3.1. Axial Offset of the Laser Beam ΔLB

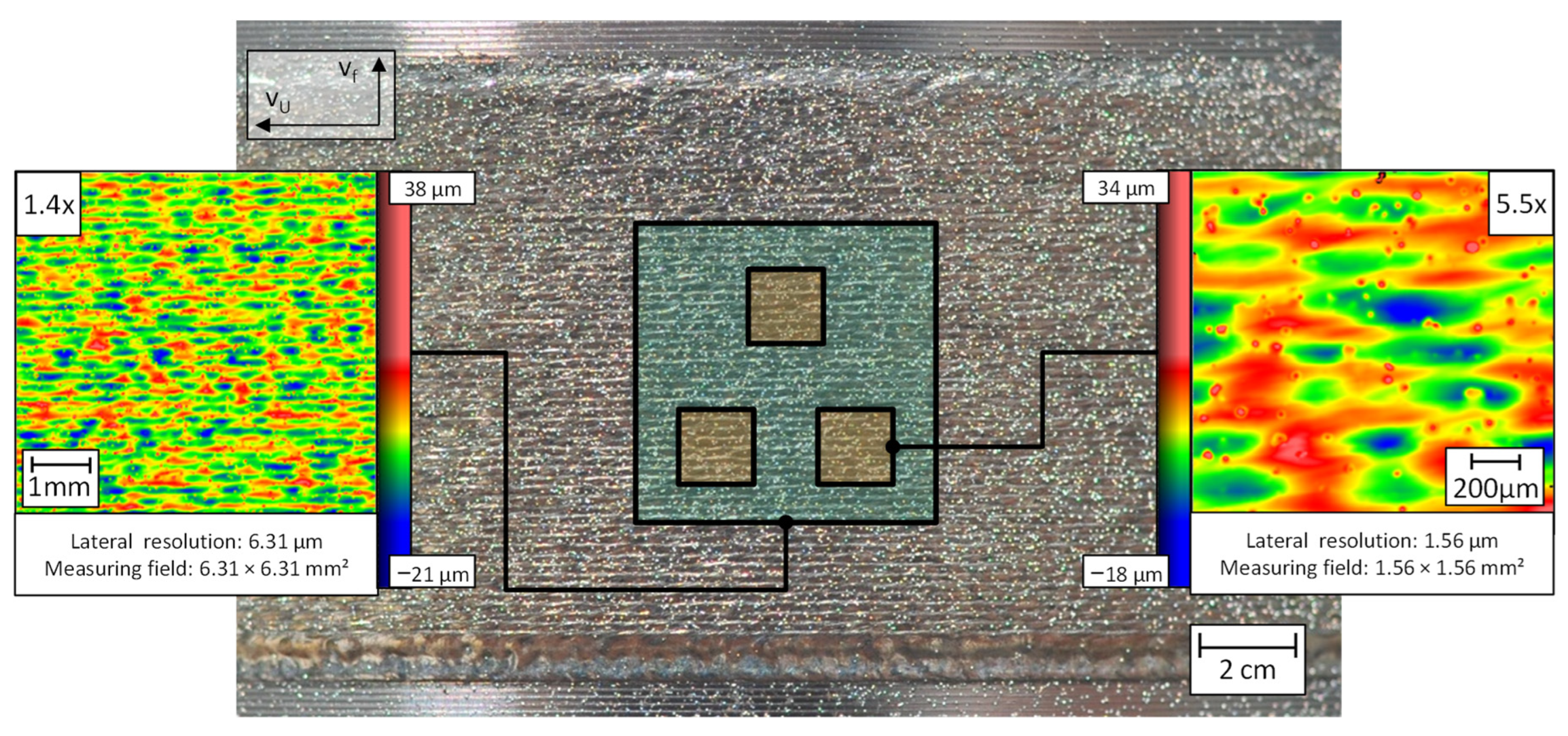

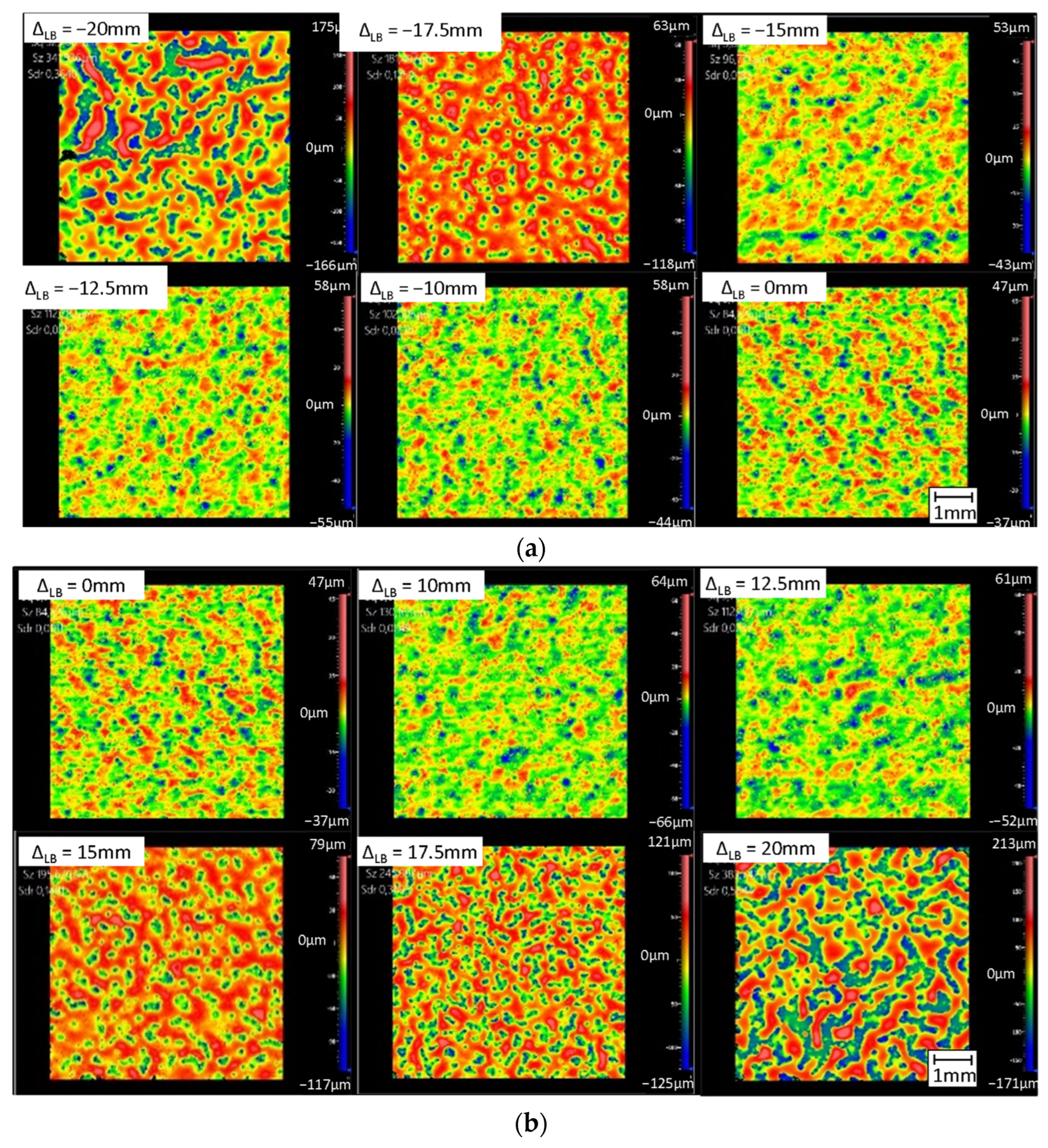

To evaluate the surface condition, the height profile in the WLI images (

Figure 12) shall be considered first. Based on the surface structures, the coatings created in a range of −15 mm ≤ Δ

LB ≤ 12.5 mm have comparable coating surfaces at standard settings (Δ

LB = 0 mm). The microstructure is fine and has a small height difference. The surface structure changes significantly with a negative offset from Δ

LB = −17.5 mm or with a positive offset from Δ

LB = 15 mm. A coarse macrostructure is formed, and defined melt islands are visible. This applies to both the lateral extent and the axial height of the structures (note the height scales). In these areas, large structures spreading over many single tracks can be recognized, which do not show any orientation.

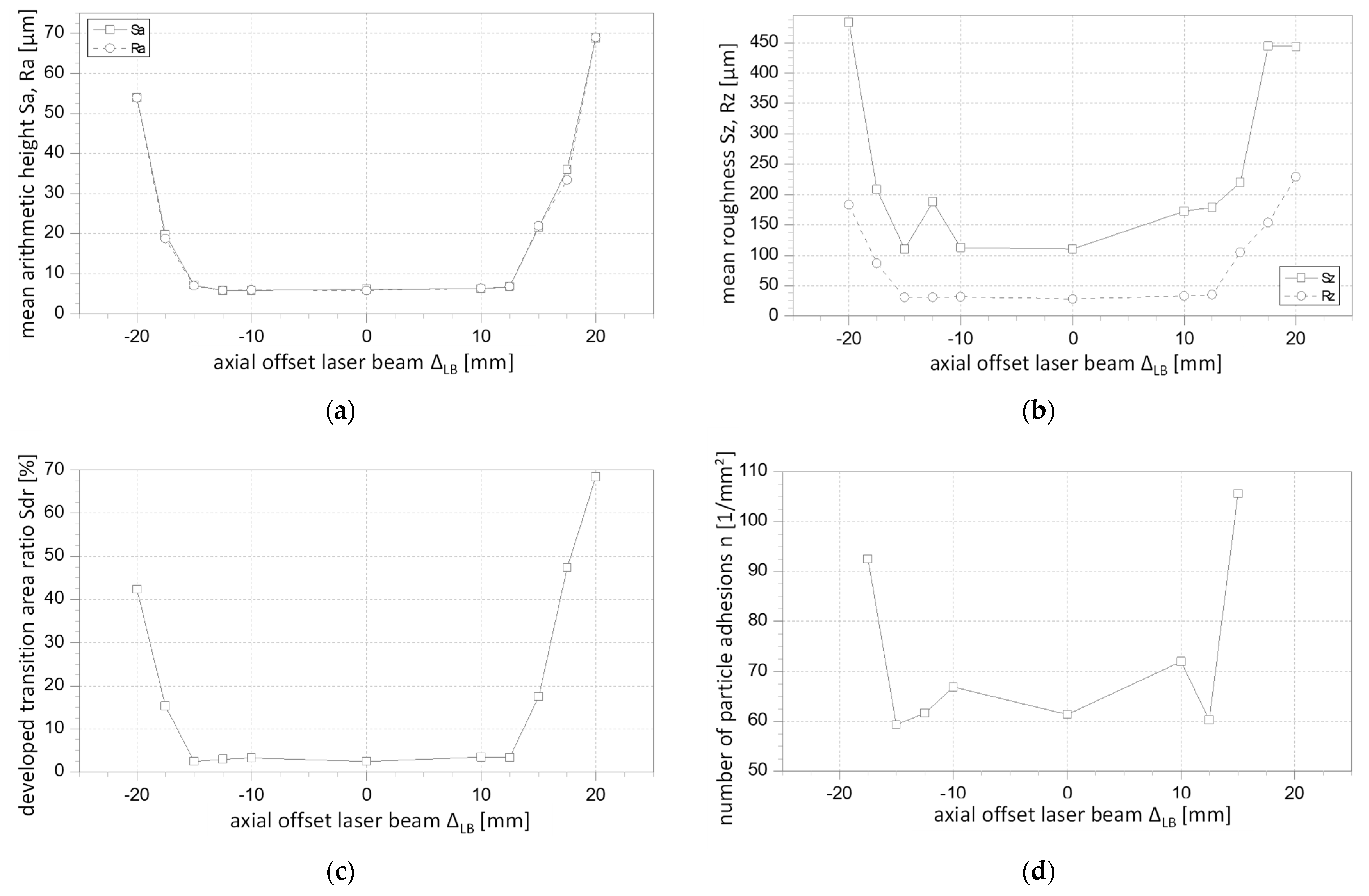

The same can be seen in the determined parameters Sa, Sz, and Sdr (

Figure 13). In the range of −15 mm ≤ Δ

LB ≤ 12.5 mm, the mean arithmetic height is comparable with values of about Sa ≈ 6.3 µm. Outside this range, the value increases to Sa = 53.9 µm at Δ

LB = −20 mm and to Sa = 68.8 µm at Δ

LB = 20 mm. The mean roughness takes values between Sz = 110.4 µm and Sz = 188 µm in the range of −15 mm ≤ Δ

LB ≤ 12.5 mm and more than doubles outside this range to Sz = 483.7 µm at Δ

LB = −20 mm and to Sz = 443.7 µm at Δ

LB = 20 mm due to the large structure heights. Since the real surface area is increased by the resulting structures, the developed area ratio also shows this trend, so that it is Sdr ≈ 3% inside the range of −15 mm ≤ Δ

LB ≤ 12.5 mm and increases to Sdr ≈ 42.3% at Δ

LB = −20 mm and to Sdr ≈ 68.4% at Δ

LB = 20 mm outside this range. The particle number could only be determined from Δ

LB = −17.5 mm to Δ

LB = 15 mm using the method described above. In the range from Δ

LB = −15 mm to Δ

LB = 12.5 mm, the coating surfaces have a number of adhering particles of 59 to 72 per mm

2, whereas at Δ

LB = −17.5 mm and at Δ

LB = 15 mm, the number increases to 93 and to 106 per mm

2, respectively.

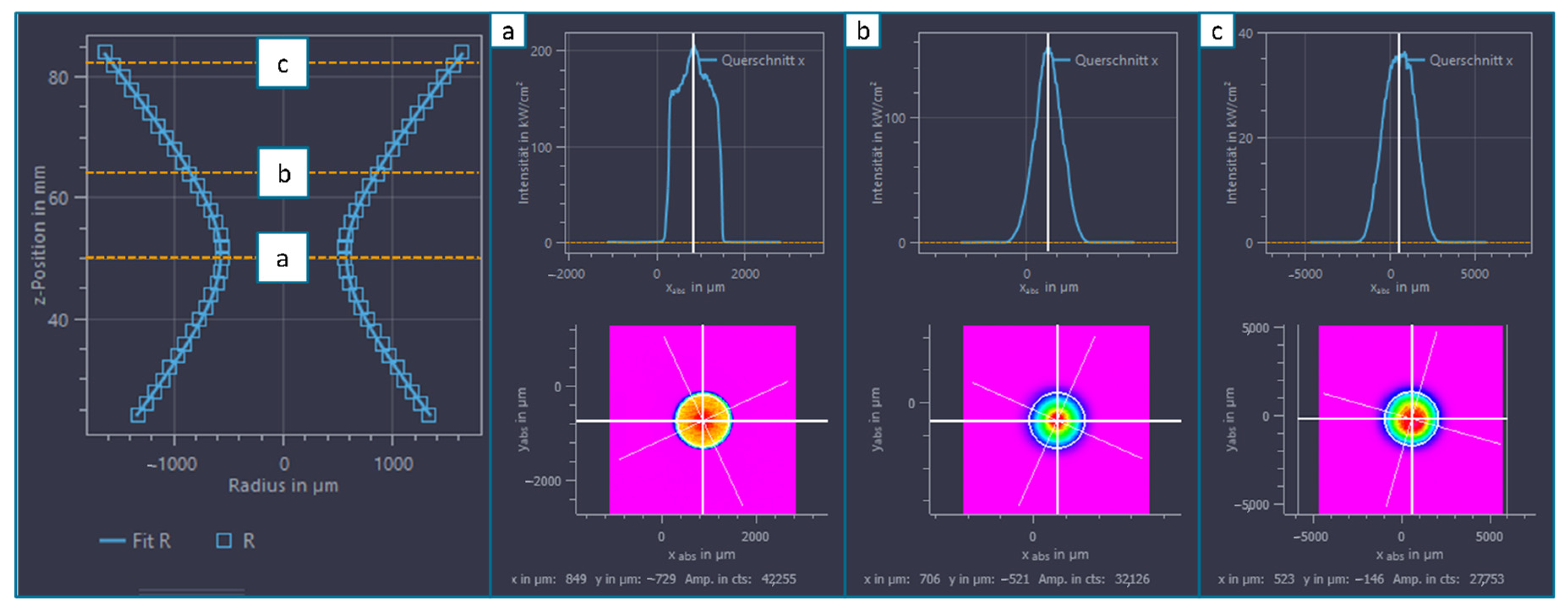

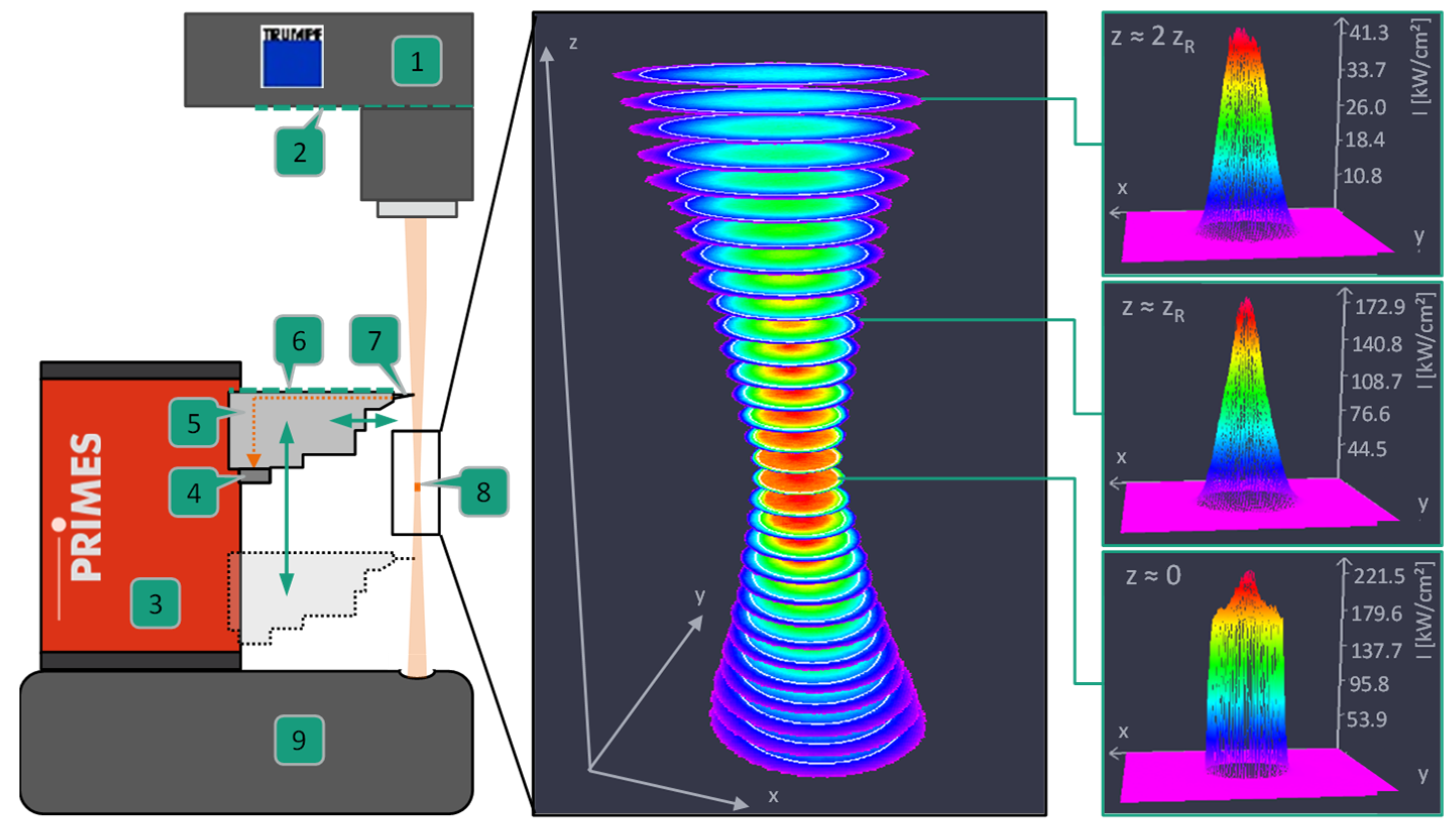

The Rayleigh length z

R of the laser beam could be the reason why the surface properties of the coatings remain almost constant over a wide range of the axial offset of the laser beam and change significantly only from Δ

LB = −17.5 mm to Δ

LB = 15 mm. The Rayleigh length indicates the axial distance from the beam waist at which the laser beam expands to √(2)-fold [

16], i.e., the laser spot area doubles. Within the Rayleigh length, intensity changes due to the caustic can be neglected (for Gaussian beams) [

1]. The range from z = −z

R to z = z

R with respect to the beam waist is called the focus length [

16]. For the laser beam used here, an approximately constant energy distribution and input into both the substrate and the PGJ is also expected in this range, so that the surface conditions are expected to be constant over the range of the focus length.

For negative offset, effects on the surface condition are first noticeable at ΔLB = −17.5 mm, whereas for positive offset, they are already noticeable at ΔLB = 15 mm. This asymmetry could be related to the change in Rayleigh length that occurs when the laser beam focus is shifted by the collimator. A negative shift increases the Rayleigh length, and a positive shift decreases it. Thus, with a positive offset, the substrate surface emerges earlier from the range of the focus length, so that differences in the energy input into the substrate and thus differences in the weld pool formation can occur earlier here than with a negative offset of the laser beam.

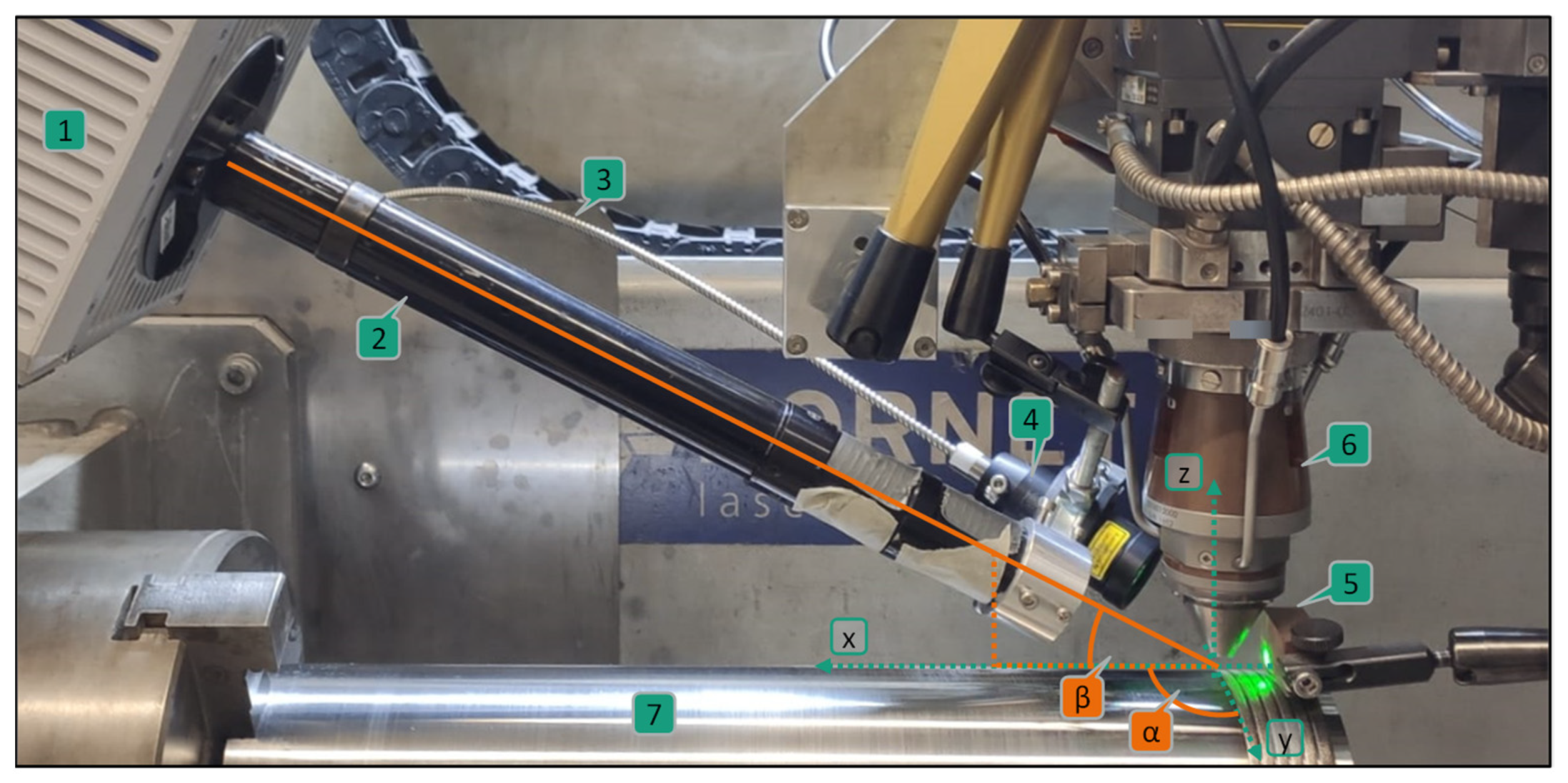

Thus, it can be said that the EHLA process with the parameter settings of

Table 5 is stable at least over the range of the focal length (±z

R). A shift beyond ±z

R can lead to an insufficient power density on the substrate surface to generate or permanently sustain a weld pool. This is shown by the single tracks (

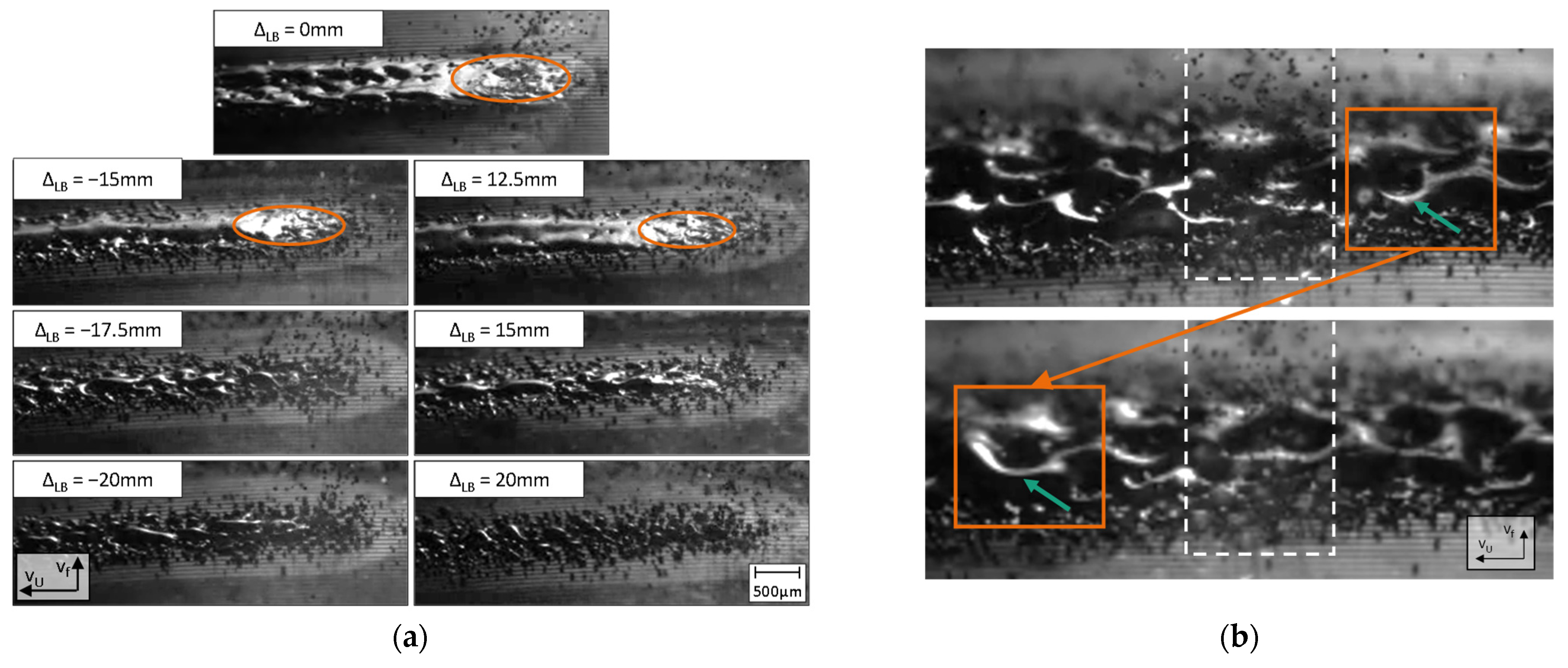

Figure 14). With the standard setting, a clear, almost uniform boundary between the deposited track and the substrate can be seen, whereas the edges of the single tracks become increasingly frayed with negative axial offset. Furthermore, up to Δ

LB = −15 mm, the material is deposited continuously in the core areas of the single tracks. From Δ

LB = −17.5 mm, however, an increasing number of defects can be seen in the core areas of the single tracks, so that no longer continuous tracks are produced. The behavior of the positive offset is equivalent to that of the negative offset.

The high-speed images (

Figure 15a) show that at Δ

LB = −15 mm, there is still a continuous, permanent weld pool. At Δ

LB = −17.5 mm, the weld pool is no longer continuous, which could be caused by the reduced energy density on the substrate surface. So, instead of a single melt line, several individual structures are formed on the substrate surface. During the next overlapping run, the material already deposited is re-melted, and due to surface tension, the newly deposited material preferably forms a molten bond with the remelted material of the existing structures. This can be seen in

Figure 15b. In the top image, the area of the already coated substrate marked by the orange rectangle is still in front of the process area of the single track now to be applied. Here, a recess with relatively small crater walls can be seen (green arrow). In the bottom image, the marked area has moved to the left, behind the process area. During the process, additional material has accumulated on the crater wall, making it more pronounced, and this structure thus extends over another single track.

The same is observed with a positive axial offset. In this case, non-continuous core areas occur in single tracks with strongly frayed edges from ΔLB = 15 mm. In the high-speed images, processes comparable to those described above can be seen. The fact that no more continuous weld pools are generated above a certain axial offset suggests that the power density on the substrate surface is no longer sufficient to apply enough energy per area and time to reach the melting temperature of the substrate material.

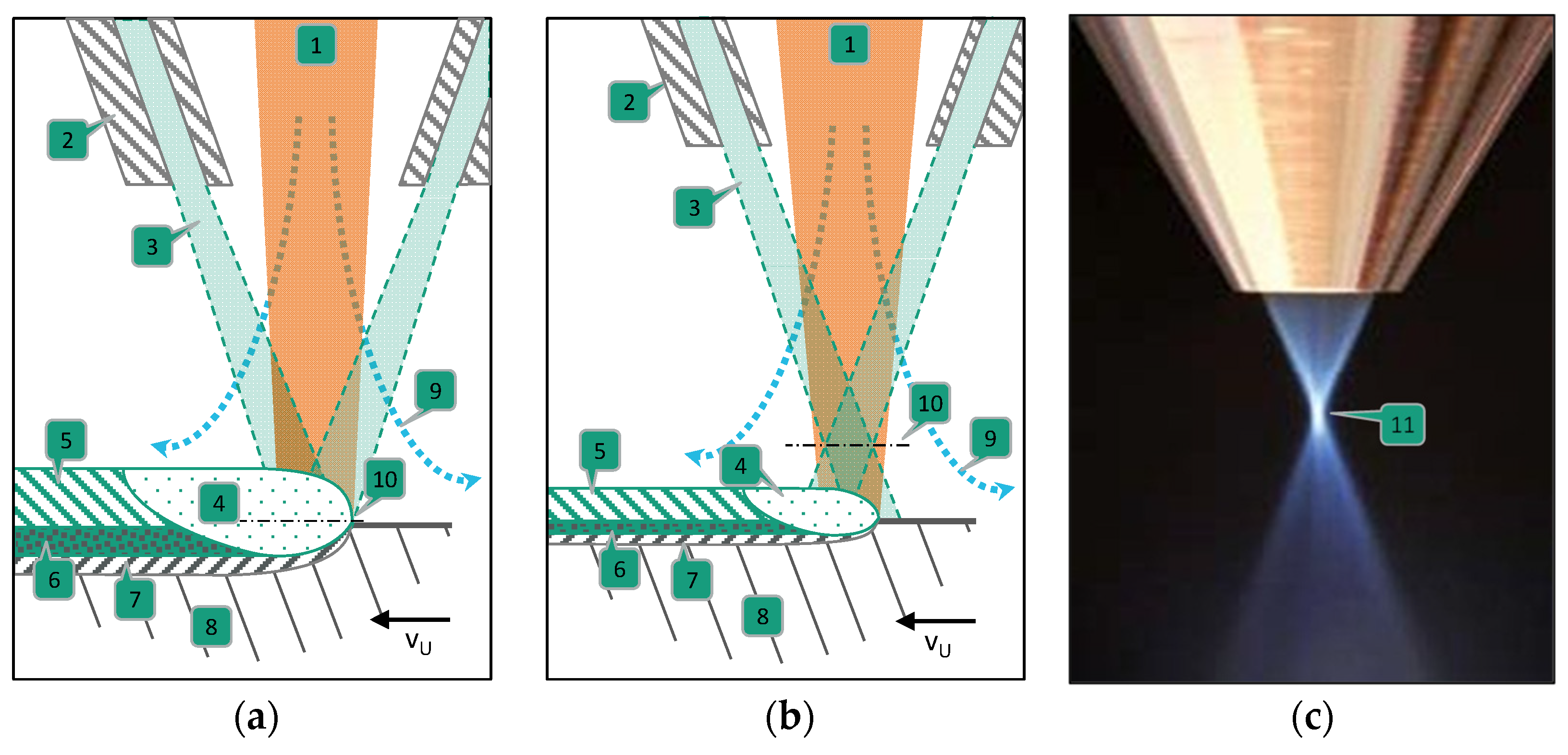

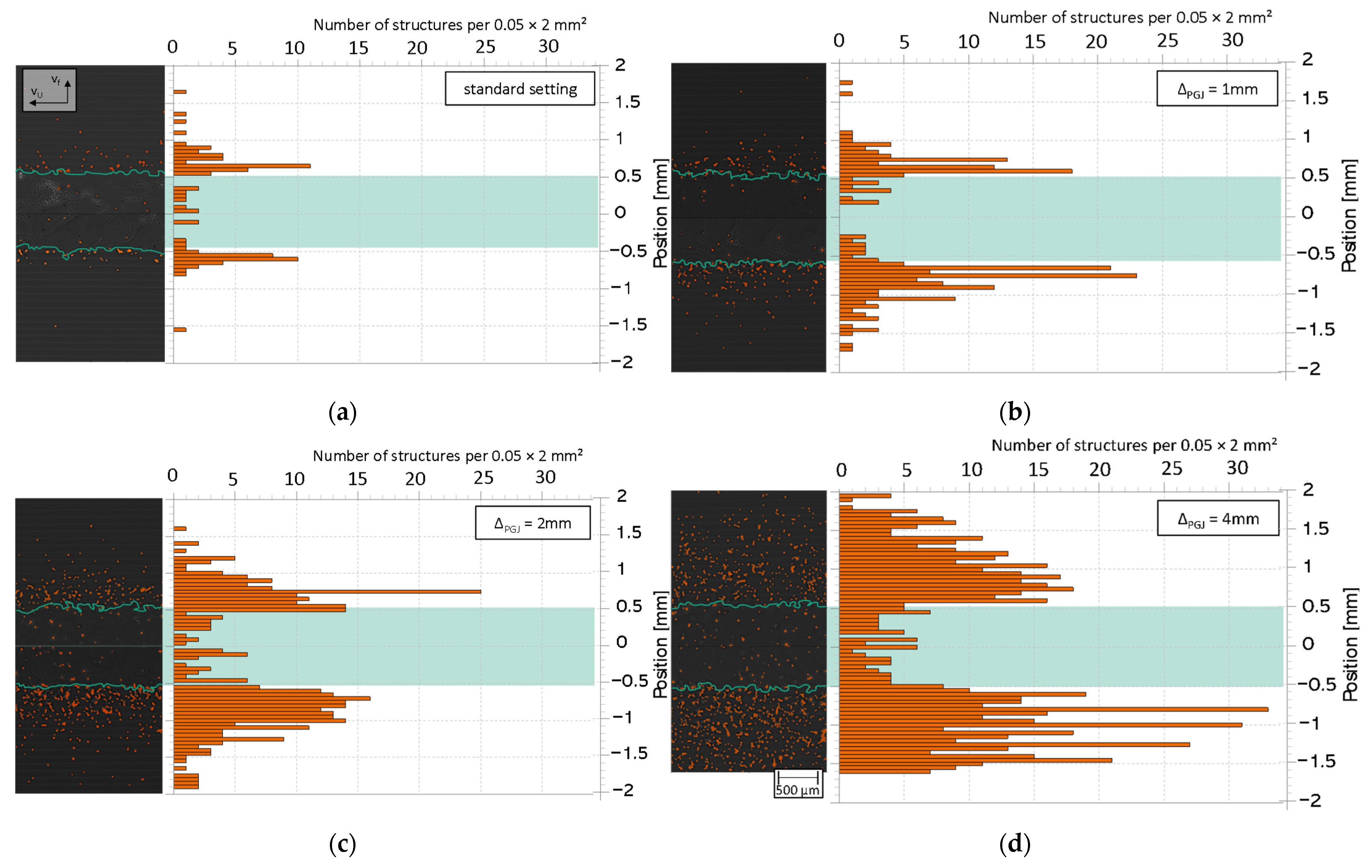

3.2. Axial Offset of the Powder–Gas Jet ΔPGJ

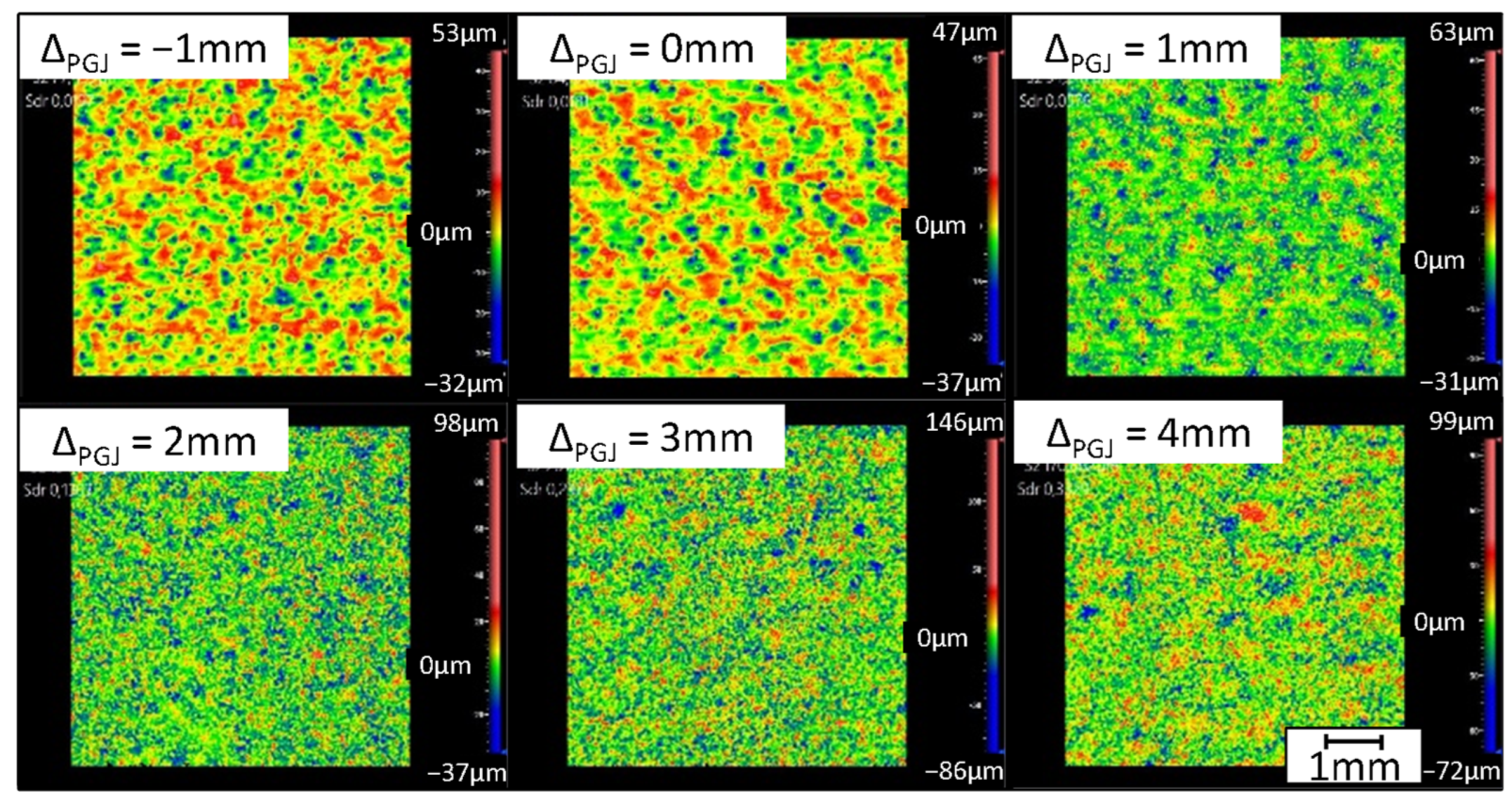

Figure 16 shows the WLI images of the coatings produced with varied axial offsets of the PGJ. At Δ

PGJ = −1 mm, the focus is approximately on the substrate surface. At this axial offset, the structure of the surface is comparable to that at the standard setting (Δ

PGJ = 0 mm). Thus, at Δ

PGJ = −1 mm, the characteristic values are Sa = 6.3 µm, Sdr = 2.7%, and a particle number of 54 per mm

2, comparable to those at Δ

PGJ = 0 mm, with values of Sa = 6.1 µm, Sdr = 2.4% and a particle number of 61 per mm

2. The average roughness depth is larger for Δ

PGJ = −1 mm with Sz = 169 µm than for Δ

PGJ = 0 mm with Sz = 110.4 µm.

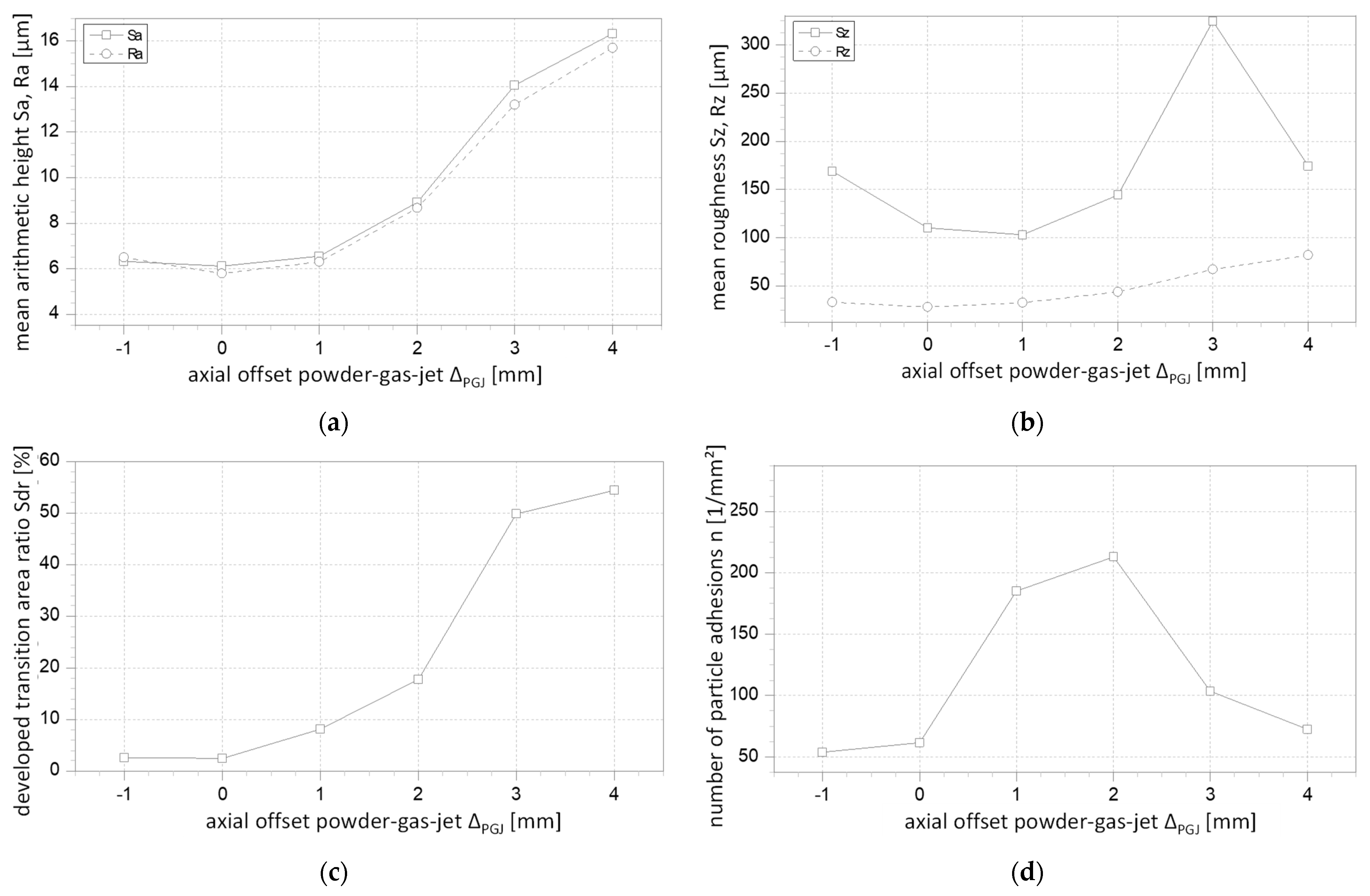

With a positive axial offset, the WLI images show that finer structures increasingly appear on the surfaces. These fine structures cause the roughness values of Sa = 16.3 µm and Sz = 174.5 µm at Δ

PGJ = 4 mm (

Figure 17). In addition, these structures enlarge the real surface area, causing the developed transition area ratio to increase to Sdr = 54.4% at Δ

PGJ = 4 mm. The investigations regarding particle adhesions suggest that these fine structures are caused by adherent particles. The number of particle adhesions is already 185 per mm

2 at Δ

PGJ = 1 mm. From Δ

PGJ = 2 mm, the particle density on the coating surface is so high that individual particles can often no longer be resolved separately using the method described above, and the number of particles on the coating therefore increases only slightly to 213 per mm

2. This effect is amplified with a further positive offset Δ

PGJ. In addition, since the particles are often deposited so close together or even one above the other, they merge more and more into agglomerates. Thus, the determined number of particles decreases.

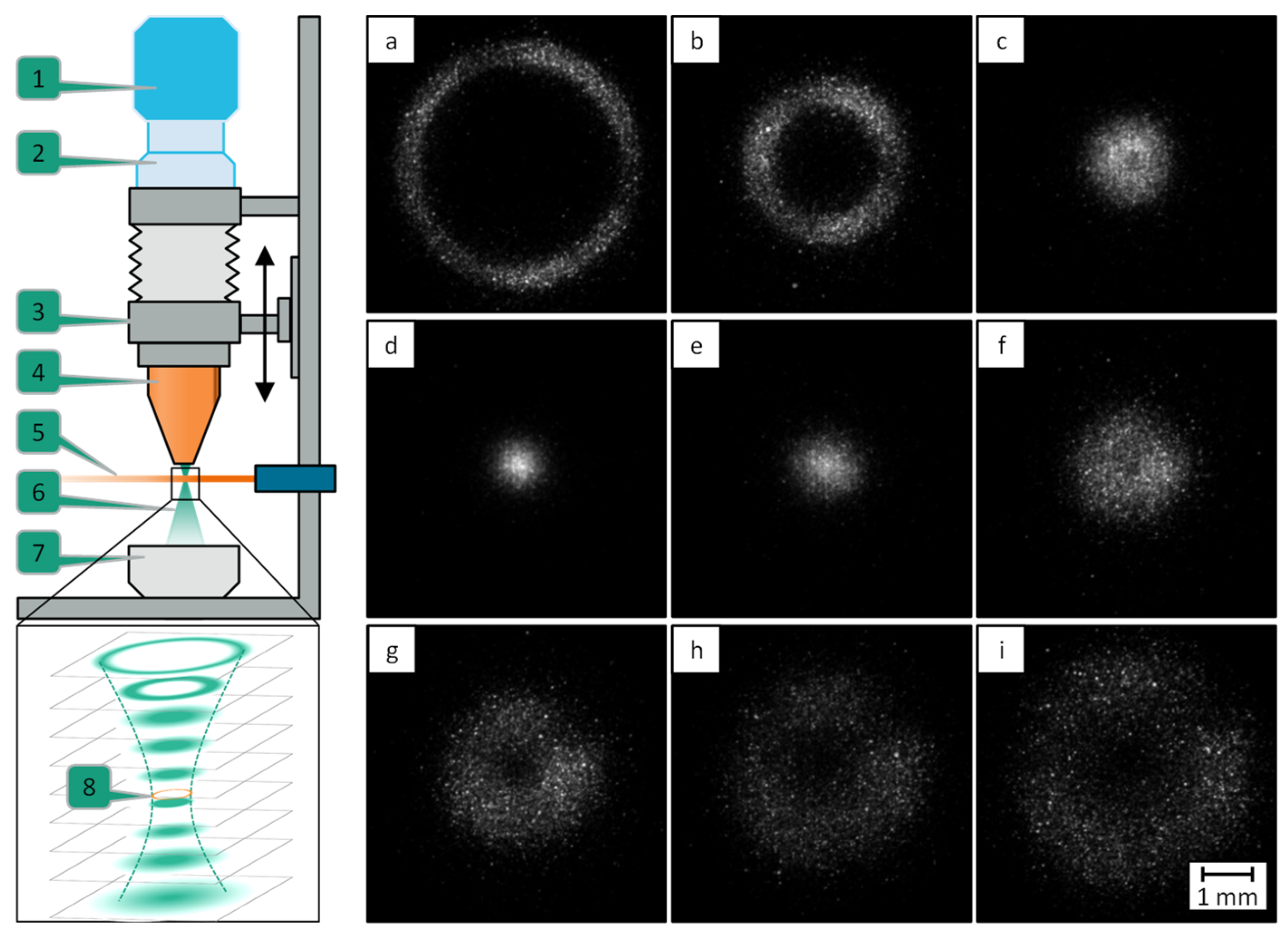

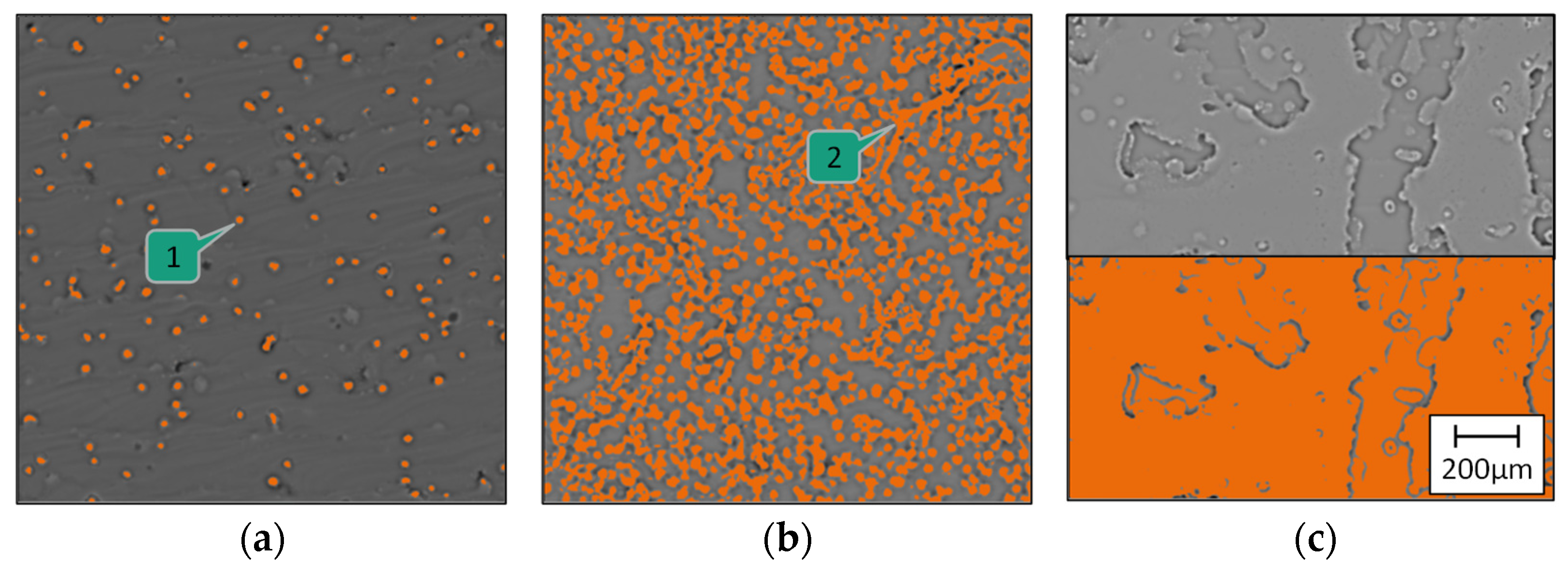

The fact that the PGJ focus in the present investigations is shifted in a range that lies within the Rayleigh length of the laser beam leads to the assumption that the energy input into the powder particles is still sufficient to melt the majority of the particles on their way to the substrate. However, due to positive Δ

PGJ, the PGJ spot on the surface becomes larger, so that an increased number of molten particles outside the weld pool hit the surface. This overspray can cause molten particles that impinge, perhaps on a sufficiently preheated substrate or coating surface, to fuse with it [

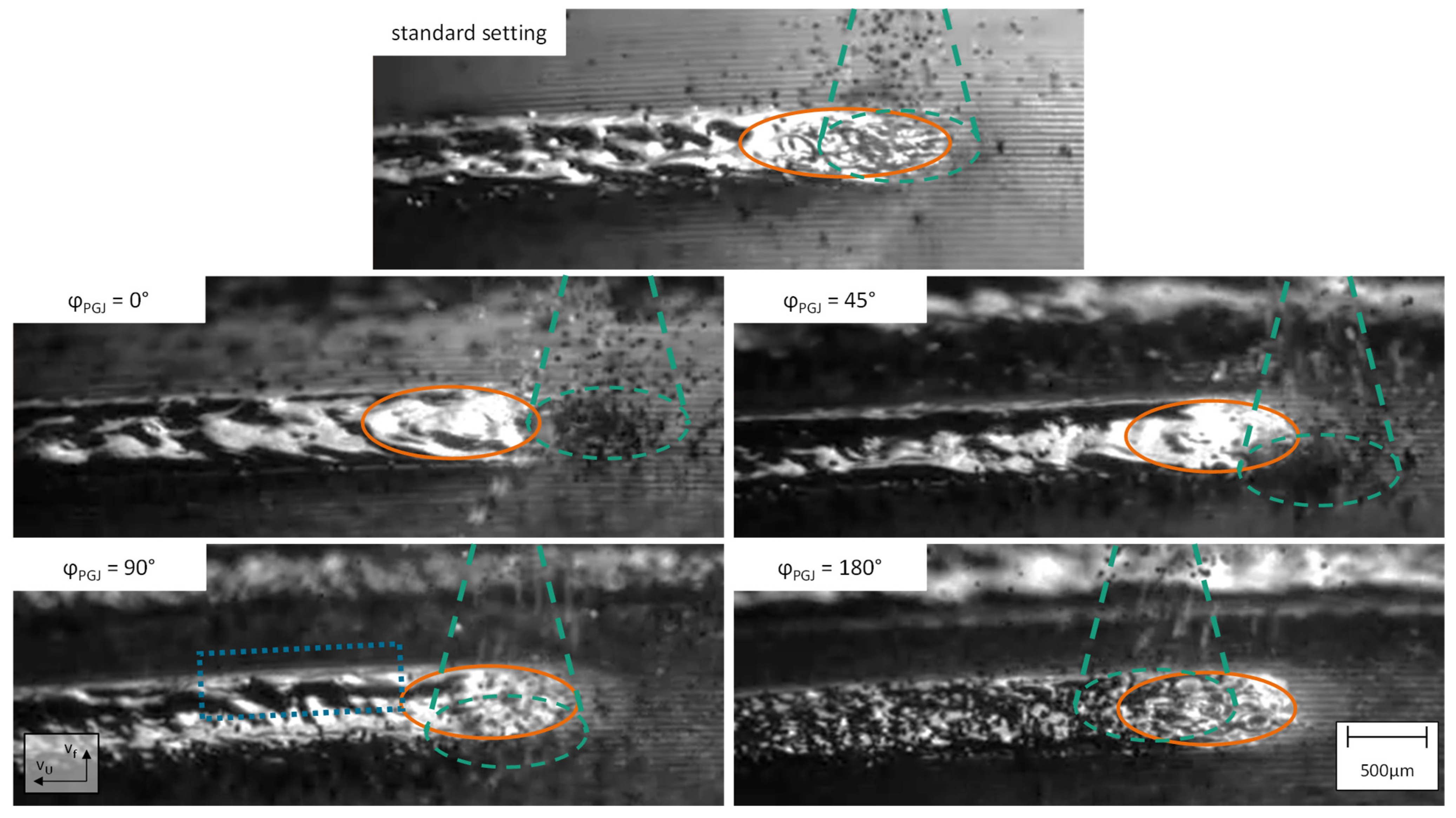

17]. This is well visible on the single tracks (

Figure 18). With greater Δ

PGJ, the particle adhesion increases on the single track and on both sides next to it. No significant differences in the form of the track edges can be seen over the investigated offset range, which indicates a continuously existing weld pool, so a sufficiently high energy input in the substrate and thus homogeneously enclosed coatings are to be assumed.

Since the overspray increases with the positive offset, the width of the particle distribution increases on the one hand, and the total number of particles deposited on the surface per run increases on the other. This means that more particles are deposited on an already coated area by the following run, but also that the number of following runs in which particles are deposited at this area increases with the offset ΔPGJ, which is the reason for the strong increase in particle adhesion and fine structures and thus in the parameters Sa, Sz, and Sdr.

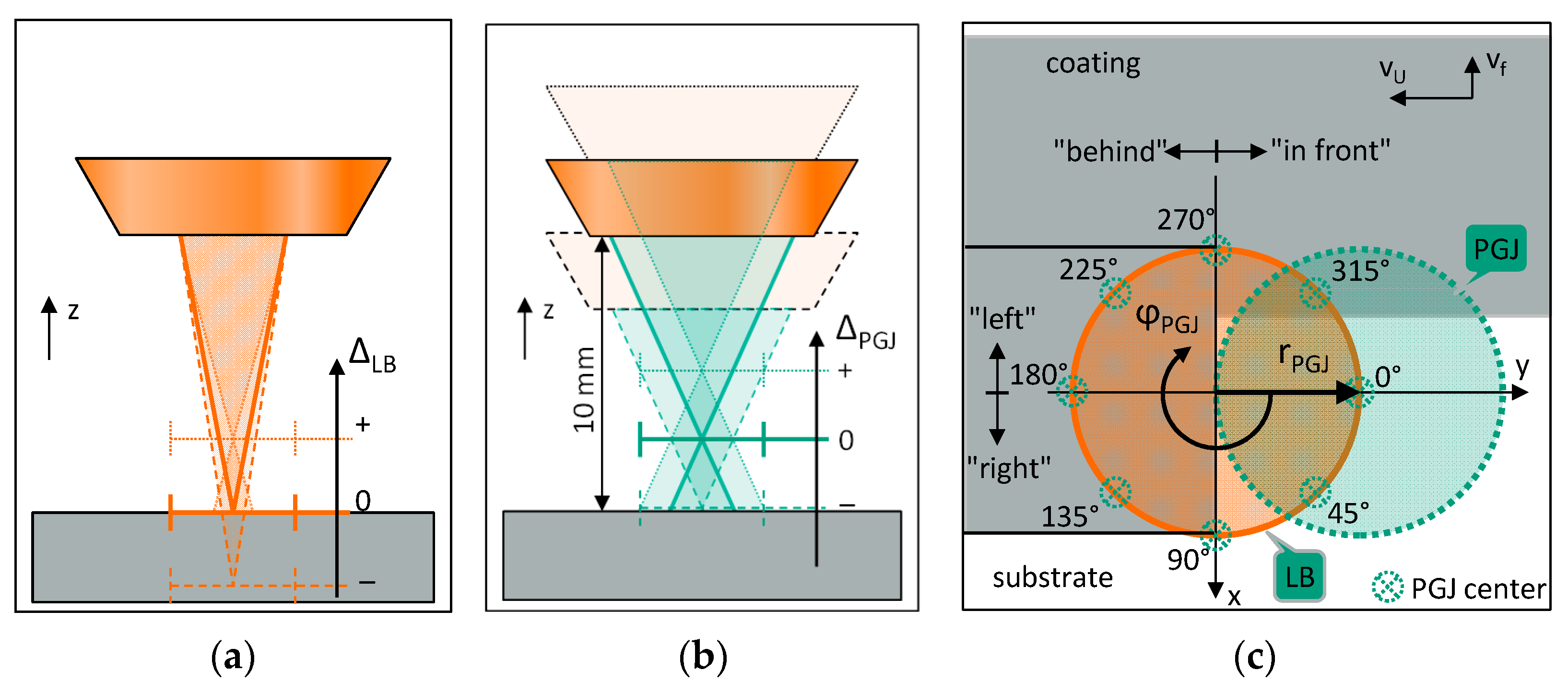

3.3. Lateral Offset of the Powder–Gas Jet φPGJ

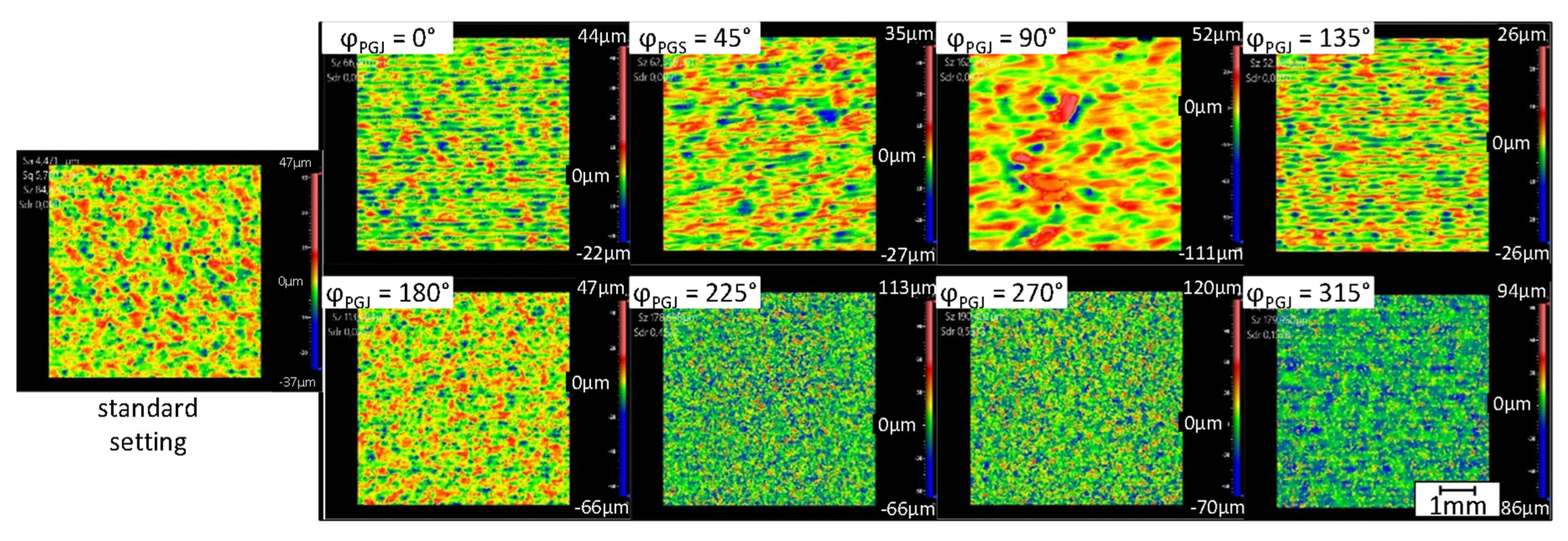

Since the lateral offsets lead to very different surface textures (

Figure 19), which are caused by different mechanisms, the lateral offsets investigated are evaluated individually. For this purpose, the WLI images of the coatings and the single tracks, the determined parameters, as well as the high-speed images, are considered.

With an offset of φ

PGJ = 0°, compared to the standard setting (r

PGJ = 0 mm), coatings with smaller overlapping structures result, which have an orientation in the scanning direction (

Figure 19). With φ

PGJ = 0°, the PGJ spot lies in front of the laser spot (see

Figure 7). Thus, less powder enters the weld pool directly; rather, the powder is first deposited in front of the weld pool and then absorbed by the weld pool when moving over it. Since the powder is not fed directly into the weld pool, fewer waves are induced in it than with the standard setting (

Figure 20).

With the standard setting, structures develop out of the waves when the weld pool solidifies, which is less prominent with φ

PGJ = 0° due to the smoother weld pool. So, the structures are less pronounced laterally and merely expand in the scanning direction. Due to the following weld pool, almost no further particles are deposited behind it (

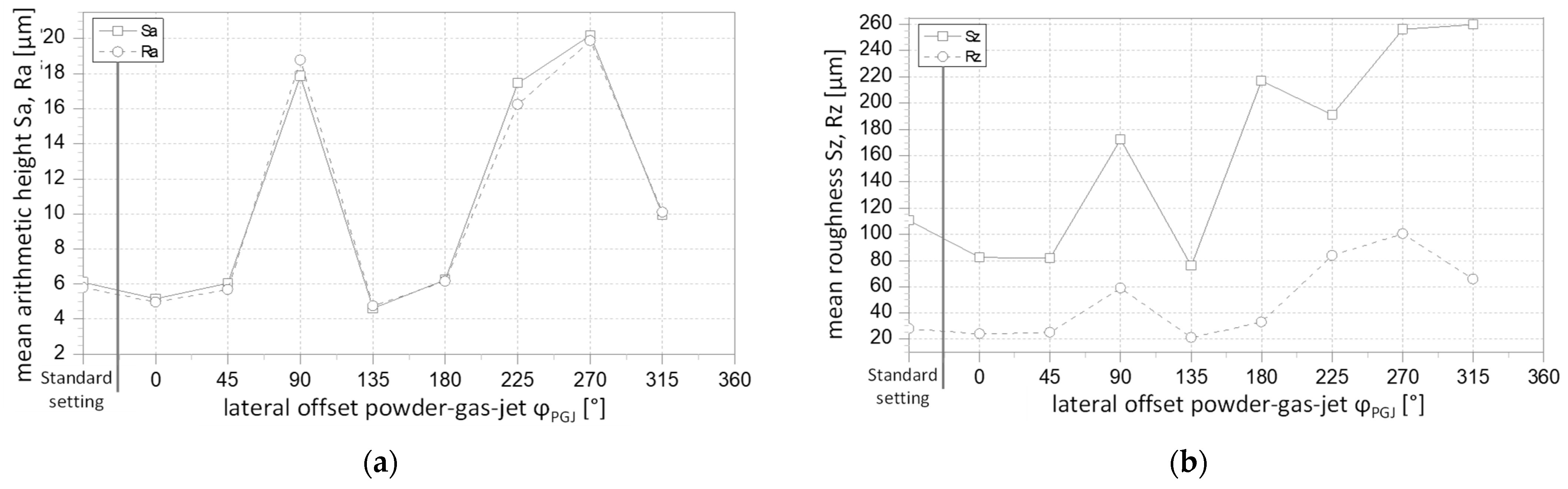

Figure 21a), and the surface is smoothed by the laser beam. In addition, fewer particles adhere on the left side next to the single track because the particles hitting the substrate’s surface there do not pass the laser beam anymore and thus are not heated up enough to adhere. Thus, all investigated parameters at φ

PGJ = 0° are reduced to Sa = 5.2 µm, Sz = 82.3 µm, Sdr = 1.8%, and the number of particle adhesions to 43 per mm

2 (

Figure 22).

At φ

PGJ = 45°, structures with an orientation in the direction of v

U appear again, whereby these structures are larger and partially spread over several tracks (

Figure 19). The PGJ is in front of the laser beam, whereby the PGJ also lies to the right of the laser beam. Due to this relative positioning, the number of particles adhering to the single tracks is relatively small due to the following laser beam as described for φ

PGJ = 0° (

Figure 21b). Additionally, since the PGJ is located to the right of the laser beam, many particles adhere to the right side, and fewer melted particles reach the area to the left of the track. However, the particle adhesions on the right side do not contribute directly to the surface condition since these are re-melted during the next run. The low particle number on the left side leads to a reduction in the particle number to 26 per mm

2 on the generated coating. Because fewer particles are deposited directly into the weld pool, which is similar to φ

PGJ = 0°, the weld pool is relatively smooth (

Figure 20). But at φ

PGJ = 45°, the particles are mainly fed to the weld pool from the side, so that they induce a wave and thus a material transport from the right to the left side of the weld pool. This leads to an accumulation of material on the left side of single tracks (

Figure 20). During the coating process, the material is thus transported in the direction of the previous track and can be deposited there. Since the weld pool extends relatively far behind the laser beam and even further behind the PGJ, transported material can partially flow back from the previous track to the center of the now deposited track (

Figure 20). This material flow could result in structures at the left edge of a single track, which could also spread over several track offsets due to the material returning to the weld pool. The combination of few particle attachments and the formation of (comparatively long-wavelength) structures due to a modified weld pool flow, leads to values of Sa = 6.1 µm, Sz = 81.6 µm, and Sdr = 1.2% at φ

PGJ = 45° (

Figure 22).

With a further shift to φ

PGJ = 90°, the resulting overlapping structures on the surface become even larger, so that they now extend over several single tracks (

Figure 19). These structures again have an orientation in the scanning direction. Since the PGJ is located to the right of the laser beam with respect to the scanning direction, powder is significantly added to the weld pool on this side. As a result, many particles are deposited on this side, too (

Figure 21c). Furthermore, adding the powder from the side forms a wave in the weld pool, which forces the material to the opposite, left side of the weld pool (

Figure 20). On the one hand, this material transport makes the left edge higher, but on the other hand, it also creates unevenness, which leads to large and deep structures. Due to these structures, the roughness values increase to Sa = 17.9 µm and Sz = 172.3 µm. Since also here relatively few particles adhere to the left side of the track, the particle number of 26 per mm

2 remains unchanged compared to φ

PGJ = 45°. The developed transition area ratio is significantly increased by particle adhesions and less by large, long-wavelength structures, as they occur here, so this value increases to only Sdr = 2.7%.

At φ

PGJ = 135°, smaller structures with an orientation in the scanning direction appear again, which are comparable to those at φ

PGJ = 45°. Since very few particles adhere to the left edge as well as to the left of the single track (

Figure 22d), the number of particles on the entire surface assumes the smallest value of 19 per mm

2 observed for all offsets. The other parameters also assume the smallest values of Sa = 4.6 µm, Sz = 75.9 µm, and Sdr = 0.9%. Thus, the roughness can be reduced by an offset of φ

PGJ = 135° with respect to the standard setting.

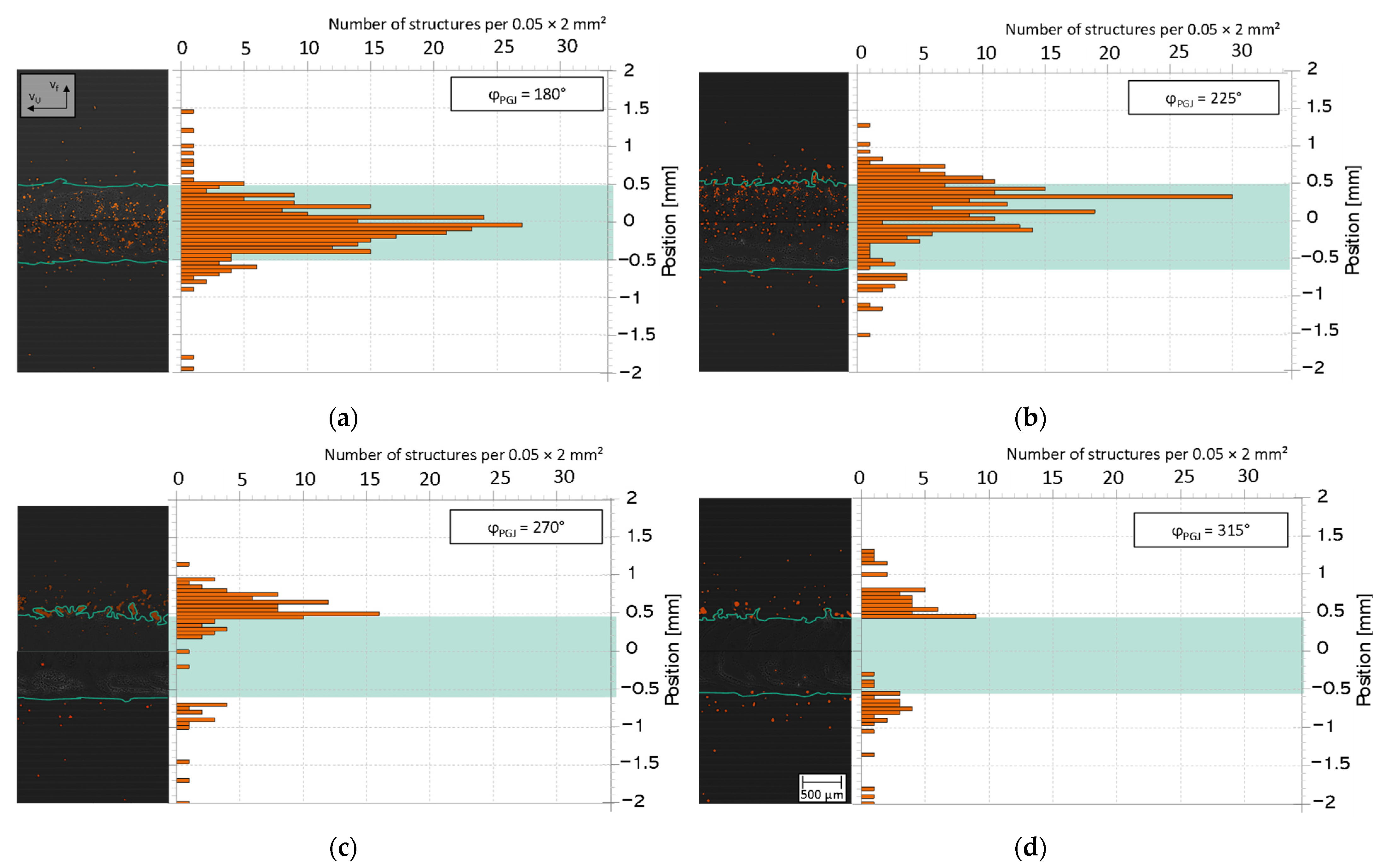

At φ

PGJ = 180°, the PGJ is located behind the laser beam with respect to the scanning direction. Since the weld pool also extends to an area behind the laser spot, the powder particles impinge on an area in which the weld pool is still present or is cooling down. This results in a very turbulent weld pool with many particles adhering to the surface (

Figure 20). These particles are not remelted by further runs, so an increased occurrence of particle adhesion on the single track (

Figure 23a) and therefore also on the coating surfaces (103 per mm

2) is observed. The structures on the coatings are therefore, again, smaller and without orientation, comparable to the standard setting. Thus, the developed transition area ratio also increases to Sdr = 3.4%. In addition, the roughness values increase to Sa = 6.2 µm and Sz = 217.2 µm.

At φ

PGJ = 225°, the PGJ is located behind the laser beam and to its left with respect to the scanning direction. For this reason, the particle distribution shifts to the left when looking at the single tracks, so that more particles adhere to the left edge area of the track and to any tracks that are already present but even on the single track itself (

Figure 23b). Since the particles on the left edge area are not re-melted during the following run and further particles adhere during the following runs, a particle number on the coatings of 240 per mm

2 is determined. However, since the particle density on the surface is so high, particles can form agglomerates, and the surface shows fine structures without orientation. Due to these fine structures, the developed transition area ratio increases rapidly to Sdr = 75.1%. In addition, a further increase in roughness values to Sa = 17.5 µm and Sz = 191.1 µm can be seen.

With a further rotation of the lateral offset to φ

PGJ = 270°, the PGJ is at the same level but to the left of the laser beam, so that few particles impinge on the right side and the weld pool dominates there. So, the single tracks on the right have few particle adhesions (

Figure 23c). The particle distribution of the single tracks thus shifts further to the left, and an increased particle adhesion can be observed both at the left edge of the track and in the area to the left of the track (i.e., on previous tracks). For this reason, the particle density on the coatings increases to such an extent that an increased formation of agglomerates takes place. Therefore, the determined number of particle adhesions on the coating surface decreases again to 225 per mm

2. The other parameters, however, increase again slightly due to the fine structures produced, so that with regard to the lateral offsets investigated, the largest values could be determined with Sa = 20.2 µm, Sz = 256.3 µm, and Sdr = 88.5% at φ

PGJ = 270°.

With φ

PGJ = 315°, the PGJ is located to the left of the laser beam as with φ

PGJ = 225°, but this time the PGJ is placed in front of the laser beam. As a result, although the particle distribution to the left of the single track at φ

PGJ = 315° is comparable to that at φ

PGJ = 225°, fewer particles are deposited on the edge region of the track this time because the following weld pool absorbs these particles (

Figure 23d). Since the number of particles adhering to the single tracks is now so small, the particles adhering to the coatings are virtually only caused by the particles adhering to the left of the single tracks. Thus, the number of particles on the coatings decreases to 175 per mm

2. At the same time, the other parameters also decrease to Sa = 10 µm, Sz = 260.1 µm, and Sdr = 22.2%.

In summary, it can be said that the lateral offset φ PGJ influences the interaction between the particle adhesions on and in the area next to the track as well as the material transport in the weld pool. On the one hand, the lateral offset of the PGJ to the left or right side causes increased particle deposition on the respective side, and on the other hand, the lateral addition of powder into the weld pool forces material transport to the opposite side. If the PGJ is placed in front of the laser beam, a smooth weld pool is created, and the surface is smoothed by the laser beam. Therefore, hardly any particles are deposited on the single tracks. If the PGJ is located behind the laser beam, more particles are deposited on the single tracks. The surface properties are influenced by the synthesis of all these effects.