Microstructure and Properties of TiN/TiCN/Al2O3/TiN Coating Enhanced by High-Current Pulsed Electron Beam

Abstract

1. Introduction

2. Materials and Methods

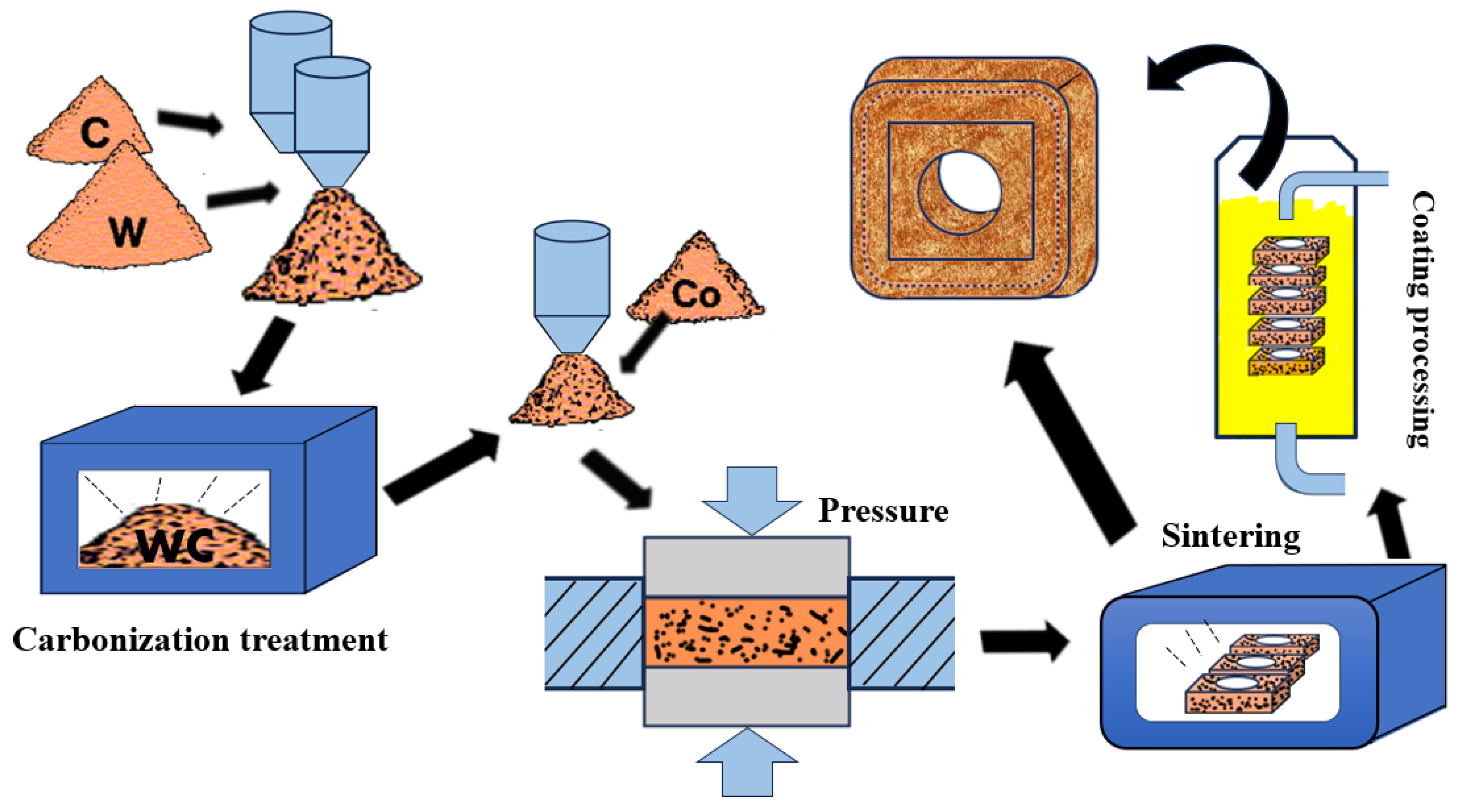

2.1. Preparation of Substrate and Coating

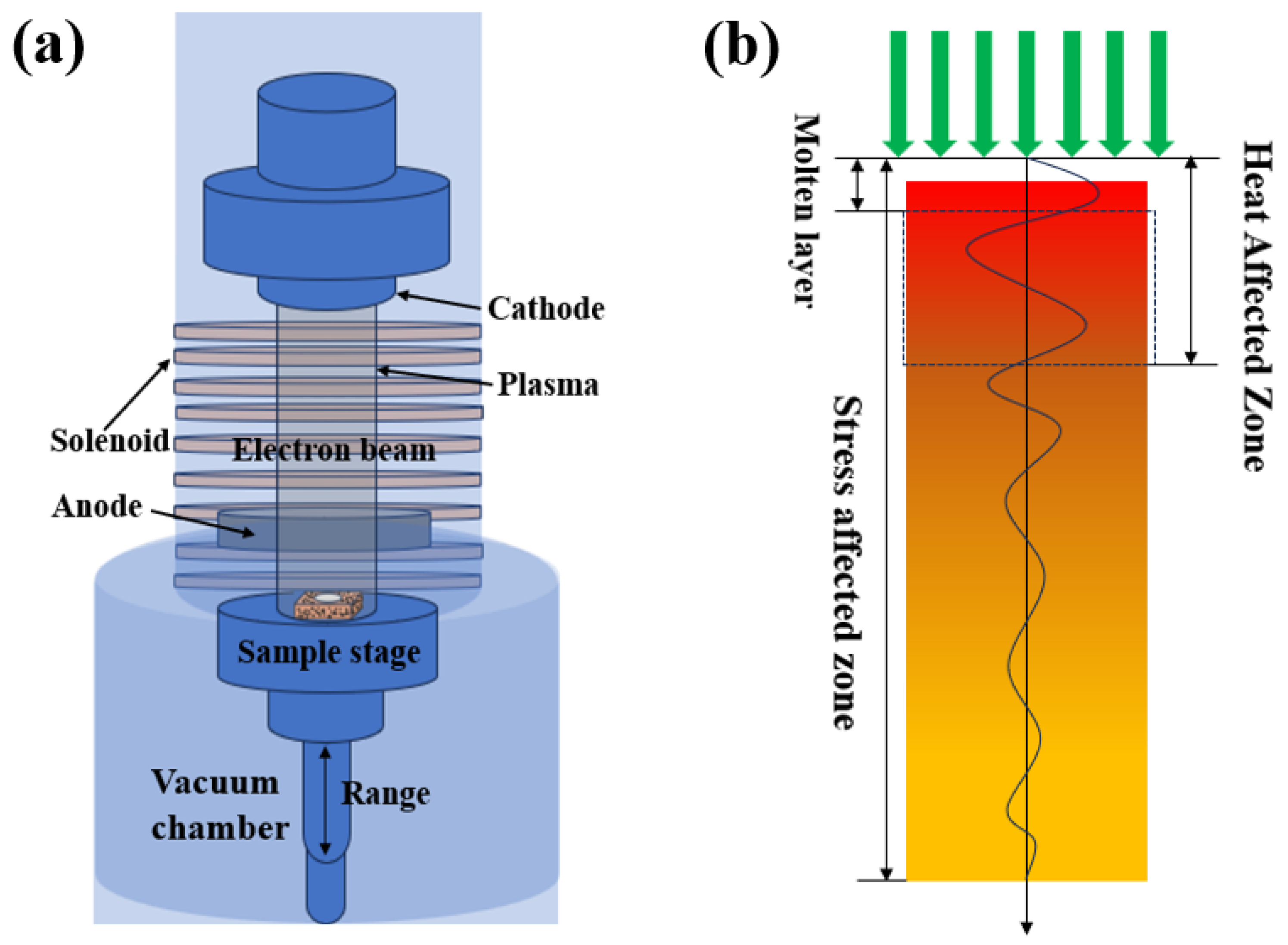

2.2. HCPEB Treatment

2.3. Characterization

3. Results and Discussion

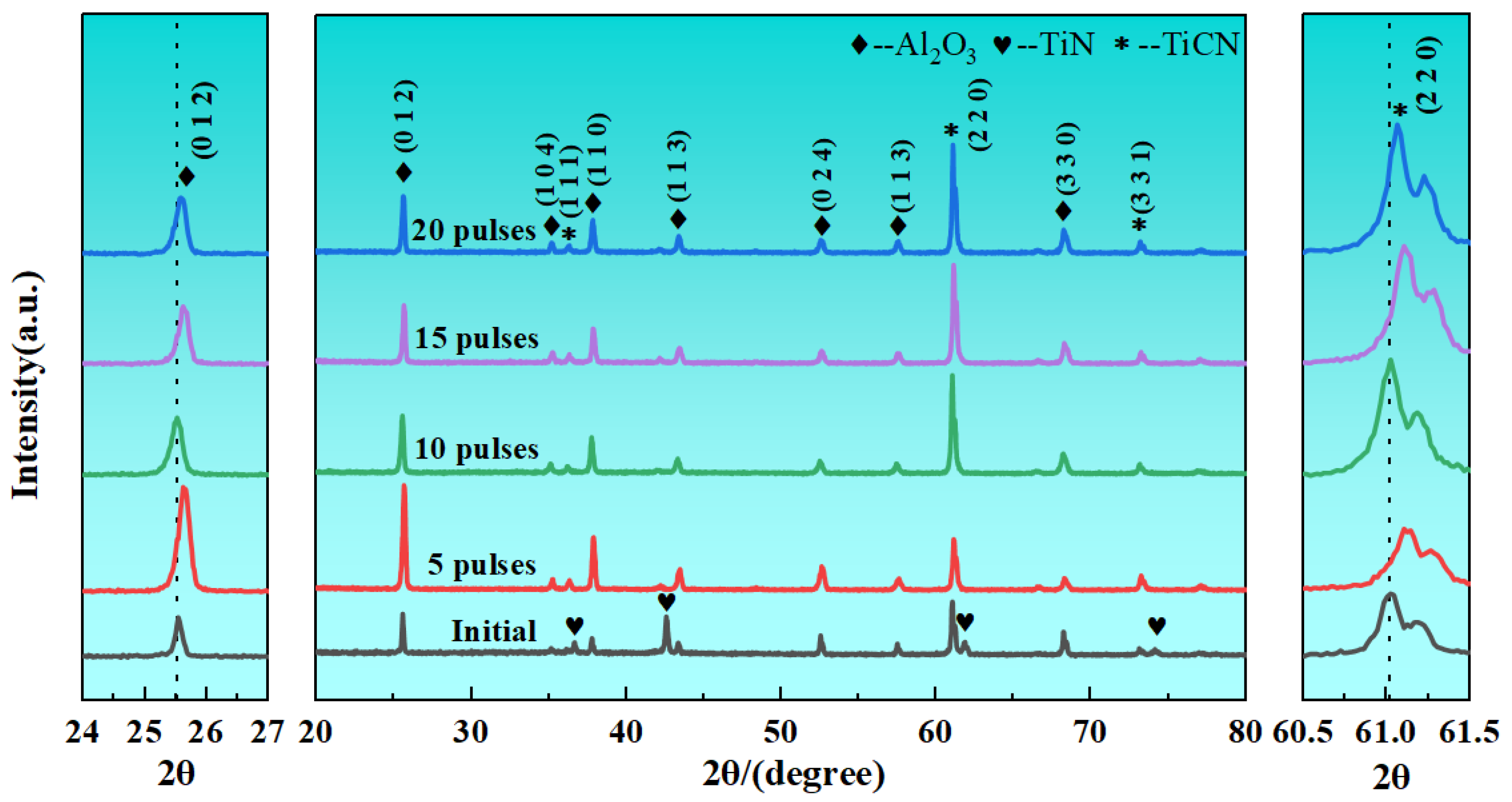

3.1. Physical Phase Analysis

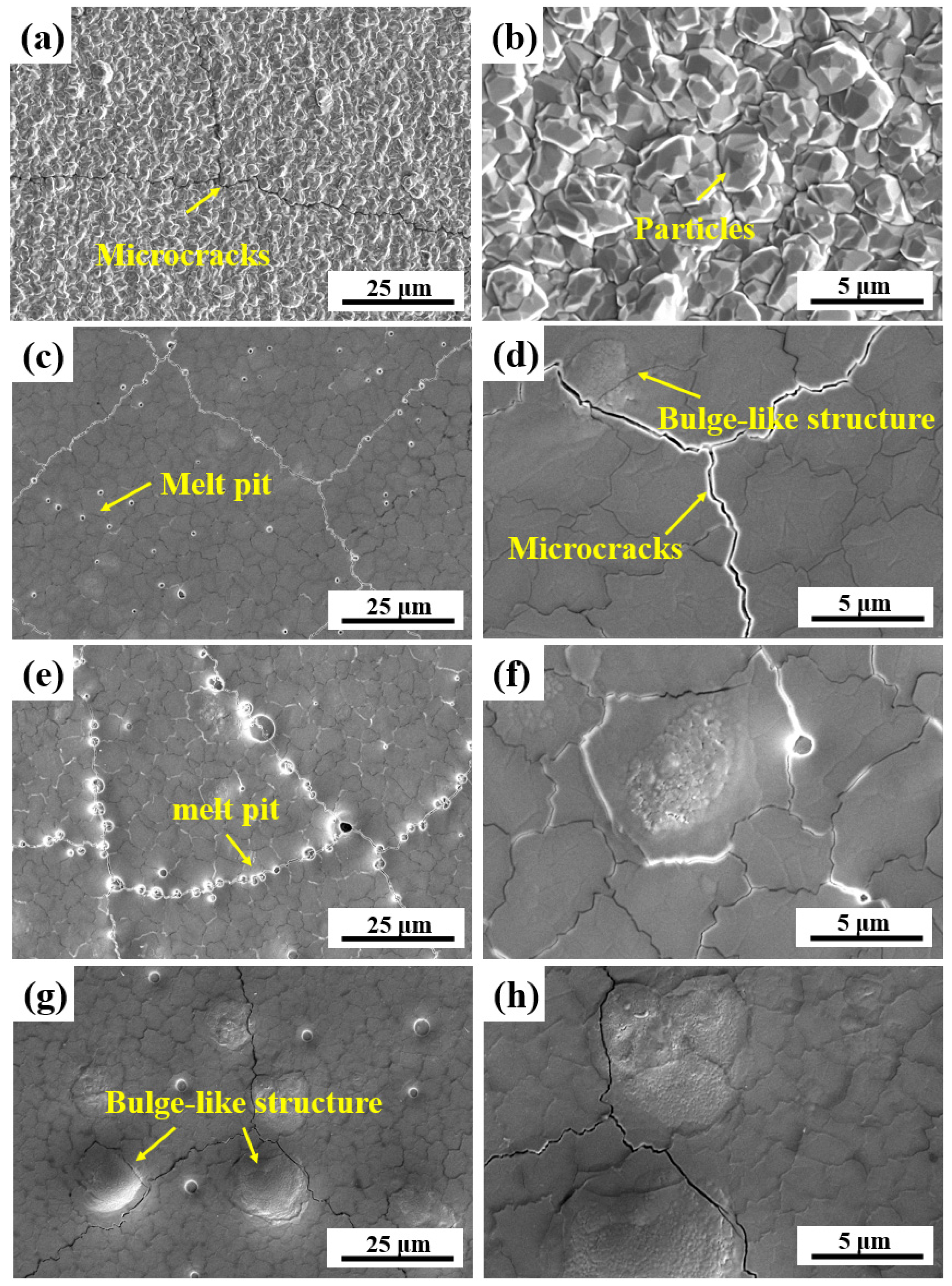

3.2. Microstructure Analysis

3.3. Mechanical Properties

4. Conclusions

- (1)

- After HCPEB treatment, the diffraction peak of the coating is widened and strengthened due to the formation of grain refinement and crystal defects. In addition, the stress state inside the coating also changes, and the diffraction peak shifts to a higher angle in different degrees compared with the original coating.

- (2)

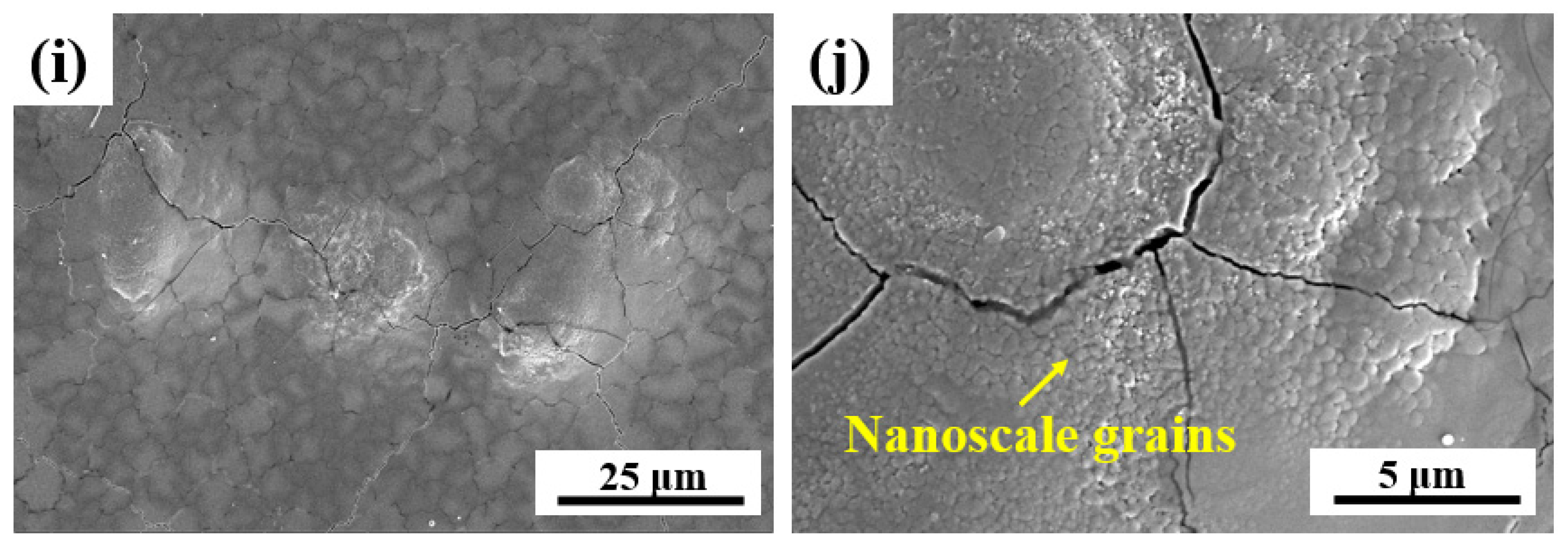

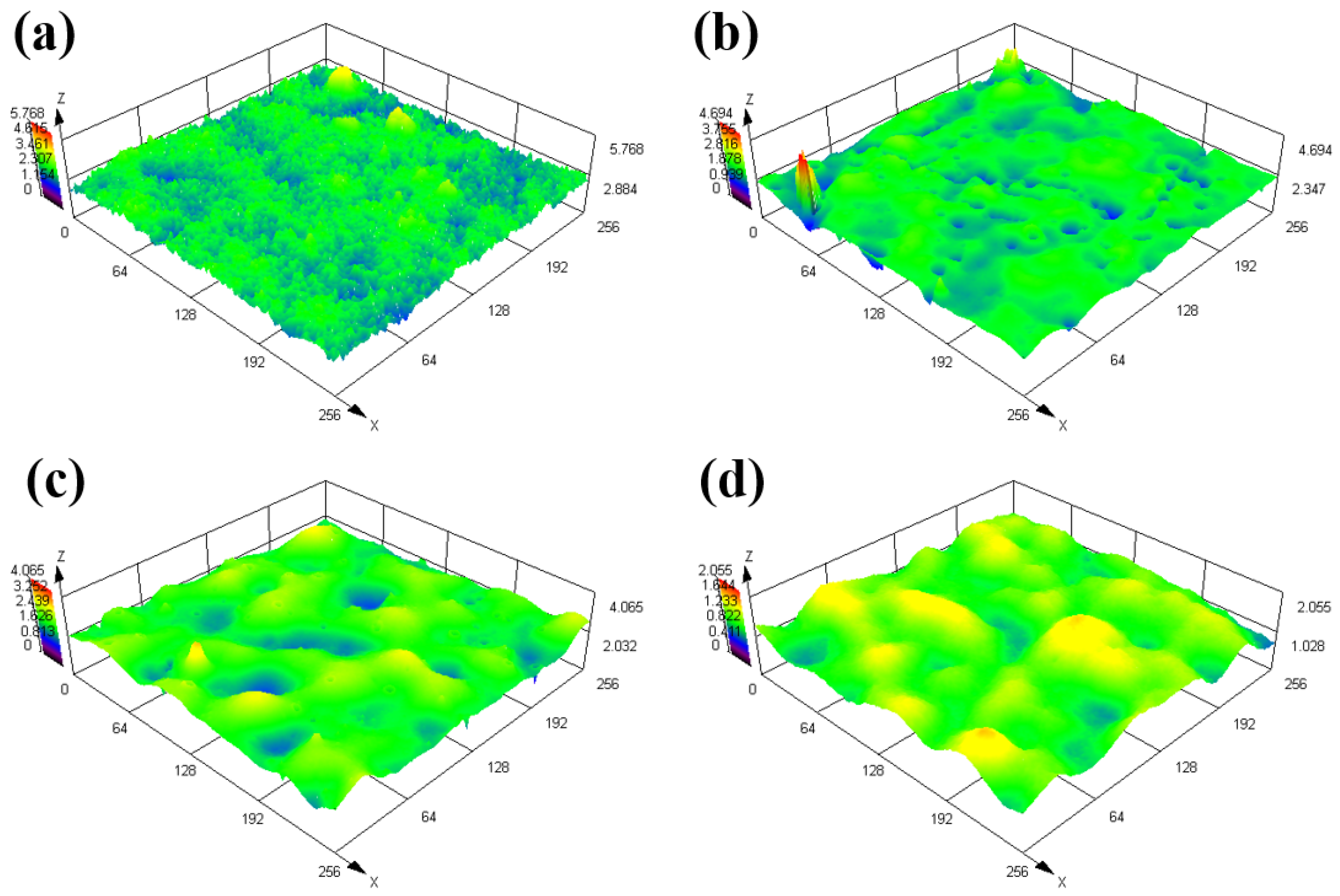

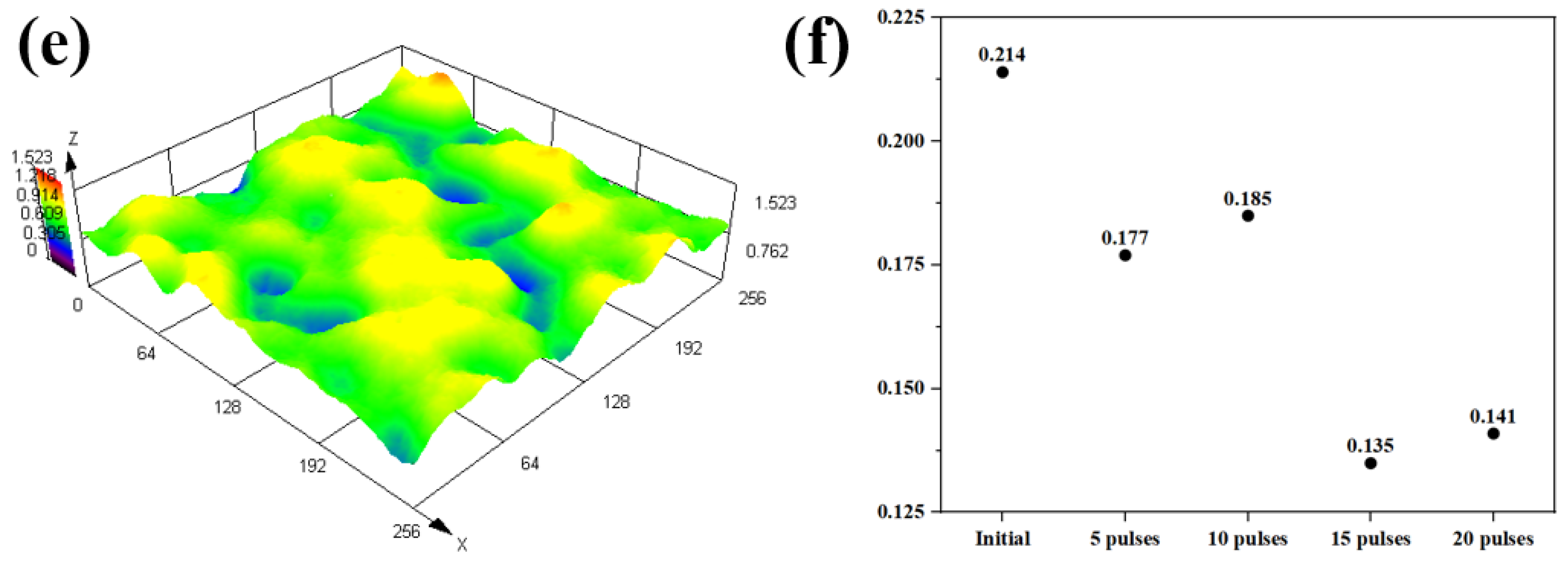

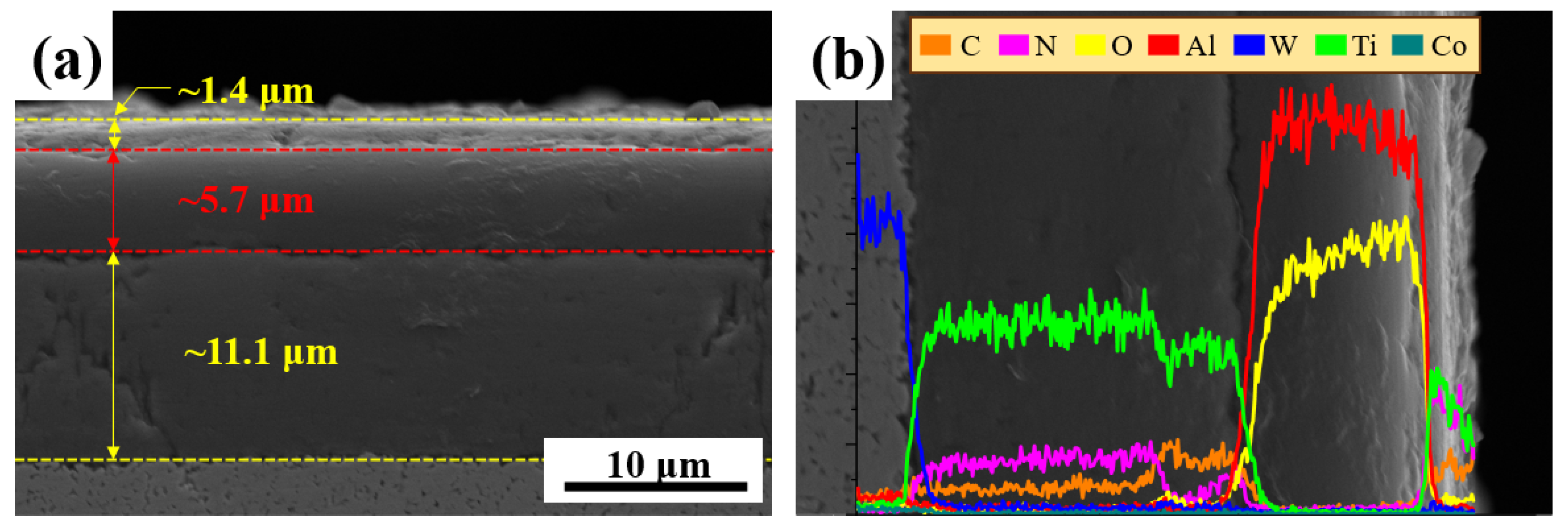

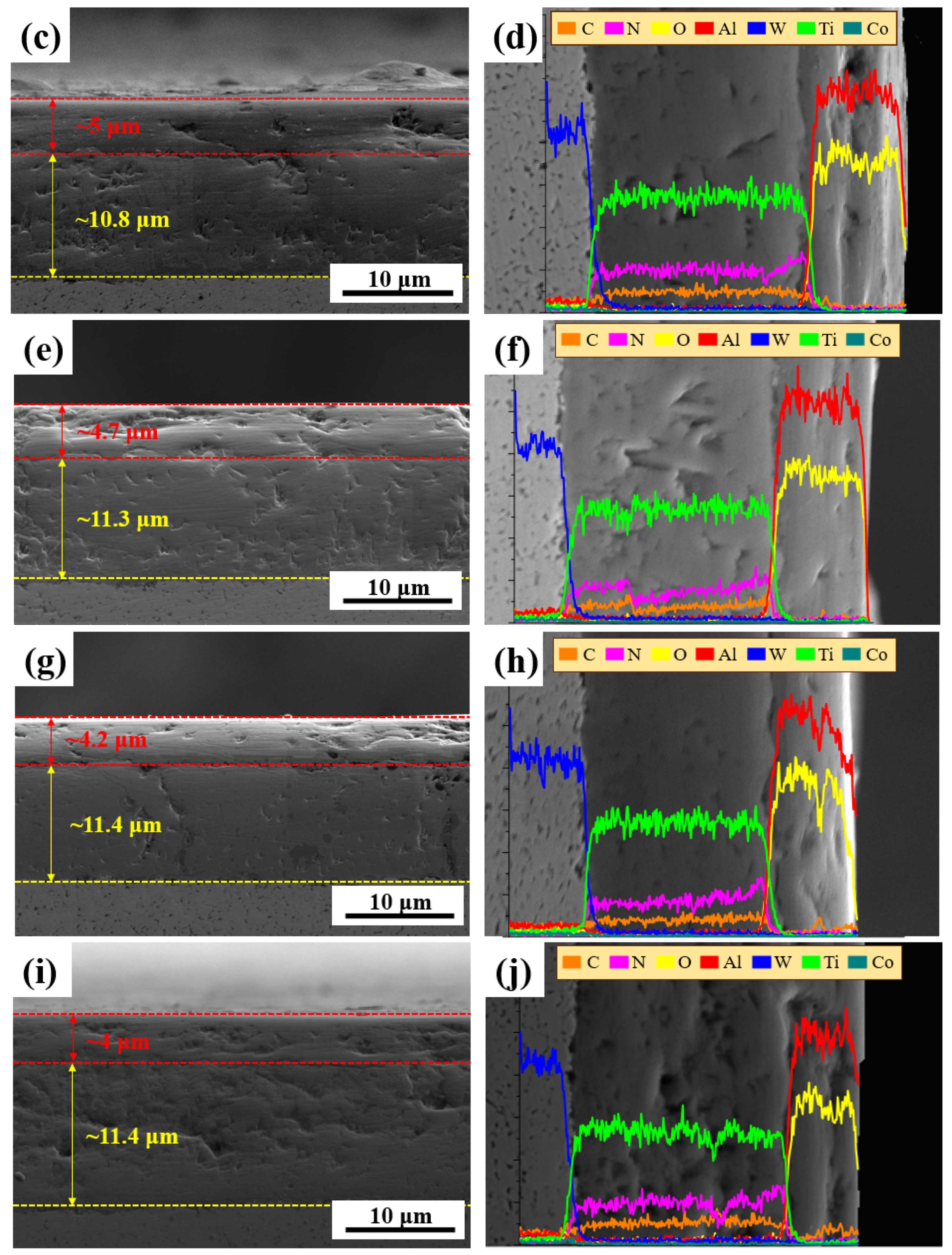

- After HCPEB treatment, the surface of the coating has a typical melt-pit appearance, and the nanoscale grain appears. In addition, the surface roughness of the coating decreases after irradiation, reaching its minimum at 15 pulses. The thickness of the coating decreases with the increase of pulse time.

- (3)

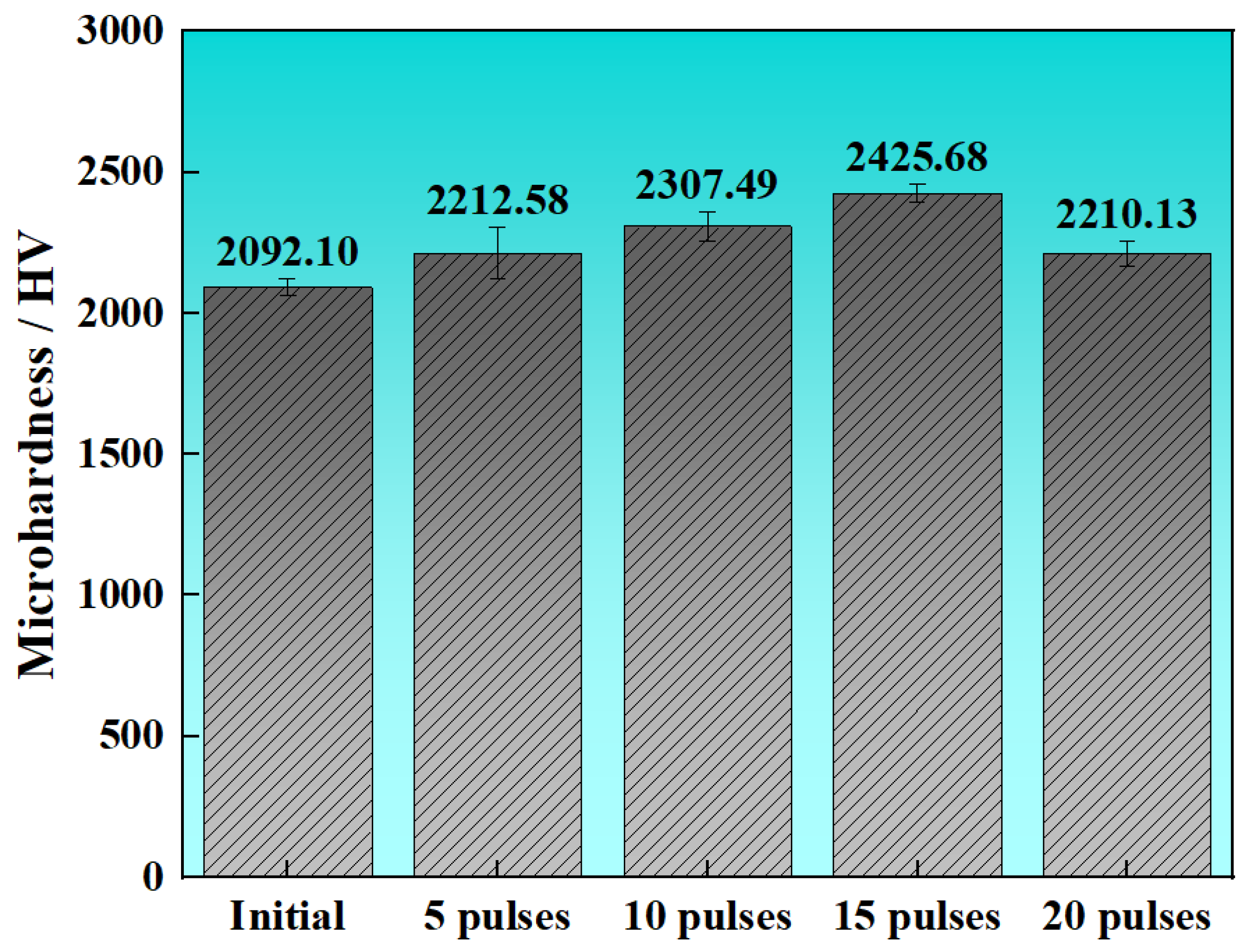

- HCPEB treatment can effectively improve the surface microhardness of TiN/TiCN/Al2O3/TiN coating. The microhardness of the coating increases first and then decreases with the number of pulses, reaching a peak at 15 pulses.

- (4)

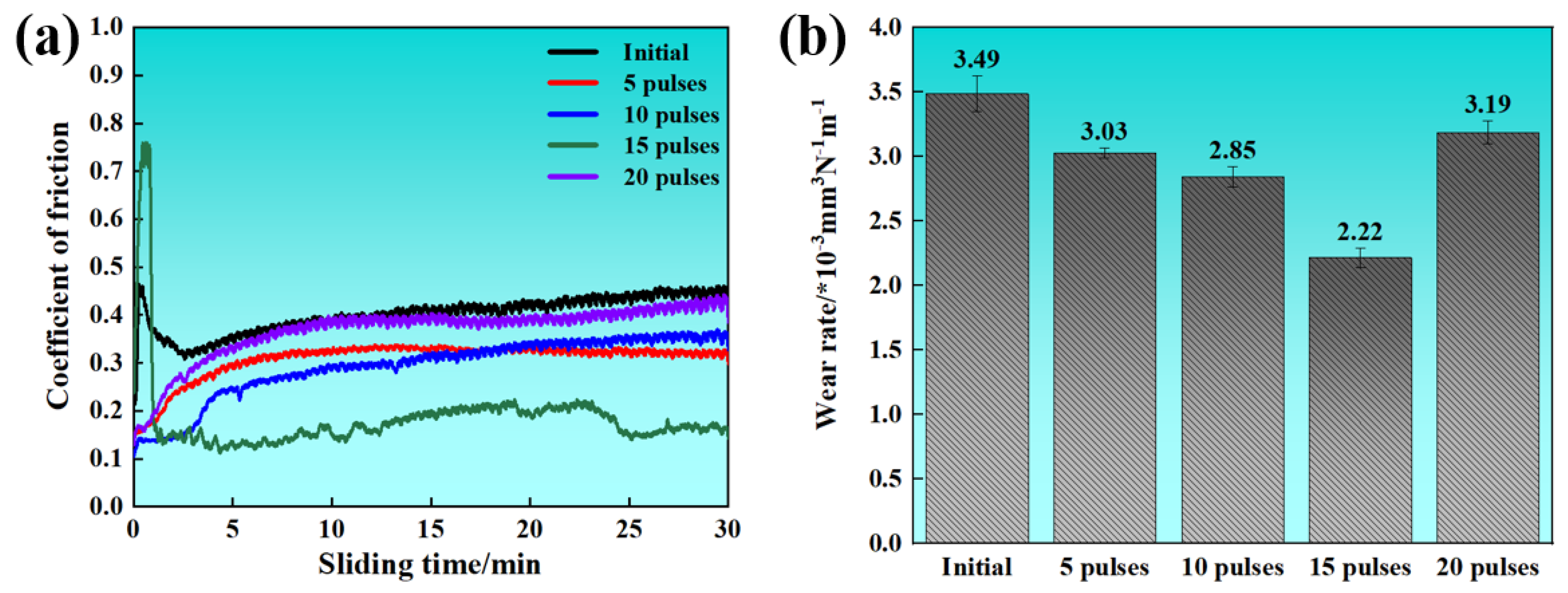

- HCPEB treatment can improve the friction and wear properties of TiN/TiCN/Al2O3/TiN coating. The wear mechanism of the original coating is mainly abrasive wear, the friction coefficient decreases after HCPEB irradiation, and the wear morphology is mainly adhesive wear. Among them, the coating wear performance after 15 pulses is the best.

- (5)

- It is proved that HCPEB treatment can change the internal structure and improve the hardness and wear resistance of the coating. This work presents the possibility of a new technology for the preparation of high-performance multilayer coatings, and also provides a new technological innovation and application prospect for the coating industry.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lopez, J.M.; Babaev, V.G.; Khvostov, V.V.; Albella, J.M. Highly adherent diamond coatings deposited onto WC-Co cemented carbides via barrier interlayers. J. Mater. Res. 1998, 13, 2841–2846. [Google Scholar] [CrossRef]

- Abdel-Aal, H.A.; Nouari, M.; El Mansori, M. The effect of thermal property degradation on wear of WC-CO inserts in dry cutting. Wear 2008, 265, 1670–1679. [Google Scholar] [CrossRef]

- Mills, B. Recent developments in cutting tool materials. J. Mater. Process. Technol. 1996, 56, 16–23. [Google Scholar] [CrossRef]

- Xian, G.; Xiong, J.; Zhao, H.; Xian, L.; Fan, H.; Li, Z.; Du, H. Study on the growth and wear behavior of the TiAlN-based composite coating deposited on TiCN-based cermets with different binder phase. Wear 2020, 460, 203460. [Google Scholar] [CrossRef]

- von Fieandt, L.; Johansson, K.; Larsson, T.; Boman, M.; Lindahl, E. On the growth, orientation and hardness of chemical vapor deposited Ti (C, N). Thin Solid Films 2018, 645, 19–26. [Google Scholar] [CrossRef]

- Long, Y.; Zeng, J.; Yu, D.; Wu, S. Microstructure of TiAlN and CrAlN coatings and cutting performance of coated silicon nitride inserts in cast iron turning. Ceram. Int. 2014, 40, 9889–9894. [Google Scholar] [CrossRef]

- Steinmann, P.A.; Hintermann, H.E. Adhesion of TiC and Ti (C, N) coatings on steel. J. Vac. Sci. Technol. A Vac. Surf. Films 1985, 3, 2394–2400. [Google Scholar] [CrossRef]

- Laugier, M.T. Adhesion of TiC and TiN coatings prepared by chemical vapour deposition on WC-Co-based cemented carbides. J. Mater. Sci. 1986, 21, 2269–2272. [Google Scholar] [CrossRef]

- Perry, A.J.; Matossian, J.N.; Bull, S.J.; Proskurovsky, D.I.; Rice-Evans, P.C.; Page, T.F.; Geist, D.E.; Taylor, J.; Vajo, J.J.; Doty, R.E.; et al. The effect of rapid thermal processing (RTP) on TiN coatings deposited by PVD and the steel-turning performance of coated cemented carbide. Surf. Coat. Technol. 1999, 120, 337–342. [Google Scholar] [CrossRef]

- De Arruda, A.C.S.; Mansano, R.D.; Ordonez, N.; Ruas, R.; Durrant, S.F. Ag Behavior on TiN Thin Films for Decorative Coatings. Coatings 2024, 14, 322. [Google Scholar] [CrossRef]

- Arrousse, N.; Ferreira, J.; Carvalho, S.; Andritschky, M. PVD Black Coating for Decorative Applications. Coatings 2023, 13, 1838. [Google Scholar] [CrossRef]

- KowalSKi, S. The influence of selected PVD coatings on fretting wear in a clamped joint based on the example of a rail vehicle wheel set. Eksploat. Niezawodn. 2018, 20, 1–8. [Google Scholar] [CrossRef]

- Matei, A.A.; Pencea, I.; Branzei, M.; Trancă, D.E.; Ţepeş, G.; Sfăt, C.E.; Stanciu, G.A.; Gherghilescu, A.I.; Ciovica, E. Corrosion resistance appraisal of TiN, TiCN and TiAlN coatings deposited by CAE-PVD method on WC–Co cutting tools exposed to artificial sea water. Appl. Surf. Sci. 2015, 358, 572–578. [Google Scholar] [CrossRef]

- Kowalski, S.; Pexa, M.; Aleš, Z.; Čedík, J. Failure analysis and the evaluation of forced-in joint reliability for selected operation conditions. Coatings 2021, 11, 1305. [Google Scholar] [CrossRef]

- Forn, A.; Picas, J.; Fuentes, G.; Elizalde, E. Mechanical and tribological properties of TiCxN1− x wear resistant coatings. Int. J. Refract. Met. Hard Mater. 2001, 19, 507–513. [Google Scholar] [CrossRef]

- Xiong, J.; Guo, Z.; Yang, M.; Xiong, S.; Chen, J.; Wu, Y.; Wen, B.; Cao, D. Effect of ultra-fine TiC0.5N0.5 on the microstructure and properties of gradient cemented carbide. J. Mater. Process. Technol. 2009, 209, 5293–5299. [Google Scholar] [CrossRef]

- Lyu, Y.; Zheng, J.; Sun, H.; Deng, X.; Liu, Y.; Zhang, Q. Effect of CH4 Flow Rate on the Tribological Behaviors of TiCN Films against Si3N4 Ceramic and Steel Ball. Lubricants 2023, 11, 209. [Google Scholar] [CrossRef]

- Escobar-Alarcón, L.; Camps, E.; Romero, S.; Muhl, S.; Camps, I.; Haro-Poniatowski, E. TiCN thin films grown by reactive crossed beam pulsed laser deposition. Appl. Phys. A 2010, 101, 771–775. [Google Scholar] [CrossRef]

- Deng, J. Manuel Braun, and Irena Gudowska. Properties of TiCN coatings prepared by magnetron sputtering. J. Vac. Sci. Technol. A Vac. Surf. Films 1994, 12, 733–736. [Google Scholar] [CrossRef]

- Fallqvist, M.; Mikael, O.; Ruppi, S. Abrasive wear of texture-controlled CVD α-Al2O3 coatings. Surf. Coat. Technol. 2007, 202, 837–843. [Google Scholar] [CrossRef]

- Connelly, R.; Pattanaik, A.K.; Sarin, V.K. Development of moderate temperature CVD Al2O3 coatings. Int. J. Refract. Met. Hard Mater. 2005, 23, 317–321. [Google Scholar] [CrossRef]

- Kuang, H.; Tan, D.; He, W.; Yi, Z.; Zou, Z.; Wang, X. Oxidation Behavior of Multilayer Hard Coatings (TiCN/Al2O3/TiN) in Process of Recycling Coated Multicomponent Hardmetal Scrap. Materials 2018, 11, 1796. [Google Scholar] [CrossRef]

- Liu, J.; Xiong, J.; Zhou, L.; Guo, Z.; Wen, H.; You, Q.; Zhao, W. Properties of TiN–Al2O3–TiCN–TiN, TiAlN, and DLC-coated Ti (C, N)-based cermets and their wear behaviors during dry cutting of 7075 aluminum alloys. Int. J. Appl. Ceram. Technol. 2021, 18, 792–802. [Google Scholar] [CrossRef]

- Nix, W.D. Mechanical properties of thin films. Metall. Trans. A 1989, 20, 2217–2245. [Google Scholar] [CrossRef]

- Lee, M.; Gilmore, R.S. Single crystal elastic constants of tungsten monocarbide. J. Mater. Sci. 1982, 17, 2657–2660. [Google Scholar] [CrossRef]

- Korhonen, M.A.; LaFontaine, W.R.; Borgesen, P.; Li, C.Y. Stress-induced nucleation of voids in narrow aluminum-based metallizations on silicon substrates. J. Appl. Phys. 1991, 70, 6774–6781. [Google Scholar] [CrossRef]

- Cai, J.; Guan, Q.; Yang, S.; Yang, S.; Wang, Z.; Han, Z. Microstructural characterization of modified YSZ thermal barrier coatings by high-current pulsed electron beam. Surf. Coat. Technol. 2014, 254, 187–194. [Google Scholar] [CrossRef]

- Ivanov, K.V.; Mark, P. Kalashnikov. Structure and phase composition of ZrO2 thin coating–aluminum substrate system processed through pulsed electron beam irradiation. Appl. Surf. Sci. 2020, 534, 147628. [Google Scholar] [CrossRef]

- Zou, J.; Zhang, K.; Dong, C.; Qin, Y.; Hao, S.; Grosdidier, T. Selective surface purification via crater eruption under pulsed electron beam irradiation. Appl. Phys. Lett. 2006, 89, 041913. [Google Scholar] [CrossRef]

- Grosdidier, T.; Zou, J.; Bolle, B.; Hao, S.; Dong, C. Grain refinement, hardening and metastable phase formation by high current pulsed electron beam (HCPEB) treatment under heating and melting modes. J. Alloys Compd. 2010, 504, S508–S511. [Google Scholar] [CrossRef]

- Ivanov, K.V.; Chesnokov, A.E.; Smirnov, A.V. Application of high current pulsed electron beam irradiation to smoothing of cold spray aluminum bronze coating. Vacuum 2022, 197, 110780. [Google Scholar] [CrossRef]

- Guan, Q.; Han, J.; Zhou, S.; Guan, J.; Zhang, C.; Cao, F.; Chen, X. Improved mechanical and tribological properties of TiAlN coatings by high current pulsed electron beam irradiation. Int. J. Refract. Met. Hard Mater. 2024, 118, 106435. [Google Scholar] [CrossRef]

- Guo, F.; Jiang, W.; Tang, G.; Xie, Z.; Dai, H.; Wang, E.; Chen, Y.; Liu, L. Enhancing anti-wear and anti-corrosion performance of cold spraying aluminum coating by high current pulsed electron beam irradiation. Vacuum 2020, 182, 109772. [Google Scholar] [CrossRef]

- Ungár, T.; Jeno, G. Nanocrystalline materials studied by powder diffraction line profile analysis. Z. Krist.-Cryst. Mater. 2007, 222, 114–128. [Google Scholar] [CrossRef]

- Le, X.; Yan, S.; Liu, Z.; Zhao, W. Detection of shocks generated by intense pulsed ion beam irradiation. Surf. Coat. Technol. 2007, 201, 4991–4994. [Google Scholar] [CrossRef]

- Neves, D.; Anselmo, E.D.; Milton, S.F.L. Microstructural analyses and wear behavior of the cemented carbide tools after laser surface treatment and PVD coating. Appl. Surf. Sci. 2013, 282, 680–688. [Google Scholar] [CrossRef]

- Teixeira, V.; Andritschky, M.; Fischer, W.; Buchkremer, H.P.; Stöver, D. Analysis of Residual Stresses in Thermal Barrier Coatings. J. Mater. Process. Technol. 1999, 92–93, 209–216. [Google Scholar] [CrossRef]

- Qin, Y.; Dong, C.; Wang, X.; Hao, S.; Wu, A.; Zou, J.; Liu, Y. Temperature profile and crater formation induced in high-current pulsed electron beam processing. J. Vac. Sci. Technol. A Vac. Surf. Films 2003, 21, 1934–1938. [Google Scholar] [CrossRef]

- Zhang, K.; Zou, J.; Grosdidier, T.; Dong, C.; Yang, D. Improved pitting corrosion resistance of AISI 316L stainless steel treated by high current pulsed electron beam. Surf. Coat. Technol. 2006, 201, 1393–1400. [Google Scholar] [CrossRef]

- Zou, J.; Grosdidier, T.; Zhang, K.; Dong, C. Mechanisms of nanostructure and metastable phase formations in the surface melted layers of a HCPEB-treated D2 steel. Acta Mater. 2006, 54, 5409–5419. [Google Scholar] [CrossRef]

- Guan, Q.F.; Yang, P.L.; Zou, H.; Zou, G.T. Nanocrystalline and amorphous surface structure of 0.45% C steel produced by high current pulsed electron beam. J. Mater. Sci. 2006, 41, 479–483. [Google Scholar] [CrossRef]

- Perry, A.J.; Sue, J.A.; Martin, P.J. Practical measurement of the residual stress in coatings. Surf. Coat. Technol. 1996, 81, 17–28. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ge, F.; Xia, Z.; Yuan, H.; Guo, S.; Hu, Z.; Guan, J.; Cai, J.; Guan, Q.; Lyu, P. Microstructure and Properties of TiN/TiCN/Al2O3/TiN Coating Enhanced by High-Current Pulsed Electron Beam. Coatings 2024, 14, 378. https://doi.org/10.3390/coatings14040378

Ge F, Xia Z, Yuan H, Guo S, Hu Z, Guan J, Cai J, Guan Q, Lyu P. Microstructure and Properties of TiN/TiCN/Al2O3/TiN Coating Enhanced by High-Current Pulsed Electron Beam. Coatings. 2024; 14(4):378. https://doi.org/10.3390/coatings14040378

Chicago/Turabian StyleGe, Feiyu, Ziteng Xia, Haoming Yuan, Siyang Guo, Zhijun Hu, Jintong Guan, Jie Cai, Qingfeng Guan, and Peng Lyu. 2024. "Microstructure and Properties of TiN/TiCN/Al2O3/TiN Coating Enhanced by High-Current Pulsed Electron Beam" Coatings 14, no. 4: 378. https://doi.org/10.3390/coatings14040378

APA StyleGe, F., Xia, Z., Yuan, H., Guo, S., Hu, Z., Guan, J., Cai, J., Guan, Q., & Lyu, P. (2024). Microstructure and Properties of TiN/TiCN/Al2O3/TiN Coating Enhanced by High-Current Pulsed Electron Beam. Coatings, 14(4), 378. https://doi.org/10.3390/coatings14040378