Atomic Layer Deposition of Y2O3 Thin Films Using Y(MeCp)2(iPr-nPrAMD) Precursor and H2O, and Their Erosion Resistance in CF4-Based Plasma

Abstract

1. Introduction

2. Materials and Methods

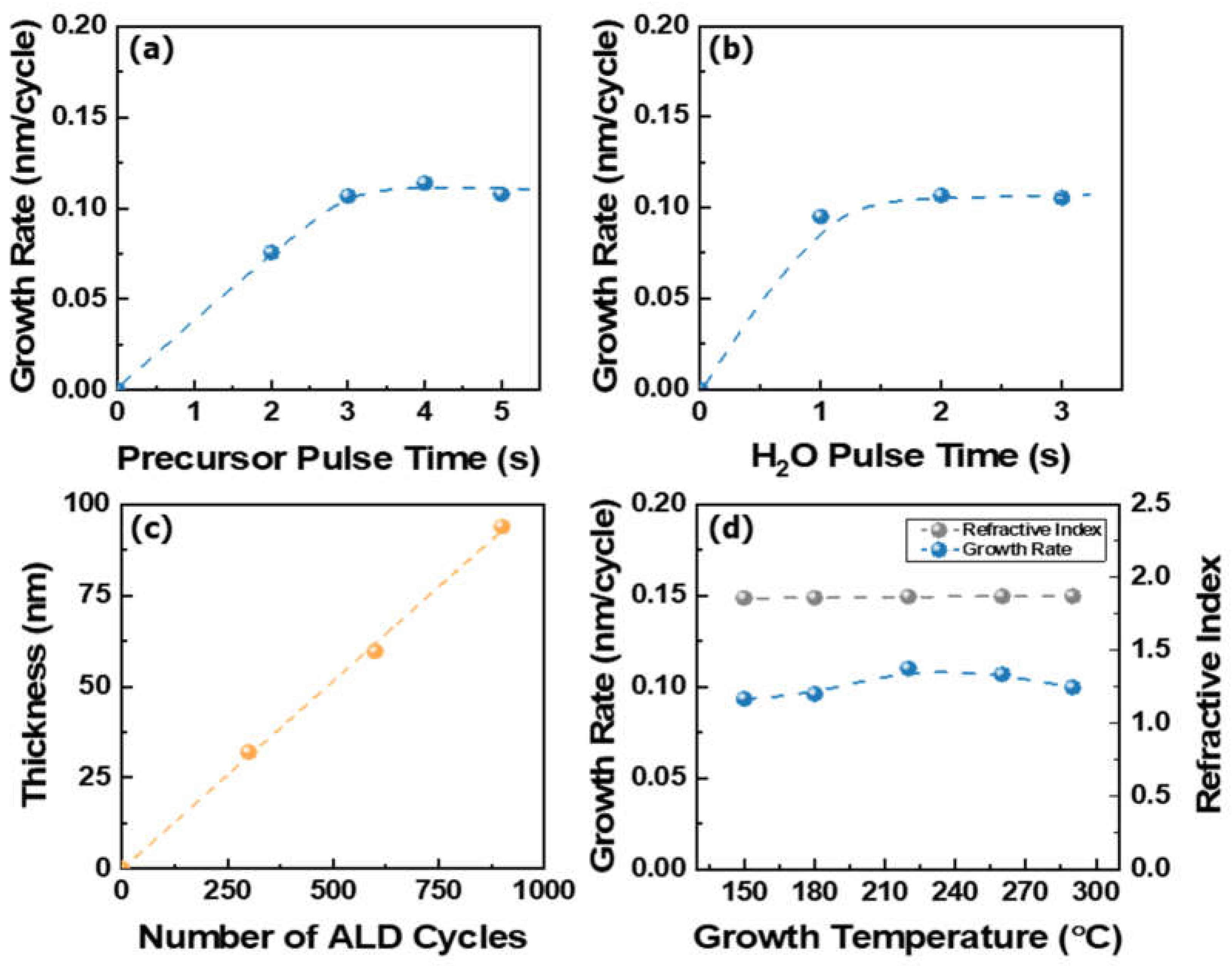

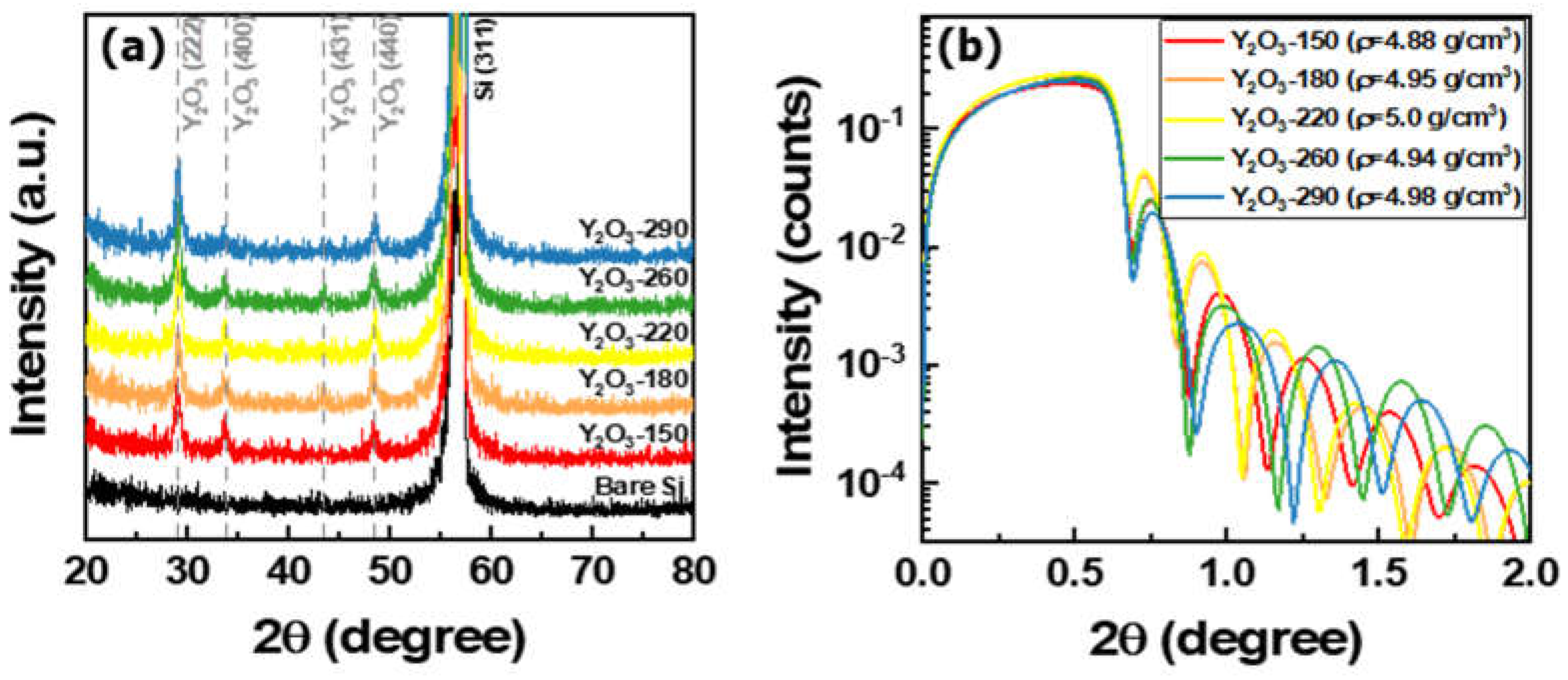

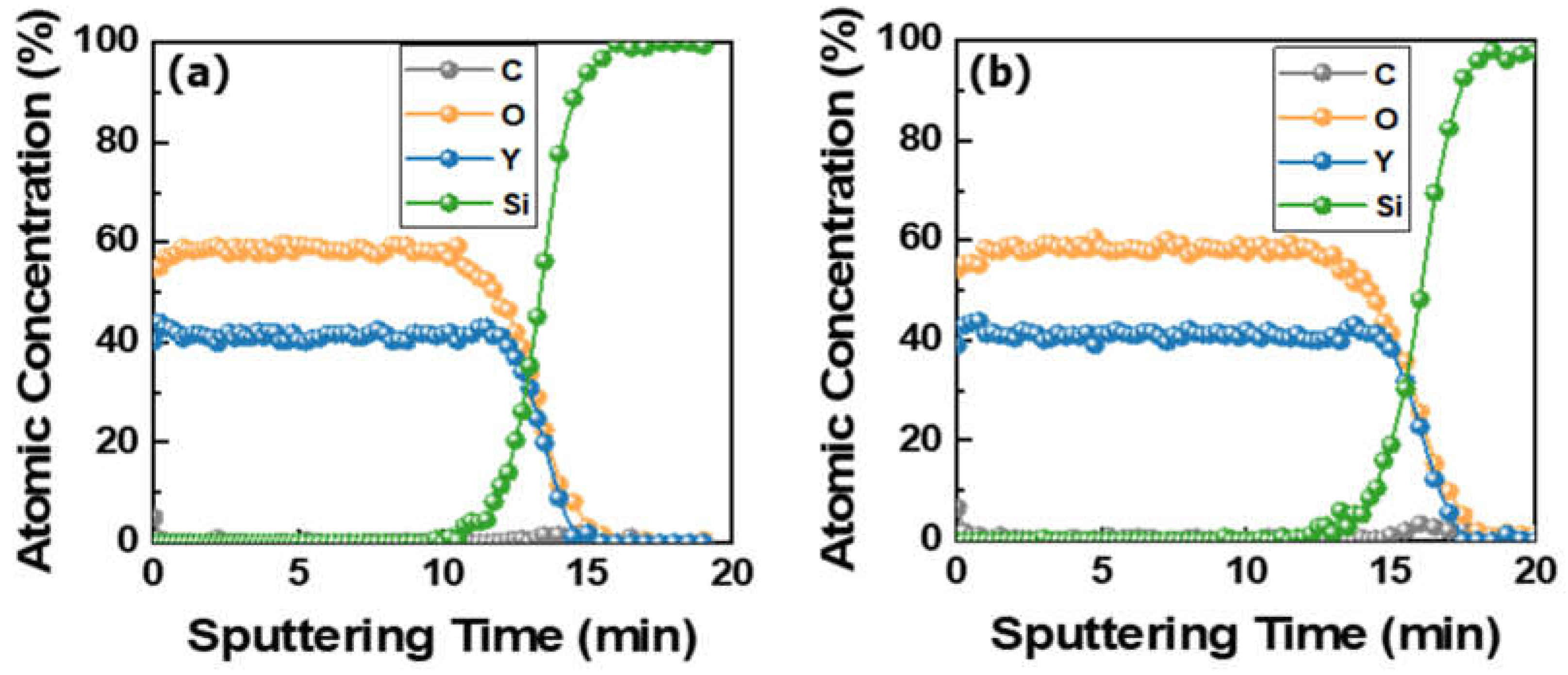

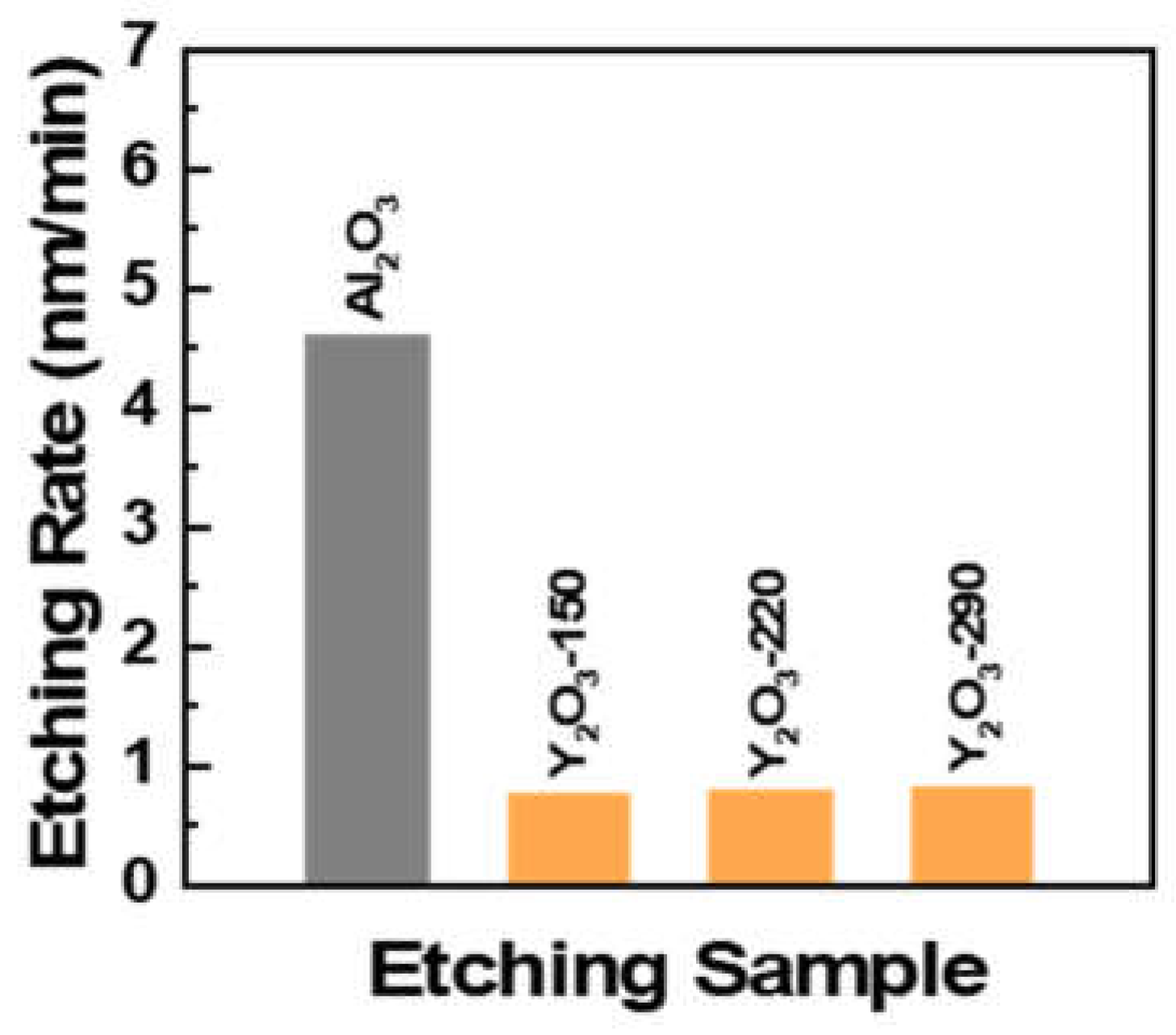

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, D.M.; Oh, Y.S.; Kim, S.W.; Kim, H.T.; Lim, D.S.; Lee, S.M. The erosion behaviors of Y2O3 and YF3 coatings under fluorocarbon plasma. Thin Solid Film. 2011, 519, 6698–6702. [Google Scholar] [CrossRef]

- Doemling, M.F.; Rueger, N.R.; Oehrlein, G.S.; Cook, J.M. Photoresist erosion studied in an inductively coupled plasma reactor employing CHF3. J. Vac. Sci. Technol. B 1998, 16, 1998–2005. [Google Scholar] [CrossRef]

- Cardinaud, C.; Peignon, M.C.; Tessier, P.Y. Plasma etching: Principles, mechanisms, application to micro-and nano-technologies. Appl. Surf. Sci. 2000, 164, 72–83. [Google Scholar] [CrossRef]

- Ito, N.; Moriya, T.; Uesugi, F.; Matsumoto, M.; Liu, S.; Kitayama, Y. Reduction of Particle Contamination in Plasma-Etching Equipment by Dehydration of Chamber Wall. Jpn. J. Appl. Phys. 2008, 47, 3630–3634. [Google Scholar] [CrossRef]

- Cunge, G.; Inglebert, R.L.; Joubert, O.; Vallier, L.; Sadeghi, N. Ion flux composition in HBr/Cl2/O2 and HBr/Cl2/O2/CF4 chemistries during silicon etching in industrial high-density plasmas. J. Vac. Sci. Technol. B 2002, 20, 2137–2148. [Google Scholar] [CrossRef]

- Fukumoto, H.; Fujikake, I.; Takao, Y.; Eriguchi, K.; Ono, K. Plasma chemical behaviour of reactants and reaction products during inductively coupled CF4 plasma etching of SiO2. Plasma Sources Sci. Technol. 2009, 18, 045027. [Google Scholar] [CrossRef]

- Miwa, K.; Sawai, T.; Aoyama, M.; Inoue, F.; Oikawa, A.; Imaoka, K. Particle reduction using Y2O3 material in an etching tool. In Proceedings of the 2007 International Symposium on Semiconductor Manufacturing, Santa Clara, CA, USA, 15–17 October 2007; pp. 1–4. [Google Scholar]

- Iwasawa, J.; Nishimizu, R.; Tokita, M.; Kiyohara, M.; Uematsu, K. Plasma-Resistant Dense Yttrium Oxide Film Prepared by Aerosol Deposition Process. J. Am. Ceram. Soc. 2007, 90, 2327–2332. [Google Scholar] [CrossRef]

- Qin, X.; Zhou, G.; Yang, H.; Wong, J.I.; Zhang, J.; Luo, D.; Wang, S.; Ma, J.; Tang, D. Fabrication and plasma resistance properties of transparent YAG ceramics. Ceram. Int. 2012, 38, 2529–2535. [Google Scholar] [CrossRef]

- Kim, D.M.; Lee, S.H.; Alexander, W.B.; Kim, K.B.; Oh, Y.S.; Lee, S.M. X-Ray Photoelectron Spectroscopy Study on the Interaction of Yttrium–Aluminum Oxide with Fluorine-Based Plasma. J. Am. Ceram. Soc. 2011, 94, 3455–3459. [Google Scholar] [CrossRef]

- Alarcón-Flores, G.; Aguilar-Frutis, M.; Falcony, C.; García-Hipolito, M.; Araiza-Ibarra, J.J.; Herrera-Suárez, H.J. Low interface states and high dielectric constant films on Si substrates. J. Vac. Sci. Technol. B. 2006, 24, 1873. [Google Scholar] [CrossRef]

- Rouffignac, P.; Park, J.S.; Gordon, R.G. Atomic layer deposition of Y2O3 Thin Films from Yttrium Tris(N,N′-diisopropylacetamidinate) and Water. Chem. Mater. 2005, 17, 4808. [Google Scholar] [CrossRef]

- Klein, P.H.; Croft, W.J. Thermal Conductivity, Diffusivity, and Expansion of Y2O3, Y3Al5O12, and LaF3 in the Range 77°–300°K. J. Appl. Phys. 1967, 38, 1603–1607. [Google Scholar] [CrossRef]

- Fan, W.; Bai, Y.; Wang, Z.Z.; Che, J.W.; Wang, Y.; Tao, W.Z.; Wang, R.J.; Liang, G.Y. Effect of point defects on the thermal conductivity of Sc2O3-Y2O3 co-stabilized tetragonal ZrO2 ceramic materials. J. Eur. Ceram. Soc. 2019, 39, 2389–2396. [Google Scholar] [CrossRef]

- Wilk, G.D.; Wallace, R.M.; Anthony, J.M. High-κ gate dielectrics: Current status and materials properties considerations. J. Appl. Phys. 2001, 89, 5243–5275. [Google Scholar] [CrossRef]

- Kim, M.; Choi, E.; Lee, D.; Seo, J.; Back, T.S.; So, J.; Yun, J.Y.; Suh, S.M. The effect of powder particle size on the corrosion behavior of atmospheric plasma spray-Y2O3 coating: Unraveling the corrosion mechanism by fluorine-based plasma. Appl. Surf. Sci. 2022, 606, 154958. [Google Scholar] [CrossRef]

- Kitamura, J.; Ibe, H.; Yuasa, F.; Mizuno, H. Plasma sprayed coatings of high-purity ceramics for semiconductor and flat-panel-display production equipment. J. Therm. Spray Technol. 2008, 17, 878–886. [Google Scholar] [CrossRef]

- Wiktorczyk, T.; Biegański, P.; Serafińczuk, J. Optical properties of nanocrystalline Y2O3 thin films grown on quartz substrates by electron beam deposition. Opt. Mater. 2016, 59, 150–156. [Google Scholar] [CrossRef]

- Varhue, W.J.; Massimo, M.; Carrulli, J.M.; Baranauskas, V.; Adams, E.; Broitman, E. Deposition of Y2O3 by plasma enhanced organometallic chemical vapor deposition using an electron cyclotron resonance source. J. Vac. Sci. Technol. A 1993, 11, 1870–1874. [Google Scholar] [CrossRef]

- Detavernier, C.; Dendooven, J.; Sree, S.P.; Ludwig, K.F.; Martens, J.A. Tailoring nanoporous materials by atomic layer deposition. Chem. Soc. Rev. 2011, 40, 5242. [Google Scholar] [CrossRef]

- Cremers, V.; Puurunen, R.L.; Dendooven, J. Conformality in atomic layer deposition: Current status overview of analysis and modelling. Appl. Phys. Rev. 2019, 6, 021302. [Google Scholar] [CrossRef]

- Johnson, R.W.; Hultqvist, A.; Bent, S.F. A brief review of atomic layer deposition: From fundamentals to applications. Mater. Today 2014, 17, 236. [Google Scholar] [CrossRef]

- Muñoz-Rojasu, D.; Maindron, T.; Esteve, A.; Piallat, F.; Kools, J.C.S.; Decams, J.M. Speeding up the unique assets of atomic layer deposition. Mater. Today Chem. 2019, 12, 96. [Google Scholar] [CrossRef]

- Niinistö, J.; Putkonen, M.; Niinistö, L. Processing of Y2O3 Thin Films by Atomic Layer Deposition from Cyclopentadienyl-Type Compounds and Water as Precursors. Chem. Mater. 2004, 16, 2953. [Google Scholar] [CrossRef]

- Majumder, P.; Jursich, G.; Kueltzo, A.; Takoudis, C. Atomic Layer Deposition of Y2O3 Films on Silicon Using Tris(ethylcyclopentadienyl) Yttrium Precursor and Water Vapor. J. Electrochem. Soc. 2008, 155, G152. [Google Scholar] [CrossRef]

- Xu, R.; Selvaraj, S.K.; Azimi, N.; Takoudis, C.G. Growth Characteristics and Properties of Yttrium Oxide Thin Films by Atomic Layer Deposition from Novel Y(iPrCp)3 Precursor and O3. ECS Trans. 2012, 50, 107. [Google Scholar] [CrossRef]

- Gusev, E.P.; Cartier, E.; Buchanan, D.A.; Gribelyuk, M.; Copel, M.; Okorn-Schmidt, H.; D’Emic, C. Ultrathin high-K metal oxides on silicon: Processing, characterization and integration issues. Microelectron. Eng. 2001, 59, 341. [Google Scholar] [CrossRef]

- Van, T.T.; Chang, J.P. Radical-enhanced atomic layer deposition of Y2O3 via a β-diketonate precursor and O radicals. Surf. Sci. 2005, 596, 1–11. [Google Scholar] [CrossRef]

- Mölsä, H.; Niinistö, L.; Utriainen, M. Growth of yttrium oxide thin films from β-diketonate precursor. Adv. Mater. Opt. Electron. 1994, 4, 389. [Google Scholar] [CrossRef]

- Putkonen, M.; Sajavaara, T.; Johansson, L.S.; Niinistö, L. Low-Temperature ALE Deposition of Y2O3 Thin Films from β-Diketonate Precursors. Chem. Vap. Depos. 2001, 7, 44. [Google Scholar] [CrossRef]

- Dussarrat, C.; Blasco, N.; Noh, W.; Lee, J.; Greet, J.; Teramoto, T.; Kamimura, S.; Gosset, N.; Ono, T. Thermal Atomic Layer Deposition of Yttrium Oxide Films and Their Properties in Anticorrosion and Water Repellent Coating Applications. Coatings 2021, 11, 497. [Google Scholar] [CrossRef]

- Mergel, D.; Buschendort, D.; Eggert, S.; Grammes, R.; Samset, B. Density and refractive index of TiO2 films prepared by reactive evaporation. Thin Solid Films 2000, 371, 218. [Google Scholar] [CrossRef]

- Cao, Y.C.; Zhao, L.; Luo, J.; Wang, K.; Zhang, B.P.; Yokota, H.; Ito, Y.; Li, J.F. Plasma etching behavior of Y2O3 ceramics: Comparative study with Al2O3. Appl. Surf. Sci. 2016, 366, 304. [Google Scholar] [CrossRef]

- Kim, D.M.; Jang, M.R.; Oh, Y.S.; Kim, S.K.; Lee, S.M.; Lee, S.H. Relative sputtering rates of oxides and fluorides of aluminum and yttrium. Surf. Coat. Technol. 2017, 309, 694. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.; Kim, H.; Kwon, S. Atomic Layer Deposition of Y2O3 Thin Films Using Y(MeCp)2(iPr-nPrAMD) Precursor and H2O, and Their Erosion Resistance in CF4-Based Plasma. Coatings 2025, 15, 22. https://doi.org/10.3390/coatings15010022

Lee S, Kim H, Kwon S. Atomic Layer Deposition of Y2O3 Thin Films Using Y(MeCp)2(iPr-nPrAMD) Precursor and H2O, and Their Erosion Resistance in CF4-Based Plasma. Coatings. 2025; 15(1):22. https://doi.org/10.3390/coatings15010022

Chicago/Turabian StyleLee, Seong, Hyunchang Kim, and Sehun Kwon. 2025. "Atomic Layer Deposition of Y2O3 Thin Films Using Y(MeCp)2(iPr-nPrAMD) Precursor and H2O, and Their Erosion Resistance in CF4-Based Plasma" Coatings 15, no. 1: 22. https://doi.org/10.3390/coatings15010022

APA StyleLee, S., Kim, H., & Kwon, S. (2025). Atomic Layer Deposition of Y2O3 Thin Films Using Y(MeCp)2(iPr-nPrAMD) Precursor and H2O, and Their Erosion Resistance in CF4-Based Plasma. Coatings, 15(1), 22. https://doi.org/10.3390/coatings15010022