A Novel (AlCrNbTaTi)N Multilayer Hard High-Entropy Alloy Nitride Coating with Variable Aluminum Content Deposited by Cathodic Arc Ion Plating

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of (AlCrNbTaTi)N Coatings

2.2. Characterization

3. Results and Discussion

4. Conclusions

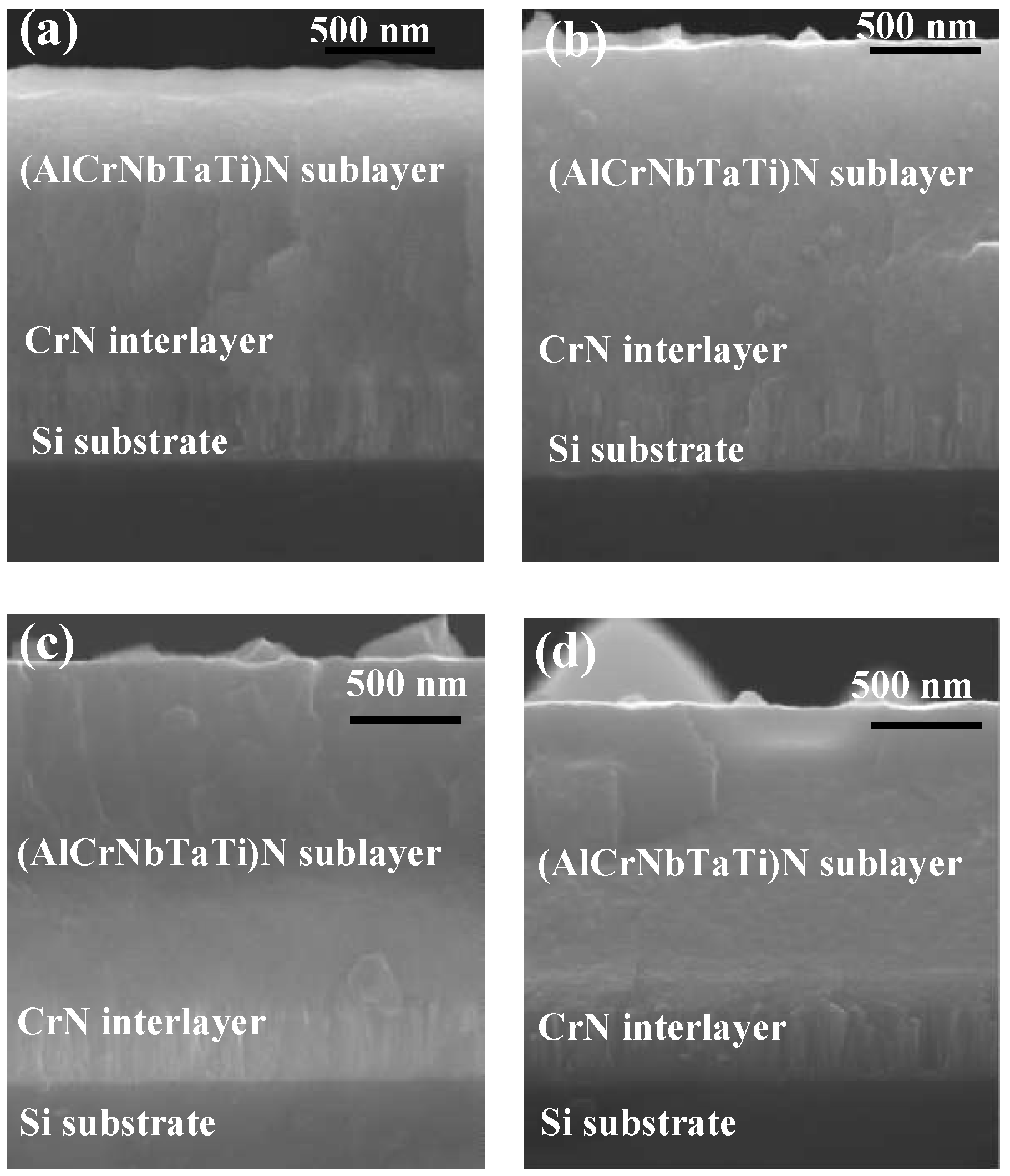

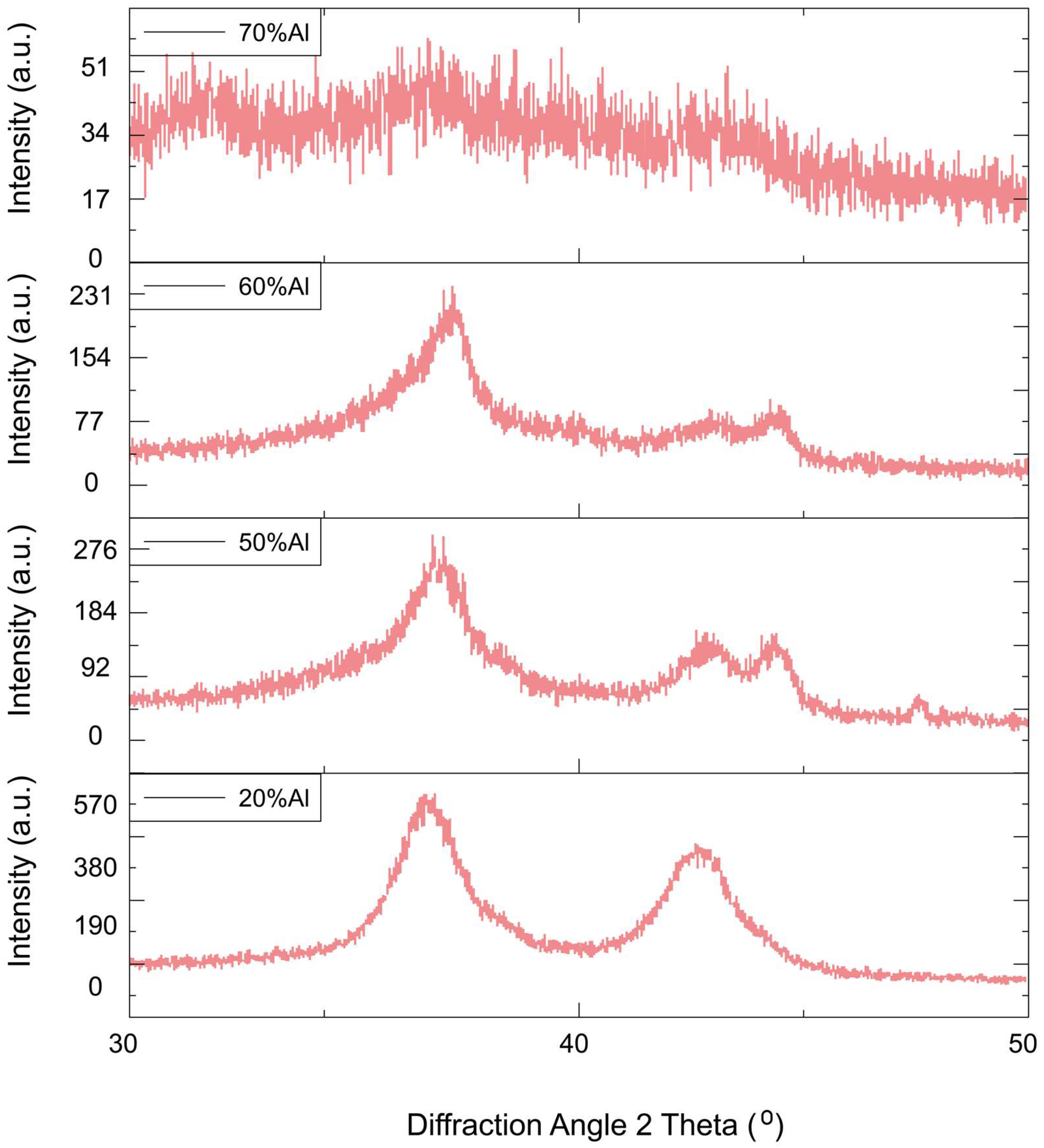

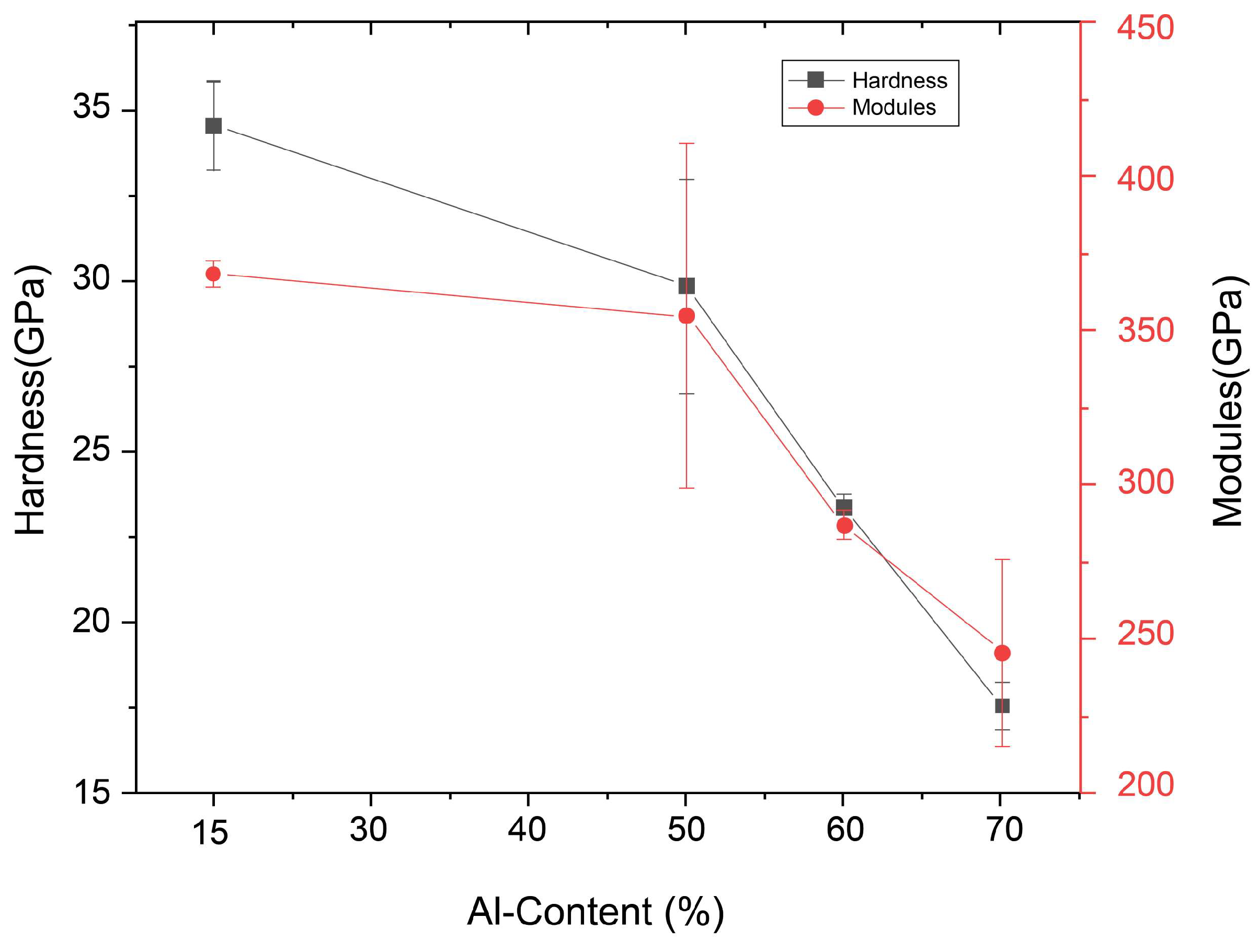

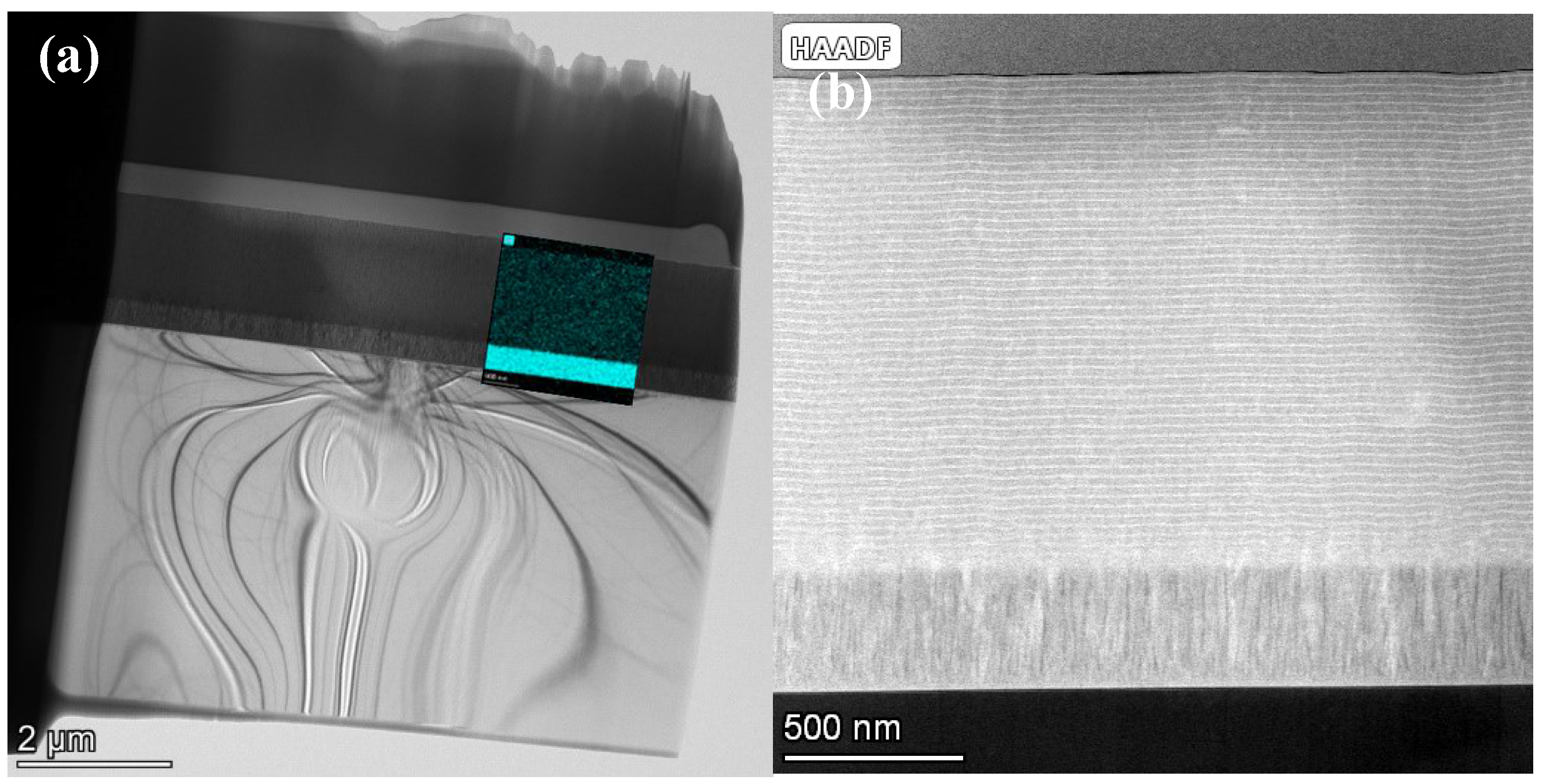

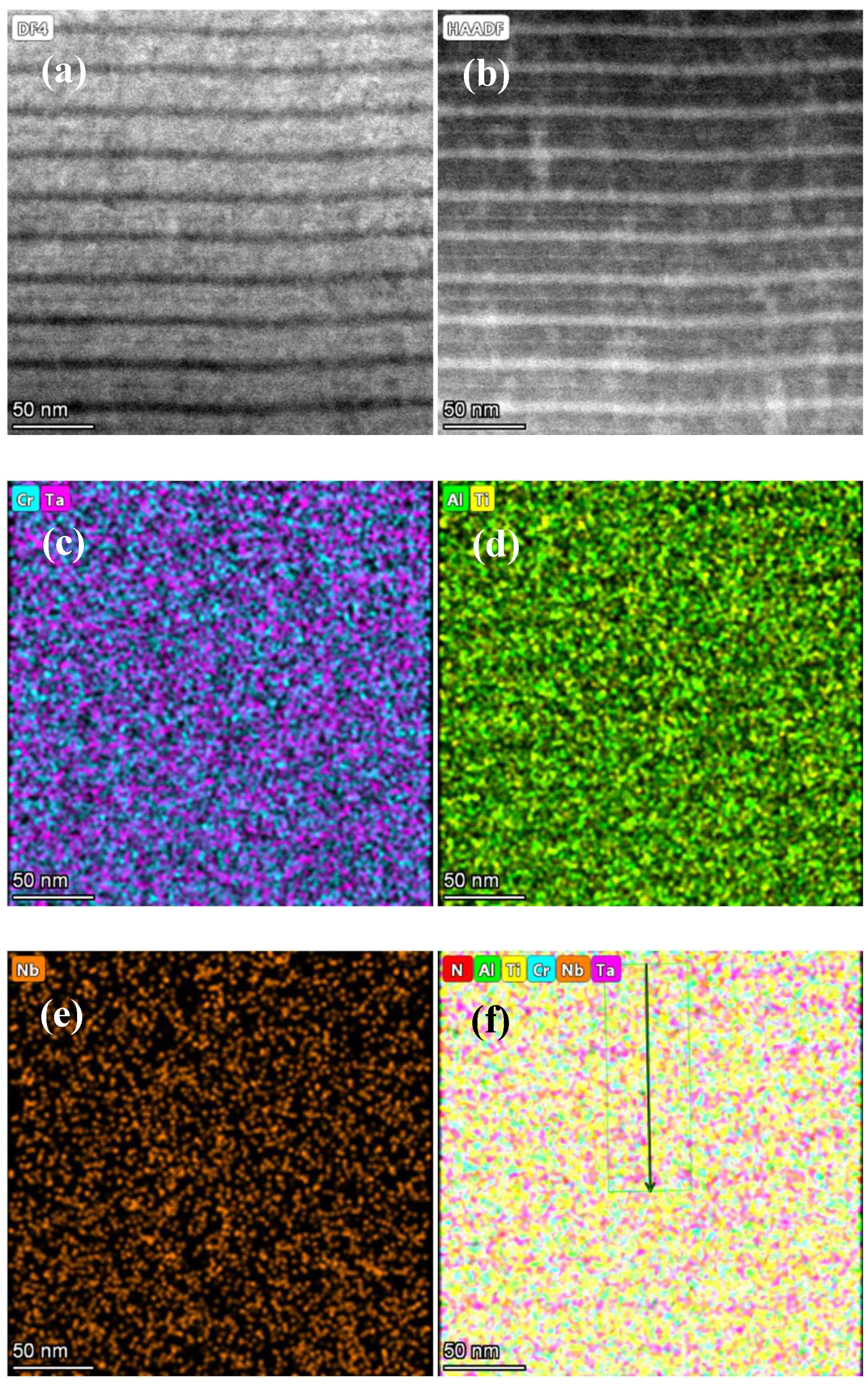

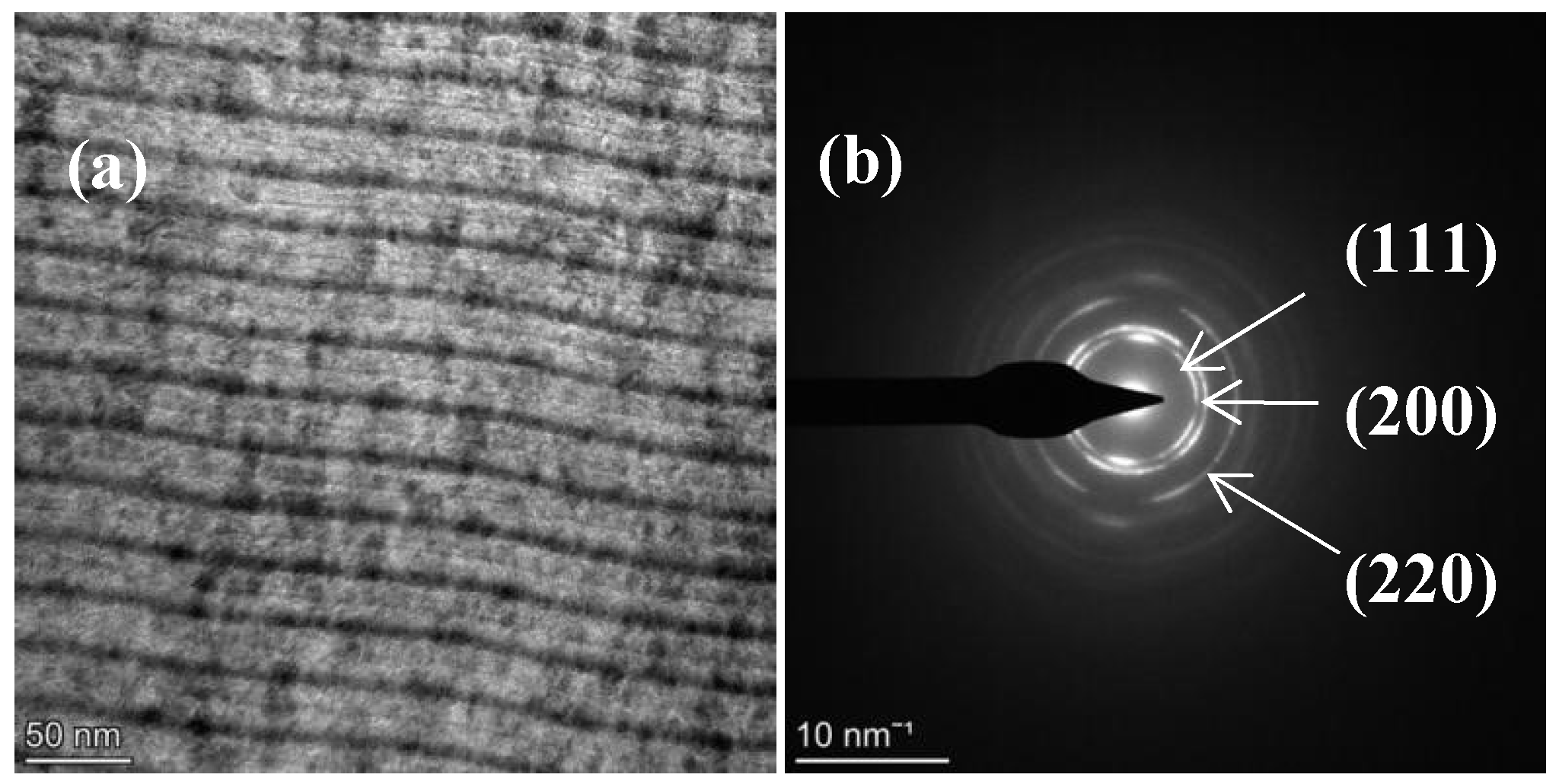

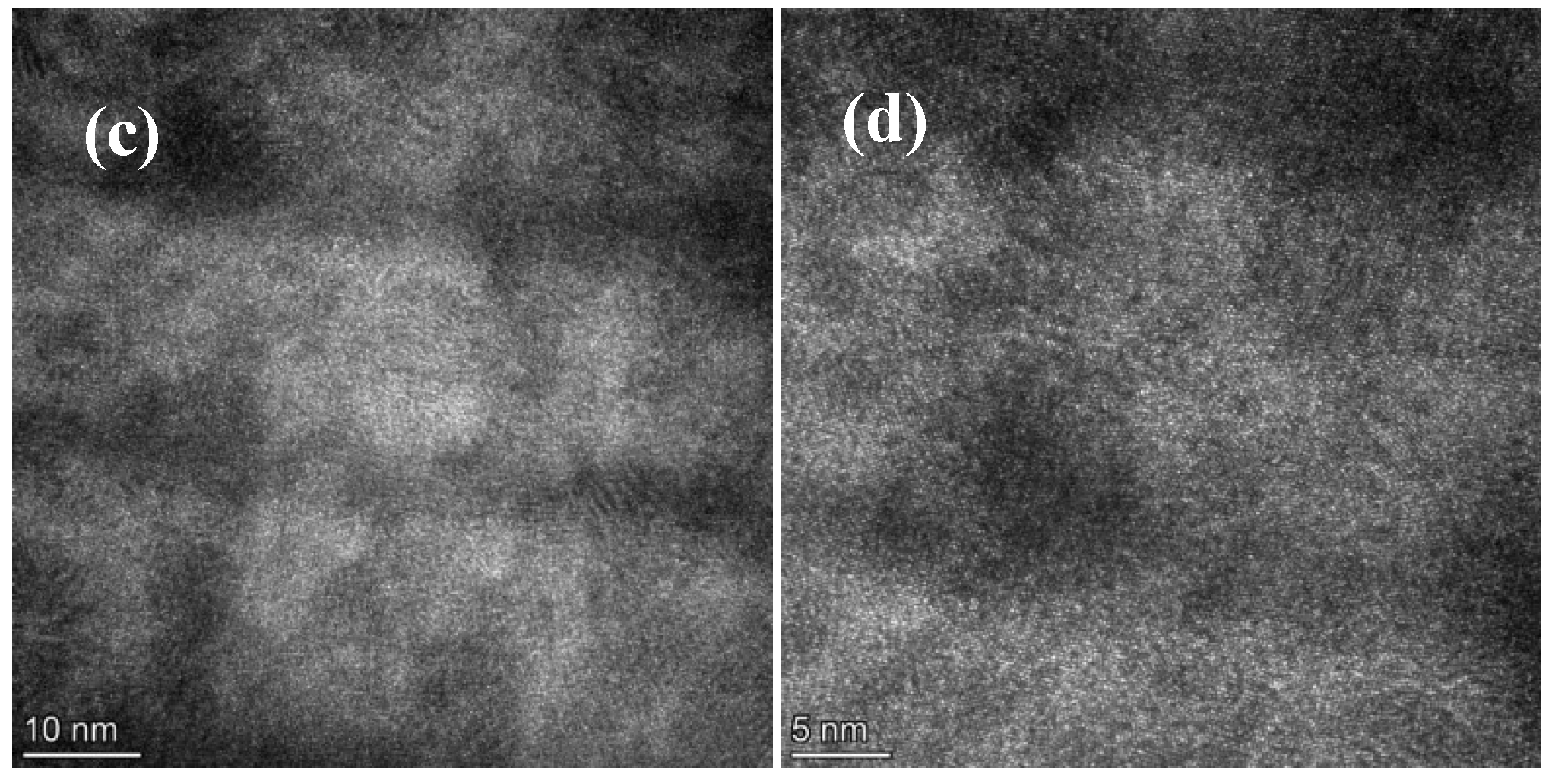

- With increasing aluminum content, the coating structure transitioned from a nanomultilayer configuration at 20%–50% Al content to a fully amorphous state at 70%. The XRD results indicated peak shifts and reductions in crystallinity, consistent with the amorphization trend.

- The equichemical (AlCrNbTaTi)N coating demonstrated a nanomultilayer structure, with a hardness of 34.5 GPa and a modulus of 369 GPa. These mechanical properties, combined with a wear rate of 8.2 × 10−19 m2·N−1, highlight the advantages of the multilayer arrangement in dissipating stress and resisting deformation under high mechanical loads.

- The superior tribological performance of the equimolar (AlCrNbTaTi)N coating, with its exceptionally low wear rate, makes it an outstanding candidate for hard tool applications. This unique combination of mechanical properties, high hardness, excellent wear resistance, and structural integrity demonstrates the potential for significantly extending tool life in industrial applications requiring high-performance materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, C.Y.; Xie, Y.X.; Qin, Z.; Lin, H.S.; Yuan, Y.H.; Wang, Q.M. Wear and breakage of TiAlN- and TiSiN-coated carbide tools during high-speed milling of hardened steel. Wear 2015, 336–337, 29–42. [Google Scholar] [CrossRef]

- Mo, J.J.; Wu, Z.T.; Yao, Y.; Zhang, Q.; Wang, Q.M. Influence of Y-addition and multilayer modulation on microstructure, oxidation resistance and corrosion behavior of Al0.67Ti0.33N coatings. Surf. Coat. Technol. 2018, 342, 129–136. [Google Scholar] [CrossRef]

- Fuentes, G.G.; Almandoz, E.; Pierrugues, R.; Martínez, R.; Rodríguez, R.J.; Caro, J.; Vilaseca, M. High temperature tribological characterisation of TiAlSiN coatings produced by cathodic arc evaporation. Surf. Coat. Technol. 2010, 205, 1368–1373. [Google Scholar] [CrossRef]

- Polcar, T.; Cavaleiro, A. High temperature properties of CrAlN, CrAlSiN and AlCrSiN coatings-structure and oxidation. Mater. Chem. Phys. 2011, 129, 195–201. [Google Scholar] [CrossRef]

- Peng, B.; Li, H.; Zhang, Q.; Xu, Y.X.; Wei, T.; Wang, Q.; Zhang, F.; Kim, K.H. Hightemperature thermal stability and oxidation resistance of Cr and Ta co-alloyed Ti Al-N coatings deposited by cathodic arc evaporation. Corros. Sci. 2020, 167, 108490. [Google Scholar] [CrossRef]

- Chen, J.; Fang, W.; Gobinda, G.; Cai, F.; Tao, L.; Zhang, S. Effects of multilayer structure on the high-speed dry-cutting performance of AlCrBN/AlCrN multilayer coatings. Int. J. Refract. Met. Hard Mater. 2024, 121, 106672. [Google Scholar] [CrossRef]

- Song, J.; Sun, A.; Zhang, P.; Li, J. Microstructure; mechanical performance, thermal stability, and oxidation resistance of AlCrN/AlCrBN nano-multilayer coating. Surf. Coat. Technol. 2024, 493, 131301. [Google Scholar] [CrossRef]

- Chen, L.; Yan, C.; Mei, F.; Yu, Y.; Gao, J.; Yuan, T. A comparative investigation of the thermal stability and oxidation resistance of AlCrSiWN and AlCrSiN/AlCrWN coatings. Ceram. Int. 2024, 50, 55766–55778. [Google Scholar] [CrossRef]

- Polcar, T.; Cavaleiro, A. High-temperature tribological properties of CrAlN, CrAlSiN and AlCrSiN coatings. Surf. Coat. Technol. 2011, 206, 1244–1251. [Google Scholar] [CrossRef]

- Tang, J.-F.; Lin, C.-Y.; Yang, F.-C.; Chang, C.-L. Effects of input power ratio of AlCr/Ti target on the microstructural and mechanical properties of AlTiCrN coatings synthesized by a high-power impulse magnetron sputtering process. Coatings 2021, 11, 826. [Google Scholar] [CrossRef]

- Yeh, J.-W.; Chen, S.-K.; Lin, S.-J.; Gan, J.-Y.; Chin, T.-S.; Shun, T.-T.; Tsau, C.-H.; Chang, S.-Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Chang, H.-W.; Huang, P.-K.; Davison, A.; Yeh, J.-W.; Tsau, C.-H.; Yang, C.-C. Nitride films deposited from an equimolar Al–Cr–Mo–Si–Ti alloy target by reactive direct current magnetron sputtering. Thin Solid Films 2008, 516, 6402–6408. [Google Scholar] [CrossRef]

- Chang, H.-W.; Huang, P.-K.; Yeh, J.-W.; Davison, A.; Tsau, C.-H.; Yang, C.-C. Influence of substrate bias, deposition temperature and post-deposition annealing on the structure and properties of multi-principal-component (AlCrMoSiTi)N coatings. Surf. Coat. Technol. 2008, 202, 3360–3366. [Google Scholar] [CrossRef]

- Lin, C.H.; Duh, J.G.; Yeh, J.W. Multi-component nitride coatings derived from Ti–Al–Cr–Si–V target in RF magnetron sputter. Surf. Coat. Technol. 2007, 201, 6304–6308. [Google Scholar] [CrossRef]

- Chang, Y.Y.; Feng, H.Q.; Huang, K.C. On the high temperature oxidation behavior of AlCrBN/TiAlNbSiN multilayer coatings with addition of boron and silicon. Surf. Coat. Int. 2023, 475, 130180. [Google Scholar] [CrossRef]

- Huang, P.-K.; Yeh, J.-W. Effects of substrate bias on structure and mechanical properties of (AlCrNbSiTiV)N coatings. J. Phys. D Appl. Phys. 2009, 42, 115401. [Google Scholar] [CrossRef]

- Huang, P.-K.; Yeh, J.-W. Inhibition of grain coarsening up to 1000 °C in (AlCrNbSiTiV)N superhard coatings. Scr. Mater. 2010, 62, 105–108. [Google Scholar] [CrossRef]

- Cheng, K.-H.; Tsai, C.-W.; Lin, S.-J.; Yeh, J.-W. Effects of silicon content on the structure and mechanical properties of (AlCrTaTiZr)–Six–N coatings by reactive RF magnetron sputtering. J. Phys. D Appl. Phys. 2011, 44, 205405. [Google Scholar] [CrossRef]

- Hsieh, M.-H.; Tsai, M.-H.; Shen, W.-J.; Yeh, J.-W. Structure and properties of two Al–Cr–Nb–Si–Ti high-entropy nitride coatings. Surf. Coat. Technol. 2013, 221, 118–123. [Google Scholar] [CrossRef]

- Zhao, S.; Stocks, G.M.; Zhang, Y. Stacking fault energies of face-centered cubic concentrated solid solution alloys. Acta Mater. 2017, 134, 334–345. [Google Scholar] [CrossRef]

- Inoue; Kong, F.; Zhu, S.; Liu, C.T.; Al-Marzouki, F. Development and applications of highly functional Al-based materials by use of metastable phases. Mater. Res. 2015, 18, 1414–1425. [Google Scholar] [CrossRef]

- Manivasagam, G.; Suwas, S. Biodegradable Mg and Mg based alloys for biomedical implants. Mater. Sci. Technol. 2014, 30, 515–520. [Google Scholar] [CrossRef]

- Chim, Y.C.; Ding, X.Z.; Zeng, X.T.; Zhang, S. Oxidation resistance of TiN, CrN, TiAlN and CrAlN coatings deposited by lateral rotating cathode arc. Thin Solid Films 2009, 517, 4845–4849. [Google Scholar] [CrossRef]

- Singh, A.; Ghosh, S.; Aravindan, S. Investigation of oxidation behaviour of AlCrN and AlTiN coatings deposited by arc enhanced HIPIMS technique. Appl. Surf. Sci. 2020, 508, 144812. [Google Scholar] [CrossRef]

- Feng, Y.-P.; Zhang, L.; Ke, R.-X.; Wan, Q.-L.; Wang, Z.; Lu, Z.-H. Thermal stability and oxidation behavior of AlTiN, AlCrN and AlCrSiWN coatings. Int. J. Refract. Met. Hard Mater. 2014, 43, 241–249. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Yang, S.-M. High temperature oxidation behavior of multicomponent TiAlSiN coatings. Thin Solid Films 2010, 518, S34–S37. [Google Scholar] [CrossRef]

- Xiao, B.; Zhang, T.F.; Guo, Z.; Li, Z.; Fan, B.; Chen, G.; Xiong, Z.; Wang, Q. Mechanical, oxidation, and cutting properties of AlCrN/AlTiSiN nano-multilayer coatings. Surf. Coat. Technol. 2022, 433, 128094. [Google Scholar] [CrossRef]

- Fukumoto, N.; Ezura, H.; Suzuki, T. Synthesis and oxidation resistance of TiAlSiN and multilayer TiAlSiN/CrAlN coating. Surf. Coat. Technol. 2009, 204, 902–906. [Google Scholar] [CrossRef]

- Liu, J.; Hao, Z.; Cui, Z.; Ma, D.; Lu, J.; Cui, Y.; Li, C.; Liu, W.; Xie, S.; Huang, P.; et al. Investigation of the oxidation mechanisms of superlattice Cr-CrN/TiSiN-Cr multilayer coatings on Zircaloy substrates under high-temperature steam atmospheres. Corros. Sci. 2021, 192, 109782. [Google Scholar] [CrossRef]

- Jäger, N.; Meindlhumer, M.; Zitek, M.; Spor, S.; Hruby, H.; Nahif, F.; Julin, J.; Rosenthal, M.; Keckes, J.; Mitterer, C.; et al. Impact of Si on the hightemperature oxidation of AlCr(Si)N coatings. J. Mater. Sci. Technol. 2022, 100, 91–100. [Google Scholar] [CrossRef]

| Process Parameters | Unit | CrN | (AlCrNbTaTi)N |

|---|---|---|---|

| Pressure | [Pa] | 0.7 | 2.0 |

| Arc Current | [A] | 80 | 100 |

| Bias Voltage | [V] | −200 | −100 |

| Time | [s] | 1200 | 3000 |

| Nitride (JCPDS Number) | AlN (46-1200) | CrN (11-0065) | NbN (38-1155) | TaN (49-1283) | TiN (38-1420) |

|---|---|---|---|---|---|

| Lattice constant (Å) | 4.04 | 4.14 | 4.40 | 4.34 | 4.24 |

| 2θ of (111) (deg) | 38.530 | 37.538 | 35.365 | 35.830 | 36.662 |

| 2θ of (200) (deg) | 44.771 | 43.737 | 41.068 | 41.605 | 42.596 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Z.; Lang, W.; Chen, Y.; Yang, B.; Wan, Q. A Novel (AlCrNbTaTi)N Multilayer Hard High-Entropy Alloy Nitride Coating with Variable Aluminum Content Deposited by Cathodic Arc Ion Plating. Coatings 2025, 15, 76. https://doi.org/10.3390/coatings15010076

Huang Z, Lang W, Chen Y, Yang B, Wan Q. A Novel (AlCrNbTaTi)N Multilayer Hard High-Entropy Alloy Nitride Coating with Variable Aluminum Content Deposited by Cathodic Arc Ion Plating. Coatings. 2025; 15(1):76. https://doi.org/10.3390/coatings15010076

Chicago/Turabian StyleHuang, Zhihong, Wenchang Lang, Yanming Chen, Bing Yang, and Qiang Wan. 2025. "A Novel (AlCrNbTaTi)N Multilayer Hard High-Entropy Alloy Nitride Coating with Variable Aluminum Content Deposited by Cathodic Arc Ion Plating" Coatings 15, no. 1: 76. https://doi.org/10.3390/coatings15010076

APA StyleHuang, Z., Lang, W., Chen, Y., Yang, B., & Wan, Q. (2025). A Novel (AlCrNbTaTi)N Multilayer Hard High-Entropy Alloy Nitride Coating with Variable Aluminum Content Deposited by Cathodic Arc Ion Plating. Coatings, 15(1), 76. https://doi.org/10.3390/coatings15010076