Abstract

Ultrasonic-assisted brazing (UAB) technology has been introduced to prepare the diamond/AlSi composite coating on Ti-6Al-4V substrate. The microstructure and wear properties of the coating were studied. The results showed that AlSi filler metal had a certain spreading and climbing phenomenon on the diamond surface, indicating a significant improvement in wettability between AlSi filler metal and diamond by ultrasonic-assisted brazing. Under ultrasound action, the microstructure of AlSi brazing alloy was greatly refined, and the Ti atoms in the Ti-6Al-4V substrate diffused to the interface between diamond and AlSi brazing alloy and formed TiC on diamond particles. There was no thermal damage to diamond particles when the brazing temperature was 750 °C. UAB improved the microhardness of the coating alloy matrix due to the increasing quantity and distribution range of TiAl3 as reinforced particles but had no obvious effect on the microhardness of the Ti-6Al-4V substrate. The wear resistance of Ti-6Al-4V substrate with diamond/AlSi composite coating was promoted due to the dense diamond particles, the formed TiC on diamond particles, and the increase in microhardness of the alloy matrix of diamond/AlSi coating under ultrasound action.

1. Introduction

Titanium alloys have a wide application prospect in manufacturing fields such as aerospace, navigation, chemical industry, metallurgy, medical treatment, and instrumentation because of their advantages of high specific strength, excellent corrosion resistance, low density, and wide working temperature [1,2,3]. In the aerospace field, titanium alloys have important applications in key components such as engine turbine blades, engine nozzles, loop heat pipe (LHP), and spacecraft solar wing hinge structures. In the field of oil, gas, and combustible ice exploration, titanium alloys have become the preferred material for the key components of drilling equipment in recent years because of their high corrosion resistance and light weight. In biomedicine, titanium alloys have become the first choice for medical implants such as bones and joints due to their excellent biocompatibility. However, the poor wear resistance greatly limits the application range of titanium alloys. Surface modification technology is one of the most effective methods to promote the wear resistance of titanium alloys, mainly including plasma spraying, electroplating, ion implantation, laser/plasma cladding, and vapor deposition [4,5,6,7].

As the hardest known material, diamond is a good choice as hard particles in the coating, which is usually brazed with brazing filler metal containing strong carbide formation elements such as Ti, Zr, and Cr [8,9]. Brazing technology provides the metallurgical bonding between diamond particles and filler metals, including Ag-Cu-Ti, Cu-Sn-Ti, and Ni-Cr alloys [8,9,10]. Huang et al. [9] used a laser to braze diamond particles on the surface of AA7075 aluminum alloy, and the TiC layer was formed at the interface between diamond and AgCuTi filler metal. Long et al. [11] prepared diamond composite coatings on 65 Mn steel substrates via fiber laser and studied the influence of laser power on the formation mechanism of the diamond braze coatings. Mishra et al. [12] reviewed the AgCuTi brazing filler metal to join ceramic to metal using active brazing metal. Sharma et al. [13] investigated the brazing characteristics of Al2O3 and 3D-printed Ti-6Al-4V alloys using a novel high-entropy AlZnCuFeSi alloy as the filler metal. Lee et al. [14] used the arc brazing method to connect electro-galvanized steel with Cu-3 wt.%Si filler alloy and evaluated the influence of the arc current and brazing speed on the joint properties, such as the droplet characteristics, arc penetration, joint hardness, and tensile/shear strength. Yin et al. [15] brazed diamond onto Q460 steel using a Cu-Sn-Ti alloy with nano-WC particles in a vacuum furnace and found that adding 15 wt.% WC particles could effectively promote the bonding force between diamond particles and improved the shear strength and wear resistance of the coating. Liu et al. [16] found that laser scanning speed would lead to a change in heat input and a different melting behavior of the diamond/NiCrSiB coating. However, high heating temperature leads to diamond carbonization when using the brazing alloys mentioned above [16,17].

By taking advantage of cavitation and acoustic streaming effects, ultrasonic-assisted brazing (UAB) technology can improve the wettability of filler alloy on materials with poor wettability at lower temperatures [18]. Huang et al. [19] applied the ultrasonic-assisted induction heating method, which promoted the shear strength of the welded joint between diamond and 1045 steel greatly and reduced the residual compressive stress. Chen et al. [20] used the ultrasonic brazing method to realize the connection between SiC ceramics and Ti-6Al-4V alloy. Zhang et al. [21] proposed ultrasonic-assisted laser brazing (UALB) and found that the ultrasonic action had improved the strengths of the joint of diamond and the NiCr filler alloy, and the acoustic effect promoted the chemical reaction process of C and Cr and increased the thickness of carbide layer.

In this study, a novel diamond/AlSi composite coating on Ti-6Al-4V substrate was prepared using UAB. The diamond particles were brazed onto Ti-6Al-4V substrate with inactive AlSi brazing alloy at 750 °C. The microstructure and wear resistance of the diamond/AlSi composite coating were investigated. An abrasive test was introduced to check the wear resistance of the coating, and the wear behavior was also discussed.

2. Experiment

First, 15 wt.% diamond particles (250–300 μm) and 85 wt.% Al12Si powder (58–74 μm) were mixed and ball milled using Al2O3 balls for 90 min. Ti-6Al-4V alloy, which was a typical α + β titanium alloy, was selected as substrate material. Ti-6Al-4V substrate was cut into 40 mm × 35 mm × 10 mm slices, and then the grooves of 25 mm × 12 mm × 2 mm were milled on the surfaces of the slices. The powder mixture was uniformly filled in the grooves of specimens with a thickness of 2 mm. Before braze coating, Ti-6Al-4V substrate was polished with 60 mesh sandpaper to remove the impurities and oxide layer on the surface.

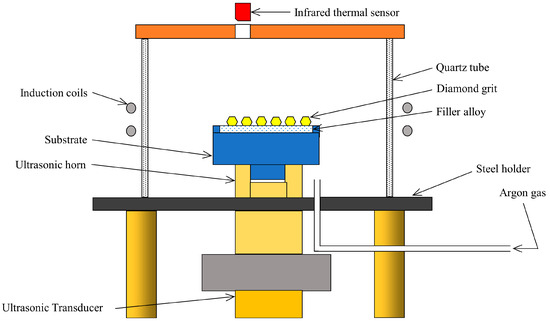

The UAB system mainly consists of an ultrasonic generator, an ultrasonic transducer, an ultrasonic horn, a high-frequency induction device with highly accurate infrared thermal sensor, and a quartz glass tube with argon protection, as shown in Figure 1. The Ti-6Al-4V substrate was mechanically connected with the ultrasonic transducer, induction heated to 750 °C, ultrasonic vibrated for 36 s, and then cooled to room temperature. The vibration frequency of the ultrasonic transducer acting on the specimen was 20.5 kHz, and the output amplitude was 3–5 μm.

Figure 1.

Schematic diagram of the ultrasonic-assisted induction brazing system.

The coated substrate was cut along the cross-section via laser equipment, and the specimens were polished step by step with 400, 800, 1000, and 2000 mesh water sandpaper. Kroll solution was used to corrode the cross-section of metallographic specimens, and the AlSi alloy in the diamond coating was dissolved in aqua regia to separate diamond particles. ZEISS Axio Vert.A1 optical microscope (OM, Carl Zeiss AG, Oberkochen, Germany) was used to observe the metallographic structure of the coating. ZEISS EVO-10 scanning electron microscope (SEM, Carl Zeiss AG, Oberkochen, Germany) with X-ray energy dispersive spectrometer (EDS, UltimMax 40, Oxford Instruments, Oxford city, U.K.) was applied to analyze the microstructure of the coating, Al12Si/Ti-6Al-4V boundary, and the worn surfaces of the specimens, and was also used to determine the element distribution in the braze coating. X-ray diffractometer (XRD, Bruker D8, Bruker Physik-AG, Saarbrücken, Germany) was used for phase analysis in the coatings. The X-ray wavelength was 1.54 Å (Cu Kα), the measuring range of diffraction angle 2θ was 10° to 100°, and the scanning speed was 4°/min. Raman spectrometer (inVia Reflex, Renishaw, Gloucestershire, U.K.) was used to determine the possible graphitization of diamond particles during the brazing process.

Vickers microhardness tester (HV-1000A, Huayin corporation, Laizhou city, China) was used to detect the hardness of specimens with a loading force of 0.49 N and a holding time of 15 s. The test points were selected at equal intervals, and the distance between the measurement points was 0.2 mm. MML-1G abrasive wear tester (Yihua Corporation, Jinan, China) was used to check the wear resistance of the coating with the corundum sand with an average particle size of 60 mesh. Under the loading force of 30 N, the specimens were pressed against the edge of the rubber wheel with rotating speed of 2.5 m s−1, and the corundum sand was conveyed between the sample and the rubber wheel at a feed rate of 4.6–5.0 g s−1, and the mass loss of the specimens was measured using an electronic balance with an accuracy of 0.1mg every 2 min.

3. Result and Discussion

3.1. The Wettability of Al12Si Alloy on Ti-6Al-4V Substrate and Diamond

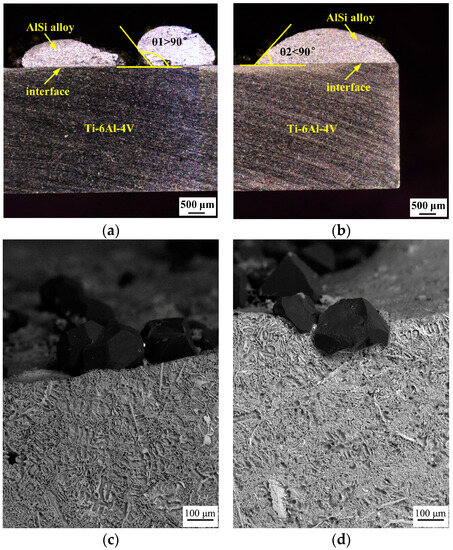

There was a tough and stable oxide film on the surface of the Ti-6Al-4V substrate, which hindered the brazing material from wetting the titanium alloy. Under vacuum or gas protection conditions, the wetting of Ti-6Al-4V alloy via aluminum-based brazing materials was mainly caused by the diffusion and dissolution of oxygen into the Ti-6Al-4V matrix, resulting in the removal of the oxide film from the surface [3]. When the solder spread on the solid surface of the substrate and kept a stable state, the contact angle θ formed between the molten solder and the substrate can be used to characterize the wetting ability. When θ remained stable above 90° without changing over time, it indicated that the molten solder could not wet the base material. When the molten solder liquid undergoes wetting and spreading on the surface of the base material, the contact angle θ gradually decreases to below 90° with time. The contact angles between AlSi solders and Ti-6Al-4V substrates formed without UAB and with UAB were measured using the cross-section pictures obtained via microscope, as presented in Figure 2a,b, respectively. Heating to 750 °C and under argon gas protection, only relying on the diffusion mechanism of the oxide film, the residual oxide film on the surface of the Ti-6Al-4V alloy still hindered the wetting of the AlSi solder on the surface of the titanium substrate, resulting in the molten solder forming an ellipsoidal shape, and the contact angle θ1 was 128°, as shown in Figure 2a. Under the heating temperature of 750 °C and ultrasonic vibration for 36 s, it can be seen that the spreading performance of the AlSi brazing material on the Ti-6Al-4V substrate surface was significantly improved, and the contact angle θ2 was 46°, which indicated that the brazing material formed a good wetting bond with the titanium substrate, as shown in Figure 2b. The mechanism was that the cavitation effect could effectively break the oxide film on the surface of the Ti-6Al-4V substrate, and the AlSi solder could be wetted spontaneously on the exposed fresh base metal. In Figure 2c, no spreading and climbing phenomenon of AlSi brazing material on the diamond was found, indicating poor wettability of AlSi filler metal on the diamond. Figure 2d shows that AlSi filler metal had a certain spreading and climbing phenomenon on the diamond surface, indicating a significant improvement in wettability between brazing material and diamond via UAB.

Figure 2.

The wettability of Al12Si alloy on Ti-6Al-4V substrate (a) without UAB and (b) with UAB; the wettability of Al12Si alloy on diamond particles (c) without UAB and (d) with UAB.

3.2. Characterization of the Diamond Composite Coatings

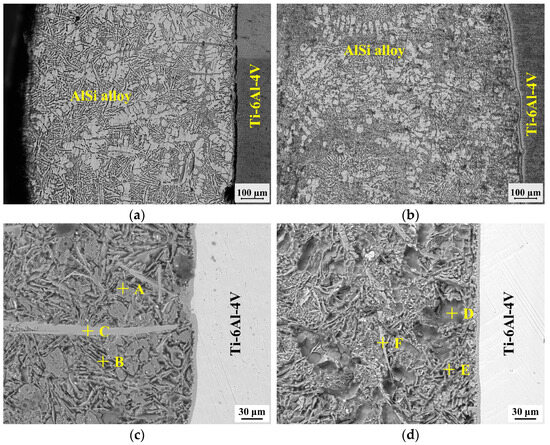

The OM morphology of diamond/AlSi composite coating without UAB is shown in Figure 3a. The composite coating was mainly composed of dendrites, a needle-like structure, and a long plate-like phase that grew from the Al12Si/Ti-6Al-4V interface. The OM morphology of diamond/AlSi composite coating with UAB is presented in Figure 3b. Under the action of ultrasound, the grain structure of the coating was obviously refined, and the long plate-like phase disappeared near the Al12Si/Ti-6Al-4V interface.

Figure 3.

OM images of diamond/AlSi coatings (a) without UAB and (b) with UAB; SEM microstructure of diamond/AlSi composite coatings (c) without UAB and (d) with UAB.

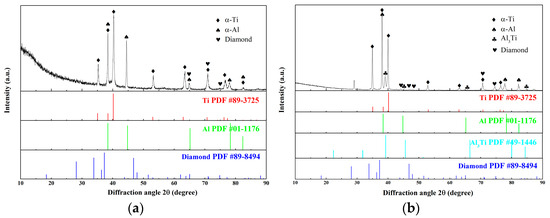

The high magnification SEM characterization of diamond/AlSi composite coating without UAB is presented in Figure 3c. According to the XRD results in Figure 4 and EDS analysis, as illustrated in Table 1, the dendrites crystals (label A) in the alloy matrix were mainly composed of ɑ-Al, while the dark needles (label B) were mainly eutectic Si phases. The long plate-like phase (label C) that appeared in the brazed joint has a composition of 62.9 at.% Al, 25.5 at.% Ti, and 12.5 at.% Si, which was marked as Ti (Al1−xSix)3 because the atomic radius of Ti (145 pm) was close to that of Si (134 pm), and Al atoms in the crystal lattice of TiAl3 can be replaced by Si atoms. The formation of Ti (Al1−xSix)3 was due to the dissolution of the Si atom, which changed the length/diameter ratio of TiAl3 at the interface of AlSi alloy and Ti-6Al-4V substrate [22].

Figure 4.

XRD patterns of diamond/AlSi coatings (a) without UAB and (b) with UAB.

Table 1.

EDS analysis of spots marked in Figure 3.

Figure 3d presents the microstructure of diamond/AlSi composite coating with UAB. Good metallurgical bonding had been formed between the coating alloy and Ti-6Al-4V substrate. Under the ultrasonic vibration, long plate-like phases disappeared, and needle-like phases composed of Eutectic Si (label E) and Ti (Al1−xSix)3 (label F) significantly increased in the coating alloy matrix. The absence of long plate-like Ti (Al1−xSix)3 in Figure 3d indicates that ultrasound had broken the directional growth trend of TiAl3 in the interface. The XRD pattern in Figure 4b proves that the TiAl3 generated via in situ reaction in coating alloy matrix, which inhibited the growth of ɑ-Al and played an important role in heterogeneous nucleation and grain refinement of alloy matrix.

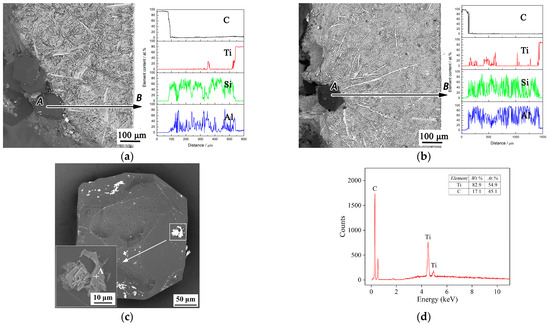

The line EDS profiles of the diamond/AlSi composite coatings without UAB and with UAB are shown in Figure 5a,b, respectively. Figure 5a shows that there was rarely a Ti element in AlSi alloy around diamond particles, which were embedded in the coating because the AlSi inactive alloy could not react metallurgically with diamond particles without the Ti element. As Figure 5b illustrates, the content of Ti element at the interface between the diamond particles and AlSi alloy increased significantly under ultrasonic action. The ultrasonic waves acted continually on the Ti-6Al-4V substrate, causing the Ti atoms to strip from the substrate. Ma et al. [23] pointed out that the movement direction of the liquid solder was the same as the surface tension waves formed via ultrasonic vibration, which propagated from the bottom to the top. The Ti atoms dispersed into the AlSi alloy and continued to diffuse upward with the direction of movement of the liquid filler alloy until they reached the diamond/AlSi brazing alloy interface. The AlSi alloy in the diamond coating was dissolved in aqua regia to separate diamond particles, which were determined using SEM. The results are presented in Figure 5c, which shows that there were some bright phases on the surface of the diamond particle in Figure 5b. Figure 5d presents the EDS analysis results of the bright phases on the diamond. According to the results of the EDS analysis, the ratio of the number of carbon atoms to the number of titanium atoms in the physical state of the particle marked A was 1:1, which indicated that the particles on the diamond were TiC carbides. At 750 °C, the Gibbs free energy of TiC (−173.1 kJmol−1) was negative [24], which indicated that the reaction could occur spontaneously under experimental conditions.

Figure 5.

BSE images and EDS line scan along lines A to B of diamond/AlSi coatings (a) without UAB and (b) with UAB; (c) SEM image of diamond from (b); (d) EDS analysis result of point A in (c).

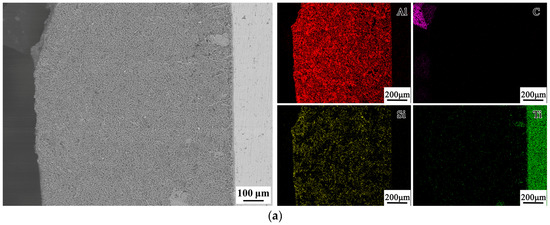

Figure 6 shows the distribution of the elements in the coatings before and after ultrasonic action. Without UAB, the element Ti was mainly distributed near the interface of the AlSi alloy/Ti-6Al-4V substrate, as shown in Figure 6a. As shown in Figure 6b, the distribution quantity and range of element Ti in the coating alloy were more obviously improved with UAB.

Figure 6.

(a) BSE image of the cross-section of the diamond/AlSi coating without UAB and corresponding EDS mapping; (b) BSE image of the cross-section of the diamond/AlSi coating with UAB and corresponding EDS mapping.

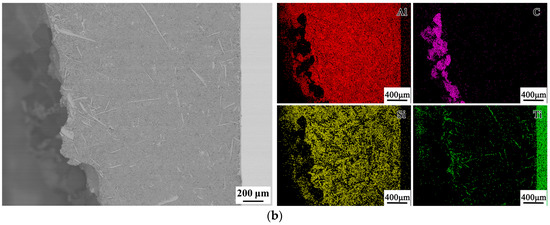

The diffusion and reaction mechanism of element Ti in the solder under ultrasonic action is shown in Figure 7. Ti, as an active element, is the key to achieving metallurgical bonding between diamond and brazing alloy. As shown in Figure 7a, without the application of ultrasound, Ti atoms in the Ti-6Al-4V substrate dissolved and reacted with AlSi solder to generate Ti7Al5Si12 [25], which was randomly distributed in the coating. As the distance from the Ti-6Al-4V substrate increased, the content of Ti atoms in the corresponding region gradually decreased. The solubility of element Ti in AlSi brazing material was low, and, in addition, diamond particles floated up to the surface of the brazing coating due to their low density and were at the farthest distance from the Ti-6Al-4V substrate. It was difficult to reach the vicinity of diamond particles and react with them via long-range diffusion under heating conditions alone. Therefore, it was difficult for diamond particles to form metallurgical bonding with the inactive AlSi alloy in the coating without the ultrasound action. As shown in Figure 7b, the cavitation and acoustic streaming generated via ultrasound accelerated the dissolution of the titanium alloy substrate in liquid AlSi brazing material. At the same time, during the propagation process of the liquid AlSi medium, the Ti atoms in the titanium substrate were transferred to the vicinity of diamond particles. On the other hand, utilizing the cavitation effect generated via the ultrasound promoted the metallurgical bonding of element Ti with diamond at lower temperatures.

Figure 7.

The diffusion and reaction mechanism of element Ti in AlSi solder (a) without UAB and (b) with UAB.

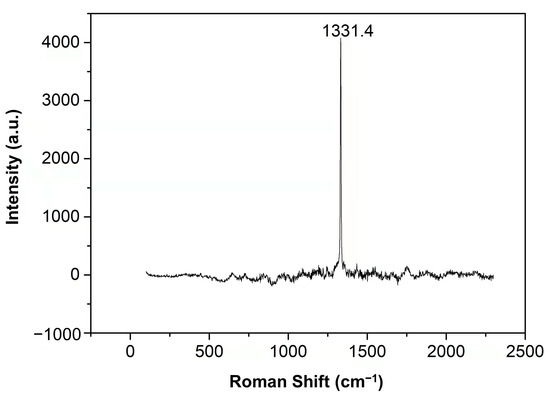

3.3. Raman Spectra Analysis

Raman spectroscopy was used to determine whether the diamond was carbonized during the heating process. The peak of the Raman spectrum of diamond can be divided into three regions [26]: (1) the Raman scattering peak of diamond crystal structure is distributed around 1332.5 cm−1, (2) the Raman scattering peak of graphite structure is usually distributed around 1580 cm−1, and (3) in the range of 1350–1600 cm−1, an amorphous carbon component of sp2 hybrid phase may appear. It was also reported by Long et al. [16] that the characteristic peak of the Raman spectrum at 1331.7 cm−1 indicated the existence of a diamond. The Raman scatting spectrum of the brazed diamond, as presented in Figure 8, shows that the peak value of Raman scattering was 1331.4 cm−1, and the single characteristic peak of the diamond indicated that there was no diamond thermal damage when the brazing temperature was 750 °C. In addition, Al, Si, and Ti are not diamond catalyst elements and will not make diamond carbonization during heating.

Figure 8.

Raman scatting spectrum of brazed diamond.

3.4. Wear Behavior Mechanism of the Composite Coatings

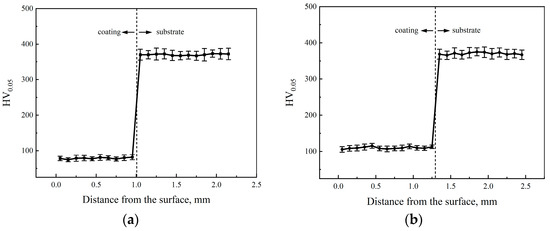

The microhardness of diamond/AlSi coatings without and with UAB is shown in Figure 9. It can be seen that the average microhardness of the coating alloy matrix without UAB (Figure 9a) was about 75 HV0.05, which was lower than that of 110 HV0.05 with UAB (Figure 9b). The average microhardness of Ti-6Al-4V substrates without and with UAB was 370 HV0.05, which showed that the application of ultrasound had no obvious effect on the microhardness of the Ti-6Al-4V substrates. Therefore, the microhardness of the coating alloy matrix was increased due to the UAB, which increased the quantity and distribution range of TiAl3 (448.5 HV [27]) as reinforced particles and made the alloy matrix structure refined. The number of grain boundaries increased with the grain refinement of the alloy matrix, which promoted the strength and hardness of the coating matrix.

Figure 9.

The microhardness of diamond/AlSi coatings (a) without UAB and (b) with UAB.

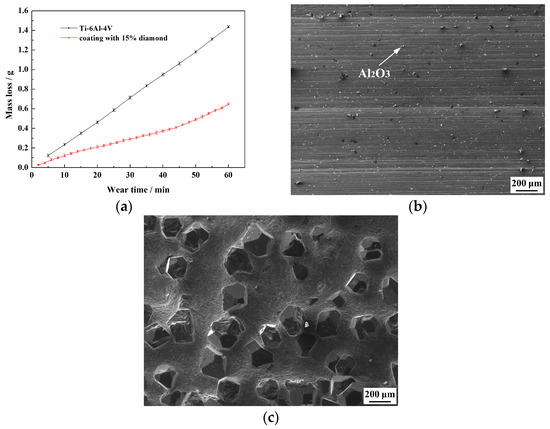

The mass loss comparison of the Ti-6Al-4V alloy and diamond/AlSi coating is shown in Figure 10a. The results illustrate that the diamond/AlSi composite coating has a superior wear resistance to the Ti-6Al-4V alloy due to the dense diamond particles providing protection for the alloy matrix. As seen in Figure 10b, Al2O3 particles produced deep and continuous furrows on the Ti-6Al-4V alloy, which indicated that the type of wear was mainly abrasive wear. Because the hardness of Al2O3 abrasives was much higher than that of Ti-6Al-4V alloy, in the grinding process, the edges and corners of abrasive particles penetrated the surface of the alloy matrix under the action of normal component, while the tangential component caused the pierced hard particles to make tangential cutting motion, resulting in furrows on the surface of Ti-6Al-4V substrate. Figure 10c shows that the AlSi coating alloy between the diamond particles was slightly worn in the area with dense diamond particles, indicating that diamond particles played an important anti-wear role in the wear process, which greatly resisted the damage caused by the micro-cutting of the Al2O3 particles and prolonged the wear life of the coating.

Figure 10.

(a) Mass loss comparison of Ti-6Al-4V alloy and diamond/AlSi coating. The micro-morphologies of worn surface of (b) Ti-6Al-4V alloy and (c) diamond/AlSi coating with UAB.

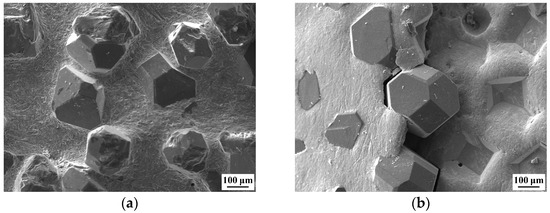

Figure 11 shows the micro-morphologies of the worn surfaces of diamond particles. In the process of abrasive wear, the failure of diamond composite coating can be divided into two stages. The first stage was that the diamond particles were crushed via the continuous sliding and scratching of corundum abrasive. When the load stress exceeded the critical fracture strength of the diamond, the cracks appeared, extended, and increased on the surface of the diamond particles, and the diamond particles finally crashed into fragments, as shown in Figure 11a. The abrasive wear of the coating matrix was aggravated via the stripped small diamond particles, and the loss of coating alloy increased the exposed height of a diamond, which further reduced the bonding strength between diamond particles and brazing alloy. The second stage was that the diamond particles were pulled out via the corundum abrasive, as shown in Figure 11b. The reason for that was the coating alloy was seriously worn when a large number of diamond particles were ground flat, and the diamond particles in the coating became loose due to the loss of support from the brazing alloy and detached from the coating surface under the action of friction force. In addition, the bonding strength of diamond particles and matrix was closely related to the active element Ti and the ultrasonic vibration. Huang et al. [15] reported that the average shear force of the brazed joints obtained via UAB was increased by 28.5% than without UAB. The higher the shear force of the brazed joints, the more difficult the diamond particle to be pulled out.

Figure 11.

The micro-morphologies of the worn surfaces of diamond particles: (a) cracked diamond particles and (b) diamond particles were ground flat and fell off.

4. Conclusions

UAB technology has been introduced to prepare the diamond/AlSi composite coating on the Ti-6Al-4V substrate. The effect of UAB on the microstructure and wear property of the coating were studied. The following conclusions can be drawn:

- (1)

- AlSi filler metal had a certain spreading and climbing phenomenon on the surfaces of diamond particles, indicating a significant improvement in the wettability between AlSi filler metal and diamond particles via UAB.

- (2)

- Under ultrasound action, the microstructure of AlSi brazing alloy was greatly refined, and the Ti atoms in the Ti-6Al-4V substrate diffused to the interface between diamond and AlSi brazing alloy and formed TiC on diamond particles. There was no thermal damage to diamond particles when the brazing temperature was 750 °C.

- (3)

- UAB improved the microhardness of the coating alloy matrix due to the increasing quantity and distribution range of TiAl3 as reinforced particles. The wear resistance of the Ti-6Al-4V substrate with diamond/AlSi composite coating was promoted due to the dense diamond particles, the formed TiC on diamond particles, and the increase in microhardness of the matrix of diamond/AlSi coating.

- (4)

- In the early wear stages, the diamond particles were crushed via the continuous sliding and scratching of the corundum abrasive. In the later wear stages, the diamond particles were pulled out via the corundum abrasive due to the loss of support from the coating alloy.

Author Contributions

Conceptualization, L.Z. and W.L.; methodology, L.Z., W.L. and D.D.; validation, Z.F.; formal analysis, C.J., X.J. and Z.F.; investigation, L.Z., Z.F. and W.L.; data curation, D.D. and C.J.; writing—original draft preparation, L.Z., C.J. and W.L.; writing—review and editing, L.Z. and W.L.; visualization, X.J. and C.J.; supervision, W.L. and D.D.; project administration, W.L. and L.Z.; funding acquisition, L.Z. and W.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by “Pioneer” and “Leading Goose” R&D Program of Zhejiang (No. 2022C01187) and the National Key Research and Development Program of China (No. 2021YFB3401100).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhao, Q.; Sun, Q.; Xin, S.; Chen, Y.; Wu, C.; Wang, H.; Xu, J.; Wan, M.; Zeng, W.; Zhao, Y. High-strength titanium alloys for aerospace engineering applications: A review on melting-forging process. Mat. Sci. Eng. A. 2022, 845, 143260. [Google Scholar] [CrossRef]

- Xie, R.; Lin, N.; Zhou, P.; Zou, J.; Han, P.; Wang, Z.; Tang, B. Surface damage mitigation of TC4 alloy via micro arc oxidation for oil and gas exploitation application: Characterizations of microstructure and evaluations on surface performance. Appl. Surf. Sci. 2018, 436, 467–476. [Google Scholar] [CrossRef]

- Jiang, J.; Han, G.; Zheng, X.; Chen, G.; Zhu, P. Characterization and biocompatibility study of hydroxyapatite coating on the surface of titanium alloy. Surf. Coatings Technol. 2019, 375, 645–651. [Google Scholar] [CrossRef]

- Richard, C.; Kowandy, C.; Landoulsi, J.; Geetha, M.; Ramasawmy, H. Corrosion and wear behavior of thermally sprayed nano ceramic coatings on commercially pure Titanium and Ti-13Nb-13Zr substrates. Int. J. Refract. Met. Hard Mater. 2010, 28, 115–123. [Google Scholar] [CrossRef]

- Agullo, J.; Bataillon, C.; Roy, M. Electrochemical dissolution of magnetite electroplated coatings on titanium. Electrochim. Acta 2018, 260, 890–897. [Google Scholar] [CrossRef]

- Weng, F.; Chen, C.; Yu, H. Research status of laser cladding on titanium and its alloys: A review. Mater. Design 2014, 58, 412–425. [Google Scholar] [CrossRef]

- Luo, X.; Wu, S.; Yang, Y.; Jin, N.; Liu, S.; Huang, B. Deposition of titanium coating on SiC fiber by chemical vapor deposition with Ti-I2 system. Appl. Surf. Sci. 2017, 406, 62–68. [Google Scholar] [CrossRef]

- Zhang, M.; Li, X.; Mao, C.; Hu, Y.; Li, K.; Zhang, J.; Tang, K.; Bi, Z. Microstructure and properties at bonds of diamond grains and NiCr filler alloy by fiber laser brazing. Diam. Relat. Mater. 2022, 125, 108969. [Google Scholar] [CrossRef]

- Duan, D.; Han, F.; Ding, J.; Lin, Q.; Li, C.; Wang, C.; Jiang, Z. Microstructure and performance of brazed diamonds with multilayer graphene-modified Cu-Sn-Ti solder alloys. Ceram. Int. 2021, 47, 22854–22863. [Google Scholar] [CrossRef]

- Huang, G.; Wang, Y.; Zhang, M.; Cui, C.; Tong, Z. Brazing diamond grits onto AA7075 aluminium alloy substrate with Ag-Cu-Ti filler alloy by laser heating. Chin. J. Aeronaut. 2021, 34, 67–78. [Google Scholar] [CrossRef]

- Long, W.; Liu, D.; Dong, X.; Wu, A. Laser power effects on properties of laser brazing diamond coating. Surf. Eng. 2020, 36, 1315–1326. [Google Scholar] [CrossRef]

- Mishra, S.; Sharma, A.; Jung, D.; Jung, J. Recent Advances in Active Metal Brazing of Ceramics and Process. Met. Mater. Int. 2020, 26, 1087–1098. [Google Scholar] [CrossRef]

- Sharma, A.; Ahn, B. Vacuum brazing of Al2O3 and 3D printed Ti6Al4V lap-joints using high entropy driven AlZnCuFeSi filler. Sci. Rep. 2021, 11, 9345. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Sharma, A.; Jung, D.; Jung, J. Influence of Arc Brazing Parameters on Microstructure and Joint Properties of Electro-Galvanized Steel. Metals 2019, 9, 1006. [Google Scholar] [CrossRef]

- Yin, X.; Xu, F.; Min, C.; Cheng, Y.; Dong, X.; Cui, B.; Xu, D. Promoting the bonding strength and abrasion resistance of brazed diamond using Cu-Sn-Ti composite alloys reinforced with tungsten carbide. Diam. Relat. Mater. 2021, 112, 108239. [Google Scholar] [CrossRef]

- Long, W.; Liu, D.; Wu, A.; Wang, D.; Huang, G. Influence of laser scanning speed on the formation property of laser brazing diamond coating. Diam. Relat. Mater. 2020, 110, 108085. [Google Scholar] [CrossRef]

- Zhao, J.; Guo, M.; Hu, S.P.; Lei, Y.Z.; Song, X.G.; Liu, D.; Long, W.; Yu, Z. Brazing of large synthetic diamond grits using graphene nanoplatelets reinforced NiCr composite fillers. Diam. Relat. Maert. 2020, 109, 108004. [Google Scholar] [CrossRef]

- Zhang, C.; Ji, H.; Xu, H.; Liang, M.; Huang, J.; Pei, S.; Li, M. Interfacial microstructure and mechanical properties of ultrasonic-assisted brazing joints between Ti-6Al-4V and ZrO2. Ceram. Int. 2020, 46, 7733–7740. [Google Scholar] [CrossRef]

- Huang, G.; Huang, J.; Zhang, M.; Mu, D.; Zhou, G.; Xu, X. Fundamental aspects of ultrasonic assisted induction brazing of diamond onto 1045 steel. J. Mater. Process. Technol. 2018, 260, 123–136. [Google Scholar] [CrossRef]

- Chen, X.; Yan, J.; Ren, S.; Wei, J.; Wang, Q. Ultrasonic-assisted brazing of SiC ceramic to Ti-6Al-4V alloy using a novel AlSnSiZnMg filler metal. Mater. Lett. 2013, 105, 120–123. [Google Scholar] [CrossRef]

- Zhang, M.; Li, K.; Huang, Y.; Hu, Y.; Mao, C.; Zhang, J.; Tong, Y.; Bi, Z. Impact of ultrasonic vibration on microstructure and mechanical properties of diamond in laser brazing with Ni-Cr filler alloy. Ceram. Int. 2022, 48, 4096–4104. [Google Scholar] [CrossRef]

- Gao, T.; Liu, G.; Liu, X. Compositions and morphologies of TiAlSi intermetallics in different diffusion couples. Mater. Charact. 2014, 95, 285–290. [Google Scholar] [CrossRef]

- Ma, L.; Xu, Z.; Zheng, K.; Yan, J.; Yang, S. Vibration characteristics of aluminum surface subjected to ultrasonic waves and their effect on wetting behavior of solder droplets. Ultrasonics 2014, 54, 929–937. [Google Scholar] [CrossRef] [PubMed]

- Barin, I. Thermochemical Data of Pure Substances, 3rd ed.; VCH Verlagsgesellschaft Mbh: Weinheim, Germany, 1995; pp. 1674–1675. [Google Scholar]

- Chen, S.; Li, L.; Chen, Y.; Huang, J. Joining mechanism of Ti/Al dissimilar alloys during laser welding-brazing process. J. Alloys Compd. 2011, 509, 891–898. [Google Scholar] [CrossRef]

- Cheng, W.; Liu, Z.; Lin, Q.; Huang, G.; Xu, X.; Huang, H.; Mu, D. Towards tailorable interface microstructure through Solid-state interface reaction between synthetic diamond grits and sputtered Ni-Cr binary alloy. Appl. Surf. Sci. 2022, 596, 153531. [Google Scholar] [CrossRef]

- Qin, J.; Chen, G.; Wang, B.; Du, Z. Formation of in-situ Al3Ti particles alloy melt from globular Ti powders and Al under ultrasonic vibration. J. Alloys Compd. 2015, 653, 32–38. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).