Study on the Performance of SBS/Polyphosphoric Acid Composite Modified Asphalt

Abstract

1. Introduction

2. Raw Materials

2.1. Asphalt

2.2. Polyphosphoric Acid

2.3. Styrene-Butadiene-Styrene Block Copolymer

3. Experimental

3.1. Formulate Sample Content and Modified Asphalt Preparation Method

3.1.1. Preliminary Formulation of Sample Content

3.1.2. Preparation of SBS Modified Asphalt

3.1.3. Preparation of SBS/PPA Composite Modified Asphalt

3.2. Basic Performance Test

3.3. Brookfield Viscosity Test

3.4. DSR

3.5. BBR

3.6. FTIR

3.7. SEM

4. Test Results and Analysis

4.1. Analysis of Basic Performance Results

4.1.1. Analysis of Performance Results of Original Group Modified Asphalt

4.1.2. Analysis of Performance Results of Aging Group Modified Asphalt

4.2. Analysis of Viscosity-Temperature Characteristics Results

4.3. Analysis of DSR Test Results

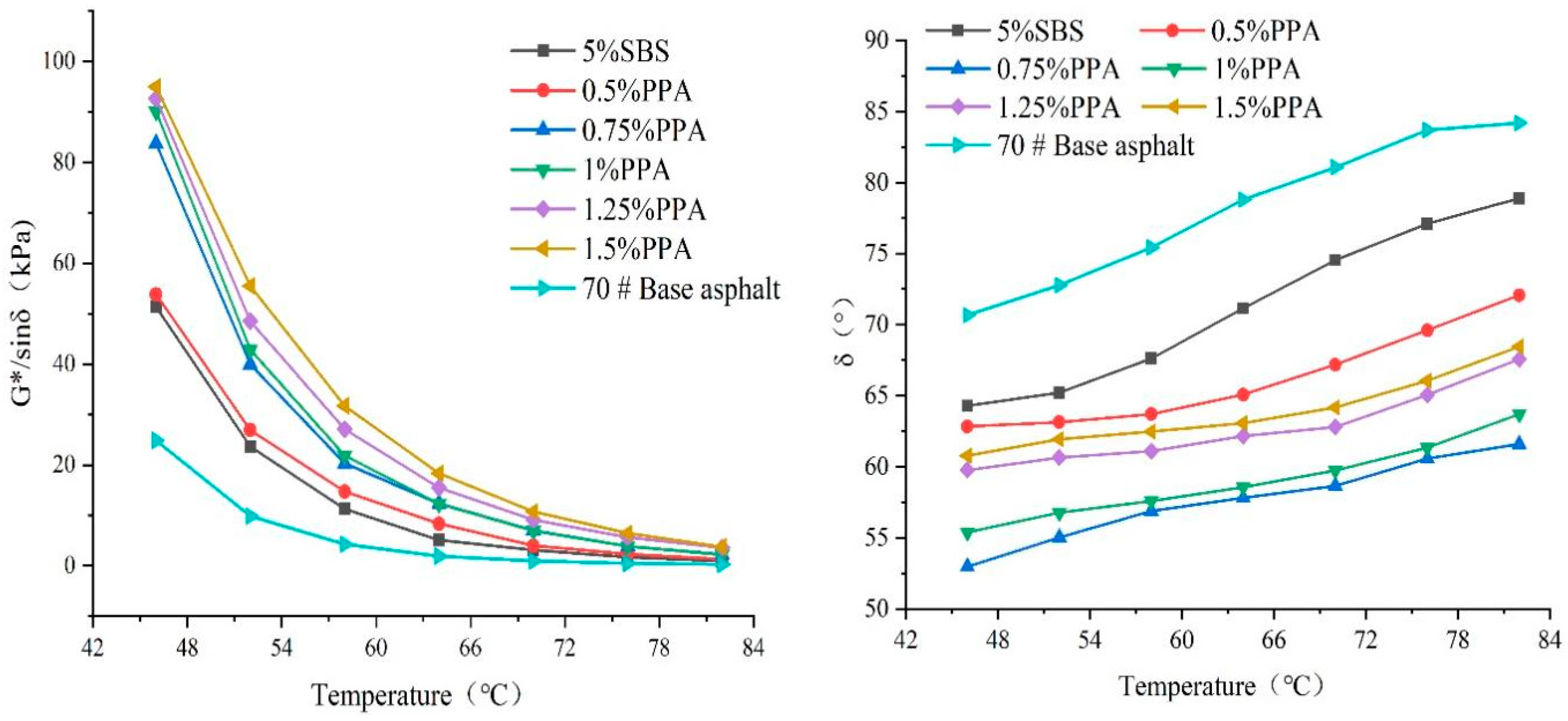

4.3.1. Analysis of Temperature Sweep

- (1)

- As the experimental temperature gets higher and higher, the experimental results of all samples in the original group and the aging group are generally that G*/sinδ decreases and δ increases. The main cause of this phenomenon is that the higher the temperature is, the weaker the close force between asphalt molecules is. The asphalt binder presents a viscous fluid at high temperature, which leads to a decrease in its recovery deformation ability and a poor anti-deformation ability.

- (2)

- Regardless of aging or not, the G*/sinδ of each composite modified asphalt group increases with increasing PPA content, suggesting the viscosity is further strengthened by adding PPA. At the same test conditions, when the content of PPA is 0.75% and 1%, the G*/sinδ value increases significantly, and the absolute value of slope reaches more than 0.5, indicating that the best dosage range of PPA in composite modified asphalt is 0.75~1%.

- (3)

- Regardless of aging or not, the δ of each group has a significant downward trend with increasing PPA dosage. When the PPA dosage is 0.75%, the phase angle is significantly smaller than that of others, suggesting that under high temperature load, when the PPA dosage is 0.75%, the improvement degree of elastic element in the composite modified asphalt is the largest, closest to the elastomer, and is easier to recover after load deformation.

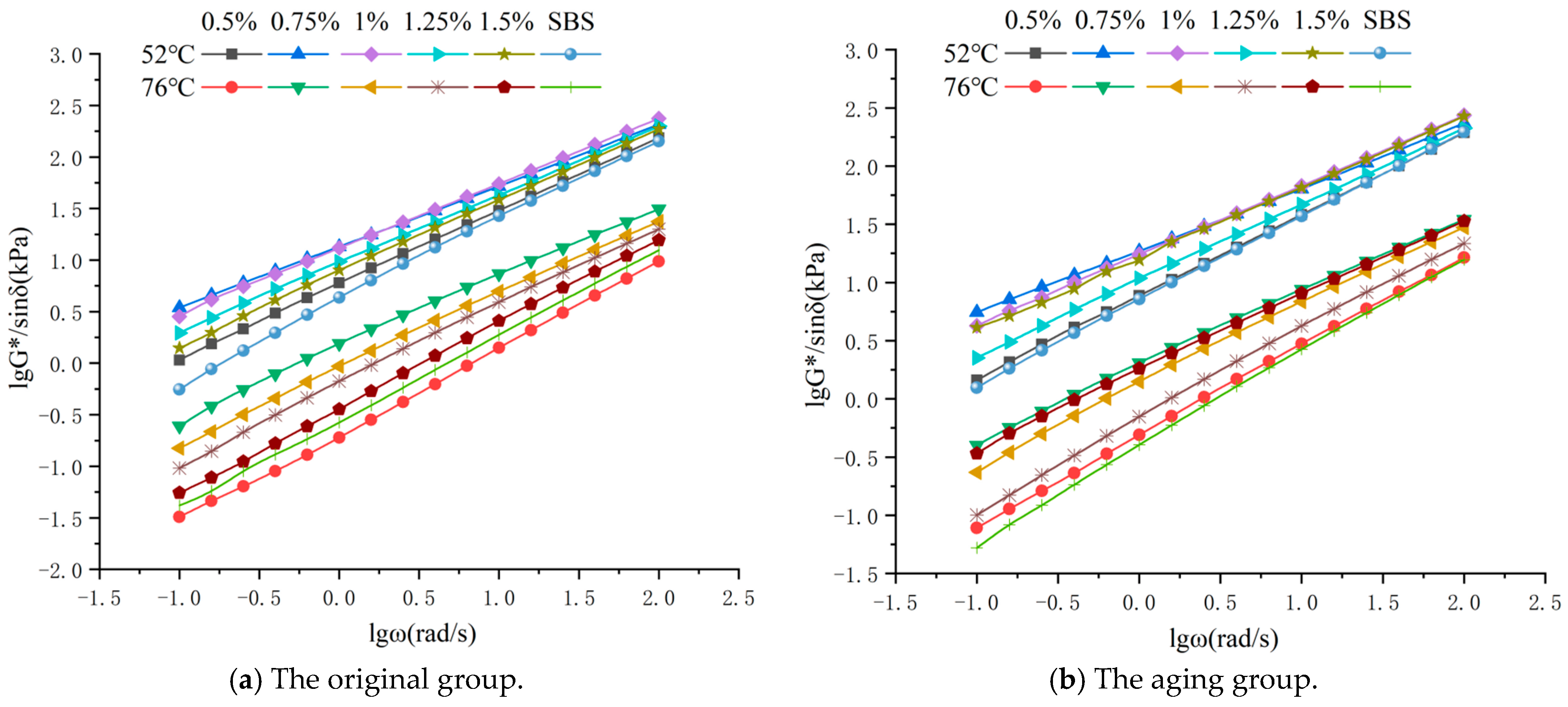

4.3.2. Analysis of Frequency Scanning

- (1)

- The G*/sinδ values in the original sample group and the aging group generally increase in parallel with the change curve of frequency, and the logarithm of the rutting factor has a good linear correlation with the logarithm of frequency, illustrating that the influence of each modified asphalt group on frequency is basically the same. The increase of G*/sinδ value in the aging group is larger than that in the original group, and the logarithmic value of G*/sinδ in each group gradually approaches with increasing frequency, suggesting the high-temperature performance has changed significantly as a result of aging. The reason why G*/sinδ in the aging group is higher than that in the original sample group is that under the action of aging, asphalt lightweight component volatilizes, asphaltene increases, elasticity of the asphalt gets stronger, and the load resistance and deformation resistance are strengthened.

- (2)

- With regard to the G*/sinδ value, the composite modified asphalt of the original group and the aging group is always greater than the SBS modified asphalt in all frequency ranges. Especially for 0.75% SBS/PPA composite modified asphalt, no matter how much the temperature is, the G*/sinδ value corresponding to this dosage is the highest. This is mainly because adding PPA can accelerate the change of asphalt structure to gel type more quickly, and the elastic behavior is more obvious when the aging effect is applied to the same degree.

- (3)

- At 76 °C, the G*/sinδ value of the compound modified asphalt with 0.75% content increases by 40.4% after aging, while the measured G*/sinδ values of the SBS modified asphalt original group and the aging group are relatively low, and the G*/sinδ value increases by 27.7% after aging. The effect of aging reduces the volatilization of the light components, which results in a lower viscosity and a hardening of the asphalt binder. However, aging will also destroy the original stable spatial structure that was initially formed by SBS decomposition, so its high-temperature rutting resistance is worse than that of composite modified asphalt.

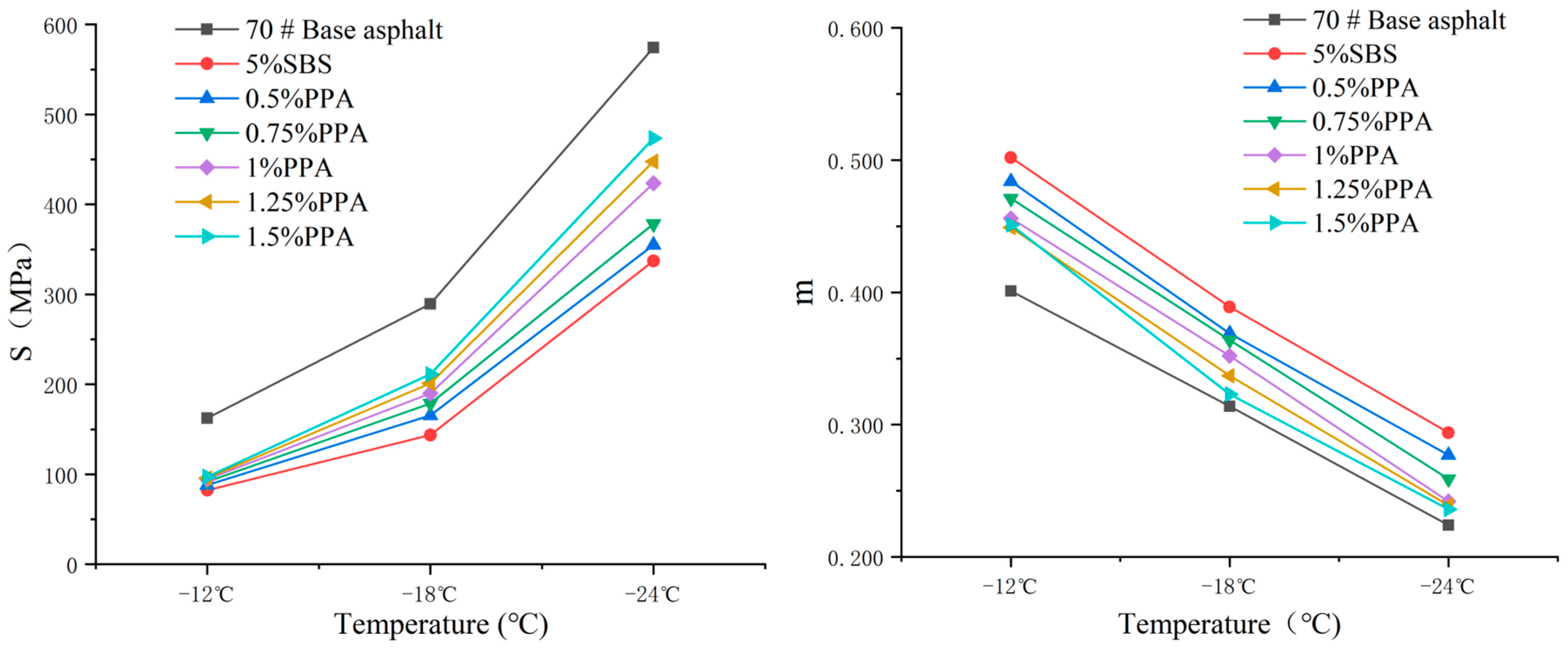

4.4. Analysis of BBR Test Results

4.5. Determination of Optimum Dosage Combination

4.6. Analysis of FTIR Test

- (1)

- After the addition of SBS, the vibration of the C-H bond in the benzene ring of the polystyrene block in SBS causes an absorption peak at 697 cm−1, and the -C=C- double bond bending vibration of the butadiene block causes an absorption peak at 964 cm−1. In the region of 1000~2000 cm−1, the absorption peaks at 1027 cm−1, 1457 cm−1, and 1610 cm−1 are simply superimposed compared with the base asphalt, so SBS and base asphalt only produce physical changes.

- (2)

- Compared with modified asphalt under different PPA dosages, the absorption peaks of SBS modified asphalt after adding PPA are mainly concentrated in the above five listed: 697 cm−1, 964 cm−1, 1027 cm−1, 1457 cm−1, and 1610 cm−1. Among them, the absorption peak intensity at 964 cm−1 is weakened because the addition of PPA will undergo a reduction reaction to open the -C=C- double bond of SBS, further promoting the copolymerization reaction between asphalt and SBS. The greater the content, the better the compatibility, and the stronger the high-temperature stability.

- (3)

- Because SBS is an immiscible system, the infrared spectrum of the SBS is only a simple superposition of the infrared spectrum of polystyrene and polybutadiene. The position and intensity of the absorption peak are basically unchanged, and no new absorption peak appears. The C=C double bond bending vibration of the butadiene block in the SBS modifier causes an absorption peak at 964 cm−1, and the C-H bond out-of-plane bending vibration in the benzene ring of the polystyrene block in the SBS modifier causes an absorption peak at 697 cm−1.

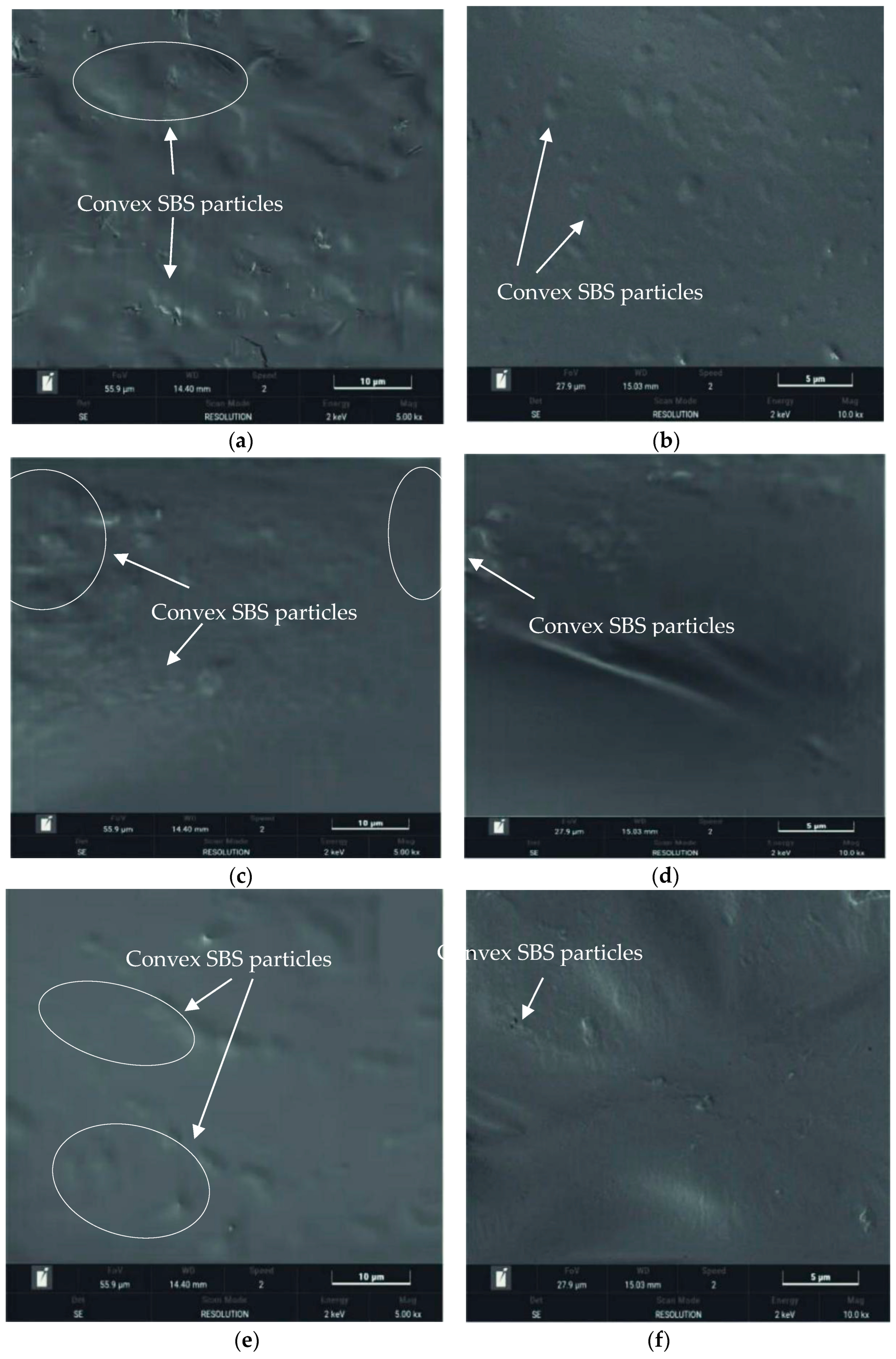

4.7. Analysis of SEM Test

4.7.1. Microstructure of Asphalt

4.7.2. Microstructure of SBS Modified Asphalt

4.7.3. Microstructure of SBS/PPA Composite Modified Asphalt

5. Conclusions

- (1)

- The softening point and viscosity of SBS/PPA composite modified asphalt increase with the increase of content, and the penetration decreases. The change range of residual penetration ratio, mass change rate, and softening point increment of aged composite modified asphalt are smaller than that of SBS modified asphalt, indicating that the addition of PPA can improve the thermal oxidation resistance, high-temperature performance, and anti-aging performance of SBS modified asphalt. After adding PPA, the ductility of composite modified asphalt decreases, and the residual ductility ratio increases after aging, indicating that PPA will weaken the low-temperature crack resistance. At 135 °C, the average viscosity of composite modified asphalt after PPA addition is 2.2 times that of SBS modified asphalt, indicating that PPA can improve the viscosity-temperature characteristics, but once the PPA content exceeds 1%, it will not meet the construction requirements due to high viscosity.

- (2)

- Under the same test temperature, when the PPA dosage is between 0.75% and 1%, the anti-rutting factor increases significantly, indicating the composite modified asphalt in this range is less sensitive to temperature, resulting in better plastic deformation resistance than other test groups. When the PPA content is 0.75%, the phase angle is the lowest. In summary, adding PPA will increase the elastic element in SBS modified asphalt and exert better high-temperature rheological properties. The S value is increased while the m value is reduced as the PPA content is increased. At −12 °C, as PPA dosage increases, the S value of aged composite modified asphalt is reduced from 40.2% to 5.3% compared with that before aging, and the creep rate m is reduced from 8.5% to 5.1%, suggesting that the aging resistance of the composite modified asphalt is improved, but adding PPA will make the low-temperature creep worse. Therefore, considering the above indexes of composite modified asphalt, the optimal PPA dosage in composite modified asphalt is 0.75%.

- (3)

- The physical effect of SBS is mainly manifested in the bending vibration of the C-H bond of the benzene ring and the bending vibration of the butadiene block C=C, resulting in new absorption peaks at 697 cm−1 and 964 cm−1, while the remaining positions are simply superimposed with asphalt. The incorporation of PPA has undergone chemical modification. The reduction reaction weakens the absorption peak intensity at 964 cm−1, new absorption peaks are produced from 1027 to 1150 cm−1, and the absorption peak after 1610 cm−1 continues to rise. The microstructure of SBS modified asphalt shows a more uniform distribution of wavy mesh space structure, and there are still stacked SBS particles with different particle sizes, indicating that the combination of SBS and asphalt is difficult. The microstructure of composite modified asphalt gradually forms a smooth wrinkle state with an increasing PPA dosage, and SBS particles basically disappear in composite modified asphalt. PPA could improve the segregation state of SBS in asphalt, and the composite modified asphalt is existed in a more stable phase structure. The results indicate that adding PPA into low-content SBS modified asphalt could shape a more stable network structure, and the macro properties are the high-temperature properties, the viscosity-temperature characteristics, and the aging resistance of the compound modified asphalt.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, L.; Huang, W.; Xiao, F.; Lv, Q. Shear adhesion evaluation of various modified asphalt binders by an innovative testing method. Constr. Build. Mater. 2018, 183, 253–263. [Google Scholar] [CrossRef]

- Lu, Y.Y.; Yu, L.M.; Fang, J.; Yun, Q.; Lu, J. Research development of polymer modified asphalt. New Chem. Mater. 2020, 48, 222–225+230. [Google Scholar] [CrossRef]

- Zhang, J.B. Application of SBS modified asphalt in highway pavement. TranspoWorld 2021, 12, 62–63. [Google Scholar]

- Min, X.B.; Ni, Y.L.; Zhang, J. Analysis on the stability of on-site storage SBS modified asphalt. Pet. Asph. 2020, 34, 34–40. [Google Scholar]

- Jiang, Z.X. Research summary of SBS modified asphalt index system. Highway 2019, 64, 272–277. [Google Scholar]

- Ma, Z.M.; Liang, J.L.; Wang, X.R.; Liu, X.; Lu, J.Y. Simulation and Optimization of Three-Step lon Polymerization Process for SBS. J. Petrochem. Univ. 2021, 34, 22–28. [Google Scholar]

- Cortizo, M.S.; Larsen, D.O.; Bianchetto, H.; Alessandrini, J.L. Effect of the thermal degradation of SBS copolymers during the ageing of modified asphalts. Polym. Degrad. Stab. 2004, 86, 275–282. [Google Scholar] [CrossRef]

- Yu, L.M.; Chen, Z.G. Stability analysis of waste rubber powder and SBS composite modified asphalt. Highway 2019, 64, 267–270. [Google Scholar]

- Dong, Z.J.; Zhou, T.; Luan, H.; Yang, C.; Wang, P.; Leng, Z. Composite Modification Technology and Mechanism of SH Blended Bio-asphalt by Combining SBS with Crumb Rubber. China J. Highw. Transp. 2019, 32, 215–225. [Google Scholar]

- Chen, Q.; Li, Y.; Wang, C.; Feng, L.; Zhang, Z. Degradation of mechanical properties of polyurethane elastomer coatings under different pavement pollution conditions. Constr. Build. Mater. 2023, 409, 134181. [Google Scholar] [CrossRef]

- Yang, X.; Liu, G.; Rong, H.; Meng, Y.; Peng, C.; Pan, M.; Wang, G. Investigation on mechanism and rheological properties of Bio-asphalt/PPA/SBS modified asphalt. Constr. Build. Mater. 2022, 347, 128599. [Google Scholar] [CrossRef]

- Wei, J.; Shi, S.; Zhou, Y.; Chen, Z.; Yu, F.; Peng, Z.; Duan, X. Research on performance of SBS-PPA and SBR-PPA compound modified asphalts. Materials 2022, 15, 2112. [Google Scholar] [CrossRef] [PubMed]

- Fu, Z.; Tang, Y.J.; Sun, Q.Y.; Wang, Y.J.; Liu, S.R. Pavement performance and compatibility of carbon nanotube/SBS composite modified asphalt. Appl. Chem. Ind. 2021, 50, 2031–2036. [Google Scholar]

- Shafabakhsh, G.; Rajabi, M.; Sahaf, A. The fatigue behavior of SBS/nanosilica composite modified asphalt binder and mixture. Constr. Build. Mater. 2019, 229, 116796. [Google Scholar] [CrossRef]

- Li, P.F.; Hu, G.F.; Wang, D.W.; Tao, J.X.; Wang, D.X.; Hong, B. Polyurethane-precursor/Styrene-Butadiene-Styrene Composite Modified Asphalt and Its Modification Mechanism. J. Beijing Univ. Technol. 2022, 48, 655–666. [Google Scholar]

- Liu, G.; Zhang, W.; Yang, X.; Ning, Z. Study on the conventional performance and microscopic properties of PPA/SBS-modified bio-mixed asphalt. Materials 2022, 15, 4101. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Li, Z.J.; Liu, S.H.; Fu, L. Analysis and prospect of polyphosphoric acid modified asphalt technology. China Adhes. 2020, 29, 63–67. [Google Scholar]

- Jafari, M.; Babazadeh, A. Evaluation of polyphosphoric acid-modified binders using multiple stress creep and recovery and linear amplitude sweep tests. Road Mater. Pavement Des. 2016, 17, 859–876. [Google Scholar] [CrossRef]

- Cuadri, A.A.; Navarro, F.J.; Partal, P. Synergistic ethylcellulose/polyphosphoric acid modification of bitumen for paving applications. Mater. Struct. 2020, 53, 42–82. [Google Scholar] [CrossRef]

- Xiao, F.; Amirkhanian, S.; Wang, H.; Hao, P. Rheological property investigations for polymer and polyphosphoric acid modified asphalt binders at high temperatures. Constr. Build. Mater. 2014, 64, 316–323. [Google Scholar] [CrossRef]

- Yadollahi, G.; Mollahosseini, H.S. Improving the performance of Crumb Rubber bitumen by means of Poly Phosphoric Acid (PPA) and Vestenamer additives. Constr. Build. Mater. 2010, 25, 3108–3116. [Google Scholar] [CrossRef]

- Cao, X.J.; Zhang, Z.; Hao, P.W.; Dong, L.P. Effect of Polyphosphoric Acid on the High-and-low Temperature Property of Matrix Asphalt Mixture. J. Wuhan Univ. Technol. 2014, 36, 47–53. [Google Scholar]

- Wang, Z.X. Research on the Warm Asphalt Binders Modified by Polyphosphoric Acid. Master’s Thesis, Hunan University, Changsha, China, 2015. [Google Scholar]

- Hou, T.J. Study on preparation and properties of polyphosphoric acid composited polymel. New Build. Mater. 2019, 46, 8–22. [Google Scholar]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. China Communications Press: Beijing, China, 2011.

- JTG F40-2004; Technical Specifications for Construction of Highway Asphalt Pavements. China Communications Press: Beijing, China, 2004.

- Ma, F.; Li, C.; Fu, Z.; Huang, Y.; Dai, J.; Feng, Q. Evaluation of high temperature rheological performance of polyphosphoric acid-SBS and polyphosphoric acid-crumb rubber modified asphalt. Constr. Build. Mater. 2021, 306, 124926. [Google Scholar] [CrossRef]

- Zhu, W. The Influence of SBS Dosage to the Pavement Performance of Modified Asphalt Mixture. Master’s Thesis, Chang’an University, Xi’ an, China, 2012. [Google Scholar]

- Ma, F.; Wen, Y.L.; Fu, Z.; Feng, Q.; Jin, Y.X.; Guo, X.L. Pavement performance of PPA composite modified asphalt mixture. Appl. Chem. Ind. 2021, 50, 887–891. [Google Scholar]

- Wang, G.Z. Study on Properties of Polyphosphoric Acid Composited Polymer Modified Asphalt and Its Mixture. Highw. Eng. 2019, 44, 225–231. [Google Scholar]

- Zhang, L.; Huang, W.; Wei, M.; Ouyang, X.; Wang, Y. Analysis of Rheological Properties of Polyphosphoric Acid Modified Asphalt. J. Mater. Sci. Eng. 2020, 38, 638–642. [Google Scholar]

- Dou, Q.P.; Shi, Y. Effect of PPA Content on the Performance of Polyphosphate Modified Asphalt. J. Lanzhou Inst. Technol. 2020, 27, 24–27. [Google Scholar]

- Huang, G.; Wang, P.; Liu, B.S. Research on Polyphosphoric Acid Modified Asphalt Performance. West. China Commun. Sci. Technol. 2018, 5–10. [Google Scholar]

- Ju, Z.; Ge, D.; Wu, Z.; Xue, Y.; Lv, S.; Li, Y.; Fan, X. The performance evaluation of high content bio-asphalt modified with polyphosphoric acid. Constr. Build. Mater. 2022, 361, 129593. [Google Scholar] [CrossRef]

- Wang, F. Effect of aging time on functional groups of SBS modifier and asphalt binder. Sci. Technol. Eng. 2023, 23, 13765–13773. [Google Scholar]

| Test Items | Unit | Test Results | Technical Requirements | Test Method | |

|---|---|---|---|---|---|

| Penetration (100 g, 5 s) | 0.1 mm | 67.6 | 60~80 | T0604 | |

| Ductility (5 cm/min, 10 °C) | cm | 48 | ≥20 | T0605 | |

| Softening point | °C | 46.5 | ≥46 | T0606 | |

| Penetration index PI | — | −0.768 | −1.5~+1.0 | T0604 | |

| After RTFOT | Quality change | % | −0.272 | −0.8~+0.8 | T0610 |

| Penetration ratio (25 °C) | % | 62.4 | ≥61 | T0604 | |

| Ductility (5 cm/min, 10 °C) | cm | 6.8 | ≥6 | T0605 | |

| Test Items | Unit | Test Results |

|---|---|---|

| P2O5 concentration | % | 82.6 |

| 25 °C vapor pressure | Pa | 2.61 × 10−6 |

| Boiling point | °C | 558 |

| Chloride (Cl) content | % | 0.0002 |

| Iron (Fe) content | % | 0.0010 |

| Arsenic (As) content | % | 0.0066 |

| Heavy metal (Pb) content | % | 0.0014 |

| Test Items | Unit | Test Results | Technical Requirements |

|---|---|---|---|

| Molecular structure | — | Linear | Linear |

| Ash | % | 0.07 | ≤0.20 |

| 300% tensile stress | MPa | 4.8 | ≥3.5 |

| Tensile strength | MPa | 28.4 | ≥24.0 |

| Elongation at break | % | 742 | ≥730 |

| Volatile matter | % | 0.54 | ≤0.70 |

| Styrene/Butadiene mass ratio | — | 20/80 | 20/80 |

| Test Number and Schemes | Penetration (25 °C, 0.1 mm) | Softening Point (K) | Ductility (5 °C, cm) | |

|---|---|---|---|---|

| 1 | 70# Base asphalt | 67.6 | 319.7 | 10.3 |

| 2 | 5% SBS | 51.9 | 339.5 | 29.7 |

| 3 | 0.5% PPA + 3.5% SBS | 54.7 | 322.9 | 26.6 |

| 4 | 0.75% PPA + 3.5% SBS | 51.8 | 331.0 | 20.3 |

| 5 | 1.0% PPA + 3.5% SBS | 49.1 | 336.4 | 16.8 |

| 6 | 1.25% PPA + 3.5% SBS | 44.7 | 342.6 | 14.4 |

| 7 | 1.5% PPA + 3.5% SBS | 42.4 | 73.2 | 12.9 |

| Test Number and Schemes | Mass Change (%) | Penetration (25 °C, 0.1 mm) | Softening Point (°C) | Ductility (5 °C, cm) | |

|---|---|---|---|---|---|

| 1 | 70# Base asphalt | 0.272 | 42.2 | 54.2 | 7.8 |

| 2 | 5% SBS | 0.218 | 34.2 | 74.7 | 21.4 |

| 3 | 0.5% PPA + 3.5% SBS | 0.204 | 34.4 | 56.4 | 20.7 |

| 4 | 0.75% PPA + 3.5% SBS | 0.192 | 33.2 | 63.9 | 14.9 |

| 5 | 1.0% PPA + 3.5% SBS | 0.167 | 32.9 | 67.1 | 12.6 |

| 6 | 1.25% PPA + 3.5% SBS | 0.133 | 32.1 | 72.7 | 11.2 |

| 7 | 1.5% PPA + 3.5% SBS | 0.119 | 31.3 | 75.1 | 10.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Li, Z.; Guo, T.; Chen, Y.; Liu, Q.; Wang, J.; Jin, L. Study on the Performance of SBS/Polyphosphoric Acid Composite Modified Asphalt. Coatings 2024, 14, 72. https://doi.org/10.3390/coatings14010072

Li C, Li Z, Guo T, Chen Y, Liu Q, Wang J, Jin L. Study on the Performance of SBS/Polyphosphoric Acid Composite Modified Asphalt. Coatings. 2024; 14(1):72. https://doi.org/10.3390/coatings14010072

Chicago/Turabian StyleLi, Chaojie, Zhenxia Li, Tengteng Guo, Yuanzhao Chen, Qi Liu, Jing Wang, and Lihui Jin. 2024. "Study on the Performance of SBS/Polyphosphoric Acid Composite Modified Asphalt" Coatings 14, no. 1: 72. https://doi.org/10.3390/coatings14010072

APA StyleLi, C., Li, Z., Guo, T., Chen, Y., Liu, Q., Wang, J., & Jin, L. (2024). Study on the Performance of SBS/Polyphosphoric Acid Composite Modified Asphalt. Coatings, 14(1), 72. https://doi.org/10.3390/coatings14010072