Investigation of the Tribological Properties and Corrosion Resistance of Multilayer Si-DLC Films on the Inner Surfaces of N80 Steel Pipes

Abstract

1. Introduction

2. Experimental Details

2.1. Preparation of Multilayer Si-DLC Films on the Inner Surfaces of N80 Steel Pipes

2.2. Characterization of Structure and Mechanical Properties of Multilayer Si-DLC Films

2.3. Evaluation of Tribological and Corrosion Properties of Multilayer Si-DLC Films

3. Results and Discussion

3.1. Microstructures and Surface Morphologies of Multilayer Si-DLC Films on the Inner Surfaces of N80 Steel Pipes

3.2. Mechanical Properties of the Films on the Inner Surfaces of N80 Steel Pipes

3.3. Tribological Properties of Si-DLC Films on the Inner Surface of N80 Steel Pipe

3.4. Corrosion Resistance of Si-DLC Films on the Inner Surface of N80 Steel Pipe

4. Conclusions

- (1)

- A series of multilayer Si-DLC films with 10, 20, and 40 modulation periods were successfully prepared on the inner surfaces of N80 steel pipes by hollow-cathode plasma-enhanced chemical vapor deposition technology. The multilayer (Si-DLC)40 film exhibited a dense and uniform structure and the best mechanical performance, with a hardness of 14.3 GPa, an elastic modulus of 115.7 GPa, and an adhesive force Lc2 of 14.2 N.

- (2)

- The tribological properties of the multilayer (Si-DLC)40 film on the inner surfaces of N80 steel pipes surpassed those of uncoated N80 steel in atmospheric conditions. While the friction coefficient of uncoated N80 steel pipes ranged from 0.7 to 0.75, the multilayer (Si-DLC)40 film demonstrated a significantly lower coefficient, approximately between 0.2 and 0.3. Moreover, the wear rate of the multilayer (Si-DLC)40 film was three orders of magnitude lower than that of the N80 steel pipe. This was mainly attributed to the high mechanical and transfer film on the mating ball.

- (3)

- The multilayer (Si-DLC)40 film possessed more interfaces due to the increase in the film thickness, effectively prolonging the penetration distance of the corrosive medium in the 3.5 wt% NaCl solution and the 3.5 wt% NaCl solution saturated with CO2. Therefore, the multilayer (Si-DLC)40 film exhibited the best corrosion resistance and protective effect compared with the multilayer (Si-DLC)10 and (Si-DLC)20 films. In particular, the corrosion current density of the multilayer (Si-DLC)40 film in the 3.5 wt% NaCl solution saturated with CO2, approximately 7.67 μA/cm2, was roughly half that of the N80 steel pipe, which recorded a corrosion current of about 18.6 μA/cm2. Additionally, the impedance value of the multilayer (Si-DLC)40 film (6790 Ω∙cm2) was approximately twice that of the uncoated N80 steel pipe (3120 Ω∙cm2).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Safi, R.; Agarwal, R.K.; Banerjee, S.J.C.E.S. Numerical Simulation and Optimization of CO2 Utilization for Enhanced Oil Recovery from Depleted Reservoirs. Chem. Eng. Sci. 2016, 144, 30–38. [Google Scholar] [CrossRef]

- Ma, W. Corrosion Behavior of Gas Storage Well Pipe Strings in Corrosive H2S–CO2 Environment. J. Fail. Anal. Prev. 2022, 22, 368–376. [Google Scholar] [CrossRef]

- Davoudi, M.; Heidari, Y.; Safadoost, A.; Samieirad, S. Chemical injection policy for internal corrosion prevention of South Pars sea-pipeline: A case study. J. Nat. Gas Sci. Eng. 2014, 21, 592–599. [Google Scholar] [CrossRef]

- Li, J.; Sun, C.; Roostaei, M.; Mahmoudi, M.; Fattahpour, V.; Zeng, H.; Luo, J.-L. Characterization and corrosion behavior of electroless Ni-Mo-P/Ni-P composite coating in CO2/H2S/Cl−brine: Effects of Mo addition and heat treatment. Surf. Coat. Technol. 2020, 403, 126416. [Google Scholar] [CrossRef]

- Sun, C.; Liu, S.; Li, J.; Zeng, H.; Luo, J.L. Insights into the Interfacial Process in Electroless Ni-P Coating on Supercritical CO2 Transport Pipeline as Relevant to Carbon Capture and Storage. ACS Appl. Mater. Interfaces 2019, 11, 16243–16251. [Google Scholar] [CrossRef]

- Wang, Q.-Y.; Wang, X.-Z.; Luo, H.; Luo, J.-L. A study on corrosion behaviors of Ni–Cr–Mo laser coating, 316 stainless steel and X70 steel in simulated solutions with H2S and CO2. Surf. Coat. Technol. 2016, 291, 250–257. [Google Scholar] [CrossRef]

- Dushik, V.V.; Lakhotkin, Y.V.; Kuzmin, V.P.; Rozhanskii, N.V. The corrosion behavior of hard W–C system chemical vapor deposition layers in HCl and H2S aqueous solutions. Prot. Met. Phys. Chem. Surf. 2017, 52, 1153–1156. [Google Scholar] [CrossRef]

- Hoque, M.J.; Li, L.; Ma, J.; Cha, H.; Sett, S.; Yan, X.; Rabbi, K.F.; Ho, J.Y. Ultra-resilient multi-layer fluorinated diamond like carbon hydrophobic surfaces. Nat. Commun. 2023, 14, 4902. [Google Scholar] [CrossRef]

- Khan, A.M.; He, X.; Wu, H.; Desanker, M.; Erdemir, A.; Chung, Y.W.; Wang, Q.J. Acid treatment of diamond-like carbon surfaces for enhanced adsorption of friction modifiers and friction performance. Tribol. Lett. 2018, 66, 128. [Google Scholar] [CrossRef]

- Mariano, S.D.F.M.; Silva, C.; Medeiros, F.I.D.; Pillaca, E.J.D.M.; Ueda, M. Graphene-like coated steel tube via biased hollow cathode discharges. Vacuum 2021, 192, 110431. [Google Scholar] [CrossRef]

- Brown, S.; Lengaigne, J.; Sharifi, N.; Pugh, M.; Moreau, C.; Dolatabadi, A.; Martinu, L.; Klemberg-Sapieha, J.E. Durability of superhydrophobic duplex coating systems for aerospace applications. Surf. Coat. Technol. 2020, 401, 126249. [Google Scholar] [CrossRef]

- Ellis, P.F.; Chambers, B.D. A diamond-like carbon pipe lining resistant to high temperature and pressure carbon dioxide/hydrogen sulfide environments. Paper presented at the CORROSION 2012, Salt Lake City, UT, USA, 11–15 March 2012. NACE-2012-1615. [Google Scholar]

- Koshigan, K.D.; Mangolini, F.; McClimon, J.B.; Vacher, B.; Bec, S.; Carpick, R.W.; Fontaine, J. Understanding the hydrogen and oxygen gas pressure dependence of the tribological properties of silicon oxide-doped hydrogenated amorphous carbon coatings. Carbon 2015, 93, 851–860. [Google Scholar] [CrossRef]

- Wang, J.; Pu, J.; Zhang, G.; Wang, L. Interface Architecture for Superthick Carbon-Based Films toward Low Internal Stress and Ultrahigh Load-Bearing Capacity. ACS Appl. Mater. Interfaces 2013, 5, 5015–5024. [Google Scholar] [CrossRef] [PubMed]

- Wei, X.; Yin, P.; Wu, J.; Nie, X.; Zhang, G. Deposition of DLC films on the inner wall of U-type pipes by hollow cathode PECVD. Diam. Relat. Mater. 2021, 114, 108308. [Google Scholar] [CrossRef]

- Wei, X.; Shi, S.; Ning, C.; Lu, Z.; Zhang, G. Si-DLC films deposited by a novel method equipped with a co-potential auxiliary cathode for anti-corrosion and anti-wear application. J. Mater. Sci. Technol. 2022, 109, 114–128. [Google Scholar] [CrossRef]

- Wei, X.; Ning, C.; Lu, Z.; Zhang, G. Si and N incorporated hydrogenated diamond like carbon film with excellent performance for marine corrosion resistance. Ceram. Int. 2022, 48, 8440–8450. [Google Scholar] [CrossRef]

- Wei, X.; Chen, L.; Zhang, M.; Lu, Z.; Zhang, G. Effect of dopants (F, Si) material on the structure and properties of hydrogenated DLC film by plane cathode PECVD. Diam. Relat. Mater. 2020, 110, 108102. [Google Scholar] [CrossRef]

- Wang, X.; Sui, X.; Zhang, S.; Yan, M.; Yang, J.; Hao, J.; Liu, W. Effect of deposition pressures on uniformity, mechanical and tribological properties of thick DLC coatings inside of a long pipe prepared by PECVD method. Surf. Coat. Technol. 2019, 375, 150–157. [Google Scholar] [CrossRef]

- Yi, X.; Li, L.; Luo, S.; Lu, Q.; Gu, J.; Lei, N.; Huo, C. Self-enhanced plasma discharge effect in the deposition of diamond-like carbon films on the inner surface of slender tube. Appl. Surf. Sci. 2017, 393, 467–473. [Google Scholar]

- Santos, N.; Mariano, S.; Ueda, M. Carbon films deposition as protective coating of titanium alloy tube using PIII&D system. Surf. Coat. Technol. 2019, 375, 164–170. [Google Scholar]

- Ferrari, A.C.; Robertson, J. Interpretation of Raman spectra of disordered and amorphous carbon. Phys. Rev. B 2000, 61, 14095–14107. [Google Scholar] [CrossRef]

- Casiraghi, C.; Ferrari, A.C.; Robertson, J. Raman spectroscopy of hydrogenated amorphous carbons. Phys. Rev. B 2005, 72, 85401. [Google Scholar] [CrossRef]

- Casiraghi, C.; Piazza, F.; Ferrari, A.C.; Grambole, D.; Robertson, J. Bonding in hydrogenated diamond-like carbon by Raman spectroscopy. Diam. Relat. Mater. 2005, 14, 1098–1102. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Resonant Raman spectroscopy of disordered, amorphous, and diamondlike carbon. Phys. Rev. B 2001, 64, 75414. [Google Scholar] [CrossRef]

- Ferrari, A.C. Determination of bonding in diamond-like carbon by Raman spectroscopy. Diam. Relat. Mater. 2002, 11, 1053–1061. [Google Scholar] [CrossRef]

- Fayed, S.M.; Chen, D.; Li, S.; Zhou, Y.; Wang, H.; Sadawy, M.M. Corrosion behavior and passive stability of multilayer DLC-Si coatings. Surf. Coat. Technol. 2022, 431, 128001. [Google Scholar] [CrossRef]

- Fayed, S.M.; Gao, P.; Chen, D.; Li, S.; Zhou, Y.; Wang, H.; Sadawy, M.M. Corrosion inhibition characteristics of multilayer Si-DLC, phosphating and anodizing coatings deposited on 2024 Al alloy: A comparative study. Diam. Relat. Mater. 2021, 117, 108460. [Google Scholar] [CrossRef]

- Wang, J.; Pu, J.; Zhang, G.; Wang, L. Tailoring the structure and property of silicon-doped diamond-like carbon films by controlling the silicon content. Surf. Coat. Technol. 2013, 235, 326–332. [Google Scholar] [CrossRef]

- Bhowmick, S.; Banerji, A.; Lukitsch, M.J.; Alpas, A.T. The high temperature tribological behavior of Si, O containing hydrogenated diamond-like carbon (a-C:H/a-Si:O) coating against an aluminum alloy. Wear 2015, 330, 261–271. [Google Scholar] [CrossRef]

- Kolodziejczyk, L.; Niedzielski, P.; Clapa, M.; Jedrzejczak, A.; Szymanski, W. Influence of the process parameters on the characteristics of silicon-incorporated a-C:H:SiOx coatings. Batory. Surf. Coat. Technol. 2015, 271, 112–118. [Google Scholar]

- Wei, Y.L.; Huang, L.L.; Han, L.J.; Chen, Y.S. Corrosion resistance and surface biocompatibility of diamond-like carbon coating on AZ31D magnesium alloy. Int. J. Surf. Sci. Eng. 2016, 10, 101–115. [Google Scholar] [CrossRef]

- Hamdy, A.S. Electrochemical behavior of diamond-like-carbon coatings deposited on AlTiC (Al2O3 + TiC) ceramic composite substrate in HCl solution. Electrochim. Acta 2011, 56, 1554–1562. [Google Scholar] [CrossRef]

- Liu, L.; Wu, Z.; Cui, S.; An, X.; Ma, Z.; Shao, T.; Fu, R.K.Y.; Wang, R.; Lin, H.; Pan, F.; et al. Abrasion and erosion behavior of DLC-coated oil-well tubings in a heavy oil/sand environment. Surf. Coat. Technol. 2019, 357, 379–383. [Google Scholar] [CrossRef]

- Jacobsohn, L.G.; Schulze, R.K.; da Costa, M.E.H.M.; Nastasi, M. X-ray photoelectron spectroscopy investigation of boron carbide films deposited by sputtering. Surf. Sci. 2004, 572, 418–424. [Google Scholar] [CrossRef]

- Tamura, Y.; Zhao, H.; Wang, C.; Morina, A.; Neville, A. Interaction of DLC and B4C coatings with fully formulated oils in boundary lubrication conditions. Tribol. Int. 2016, 93, 666–680. [Google Scholar] [CrossRef]

| Process Step | Precursors | Pressure (Pa) | Voltage (V) | Time (min) |

|---|---|---|---|---|

| Cleaning | Ar | 5 | −6000 | 30 |

| Adhesion | SiH4 + Ar | 15 | −15,000 | 20 |

| Six-DLC | C2H2 + SiH4 + Ar | 18–20 | −650~−800 | 4.5 |

| Siy-DLC | 11–13 | −650~−800 | 1.5 |

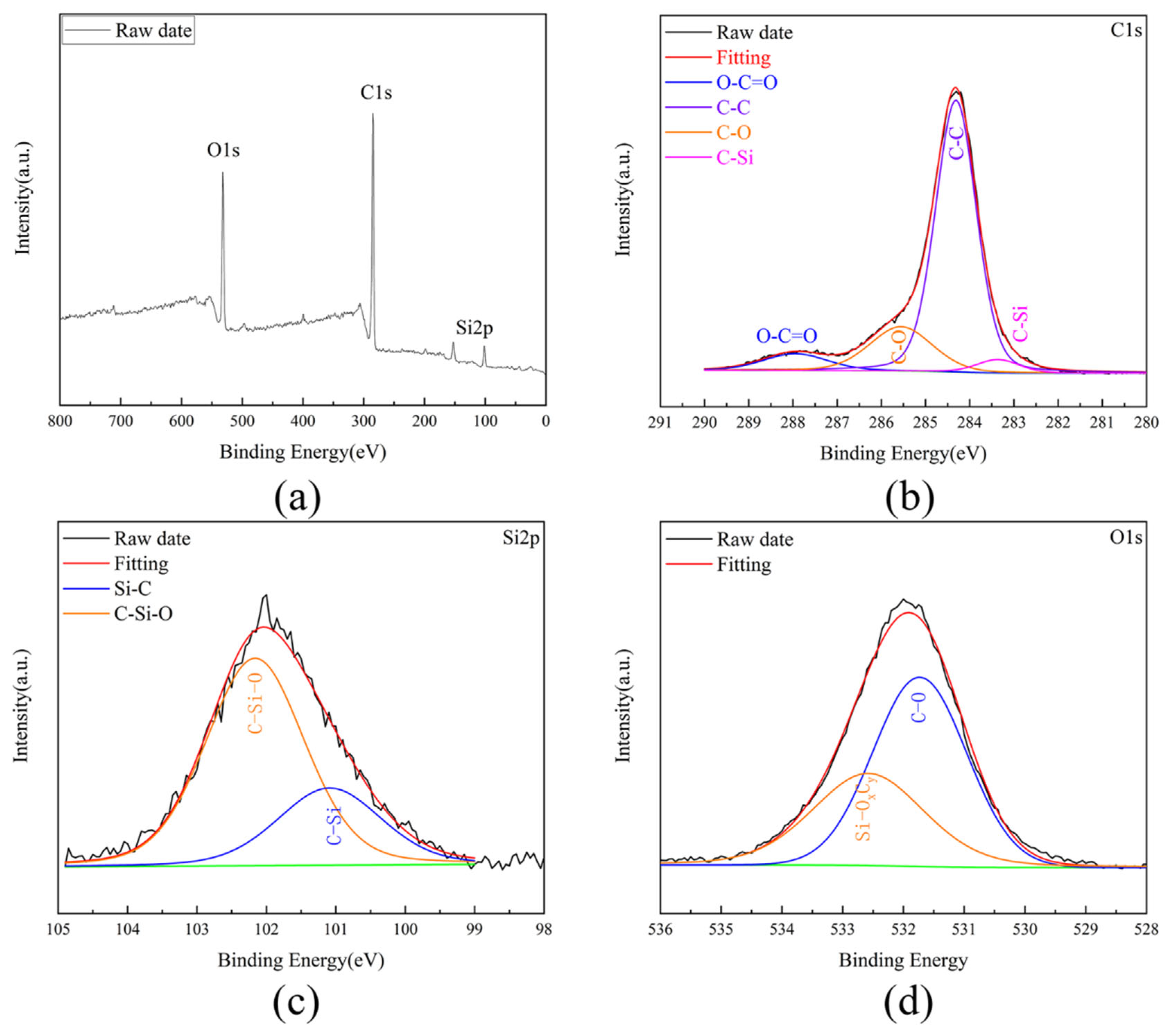

| Sample | Concentration (at.%) | ||

|---|---|---|---|

| C | Si | O | |

| Si-poor DLC layer | 82.34 | 7.14 | 10.52 |

| Si-rich DLC layer | 74.49 | 14.79 | 10.73 |

| Sample | Friction Coefficient | Wear Rate/mm3·N−1·m−1 |

|---|---|---|

| N80 | ~0.75 | 2.3 × 10−4 |

| (Si-DLC)10 | ~0.4 | 3.8 × 10−6 |

| (Si-DLC)20 | ~0.21 | 1.3 × 10−6 |

| (Si-DLC)40 | ~0.23 | 6.8 × 10−7 |

| Sample | Ecorr (V) | jcorr (A∙cm2) | Rp (Ω∙cm2) | P (Ω∙cm2) |

|---|---|---|---|---|

| N80 | −0.431 | 8.21 × 10−5 | 1.85 × 103 | — |

| 10 cycles | −0.582 | 1.39 × 10−5 | 2.21 × 103 | 3.09 |

| 20 cycles | −0.710 | 5.22 × 10−6 | 4.46 × 103 | 2.85 |

| 40 cycles | −0.683 | 4.99 × 10−7 | 7.51 × 104 | 0.89 |

| Sample | Ecorr (V) | jcorr (A∙cm2) | Rp (Ω∙cm2) | P (Ω∙cm2) |

|---|---|---|---|---|

| N80 | −0.628 | 1.86 × 10−5 | 3.12 × 103 | — |

| Si-DLC | −0.604 | 7.67 × 10−6 | 6.79 × 103 | 3.09 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Zhang, G.; Fu, A.; Cao, X.; Yin, C.; Liu, Z. Investigation of the Tribological Properties and Corrosion Resistance of Multilayer Si-DLC Films on the Inner Surfaces of N80 Steel Pipes. Coatings 2024, 14, 385. https://doi.org/10.3390/coatings14040385

Wang S, Zhang G, Fu A, Cao X, Yin C, Liu Z. Investigation of the Tribological Properties and Corrosion Resistance of Multilayer Si-DLC Films on the Inner Surfaces of N80 Steel Pipes. Coatings. 2024; 14(4):385. https://doi.org/10.3390/coatings14040385

Chicago/Turabian StyleWang, Shaolong, Guangan Zhang, Anqing Fu, Xueqian Cao, Chengxian Yin, and Zhengyu Liu. 2024. "Investigation of the Tribological Properties and Corrosion Resistance of Multilayer Si-DLC Films on the Inner Surfaces of N80 Steel Pipes" Coatings 14, no. 4: 385. https://doi.org/10.3390/coatings14040385

APA StyleWang, S., Zhang, G., Fu, A., Cao, X., Yin, C., & Liu, Z. (2024). Investigation of the Tribological Properties and Corrosion Resistance of Multilayer Si-DLC Films on the Inner Surfaces of N80 Steel Pipes. Coatings, 14(4), 385. https://doi.org/10.3390/coatings14040385