Study on the Forming Process and Properties of AlSi60 Alloy by Selective Laser Melting

Abstract

1. Introduction

2. Experimental Details

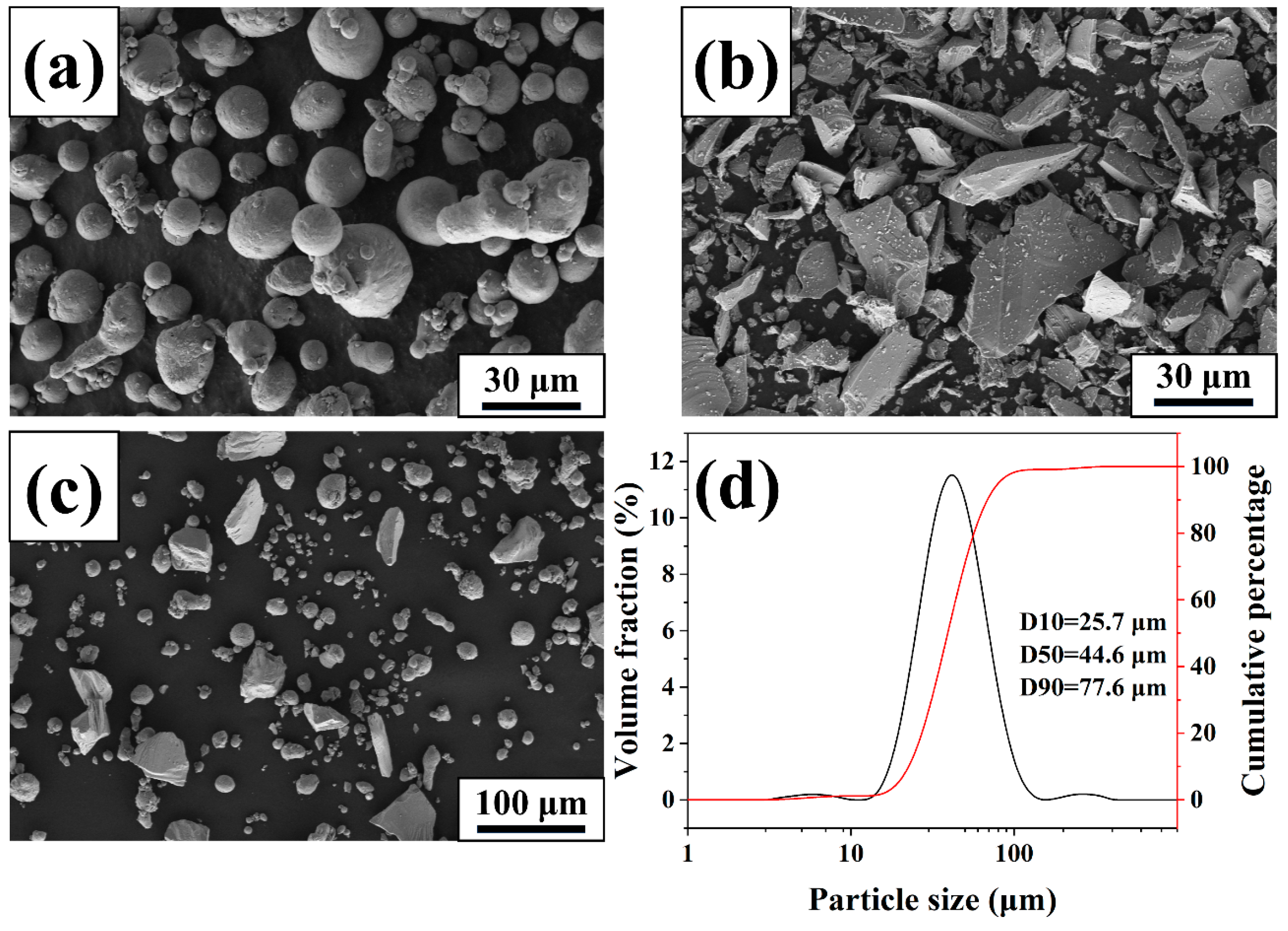

2.1. Powder Preparation

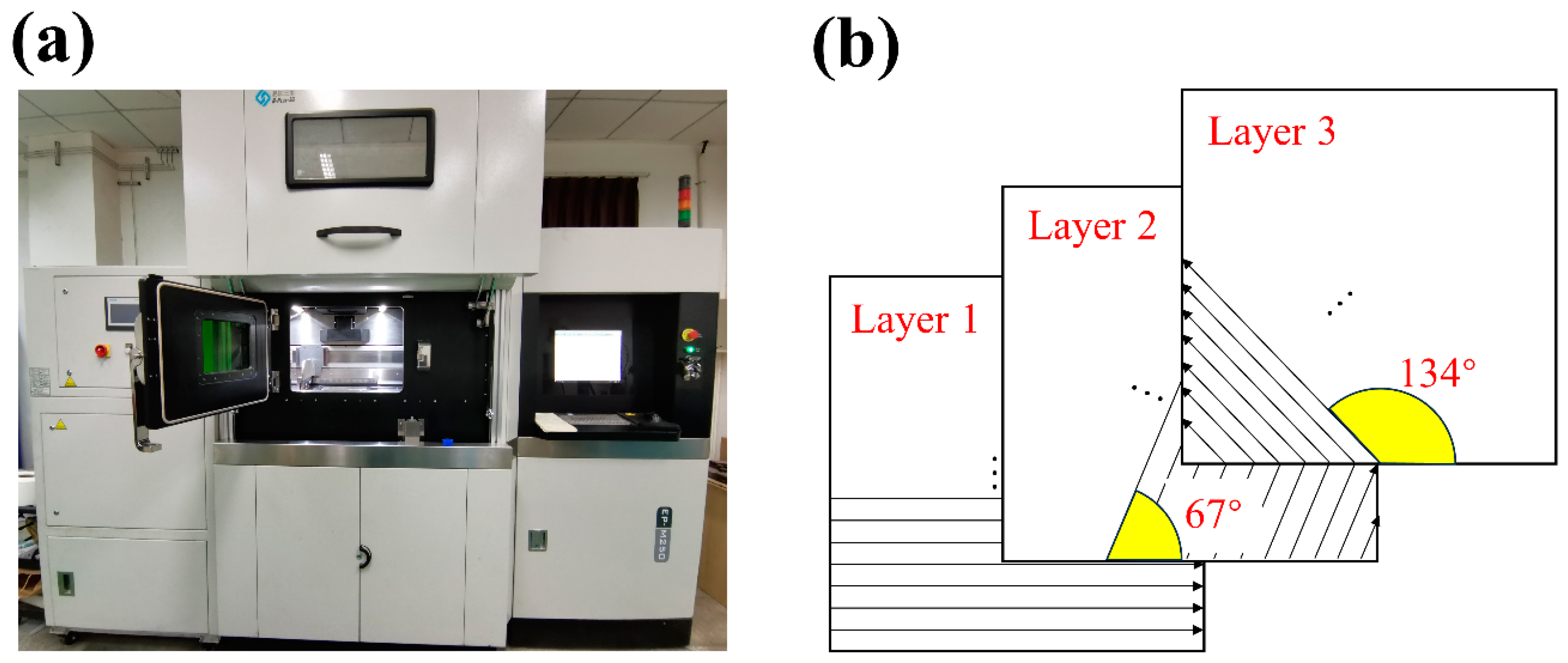

2.2. SLM Fabrication

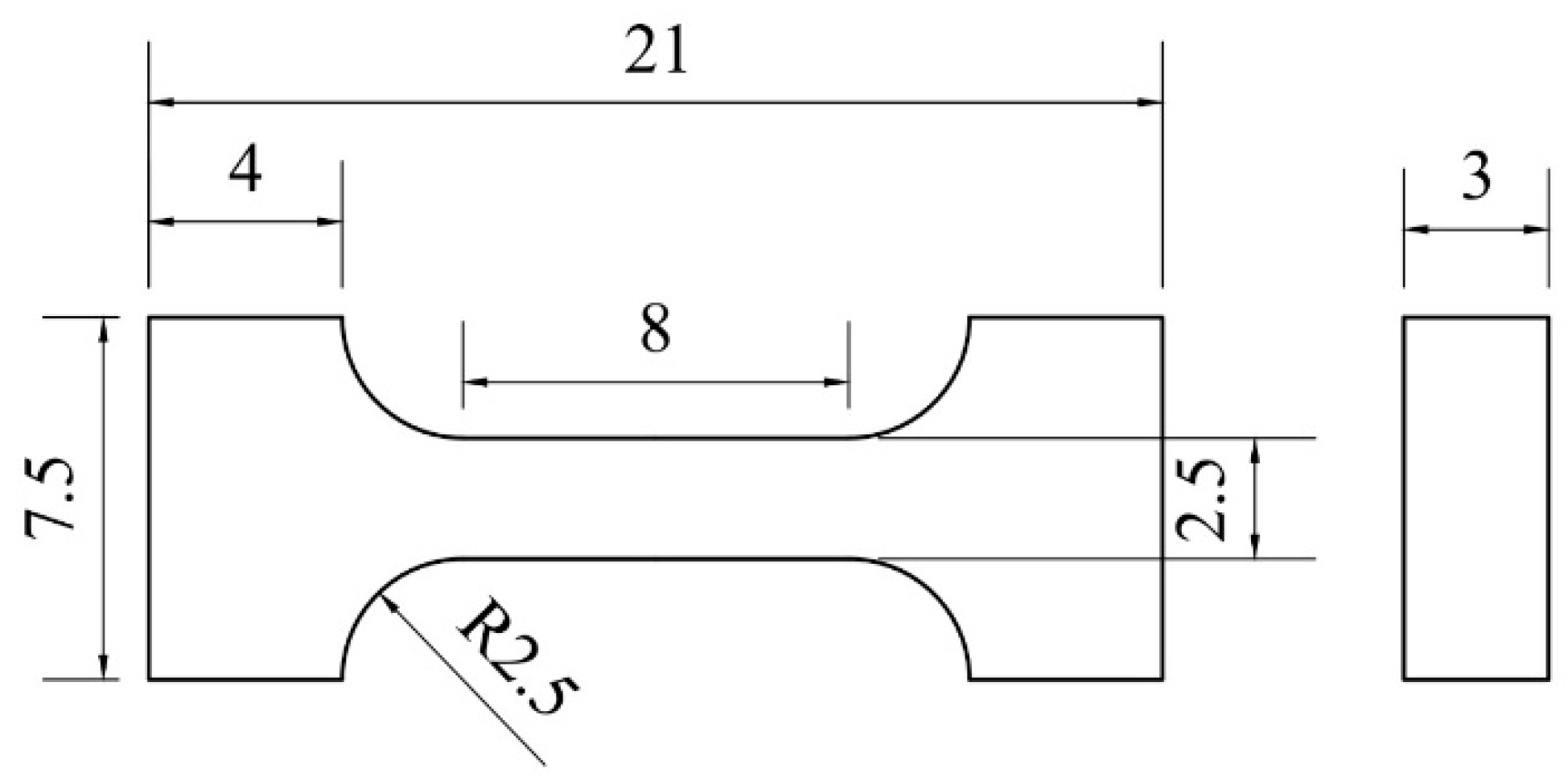

2.3. Characterization and Testing

3. Results and Discussion

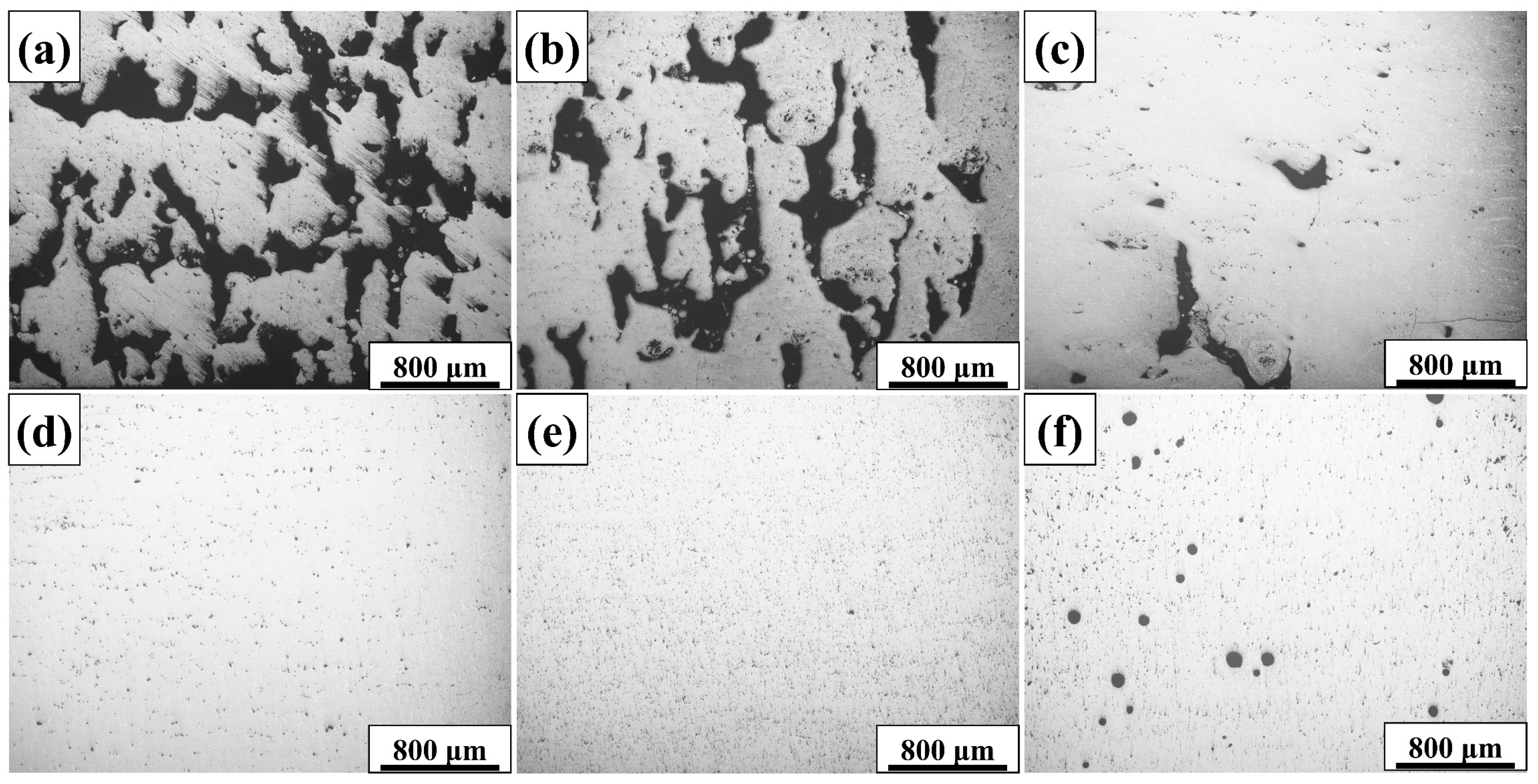

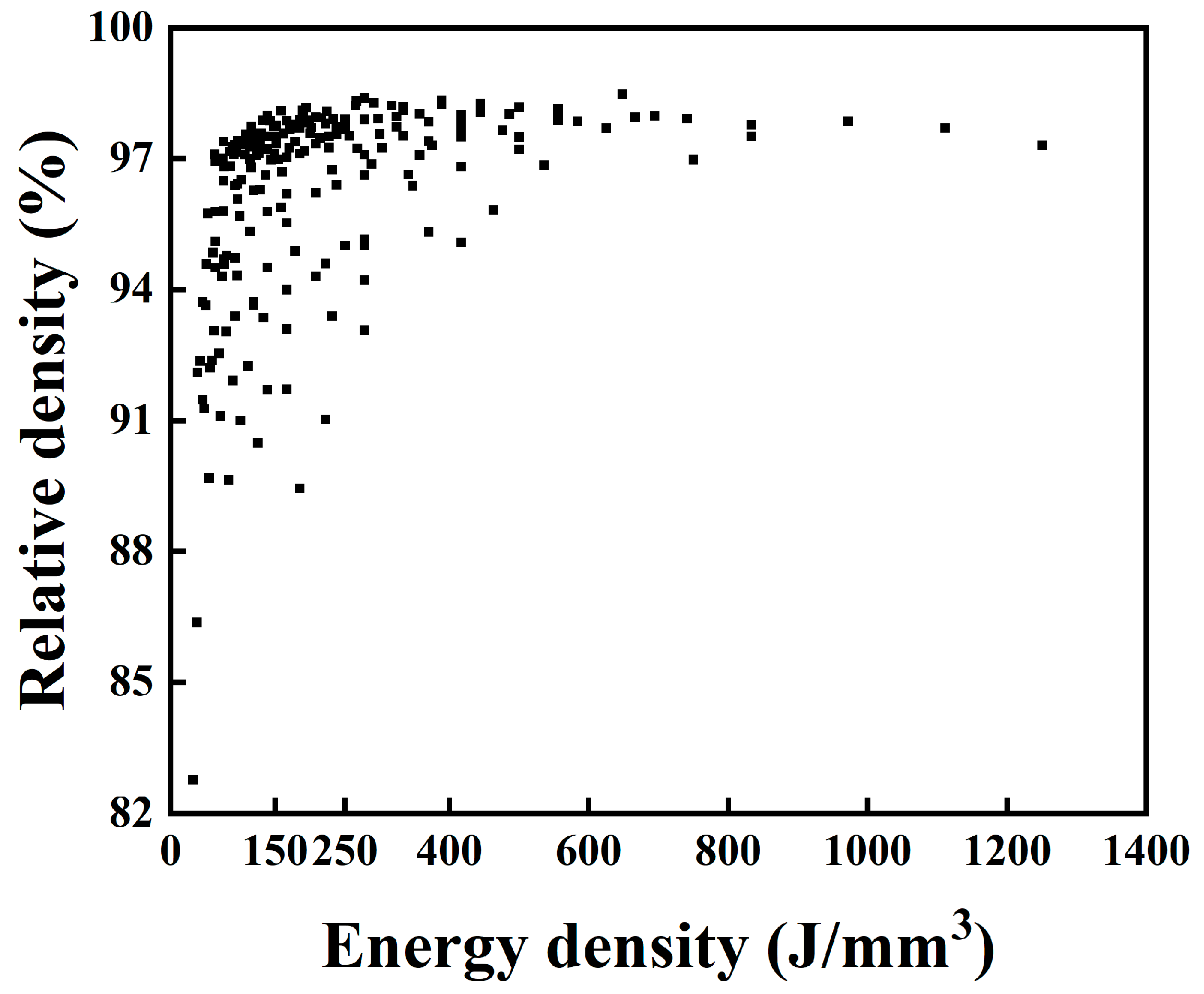

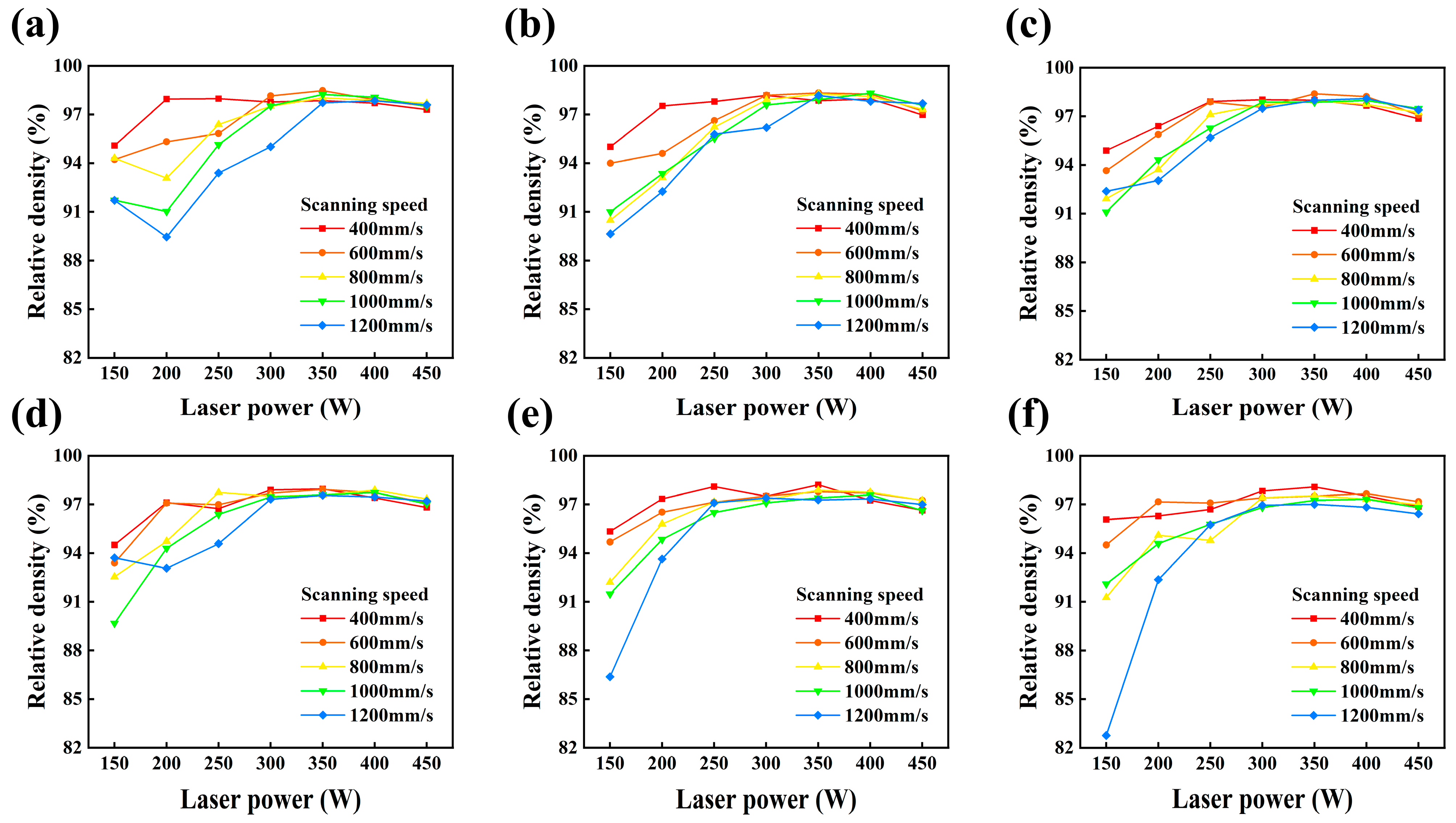

3.1. Effect of Process Parameters on SLM Forming of AlSi60 Alloy

3.2. Microstructure and Properties

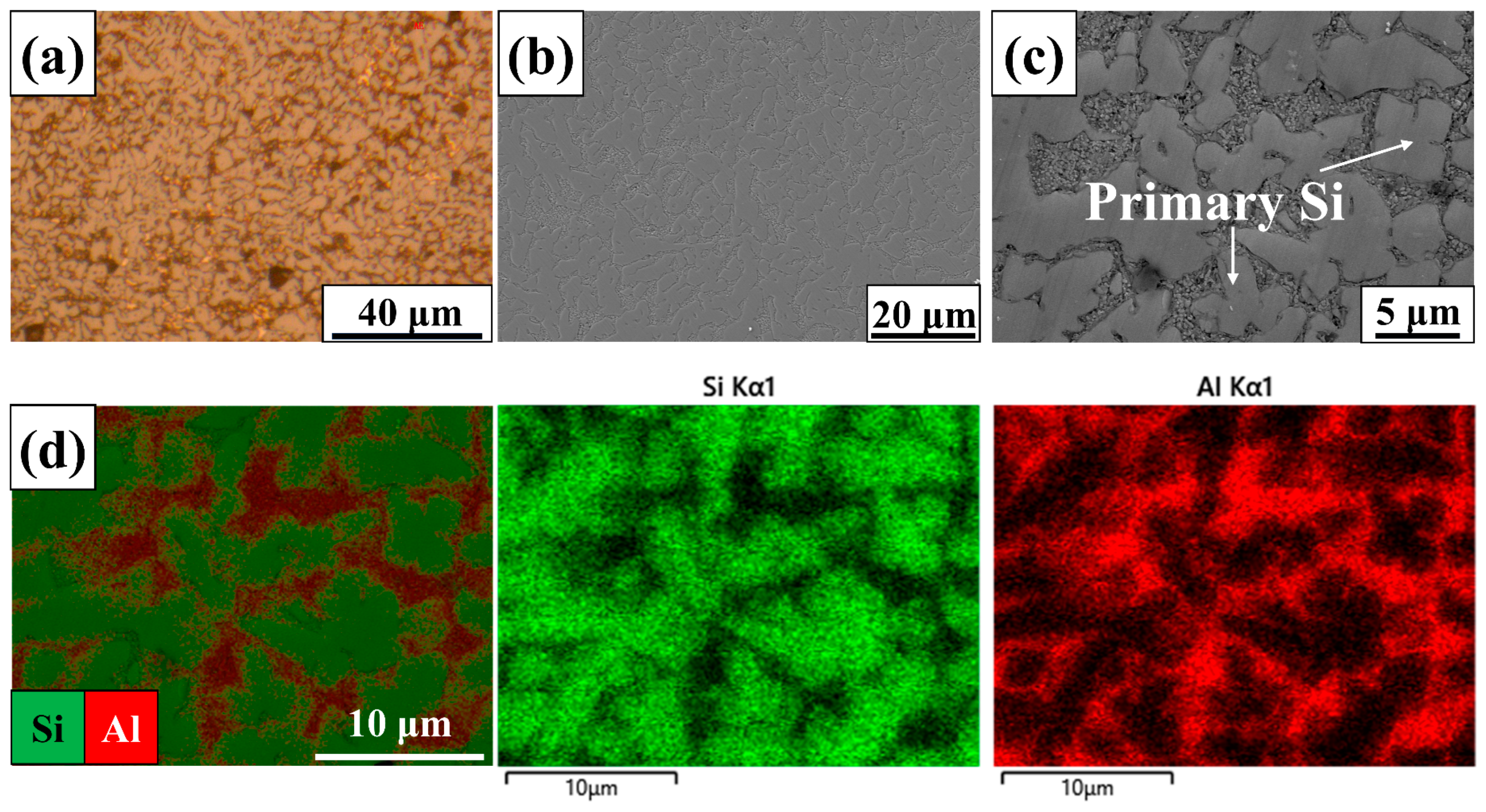

3.2.1. Phase Analysis and Microstructural Characterization

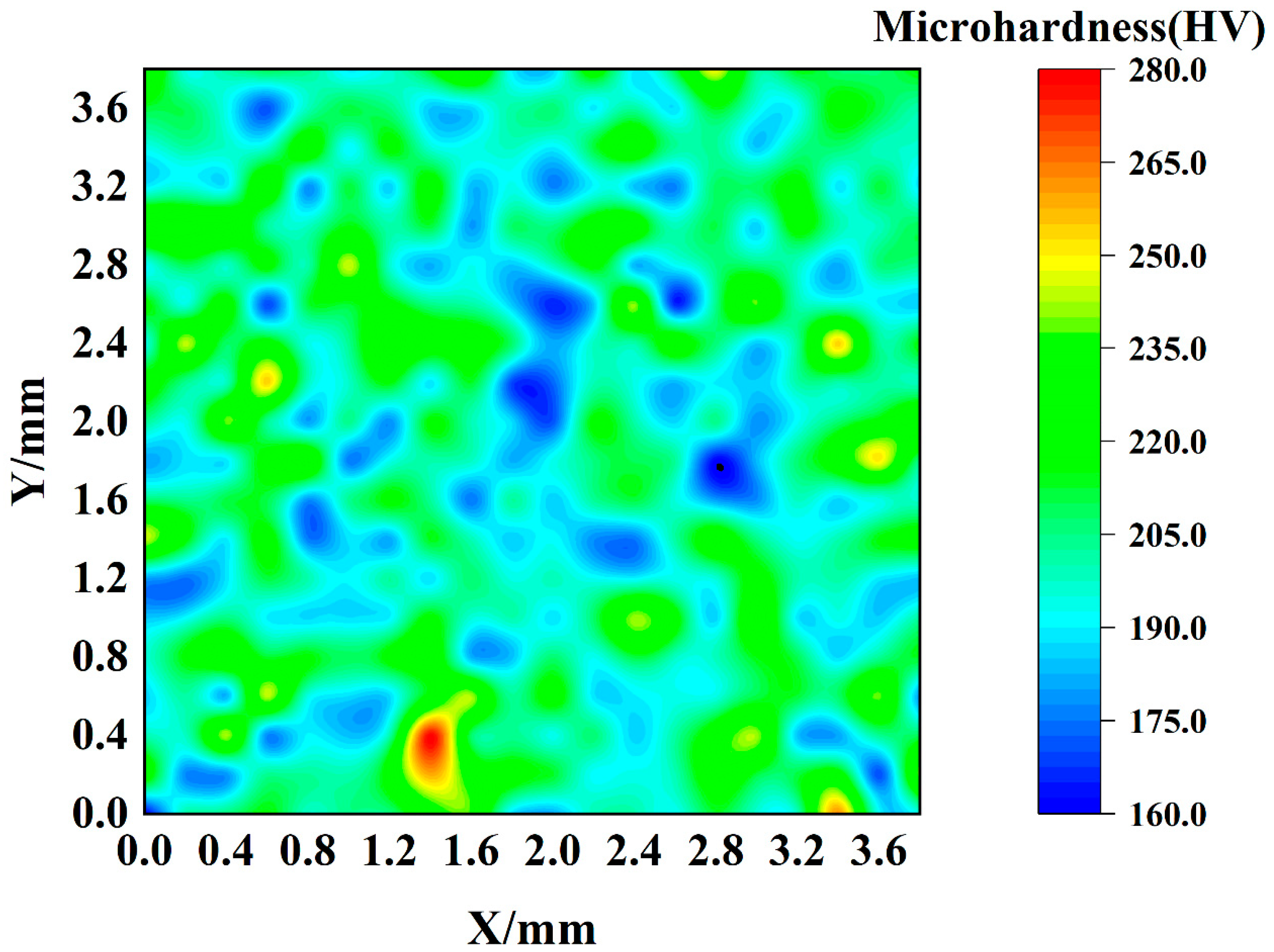

3.2.2. Microhardness

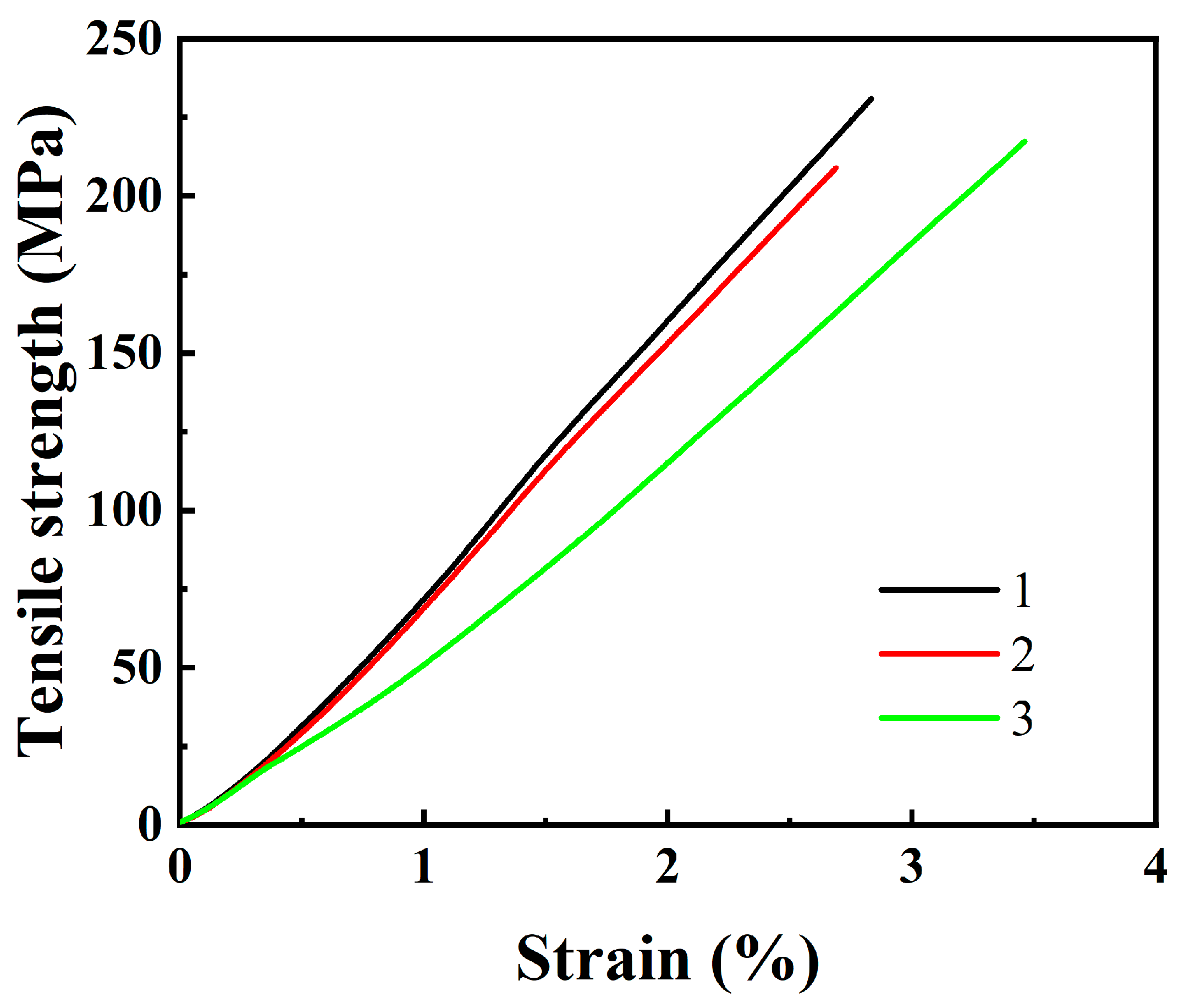

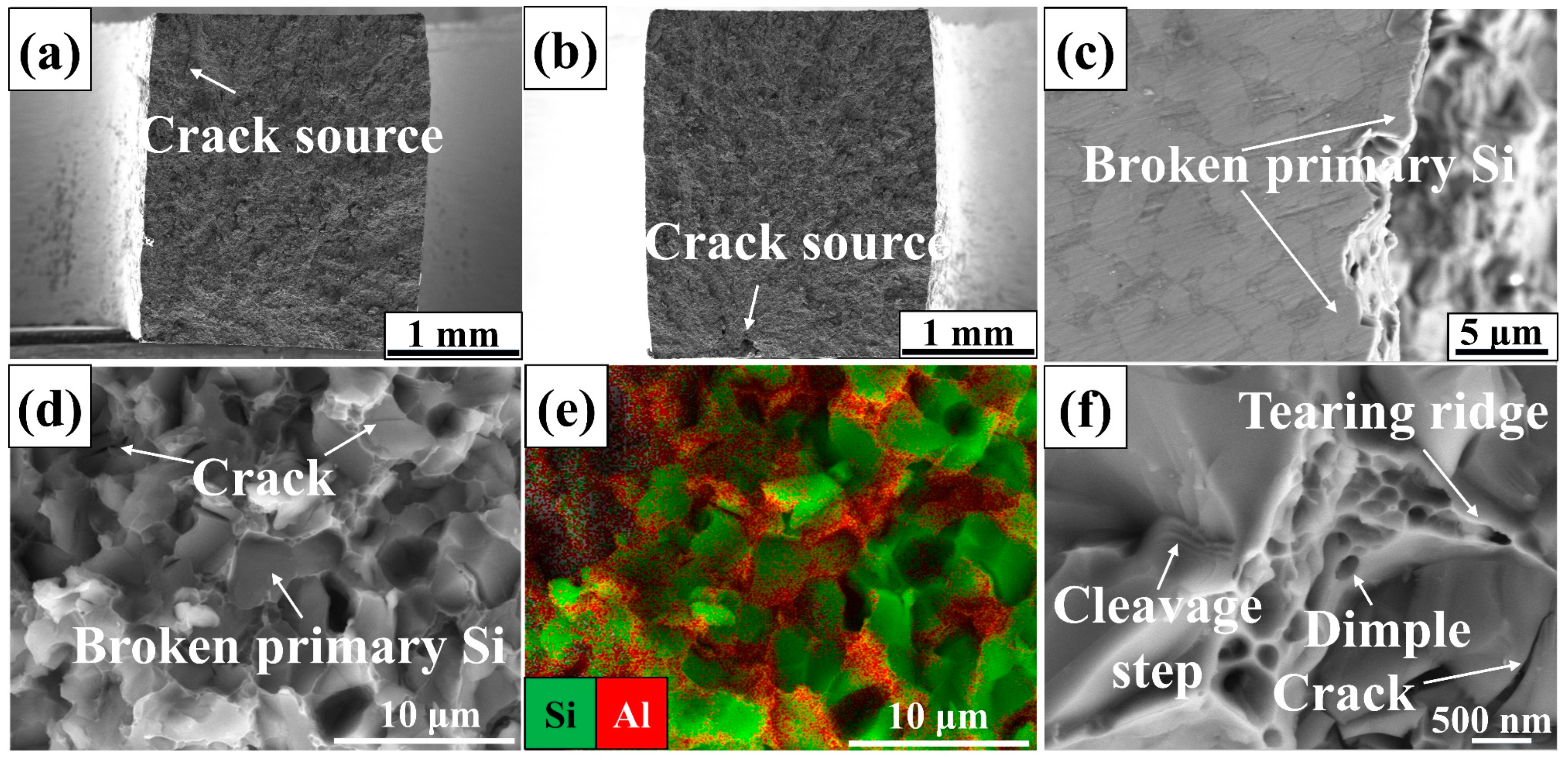

3.2.3. Tensile Properties and Fracture Mechanism

4. Conclusions

- The main defects in the SLM forming process of the AlSi60 alloy include surface balling, lack of fusion, and porosity. Volumetric energy density is a key factor affecting forming, with well-formed samples obtainable within a process window of 150 J/mm3 to 250 J/mm3. However, volumetric energy density merely represents a simplification of the relationships between parameters such as laser power, scanning speed, and hatch spacing. The same volumetric energy density achieved through different combinations of process parameters can lead to variations in sample forming quality. Therefore, the further refined process window is: laser power of 300 W–350 W, scanning speed of 400 mm/s–800 mm/s, hatch spacing of 0.09 mm–0.13 mm, and volumetric energy density of 150 J/mm3 to 250 J/mm3.

- The SLM-formed AlSi60 alloy consists of primary Si, eutectic Si, and α-Al. The primary Si phase has sizes between 5 μm and 10 μm, characterized by sharp edges. The eutectic Si appears granular, about 0.5 μm in size, and is dispersed throughout the α-Al matrix.

- The SLM-formed AlSi60 alloy has an average hardness of 203 HV, higher than that of the AlSi60 alloy prepared by spray forming. The hardness values in the X and Y directions do not show significant anisotropy, due to the finer size and more uniform distribution of the primary Si phase prepared by SLM compared to other methods like spray forming.

- The SLM-formed AlSi60 alloy samples have an average tensile strength of 219 MPa and an average elongation of 2.99%. During the tensile process, cracks initiated in the primary Si phase propagate throughout the entire Si phase and then extend to the Al matrix, where the Al matrix undergoes ductile fracture. Due to the high volume fraction of the Si phase, the tensile fracture is predominantly brittle, with only minor ductile fracture characteristics in the aluminum phase. This is why the tensile stress–strain curve exhibits only the elastic stage.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, W.; Wang, R.-C.; Peng, C.-Q.; Cai, Z.-Y. Microstructure and properties of Al–Si functionally graded materials for electronic packaging. Trans. Nonferrous Met. Soc. China 2023, 33, 3583–3596. [Google Scholar] [CrossRef]

- Hogg, S.C.; Lambourne, A.; Ogilvy, A.; Grant, P.S. Microstructural characterisation of spray formed Si–30Al for thermal man-agement applications. Scr. Mater. 2006, 55, 111–114. [Google Scholar] [CrossRef]

- Xie, L.; Peng, C.; Wang, R.; Wang, X.; Cai, Z.; Liu, B. Research progress of high aluminum-silicon alloys in electronic packaging. Chin. J. Nonferrous Met. 2012, 22, 2578–2587. [Google Scholar]

- Dong, Y.; Lv, H. Research status and prospect of high silicon aluminum alloys. Light Alloy Fabr. Technol. 2021, 49, 11–16. [Google Scholar]

- Li, Q.; Xia, T.; Lan, Y.; Zhao, W.; Fan, L.; Li, P. Effect of rare earth cerium addition on the microstructure and tensile properties of hypereutectic Al–20%Si alloy. J. Alloys Compd. 2013, 562, 25–32. [Google Scholar] [CrossRef]

- Srirangam, P.; Kramer, M.; Shankar, S. Effect of strontium on liquid structure of Al–Si hypoeutectic alloys using high-energy X-ray diffraction. Acta Mater. 2011, 59, 503–513. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, S.; Li, H.; Liu, X. A new technique to modify hypereutectic Al–24%Si alloys by a Si–P master alloy. J. Alloys Compd. 2009, 477, 139–144. [Google Scholar] [CrossRef]

- Hogg, S.C.; Atkinson, H.V. Inhibited coarsening of a spray-formed and extruded hypereutectic aluminum-silicon alloy in the semisolid state. Met. Mater. Trans. A 2005, 36, 149–159. [Google Scholar] [CrossRef]

- Qu, X.; Zhang, L.; Wu, M.; Ren, S. Review of metal matrix composites with high thermal conductivity for thermal man-agement applications. Prog. Nat. Sci. Mater. Int. 2011, 21, 189–197. [Google Scholar] [CrossRef]

- Liu, W.; Wang, R.; Peng, C.; Mo, J.; Zhu, X.W.; Peng, J. Research progress of spray deposited high Si-Al al-loys for electronic packaging. Chin. J. Nonferrous Met. 2012, 22, 3446–3455. [Google Scholar]

- Jia, Y.; Cao, F.; Ma, P.; Scudino, S.; Eckert, J.; Sun, J.; Wang, G. Microstructure and thermal conductivity of hypereutectic Al-high Si produced by casting and spray deposition. J. Mater. Res. 2016, 31, 2948–2955. [Google Scholar] [CrossRef]

- Zhao, Z.; Bo, L.; Li, L.; Huang, J. Status and Progress of Selective Laser Melting Forming Technology. Aeronaut. Manu-Facturing Technol. 2014, 57, 46–49. [Google Scholar] [CrossRef]

- Li, Y.; Gu, D. Parametric analysis of thermal behavior during selective laser melting additive manufacturing of aluminum alloy powder. Mater. Des. 2014, 63, 856–867. [Google Scholar] [CrossRef]

- Wang, M.; Zhu, H.; Qi, T.; Zhang, H.; Zeng, X. Selective laser melting Al-Si aluminum alloy and the crack formation mechanism. Laser Technol. 2016, 40, 219–222. [Google Scholar]

- Zhang, C.; Zhu, J.; Zheng, H.; Li, H.; Liu, S.; Cheng, G.J. A review on microstructures and properties of high entropy alloys manufactured by selective laser melting. Int. J. Extreme Manuf. 2020, 2, 032003. [Google Scholar] [CrossRef]

- Lu, J.; Lu, H.; Xu, X.; Yao, J.; Cai, J.; Luo, K. High-performance integrated additive manufacturing with laser shock peening–induced microstructural evolution and improvement in mechanical properties of Ti6Al4V alloy components. Int. J. Mach. Tools Manuf. 2020, 148, 103475. [Google Scholar] [CrossRef]

- Sheng, Z.; Ruizhi, G.; Qingsong, W.; Yusheng, S. Cracking Behavior and Formation Mechanism of TC4 Alloy Formed by Se-lective Laser Melting. J. Mech. Eng. 2013, 49, 21–27. [Google Scholar]

- Gao, P.; Huang, W.; Yang, H.; Jing, G.; Liu, Q.; Wang, G.; Wang, Z.; Zeng, X. Cracking behavior and control of β-solidifying Ti-40Al-9V-0.5 Y alloy produced by selective laser melting. J. Mater. Sci. Technol. 2020, 39, 144–154. [Google Scholar] [CrossRef]

- Duan, R.X.; Huang, B.Y.; Liu, Z.M.; Peng, K.; Lu, X.Q. Selective laser melting fabrication and cracking behavior of Rene104 nickel-based superalloy. Chin. J. Nonferrous Met. 2018, 28, 1568–1578. [Google Scholar]

- Zhang, J.; Li, S.; Wei, Q.; Shi, Y.; Wang, L.; Guo, L. Cracking Behavior and Inhibiting Process of Inconel 625 Alloy Formed by Selective Laser Melting. Chin. J. Rare Met. 2015, 39, 961–966. [Google Scholar]

- Kempen, K.; Vrancken, B.; Buls, S.; Thijs, L.; Van Humbeeck, J.; Kruth, J.-P. Selective Laser Melting of Crack-Free High Density M2 High Speed Steel Parts by Baseplate Preheating. J. Manuf. Sci. Eng. 2014, 136, 061026. [Google Scholar] [CrossRef]

- Zhang, W.; Zhu, H.; Hu, Z.; Zeng, X. Study on the Selective Laser Melting of AlSi10Mg. Acta Met. Sin. 2017, 53, 918–926. [Google Scholar]

- Aboulkhair, N.T.; Maskery, I.; Tuck, C.; Ashcroft, I.; Everitt, N.M. On the formation of AlSi10Mg single tracks and layers in selective laser melting: Microstructure and nano-mechanical properties. J. Am. Acad. Dermatol. 2016, 230, 88–98. [Google Scholar] [CrossRef]

- Kempen, K.; Thijs, L.; Van Humbeeck, J.; Kruth, J.-P. Mechanical Properties of AlSi10Mg Produced by Selective Laser Melting. Phys. Procedia 2012, 39, 439–446. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Klauss, H.J.; Surreddi, K.B.; Löber, L.; Wang, Z.; Chaubey, A.K.; Kühn, U.; Eckert, J. Microstruc-ture and mechanical properties of Al–12Si produced by selective laser melting: Effect of heat treatment. Mater. Sci. Eng. A 2014, 590, 153–160. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, L.; Fang, M.; Sercombe, T. The effect of atmosphere on the structure and properties of a selective laser melted Al–12Si alloy. Mater. Sci. Eng. A 2014, 597, 370–375. [Google Scholar] [CrossRef]

- Jia, Y.D.; Ma, P.; Prashanth, K.G.; Wang, G.; Yi, J.; Scudino, S.; Cao, F.Y.; Sun, J.F.; Eckert, J. Microstructure and thermal expan-sion behavior of Al-50Si synthesized by selective laser melting. J. Alloys Compd. 2017, 699, 548–553. [Google Scholar] [CrossRef]

- Kang, N.; Coddet, P.; Chen, C.; Wang, Y.; Liao, H.; Coddet, C. Microstructure and wear behavior of in-situ hypereutectic Al–high Si alloys produced by selective laser melting. Mater. Des. 2016, 99, 120–126. [Google Scholar] [CrossRef]

- Hanemann, T.; Carter, L.N.; Habschied, M.; Adkins, N.J.; Attallah, M.M.; Heilmaier, M. In-situ alloying of AlSi10Mg+Si using Selective Laser Melting to control the coefficient of thermal expansion. J. Alloys Compd. 2019, 795, 8–18. [Google Scholar] [CrossRef]

- Murray, J.L.; McAlister, A.J. The AI-Si (Aluminum-Silicon) System. Bull. Alloy Phase Diagr. 1984, 5, 74–84. [Google Scholar] [CrossRef]

- Wang, S.-R.; Ma, R.; Wang, Y.-Z.; Wang, Y.; Yang, L.-Y. Growth mechanism of primary silicon in cast hypoeutectic Al-Si alloys. Trans. Nonferrous Met. Soc. China 2012, 22, 1264–1269. [Google Scholar] [CrossRef]

- Wang, K.; Liu, Y.; Wang, J.; Li, Y. Influences of extrusion temperature on microstructure and properties of spray formed 60si40al alloy parts. Powder Metall. Ind. 2008, 18, 6–11. [Google Scholar]

- Xu, C.; Wang, H.; Liu, C.; Jiang, Q. Growth of octahedral primary silicon in cast hypereutectic Al–Si alloys. J. Cryst. Growth 2006, 291, 540–547. [Google Scholar] [CrossRef]

- Wang, R.-Y.; Lu, W.-H.; Hogan, L.M. Faceted growth of silicon crystals in Al-Si alloys. Met. Mater. Trans. A 1997, 28, 1233–1243. [Google Scholar] [CrossRef]

- Zhao, L.; Zhao, M.; Song, L.; Mazumder, J. Ultra-fine Al–Si hypereutectic alloy fabricated by direct metal deposition. Mater. Des. 2014, 56, 542–548. [Google Scholar] [CrossRef]

- Yamauchi, I.; Ohnaka, I.; Kawamoto, S.; Fukusako, T. Hot Extrusion of Rapidly Solidified Al–Si Alloy Powder by the Rotating-Water-Atomization Process. Trans. Jpn. Inst. Met. 1986, 27, 195–203. [Google Scholar] [CrossRef]

| Laser Power (W) | Scanning Speed (mm/s) | Hatch Spacing (mm) | Volumetric Energy Density (J/mm3) |

|---|---|---|---|

| 300–350 | 400–800 | 0.09–0.13 | 150–250 |

| Sample | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|

| 1 | 231 | 2.83 |

| 2 | 209 | 2.69 |

| 3 | 217 | 3.46 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Zhi, G.; He, Y.; Zhang, Z.; Chen, Y.; Rong, P.; Ma, S.; Xie, P.; Chen, H. Study on the Forming Process and Properties of AlSi60 Alloy by Selective Laser Melting. Coatings 2024, 14, 259. https://doi.org/10.3390/coatings14030259

Li G, Zhi G, He Y, Zhang Z, Chen Y, Rong P, Ma S, Xie P, Chen H. Study on the Forming Process and Properties of AlSi60 Alloy by Selective Laser Melting. Coatings. 2024; 14(3):259. https://doi.org/10.3390/coatings14030259

Chicago/Turabian StyleLi, Guo, Geng Zhi, Youling He, Zhenlin Zhang, Yong Chen, Peng Rong, Sida Ma, Pu Xie, and Hui Chen. 2024. "Study on the Forming Process and Properties of AlSi60 Alloy by Selective Laser Melting" Coatings 14, no. 3: 259. https://doi.org/10.3390/coatings14030259

APA StyleLi, G., Zhi, G., He, Y., Zhang, Z., Chen, Y., Rong, P., Ma, S., Xie, P., & Chen, H. (2024). Study on the Forming Process and Properties of AlSi60 Alloy by Selective Laser Melting. Coatings, 14(3), 259. https://doi.org/10.3390/coatings14030259