Microstructural, Nanomechanical, and Tribological Properties of Thin Dense Chromium Coatings

Abstract

1. Introduction

2. Experimental Section

2.1. Steel Substrate and Coating

2.2. Microstructural, Nanomechanical, and Adhesion Characterizations

2.3. Tribological Characterization

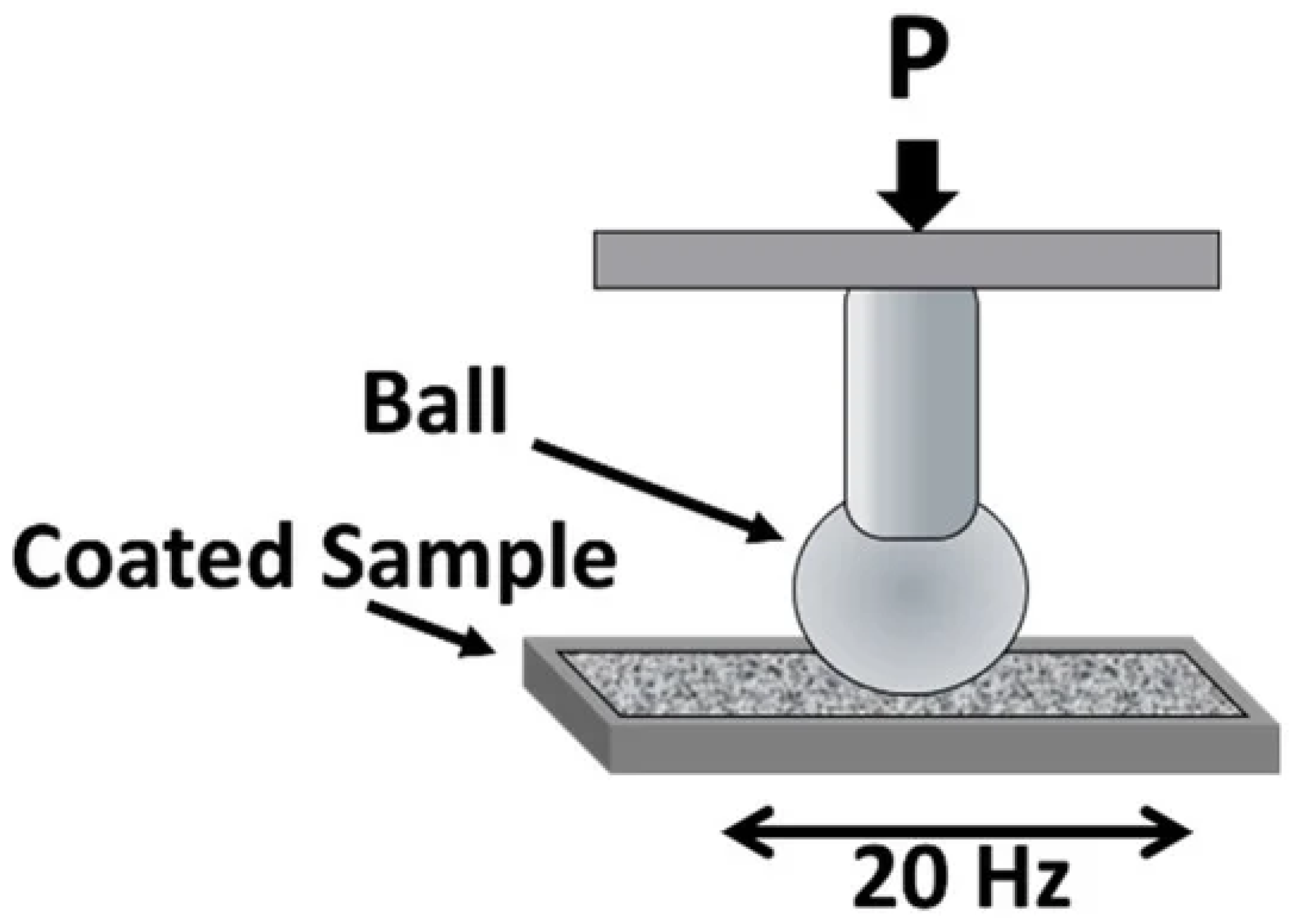

2.3.1. Reciprocating Sliding Test

2.3.2. Ball-on-Disk Rolling/Sliding Tests

3. Results and Discussion

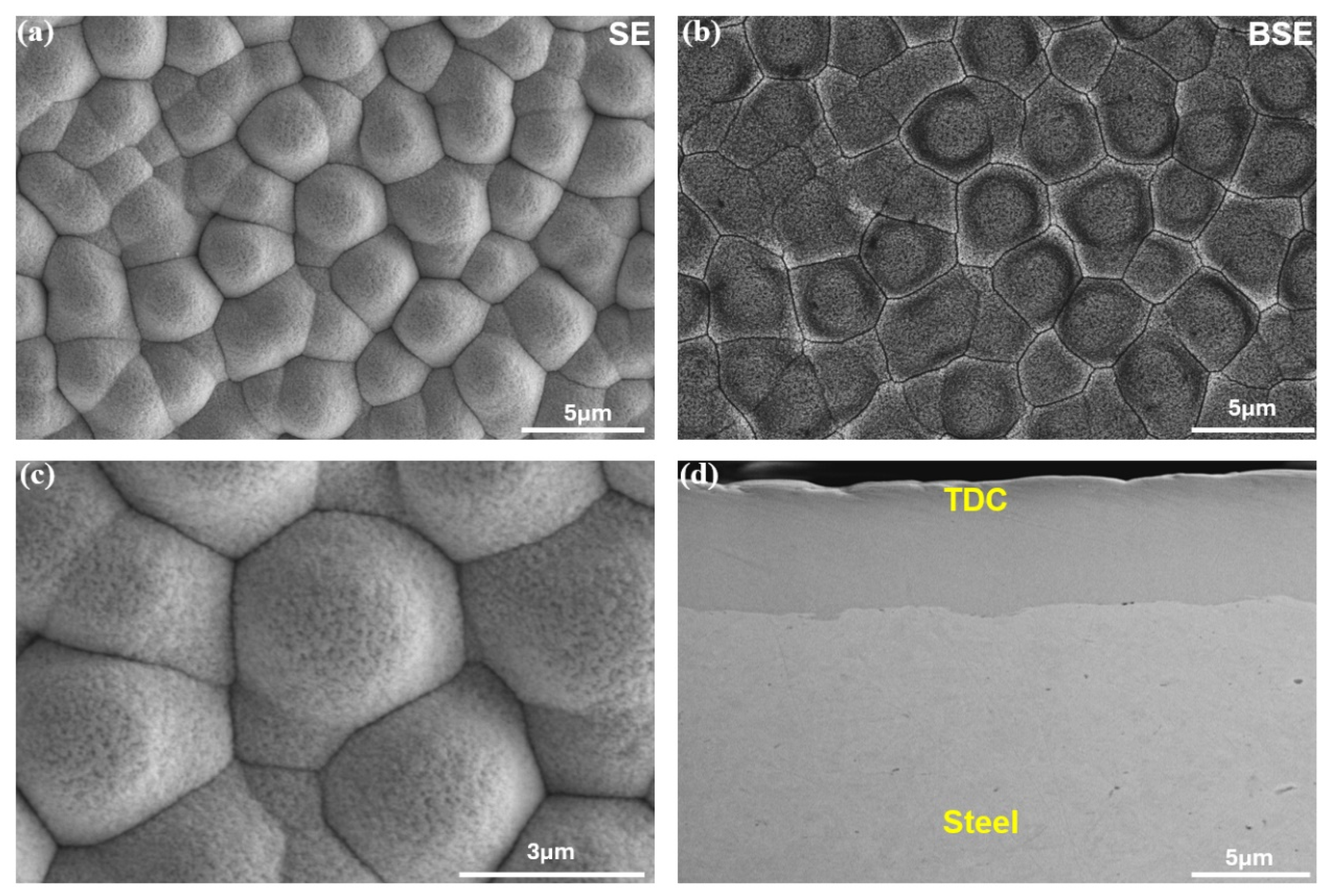

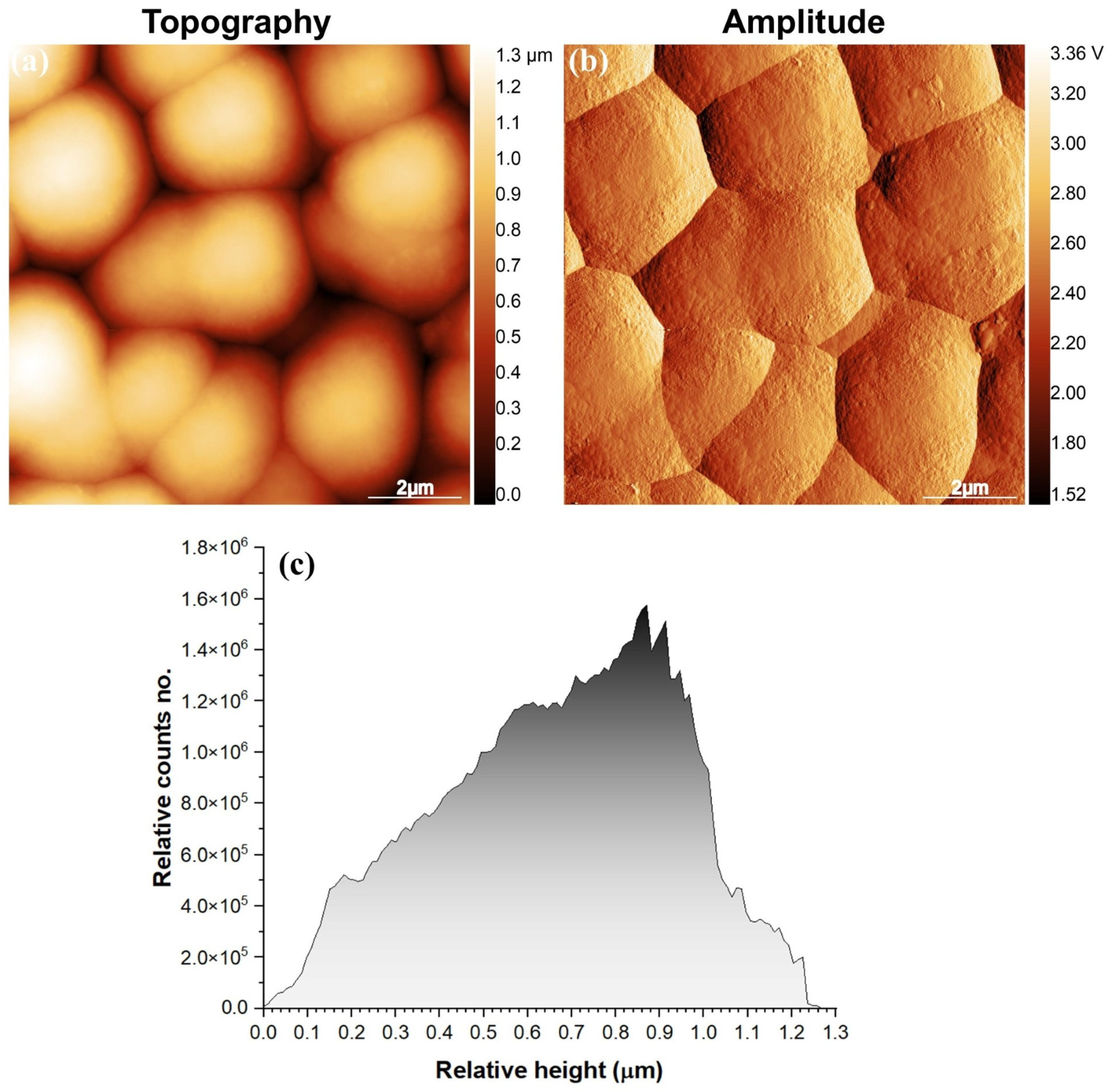

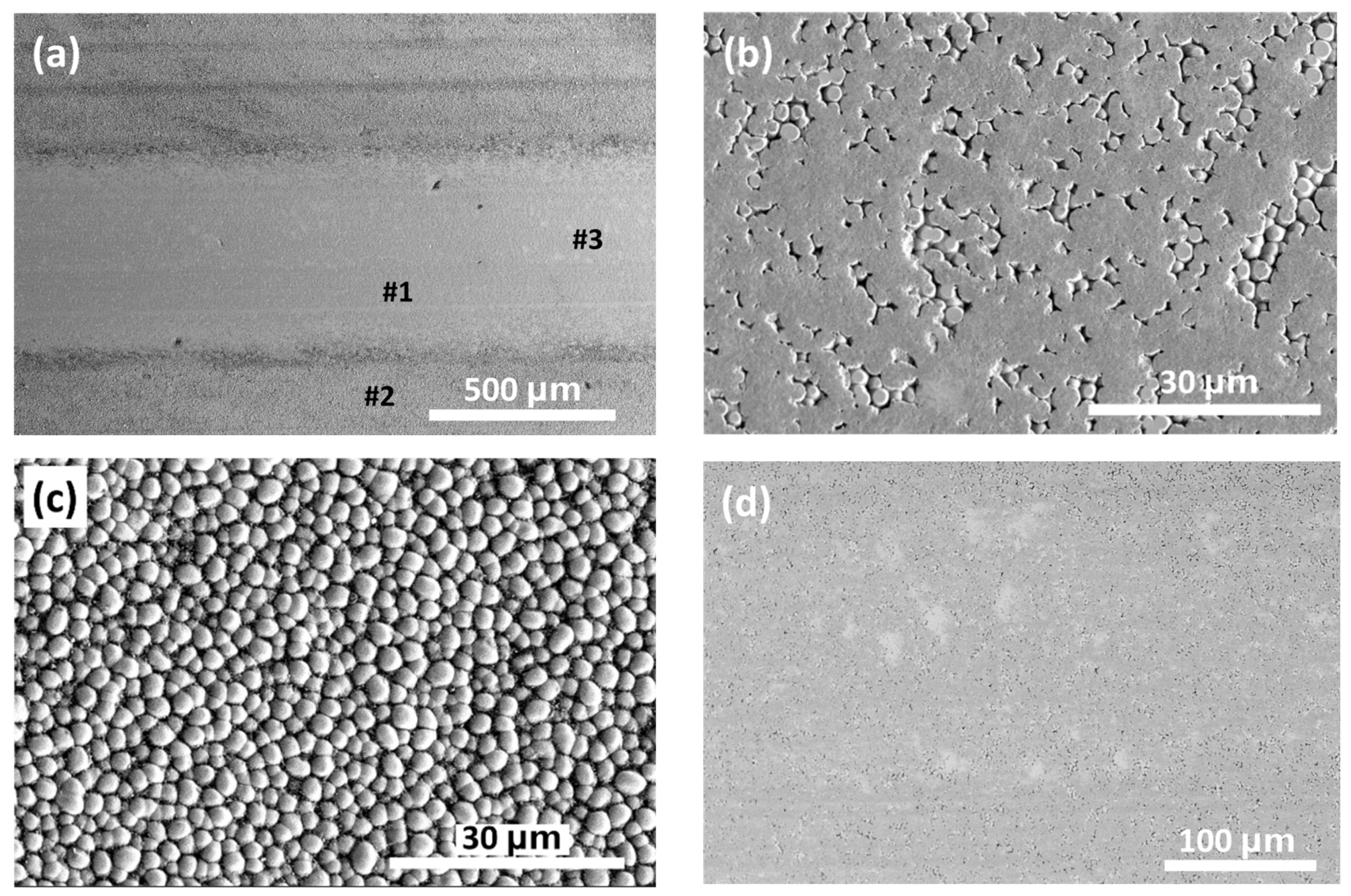

3.1. Morphology

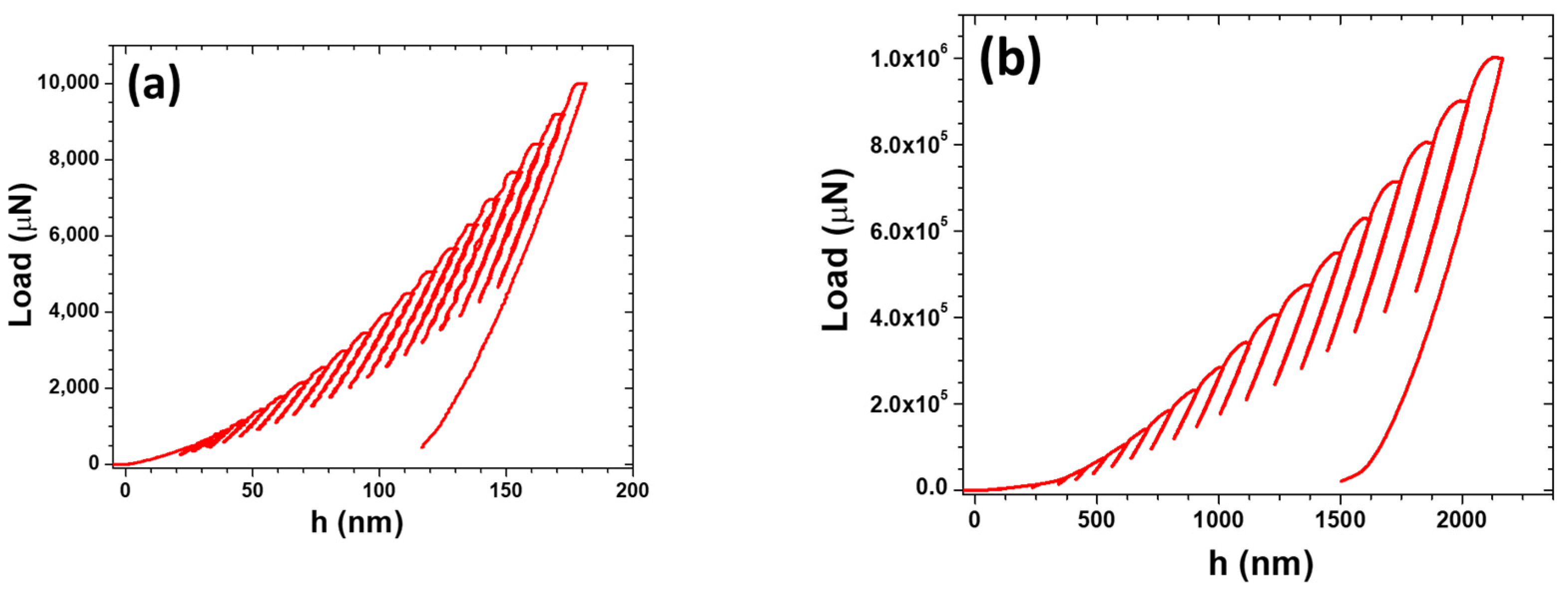

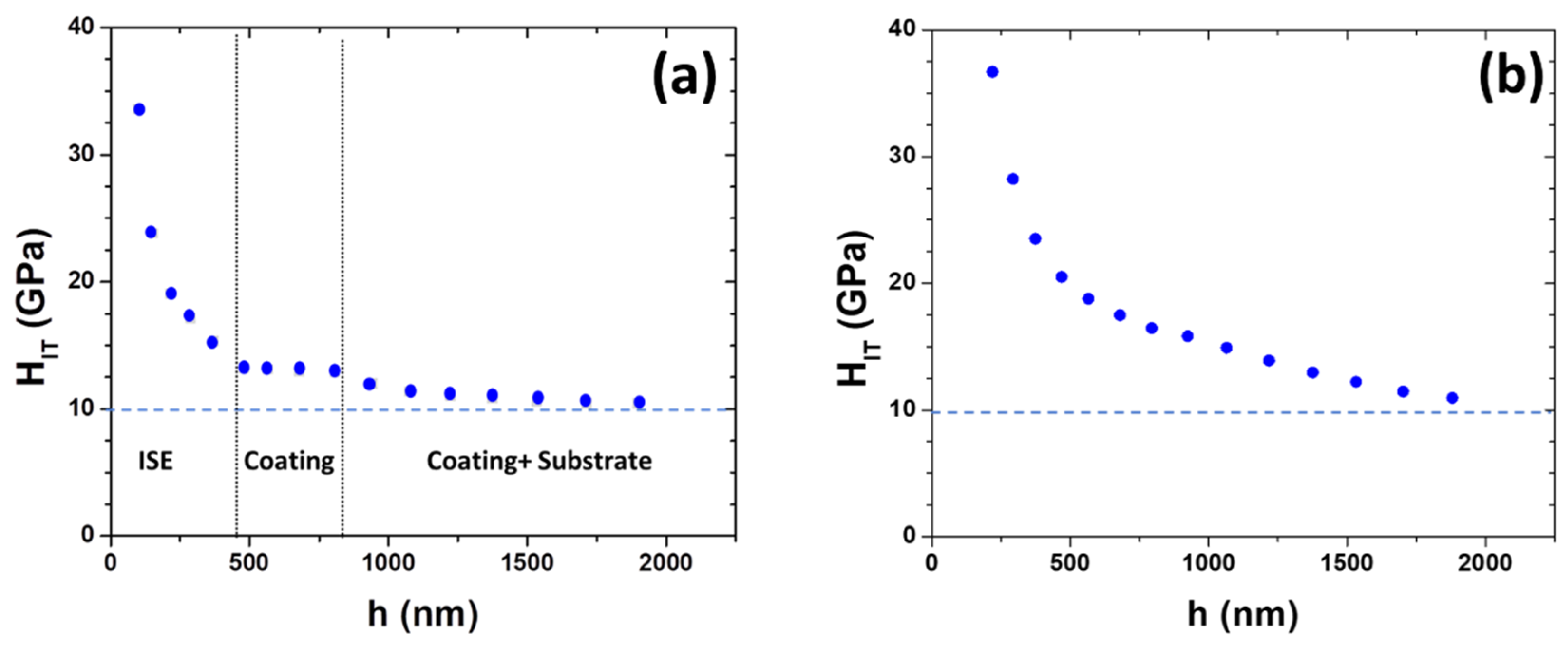

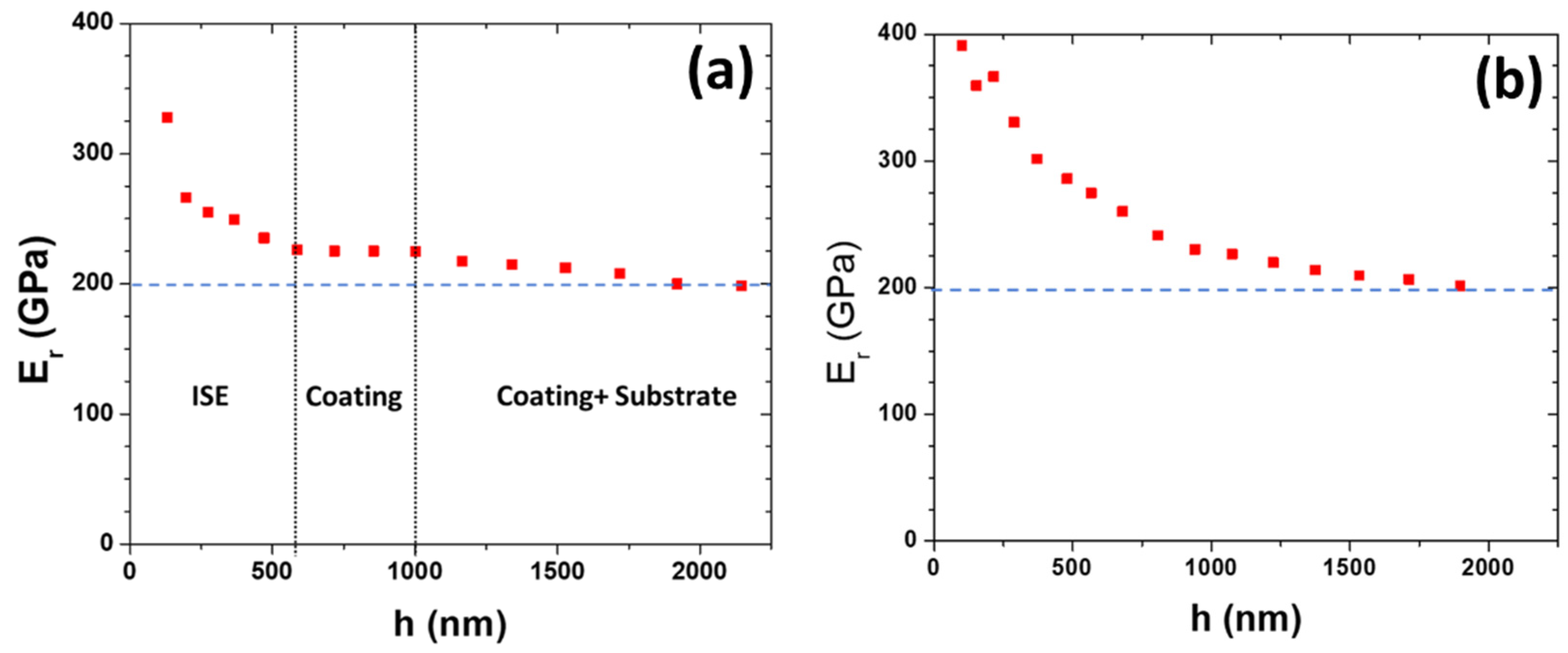

3.2. Mechanical Properties

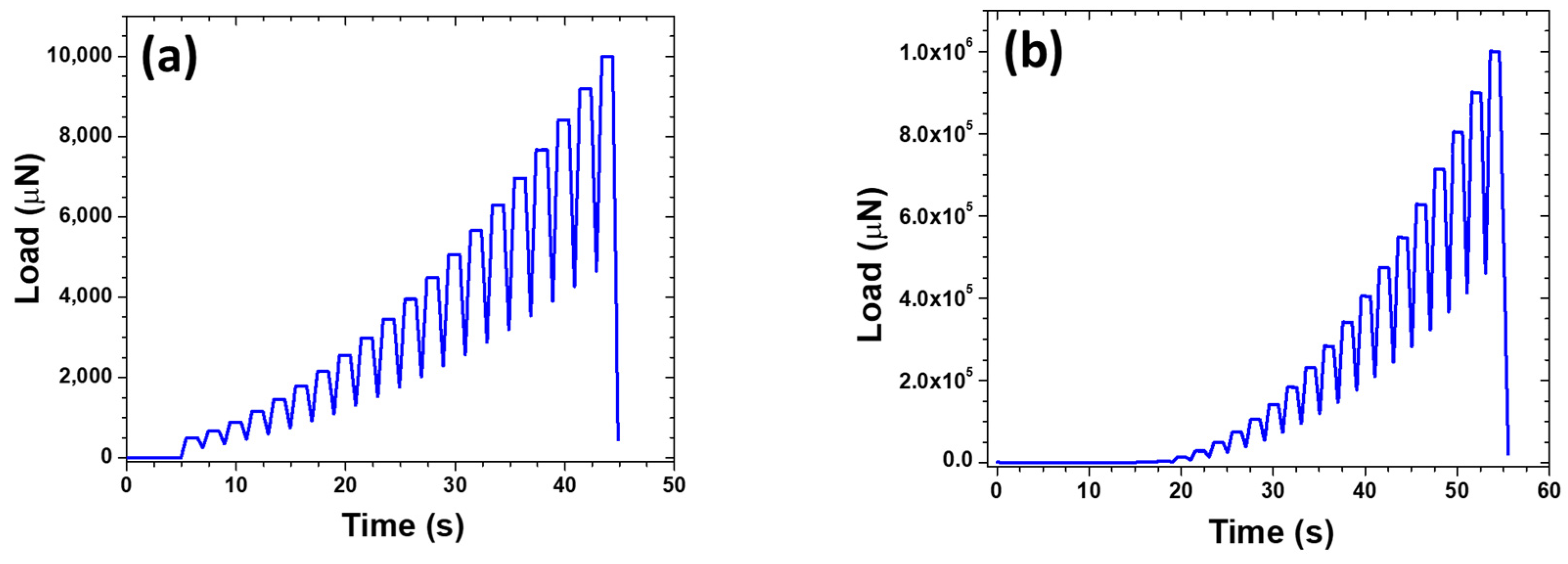

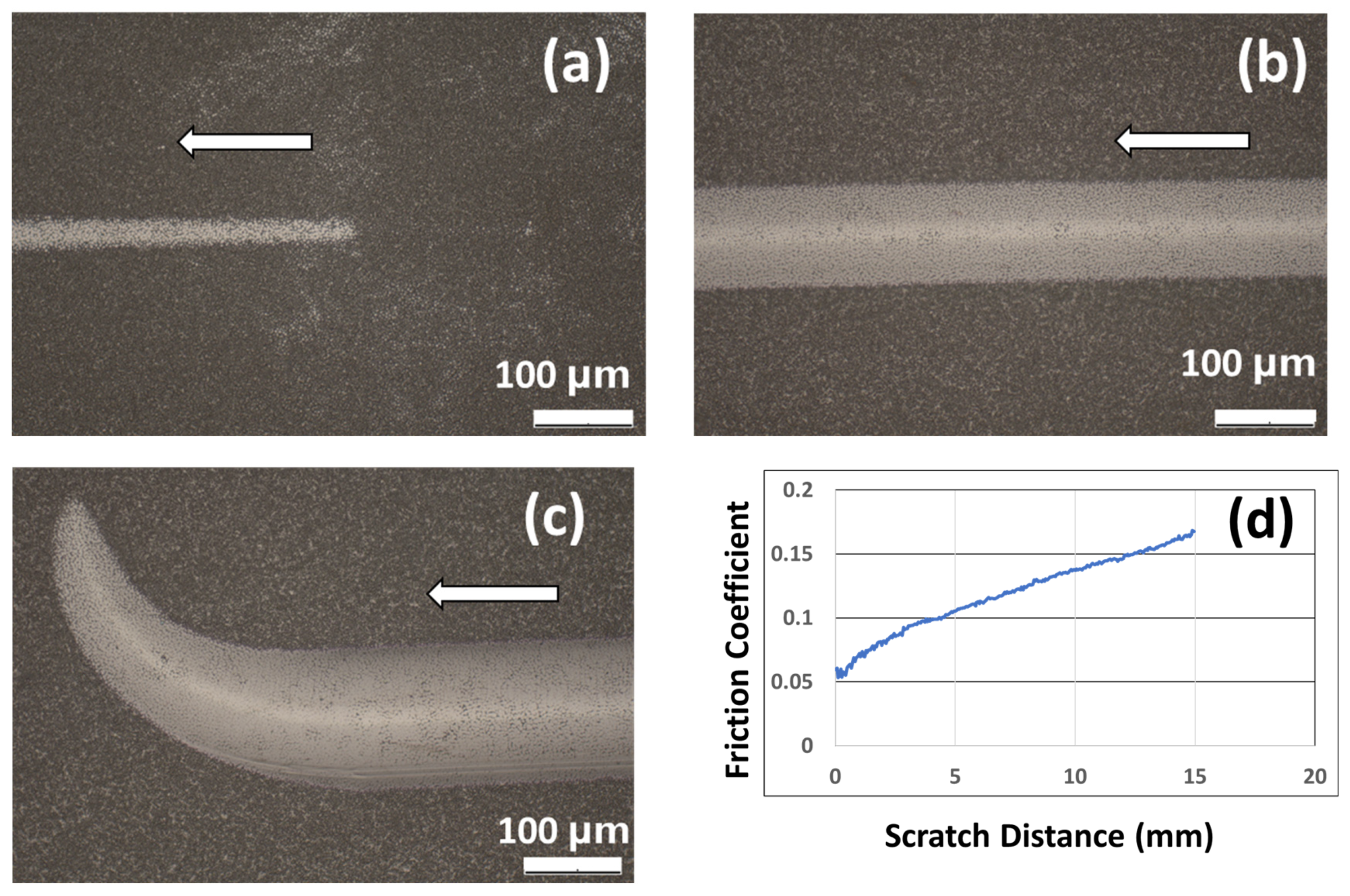

3.3. Adhesion Characterization

3.4. Reciprocal Sliding Tribological Tests

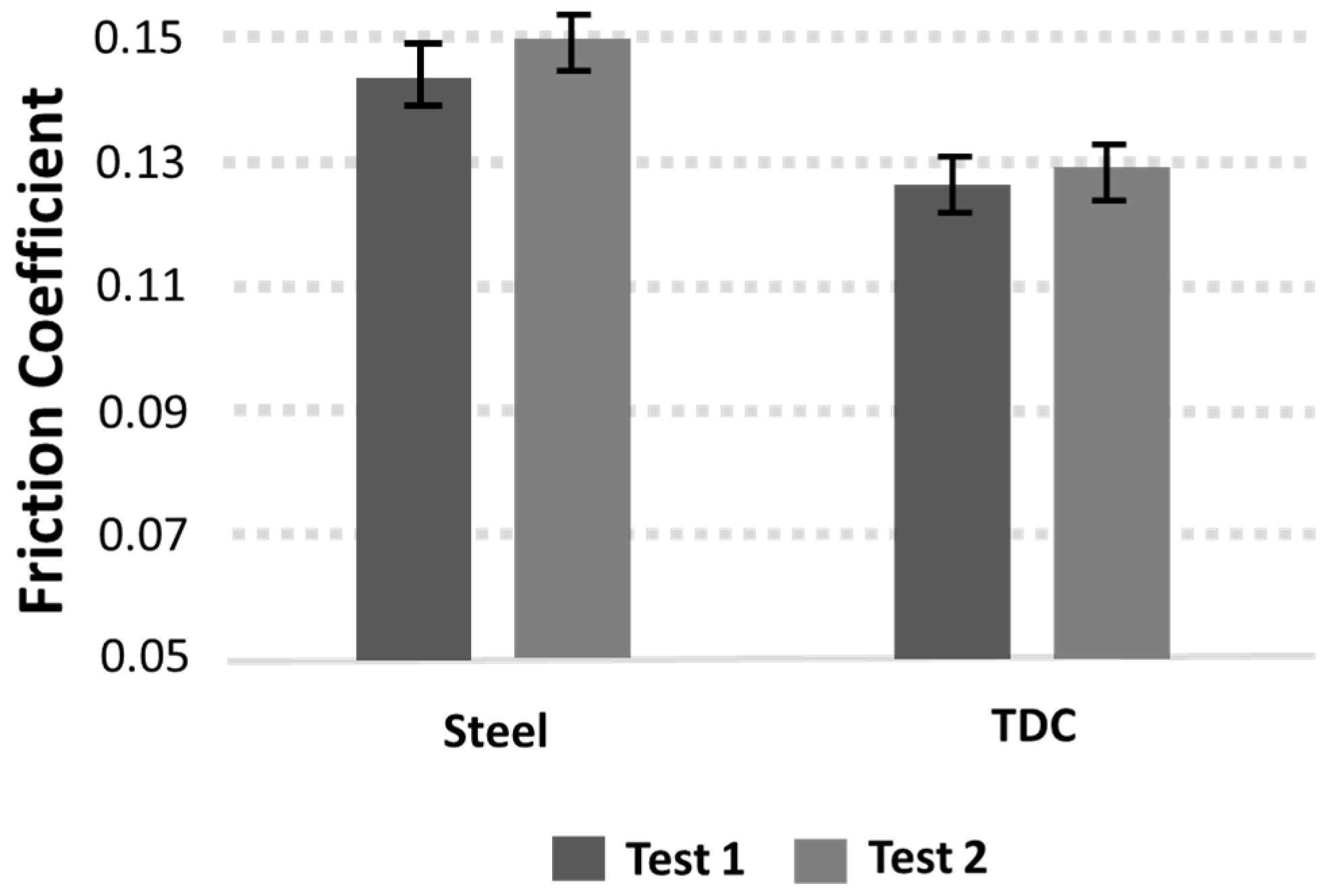

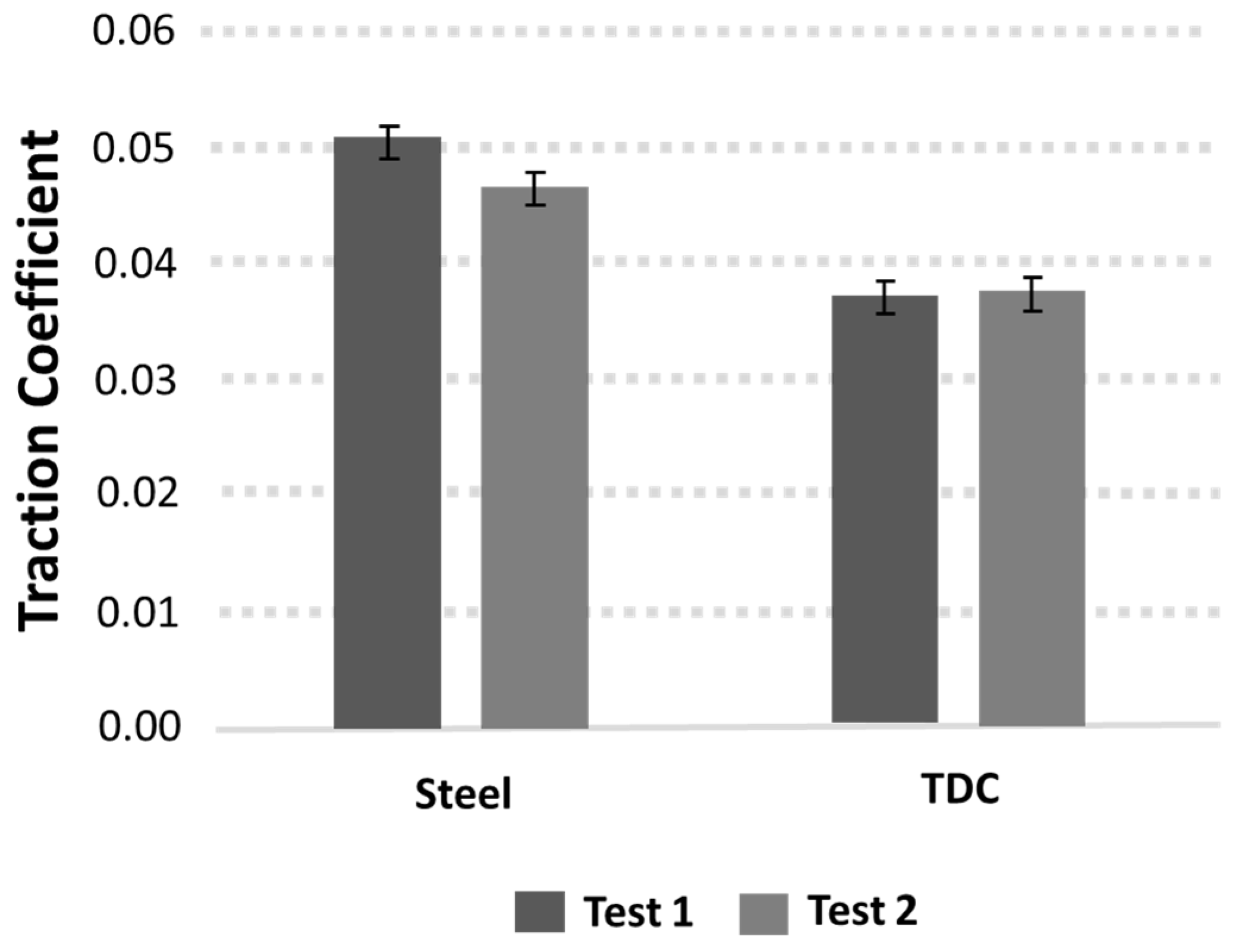

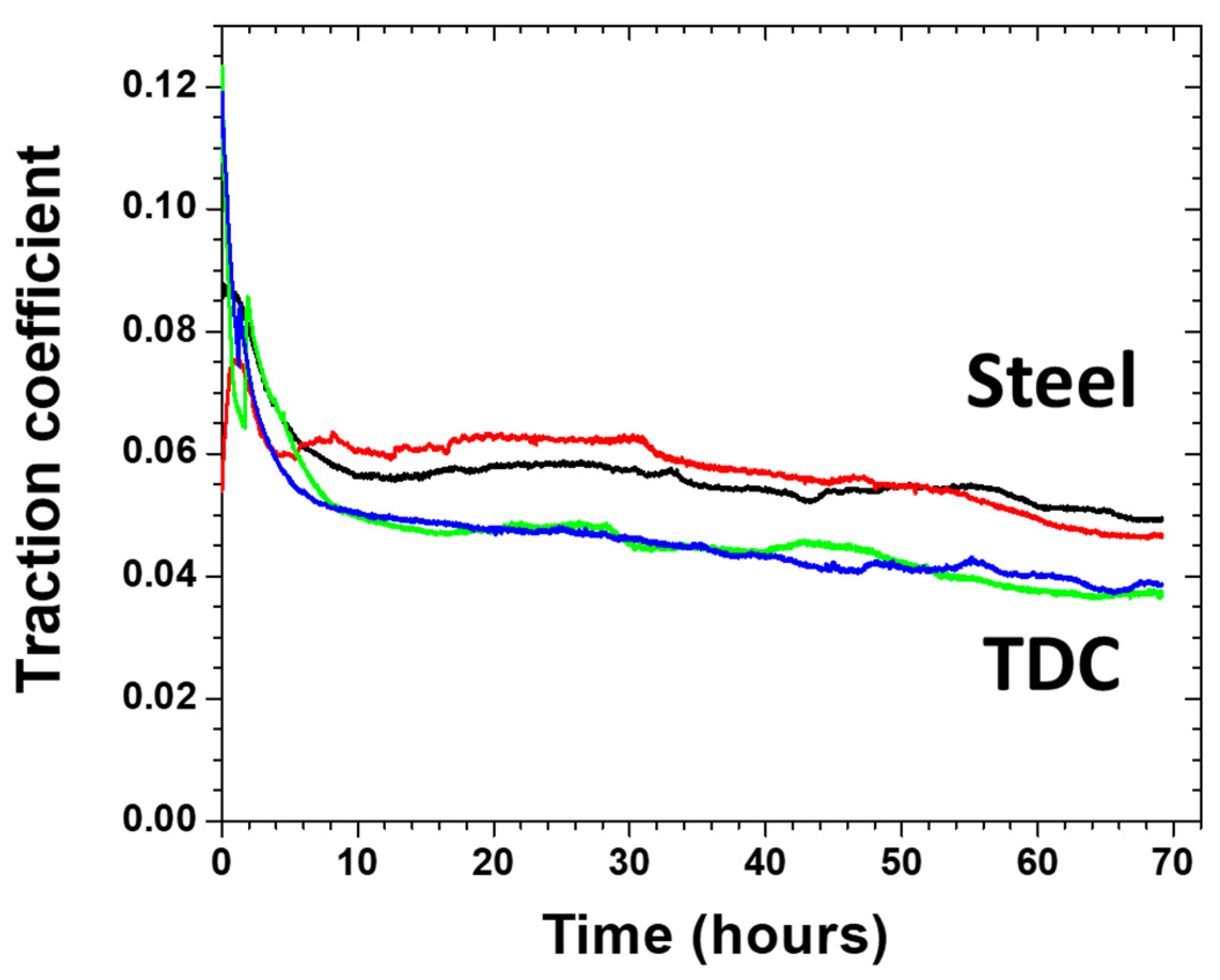

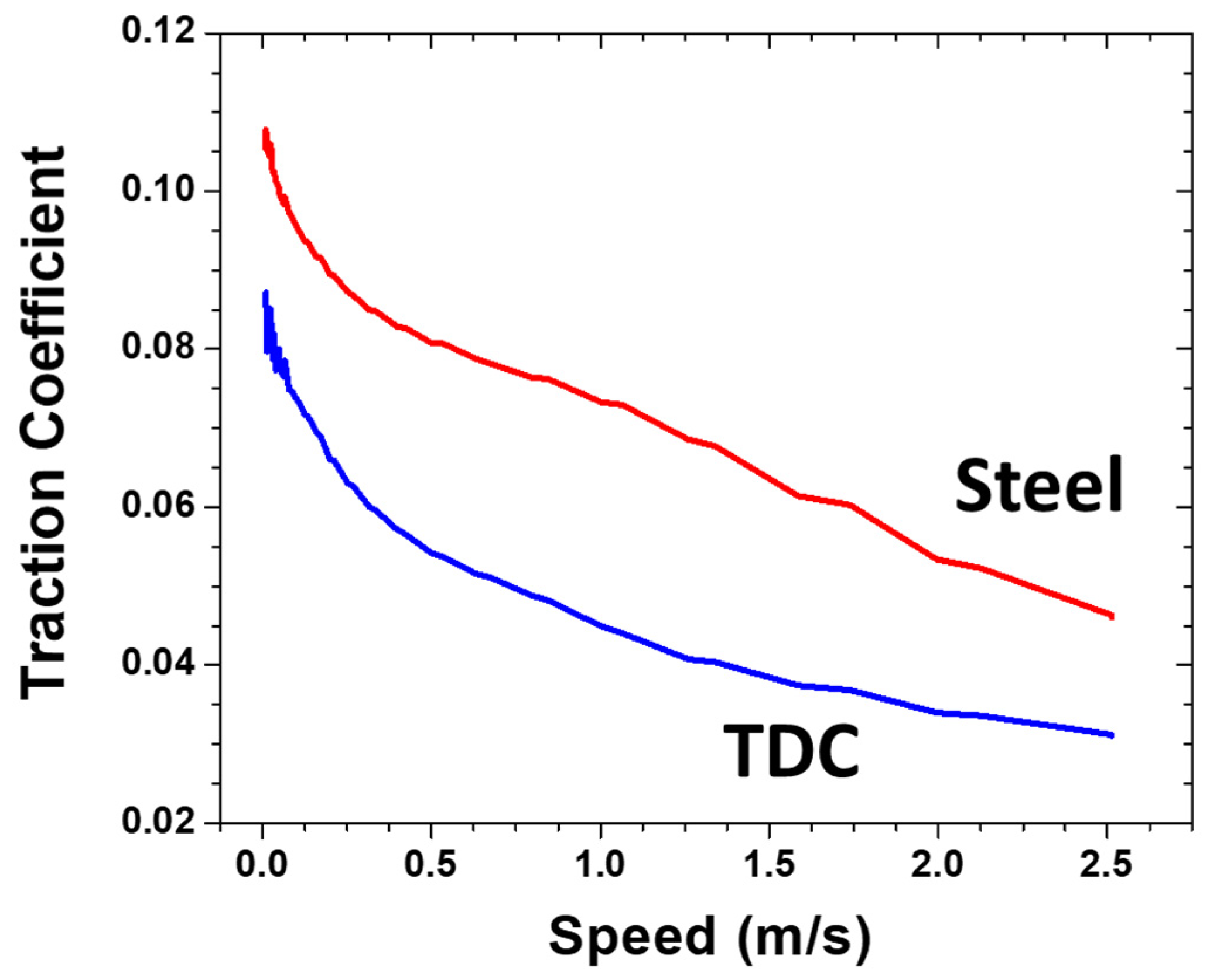

3.5. Rolling-Sliding Tribological Tests

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bussy, J.D. Revêtements de Chrome. France Patent 3564, 1848. [Google Scholar]

- Sargent, G.J. Electrolytic Chromiun. Trans. Electrochem. Soc. 1920, 37, 479–496. [Google Scholar]

- Dennis, J.K.; Such, T.E. Chapter 1—Introduction and Historical Review. In Nickel and Chromiun Plating; Woodhead Publishing: Cambridge, UK, 1993; pp. 1–12. [Google Scholar]

- Nagrale, P. Global Chrome Plating Market Overview; Market Research Future: New York, NY, USA, 2024. [Google Scholar]

- Bejbl, J. Thin, Dense, Chromium Coatings Protects Parts. Adv. Mater. Process. 2002, 6, 1–2. [Google Scholar]

- Waskiewicz, W.P. Extending Bearing Life in Off-Highway Equipment. In International Off-Highway & Powerplant Congress & Exposition; Milwaukee: Brookfield, WI, USA, 1984. [Google Scholar]

- Maurer, R. Friction, wear, and corrosion control in rolling bearings through coatings and surface. J. Vac. Sci. Technol. A 1986, 4, 3002–3006. [Google Scholar] [CrossRef]

- Bamberger, E.N.; Averbach, B.L.; Pearson, P.K. Improved Fatigue Life Bearing Development—Report AFWAL-TR-89-2012; Wright Research and Development Center: Wright Patterson AFB, OH, USA, 1989. [Google Scholar]

- Hirvonen, J.K. Ion Beam Assisted Thin Film Deposition: Fundamentals and Applications of IBAD Processing. In Proceedings of the Nato Advance Study on Materials and Processes for Surface and Interface Engineering, Chateau de Bonas, Gers, France, 18–29 July 1995. [Google Scholar]

- Pearson, P.K. The history and future of aircraft turbine engine bearing steels. In Bearing Steels: Into the 21st Century; ASTM International: West Conshohocken, PA, USA, 1998; pp. 335–353. [Google Scholar] [CrossRef]

- Beswick, J.; Voskamp, A.; Sanden, J.v.D.; Verburgh, M.; Horton, S. Bearing Material/Treatment Developments at the SKF Engineering and Research Centre. In Creative Use of Bearing Steels, ASTM STP 1195; Hoo, J.J.C., Ed.; American Society for Testing and Materials: West Conshohocken, PA, USA, 1993; pp. 222–234. [Google Scholar]

- Armoloy Corporation. Nodular Thin Dense Chrome. Available online: https://armoloy.com/coatings/thin-dense-chrome/ (accessed on 21 October 2024).

- U. S. Chrome. Thin Dense Chrome. Available online: https://www.uschrome.com/thin-dense-chrome/ (accessed on 21 October 2024).

- Duro-Chrome. Thin Dense Hard Chrome. Available online: https://duro-chrome.com/thin-dense-hard-chrome/ (accessed on 21 October 2024).

- ATC Technology Coatings. Thin Dense Chromiun Technology. Available online: https://www.atc-armoloy.com/en/general-information/chromium.html (accessed on 21 October 2024).

- Pinedo, B.; López, G.A.; Zubizarreta, C.; Mendizabal, L.; Fraile, S.; Ionescu, L. Tribological Investigation on WC/C Coatings Applied on Bearings Subjected to Fretting Wear. Tribol. Lett. 2024, 72, 87. [Google Scholar] [CrossRef]

- The Armoloy Corporation. The Electrolizing Thin, Dense, Chromium Process. In Coatings Technology Handbook; CRC Press: Boca Raton, FL, USA, 2005; p. 28. [Google Scholar]

- Broitman, E. Indentation Hardness Measurements at Macro-, Micro-, and Nanoscale: A Critical Overview. Tribol. Lett. 2017, 65, 23. [Google Scholar] [CrossRef]

- ASTM B578-21; Standard Test Method for Microindentation Hardness of Electroplated Coatings. ASTM International: West Conshohocken, PA, USA, 2021.

- Broitman, E. Coatings to Improve Bearing Perfomance. Evolution 2022, 1–7. Available online: https://evolution.skf.com/coatings-to-improve-bearing-performance/ (accessed on 21 October 2024).

- SKF Coatings Catalogue. Available online: https://cdn.skfmediahub.skf.com/api/public/0901d19680a4e17f/pdf_preview_medium/0901d19680a4e17f_pdf_preview_medium.pdf (accessed on 21 October 2024).

- SKF. Kaydon Endurakote®—Plated Bearings. Kaydon Bearing Solutions—SKF. Available online: https://www.kaydonbearings.com/Endurakote_bearings.htm&r=1 (accessed on 21 October 2024).

- Oliver, W.; Pharr, G. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Bull, S.J.; Berasetegui, E.G. An overview of the potential of quantitative coating adhesion measurement by scratch testing. Tribol. Int. 2006, 39, 99–114. [Google Scholar] [CrossRef]

- Broitman, E.; Ruellan, A.; Meeuwenoord, R.; Nijboer, D.; Brizme, V. Comparison of Various Conversion Layers for Improved Friction Performance of Railway Wheel-End Bearings. Coatings 2023, 13, 1980. [Google Scholar] [CrossRef]

- ISO-14577-1; Metallic Materials—Instrumented Indentation Test for Hardness and Materials Parameters—Part 1: Test Method. International Organization for Standardization: Geneve, Switzerland, 2015.

- Fischer-Cripps, A.C. Nanoindentation; Springer: New York, NY, USA, 2011. [Google Scholar]

- Dezzani, M.M.; Pearson, P.K. Hybrid Ceramic Bearings for Difficult Applications. J. Eng. Gas Turbines Power 1996, 118, 449–452. [Google Scholar] [CrossRef]

- Mohn, J.H.; Munson, H.E.; Poole, W.E.; Hodgens, H.M., II. Improvement of the Corrosion Resistance of Turbine Engine Bearings (Report AFWAL-TR-84-2014); AF Wright Aeronautical Laboratories: Wright-Patterson, OH, USA, 1984. [Google Scholar]

- AMS2438F; Plating, Chromium Thin, Hard, Dense Deposit. Society of Automotive Engineers: Warrendale, PA, USA, 2021.

- Jones, A.; Sugawara, S.; Enloe, J. Adhesion Testing of Hard Chromium Electrodeposits. In AESF SUR/FIN; American Electroplaters & Surface Finishers Society: Chicago, IL, USA, 2000. [Google Scholar]

- Stallard, J.; Poulat, S.; Teer, D.G. The study of the adhesion of a TiN coating on steel and titanium alloy substrates using a multi-mode scratch tester. Tribol. Int. 2006, 39, 159–166. [Google Scholar] [CrossRef]

- Broitman, E.; Czigány, Z.; Greczynski, G.; Böhlmark, J.; Cremer, R.; Hultman, L. Industrial-scale deposition of highly adherent CNx films on steel substrates. Surf. Coat. Technol. 2010, 204, 3349–3357. [Google Scholar] [CrossRef][Green Version]

- Armoloy of Illinois. Thin Dense Chrome Plating Performance Characteristics. Available online: https://armoloy-il.com/armoloy-tdc-thin-dense-chrome/ (accessed on 27 October 2024).

- ATC. Thin, Dense, Chromium Coating Technology. ATC Technology Coatings GMBH & CO. Available online: https://www.solidcomponents.com/files/company/SCCNS20DW/companyfiles/doc/atc-armoloy-general-information_engelsk_version.pdf (accessed on 27 October 2024).

- Braza, J.F. Sliding wear evaluation of various coating processes on AISI 52100 and M 50 steels. Mater. Sci. Technol. 1992, 8, 582–588. [Google Scholar] [CrossRef]

| Parameter | Values |

|---|---|

| Ball Diameter | 12.7 mm |

| Initial Hertzian Contact Pressure | 1.25 GPa |

| Reciprocal stroke | 100 µm |

| Frequency | 20 Hz |

| Temperature | Room Temperature |

| Number of Cycles | 72,000 |

| Total Distance | 7.2 m |

| Test Duration | 1 h |

| Lubricant | Grease (PAO base oil ISO VG100) |

| Setup | Ball-on-Disk |

|---|---|

| Initial Contact Pressure PH | 1.5 GPa |

| Entrainment Speed | 0.8 m/s (Stribeck: 0 to 2.5 m/s) |

| SRR (slide-to-rolling ratio) | 5%; −15% to +15% |

| Lubricant | Mineral oil of 32 cSt at 100 °C with no EP/AW additives |

| Temperature | 100 °C |

| Lubrication Parameter λ | λ = 0.3 |

| Test duration | 70 h |

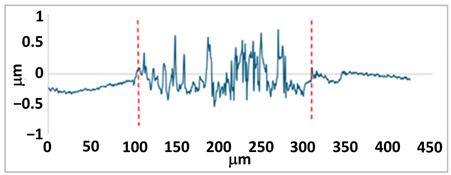

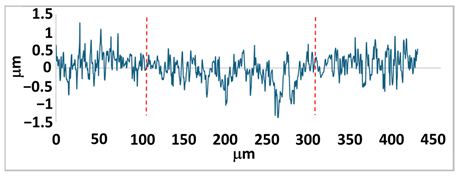

| Micrograph | Profile | |

|---|---|---|

| Steel |  |  |

| TDC |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Broitman, E.; Jahagirdar, A.; Rahimi, E.; Meeuwenoord, R.; Mol, J.M.C. Microstructural, Nanomechanical, and Tribological Properties of Thin Dense Chromium Coatings. Coatings 2024, 14, 1597. https://doi.org/10.3390/coatings14121597

Broitman E, Jahagirdar A, Rahimi E, Meeuwenoord R, Mol JMC. Microstructural, Nanomechanical, and Tribological Properties of Thin Dense Chromium Coatings. Coatings. 2024; 14(12):1597. https://doi.org/10.3390/coatings14121597

Chicago/Turabian StyleBroitman, E., A. Jahagirdar, E. Rahimi, R. Meeuwenoord, and J. M. C. Mol. 2024. "Microstructural, Nanomechanical, and Tribological Properties of Thin Dense Chromium Coatings" Coatings 14, no. 12: 1597. https://doi.org/10.3390/coatings14121597

APA StyleBroitman, E., Jahagirdar, A., Rahimi, E., Meeuwenoord, R., & Mol, J. M. C. (2024). Microstructural, Nanomechanical, and Tribological Properties of Thin Dense Chromium Coatings. Coatings, 14(12), 1597. https://doi.org/10.3390/coatings14121597