Abstract

Using microencapsulation technology and the natural antimicrobial properties of aloe-emodin, the antimicrobial microcapsules were prepared by in situ polymerization using urea-formaldehyde resin as the wall material and aloe-emodin as the core material. The antimicrobial microcapsules were mixed into waterborne coatings to improve the antimicrobial ability of waterborne paint films against bacteria for better protection of substrates. The purpose of this study was to optimize the preparation process of aloe-emodin antibacterial microcapsules. With the variety and concentration of emulsifiers as the changing factors, three different emulsifiers, namely sodium dodecyl benzene sulfonate SDBS, OP-10, and Tween-80, were selected to explore the effects of emulsifier type and microcapsule loading on the physicochemical and the antibacterial properties of waterborne paint films, and the morphology, chemical composition, antibacterial properties, optical properties, and roughness of the paint films were tested and analyzed. The results showed that all the emulsifiers with 3.0% concentration in the microencapsulation preparation were better than 1.0%. The performance of the microencapsulated varnish films prepared with the addition of the three emulsifiers had advantages and disadvantages, with the highest antibacterial rates of 77.1%, 55.4%, and 65.9% for Escherichia coli and 70.0%, 63.9%, and 60.7% for Staphylococcus aureus, respectively. The antibacterial properties of the microencapsulated varnish film prepared by adding SDBS emulsifier were slightly above those of the other two groups. The three sets of paint films’ color differences rose, the gloss reduced, the rate of light loss increased, the rate of light transmission fell, and the roughness increased with an increase in microencapsulated content. Aloe-emodin microcapsules enable the water-based coating to have antibacterial properties, expanding the application range of water-based coatings.

1. Introduction

In a contemporary society where living standards are gradually rising, the health of human life is becoming increasingly important to people [1,2,3]. The living environment in which human beings live is also getting more and more attention [4,5]. The pollution of bacteria and other microorganisms in the human living environment affects people’s health [6]. Coatings are commonly used in the decoration of furniture, artifacts, and other household objects, which are frequently touched by people in their daily lives and work [7]. Bacteria may be transmitted indirectly by contact through the carrier of furniture surface paint film, so making a coating with antimicrobial properties is one of the ways to effectively block indirect transmission [8]. In practice, coatings with antibacterial properties are effective in reducing the density of bacteria on furniture and other objects, optimizing people’s living environment [9]. This requires us to investigate the antimicrobial function of coatings.

Compared to traditional paints, water-based paints are increasingly used because of their green, energy-saving, and low formaldehyde benefits [9,10,11,12,13]. However, waterborne coatings do not possess antimicrobial properties and cannot act as antimicrobial agents [14]. Microencapsulation technology can be used to wrap the wall material on the surface of the core material by physical or chemical methods to produce tiny “core-shell structure” spherical particles [15]. The use of microencapsulation technology to cover the core with antimicrobial properties stabilizes the core, resulting in a long-lasting and stable antimicrobial effect [16]. The preparation of antimicrobial agents into microcapsules can optimize the performance of the antimicrobial agent and make the coating antimicrobial at the same time [17]. This has important implications for optimizing the preparation of antimicrobial agents and enriching the functionality of the coatings for real-life applications. The practical application of microencapsulation technology in various coating fields is very extensive, such as construction, road, medical, marine, aerospace, and wood surfaces. Microcapsule technology applied to coatings can not only enhance the performance of the coating itself, but also enable the coating to have better performance, to obtain multi-functional coatings. For example, toughening microcapsules can enhance the toughness of the coating, self-repair microcapsules can make the coating obtain a self-repairing function, discoloring microcapsules can make the coating gain the function of discoloration, etc. Therefore, the application of microcapsule technology in coatings has a great application prospect.

Aloe-emodin is an anthraquinone compound, mainly from the natural plant Aloe curaçao, palm leaf rhubarb, etc. [18]. It is one of the active ingredients of the antibacterial function of aloe-emodin, which Staphylococcus and Streptococcus are extremely sensitive to. It is one of the natural antibacterial agents which can destroy bacteria efficiently, but is also safe, harmless, and non-irritating [18,19,20]. It can remove harmful metabolites released during bacterial infections as well as endotoxins left behind by the bacteria after they are killed [20]. Aloe-emodin has a strong suppressive effect on the nucleic acid and protein synthesis in Staphylococci [21,22,23]. At the same time, the key exotoxin of Staphylococcus aureus that causes many infections is α-toxin, which is an important virulence factor secreted by Staphylococcus aureus. Aloe-emodin possesses the ability to inhibit the hemolytic activity of α-toxin, thus achieving an antibacterial effect [23]. In addition, aloe-emodin is often used in cosmetic ingredients and is safe and non-toxic. As such, applying it in coatings in direct contact with the human body will not cause any harm to the skin [24]. The use of green materials to prepare microcapsules is a hot research topic nowadays. Aloe-emodin itself is dark in color, has orange–red crystals as its state of matter, and has large, asymmetrical particles with low stability, making it unsuitable for direct addition to coatings [25]. By changing its own processing properties through microencapsulation technology, it can be well used in actual production and life and has a broad development prospect.

During the preparation of microcapsules, a suitable emulsifier must be selected in order to obtain a stable core emulsion [26,27,28]. An emulsifier is a class of substances that is a surfactant that enables a mixture of two or more immiscible components to form a stable emulsion [29]. The principle of action of emulsifiers is that during emulsification, the dispersed phase is dispersed in the continuous phase in the form of micro-droplets [29,30,31]. The hydrophilic–lipophilic balance value (HLB value) was used to indicate the hydrophilic or lipophilic emulsifier [32]. When the HLB value of the emulsifier is lower, the stronger its lipophilicity. When the HLB value is less than 10, in the emulsification process the microcapsules can be formed for the state of water-in-oil, which can make the water disperse into the oil. When the HLB value is higher, its hydrophilicity is stronger. When the HLB value is greater than 10, in the emulsification process, the microcapsules can be formed for the state of oil-in-water, which can make the oil disperse into the water [33]. The higher the HLB value of the emulsifier, the more hydrophilic it is.

The aim of this study was to optimize the preparation process of antibacterial microcapsules of aloe-emodin using emulsifier type and concentration as variables. Using microencapsulation technology, the antimicrobial microcapsules were prepared with urea-formaldehyde resin as a wall material and aloe-emodin as a core material, and the prepared microcapsules were added into the waterborne coatings at different contents to make waterborne coatings with antimicrobial properties. In this experiment, the type and concentration of emulsifier were used as variables to investigate the optimal type and concentration of emulsifier for preparing microcapsules, and three different HLB values and types of emulsifiers were selected, namely SDBS, OP-10, and Tween-80. SDBS and Tween-80 are both hydrophilic emulsifiers. OP-10 is a non-ionic emulsifier with both hydrophilic and hydrophobic groups, and its hydrophilic group interacts with water molecules. When water is added to the OP-10 emulsifier, the molecular space configuration of OP-10 changes under the action of water, forming a zig-zag structure, its hydrophilic group encases the hydrophobic group inside, so that the whole hydrophilic group is on the outside, and water molecules in the form of hydrogen bonding are connected with the ether group. Many water molecules are linked around the OP-10 molecule to form a larger hydrophilic group, which greatly improves its hydrophilic ability, thus improving the HLB value [34].

The core material of microcapsules in this experiment, aloe-emodin, is an oily substance [33], and to disperse aloe-emodin evenly in water, it is necessary to use hydrophilic emulsifier, i.e., an emulsifier with an HLB value greater than 10. Therefore, the three emulsifiers selected for this experiment all have HLB values greater than 10 and are hydrophilic emulsifiers [34]. The effect of the emulsifiers on the microcapsules and the paint film was investigated by comparing the morphology, yield, and encapsulation rate of the prepared microcapsules as well as the antimicrobial and optical characteristics of the paint film. The results of this study can provide a reference for the research of preparation and optimization of antibacterial microcapsules of aloe-emodin in waterborne coatings.

2. Experimental Materials and Methods

2.1. Experimental Materials

Table 1 displays the supplies used for this experimental investigation. Silicone abrasives were 50 mm × 50 mm × 10 mm in size and were used to prepare coatings. Polyvinyl alcohol has a molecular weight of 13,000–23,000. The degree of substitution (relative to vinyl acetate groups) was 88%. Dulux aqueous coating was used as the finish. The Petri dish had a 90 mm diameter. Both the Staphylococcus aureus and the Escherichia coli were second generation standard strains from the Beijing Biological Preservation Center, designated ACTT6538 and ATCC25922, respectively. The emulsifiers used in this experiment were supplied by Tianjin City Beichen District Fang Zheng Reagent Factory.

Table 1.

List of experimental materials.

2.2. Preparation Method of the Aloe-Emodin Microcapsules

In this experiment, antimicrobial microcapsules were prepared by in situ polymerization using microencapsulation technology and the natural anti-microbial properties of aloe-emodin, with aloe-emodin as the core substance and urea-formaldehyde resin as the wall substance. By varying the kind and concentration of emulsifier, the optimal process parameters for producing microcapsules were investigated. The type of emulsifier and HLB value are presented in Table 2. The microcapsules were prepared according to a certain formaldehyde to urea molar ratio, core to wall ratio, reaction temperature, and stirring rate of microencapsulation. The preparation parameters are shown in Table 3 and the materials used in the test are shown in Table 4. The microencapsulation preparation process in this experiment was repeated four times with a deviation of ±5%.

Table 2.

Different emulsifier types and HLB values.

Table 3.

Preparation parameters of the test.

Table 4.

Material list.

- (1)

- Preparation of wall material: Formaldehyde solution and urea were combined thoroughly, triethanolamine was added to bring the pH level down to about 8, and then 0.1 g of polyvinyl alcohol was added. The mixture was then placed in a magnetic stirrer and heated to 80 °C while being stirred at a rate of 600 rpm for one hour.

- (2)

- Preparation of core material: In order to fully emulsify the core material, for 45 min different types of emulsifiers were mixed with water and thoroughly stirred before the core material, aloe-emodin, was added and placed into the magnetic stirrer. The reaction temperature was then set to 60 °C and the stirring rate to 1000 rpm.

- (3)

- Microencapsulation: The solution of urea-formaldehyde resin wall material was slowly added into the core material with a dropper at 600 rpm. Citric acid monohydrate crystals were added in small amounts to adjust the pH of the solution to 2.5–3.0. The reaction was then continued for another two hours while being stirred with the addition of the proper amounts of NaCl and SiO2 powder. The final product was aged for 24 h at room temperature. After aging, the product was filtered several times with ethanol and water using a filtering machine and put into an oven and dried at 40 °C for 24 h. After drying, the product was ground and the resulting powder was microencapsulated.

The addition of polyvinyl alcohol in the process of microcapsule preparation can reduce the free formaldehyde content, and at the same time, in the actual use of the process, it can enhance the water resistance of the interface between the waterborne coating and the wood material and reduce the brittleness of the coating while improving the toughness and stability of the coating. The addition of NaCl and SiO2 improves the phenomenon of agglomeration of microcapsule particles bonded to each other and makes the microcapsule material stronger.

2.3. Preparation Method of the Paint Films

The aloe-emodin microcapsules prepared from three different types of emulsifiers were added to the waterborne topcoats to prepare three different types of films. The added contents were 0%, 1.0%, 3.0%, 6.0%, 7.0%, and 9.0%, respectively. The breakdown of the materials used in the waterborne paint films is shown in Table 5. Firstly, the microcapsules were mixed with the coatings, and then the coatings were applied to the silicone molds. After the coatings were applied, they were dried at room temperature for 45 min and then in a constant temperature oven at 40 °C for 45 min. After the paint film was cured, the samples were demolded and used to test the antibacterial and optical properties of the paint film. The coatings were then applied to a transparent glass plate to test the roughness of the paint film.

Table 5.

List of materials for paint films.

2.4. Testing and Characterization

2.4.1. Yield and Coverage Rate Test of the Microcapsules

After the microcapsules were dried to a constant mass, their mass was weighed and the yield of the resulting microcapsules was recorded. The microcapsule powder was weighed with mass m1, ground with a mortar to destroy the microcapsule wall material, and put into a glassware. The hot ethanol was added, the powder was soaked in it, and put in a constant temperature water bath at 65 °C for 2 h. The hot ethanol was added again and soaked for 2 h. Following the soaking, it was rinsed with ethanol and deionized water before being extracted and filtered. The final product, which was the wall material, was dried in an oven set at 40 °C until the mass remained constant. The weight of the wall material was denoted as m2. Equation (1) was used to determine the encapsulation rate of the microcapsules:

P = (m1 − m2)/m1 × 100%

2.4.2. Micromorphology and Chemical Composition Test

Optical and scanning electron microscopy were used to describe the microscopic morphology of the microcapsules. The produced aloe-emodin microcapsules were equally distributed on clean slides, covered with coverslips, and positioned upward on the carrier table. After securing the slides with spring clamp grips, the microscope’s focal length and brightness were adjusted. To examine and record the microscopic morphology of the microcapsules, the 20× microscope lens was chosen. Microcapsules and varnishes were examined to determine their chemical composition using infrared spectroscopy.

2.4.3. Antibacterial Test of the Paint Films

In the antimicrobial test of the coating, the strains tested were Staphylococcus aureus and Escherichia coli. According to GB/T 21866-2008 [35], the antimicrobial properties of the paint film were tested. Firstly, numerous flat nutrient agar mediums were created as a backup using nutrient agar medium powder that had been heated, dissolved in filtered water, and then dispensed into Petri dishes. To create broth culture solution, nutrient broth powder was heated with purified water until it was completely dissolved. To generate an eluent with a concentration of 0.85%, sodium chloride was added to filtered water and heated to dissolve. This mixture was then placed aside. The broth culture solution, eluate, and plane nutrition agar medium were all autoclaved at 121 °C for 30 min. The polyethylene film needed to soak in a solution of 70.0% ethanol for 30 min before being rinsed with eluate, dried, and prepared for use.

The slant conserved strains were fresh strains that were conserved for no more than one month. After 20 h of incubation at 37 °C in a constant temperature and humidity chamber, the bacteria on the slant medium were transferred to the flat nutrient agar medium using the sterilized treated inoculation loop. Then, 1–2 loops of fresh bacteria were scraped from the flat nutrient agar medium with the inoculation loop and added to the broth culture solution. According to GB/T 4789.2-2016 [36], ten-fold incremental dilutions were made in turn to make a 1:1000 bacterial suspension. The 0.5 mL of bacterial suspension was taken drop by drop and added on the prepared lacquer film. The polyethylene film was picked up with sterilized forceps and covered the lacquer film flatly to ensure there were no air bubbles between the covering film and the lacquer film, so that the bacterial solution evenly touched the lacquer film. The samples were placed in Petri dishes and incubated in a constant temperature and humidity chamber at 37 °C and 98.0% for 24 h. Two sets of parallel tests were performed for each sample. The samples were taken out after 24 h incubation, and 20 mL of eluent was added to rinse the sample lacquer film and the covering film repeatedly. After stirring the eluate well, 0.5 mL was inoculated into the flat nutrient agar medium and incubated in a constant temperature and humidity chamber at 37 °C and 98.0% for 48 h.

The flat nutrient agar medium that had been incubated for 48 h was taken out, placed in the bacterial colony counter, and carefully observed using a magnifying glass. All the colonies at the bottom of the medium were counted one by one with a probe pen, and the number on the display after counting was the number of colonies in that medium. The average of the 2 sets of parallel tests was taken as the final result. After 48 h of incubation for each sample, the measured number of colonies was multiplied by 1000 to determine the real value of the recovered live bacteria. Equation (2) is a calculation of the lacquer film’s antibacterial rate. Where B stands for the typical number of colonies recovered after 48 h for the lacquer film without microcapsules, and C stands for the typical number of colonies recovered after 48 h for the lacquer film with microcapsules. R stands for the antibacterial rate.

R = (B − C)/B × 100%

2.4.4. Optical Properties Test of the Paint Films

According to GB/T 11186.3-1989 [37], the color difference of paint film was tested by using a portable colorimeter. The values of L, a, and b were noted during the test. The L value represents the lightness value of the sample tested; the larger the L value, the brighter the color. The a value represents the red-green value of the sample tested; a positive value means the color is red, a negative value means the color is green. The b value represents the yellow–blue value of the sample tested; the positive value means the color is yellow, and the negative value means the color is blue. The values of L1, a1, and b1 indicate the paint film without adding core or microcapsules and L2, a2, and b2 are for the paint film with adding core or microcapsules, and the color difference ΔE was calculated according to Equation (3), where ΔL = L2 − L1, Δa = a2 − a1, and Δb = b2 − b1.

ΔE* = [(ΔL*)2 + (Δa*)2 + (Δb*)2]1/2

According to GB/T 4893.6-2013 [38], at 20°, 60°, and 85°, the gloss level of the paint films was measured using the glossmeter. Based on Formula (4), the gloss loss rate of the paint films at a 60° incidence angle was determined. G0 is the paint film’s gloss without the addition of core material or microcapsules, and G1 is the gloss after adding core material or microcapsules. GL stands for the light loss rate.

GL = (G0 − G1)/G0 × 100%

UV spectrophotometers were used to test the transmittance of paint films. The wavelength of visible light in the band 380–780 nm was the wavelength range for testing. When a beam of light had passed through the sample, the ratio of the remaining light intensity to the light intensity of the incident light was the transmittance.

2.4.5. Roughness Test of the Paint Films

According to GB/T 6062-1985 [39], the surface roughness of the paint film was tested by placing the coated glass plate on the test bench, adjusting the position of the stylus until it touches the paint film, testing, and recording the surface roughness of the paint film.

3. Results and Discussion

3.1. Analysis of Microcapsule Preparation Results

3.1.1. Analysis of Microcapsule Yield and Coverage Rate

The yield of microcapsules is one of the important indicators to evaluate the results of microcapsule preparation. Table 6 shows the results of microcapsule yield and encapsulation rate of different emulsifier types and concentrations. Among them, the highest yield of 14.25 g was obtained for Sample 6 microcapsules, and the highest encapsulation rate of 9.4% was obtained for Sample 2 microcapsules. By comparing the different concentrations, it can be found that the yields of microcapsules prepared by the three emulsifiers at 3.0% concentration were higher than those at 1.0% concentration, and the coverage rates were basically the same with very small differences. In this way, it can be known that the emulsifier at 3.0% concentration is more suitable, so in the preparation of waterborne paint film, three microcapsules prepared at 3.0% emulsifier concentration were chosen to be added to the paint, namely, Sample 2 microcapsules, Sample 4 microcapsules, and Sample 6 microcapsules.

Table 6.

Microcapsule yield and coverage rate under different emulsifier types and concentrations.

3.1.2. Analysis of Microcapsule Morphology

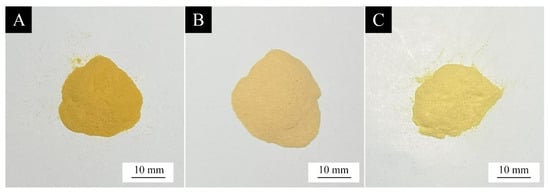

Figure 1 shows the macroscopic morphology of the microcapsules of Sample 2, Sample 4, and Sample 6. The color of the microcapsules of Sample 2 prepared with SDBS as the emulsifier was relatively darker, and the color of the microcapsules of Sample 6 prepared with Tween-80 as the emulsifier was relatively lighter. This indicates that the microcapsules with Tween-80 as the emulsifier can better reduce the staining of the core material to the wall material during the transformation process and lighten the overall color of the microcapsules so that their color is more suitable for mixing in the paint film. While the microcapsules with SDBS as the emulsifier had the most obvious effect of staining of the core material on the wall material during the conversion process, so the microcapsules had the darkest color.

Figure 1.

Macro-topography of microcapsules: (A) Sample 2, (B) Sample 4, (C) Sample 6.

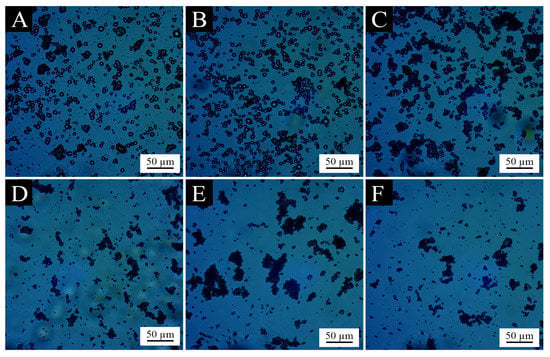

Figure 2 shows the microscopic images of the six microcapsules. From the figure, it can be seen that the microcapsules of Sample 1 and Sample 2 prepared with SDBS as the emulsifier were spherical, round, and full, basically without large agglomerates and needle crystals. The microcapsules of Sample 3 and Sample 4 prepared with OP-10 as the emulsifier showed obvious agglomeration. Sample 5 and Sample 6 microcapsules prepared with Tween-80 as the emulsifier also showed obvious agglomeration and poor dispersibility. This indicates that the SDBS emulsifier can make the core material of the microcapsules be better emulsified and dispersed, so that the wall material of the microcapsules is also more uniformly coated on the surface of the core material. Taken together, the dispersion of microcapsules prepared with SDBS as the emulsifier was better, and the agglomeration phenomenon of microcapsules with OP-10 and Tween-80 as emulsifiers were more serious.

Figure 2.

OM images of microcapsules: (A) Sample 1, (B) Sample 2, (C) Sample 3, (D) Sample 4, (E) Sample 5, (F) Sample 6.

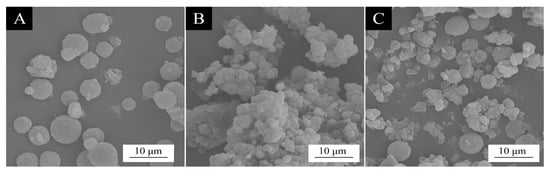

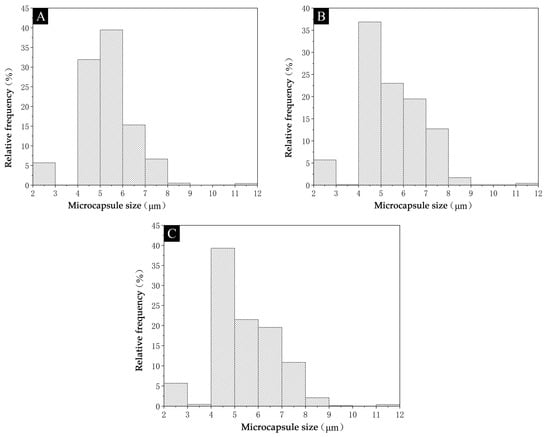

Figure 3 shows the SEM images of three microcapsules of Sample 2, Sample 4, and Sample 6. It can be clearly seen that the microcapsules were all round spheres. The particle size distribution of the microcapsules is shown in Figure 4. Sample 2 prepared with 3.0% SDBS emulsifier had the best dispersion, little adhesive material on the surface of the microcapsules, and concentrated distribution of microcapsule size. More than 70.0% of the microcapsules were between 4 and 7 μm in size, and the distribution of the microcapsules between 5 and 6 μm in size was the most, accounting for about 40.0%, with an average size of 5.82 μm. The Sample 4 microcapsules prepared with 3.0% concentration of OP-10 emulsifier were more seriously agglomerated though, with microcapsules adhered together and poorly dispersed, and the microcapsule size was most distributed between 4 and 5 μm, exceeding 35.0%, with an average particle size of 5.98 μm. The average particle size of the microcapsules of Sample 6 prepared with 3.0% concentration of Tween-80 emulsifier was 5.97 μm, and the microcapsule particle size was most distributed between 4 and 5 μm, which was close to 40.0%. The analysis of the graph shows that the particle size distribution and average particle size of the three microcapsules are relatively similar, Sample 2 microcapsules have the smallest average particle size and better dispersion, while Sample 4 and Sample 6 microcapsules have a larger proportion of small particles.

Figure 3.

SEM images of microcapsules: (A) Sample 2, (B) Sample 4, (C) Sample 6.

Figure 4.

Particle size distribution of microcapsules: (A) Sample 2, (B) Sample 4, (C) Sample 6.

In general, the higher the HLB value, the more hydrophilic the emulsifier is, and the better the emulsification and dispersion of aloe-emodin in aqueous wall materials. However, the HLB value of SDBS was the lowest among the three emulsifiers, and the prepared microcapsules were the best dispersed. This may be due to the strong emulsifying effect of OP-10 and Tween-80 on aloe-emodin, which dispersed the core material into too small microdroplets, leading to the difficulty of depositing the wall material on the surface of the central material during microencapsulation. As a result, the agglomerative deposition of the wall material appeared, affecting the generation and dispersion of microcapsules, making the particle size of part of the successfully encapsulated microcapsules smaller.

In summary, Sample 2 microcapsules prepared with 3.0% concentration of SDBS emulsifier were dark in color but had good dispersion and concentrated particle size distribution. The Sample 4 microcapsules prepared with 3.0% concentration of OP-10 emulsifier and the Sample 6 microcapsules prepared with 3.0% concentration of Tween-80 emulsifier were lighter in color, with more microcapsules of small size, but more serious agglomeration. Therefore, the microcapsules prepared by these three different emulsifiers have their own advantages and disadvantages, and they need to be added into the paint to prepare the paint film to further compare and explore the role played by microcapsules in the paint film.

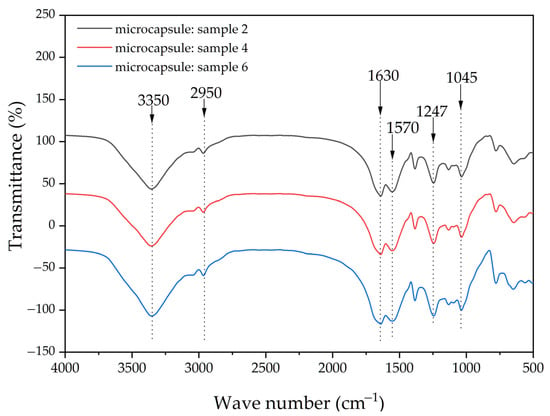

3.1.3. Analysis of Chemical Composition of Microcapsules

Figure 5 shows the IR spectra of Sample 2, Sample 4, and Sample 6 microcapsules. The trends of the absorption peaks of the three microcapsules were basically the same. As can be seen from the figure, there is an O–H stretching vibration peak at 3350 cm−1, a C–H bending vibration peak at 2950 cm−1, and a C=O stretching vibration peak at 1630 cm−1. The chemical composition of the urea-formaldehyde resin in the microcapsules is indicated by the absorption peak at 1247 cm−1, which is brought on by the deformation vibration of N–H in the resin [40]. The peak at 1045 cm−1, on the other hand, is the C–O–C absorption peak of dihydroxymethylurea in the urea-formaldehyde resin. The peak at 1570 cm−1 is the aloe-emodin C=C peak, which reveals the chemical make-up of aloe-emodin within the microcapsules [41,42]. The presence of both core and wall materials in the microcapsules, as well as the fact that their chemical composition has not been altered, is shown by all of these feature peaks, demonstrating the success of the microcapsule encapsulation.

Figure 5.

FTIR image of the microcapsules.

3.2. Analysis of Paint Film Properties

3.2.1. Analysis of Paint Film Morphology

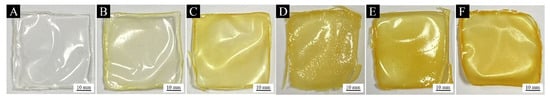

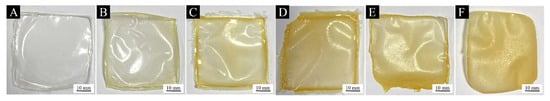

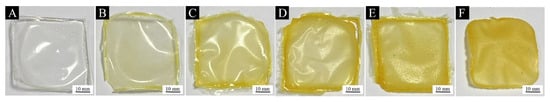

Figure 6 shows the macroscopic morphology of the paint film of Sample 2 microcapsules prepared by adding different contents of SDBS emulsifier with 3.0% concentration. Figure 7 shows the macroscopic morphology of the paint film of Sample 4 microcapsules prepared by adding different contents of OP-10 emulsifier with 3.0% concentration. Figure 8 shows the macroscopic morphology of the paint film of Sample 6 microcapsules prepared by adding different contents of Tween-80 emulsifier with 3.0% concentration. It can be seen from the figures that all three groups of paint films are yellow and transparent, and the color gradually becomes darker with the increase in microcapsule content. When the microcapsule content is lower than 6.0%, the color of the paint film is lighter, and when the microcapsule content is higher than 6.0%, the color of the paint film becomes significantly darker, which may have a greater impact on the furniture color when it is actually applied to the furniture surface. The surface flatness of all the three groups of paint films was fair by observing the smoothness of the paint film surface, and there were no obvious large particles and agglomerates, and the paint films were all more complete with less cracking. Therefore, in the subsequent analysis of the paint film morphology and chemical composition, the sample with 6.0% microcapsule addition was chosen as the representative for observation.

Figure 6.

Macro-morphology of paint films with different contents of Sample 2 microcapsules added: (A) 0%, (B) 1.0%, (C) 3.0%, (D) 6.0%, (E) 7.0%, (F) 9.0%.

Figure 7.

Macro-morphology of paint films with different contents of Sample 4 microcapsules added: (A) 0%, (B) 1.0%, (C) 3.0%, (D) 6.0%, (E) 7.0%, (F) 9.0%.

Figure 8.

Macro-morphology of paint films with different contents of Sample 6 microcapsules added: (A) 0%, (B) 1.0%, (C) 3.0%, (D) 6.0%, (E) 7.0%, (F) 9.0%.

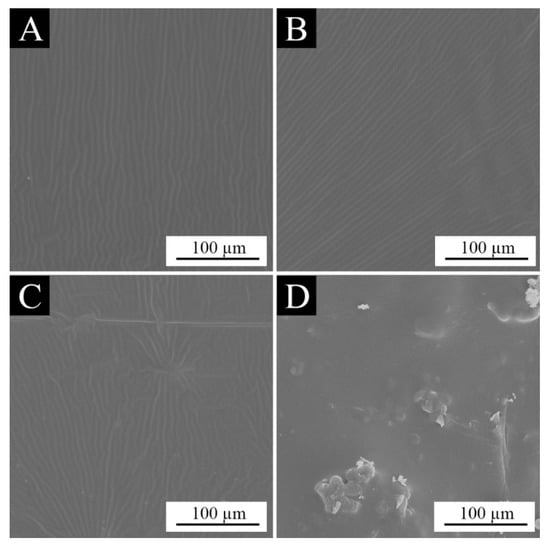

Figure 9 shows the microscopic morphology of the paint film without any microcapsules and the paint film with aloe-emodin microcapsules prepared with three different emulsifiers, both with 6.0% microcapsules and 3.0% emulsifiers. It was observed that there was a slight wrinkling on the surface of the paint film without the addition of microcapsules. The surface of the paint film with the microcapsules prepared by adding Sample 2 with SDBS as the emulsifier and Sample 4 with OP-10 as the emulsifier had slight wrinkles, but the particles were fewer and the surface was flat. Tween-80 was used as the emulsifier on the paint film surface of Sample 6, which resulted in more pronounced bumps and particle aggregation. This phenomenon shows that the Sample 6 microcapsules were strongly agglomerated and could not be equally disseminated in the coatings, therefore, they were gathered together and generated bigger particles on the surface. It is obvious that adding Tween-80 as the emulsifier microcapsule to coatings can have a significant negative impact on the smoothness of the paint film.

Figure 9.

SEM images of paint films: (A) without microcapsules, (B) with 6.0% Sample 2 microcapsules, (C) with 6.0% Sample 4 microcapsules, (D) with 6.0% Sample 6 microcapsules.

By observing the macroscopic and microscopic morphology of the three groups of paint films, it can be found that the paint films made from microcapsules prepared with the three emulsifiers at a concentration of 3.0% had a transparent yellow color, and the smoothness and integrity of the paint films were good, which indicates that the concentration and type of emulsifier of the microcapsules have a positive effect on the morphology of the paint films.

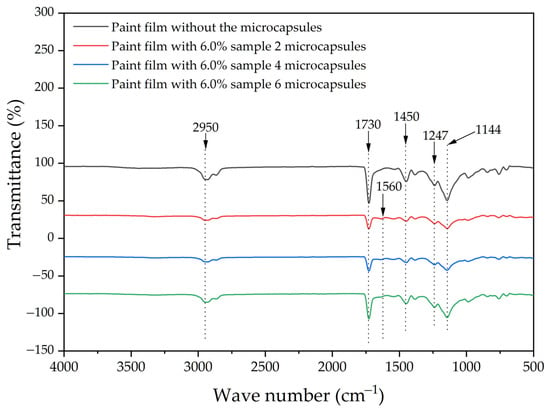

3.2.2. Analysis of Chemical Composition of Paint Film

Figure 10 shows the IR spectra of the blank waterborne paint film and three different paint films spiked at 6.0% microcapsule content. The 2950 cm−1 and 1144 cm−1 are the C–H bending vibration peaks and the C–O vibration peaks present in both the waterborne paint film and the microcapsules. The C=O and the characteristic (–CH2)–CH2 stretching vibrational peaks in the waterborne paint film appear at 1730 cm−1 and 1450 cm−1, respectively. These distinctive peaks can be seen in all four curves, proving that the aqueous coatings’ chemical composition was not altered when combined with the microcapsules. The typical N–H peak can be seen in the microcapsule wall material at 1247 cm−1. The typical peak for C=C in the microcapsule core material can be seen at 1560 cm−1. These peaks are present in all three curves for the paint film with the three different microcapsules added, proving that the wall and core materials of the microcapsules in the waterborne coating remained unchanged, indicating that the microcapsules did not react chemically with the paint when added to the waterborne coatings and that both the waterborne coatings and the microcapsules remained intact.

Figure 10.

FTIR image of the paint films.

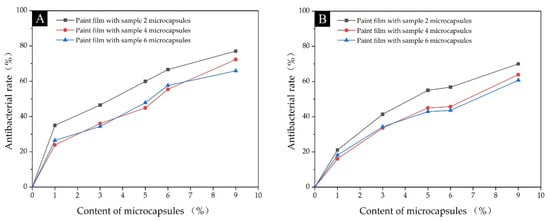

3.2.3. Analysis of Antimicrobial Properties of Paint Film

Table 7 and Figure 11 show the actual number of colonies and antimicrobial rates recovered after antimicrobial testing for three groups of paint films added with Sample 2 microcapsules prepared with 3.0% concentration of SDBS emulsifier, Sample 4 microcapsules prepared with 3.0% concentration of OP-10 emulsifier, and Sample 6 microcapsules prepared with 3.0% concentration of Tween-80 emulsifier, respectively. As can be seen from the graphical data, compared to the paint films without microcapsules, all three groups of paint films with added microcapsules showed a gradual increase in the antibacterial rate against both bacteria as the amount of microcapsules added increased, and the antibacterial effect against Escherichia coli was slightly better than that of Staphylococcus aureus overall. The highest antibacterial rates against both bacteria were 77.1% and 70.0% for the paint film with Sample 2 microcapsules, 72.3% and 63.9% for the paint film with Sample 4 microcapsules, and 70.7% and 60.7% for the paint film with Sample 6 microcapsules. The antibacterial effect of the paint film with Sample 2 microcapsules was slightly better than the other two groups for both Escherichia coli and Staphylococcus aureus. This is because the coating rate of Sample 2 microcapsules prepared with SDBS as the emulsifier was higher than that of Sample 4 and Sample 6 microcapsules, and the microcapsules themselves were less agglomerated, so they were evenly dispersed in the coatings, making the antibacterial effect even better. These results show that the microcapsules successfully acted as antibacterial agents in the paint film. The microcapsules prepared with different emulsifiers all have antimicrobial functions and the strength of the antimicrobial effect depends to a large extent on the effectiveness of the microcapsule coating.

Table 7.

Actual recovery of viable bacteria and antibacterial rate of paint films.

Figure 11.

Antibacterial rate of paint films: (A) against Escherichia coli, (B) against Staphylococcus aureus.

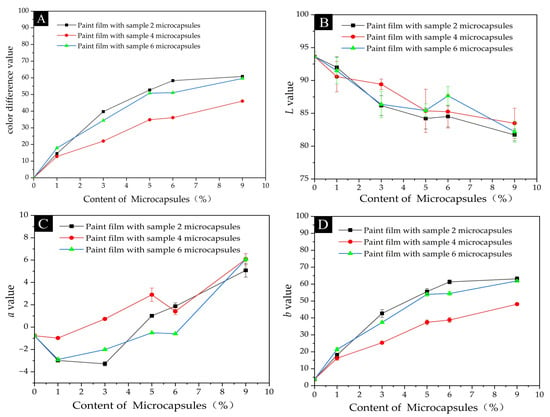

3.2.4. Analysis of Optical Properties of Paint Film

The data on the chromaticity values and color difference values of the paint films with different microcapsules added are shown in Table 8. The effect of microcapsules prepared with different emulsifiers on the chromaticity values and color difference of the paint films is shown in Figure 12. Figure 12A shows that as the microcapsule content increased, the color difference of all three groups of paint films with added microcapsules increased continuously compared to the blank paint films without added microcapsules. Figure 12B shows that as the microcapsule content increased, the L value, which represents the degree of brightness, decreased slightly for all three groups of paint films. When granular microcapsules were added to the coatings and prepared into paint films, the smoothness of the paint films was impacted by the microcapsules and, as a result, the paint films’ brightness slightly diminished. Figure 12C shows that the increase in microcapsule content had little effect on the value representing the red–green value in the three groups of paint films. In contrast to the L value, Figure 12D shows that the b value representing the yellow values in the three groups of films showed an increasing trend, with the yellow color of the paint film increasing as the microcapsule content increases. Of the three groups of films, the difference in color was greatest in the paint film with the addition of Sample 2 microcapsules, this is because Sample 2 microcapsules prepared with the SDBS emulsifier were themselves the darkest of the three microcapsules. Therefore, the addition to the paint film resulted in a greater color difference compared to the blank film. This trend is also reflected in the b value, which represents the degree of yellow color, with the paint film with the addition of microcapsules from Sample 2 having the highest b value and the a and L value not differing much from the other two groups. Sample 4 microcapsules prepared with the OP-10 emulsifier had the lightest color itself and, therefore, the least color difference compared to the blank paint film without the addition of microcapsules, which is a better choice for addition to clear waterborne coatings.

Table 8.

Chromaticity and color difference of paint films with different contents of microcapsules.

Figure 12.

Effect of the microcapsule content on chromaticity and color difference of the paint films: (A) color difference value, (B) value of L, (C) value of a, (D) value of b.

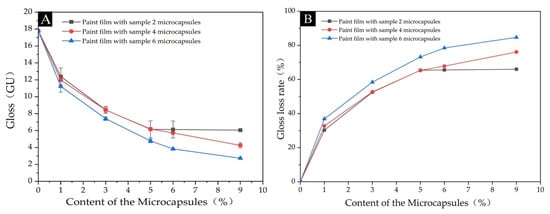

The impact of various microcapsule additions on the gloss and light loss of the paint films are shown in Table 9. The three groups of paint films all experienced a steady decline in gloss as the amount of microcapsules in each set of paint films increased. The gloss of the paint film of Sample 6, which was prepared by adding Tween-80 emulsifier, was slightly lower than that of the other two groups, probably due to the poor dispersibility of Sample 6 microcapsules, which could not be dispersed evenly in the coatings, and the agglomeration and accumulation of particles caused the low gloss of the paint film. As shown in Figure 13, at an incidence angle of 60°, with the increase of the microcapsule content, the gloss of all three groups gradually decreased and the light loss rate gradually increased. When the microcapsules content reached 9.0%, the gloss of the paint film was the lowest and the light loss rate was the highest. This is because the granular microcapsules affect the flatness of the paint film after drying. At the same time, the increase in the microcapsule content also makes the diffuse reflection of light on the surface of the paint film increase, and the gloss level decreases.

Table 9.

Gloss and gloss loss rate of paint films with different contents of microcapsules.

Figure 13.

Effect of content on gloss and loss of gloss of paint films at 60°: (A) gloss, (B) gloss loss rate.

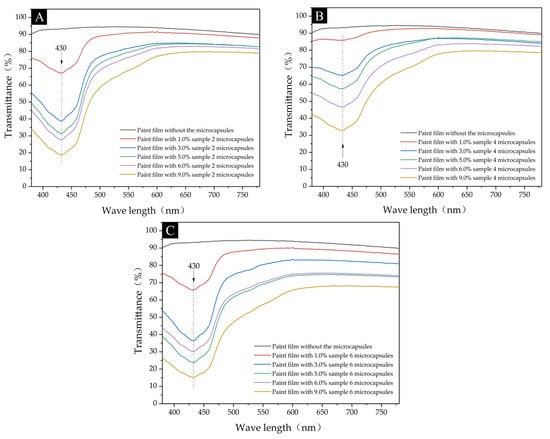

Figure 14 shows the light transmission rates of the three groups of paint films. The trend of the visible light transmission rates of the three groups of paint films is basically the same and shows a negative correlation with the amount of microcapsules added; the higher the content, the lower the overall transmission rate of visible light. This is because when the opaque yellow microcapsules are added to the colorless and transparent coatings, the degree of transparency of the paint film decreases. When the microcapsules are added at levels higher than 6.0%, the transmittance of the three groups of paint films decreases sharply between the blue and violet wavelengths of 400–430 nm. This is because when the microcapsules are added at higher levels, the yellow color of the paint film increases, the absorption of blue–violet light increases, and the intensity of visible light remaining after passing through the paint film is greatly reduced compared to the incident light intensity, thus reducing the transmission rate. Figure 14B shows that the absorption peak at 430 nm for the paint film of Sample 4 microcapsules prepared with the addition of OP-10 emulsifier is weaker compared to Figure 14A,C. This is because the Sample 4 microcapsules were the lightest in color and, therefore, absorbed less blue–violet light than the other two groups.

Figure 14.

Effect of the adding content on light transmittance of the paint films: (A) the films with Sample 2 microcapsules, (B) the films with Sample 4 microcapsules, (C) the films with Sample 6 microcapsules.

In summary, among the three groups of paint films with three different microcapsules, the films with the addition of microcapsules prepared with OP-10 as the emulsifier had the lowest color difference, higher gloss, and highest light transmission. The trend of color difference, chromaticity value, gloss, and light transmission was the same for all three groups; increasing microcapsule addition had similar data values, indicating that the effect of the different emulsifier types on the optical properties of the paint films was small, while the effect on the optical properties of the paint films for practical application on wood surfaces needs to be further investigated.

3.2.5. Analysis of Paint Film Roughness

Table 10 shows the roughness of the three groups of paint films. It can be observed from the data that the roughness of the three groups of paint films increases as the microcapsule content increases. This is because as the microcapsule content increases, the microcapsules are present in the paint film in the form of spherical particles, and the increase in particles leads to unevenness on the surface of the paint film, causing the roughness of the paint film to increase. The roughness of the paint film with Sample 6 microcapsules was the highest among the three groups of paint films. This was due to the fact that the microcapsules prepared with Tween-80 as the emulsifier were more agglomerated, so the surface of the paint film was rough and uneven when added to the coatings. The roughness of the paint film with Sample 2 microcapsules was lower because the microcapsules prepared with SDBS as the emulsifier were evenly dispersed and the particle size distribution of the microcapsules was more concentrated, so the surface flatness of the paint film prepared by adding to the coatings was higher than the other two groups. At the same time, because the granularity of the microcapsules affects the flatness of the paint film after drying, with the addition of microcapsule content, the gloss of the paint film decreases, the light loss rate increases, the light transmission rate decreases, and the roughness rises.

Table 10.

Roughness of paint films with different contents of microcapsules.

4. Conclusions

All microcapsules prepared with 3.0% concentration of emulsifier were better than 1.0%. The microcapsules prepared with SDBS as the emulsifier had high coverage, uniform dispersion, and small average particle size, but were darker in color. The yield of microcapsules (Sample 2) was 4.5% and the coverage rate was 9.4%. The microcapsules prepared with OP-10 as the emulsifier were light in color, with a larger proportion of small-sized microcapsules, but with more obvious agglomeration. The yield of microcapsules (Sample 4) was 5.1% and the coverage rate was 7.5%. The highest yield of microcapsules was prepared using Tween-80 as the emulsifier, with the largest proportion of small size microcapsules, but with more obvious agglomeration. The yield of microcapsules (Sample 6) was 5.4% and the coverage rate was 8.0%. The antibacterial properties of the paint films prepared by adding microcapsules with the three different emulsifiers all increased with the addition of microcapsules, up to 77.1%, 72.3%, and 70.7% against Escherichia coli and 70.0%, 63.9%, and 60.7% against Staphylococcus aureus, respectively. The antibacterial properties of the paint films with the addition of microcapsules prepared with SDBS as the emulsifier were slightly higher than those of the other two groups. As the microcapsules themselves have color, the addition of microcapsule content increases the color difference between the three groups of paint film. With the addition of microcapsules, the color difference of the three groups increased, the gloss decreased, the light loss increased, the light transmission decreased, and the roughness increased. The paint film with the addition of microcapsules prepared with OP-10 as the emulsifier had the lowest overall color difference, higher gloss, and highest light transmission. The coatings with antimicrobial function have potential applications in furniture coating and construction. The performance test was limited by coating the paint film with a slide as the substrate. The effect of the lacquer film and its use in various wood substrates has to be further explored at a more biological level for future practical applications.

Author Contributions

Conceptualization, methodology, validation, resources, data management, and supervision, T.D.; writing—review and editing, N.H.; and formal analysis, investigation, X.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This project was partly supported by the Natural Science Foundation of Jiangsu Province (BK20201386).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare that there is no conflict of interest.

References

- Zhou, Y.J.; Xie, C.Y. City garden environment research: Optimal design can improve the therapeutic benefit of therapy garden. Fresenius Environ. Bull. 2020, 29, 11615–11623. [Google Scholar]

- Hu, W.G.; Yu, R.Z. Mechanical and acoustic characteristics of four wood species subjected to bending load. Maderas-Cienc. Tecnol. 2023, 25, 39. [Google Scholar]

- Hu, W.G.; Luo, M.Y.; Hao, M.M.; Tang, B.; Wan, C. Study on the Effects of Selected Factors on the Diagonal Tensile Strength of Oblique Corner Furniture Joints Constructed by Wood Dowel. Forests 2023, 14, 1149. [Google Scholar] [CrossRef]

- Hu, W.G.; Yu, R.Z.; Luo, M.Y.; Konukcu, A.C. Study on tensile strength of single dovetail joint: Experimental, numerical, and analytical analysis. Wood Mater. Sci. Eng. 2022, 17, 2155875. [Google Scholar] [CrossRef]

- Han, M.J.N.; Kim, M.J. Green environments and happiness level in housing areas toward a sustainable life. Sustainability 2019, 11, 4768. [Google Scholar] [CrossRef]

- Gao, J.; Wang, R.; Zhang, Z.M.; Song, D.D.; Li, X.G. Effect of membrane structure of waterborne coatings on the transport process of corrosive medium. Prog. Org. Coat. 2018, 124, 8–15. [Google Scholar] [CrossRef]

- Ge, H.W.; Zhang, J.F.; Yuan, Y.; Liu, J.C.; Liu, R.; Liu, X.Y. Preparation of organicinorganic hybrid silica nanoparticles with contact antibacterial properties and their application in UV-curable coatings. Prog. Org. Coat. 2017, 106, 20–26. [Google Scholar] [CrossRef]

- Rosu, L.; Varganici, C.D.; Mustata, F.; Rosu, D.; Rosca, I.; Rusu, T. Epoxy coatings based on modified vegetable oils for wood surface protection against fungal degradation. ACS Appl. Mater. Interfaces 2020, 12, 14443–14458. [Google Scholar] [CrossRef]

- Huang, N.; Yan, X. Preparation of Aloe-Emodin Microcapsules and Its Effect on Antibacterial and Optical Properties of Water-Based Coating. Polymers 2023, 15, 1728. [Google Scholar] [CrossRef]

- Luo, Y.R.; Xu, W. Optimization of Panel Furniture Plates Rework Based on Intelligent Manufacturing. Bioresources 2023, 18, 5198–5208. [Google Scholar] [CrossRef]

- Luo, Z.Y.; Xu, W.; Wu, S.S. Performances of Green Velvet Material (PLON) Used in Upholstered Furniture. Bioresources 2023, 18, 5108–5119. [Google Scholar] [CrossRef]

- Zheng, S.; Bawazir, M.; Dhall, A.; Kim, H.E.; He, L.; Heo, J.; Hwang, G. Implication of Surface Properties, Bacterial Motility, and Hydrodynamic Conditions on Bacterial Surface Sensing and Their Initial Adhesion. Front. Bioeng. Biotechnol. 2021, 9, 643722. [Google Scholar] [CrossRef] [PubMed]

- Song, L.; Xiao, Y.F.; Gan, L.; Wu, Y.; Wu, F.; Gu, Z.W. The effect of antibacterial ingredients and coating microstructure on the antibacterial properties of plasma sprayed hydroxyapatite coatings. Surf. Coat. Technol. 2012, 206, 2986–2990. [Google Scholar]

- Lu, Z.; Hu, J.B.; Zhang, M.H.; Chang, S.S.; Liu, Y.; Zheng, L.; Li, X.J. Research on wettability of wood surface with waterborne-resin priming paint. J. For. Eng. 2021, 6, 178–183. [Google Scholar]

- Han, S.J.; Chen, Y.P.; Lyu, S.Y.; Chen, Z.L.; Wang, S.Q.; Fu, F. Effects of processing conditions on the properties of paraffin/melamine-urea-formaldehyde microcapsules prepared by in situ polymerization. Colloids Surf. B 2019, 585, 124046. [Google Scholar] [CrossRef]

- You, K.X.; Gao, B.; Wang, M.Y.; Wang, X.Y.; Okoro, K.C.; Rakhimbekzoda, A.; Feng, Y.K. Versatile polymer-based strategies for antibacterial drug delivery systems and antibacterial coatings. J. Mater. Chem. B 2022, 10, 1005–1018. [Google Scholar] [CrossRef]

- Zhao, Y.; Ren, J.; Zheng, X.; Pan, B.; Leng, W. Effects of three kinds of fungi on color, chemical composition and route of infection of Picea sitchensis. J. For. Eng. 2021, 6, 88–93. [Google Scholar]

- Das, S.; Das, A.; Bhavya, T.; Nivashini, S.R. Molecular characterisation and antibacterial activity of Aloe barbadensis miller on textiles. J. Text. Inst. 2020, 111, 1116–1122. [Google Scholar] [CrossRef]

- Xiong, X.Y.; Li, X.B.; Zhu, Z.F.; Zhang, E.D.; Shi, J.; Lu, M.G. Antibacterial and alkali-responsive cationic waterborne polyurethane based on modification of aloe emodin. Chem. Res. Chin. Univ. 2023, 39, 266–275. [Google Scholar] [CrossRef]

- Xiang, H.; Cao, F.J.; Ming, D.; Zheng, Y.Y.; Dong, X.Y.; Zhong, X.B.; Mu, D.; Li, B.B.; Zhong, L.; Cao, J.J. Aloe-emodin inhibits Staphylococcus aureus biofilms and extracellular protein production at the initial adhesion stage of biofilm development. Appl. Microbiol. Biotechnol. 2017, 101, 6671–6681. [Google Scholar] [CrossRef]

- Hu, X.K.; Ma, Y.; Liu, Z.D.; Zhao, M.X.; Dong, S.M.; Yang, H.; Dai, C.M. Microcalorimetric evaluation of the effects of three anthraquinone derivatives from Chinese Rhubarb and the synergistic effect of the mixture on Staphylococcus aureus. J. Therm. Anal. Calorim. 2020, 141, 739–749. [Google Scholar] [CrossRef]

- Ding, L.J.; Wang, H.; Liu, D.; Zheng, Z.N. Surface attachment of natural antimicrobial coatings onto conventional polypropylene nonwoven fabric and its antimicrobial performance assessment. J. Food Protect. 2018, 81, 172–177. [Google Scholar] [CrossRef] [PubMed]

- Jiang, L.X.; Yi, T.; Shen, Z.Y.; Teng, Z.H.; Wang, J.F. Aloe-emodin attenuates staphylococcus aureus pathogenicity by interfering with the oligomerization of alpha-toxin. Front. Cell. Infect. Microbiol. 2019, 9, 157. [Google Scholar] [CrossRef] [PubMed]

- Donkor, A.M.; Donkor, M.N.; Kuubabongnaa, N. Evaluation of anti-infective potencies of formulated aloin A ointment and aloin A isolated from Aloe barbadensis Miller. BMC Chem. 2020, 14, 8. [Google Scholar] [CrossRef]

- Coopoosamy, R.M.; Magwa, M.L. Antibacterial activity of aloe emodin and aloin A isolated from Aloe excelsa. Afr. J. Biotechnol. 2006, 5, 1092–1094. [Google Scholar]

- Alvaro, G.; Schlangen, E. Preparation of capsules containing rejuvenators for their use in asphalt concrete. J. Hazard. Mater. 2010, 184, 603–611. [Google Scholar]

- Zotiadis, C.; Patrikalos, I.; Loukaidou, V.; Korres, D.M.; Karantonis, A.; Vouyiouka, S. Self-healing coatings based on poly(urea-formaldehyde) microcapsules: In situ polymerization, capsule properties and application. Prog. Org. Coat. 2021, 161, 106475. [Google Scholar] [CrossRef]

- An, S.; Lee, M.W.; Yarin, A.L.; Yoon, S.S. A review on corrosion-protective extrinsic self-healing: Comparison of microcapsulebased systems and those based on core-shell vascular networks. Chem. Eng. J. 2018, 344, 206–220. [Google Scholar] [CrossRef]

- Scheiner, M.; Dickens, T.J.; Okoli, O. Progress towards self-healing polymers for composite structural applications. Polymer 2016, 83, 260–282. [Google Scholar] [CrossRef]

- Farooq, A.; Lee, H.W.; Jae, J.; Kwon, E.E.; Park, Y.K. Emulsification characteristics of ether extracted pyrolysis-oil in diesel using various combinations of emulsifiers (Span 80, Atlox 4916 and Zephrym PD3315) in double reactor system. Environ. Res. 2020, 184, 109267. [Google Scholar] [CrossRef]

- Liu, R.D.; Yan, J.L.; Li, Z.Y.; Zhang, Y.C.; Tian, C.Y.; Fu, P.; Li, X.B.; Zhou, L.; Xu, X.W. Research on the Upgrading of Bio-Oil Based on Low-Carbon Alcohol Solvents and Ultrasonic-Emulsification. BioResources 2022, 17, 4241–4261. [Google Scholar] [CrossRef]

- Yan, X.X.; Peng, W.W.; Qian, X.Y. Effect of water-based acrylic acid microcapsules on the properties of paint film for furniture surface. Appl. Sci. 2021, 11, 7586. [Google Scholar] [CrossRef]

- Yamazaki, N.; Du, Y.Z.; Nagai, M.; Omi, S. Preparation of polyepoxide microcapsule via interfacial polyaddition reaction in W/O and O/W emulsion systems. Colloids Surf. B Biointerfaces 2003, 29, 159–169. [Google Scholar] [CrossRef]

- Tao, Y.; Yan, X.X. Influence of HLB Value of Emulsifier on the Properties of Microcapsules and Self-Healing Properties of Waterborne Coatings. Polymers 2022, 14, 1304. [Google Scholar] [CrossRef]

- GB/T 21866-2008; Test Method and Effect for Antibacterial Capability of Paints Film. Standardization Administration of the People’s Republic of China: Beijing, China, 2008.

- GB/T 4789.2-2016; National Food Safety Standard Food Microbiological Examination: Aerobic Plate Count. Standardization Administration of the People’s Republic of China: Beijing, China, 2016.

- GB/T 11186.3-1989; Methods for Measuring the Colour of Paint Films. Part III: Calculation of Colour Differences. Standardization Administration of the People’s Republic of China: Beijing, China, 1990.

- GB/T 4893.4-2013; Test of Surface Coatings of Furniture. Standardization Administration of the People’s Republic of China: Beijing, China, 2013.

- GB/T 6062-1985; Stylus Instruments for the Measurement of Surface Roughness by the Profile Method Profile Recording Instruments and Profile Meters by the System M. Standardization Administration of the People’s Republic of China: Beijing, China, 1985.

- Chen, S.W.; Lu, X.C.; Wang, T.Z.; Zhang, Z.M. Preparation and characterization of urea-formaldehyde resin/reactive kaolinite composites. Particuology 2016, 24, 203–209. [Google Scholar] [CrossRef]

- Poljansek, I.; Sebenik, U.; Krajnc, M. Characterization of phenol-urea-formaldehyde resin by infine FTIR spectroscopy. J. Appl. Polym. Sci. 2006, 99, 2016–2028. [Google Scholar] [CrossRef]

- Xie, Y.F.; Huan, N.; Cao, Y.Y.; Wang, H.Y.; Zhong, Y.; Yao, W.R.; Qian, H. Structural characterization and spectroscopic analysis of the aloin. Spectrosc. Spect. Anal. 2014, 34, 385–388. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).