Insights into Interfacial Features of Metal/Eco-Composites Designed for Energy Storage

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

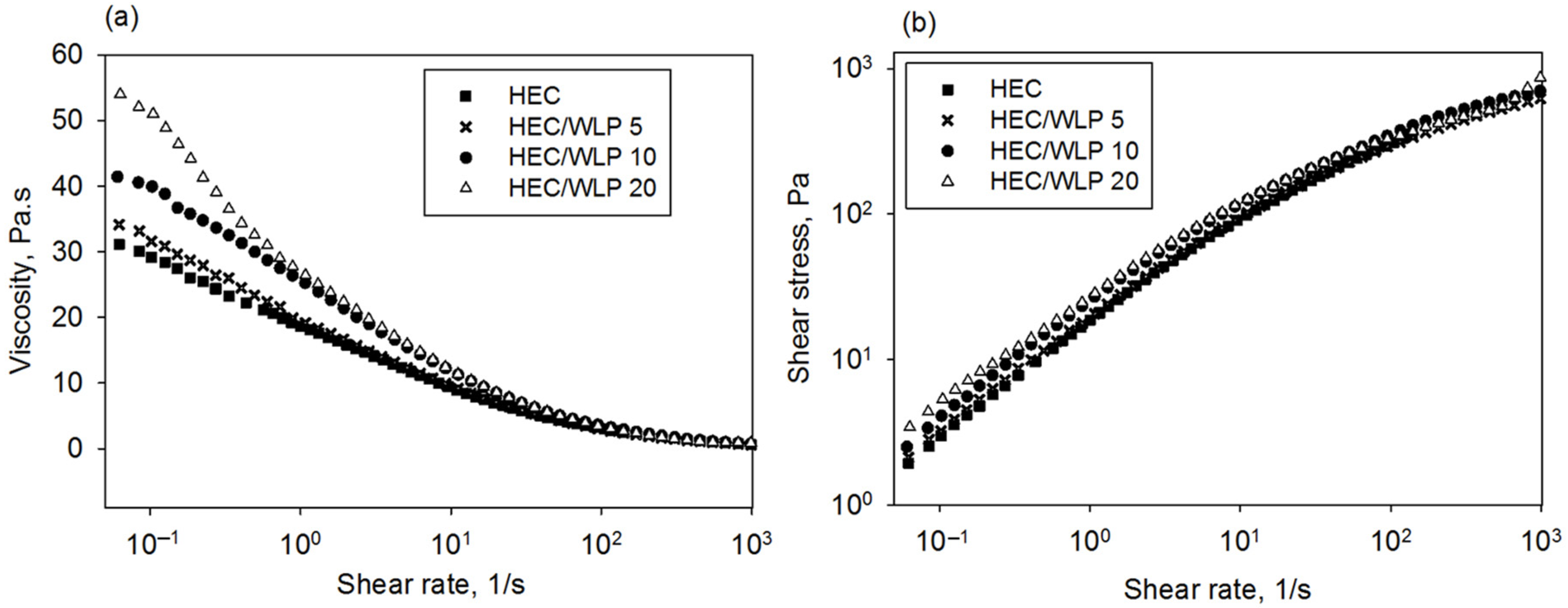

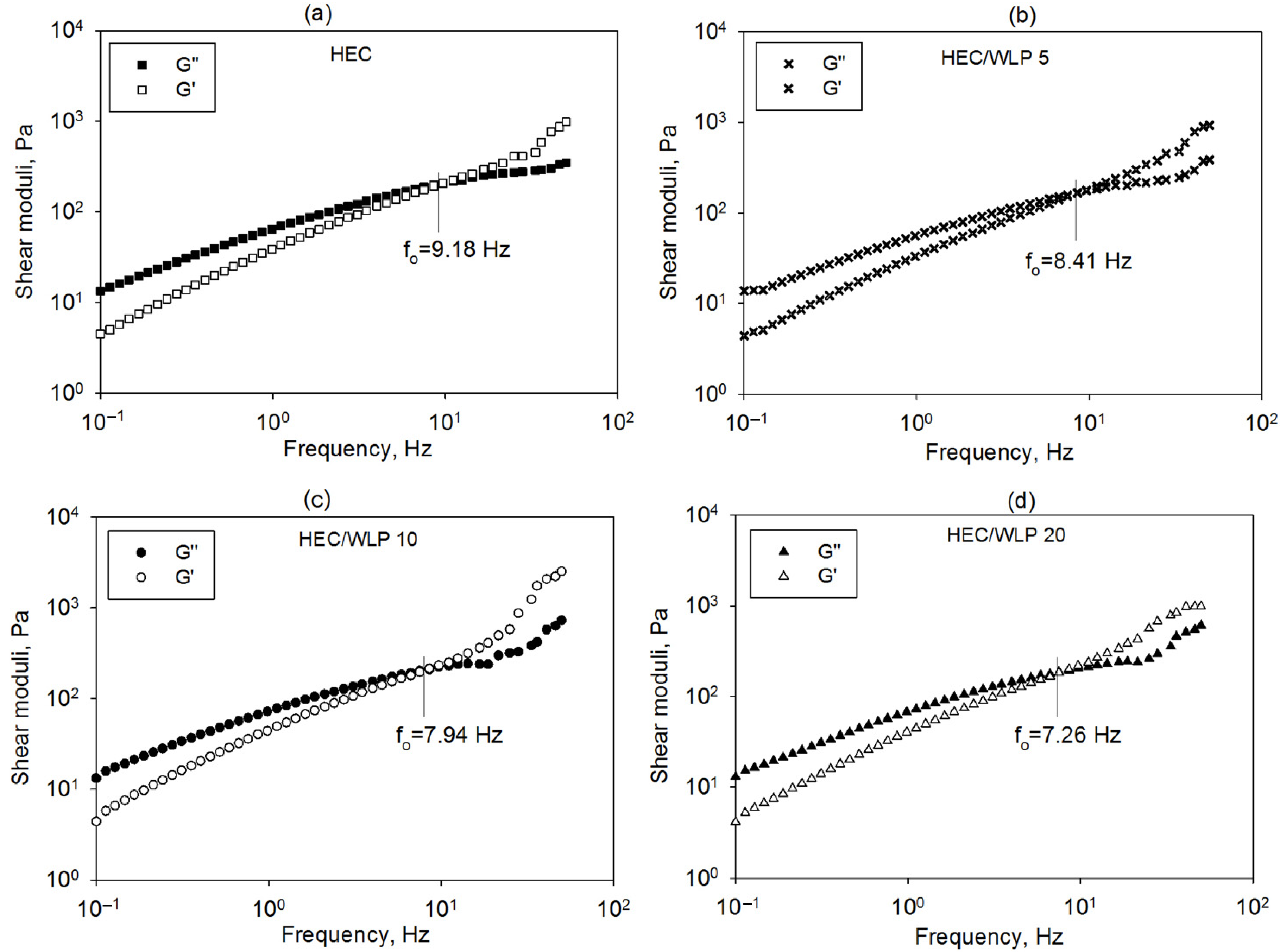

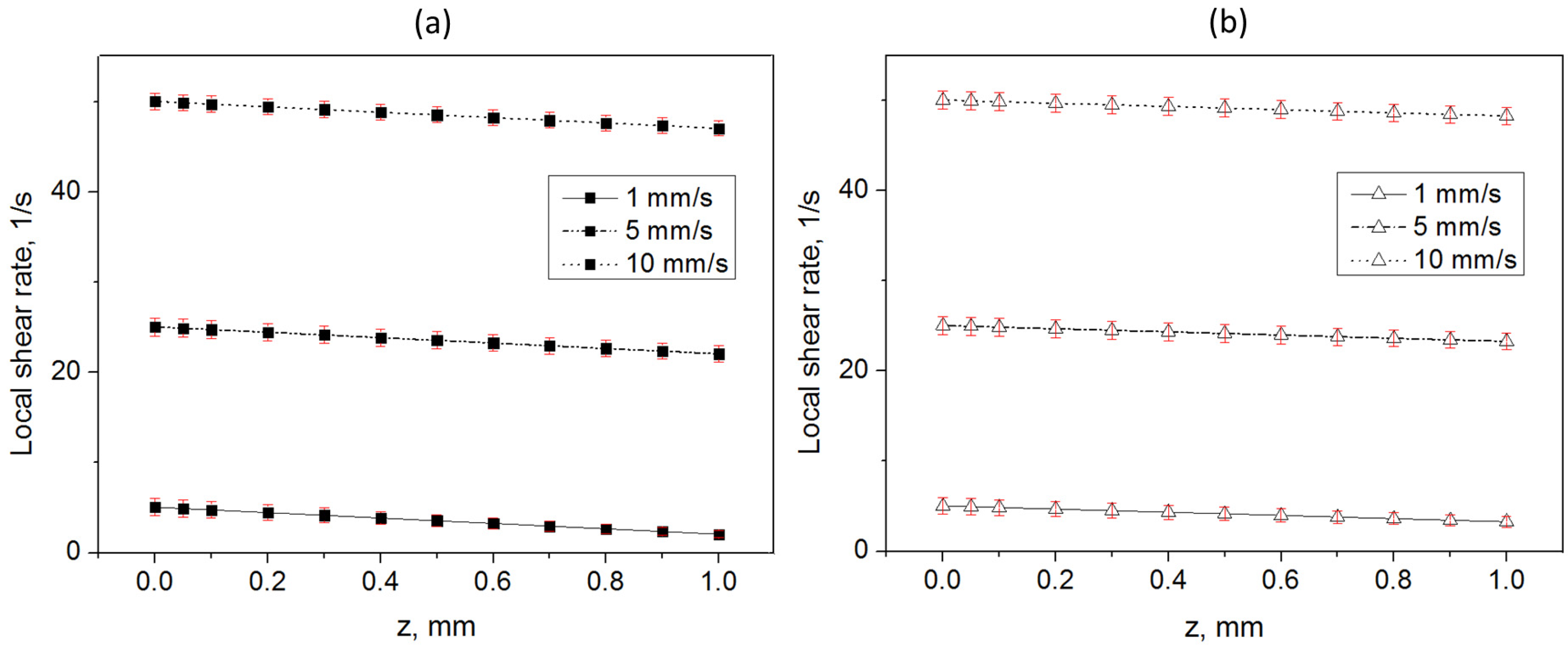

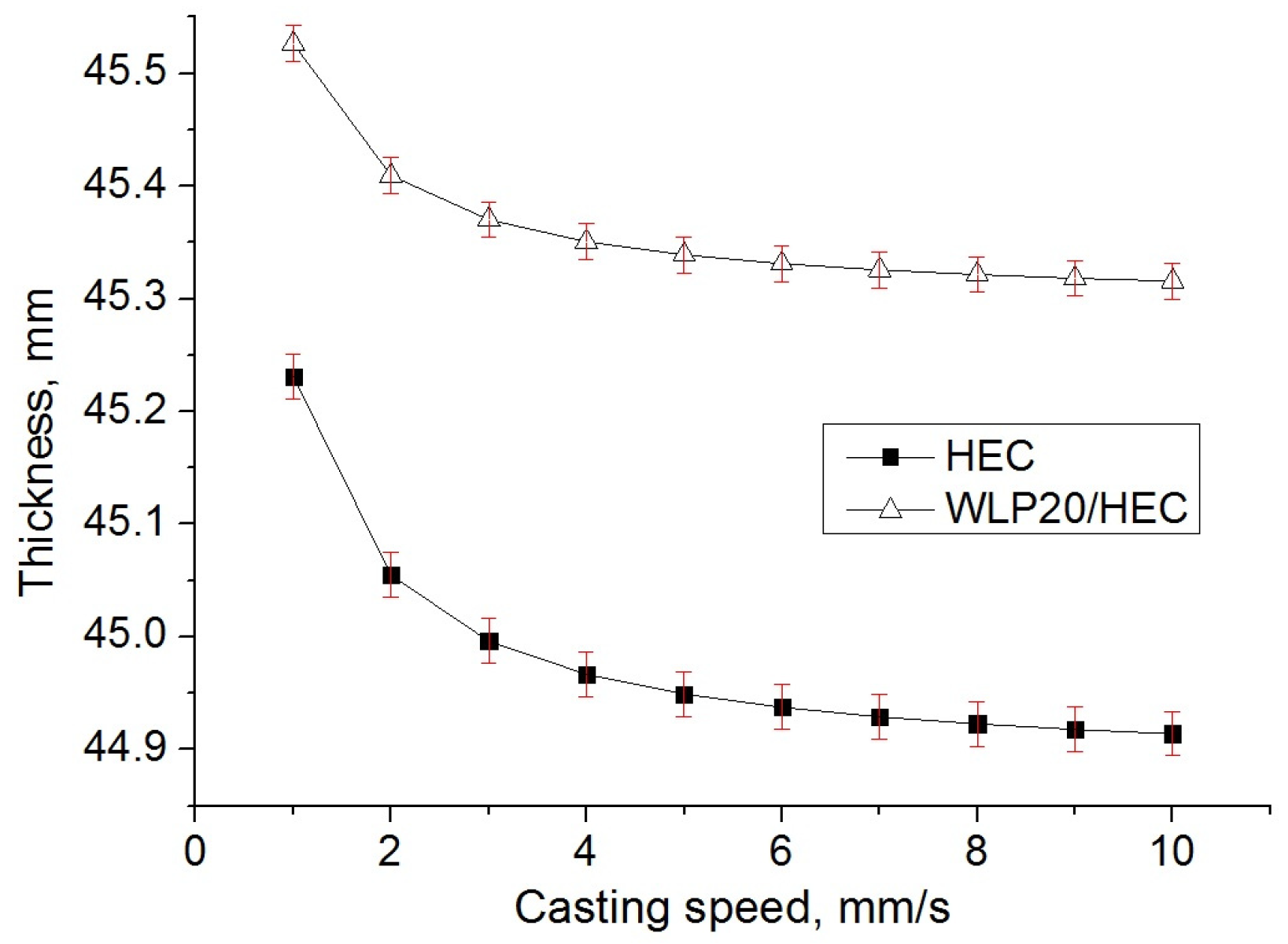

3.1. The Influence of Shear Flow Behavior on Coating Uniformity

3.2. Interfacial Adhesion with the Metal Layer

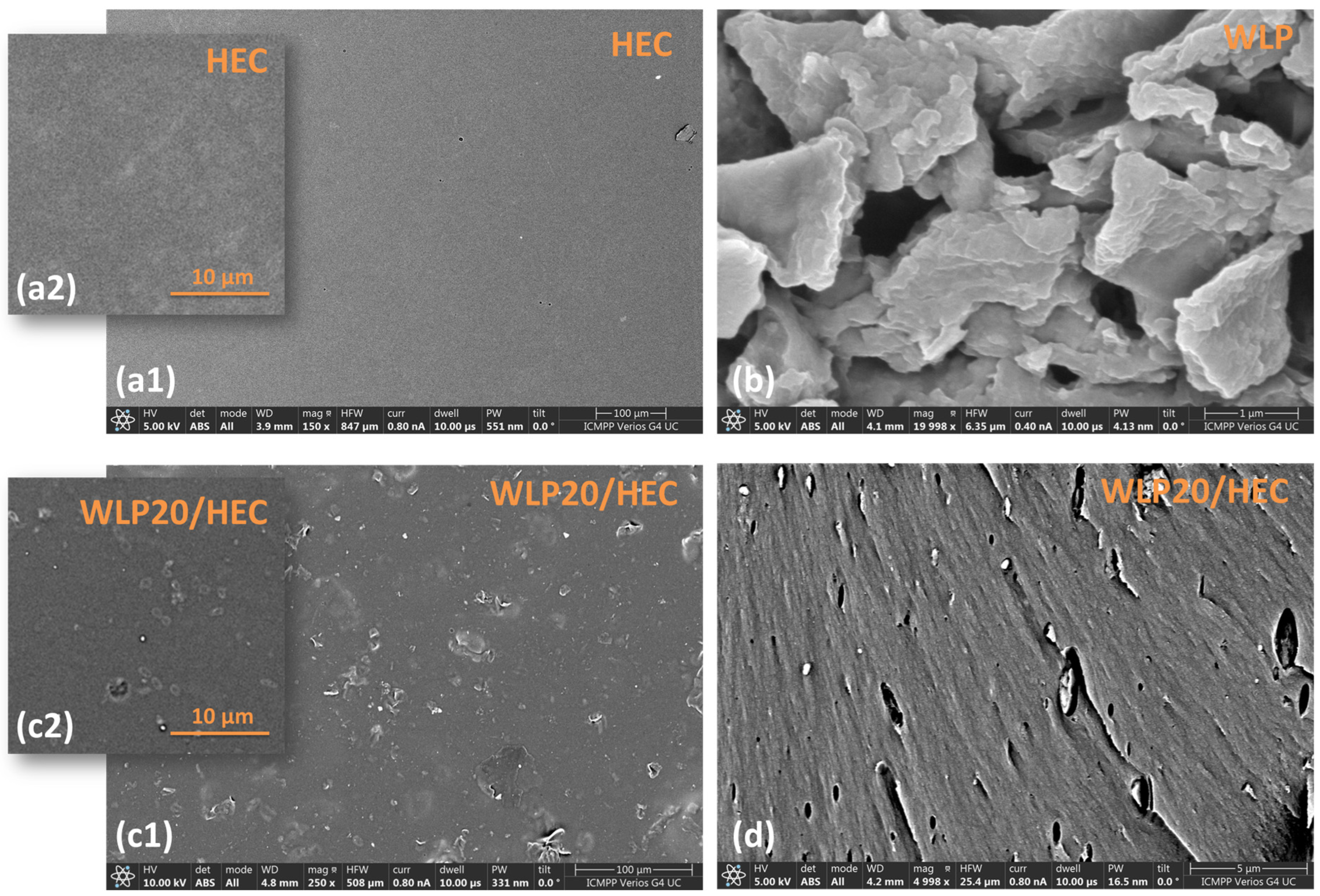

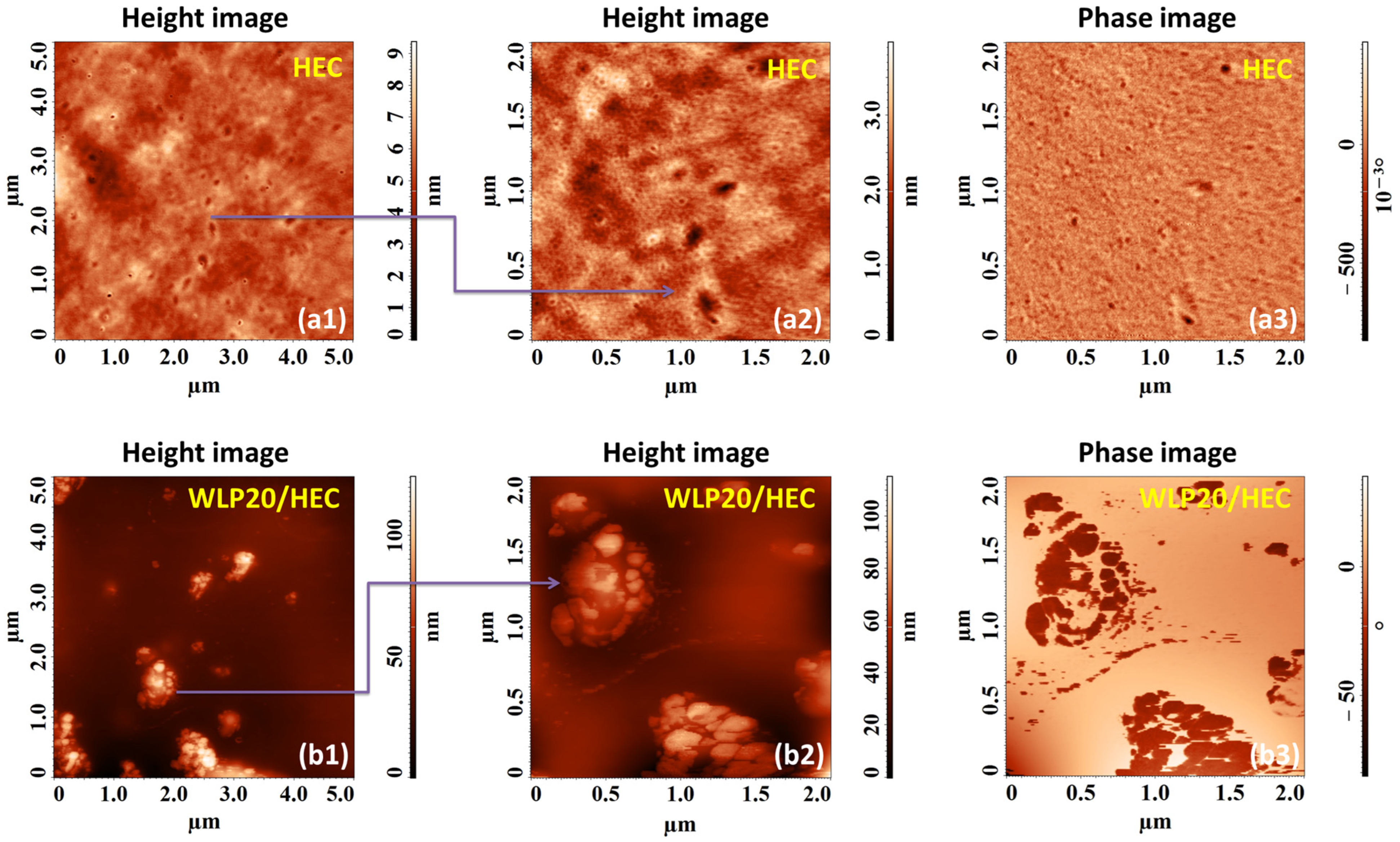

3.3. Morphology and Local Adhesion Features

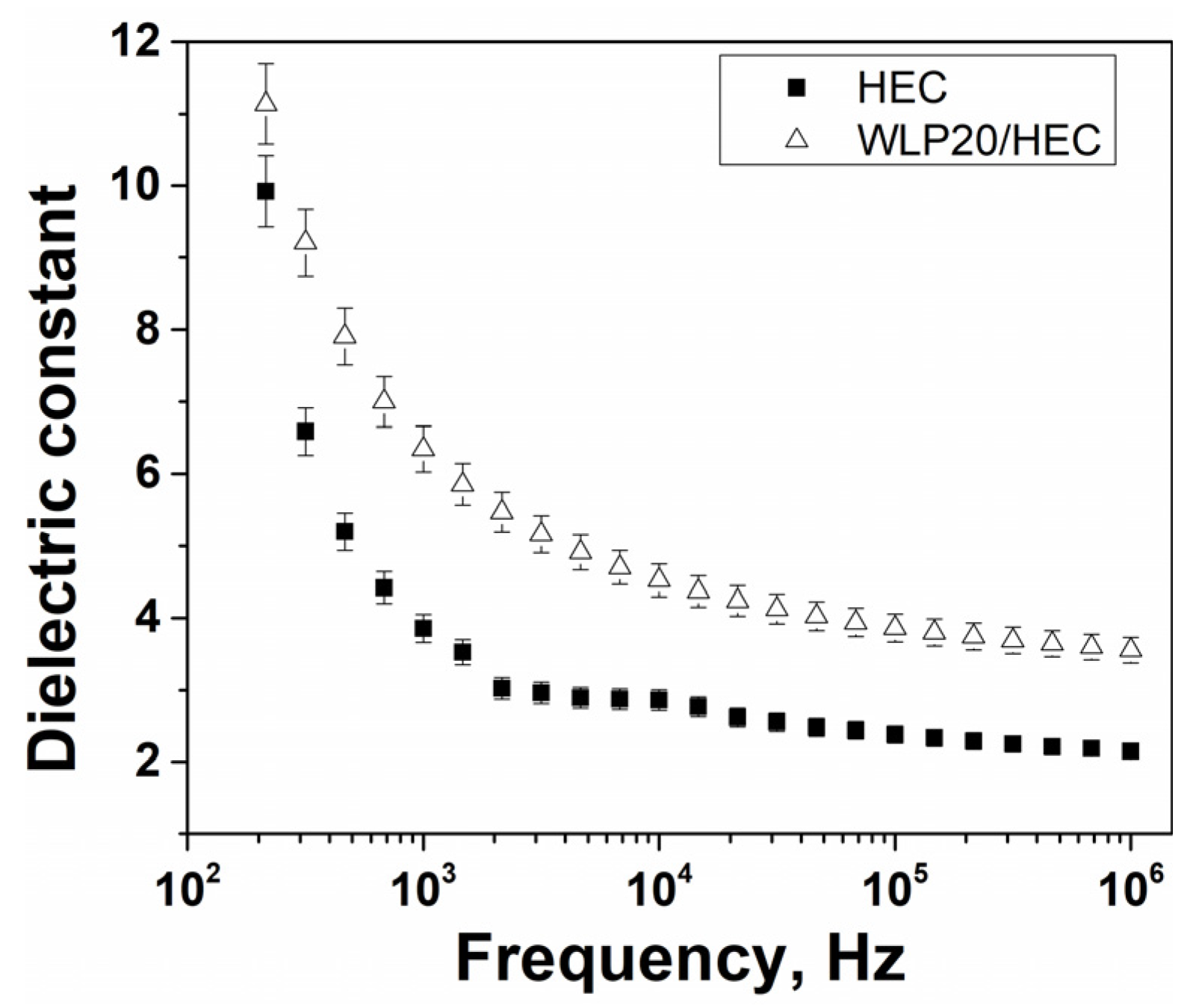

3.4. Dielectric Behavior

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Smith, J.R.; Lamprou, D.A. Polymer coatings for biomedical applications: A review. Trans. IMF 2014, 92, 9–19. [Google Scholar] [CrossRef]

- Sun, W.; Liu, W.; Wu, Z.; Chen, H. Chemical Surface Modification of Polymeric Biomaterials for Biomedical Applications. Macromol. Rapid Commun. 2020, 41, 1900430. [Google Scholar] [CrossRef] [PubMed]

- Barzic, A.I.; Albu, R.M.; Stoica, I.; Hulubei, C. New shielding covers based on transparent polyimide/ferrous sulfide composites that reduce optical losses in solar cells. Compos. Sci. Technol. 2022, 218, 109140. [Google Scholar] [CrossRef]

- Albu, R.M.; Avram, E.; Stoica, I.; Ioanid, E.G.; Ioan, S. Miscibility and morphological properties of quaternized polysulfone blends with polystyrene and poly(4-vinylpyridine). Polym. Compos. 2011, 32, 1661–1670. [Google Scholar] [CrossRef]

- Fang, Q.; Lafdi, K. Effect of nanofiller morphology on the electrical conductivity of polymer nanocomposites. Nano Express 2021, 2, 010019. [Google Scholar] [CrossRef]

- Barzic, R.F.; Barzic, A.I.; Dumitrascu, G. Percolation network formation in poly(4-vinylpyridine)/aluminum nitride nanocomposites: Rheological, dielectric, and thermal investigations. Polym. Compos. 2014, 35, 1543–1552. [Google Scholar] [CrossRef]

- Zhou, T.; Zha, J.-W.; Cui, R.-Y.; Fan, B.-H.; Yuan, J.-K.; Dang, Z.-M. Improving Dielectric Properties of BaTiO3/Ferroelectric Polymer Composites by Employing Surface Hydroxylated BaTiO3 Nanoparticles. ACS Appl. Mater. Interfaces 2011, 3, 2184–2188. [Google Scholar] [CrossRef]

- Zha, J.-W.; Zheng, M.-S.; Fan, B.-H.; Dang, Z.-M. Polymer-based dielectrics with high permittivity for electric energy storage: A review. Nano Energy 2021, 89, 106438. [Google Scholar] [CrossRef]

- Barzic, A.I.; Soroceanu, M.; Rotaru, R.; Doroftei, F.; Asandulesa, M.; Tugui, C.; Dascalu, I.A.; Harabagiu, V. Cellulose derivative/barium titanate composites with high refractive index, conductivity and energy density. Cellulose 2022, 29, 863–878. [Google Scholar] [CrossRef]

- Wen, F.; Zhu, C.; Li, L.; Zhou, B.; Zhang, L.; Han, C.; Li, W.; Yue, Z.; Wu, W.; Wang, G.; et al. Enhanced energy storage performance of polymer nanocomposites using hybrid 2D ZnO@MoS2 semiconductive nano-fillers. Chem. Eng. J. 2022, 430, 132676. [Google Scholar] [CrossRef]

- Li, S.; Dong, J.; Niu, Y.; Li, L.; Wang, F.; Hu, R.; Cheng, J.; Sun, L.; Pan, Z.; Xu, X.; et al. Enhanced high-temperature energy storage properties of polymer composites by interlayered metal nanodots. J. Mater. Chem. A 2022, 10, 18773–18781. [Google Scholar] [CrossRef]

- Han, Q.; Sheng, Y.; Liu, X.; Zhang, X.; Chen, X.; Li, B.; Han, Z. Carbon fiber reinforced epoxy composite combining superior electrochemical energy storage and mechanical performance. Chem. Eng. J. 2022, 437, 135228. [Google Scholar] [CrossRef]

- Almeida, G.N.; de Souza, R.N.; Lima, L.F.S.; Mohallem, N.D.S.; da Silva, E.P.; Silva, A.M.A. The Influence of the Synthesis Method on the Characteristics of BaTiO3. Materials 2023, 16, 3031. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.-Y.; Chang, C.-W. Dielectric Constant Enhancement with Low Dielectric Loss Growth in Graphene Oxide/Mica/Polypropylene Composites. J. Compos. Sci. 2021, 5, 52. [Google Scholar] [CrossRef]

- Pihtili, G.; Torğut, G.; Biryan, F. Electrical properties of two-armed poly(ε-CL-co-BMA) composites filled with bentonite. J. Polym. Res. 2020, 27, 156. [Google Scholar] [CrossRef]

- Maw, A.M.; Theingi, M.; Yee, K.T. A Study on the Dielectric Properties of Polypyrrole-Bentonite Composites. J. Myanmar Acad. Arts Sci. 2019, XVII, 581–598. [Google Scholar]

- Elloumi, I.; Koubaa, A.; Kharrat, W.; Bradai, C.; Elloumi, A. Dielectric Properties of Wood-Polymer Composites: Effects of Frequency, Fiber Nature, Proportion, and Chemical Composition. J. Compos. Sci. 2021, 5, 141. [Google Scholar] [CrossRef]

- Tiwari, M. Dielectric Investigations in Iodine Doped Polystyrene Thin Films. Int. J. Adv. Res. Sci. Commun. Technol. 2020, 11, 179–183. [Google Scholar] [CrossRef]

- Matławska, I.; Bylka, W.; Widy-Tyszkiewicz, E.; Stanisz, B. Determination of the Juglone Content of Juglans regia Leaves by GC/MS. Nat. Prod. Commun. 2015, 10, 1239–1242. [Google Scholar] [CrossRef]

- Noreen, A.; Zia, K.M.; Tabasum, S.; Khalid, S.; Shareef, R. A review on grafting of hydroxyethylcellulose for versatile applications. Int. J. Biol. Macromol. 2020, 150, 289–303. [Google Scholar] [CrossRef]

- Huang, J.; Hua, L.; Song, L.; Li, J.; E., S.; Lu, Z. Hydroxyethyl cellulose/boron nitride nanosheet films coated with silver nanowires for electronic packaging applications. Mater. Today Sustain. 2023, 21, 100307. [Google Scholar] [CrossRef]

- Azha, M.A.S.; Dannoun, E.M.A.; Aziz, S.B.; Kadir, M.F.Z.; Zaki, Z.I.; El-Bahy, Z.M.; Sulaiman, M.; Nofal, M.M. High Cyclability Energy Storage Device with Optimized Hydroxyethyl Cellulose-Dextran-Based Polymer Electrolytes: Structural, Electrical and Electrochemical Investigations. Polymers 2021, 13, 3602. [Google Scholar] [CrossRef] [PubMed]

- Chavan, C.; Bhajantri, R.F.; Cyriac, V.; Ismayil; Bulla, S.S.; Sakthipandi, K. Investigations on anomalous behavior of ionic conductivity in NaPF6 salt loaded hydroxyethyl cellulose biodegradable polymer electrolyte for energy storage applications. Polym. Adv. Technol. 2023, 34, 1698–1715. [Google Scholar] [CrossRef]

- Kim, E.-K.; Chang, H.S.; Lee, B.-M.; Park, J.-J.; Yun, J.-M.; Choi, J.-H. KCl-assisted synthesis of hierarchically porous carbon materials from water-soluble 2-hydroxyethyl cellulose for high-performance green supercapacitors. Sustain. Mater. Technol. 2022, 34, e00520. [Google Scholar] [CrossRef]

- Rosi, M.; Iskandar, F.; Abdullah, M. Khairurrijal Hydrogel-polymer electrolytes based on polyvinyl alcohol and hydroxyethylcellulose for supercapacitor applications. Int. J. Electrochem. Sci. 2014, 9, 4251–4256. [Google Scholar] [CrossRef]

- Youssef, A.M.; Hasanin, M.S.; El-Aziz, M.E.A.; Turky, G.M. Conducting chitosan/hydroxylethyl cellulose/polyaniline bionanocomposites hydrogel based on graphene oxide doped with Ag-NPs. Int. J. Biol. Macromol. 2021, 167, 1435–1444. [Google Scholar] [CrossRef] [PubMed]

- Brige, A.; Olsson, M.; Xiong, S.; Matic, A. A comparative study of hydroxyethylcellulose-based solid polymer electrolytes for solid state Zn batteries. Nano Sel. 2023, 4, 102–111. [Google Scholar] [CrossRef]

- Stoica, I.; Buruiana, L.I.; Albu, R.M.; Soroceanu, M.; Barzic, A.I. Rheological and optical response of hydroxypropyl methylcellulose under variable temperatures for optical switching based on thermo-optical effect. Polym. Adv. Technol. 2023, 34, 1245–1252. [Google Scholar] [CrossRef]

- Albu, R.M.; Hulubei, C.; Stoica, I.; Barzic, A.I. Semi-alicyclic polyimides as potential membrane oxygenators: Rheological implications on film processing, morphology and blood compatibility. Express Polym. Lett. 2019, 13, 349–364. [Google Scholar] [CrossRef]

- Barzic, A.I.; Soroceanu, M.; Albu, R.M.; Ioanid, E.G.; Sacarescu, L.; Harabagiu, V. Correlation Between Shear-Flow Rheology and Solution Spreading During Spin Coating of Polysilane Solutions. Macromol. Res. 2019, 27, 1210–1220. [Google Scholar] [CrossRef]

- Barzic, A.I.; Albu, R.M.; Stoica, I.; Varganici, C.D.; Hulubei, C. Polyimides containing cycloaliphatic units and chalcogen atoms as alternative shielding coatings for solar cells. Polym. Bull. 2023, 80, 4503–4522. [Google Scholar] [CrossRef]

- Kahouli, A. Effect of film thickness on structural, morphology, dielectric and electrical properties of parylene C films. J. Appl. Phys. 2012, 112, 064103. [Google Scholar] [CrossRef]

- Iqbal, H.M.S.; Bhowmik, S.; Benedictus, R. Study on the effect of surface morphology on adhesion properties of polybenzimidazole adhesive bonded composite joints. Int. J. Adhes. Adhes. 2017, 72, 43–50. [Google Scholar] [CrossRef]

- Soroceanu, M.; Barzic, A.I.; Stoica, I.; Sacarescu, L.; Ioanid, E.G.; Harabagiu, V. Plasma effect on polyhydrosilane/metal interfacial adhesion/cohesion interactions. Int. J. Adhes. Adhes. 2017, 74, 131–136. [Google Scholar] [CrossRef]

- Siddiqui, A.A. On transient-flows of the Ostwald-de Waele fluids-transport in the Darcy-Brinkman porous medium. AIP Adv. 2017, 7, 075316. [Google Scholar] [CrossRef]

- De Gennes, P.G. Scaling Concepts in Polymer Physics; Cornell University Press: Ithaca, NY, USA, 1979; ISBN 080141203X. [Google Scholar]

- Jabbari, M.; Bulatova, R.; Hattel, J.H.; Bahl, C.R.H. Quasi-steady state power law model for flow of (La0·85Sr0·15)0·9MnO3 ceramic slurry in tape casting. Mater. Sci. Technol. 2013, 29, 1080–1087. [Google Scholar] [CrossRef]

- Tok, A.I.Y.; Boey, F.Y.C.; Lam, Y.C. Non-Newtonian fluid flow model for ceramic tape casting. Mater. Sci. Eng. A 2000, 280, 282–288. [Google Scholar] [CrossRef]

- Fowkes, F.M. Attractive forces at interfaces. Ind. Eng. Chem. 2002, 56, 40–52. [Google Scholar] [CrossRef]

- Rankl, M.; Laib, S.; Seeger, S. Surface tension properties of surface-coatings for application in biodiagnostics determined by contact angle measurements. Colloids Surfaces B Biointerfaces 2003, 30, 177–186. [Google Scholar] [CrossRef]

- Hong, S.; Kang, B.; Ahn, S.; Lee, M.J.; Lee, S.J.; Ma, Y.W.; Park, C.; Kang, M.S.; Shin, B.S. A study on micro/nano pattern replication using a hydroxyethyl cellulose polymer. J. Korean Phys. Soc. 2015, 67, 1966–1969. [Google Scholar] [CrossRef]

- Hamdi, M.; Saleh, M.N.; Poulis, J.A. Improving the adhesion strength of polymers: Effect of surface treatments. J. Adhes. Sci. Technol. 2020, 34, 1853–1870. [Google Scholar] [CrossRef]

| System | b | Ci, Pa·s b |

|---|---|---|

| HEC | 0.77 | 17.87 |

| WLP5/HEC | 0.73 | 18.41 |

| WLP10/HEC | 0.72 | 23.23 |

| WLP20/HEC | 0.68 | 25.59 |

| Sample Code | θ, ° | , dyn/cm | , dyn/cm | , dyn/cm | |

|---|---|---|---|---|---|

| F | Gly | ||||

| HEC | 60.0 ± 0.6 | 68.7 ± 0.6 | 29.2 ± 1.7 | 4.9 ± 0.9 | 73.2 ± 0.7 |

| WLP5/HEC | 62.7 ± 0.6 | 67.0 ± 0.0 | 18.6 ± 1.5 | 12.6 ± 1.1 | 76.2 ± 0.2 |

| WLP10/HEC | 65.7 ± 0.6 | 62.7 ± 0.6 | 5.7 ± 0.1 | 35.8 ± 0.2 | 82.7 ± 0.5 |

| WLP20/HEC | 70.0 ± 1.0 | 59.7 ± 0.6 | 0.2 ± 0.1 | 70.3 ± 2.8 | 88.0 ± 0.4 |

| Sample | Vb, V | Thickness, μm | Eb, V/μm |

|---|---|---|---|

| HEC | 2860 | 33 | 86.7 |

| WLP5/HEC | 2673 | 47 | 56.9 |

| WLP10/HEC | 2571 | 55 | 46.7 |

| WLP20/HEC | 2402 | 59 | 40.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Albu, R.M.; Barzic, A.I.; Asandulesa, M.; Rusu, B.-G.; Stoica, I.; Sava, I. Insights into Interfacial Features of Metal/Eco-Composites Designed for Energy Storage. Coatings 2023, 13, 1390. https://doi.org/10.3390/coatings13081390

Albu RM, Barzic AI, Asandulesa M, Rusu B-G, Stoica I, Sava I. Insights into Interfacial Features of Metal/Eco-Composites Designed for Energy Storage. Coatings. 2023; 13(8):1390. https://doi.org/10.3390/coatings13081390

Chicago/Turabian StyleAlbu, Raluca Marinica, Andreea Irina Barzic, Mihai Asandulesa, Bogdan-George Rusu, Iuliana Stoica, and Ion Sava. 2023. "Insights into Interfacial Features of Metal/Eco-Composites Designed for Energy Storage" Coatings 13, no. 8: 1390. https://doi.org/10.3390/coatings13081390

APA StyleAlbu, R. M., Barzic, A. I., Asandulesa, M., Rusu, B.-G., Stoica, I., & Sava, I. (2023). Insights into Interfacial Features of Metal/Eco-Composites Designed for Energy Storage. Coatings, 13(8), 1390. https://doi.org/10.3390/coatings13081390