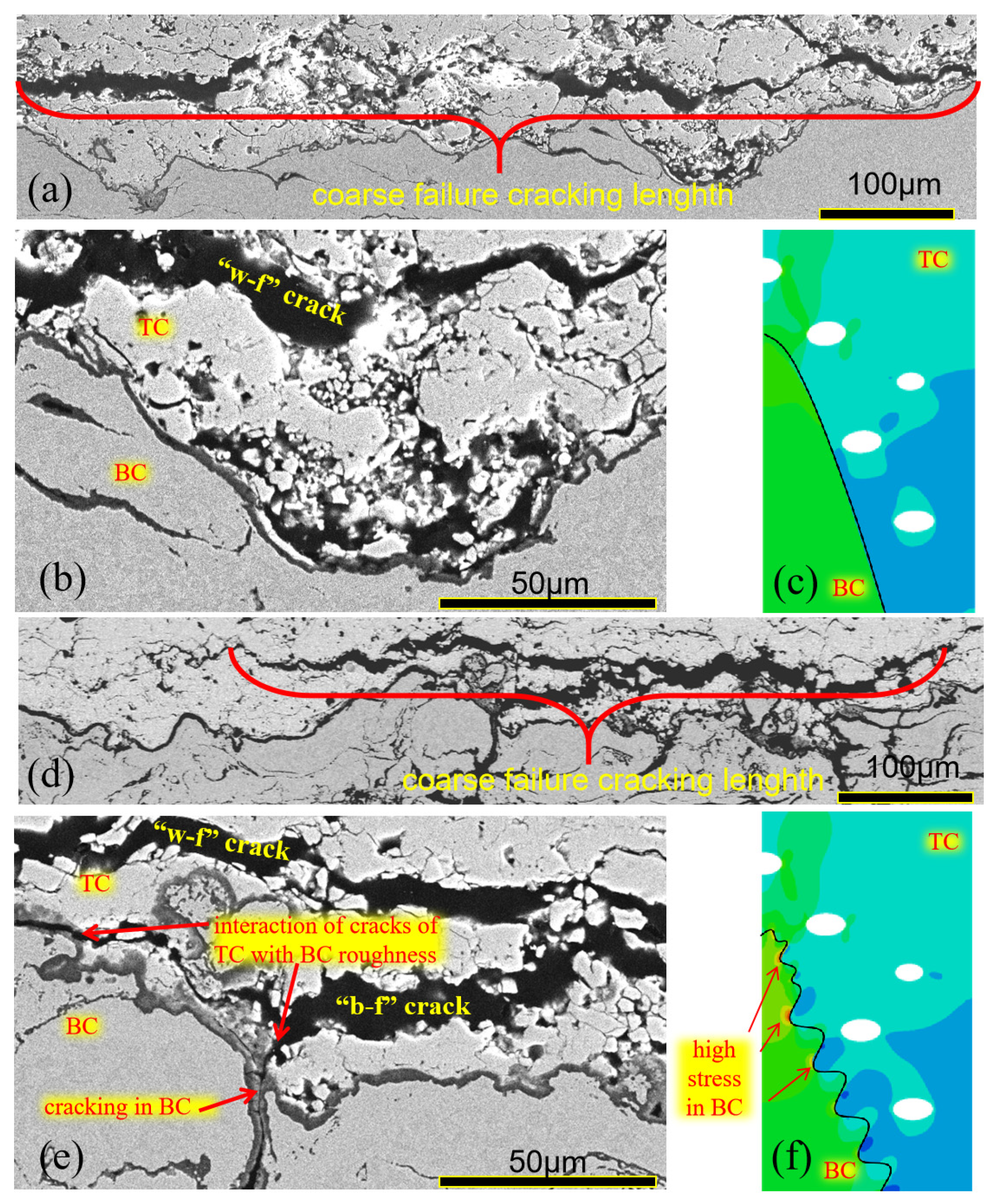

- The function of the voids in TCs included the dilution effect of the stress concentration at the macro-scale, a releasing effect of the tensile stress along the vertical direction above the BC peak, and the “stress trapping” effect, causing higher stress at the horizontal tips of the voids at a micro-scale. As the tensile stress of the TC was higher at the horizontal tip positions of the voids above the TC peak, cracks preferably propagated horizontally along such voids to cause white failure in HVOF BC TBCs.

- 2.

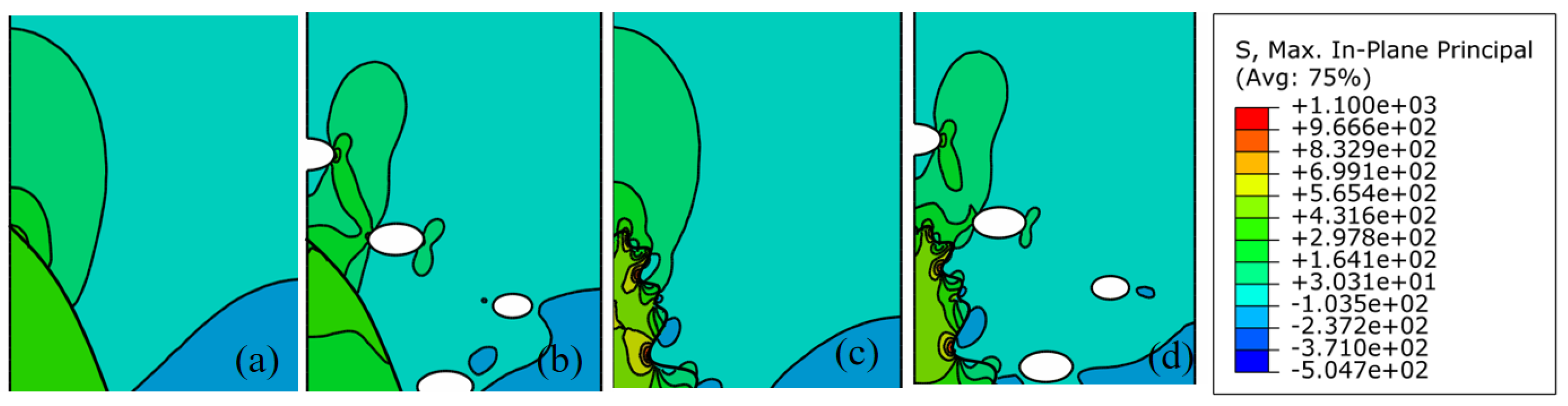

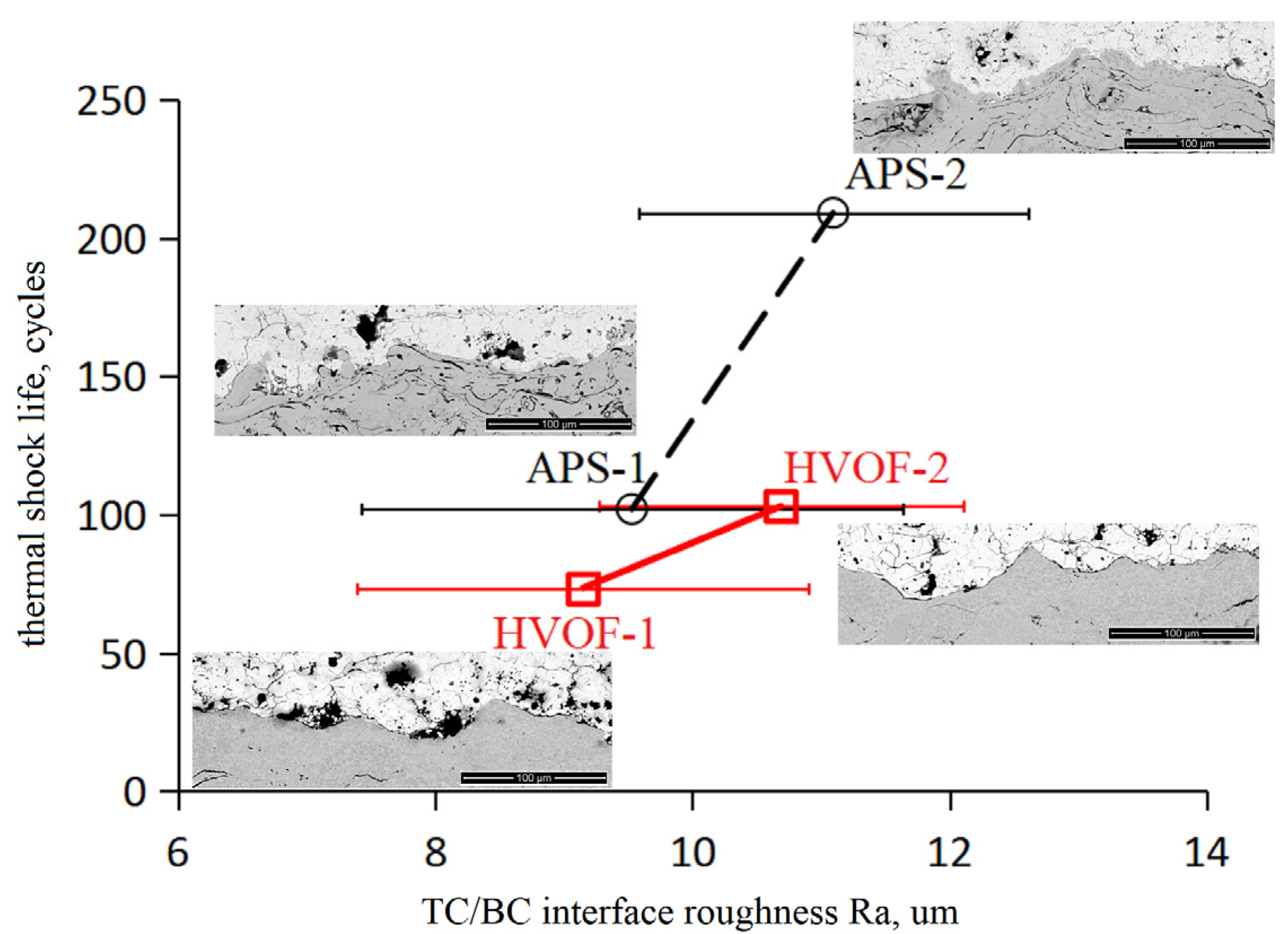

- In APS BC TBCs, the micro-rough BC interface played an important role. The micro-interface roughness did not have much effect on the stresses in the TC, aside from at the TC peak, but had a significant influence on the increased “stress trapping” effect at the interface. This “stress trapping” effect occurred both in the TC and BC sections, which promoted more interactions between the TC cracks and the interface to cause more black failures. The improved thermal shock lifetime of the TBCs by using APS-made BCs confirmed the modelling results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Clarke, D.R.; Phillpot, S.R. Thermal Barrier Coatings. Mater. Today 2005, 6, 22–29. [Google Scholar] [CrossRef]

- Vassen, R.; Stuke, A.; Stöver, D. Recent developments in the field of thermal barrier coatings. J. Therm. Spray. Technol. 2009, 18, 181–186. [Google Scholar] [CrossRef]

- Beele, W.; Marijnissen, G.; Van Lieshout, A. The evolution of thermal barrier coatings—Status and upcoming solutions for today’s key issues. Surf. Coat. Technol. 2002, 120, 61–67. [Google Scholar] [CrossRef]

- Vassen, R.; Giesen, S.; Stöver, D. Lifetime of plasma-sprayed thermal barrier coatings: Comparison of numerical and experimental results. J. Therm. Spray. Technol. 2009, 18, 835–845. [Google Scholar] [CrossRef]

- Rtzer-Scheibe, H.J.; Schulz, U. The Effects of Heat Treatment and Gas Atmosphere on the Thermal Conductivity of APS and EB-PVD PYSZ Thermal Barrier Coatings. Surf. Coat. Technol. 2007, 201, 7880–7888. [Google Scholar] [CrossRef]

- Yuan, K.; Peng, R.L.; Li, X.H.; Johansson, S.; Wang, Y.D. Some Aspects of Elemental Behaviour in HVOF MCrAlY Coatings in High-Temperature Oxidation. Surf. Coat. Technol. 2014, 261, 86–101. [Google Scholar] [CrossRef]

- Yuan, F.H.; Chen, Z.X.; Huang, Z.W.; Wang, Z.G.; Zhu, S.J. Oxidation behavior of thermal barrier coatings with hvof and detonation-sprayed NiCrAlY bondcoats. Corros. Sci. 2008, 50, 1608–1617. [Google Scholar] [CrossRef]

- Gupta, M. Establishment of Relationships Between Coating Microstructure and Thermal Conductivity in Thermal Barrier Coatings by Finite Element Modelling. Master’s Thesis, University West, Trollhättan, Sweden, 2011. [Google Scholar]

- Lee, S.S.; Jeon, S.; Lee, J.H.; Jung, Y.G.; Myoung, S.W.; Yang, B.I.; Lu, Z. Effects of microstructure design and feedstock species in the bond coat on thermal stability of thermal barrier coatings. Int. J. Nanotechnol. 2018, 15, 545–554. [Google Scholar] [CrossRef]

- Goral, M.; Sosnowy, P. Microstructure of thermal barrier coatings deposited by APS method with application of new type ceramic powders. J. Achiev. Mat. Manuf. Eng. 2012, 55, 912–917. [Google Scholar]

- Huang, J.B.; Wang, W.Z.; Li, Y.J.; Fang, H.J.; Ye, D.D.; Zhang, X.C.; Tu, S.T. A novel strategy to control the microstructure of plasma-sprayed YSZ thermal barrier coatings. Surf. Coat. Technol. 2020, 402, 126304. [Google Scholar] [CrossRef]

- Jonnalagadda, K.P.; Eriksson, R.; Yuan, K.; Li, X.H.; Ji, X.; Yu, Y.; Peng, R.L. Comparison of damage evolution during thermal cycling in a high purity nano and a conventional thermal barrier coating. Surf. Coat. Technol. 2017, 322, 47–56. [Google Scholar] [CrossRef]

- Scrivani, A.; Rizzi, G.; Berndt, C.C. Enhanced thick thermal barrier coatings that exhibit varying porosity. Mat. Sci. Eng. A 2008, 476, 1–7. [Google Scholar] [CrossRef]

- Jonnalagadda, K.P.; Eriksson, R.; Yuan, K.; Li, X.H.; Ji, X.; Yu, Y.; Peng, R.L. A study of damage evolution in high purity nano TBCs during thermal cycling_ A fracture mechanics based modelling approach. J. Eur. Ceram. Soc. 2017, 37, 2889–2899. [Google Scholar] [CrossRef]

- Sjöström, S.; Brodin, H.; Jinnestrand, M. Thermomechanical fatigue life of a TBC—Comparison of computed and measured behaviour of delamination cracks. In Proceedings of the 13th International Conference on Fracture, Beijing, China, 16–21 June 2013; pp. 1170–1179. [Google Scholar]

- Funke, C.; Mailand, J.C.; Siebert, B.; Vaβen, R.; Stöver, D. Characterization of ZrO2-7 wt.% Y2O3 thermal barrier coatings with different porosities and FEM analysis of stress redistribution during thermal cycling of TBCs. Surf. Coat. Technol. 1997, 94, 106–111. [Google Scholar] [CrossRef]

- Weeks, M.D.; Subramanian, R.; Vaidya, A.; Mumm, D.R. Defining optimal morphology of the bond coat-thermal barrier coating interface of air-plasma sprayed thermal barrier coating systems. Surf. Coat. Technol. 2015, 273, 50–59. [Google Scholar] [CrossRef]

- Ranjbar-Far, M.; Absi, J.; Mariaux, G.; Dubois, F. Simulation of the effect of material properties and interface roughness on the stress distribution in thermal barrier coatings using finite element method. Mater. Des. 2010, 31, 772–781. [Google Scholar] [CrossRef]

- Liu, Y.; Persson, C.; Wigren, J. Experimental and numerical life prediction of thermally cycled thermal barrier coatings. J. Therm. Spray. Technol. 2004, 13, 415–424. [Google Scholar] [CrossRef]

- Busso, E.P.; Wright, L.; Evans, H.E.; McCartney, L.N.; Saunders, S.R.J.; Osgerby, S.; Nunn, J. A physics-based life prediction methodology for thermal barrier coating systems. Acta Mater. 2007, 55, 1491–1503. [Google Scholar] [CrossRef]

- Nowak, W.; Naumenko, D.; Mor, G.; Mor, F.; Mack, D.E.; Vassen, R.; Singheiser, L.; Quadakkers, W.J. Effect of processing parameters on MCrAlY bondcoat roughness and lifetime of APS-TBC systems. Surf. Coat. Technol. 2014, 260, 82–89. [Google Scholar] [CrossRef]

- Eriksson, R.; Sjöström, S.; Brodin, H.; Johansson, S.; Östergren, L.; Li, X.H. TBC bond coat–top coat interface roughness: Influence on fatigue life and modelling aspects. Surf. Coat. Technol. 2013, 236, 230–238. [Google Scholar] [CrossRef]

- Yuan, K.; Yu, Y.; Wen, J.-F. A study on the thermal cyclic behavior of thermal barrier coatings with different MCrAlY roughness. Surf. Coat. Technol. 2017, 137, 72–80. [Google Scholar] [CrossRef]

| Component | Young’s Modulus (GPa) | Poisson’s Ratio | Coefficient of Expansion (10−6 1/°C) |

|---|---|---|---|

| Ceramic TC (YSZ) | 53 | 0.25 | 10.2 |

| Metallic BC (MCrAlY) | 225 | 0.3 | 14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, X.; Huang, S.; Shi, T.; Pang, X. Modelling on How Topcoat/Bond Coat Micro-Rough Interface and Nearby Voids Affect the Stress Distribution in Thermal Barrier Coating Systems in Quenching Process. Coatings 2025, 15, 97. https://doi.org/10.3390/coatings15010097

Lu X, Huang S, Shi T, Pang X. Modelling on How Topcoat/Bond Coat Micro-Rough Interface and Nearby Voids Affect the Stress Distribution in Thermal Barrier Coating Systems in Quenching Process. Coatings. 2025; 15(1):97. https://doi.org/10.3390/coatings15010097

Chicago/Turabian StyleLu, Xiaoliang, Songtao Huang, Tianjie Shi, and Xiaoxiao Pang. 2025. "Modelling on How Topcoat/Bond Coat Micro-Rough Interface and Nearby Voids Affect the Stress Distribution in Thermal Barrier Coating Systems in Quenching Process" Coatings 15, no. 1: 97. https://doi.org/10.3390/coatings15010097

APA StyleLu, X., Huang, S., Shi, T., & Pang, X. (2025). Modelling on How Topcoat/Bond Coat Micro-Rough Interface and Nearby Voids Affect the Stress Distribution in Thermal Barrier Coating Systems in Quenching Process. Coatings, 15(1), 97. https://doi.org/10.3390/coatings15010097