Abstract

In order to improve the service quality of roads and resolve the problem of defects in the conventional asphalt pavement in service, this paper uses a 5.3% aluminate coupling agent to modify the surface of nano-ZnO and prepares a composite-modified asphalt with nano-ZnO and basalt fiber (BF) as modifiers. First, the basic performance of different types of asphalt was investigated by means of a rotary film oven experiment. Then, a dynamic shear rheology experiment was carried out to analyze the high-temperature anti-rutting performance of the composite-modified asphalt at different temperatures and frequencies. Then, using a bending creep stiffness test, the low-temperature properties of the composite-modified asphalt were investigated. Finally, the microstructure and modification mechanisms of the composite-modified asphalt were analyzed with scanning electron microscopy and infrared spectroscopy. The results indicate that the anti-aging performance of the nano-ZnO/BF composite-modified asphalt is significantly improved after adding fibers to the modified asphalt. The average mass loss ratio is only 0.192%. At 46 °C, the rutting coefficient of the composite-modified asphalt was increased by 62.3%. The frequency master curve is always at the highest position and continues to rise, indicating a significant improvement in the high-temperature anti-rutting performance of the composite-modified asphalt. At 24 °C, the creep stiffness modulus S value of the composite-modified asphalt increased by 24.9%; moreover, there is no obvious effect of improving low temperature, but the variation range of creep tangent slope m of the modified asphalt after aging is decreased, which further shows that the addition of a modifier can decrease the influence of aging on asphalt. Nanoparticles are uniformly dispersed in the asphalt and form a three-dimensional interconnected structure with BF, which effectively improves the overall performance of the asphalt. Nano-ZnO and fibers have weak chemical reactions in matrix asphalt, but they are physically dispersed and compatible.

1. Introduction

With the fast development of the highway transportation system, the total mileage of the national expressway is increasing year by year. During the 14th Five-Year Plan, China will achieve the goal of 25,000 km of expressway reconstruction and realize the main line of the “71,118” national highway network [1]. Asphalt pavement has the advantages of simple construction and comfortable driving, and more than 90% of expressways in China are paved with asphalt. Due to complex environmental changes and the increasing proportion of heavy-duty channelized traffic, conventional asphalt pavement is liable to be damaged during its service period, which makes the service quality of the road decline rapidly [2,3]. This is one of the main difficulties in the construction of high-quality modern highway systems in the new era. Therefore, improving the original asphalt to improve its road performance has become an important research direction in the field of transportation [4,5]. The unique and outstanding efficacy of nano-ZnO makes the performance of nano-ZnO-modified asphalt incomparable with other modified asphalt. The nano-ZnO-modified asphalt has a lower complex module and a higher phase angle, which shows that the asphalt has excellent heat-oxidation and photo-oxidation resistance, and the nano-ZnO modifier can significantly improve the high-temperature properties of matrix asphalt after PAV aging [6,7]. The increase in nano-ZnO content causes the Marshall stability, the indirect tensile strength, the pull-off adhesion, and the fracture energy of asphalt mixture to obviously increase, and the coating degree of asphalt on aggregate increases [8,9]. Nano-ZnO has a cross-linking reaction with asphalt, and nano-ZnO has physical and chemical modifications on matrix asphalt [10,11,12]. Compared to other modified asphalt, nano-ZnO-modified asphalt has outstanding road performance, but the addition of only nano-ZnO modifiers to improve the low-temperature performance of the asphalt mixture is not significant [13,14]. Studying nano-ZnO in asphalt and how to improve its low-temperature properties and deepen its high-temperature properties is an urgent problem.

Because of the high strength and green environmental protection of BF, the related research on BF-modified asphalt has entered people’s field of vision [15,16]. When the BF content is 2% and the length is 9 mm, BF-modified asphalt enhances the stress dissipation capacity at low temperatures to a certain extent, showing excellent rheological properties, and the BF is spatially distributed in the asphalt mortar, which has better stability and enhancement [17,18]. Compared to normal asphalt, adding BF greatly reduces the freeze–thaw splitting strength of aged specimens, effectively prevents the asphalt from aging, and improves the resistance to low temperatures and water damage. BF can effectively improve the combination of mineral aggregate and asphalt. Adding a small amount of fiber can significantly increase the viscosity of the asphalt mortar, hinder the effective flow of the asphalt, and, to some extent, lower the cracking probability of asphalt mortar, thus improving its low-temperature crack resistance. This provides the theoretical foundation for the popularization and application of BF in asphalt pavement [19,20,21,22].

In summary, as opposed to conventional asphalt blends, the addition of nanoparticles can significantly improve the performance of the asphalt mixture at high temperatures and water stability. The BF is added to the asphalt to strengthen the anti-crack and fatigue resistance of the asphalt mixture, thus increasing the durability of the pavement materials. However, in the results of recent research, there are few literature studies on the addition of multi-dimensional, multi-scale fibers and nanomaterials to the matrix bitumen. Therefore, nano-ZnO and BF are used as composite admixtures to modify the matrix asphalt in this paper. Nano-ZnO and BF are adopted as compound admixtures for modification of base asphalt. The performance of nano-ZnO/BF compound-modified asphalt at high and low temperatures is evaluated, and the micro-modification mechanism and road performance of composite-modified bitumen are also analyzed. This study may provide new optimization and improvement ideas for the development of China’s transportation field.

2. Raw Material

2.1. Asphalt

This article uses grade 70# asphalt from the Jintan Municipal Construction Co., Ltd. (Jintan, China). The basic performance index is determined according to the test procedure [23]. The results of the test are given in Table 1. In accordance with the requirements of the Technical Specification [24], the 70# asphalt specification meets the specification conditions.

Table 1.

Basic performance index of 70# asphalt.

2.2. Nano-Zinc Oxide

The nano-Zinc Oxide (nano-ZnO) used in the test is provided by Pinyu New Material Co., Ltd. (Shanghai, China). The shape of the nano-ZnO particles is approximately spherical, and the particle diameter is about 30 nm. It has the morphological characteristics of nanomaterials and belongs to the standard nanomaterials. Its technical index is shown in Table 2.

Table 2.

Technical Indicators of Nano-ZnO.

2.3. Basalt Fiber

The basalt fiber (BF) used is a high-quality fiber provided by Hunan Basalt Stone Co., Ltd. (Changsha, China). The BF is linearly distributed, the surface is smooth, and it is not easy to deform and distort. The conventional performance index parameters are shown in Table 3.

Table 3.

Performance index of BF.

3. Test Scheme

3.1. Optimization of Surface Properties of Nano-ZnO

In this paper, an aluminate coupling agent was selected to modify the surface of nano-ZnO [25]. The experimental equipment was a heat-collecting constant temperature heating magnetic stirrer. The concrete steps are as follows:

- (1)

- Different doses of aluminate coupling agent were added to the prepared ethanol solution (anhydrous ethanol:water = 9:1). The mixture was stirred with a glass rod evenly and then added to a conical flask. By stirring the mixture for 5 min at room temperature with a magnetic stirrer, the nano-ZnO was brought into full contact with the coupling agent.

- (2)

- A certain amount of nano-ZnO was weighed and dried in the electric blast drying box and slowly added to a conical bottle. The motor temperature was adjusted to 70 °C, the speed to 300 rpm, and stirring was continued for 40 min.

- (3)

- The activated nano-ZnO was placed in an electric blast drying furnace, and the temperature was controlled at about 100 °C. Finally, the dried nano-ZnO was placed in a mortar for grinding.

Each type of test includes three samples, including parallel experiments. The lipophilicity of the nano-ZnO was tested after modification, and the dose modification effect corresponding to the maximum lipophilicity value was the best. Finally, a 5.3% aluminate coupling agent was selected to activate the nano-ZnO.

3.2. Preparation of Composite-Modified Asphalt

The matrix asphalt was placed in an electric hot blast drying box and heated to melting at a temperature of 180 °C for dehydration. Then, 500 g of the matrix asphalt was quickly weighed into the heating furnace of the high-speed shear machine to keep it flowing. The temperature was set to about 150 °C for heating. In the course of heating, continuous mixing of the base asphalt with the glass rod can avoid local heating and aging of the asphalt. First, 4% of the surface-modified dry nano-ZnO was slowly added in batches to the matrix asphalt, and then the high-speed shear machine was used to slowly shear for about 15 min. When the white powder in the asphalt was evenly dispersed, 2% of the dry BF was slowly added in batches, and it was necessary to continuously carry out manual stirring to ensure it was evenly dispersed during the addition process. The shear rate was kept at 5000 r/min. The shear rate was cut for 60 min, then, it was placed in an electrothermal blast drying oven at 180 °C to swell and develop until the asphalt surface was smooth and free of bubbles. In this way, the nano-ZnO/BF compound-modified asphalt was prepared.

3.3. Rolling Thin Film Oven Test

The aging test of 50 ± 0.5 g matrix asphalt, nano-ZnO-modified asphalt and nano-ZnO/BF composite-modified asphalt was carried out according to the requirements of T0610 in the specification [23] using an asphalt rotating film oven. The oven temperature was kept at 163 ± 0.5 °C for a total duration of 85 min. All test procedures should be completed within 72 h. The basic performance of three kinds of asphalt after aging was analyzed and the anti-aging properties of the compound-modified asphalt were compared and evaluated.

3.4. Rheological Test of High-Temperature Dynamic Shear

The rheological behavior of asphalt was investigated by means of a DHP-1 dynamic shear rheometer according to T0628 in the regulation [23]. A sample of 25 mm in diameter and 1 mm thick was used in the test. The strain level selected for temperature scanning was 10%, and the shear frequency was 10 rad/s. The trend of complex shear modulus G*, the phase angle δ, and the rutting factor G*/sinδ at different temperatures was analyzed. The high-temperature performance of the matrix asphalt, the nano-ZnO-modified asphalt, and the nano-ZnO/BF composite-modified asphalt before and after aging was studied. Frequency scanning was used to select the strain level of 1%, and the frequency range was within 0.1 to 100 rad/s. The trend of G* at different angular frequencies was analyzed, and the anti-deformation ability of the three types of asphalt before and after aging was further studied. Based on the theory of the time–temperature equivalence principle, the change rule of the three types of asphalt G* was compared with that of the main curve of viscoelasticity.

3.5. Rheological Test of Low-Temperature Bending Beam

An ATS low-temperature bending rheometer made in the United States was adopted to investigate the low-temperature properties with reference [26]. Preparation of the asphalt was performed for 127 mm; it was 12.7 mm wide and 6.35 mm thick. The specimens were subjected to continuous stress loading for 4 min in a cold environment. Then, the creep stiffness modulus S value and the creep tangent slope m value of the three kinds of trabecular bending specimens were recorded, respectively. To ensure the data were accurate, the creep stiffness, S ≤ 300 Mpa, and the creep rate, m ≥ 0.3 at 60 s, were required in the specification. Comparison and analysis of the experimental results were performed to evaluate the low-temperature properties of matrix asphalt, nano-ZnO-modified asphalt, and nano-ZnO/BF composite asphalt before and after aging.

3.6. Scanning Electron Microscope Experiments

The morphology of matrix asphalt, nano-ZnO-modified asphalt, and nano-ZnO/BF composite-modified asphalt were studied using a field emission scanning electron microscope. The magnification of the matrix asphalt and nano-ZnO-modified asphalt was 2000 times, and the magnification of the nano-ZnO/BF composite-modified asphalt was 500 times. The sample size was in the size range of 10 mm × 10 mm × 5 mm, in order to more clearly study the combination of admixture and asphalt and the specific distribution characteristics, so as to better distinguish the differences in microstructure.

3.7. Fourier Infrared Spectroscopy Test

A VERTEX70 Fourier transform infrared spectrometer was used. The test scanning range was 4000 cm−1~500 cm−1, 64 times of scan, and 4 cm−1 resolution. The matrix asphalt, nano-ZnO-modified asphalt, and nano-ZnO/BF composite-modified asphalt were tested using infrared spectroscopy. Based on the position and strength of the characteristic peaks, the modification mechanism of the two modifiers on the base asphalt was studied.

4. Experiment Results and Analysis

4.1. Aging Performance Analysis

The matrix asphalt, nano-ZnO-modified asphalt, and nano-ZnO/BF composite-modified asphalt were subjected to RTFOT short-term aging, respectively. The comparison results are shown in Table 4.

Table 4.

Short-term aging test results of modified asphalt.

As shown in Table 4, the residual penetration ratio of the modified asphalt increased by 1.7% and 3.4%, respectively, the residual ductility ratio increased by 3.8% and 1.7%, respectively, the softening point increment decreased by 0.5 °C and 0.8 °C, respectively, and the mass change decreased by 0.027% and 0.072%, respectively. The greater the residual penetration ratio of asphalt after aging, the smaller the increment of softening point increment and the change in mass, the better the anti-aging performance of asphalt. This shows that the addition of two additives promoted the aging of asphalt and effectively reduced the volatilization of light components in asphalt. Both modified asphalts have better heat-aging resistance than matrix asphalt. It also proves that the nano-ZnO/BF composite-modified asphalt has the strongest anti-aging ability.

4.2. Analysis of Dynamic Shear Rheological Test

4.2.1. Temperature Scanning

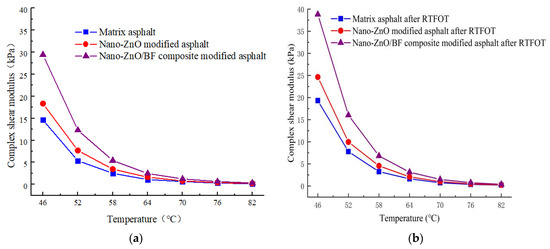

The rutting factor G*/sinδ is used to predict the viscoelastic properties of asphalt. The temperature scanning test of the three types of asphalt before and after aging was carried out at 46~82 °C. The temperature interval was 6 °C. The results are shown in Figure 1 and Figure 2.

Figure 1.

Complex shear modulus–temperature variation diagram of three kinds of asphalt. (a) Unaged asphalt. (b) Aged asphalt.

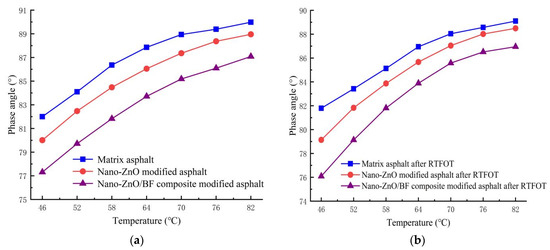

Figure 2.

Phase angle–temperature variation diagram of three kinds of asphalt. (a) Unaged asphalt. (b) Aged asphalt.

① When the temperature condition is relatively low, the complex shear modulus of the three kinds of asphalt is larger, but the phase angle value at the same temperature is smaller, indicating that the asphalt is more elastic at low temperatures, and has a stronger capacity to withstand deformation. As the temperature rises, the complex shear modulus decreases, and the phase angle increases gradually, which demonstrates that the viscosity of the asphalt is stronger under the condition of a high-temperature environment, and the anti-deformation capability of the asphalt is reduced to a certain extent. After the nano-ZnO and BF were added to the matrix asphalt, under the same temperature conditions, the complex shear modulus G* of the nano-ZnO-modified asphalt and nano-ZnO/BF composite-modified asphalt showed an upward trend compared with the matrix asphalt, and the phase angle δ showed a corresponding decreasing trend, but the increase in G* and the decrease in δ of the composite-modified asphalt were obviously greater than that of nano-ZnO-modified asphalt. Therefore, the addition of BF to nano-ZnO-modified asphalt can effectively promote resistance to permanent deformation.

② After aging, the G* and δ of the three types of asphalt are almost the same as those before aging. From Figure 1b, it can be seen that the G* values of the three kinds of asphalt will increase when aging occurs. However, compared with the G* value changes of nano-ZnO-modified asphalt and matrix asphalt, it can be seen that after adding BF, the G* value increases greatly. From Figure 2b, it can be seen that the δ value of asphalt decreases during aging, but the decreasing trend also increases with the addition of BF. Through the above analysis, it can be seen that in the process of asphalt RTFOT aging, adding BF to modified asphalt can play a helpful role in resisting RTFOT aging.

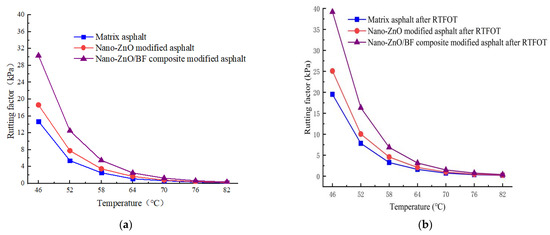

According to the result data, three diverse classifications of asphalt rutting factor–temperature change trend diagrams are further analyzed. As shown in Figure 3, the temperature scanning test results before and after aging can be studied more clearly and intuitively.

Figure 3.

Rutting factor–temperature variation diagram of three kinds of asphalt. (a) Unaged asphalt. (b) Aged asphalt.

Analysis of Figure 3 shows:

① As the test temperature rises, the rutting factors of the original asphalt and the aged asphalt have the same decreasing tendency. Rutting factor in the environmental conditions of 46 °C gradually warming process, the overall trend of rutting factor suddenly decreased, but the three kinds of asphalt curve after 64 °C numerical change slowly and gradually overlap. The reason is that the relative proportion of viscous behavior is increased with the increase in test temperature, and the viscous components increase while the elastic components gradually decrease. Under the same temperature conditions, the rutting factor G*/sinδ from large to small is nano-ZnO/BF-modified asphalt > nano-ZnO-modified asphalt > matrix asphalt. If the asphalt shows a large G*/sinδ value, it shows that asphalt has strong high-temperature deformation resistance, which can more effectively resist the traffic gravity load so that the rutting deformation phenomenon appears slowly or decreases significantly.

② RTFOT aging makes the rutting factor of asphalt larger. Analysis of the reasons shows that aging changes asphalt’s composition, and the gradual transformation of light components to heavy components causes the nano-ZnO/BF composite-modified asphalt to be harder. When the asphalt pavement undergoes heavy traffic under high-temperature conditions, its good viscoelastic behavior makes it less prone to rutting deformation, indicating that aging causes the modified asphalt to have better thermal stability. The increase in the rutting factor of modified asphalt after aging also shows that the high strength characteristics of BF itself are effectively combined with nanoparticles to form a unified system, and the integral performance of modified asphalt is effectively reinforced. The incorporation of nano-ZnO and BF into the matrix asphalt significantly reduces the probability of rutting deformation of the asphalt, which is of great importance for the anti-damage ability of the asphalt under high-temperature conditions.

4.2.2. Frequency Scanning

- (1)

- Frequency scanning test

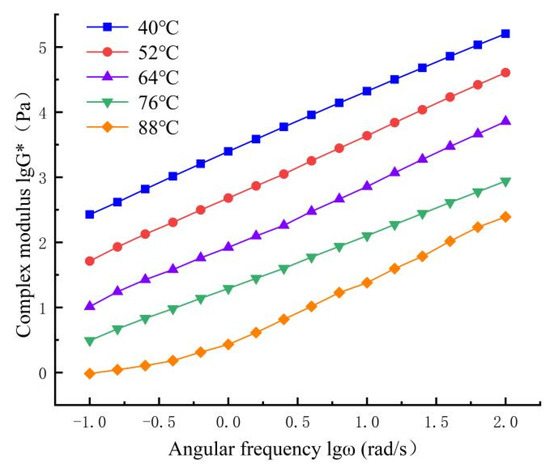

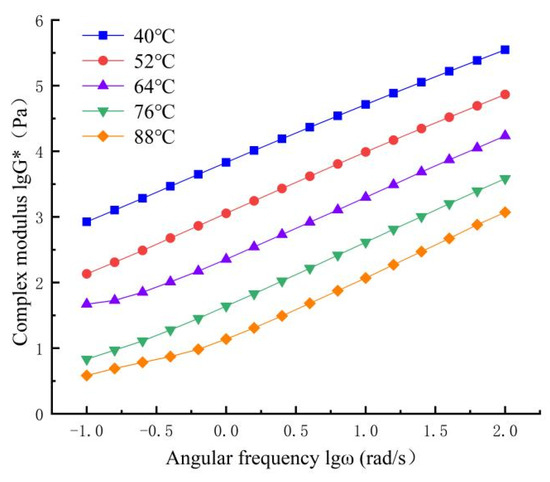

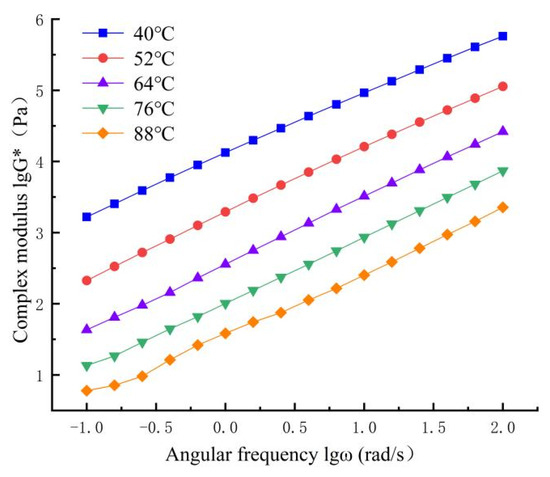

The frequency scanning experiment can accurately and comprehensively analyze the dynamic high-temperature characteristics of different asphalts at different shear angle frequencies. In this section, frequency scanning tests in the three types of asphalt were carried out at temperatures of 40~88 °C, and the temperature interval was 12 °C. The results of the test are shown in Figure 4, Figure 5 and Figure 6.

Figure 4.

Complex modulus–angular frequency change diagram of base asphalt.

Figure 5.

Complex modulus–angular frequency change diagram of nano-ZnO-modified asphalt.

Figure 6.

Complex modulus–angular frequency change diagram of nano-ZnO/BF composite-modified asphalt.

① Under the same temperature conditions, as the angular frequency gradually increases, the complex modulus values of the three asphalts also increase and are almost linear. In practical road applications, the increase in the frequency of pavement loading indicates that the higher the vibration frequency of the road in unit time, that is, the total shear strain generated in unit time decreases, and the complex modulus of asphalt increases. Under the state of relatively low temperature, the increase in load frequency has little effect on asphalt road pavement, and the deformation of asphalt road pavement is small. However, under the state of relatively high temperatures, when the pavement is subjected to heavy traffic vehicles, its G* is small, and the asphalt pavement is prone to deformation, which may result in the destruction of the road surface.

② The change rate of G* of matrix asphalt, nano-ZnO-modified asphalt, and nano-ZnO/BF composite-modified asphalt is basically the same and roughly parallel under five different test temperature conditions. Analysis of experimental data shows that with the change in environmental conditions, the G* of asphalt is negatively correlated with temperature. The reason is that the asphalt softens in a high-temperature environment, which leads to the weakening of the interaction force between the interior of the asphalt, the weakening of the elastic properties of the modified asphalt, and a change in the direction of viscoelasticity. The final result is that the G* decreases, and the viscous component of asphalt increases. The transformation of asphalt to viscous characteristics reduces its ability to resist high-temperature deformation. It shows that in a high-temperature environment, the probability of road rutting will increase significantly, and the performance of asphalt pavement will be weakened.

- (2)

- Main curve analysis of frequency scanning results

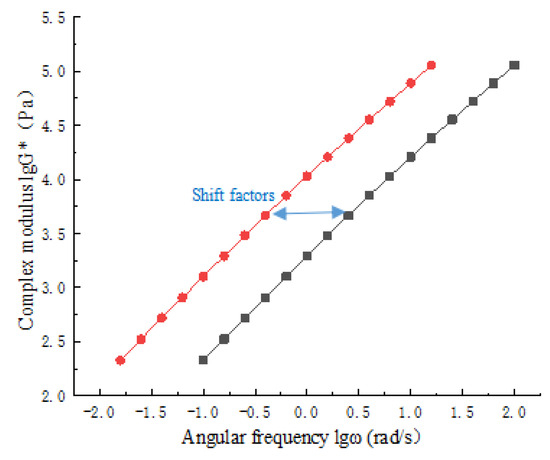

First, the data of the complex modulus and angular frequency of the three original asphalts are fitted to the curve equation. Then, by selecting the G* value, the displacement factors corresponding to the matrix asphalt, nano-ZnO-modified asphalt, and nano-ZnO/BF composite-modified asphalt are calculated in turn. Finally, with the help of the time–temperature equivalence principle, the main curve diagram of lgG* − lgω is constructed to increase the research interval. The time–temperature equivalence principle is based on the fact that there is a certain distance between the data curves of other temperatures and the data curves of this temperature at a certain temperature. This distance is called the displacement factor.

① Determination of displacement factors of the three original asphalts.

Through the analysis of the frequency scanning data of matrix asphalt at different test temperatures, and then the double logarithm curve equation is fitted. The results are presented in Table 5.

Table 5.

Matrix asphalt double logarithmic fitting curve summary table.

In this section, by selecting G* = 1000 Pa, it is substituted into lgG* to obtain lgG* = 3, and then the lgG* value is substituted into the fitting curve equation of Table 5, respectively. The corresponding lgω values at various temperatures can be obtained. On the basis of the displacement factor of the test temperature of 40 °C, the displacement factor values corresponding to the angular frequency lgω under the remaining temperatures are calculated in turn. The results are in Table 6 below.

Table 6.

Matrix asphalt displacement factor table.

Taking the same analysis method as matrix asphalt, the fitting curve equations and corresponding displacement factor values of nano-ZnO-modified asphalt and nano-ZnO/BF composite-modified asphalt were calculated in turn, as given in Table 7 and Table 8, respectively.

Table 7.

Two modified asphalt double logarithmic fitting curve equation summary table.

Table 8.

Two modified asphalt displacement factor tables.

② Main curve analysis of the three original asphalts.

When the time–temperature equivalence principle is used for graphic drawing, the curves of different temperatures will move horizontally on the basis of the displacement factor. Then, by studying the generated lgG* − lgω curve of a wider area, the temperature susceptibility of different asphalts under the action of the external environment can be evaluated and analyzed. The diagrammatic drawing of the displacement factor principle is illustrated in Figure 7.

Figure 7.

Schematic diagram of displacement factor.

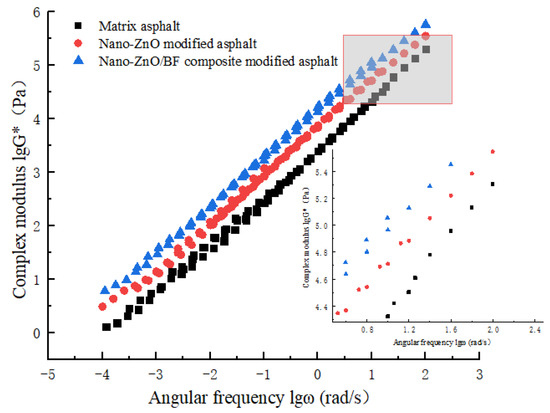

Based on the principle of time–temperature equivalence, the temperature of 40 °C is used as the benchmark. According to the displacement scale factor values of the three original asphalts calculated in Table 6 and Table 8, the remaining complex modulus change diagrams are moved horizontally to the left, and the main curve of lgG* − lgω is obtained, as shown in Figure 8.

Figure 8.

The complex modulus–angular frequency main curves of the three original asphalts.

According to the analysis of Figure 8, under the same loading conditions of angular frequency, especially in the high-temperature and low-frequency section, the G* value of nano-ZnO/BF composite-modified asphalt is larger than that of nano-ZnO-modified asphalt, and the complex modulus value of matrix asphalt is the smallest, indicating that matrix asphalt has poor rutting resistance. BF can improve the high-temperature properties of asphalt, but the improvement effect is not as obvious as that of composite materials. It can be seen intuitively from Figure 8 that in the low-temperature and high-frequency section, as the angular frequency increases, the G* of the three types of asphalt also increases. The main curve of matrix asphalt and nano-ZnO-modified asphalt gradually approaches, and the complex modulus values are not much different, indicating that the nanoparticles as modifiers in the low-temperature environment have no significant effect in improving the temperature sensitivity of the asphalt. However, the complex modulus of the nano-ZnO/BF compound-modified asphalt is still at the highest position and is in a continuous rising stage; this shows that the two admixtures can effectively upgrade the high-temperature anti-rutting properties of asphalt, and the promotional effects are still remarkable in the high-frequency section.

4.3. Analysis of Bending Beam Rheological Test

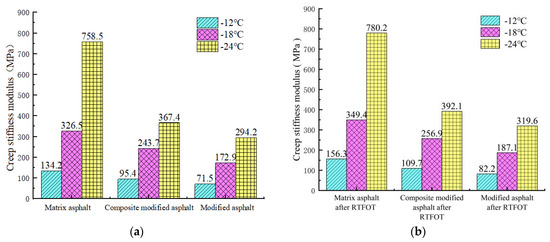

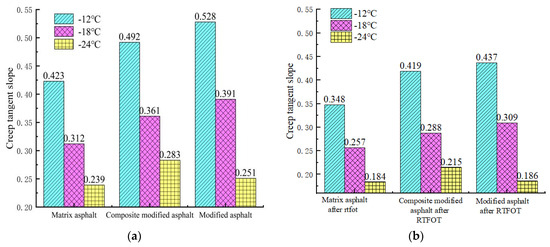

Three temperature conditions were selected for the three kinds of asphalt: −12 °C, −18 °C, and −24 °C. The loading time was determined to be 240 s. The stiffness modulus S value and tangent slope m value of the bending creep stiffness test were automatically collected and recorded by the sensing system, as given in Figure 9 and Figure 10.

Figure 9.

Creep stiffness modulus of asphalt at different temperatures. (a) Unaged asphalt. (b) Aged asphalt.

Figure 10.

Creep tangent slope of asphalt at different temperatures. (a) Unaged asphalt. (b) Aged asphalt.

From the analysis of Figure 9a and Figure 10a, it can be seen that the creep stiffness modulus of the three different types of asphalt increases, and the creep tangent slope decreases as the temperature decreases. Among them, the increase (decrease) of matrix asphalt is the most significant, which reflects that matrix asphalt shows more significant brittleness under low-temperature conditions and has poor deformation resistance. After the nanoparticle modifier is added, the S value decreases and the m value increases. After the addition of BF to the nano-modified asphalt, the S value increases and the m value decreases. The reason may be that the BF absorbs a part of the light component content in the asphalt so that the content of heavy components is relatively high. Nanoparticles and BF form a dense three-dimensional mesh system, which increases its synergy, thus promoting the creep stiffness modulus of nano-ZnO/BF composite-modified asphalt to be higher than that of nano-ZnO-modified asphalt.

It can be seen from Figure 9b and Figure 10b that the parameter S of matrix asphalt, nano-ZnO-modified asphalt, and nano-ZnO/BF composite-modified asphalt increased to a certain extent after RTFOT aging. Analysis at −12 °C shows that the S value of matrix asphalt increased by 16.5% after aging, the S value of nano-ZnO-modified asphalt increased by 14.9% after aging, and the S value of composite-modified asphalt increased by 15.0% after aging. The creep tangent slope of the three test asphalts decreased after short-term aging. The m values of matrix asphalt, nano-ZnO-modified asphalt, and nano-ZnO/BF composite-modified asphalt at −12 °C decreased by 21.6%, 14.8%, and 13.4%, respectively. In summary, nanoparticles can improve the low-temperature creep property of asphalt to some degree, while the effect of adding fiber is not obvious. After short-term aging, the modified asphalt with admixture weakens the change range of creep rate, which further verifies that the addition of nanoparticles and fibers can enhance the anti-aging properties of asphalt.

4.4. Micromorphology Analysis

4.4.1. Study on the Microstructure of Raw Materials

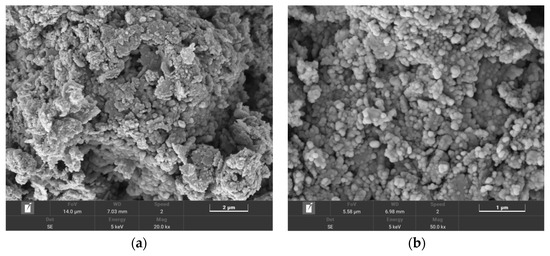

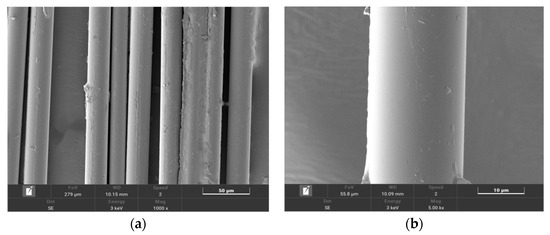

The scanning electron microscope morphology of nano-ZnO and basalt fiber was studied, as shown in Figure 11 and Figure 12.

Figure 11.

Scanning electron microscopy of two multiples of nano-ZnO. (a) The magnification is 20,000 times. (b) The magnification is 50,000 times.

Figure 12.

Scanning electron microscopy of two kinds of basalt fiber. (a) The magnification is 1000 times. (b) The magnification is 5000 times.

It can be seen from Figure 11 that the shape of the surface-modified nano-zinc oxide particles is approximately spherical, and the particle diameter is about 30 nm. The aluminate coupling agent reacts with nano-zinc oxide so that the surface of the particles is coated with a layer of film, which improves its dispersion.

It can be seen from Figure 12 that the basalt fiber is linearly distributed, the surface is smooth, and it is not easy to deform and distort, indicating that the fiber has high strength and can have a good reinforcement effect on the asphalt mixture.

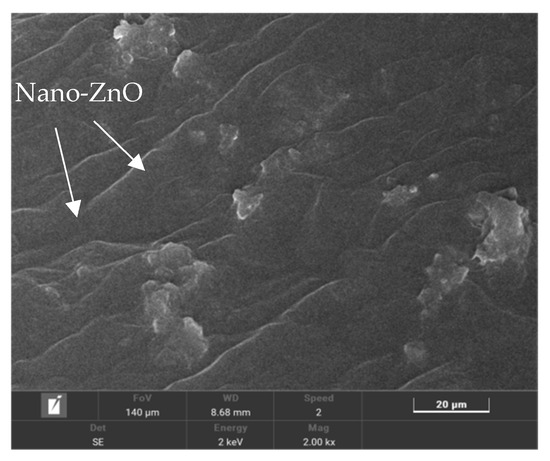

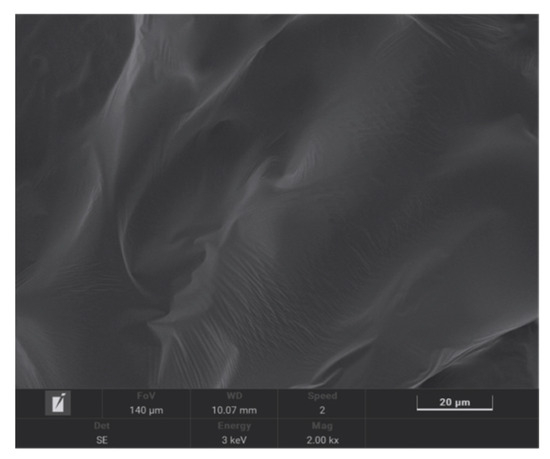

4.4.2. Morphology Characterization Analysis of Composite-Modified Asphalt

The morphology of matrix asphalt, nano-ZnO-modified asphalt, and nano-ZnO/BF composite-modified asphalt was studied using scanning electron microscopy (SEM), as shown in Figure 13, Figure 14 and Figure 15.

Figure 13.

Ase asphalt scanning electron microscope.

Figure 14.

Scanning electron microscopy of nano-ZnO-modified asphalt.

Figure 15.

Scanning electron microscopy of nano-ZnO/BF composite-modified asphalt.

It can be seen from Figure 13 that after the matrix asphalt is magnified by 2000 times, no other impurities or particles appear in the scanning electron microscope image, the surface is very smooth, and the micro-morphology is evenly distributed. This also proves that the matrix asphalt selected in this paper is relatively clean and pure, which is convenient for later comparison with the images of nano-ZnO-modified asphalt and nano-ZnO/BF composite-modified asphalt.

It can be seen from Figure 14 that, compared with the matrix asphalt, the surface of the modified asphalt added with nano-ZnO has some protrusions, and a small amount of agglomeration occurs, but on the whole, it is still evenly dispersed in the asphalt, and a relatively stable network structure is formed with the asphalt. This may be due to the damage to the structure of the nanoparticles themselves during the high-speed stirring process. The chemical structures, such as functional groups and covalent bonds, change, and the increase in their surface activity makes it easier to integrate with the asphalt, increasing the viscosity and toughness of the overall structure, thereby improving the asphalt’s performance.

It can be seen from Figure 15 that the microstructure of the composite-modified asphalt becomes more complex, and the surface presents an intricate irregular wrinkle phase. This is because the fiber itself has high oil absorption. After the adsorption of the surrounding asphalt reaches saturation, the fiber is completely coated by the asphalt, forming a wrinkle phenomenon around the vacancy, indicating that the fiber and the asphalt have good compatibility. There is no reaction between the two admixtures. The mutual extension of the surface of the asphalt phase and the fiber phase forms a denser structure, which helps to improve the stability of the asphalt.

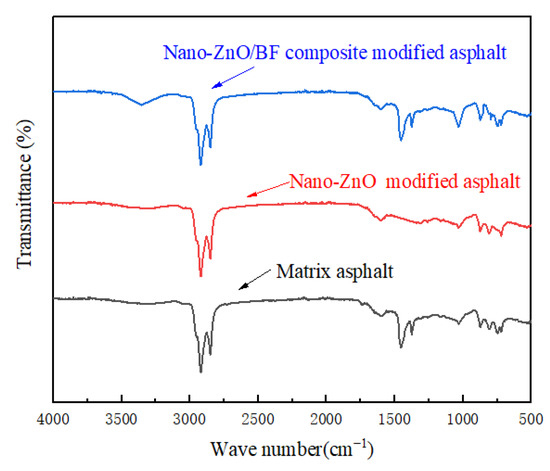

4.5. Infrared Spectrum Test Analysis of Composite-Modified Asphalt

The data obtained from the wavenumber-transmittance test of the three kinds of asphalt are summarized into an infrared spectrum, and then the characteristic peaks are compared and analyzed. The test results are shown in Figure 16.

Figure 16.

Infrared spectra of the three kinds of modified asphalt.

The infrared spectra of the three kinds of asphalt in Figure 14 are studied and analyzed. The main conclusions are as follows:

- (1)

- The infrared spectra of matrix asphalt are analyzed as follows: There are two significant characteristic absorption peaks at 2905 cm−1 and 2817 cm−1, which are caused by the stretching vibration of the C–H bond in asymmetric methylene and symmetric methylene (-CH2-), respectively. The stretching vibration peaks at 1486 cm−1 and 1378 cm−1 were observed, which may be caused by the bending vibration of the C–H bond in the asymmetric group and the symmetrical methyl (-CH3-). A weak absorption peak was found at a wave number of about 1035 cm−1, corresponding to the stretching vibration of the functional group S=O in the sulfoxide (R1-SO-R2). The absorption peaks found at 815 cm−1 and 738 cm−1 at the end are due to the out-of-plane bending of the =C–H group in the olefin. It can be seen that the matrix asphalt contains aromatic hydrocarbon compounds.

- (2)

- After adding nanoparticles into the matrix asphalt, the peak position of the infrared spectrum of the asphalt changed significantly. The absorption peak of nano-ZnO-modified asphalt gradually weakens and disappears in the range of 1300 cm−1 to 1530 cm−1, indicating that there is a certain amount of strong oxidizing hydroxyl (-OH) on the surface of the surface-treated nano-materials. Under the action of high-speed shear, a certain chemical reaction occurs between the matrix asphalt. The intensity and position of the absorption peaks found at 726 cm−1 and 613 cm−1 at the end changed slightly. The reason may be that nano-ZnO has a certain influence on the out-of-plane swing vibration of CH2 olefins and the in-plane swing of long-chain alkanes CH2 groups. In short, nano-ZnO and matrix asphalt have a certain chemical reaction, but mainly a physical reaction.

- (3)

- On the whole, nano-ZnO/BF composite-modified asphalt has a certain wave number absorption peak band in the range of 3150~3460 cm−1. On the one hand, the CH functional group in the asphalt may have a weak chemical reaction with the composite modifier during the preparation process. On the other hand, it is caused by the stretching vibration of O–H and N–H bonds in the phenolic hydroxyl group. At the wave numbers 815 cm−1 and 726 cm−1, there are moderate stretching vibration peaks, which are mainly caused by the bending vibration of the crystalline long chain (-(CH2)n-, (n ≥ 4)). At the wave number 1035 cm−1, the absorption peak with obvious strength is found. The reason may be the degradation reaction of the polymer chain segment, which leads to the change in the content of the related group C=C, and the C=C group is a conjugated double bond. The value can characterize the mechanical properties of asphalt, which further indicates that nano-ZnO/BF composite-modified asphalt has strong mechanical properties.

In summary, when nano-ZnO and BF are added to matrix asphalt, the types of functional groups remain almost unchanged, and only the content of functional groups changes. It shows that after adding the composite modifier, there is basically no chemical reaction inside the asphalt, mainly physical dispersion and compatibility.

5. Conclusions

- (1)

- After adding nano-ZnO and BF to matrix asphalt, the three performance indicators before and after RTFOT aging improved to varying degrees. Compared with nano-ZnO-modified asphalt, the residual ductility ratio, softening point increment, and mass change in nano-ZnO/BF composite-modified asphalt decreased by 1.7%, 0.3 °C and 0.045%, respectively, and the residual penetration ratio increased by 1.7%, indicating that the fiber can reduce the effect of aging on asphalt and further improve its anti-aging performance.

- (2)

- The rutting factor of the three kinds of original asphalt and thermal aging asphalt decreases with the increase in test temperature, and at the same temperature, the G*/sinδ of the three kinds of asphalt from large to small is nano-ZnO/BF composite-modified asphalt > nano-ZnO-modified asphalt > matrix asphalt, indicating that the composite-modified asphalt has the strongest high-temperature deformation resistance. RTFOT aging makes the rutting factor of asphalt larger, which is of great significance to its damage resistance in a high-temperature environment.

- (3)

- The complex modulus of three kinds of original asphalt and aged asphalt increased gradually with the increase in angular frequency, almost linear relationship; nano-ZnO/BF composite-modified asphalt has good deformation resistance in both high-frequency and low-frequency regions, which improves the pavement’s performance from a macro perspective. After short-term aging, the complex modulus of the three kinds of asphalt showed a significant growth trend; that is, aging improved the high-temperature stability of the asphalt.

- (4)

- After adding BF to nano-ZnO-modified asphalt, the S value increases and the m value decreases, that is, nanoparticles can improve the low-temperature creep performance of asphalt to a certain extent, while the low-temperature improvement effect of nano-ZnO/BF composite-modified asphalt is not obvious. The S value of nano-ZnO-modified asphalt and composite-modified asphalt increased by 14.9% and 15.0%, respectively, while the m value decreased by 14.8% and 13.4%, respectively, and the change range of creep rate of modified asphalt decreased at −12 °C. After RTFOT aging, the creep rate of modified asphalt decreased, indicating that the incorporation of modifiers can improve the anti-aging performance of asphalt.

- (5)

- The modified asphalt mixed with nanoparticles and BF increases the viscosity and toughness of the whole structure and forms a three-dimensional network structure, which can effectively improve the performance of the asphalt. It can be seen from the infrared spectrum that nano-ZnO/BF composite-modified asphalt has strong mechanical properties. Nano-ZnO and BF have weak chemical reactions in matrix asphalt, but they are mainly physically dispersed and compatible.

Author Contributions

Writing—original draft preparation, C.L., Z.L. and J.M.; Writing—review and editing, T.G., Y.C. and J.M.; Investigation, J.W. and L.J.; Discussion, T.G., Y.C. and J.M. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by Key R&D and Promotion of Special Scientific and Technological Research Projects of Henan Province: [Grant Number 182102210061, 212102310089]; Key Scientific Research Projects of Colleges and Universities in Henan Province in 2021: Study on pavement performance of cotton straw cellulose modified asphalt [Grant Number 21A580004].

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Some or all data, models, or code that support the findings of this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

Author Chaojie Li was employed by the company Henan Transportation Research Institute Co., Ltd., Zhengzhou 450045, Henan, China. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Rao, Z.; Wang, Y.; Cui, Z. Key Interpretation of ‘14th Five-Year’ Expressway Construction. China Highw. 2022, 623, 28–32. [Google Scholar]

- Shen, L.; Ma, Q. Comparative Analysis of Long-life Asphalt Pavement and Traditional Asphalt Pavement. Traffic Stand. 2014, 42, 60–62. [Google Scholar]

- Wang, H. Comparative Study on Construction Equipment of MOH Semi-Flexible Pavement and Traditional Asphalt Pavement; Chang’an University: Xi’an, China, 2019. [Google Scholar]

- Wang, F. Analysis of the influence of different kinds of modifiers on the performance of matrix asphalt. Appl. Chem. 2021, 50, 2132–2135+2139. [Google Scholar]

- Wang, Y. Application research status of nano-modified asphalt materials in pavement engineering. Aging Appl. Synth. Mater. 2022, 51, 159–161. [Google Scholar]

- Zhu, C.; Zhang, H.; Shi, C.; Li, S. Effect of nano-zinc oxide and organic expanded vermiculite on rheological properties of different bitumens before and after aging. Constr. Build. Mater. 2017, 146, 30–37. [Google Scholar] [CrossRef]

- Xu, X.; Guo, H.; Wang, X.; Zhang, M.; Wang, Z.; Yang, B. Physical properties and anti-aging characteristics of asphalt modified with nano-zinc oxide powder. Constr. Build. Mater. 2019, 224, 732–742. [Google Scholar] [CrossRef]

- Hamedi, G.H.; Nejad, F.M.; Oveisi, K. Estimating the moisture damage of asphalt mixture modified with nano zinc oxide. Mater. Struct. 2016, 49, 1165–1174. [Google Scholar] [CrossRef]

- Mansour, F.; Ehsan, S. The effects of nano zinc oxide (ZnO) and nano reduced graphene oxide (RGO) on moisture susceptibility property of stone mastic asphalt (SMA). Case Stud. Constr. Mater. 2021, 15, e00655. [Google Scholar]

- Zhang, H.; Zhu, C.; Wu, C. Effects of multi-scale nanomaterials on the rheological and aging properties of asphalt. J. Build. Mater. 2019, 22, 238–244. [Google Scholar]

- Wang, J.; Li, Y. Preparation of nano modified asphalt and its mixture road performance. Road Constr. Mach. Constr. Mech. 2020, 37, 22–28. [Google Scholar]

- Bao, M.; Xie, X.; Li, G. Phase analysis of nano zinc oxide modified asphalt under ultraviolet irradiation. Highway 2022, 67, 228–236. [Google Scholar]

- Dong, T. Study on the Properties of Nano-ZnO/SBS/SBR Composite Modified Materials; Chongqing Jiaotong University: Chongqing, China, 2020. [Google Scholar]

- Tao, H.; Liu, H.; Xie, X.; Sun, T.; Dong, R.; Lu, X. Preparation and Properties of Nano-ZnO Combined with Biomass Heavy Oil Composite-Modified Asphalt. Adv. Mater. Sci. Eng. 2022, 2022, 5179787. [Google Scholar] [CrossRef]

- Vamsikrishna, D.; Manikanta, K.V. Tyre Rubber Modified Bitumen for Ashpalt Mixture. J. Trend Sci. Res. Dev. 2019, 3, 42–46. [Google Scholar]

- Abdelsalam, M.; Yue, Y.; Khater, A.; Luo, D.; Musanyufu, J.; Qin, X. Laboratory Study on the Performance of Asphalt Mixes Modified with a Novel Composite of Diatomite Powder and Lignin Fiber. Appl. Sci. 2020, 10, 5517. [Google Scholar] [CrossRef]

- Gu, Q.; Kang, A.; Li, B.; Xiao, P.; Ding, H. Effect of fiber characteristic parameters on the high and low temperature rheological properties of basalt fiber modified asphalt mortar. Case Stud. Constr. Mater. 2022, 17, e01247. [Google Scholar] [CrossRef]

- Celauro, C.; Praticò, F. Asphalt mixtures modified with basalt fibres for surface courses. Constr. Build. Mater. 2018, 170, 245–253. [Google Scholar] [CrossRef]

- Zhao, Y. Experimental study on crack resistance of basalt fiber reinforced asphalt concrete. Highw. Eng. 2014, 39, 48–51. [Google Scholar]

- Fu, Z.; Huang, Z.; Ma, F. Effect of basalt fiber on road performance of aged asphalt mixture. Mater. Bull. 2016, 30, 118–122. [Google Scholar]

- Yan, J.; Zheng, J.; Li, N. Study on the crack resistance of basalt fiber asphalt mortar. J. Build. Mater. 2019, 22, 800–804. [Google Scholar]

- Wang, G.; Li, B.; Xiao, P. Analysis of crack resistance of basalt fiber recycled asphalt mixture. J. Yangzhou Univ. (Nat. Sci. Ed.) 2021, 24, 69–73. [Google Scholar]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. People’s Transportation Press: Beijing, China, 2011.

- JTG F40-2004; Standard Specification for Construction and Acceptance of Highway Asphalt Pavement. People’s Transportation Press: Beijing, China, 2004.

- Zhou, L.; Zang, S.; Hu, X. Study on Surface Modification of Nanometer Zinc Oxide. J. Petrochem. Univ. 2009, 22, 5–8. [Google Scholar]

- SH/T 0775-2005; Standard Test Methods for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer (BBR). National Development and Reform Commission of the People’s Republic of China: Beijing, China, 2005.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).