An Improved Fick Model for Predicting Carbonation Depth of Concrete

Abstract

1. Introduction

2. Fick Model and the Improved Model

3. Case Study

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Men, P.; Wang, X.; Liu, D.; Zhang, Z.; Zhang, Q.; Lu, Y. On use of polyvinylpyrrolidone to modify polyethylene fi-bers for improving tensile properties of high strength ECC. Constr. Build. Mater. 2024, 417, 135354. [Google Scholar] [CrossRef]

- Zhang, G.Z.; Liu, C.; Cheng, P.F.; Li, Z.; Han, Y.; Wang, X.Y. Enhancing the Interfacial Compatibility and Self-Healing Performance of Microbial Mortars by Nano-SiO2-Modified Basalt Fibers. Cem. Concr. Composites. 2024, 152, 105650. [Google Scholar] [CrossRef]

- Peng, X.; Shi, F.; Yang, J.; Yang, Q.; Wang, H.; Zhang, J. Modification of construction waste derived recycled aggre-gate via CO2 curing to enhance corrosive freeze-thaw durability of concrete. J. Clean. Production. 2023, 405, 137016. [Google Scholar] [CrossRef]

- Kim, D.; Lee, Y.; Lee, M. Development of risk-based bridge maintenance prioritization methodology. KSCE J. Civ. Eng. 2018, 22, 3718–3725. [Google Scholar] [CrossRef]

- Hamidpour, S.; Scattarreggia, N.; Nascimbene, R.; Monteiro, R. A risk-based quantitative approach for priority assessment of ageing bridges accounting for deterioration. Struct. Infrastruct. Eng. 2024, 4, 1–16. [Google Scholar] [CrossRef]

- Feng, H. The influencing factors and control measures of concrete carbonation. Chin. Foreign Archit. 2015, 8, 143–145. [Google Scholar]

- Felix, F.E.; Carrazedo, R.; Possan, E. Carbonation model for fly ash concrete based on artificial neural network: Development and parametric analysis. Constr. Build. Mater. 2021, 266 Pt A, 121050. [Google Scholar] [CrossRef]

- Paul, S.C.; Panda, B.; Huang, Y.; Garg, A.; Peng, X. An empirical model design for evaluation and estimation of carbonation depth in concrete. Measurement 2018, 124, 205–210. [Google Scholar] [CrossRef]

- Wei, Y.; Chen, P.; Cao, S.; Wang, H.; Liu, Y.; Wang, Z.; Zhao, W. Prediction of Carbonation Depth for Concrete Containing Mineral Admixtures Based on Machine Learning. Arab. J. Sci. Eng. 2023, 48, 13211–13225. [Google Scholar] [CrossRef]

- Niu, D.; Zhang, B.; Liu, J.; Zhang, B. Prediction model for length of partially carbonized zone in concrete under natural exposure environment. Ind. Build. 2022, 52, 146–151+106. [Google Scholar]

- Silva, R.V.; Silva, A.; Neves, R.; de Brito, J. Statistical modeling of carbonation in concrete incorporating recycled aggregates. J. Mater. Civ. Eng. 2016, 28, 04015082. [Google Scholar] [CrossRef]

- Qu, F.; Xia, W.; Sun, C.; Hou, H.; Huang, B.; Wang, G.; Hu, S. Modeling carbonation depth of recycled aggregate concrete containing chlorinated salts. Constr. Build. Mater. 2024, 430, 136478. [Google Scholar] [CrossRef]

- Qin, H.; Wang, J. Probabilistic prediction model of concrete carbonation depth considering the influence of multiple factors. Struct. Concr. 2023, 24, 6209–6238. [Google Scholar] [CrossRef]

- Liu, Y.; Lin, P.; He, Z.; Ma, J. Statistical Modelling of Carbonation Process in Reinforced Concrete Structure. Materials 2022, 15, 2711. [Google Scholar] [CrossRef]

- Jaynes, D.B.; Rogowski, A.S. Applicability of Fick’s law to gas diffusion. Soil Sci. Soc. Am. J. 1983, 47, 425–430. [Google Scholar] [CrossRef]

- Thorstenson, D.C.; Pollock, D.W. Gas transport in unsaturated zones: Multicomponent systems and the adequacy of Fick’s laws. Water Resour. Res. 1989, 25, 477–507. [Google Scholar] [CrossRef]

- Ta, V.; Bonnet, S.; Kiesse, S.T.; Ventura, A. A new meta-model to calculate carbonation front depth within concrete structures. Constr. Build. Mater. 2016, 129, 172–181. [Google Scholar] [CrossRef]

- Zhang, K.; Xiao, J. Prediction model of carbonation depth for recycled aggregate concrete. Cem. Concr. Compos. 2018, 88, 86–99. [Google Scholar] [CrossRef]

- He, R.; Li, S.; Fu, C.; Zhou, K.; Dong, Z. Influence of cyclic drying–wetting and carbonation on oxygen diffusivity of cementitious materials: Interpretation from the perspective of microstructure. J. Mater. Civ. Eng. 2022, 34, 04022256. [Google Scholar] [CrossRef]

- Jiang, C.; Huang, Q.; Gu, X.; Zhang, W. Modeling the effects of fatigue damage on concrete carbonation. Constr. Build. Mater. 2018, 191, 942–962. [Google Scholar] [CrossRef]

- Li, S.; Chen, Y.; Tang, C.; Wang, J.; Liu, R.; Wang, H. Experimental and Theoretical Study on Carbonization Coefficient Model of NS/SAP Concrete. Buildings 2022, 12, 2227. [Google Scholar] [CrossRef]

- He, H.; Li, R.; Chen, K. Durability evolution of RC bridge under coupling action of chloride corrosion and carbonization based on DLA model. Math. Probl. Eng. 2015, 2015, 951846. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, X.; Zhou, H.; Gao, K.; Wang, Z. Studies on forecasting of carbonation depth of slag high performance concrete considering gas permeability. Appl. Clay Sci. 2013, 79, 36–40. [Google Scholar] [CrossRef]

- Chen, D.; Liu, S.; Shen, J.; Sun, G.; Shi, J. Experimental study and modelling of concrete carbonation under the coupling effect of freeze-thaw cycles and sustained loads. J. Build. Eng. 2022, 52, 104390. [Google Scholar] [CrossRef]

- Possan, E.; Andrade, J.J.O.; Dal Molin, D.C.C.; Ribeiro, J.L.D. Model to estimate concrete carbonation depth and service life prediction. In Hygrothermal Behaviour and Building Pathologies; Springer: Berlin/Heidelberg, Germany, 2021; pp. 67–97. [Google Scholar]

- Peng, J.; Tang, H.; Zhang, J.; Cai, S.C.S. Numerical Simulation on Carbonation Depth of Concrete Structures considering Time-and Temperature-Dependent Carbonation Process. Adv. Mater. Sci. Eng. 2018, 2018, 2326017. [Google Scholar] [CrossRef]

- Wang, X.; Yang, Q.; Peng, X.; Qin, F. A Review of Concrete Carbonation Depth Evaluation Models. Coatings 2024, 14, 386. [Google Scholar] [CrossRef]

- Papadakis, V.G.; Vayenas, C.G.; Fardis, M.N. Fundamental modeling and experimental investigation of concrete carbonation. Mater. J. 1991, 88, 363–373. [Google Scholar]

- Papadakis, V.G. Effect of supplementary cementing materials on concrete resistance against carbonation and chloride ingress. Cem. Concr. Res. 2000, 30, 291–299. [Google Scholar] [CrossRef]

- Du, T.; Qu, P.Y.; Ji, X.K.; Li, Z.Y.; Wang, B.W.; Chen, S. Predictions for the carbonation depth of marine concrete under various temperature and humidity environments based on the Levenberg-Marquardt algorithm. Ind. Constr. 2024, 54, 217–222. [Google Scholar]

- Zhang, X.H.; Liu, B.W.; Yang, L.; Luo, Y.M.; Yang, C.Q. Experimental study on concrete carbonation performance under the influence of different temperature and strength. Build. Struct. 2020, 50, 110–115. [Google Scholar]

- Ning, C.P.; Yang, Y. Experimental Study on Carbonation Performance of Fly Ash Concrete under Freeze-thaw Dry Wet Coupling. Fly Ash Compr. Util. 2020, 34, 77–81. [Google Scholar]

- Xu, X.H.; Xie, J.F.; Xia, W.H.; Li, B.X. Influence of mineral admixtures on performance and microstructure of bridge tower concrete. China Harb. Eng. 2021, 41, 40–45. [Google Scholar]

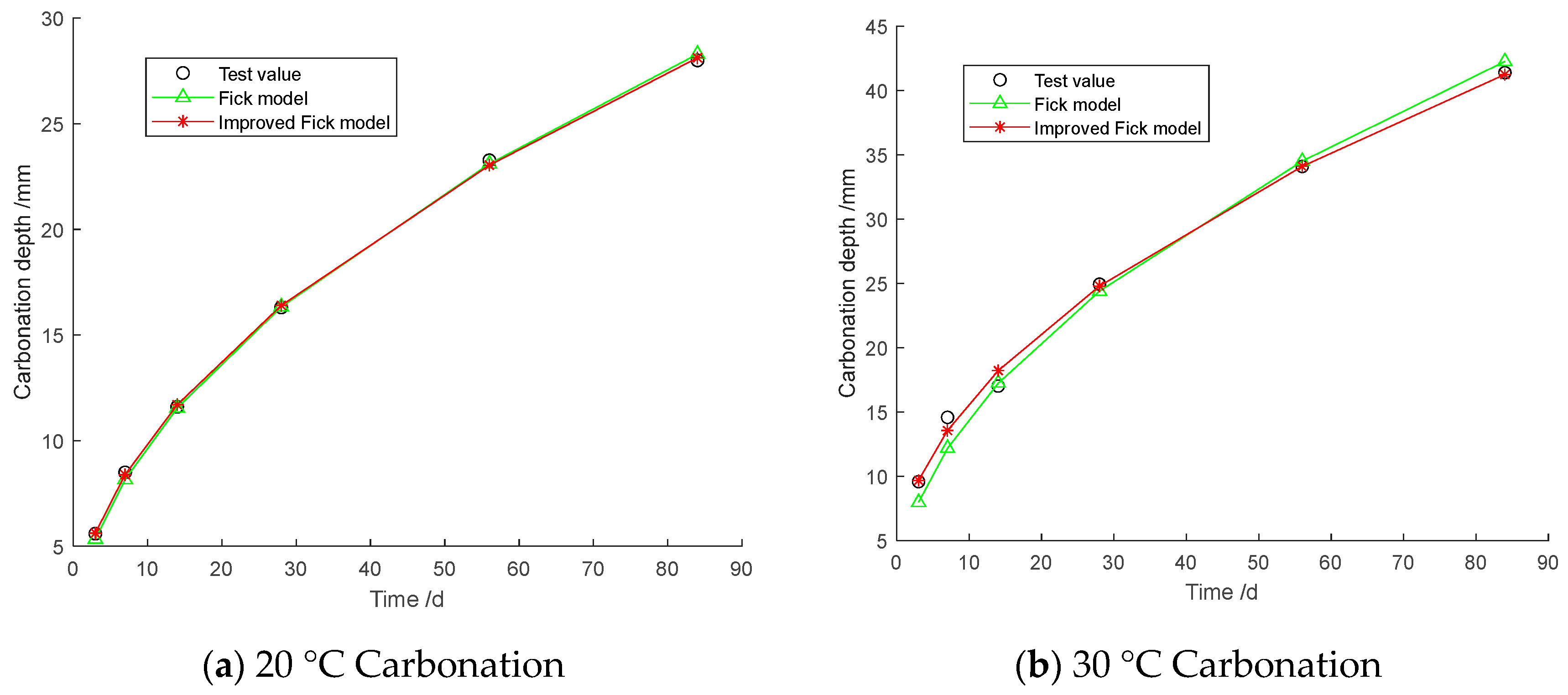

| Carbonation Conditions | Fick Model | New Model |

|---|---|---|

| 20 °C Carbonation | ||

| 30 °C Carbonation |

| Carbonation Conditions | Statistical Indicators | Fick Model | New Model |

|---|---|---|---|

| 20 °C Carbonation | Mean error value | 0.0180 | 0.0078 |

| Standard deviation | 0.0191 | 0.0035 | |

| 30 °C Carbonation | Mean error value | 0.0667 | 0.0267 |

| Standard deviation | 0.0770 | 0.0339 |

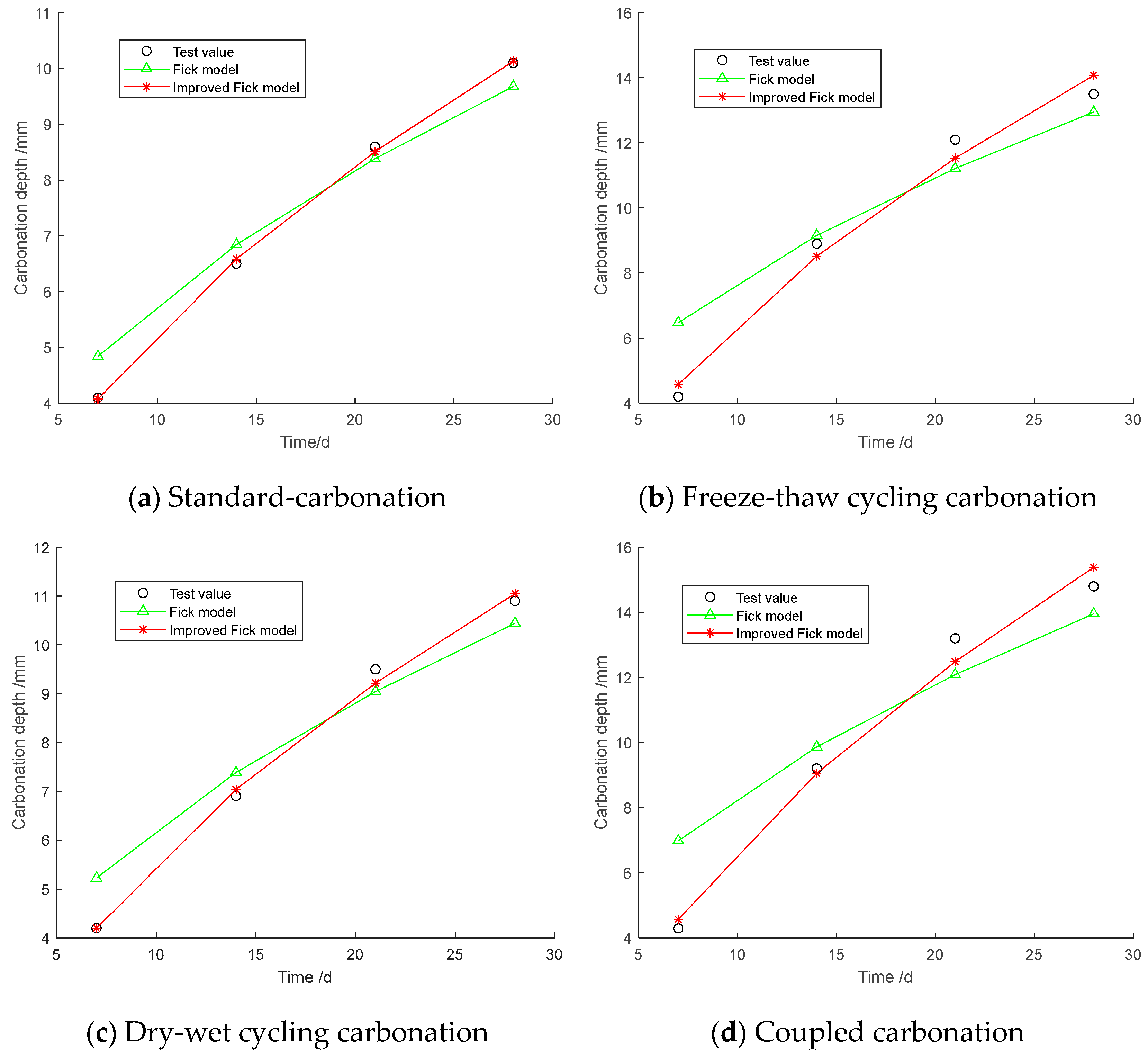

| Carbonation Conditions | Fick Model | New Model |

|---|---|---|

| Standard carbonation | ||

| Freeze–thaw cycling carbonation | ||

| Dry–wet cycling carbonation | ||

| Coupled carbonation |

| Carbonation Conditions | Statistical Indicators | Fick Model | New Model |

|---|---|---|---|

| Standard carbonation | Mean error value | 0.1253 | 0.0407 |

| Standard deviation | 0.1104 | 0.0117 | |

| Freeze–thaw cycling carbonation | Mean error value | 0.1955 | 0.0492 |

| Standard deviation | 0.2109 | 0.0324 | |

| Dry–wet cycling carbonation | Mean error value | 0.1543 | 0.0411 |

| Standard deviation | 0.1247 | 0.0258 | |

| Coupled carbonation | Mean error value | 0.1931 | 0.0095 |

| Standard deviation | 0.2249 | 0.0056 |

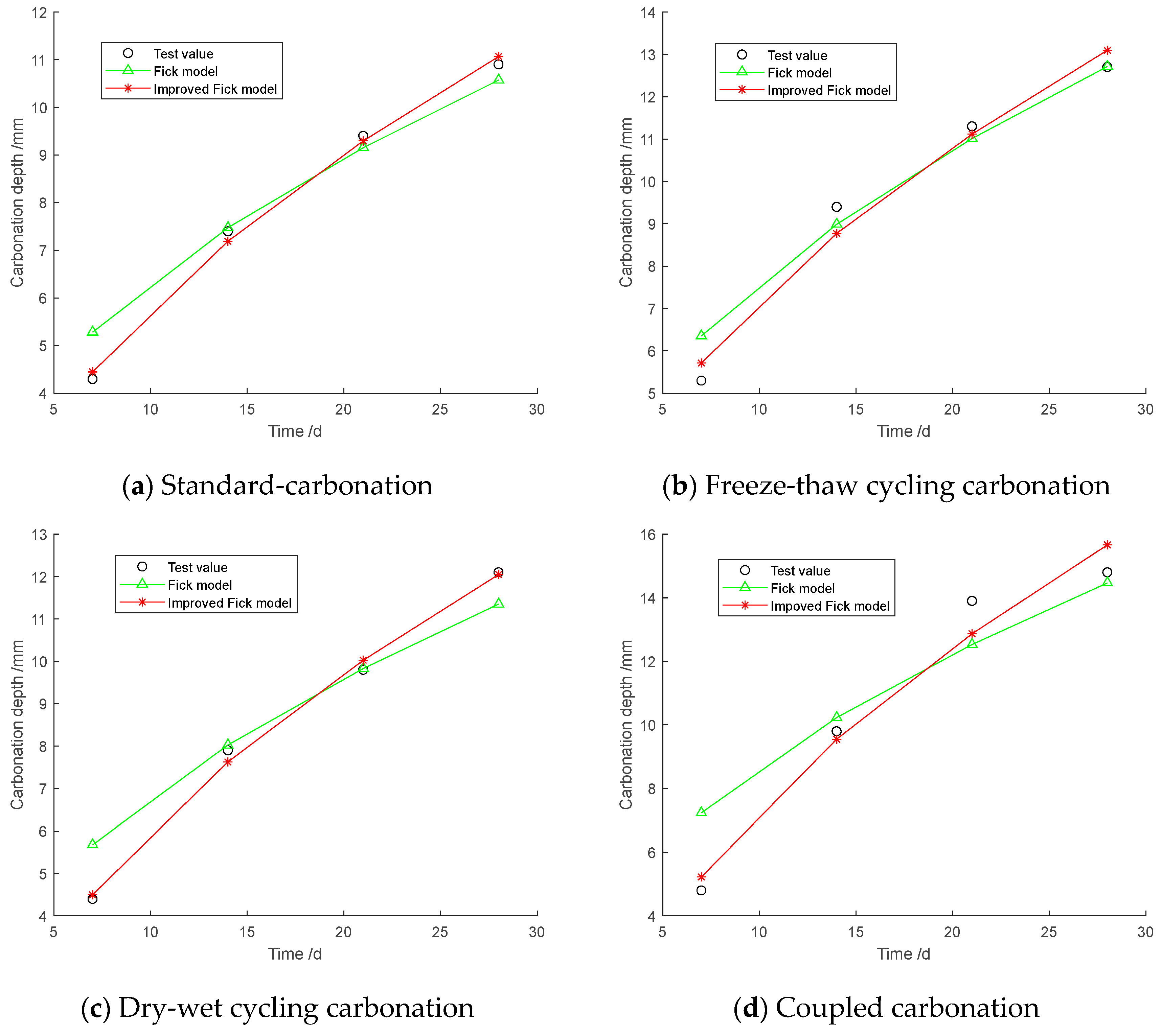

| Carbonation Conditions | Fick Model | New Model |

|---|---|---|

| Standard carbonation | ||

| Freeze–thaw cycling carbonation | ||

| Dry–wet cycling carbonation | ||

| Coupled carbonation |

| Carbonation Conditions | Statistical Indicators | Fick Model | New Model |

|---|---|---|---|

| Standard carbonation | Mean error value | 0.0751 | 0.0082 |

| Standard deviation | 0.0710 | 0.0044 | |

| Freeze–thaw cycling carbonation | Mean error value | 0.1711 | 0.0559 |

| Standard deviation | 0.2477 | 0.0230 | |

| Dry–wet cycling carbonation | Mean error value | 0.1008 | 0.0161 |

| Standard deviation | 0.0957 | 0.0122 | |

| Coupled carbonation | Mean error value | 0.2092 | 0.0434 |

| Standard deviation | 0.2759 | 0.0210 |

| Carbonation Conditions | Fick Model | New Model |

|---|---|---|

| Standard carbonation | ||

| Freeze–thaw cycling carbonation | ||

| Dry–wet cycling carbonation | ||

| Coupled carbonation |

| Carbonation Conditions | Statistical Indicators | Fick Model | New Model |

|---|---|---|---|

| Standard carbonation | Mean error value | 0.0739 | 0.0225 |

| Standard deviation | 0.1038 | 0.0111 | |

| Freeze–thaw cycling carbonation | Mean error value | 0.0674 | 0.0481 |

| Standard deviation | 0.0897 | 0.0294 | |

| Dry–wet cycling carbonation | Mean error value | 0.0926 | 0.0212 |

| Standard deviation | 0.1338 | 0.0125 | |

| Coupled carbonation | Mean error value | 0.1680 | 0.0617 |

| Standard deviation | 0.2283 | 0.0270 |

| Time | 3d | 7d | 14d | 28d | 56d |

|---|---|---|---|---|---|

| Carbonation depth | 0.2 mm | 1.0 mm | 2.5 mm | 4.0 mm | 6.6 mm |

| Bridge Tower Concrete Carbonation | Fick Model | New Model |

|---|---|---|

| Equation |

| Time: The 56th Day | Measured Value | Predicted Value | ||||

|---|---|---|---|---|---|---|

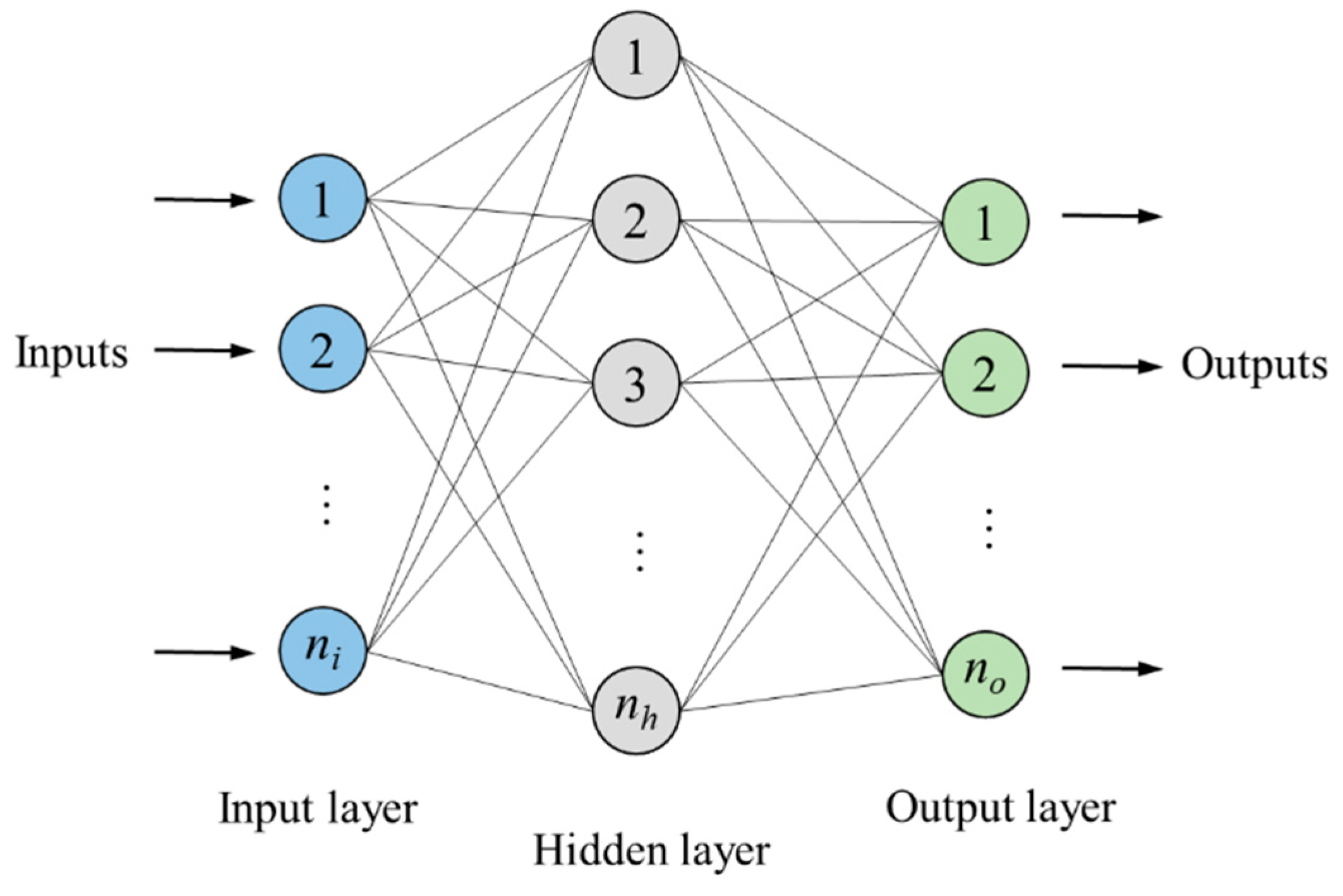

| Fick Model | New Model | ANN with = 3 | ANN with = 4 |

ANN with = 5 | ||

| Carbonation depth (mm) | 6.6 | 4.8228 | 6.4428 | 4.5008 | 5.7763 | 4.8487 |

| Relative error of prediction | / | 27% | 2% | 32% | 12% | 27% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, H.; Xu, Z.; Peng, X. An Improved Fick Model for Predicting Carbonation Depth of Concrete. Coatings 2024, 14, 1345. https://doi.org/10.3390/coatings14111345

Cao H, Xu Z, Peng X. An Improved Fick Model for Predicting Carbonation Depth of Concrete. Coatings. 2024; 14(11):1345. https://doi.org/10.3390/coatings14111345

Chicago/Turabian StyleCao, Hongfei, Zhenjie Xu, and Xi Peng. 2024. "An Improved Fick Model for Predicting Carbonation Depth of Concrete" Coatings 14, no. 11: 1345. https://doi.org/10.3390/coatings14111345

APA StyleCao, H., Xu, Z., & Peng, X. (2024). An Improved Fick Model for Predicting Carbonation Depth of Concrete. Coatings, 14(11), 1345. https://doi.org/10.3390/coatings14111345