Microstructure and Properties of Al-Cu-Fe-Ce Quasicrystalline-Reinforced 6061 Aluminum Matrix Composites after Aging

Abstract

1. Introduction

2. Experimental

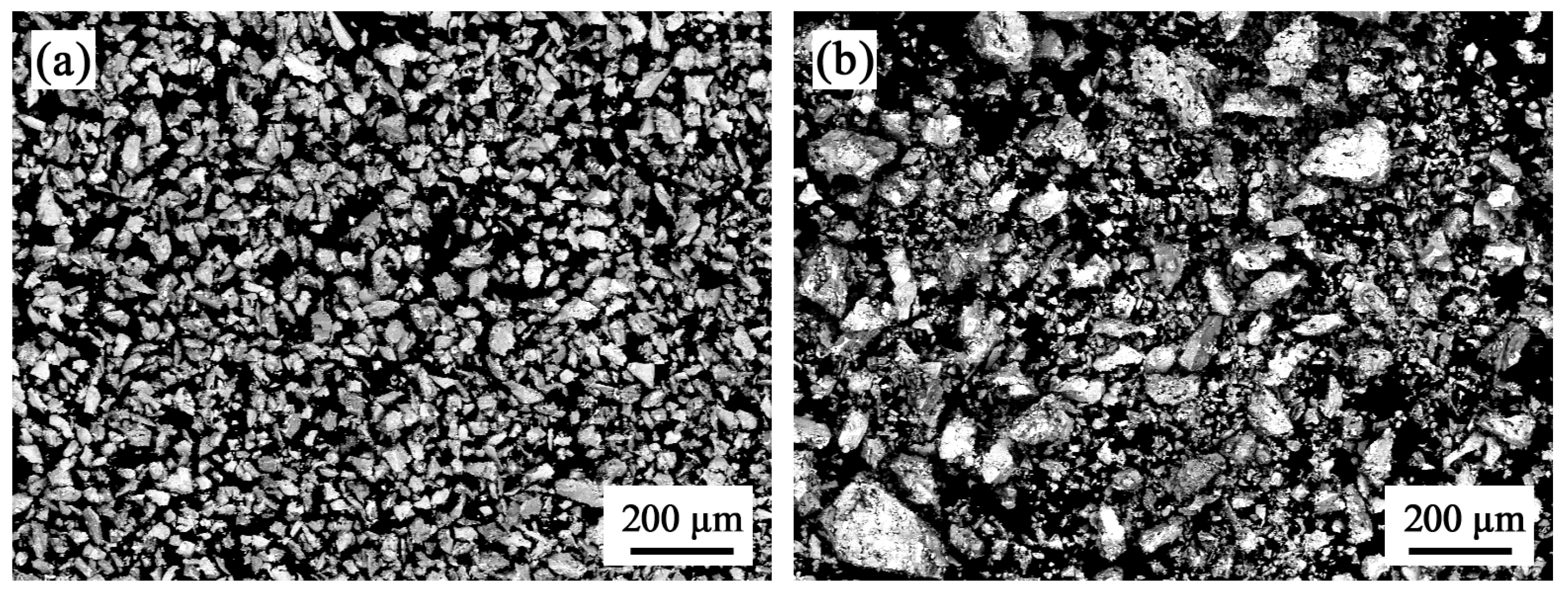

2.1. Characterization of the Matrix and Reinforcing Materials

2.2. Preparation and Characterization of Composite Materials

3. Results

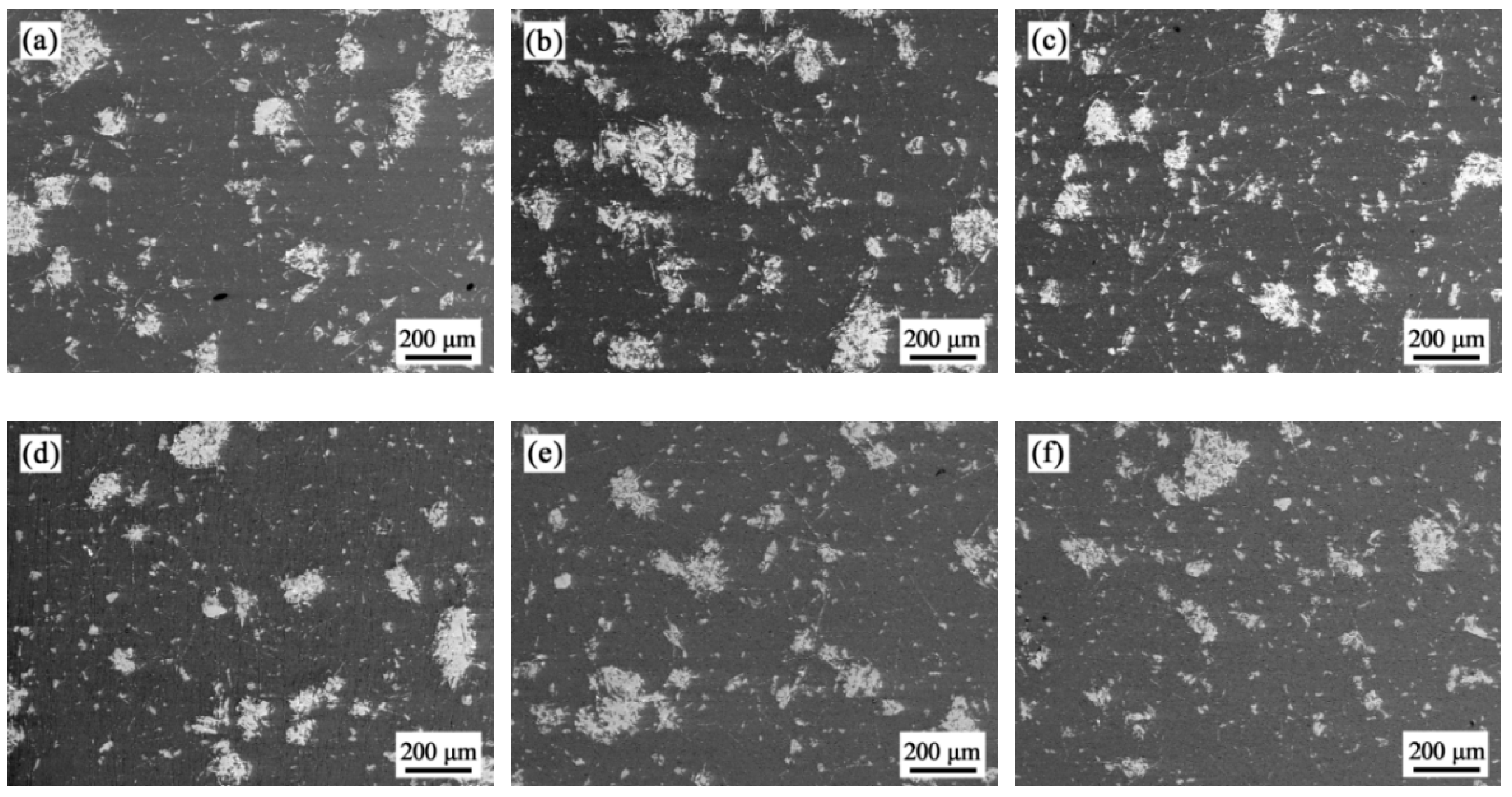

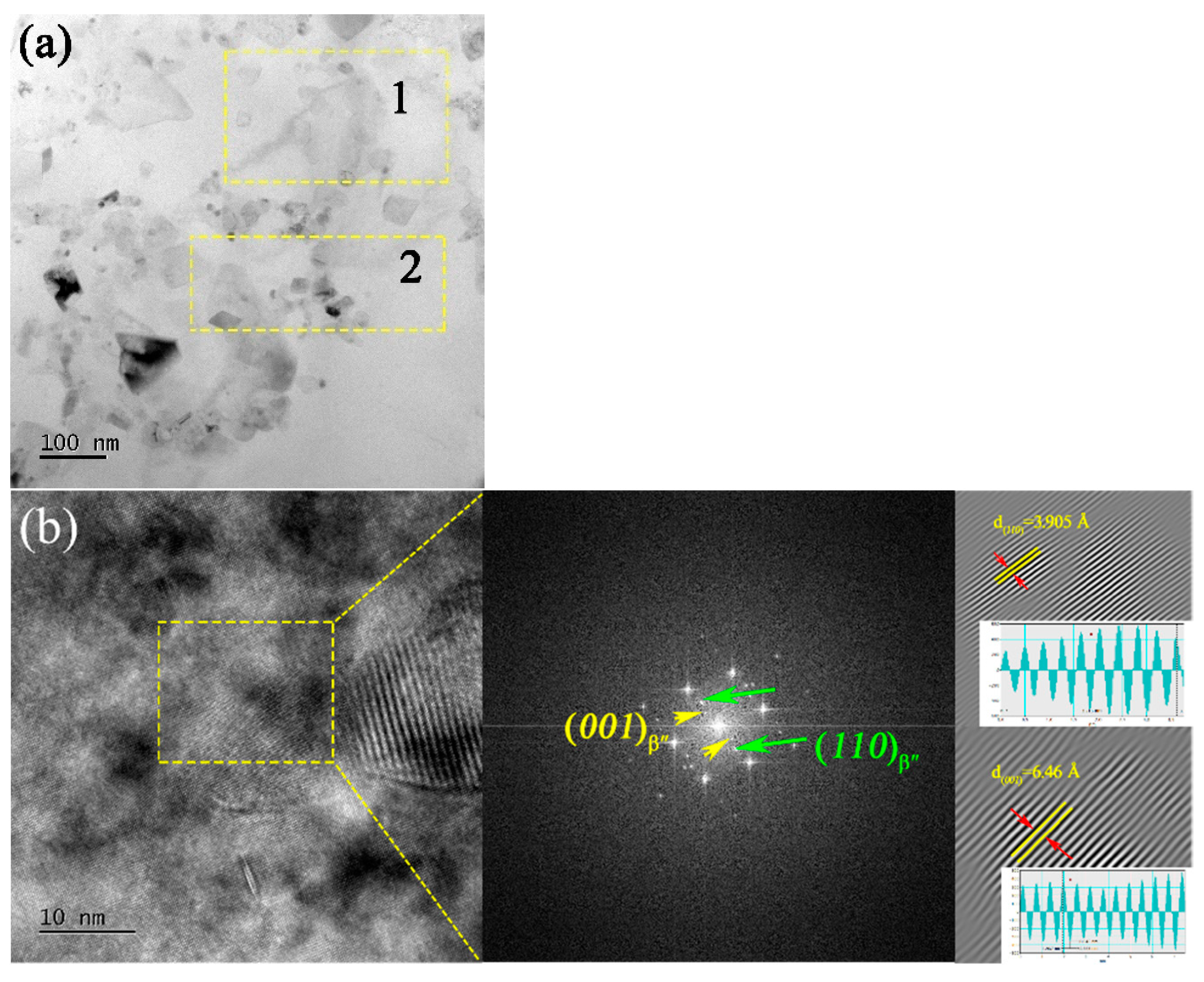

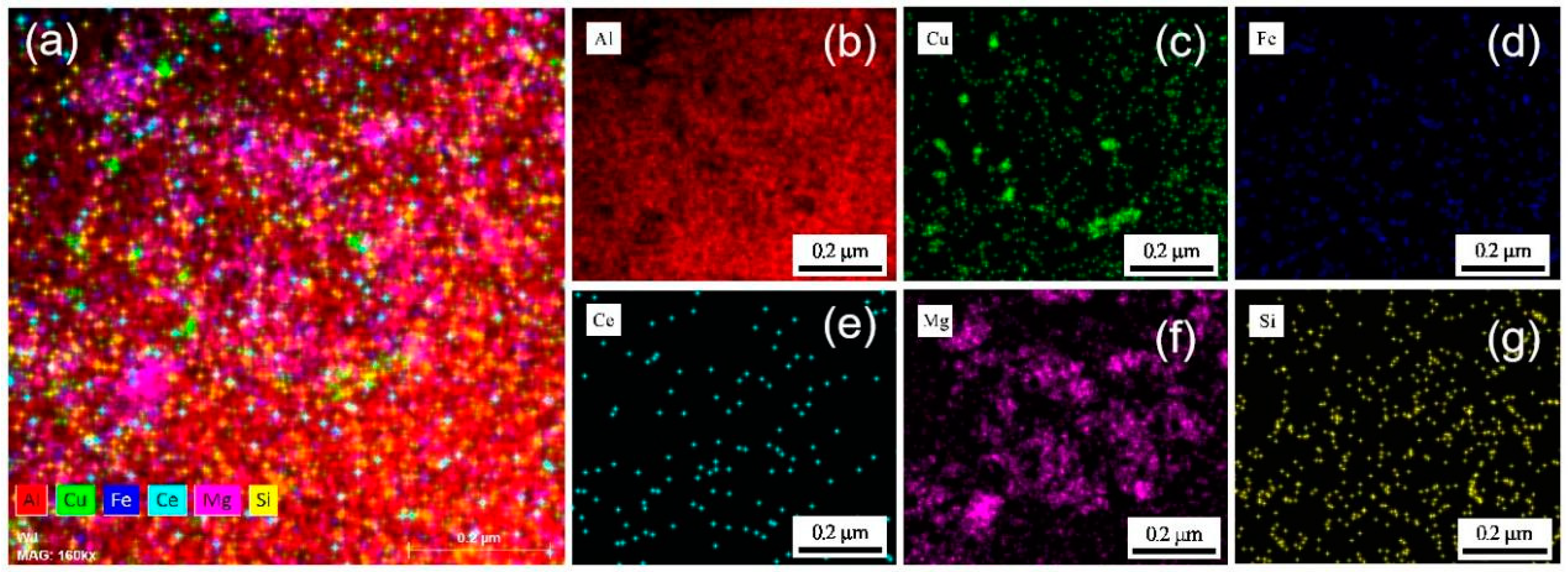

3.1. Effect of Aging Time on the Microstructure of 1Ce-IQCp/6061

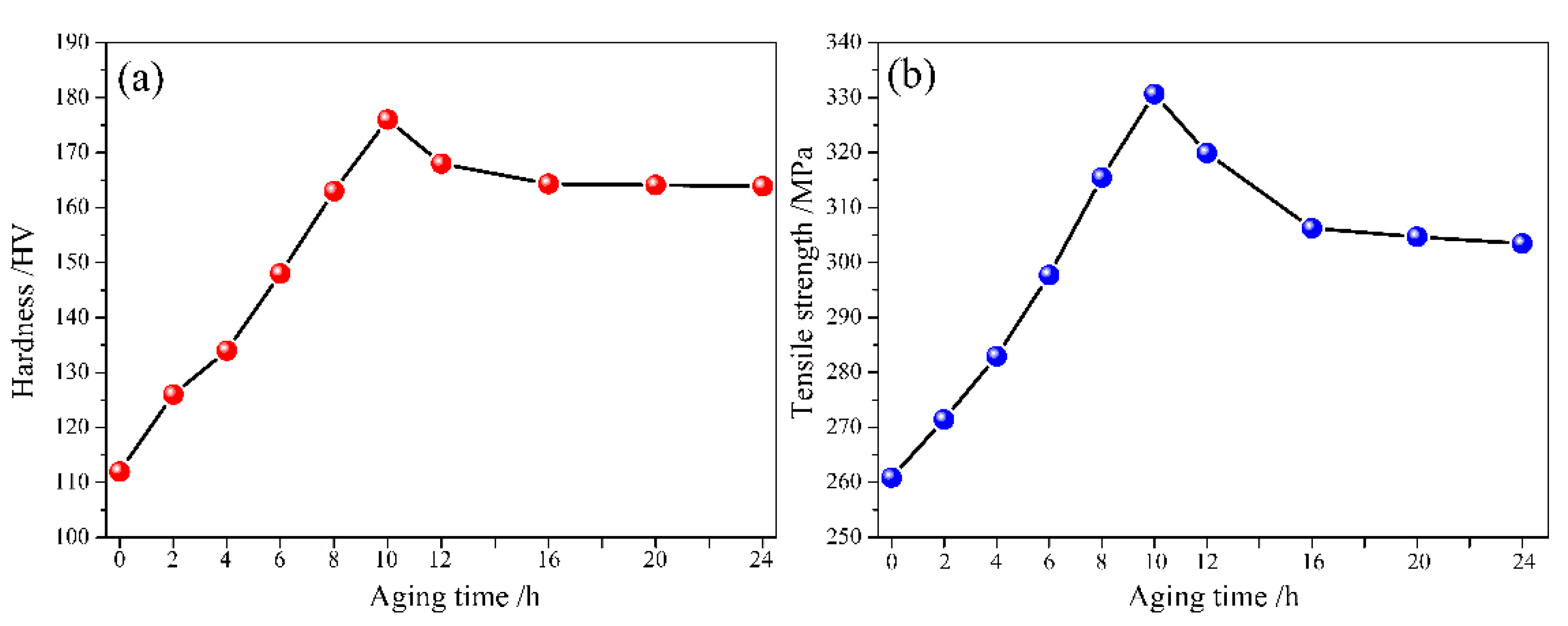

3.2. Effect of Aging Time on Hardness and Tensile Strength of 1Ce-IQCp/6061

4. Conclusions

- (1)

- It has been clarified that the optimum heat treatment process for (Al63Cu25Fe12)99Ce1 quasicrystalline particle-reinforced 6061 aluminum matrix composites is a solid solution temperature of 530 °C, a holding time of 1 h, and water cooling, followed by an aging treatment with an aging temperature of 170 °C and a holding time of 10 h.

- (2)

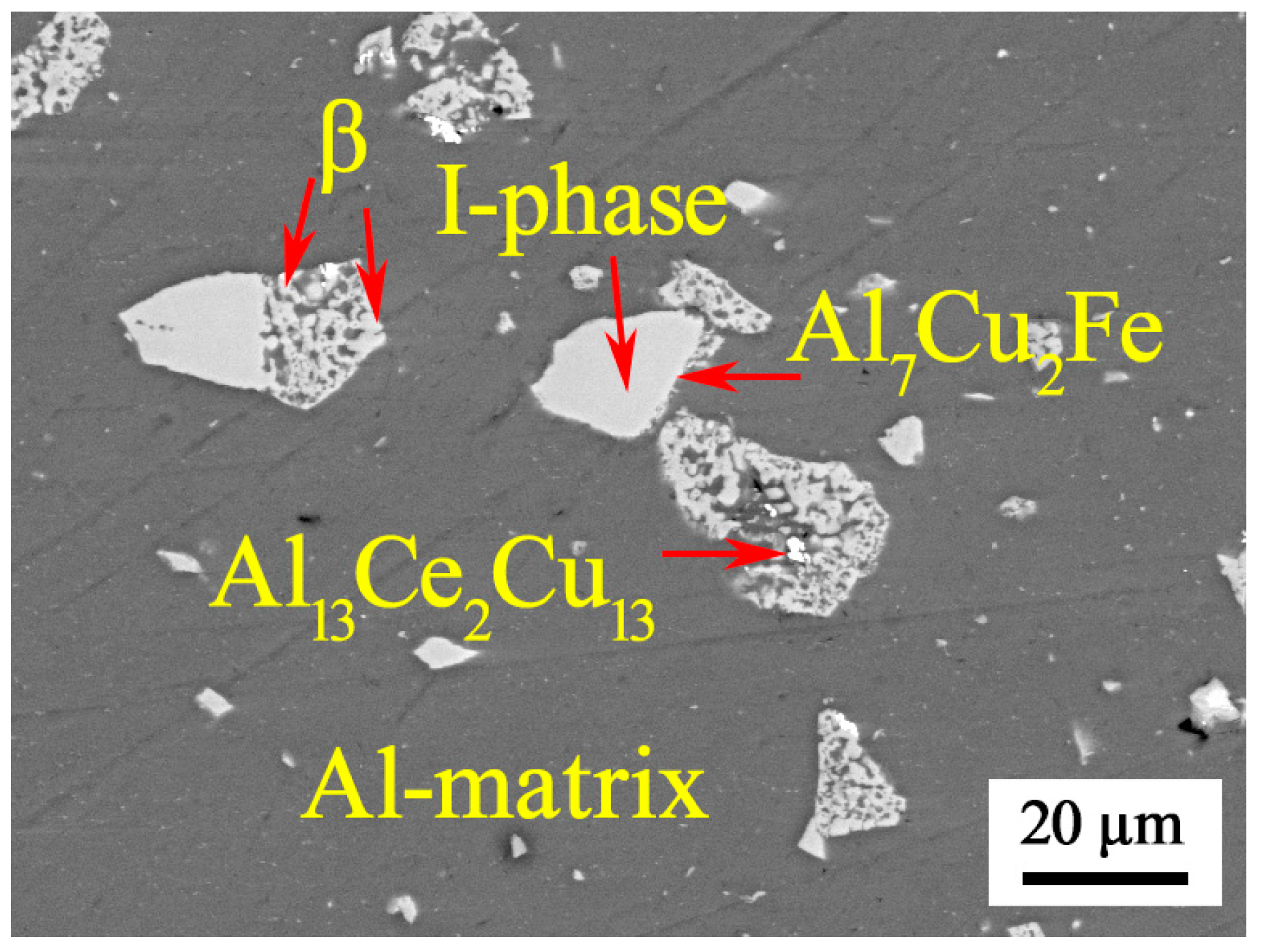

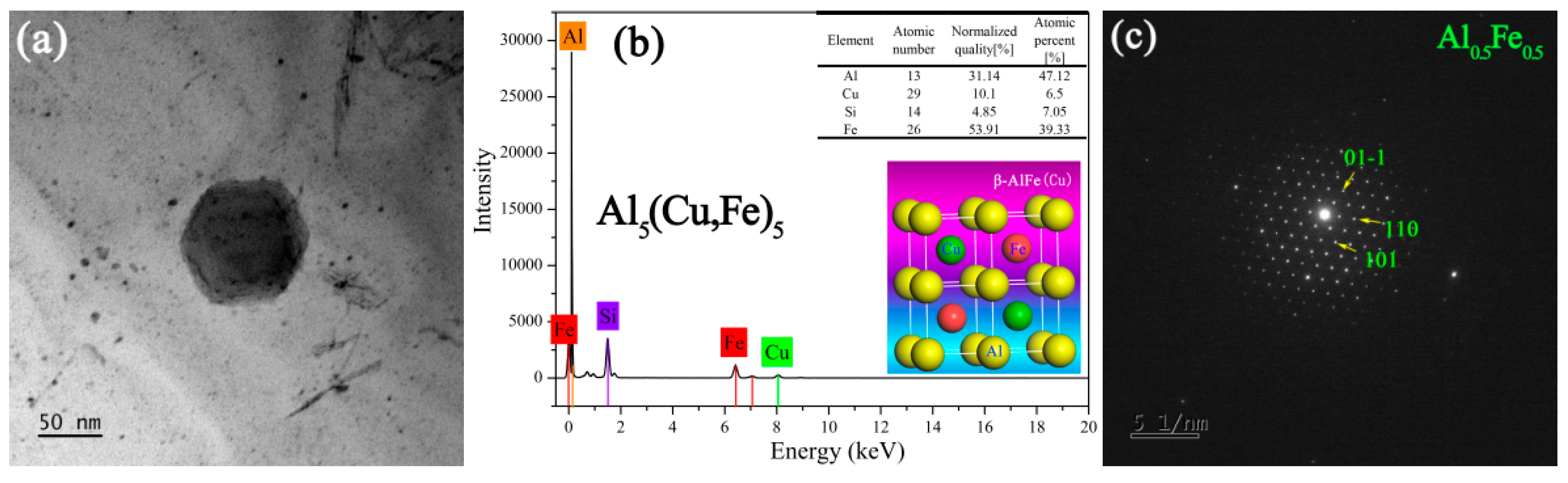

- The phases of (Al63Cu25Fe12)99Ce1 quasicrystalline particle-reinforced 6061 aluminum matrix composites after the aging treatment include the β phase, a small amount of the Al2CuMg phase belonging to the orthorhombic crystalline system, as well as the β″ phase and a small amount of the β′ precipitated phase. The phases are meticulously and uniformly distributed, contributing to the strength and hardness of the 1Ce-IQCp/6061 alloy.

- (3)

- With the increase in aging time, the Vickers hardness and tensile strength of 1Ce-IQCp/6061 initially increase and then decrease, reaching their maximum value at 10 h of aging time.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cui, Z.; Jiang, H.; Zhang, D.; Rong, L. Inhibiting of the negative natural aging effect in Al–Mg–Si alloys. Mater. Sci. Eng. A 2024, 894, 146196. [Google Scholar] [CrossRef]

- Martins, P.S.; Drumond, R.M.; Silva, E.R.D.; Ba, E.C.T.; de Souza Lima, V.E.; Barbosa, J.W.; Fernandes, G.H.N.; Firpe, P.M. Evaluation of the drilling process in 6061-T6 Al-Mg-Si alloys using AISI M-35 diamond-like carbon coated high-speed steel drill. Tribol. Int. 2024, 192, 109250. [Google Scholar] [CrossRef]

- Howard, R.H.; Gallagher, R.C.; Field, K.G. Mechanical performance of neutron-irradiated dissimilar transition joints of aluminum alloy 6061-T6 and 304l stainless steel. J. Nucl. Mater. 2018, 508, 348–353. [Google Scholar] [CrossRef]

- Milagre, M.X.; Pereira, M.S.; Gomes, A.A.; Scapin, M.; Franco, M.; Yokaichiya, F.; Genezini, F.; Costa, I. Corrosion characterization of the 6061 Al-Mg-Si alloy in synthetic acid rain using neutron tomography. Appl. Radiat. Isot. 2022, 184, 110197. [Google Scholar] [CrossRef]

- Sun, Y.; Wu, G. Preparation and characterization of Al-Mg-Si matrix composites reinforced with Ti2(Al,Si)C solid solution. Mater. Lett. 2023, 353, 135266. [Google Scholar] [CrossRef]

- Qi, Y.; Jia, L.; Ye, C.; Jin, Z.; Liu, Y.; Wang, W.; Zhang, H. Strengthening effects of gp zone induced by SiCp size variations in Al–Si–Mg matrix composites. J. Mater. Res. Technol. 2023, 27, 7521–7531. [Google Scholar] [CrossRef]

- Yi, R.; Chen, C.; Shi, C.; Li, Y.; Li, H.; Ma, Y. Research advances in residual thermal stress of ceramic/metal brazes. Ceram. Int. 2021, 47, 20807–20820. [Google Scholar] [CrossRef]

- Wolf, W.; Bolfarini, C.; Kiminami, C.S.; Botta, W.J. Recent developments on fabrication of Al-matrix composites reinforced with quasicrystals: From metastable to conventional processing. J. Mater. Res. 2021, 36, 281–297. [Google Scholar] [CrossRef]

- Schurack, F.; Eckert, J.; Schultz, L. Synthesis and mechanical properties of cast quasicrystal-reinforced Al-alloys. Acta Mater. 2001, 49, 1351–1361. [Google Scholar] [CrossRef]

- Wolf, W.; Bolfarini, C.; Kiminami, C.S.; Botta, W.J. Designing new quasicrystalline compositions in Al-based alloys. J. Alloys Compd. 2020, 823, 153765. [Google Scholar] [CrossRef]

- Wang, J.; Yang, Z.; Wang, L.; Li, J. Interfacial reaction kinetics of (Al63Cu25Fe12) 99Ce1 quasicrystal reinforced 6061 aluminum matrix composites. J. Alloys Compd. 2023, 955, 170261. [Google Scholar] [CrossRef]

- Shadangi, Y.; Sharma, S.; Shivam, V.; Basu, J.; Chattopadhyay, K.; Majumdar, B.; Mukhopadhyay, N.K. Fabrication of Al–Cu–Fe quasicrystal reinforced 6082 aluminium matrix nanocomposites through mechanical milling and spark plasma sintering. J. Alloys Compd. 2020, 828, 154258. [Google Scholar] [CrossRef]

- Wang, J.; Yang, Z.; Ma, Z.; Duan, H.; Zhang, J.; Tao, D.; Li, J. Effect of the addition of cerium on the microstructure evolution and thermal expansion properties of cast Al-Cu-Fe alloy. Mater. Res. Express 2021, 8, 36503. [Google Scholar] [CrossRef]

- Silva, L.P.M.E.; Zepon, G.; Santos, A.J.; Câmara, M.A.; Kiminami, C.S.; Bolfarini, C.; Botta, W.J.; Wolf, W. A wear-resistant Al85Cu6Fe3Cr6 spray-formed quasicrystalline composite. Materialia 2022, 21, 101367. [Google Scholar] [CrossRef]

- de Araujo, A.P.M.; Kiminami, C.S.; Uhlenwinkel, V.; Gargarella, P. Processability of recycled quasicrystalline Al-Fe-Cr-Ti composites by selective laser melting—A statistical approach. Materialia 2022, 22, 101377. [Google Scholar] [CrossRef]

- Yao, S.J.; Tang, Q.H.; Yang, J.; Wang, C.Y.; Sun, H.F.; Rong, R.L.; Sun, H.R.; Chu, G.N. Microstructural characterization and mechanical properties of 6061 aluminum alloy processed with short-time solid solution and aging treatment. J. Alloys Compd. 2023, 960, 170704. [Google Scholar] [CrossRef]

- Kang, N.; Zhang, Y.; Mansori, M.E.; Lin, X. Laser powder bed fusion of a novel high strength quasicrystalline Al–Fe–Cr reinforced Al matrix composite. Adv. Powder Mater. 2023, 2, 100108. [Google Scholar] [CrossRef]

- Farshidi, M.H.; Kazeminezhad, M.; Miyamoto, H. On the natural aging behavior of aluminum 6061 alloy after severe plastic deformation. Mater. Sci. Eng. A 2013, 580, 202–208. [Google Scholar] [CrossRef]

- Prosviryakov, A.S.; Bazlov, A.I.; Mikhaylovskaya, A.V. Development of heat-resistant composites based on Al-Mg-Si alloy mechanically alloyed with aluminide particles. JOM 2024, 76, 1306–1318. [Google Scholar] [CrossRef]

- Cui, C.Y.; Wan, T.Y.; Shu, Y.X.; Meng, S.; Cui, X.G.; Lu, J.Z.; Lu, Y.F. Microstructure evolution and mechanical properties of aging 6061 Al alloy via laser shock processing. J. Alloys Compd. 2019, 803, 1112–1118. [Google Scholar] [CrossRef]

- Zang, A.; Khajezade, A.; Wang, X.; Parson, N.; Wells, M.; Poole, W.J. The spatial variation of crystallographic texture during axisymmetric solid bar extrusion of an Al–Mg–Si alloy. Metall. Mater. Trans. A 2024, 55, 1122–1136. [Google Scholar] [CrossRef]

- Wang, J.; Yang, Z.; Duan, H.; Ma, Z.; Tao, D.; Li, J. Effect of heat treatment on microstructure and thermal expansion properties of as-cast (Al63Cu25Fe12)99Ce1 alloy. Met. Mater. 2021, 59, 367–377. [Google Scholar] [CrossRef]

- Yuan, W.; An, B. Effect of heat treatment on microstructure and mechanical property of extruded 7090/SICp composite. Trans. Nonferrous Met. Soc. China 2012, 22, 2080–2086. [Google Scholar] [CrossRef]

- Yang, W.; Wang, M.; Zhang, R.; Zhang, Q.; Sheng, X. The diffraction patterns from β″ precipitates in 12 orientations in Al–Mg–Si alloy. Scr. Mater. 2010, 62, 705–708. [Google Scholar] [CrossRef]

- Vissers, R.; van Huis, M.A.; Jansen, J.; Zandbergen, H.W.; Marioara, C.D.; Andersen, S.J. The crystal structure of the β′ phase in Al–Mg–Si alloys. Acta Mater. 2007, 55, 3815–3823. [Google Scholar] [CrossRef]

- Zi, Y.; Zeqin, L.; Leyvraz, D.; Banhart, J. Effect of pre-ageing on natural secondary ageing and paint bake hardening in Al–Mg–Si alloys. Materialia 2019, 7, 100413. [Google Scholar] [CrossRef]

| Powders | Fe | Si | Mg | Cu | Mn | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| 6061 | 0.157 | 0.56 | 0.81 | 0.166 | 0.071 | 0.051 | 0.031 | 0.002 | Residuals |

| Hot Pressing Sintering Temperature | Area | Al | Fe | Cu | Ce | Corresponding Phase | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| wt% | at% | wt% | at% | wt% | at% | wt% | at% | |||

| 490 °C | A | 97.29 | 98.83 | 2.71 | 1.17 | Al matrix | ||||

| B | 53.83 | 72.44 | 15.04 | 9.78 | 31.12 | 17.78 | ω-phase | |||

| C | 36.7 | 63.52 | 2.05 | 1.72 | 35.72 | 26.26 | 25.52 | 8.51 | I phase | |

| D | 24.19 | 46.3 | 6.98 | 6.4 | 51.33 | 41.88 | 17.5 | 5.42 | Al13Ce2Cu13-phase | |

| E | 31.96 | 49.56 | 63.19 | 47.24 | 4.85 | 3.2 | β-Al5(Cu,Fe)5-phase | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; He, Y.; Yang, Z. Microstructure and Properties of Al-Cu-Fe-Ce Quasicrystalline-Reinforced 6061 Aluminum Matrix Composites after Aging. Coatings 2024, 14, 372. https://doi.org/10.3390/coatings14030372

Wang J, He Y, Yang Z. Microstructure and Properties of Al-Cu-Fe-Ce Quasicrystalline-Reinforced 6061 Aluminum Matrix Composites after Aging. Coatings. 2024; 14(3):372. https://doi.org/10.3390/coatings14030372

Chicago/Turabian StyleWang, Juan, Yanhu He, and Zhong Yang. 2024. "Microstructure and Properties of Al-Cu-Fe-Ce Quasicrystalline-Reinforced 6061 Aluminum Matrix Composites after Aging" Coatings 14, no. 3: 372. https://doi.org/10.3390/coatings14030372

APA StyleWang, J., He, Y., & Yang, Z. (2024). Microstructure and Properties of Al-Cu-Fe-Ce Quasicrystalline-Reinforced 6061 Aluminum Matrix Composites after Aging. Coatings, 14(3), 372. https://doi.org/10.3390/coatings14030372