3.1. Analysis of Gas Dynamics

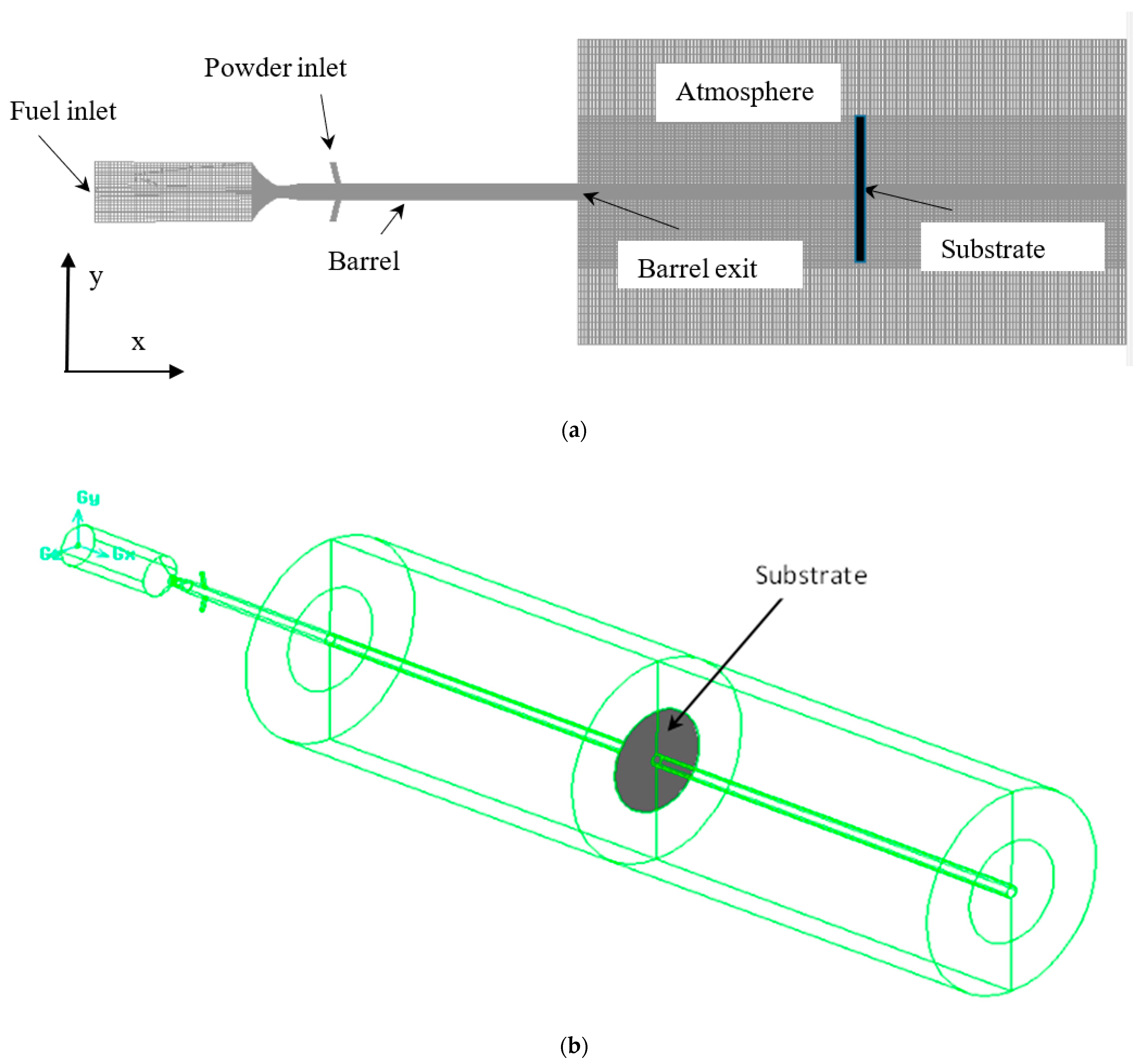

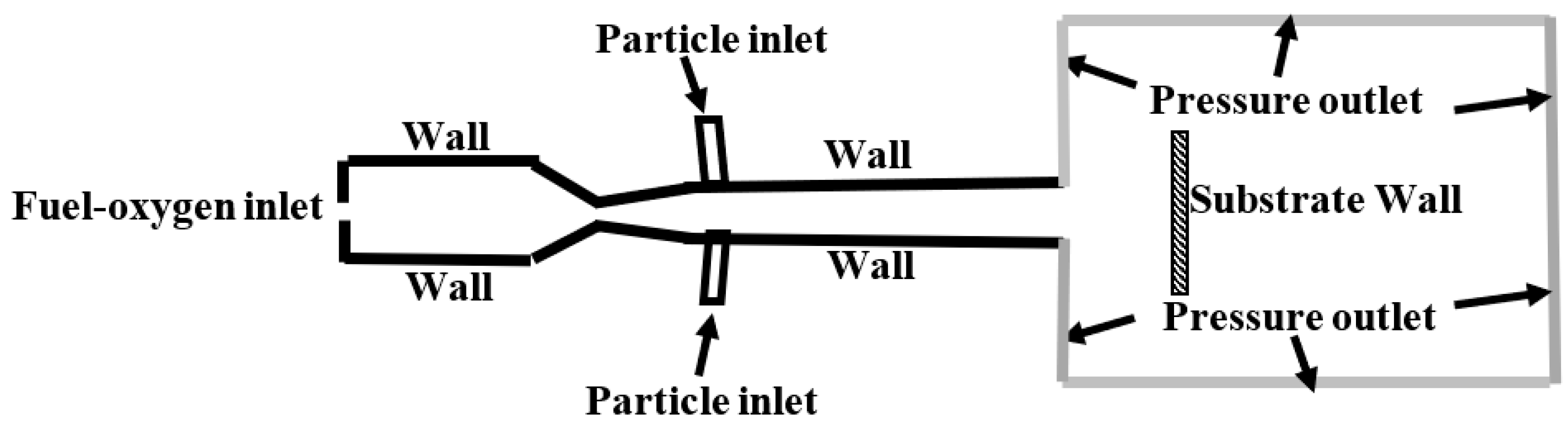

We first performed a validation study of the gas flow characteristics against the best available measurements reported in the open literature [

21].

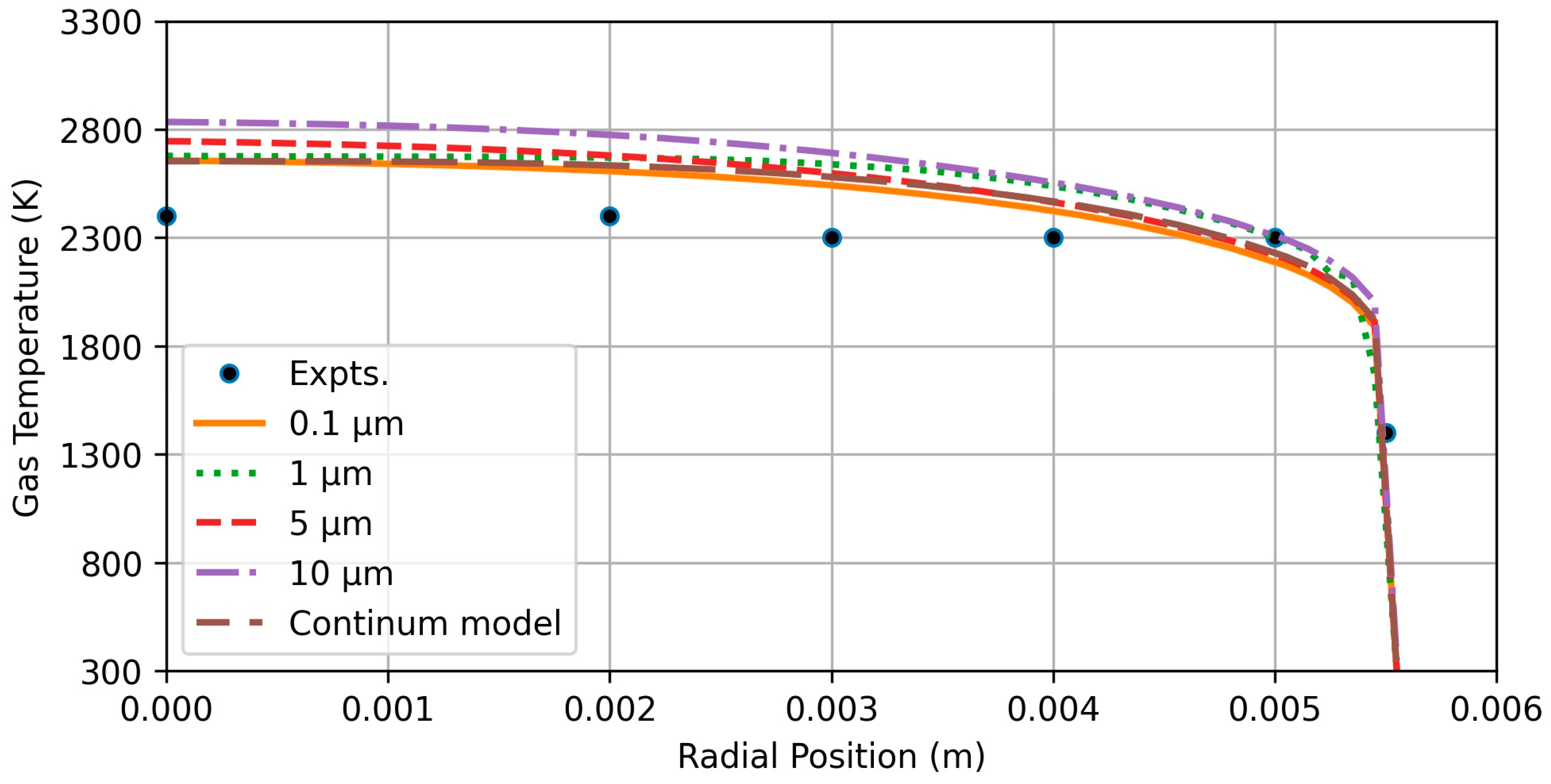

Measurements are available only for the gas temperature along the radial axis at the torch nozzle exit. A comparison of the present 3D CFD predictions and measurements show good agreement (

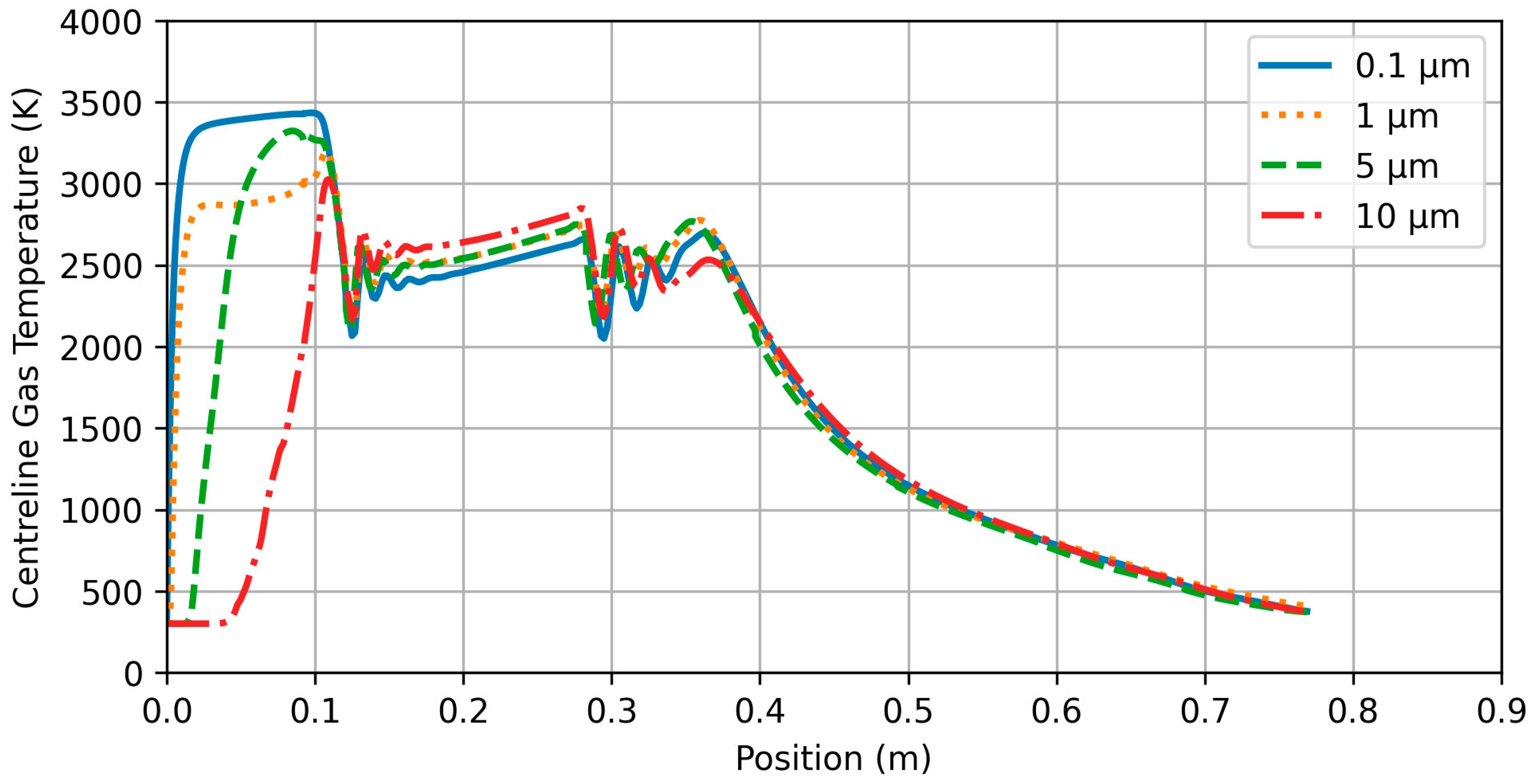

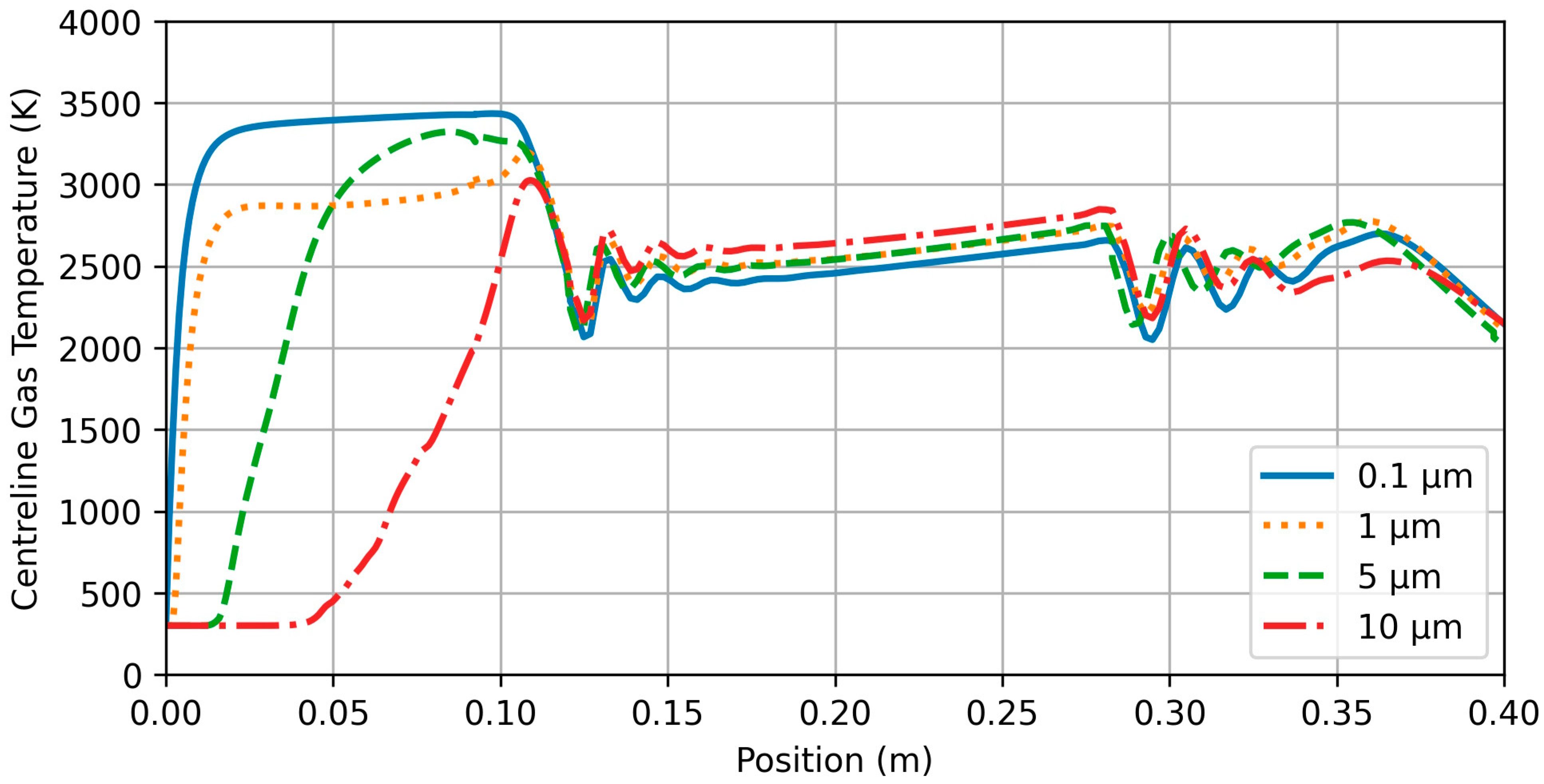

Figure 4). Modelling fuel as discrete droplets and using continuum models results in slight variations in the radial temperature distribution at the nozzle exit. If the discrete droplet size is small, the corresponding CFD predictions are a good match with the measurements, such as that of the continuum assumption where the fluid parcels are assumed to be infinitesimally small. However, when the discrete droplets are at 5 μm and above, there exist slight variations, about 200 K, in the gas temperature along the radial direction compared to that of measurements. This is anticipated because when the droplet size is larger, it experiences a large drag force due to the large surface area. Thus, the droplet results in a higher temperature due to prolonged heating in the barrel. However, it is vice-versa inside the combustion chamber. That is, for fuel droplets less than 5 μm, the fuel reacts quickly within the combustion chamber, and, hence, the elevated mixture temperature inside the combustion chamber is observed for small fuel droplets (<5 μm) (

Figure 5).

However, above 5 μm, fuel droplets experience less momentum, thus resulting in low reaction rates. This is due to a higher turbulent/eddy turn-over time, which leads to lower fuel centreline temperatures inside the combustion chamber (

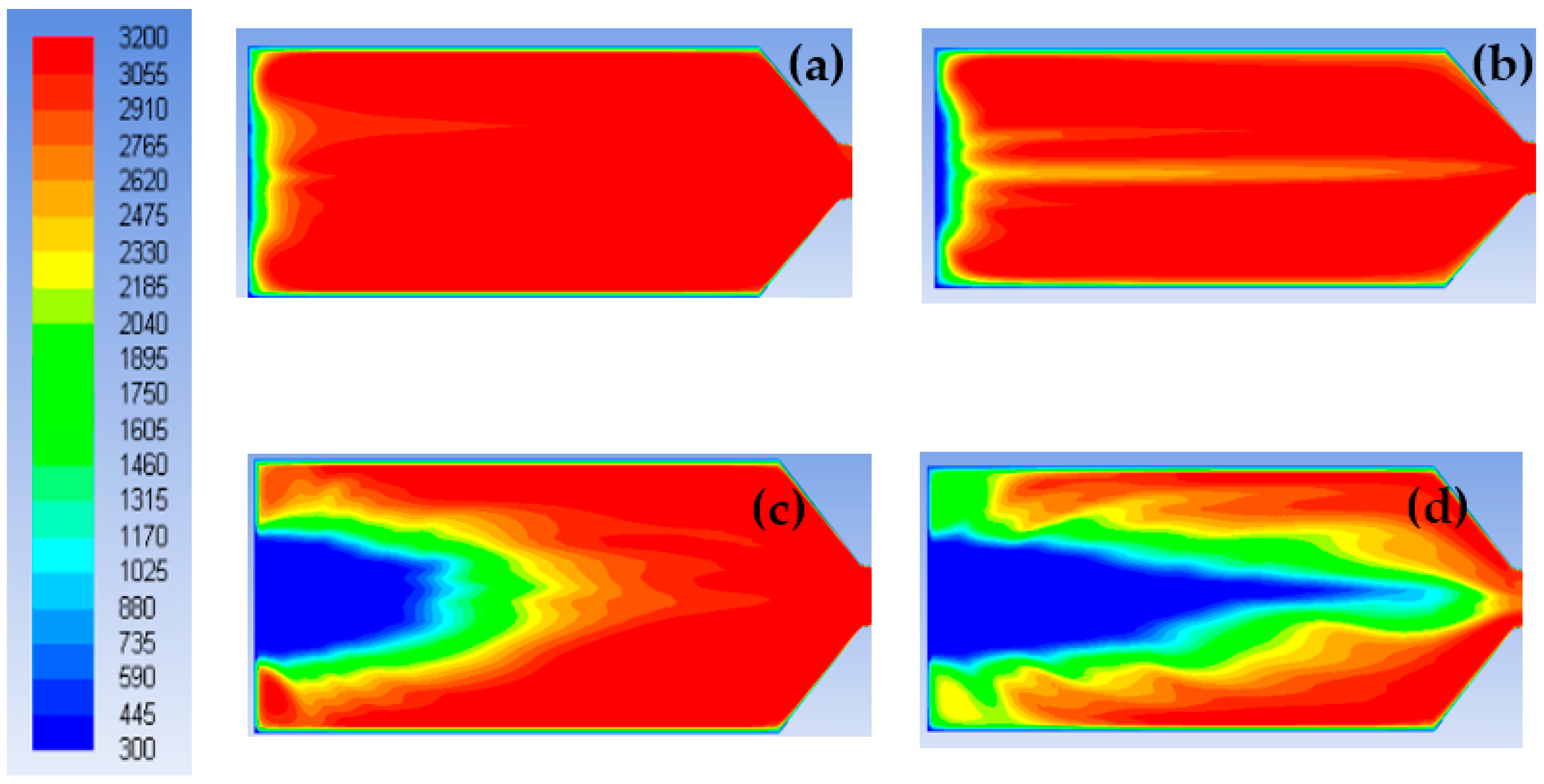

Figure 5). The contours of the mixture temperature depicted in

Figure 6 also substantiate this finding.

Apparently, small droplets only endure short distances and are confined within a more uniform pattern, while large droplets travel much further and then get burnt completely. We also note here that the highest fuel temperature occurs inside the HVOF system rather than outside the system as reported in [

9]. This implies that the external thermal field plays a less significant role in particle heating, as it is dominated by thermal transfer from the gas temperature.

The fuel droplet size above 1 μm significantly alters the centreline mass fraction [

11], thus resulting in a drop in the temperature inside the combustion chamber. We observed that fuel droplets of sizes ≤5 μm react completely within the combustor, as reported earlier by Tabbara and Gu [

11], whereas fuel droplet sizes >5 μm extend downstream in the combustion chamber, even entering the nozzle section, and continues to react there. For the same reason, there is a noticeable difference in the centreline gas temperature throughout the combustion chamber, in the CD nozzle, and in the first half of the barrel for droplets of 5 μm diameter and above (

Figure 7). The magnitudes of burnt fuel mass fraction corresponding to different fuel droplet sizes are found to be slightly different here compared to that of Tabbara and Gu [

11], which may be attributed to the slightly different reactant coefficients adopted here [

18].

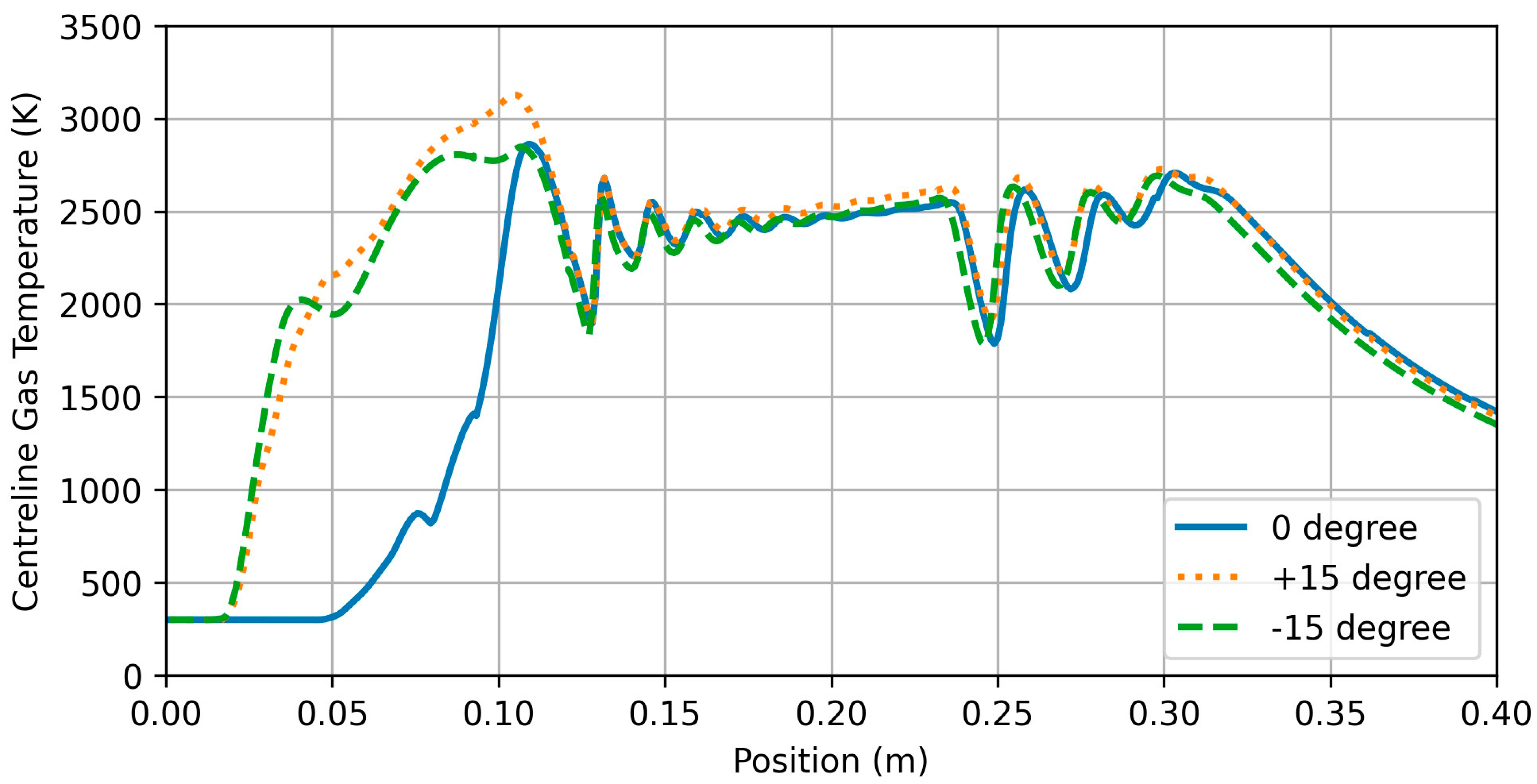

The centreline temperatures of the fuel mixture, corresponding to 10 µm fuel droplet size, are shown in

Figure 8 with two different liquid fuel injection angles, viz., −15° and +15°, with reference to the centreline, assumed to be 0° injection here. These two injection angles correspond to upward and downward directions with reference to the combustor centreline.

As the injection angle is changed from 0° to −15°/+15° (downwards/upwards), the centreline fuel mixture temperatures are found to be altered significantly, resulting in higher/lower temperatures inside the combustor compared to 0° (

Figure 8). It is inferred from this figure that the injection angle may be optimized to alter the fuel mixture characteristics inside the combustion chamber, especially when fuel droplets are larger than 1 μm.

Figure 8 is for the fuel droplet size of 10 μm, and similar trends are observed for droplet sizes larger than 1 μm. Thus, it is inferred that by changing the fuel injection angles from 0° to ±15°, we may achieve higher temperatures inside the combustion chamber, such as that of 10 μm fuel droplet.

This conclusion is a new finding from the present investigation, which revealed that the injection angles, viz., −15°/+15°, do not alter the temperature profiles for the 1 μm droplet size significantly [

10].

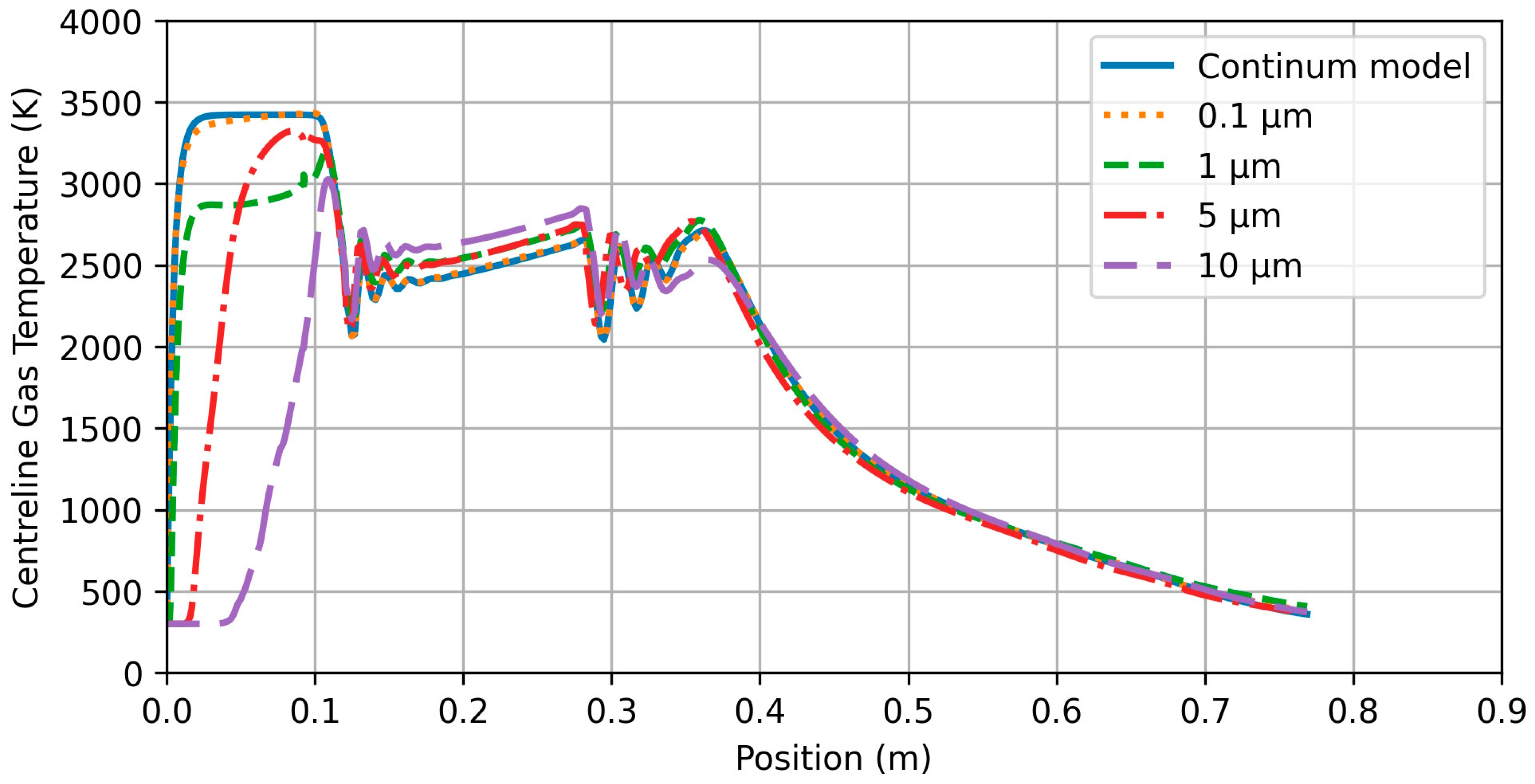

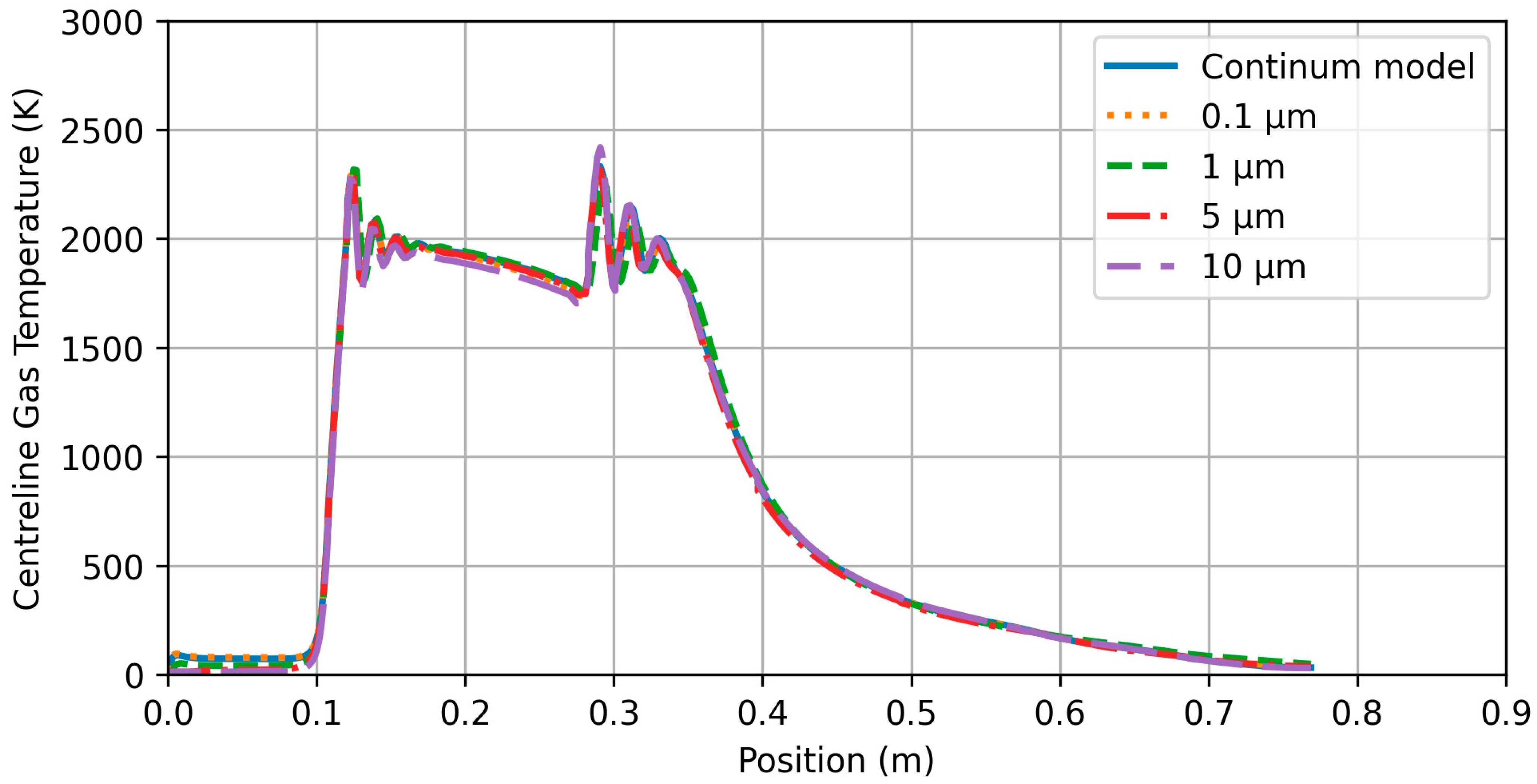

Having carried out detailed investigations of the influence of fuel droplet size on the mixture temperature characteristics, we now look at the influence of the assumption of fuel mixture as continuum. This will, in turn, make the numerical computations easier by the way of having one universal modelling approach for all primary phase species transport occurring inside and outside the HVOF spray system. A comparison of the centreline temperature profiles obtained using the continuum model against those of the discrete fuel droplet model is shown in

Figure 9. It is shown clearly that the continuum model predicts temperatures close to the submicron fuel (0.1 μm) droplet predictions.

However, when compared to the 10 μm fuel droplet predictions, continuum model predictions are much higher inside the combustion chamber but relatively small downstream in the chamber that is in the barrel section. The difference (about 200 K) is only 10% of the peak temperature, and, hence, we consider this as insignificant. It is small because when the power particles are injected after the CD nozzle, the resulting particle temperatures are found to be insensitive to this 200 K difference.

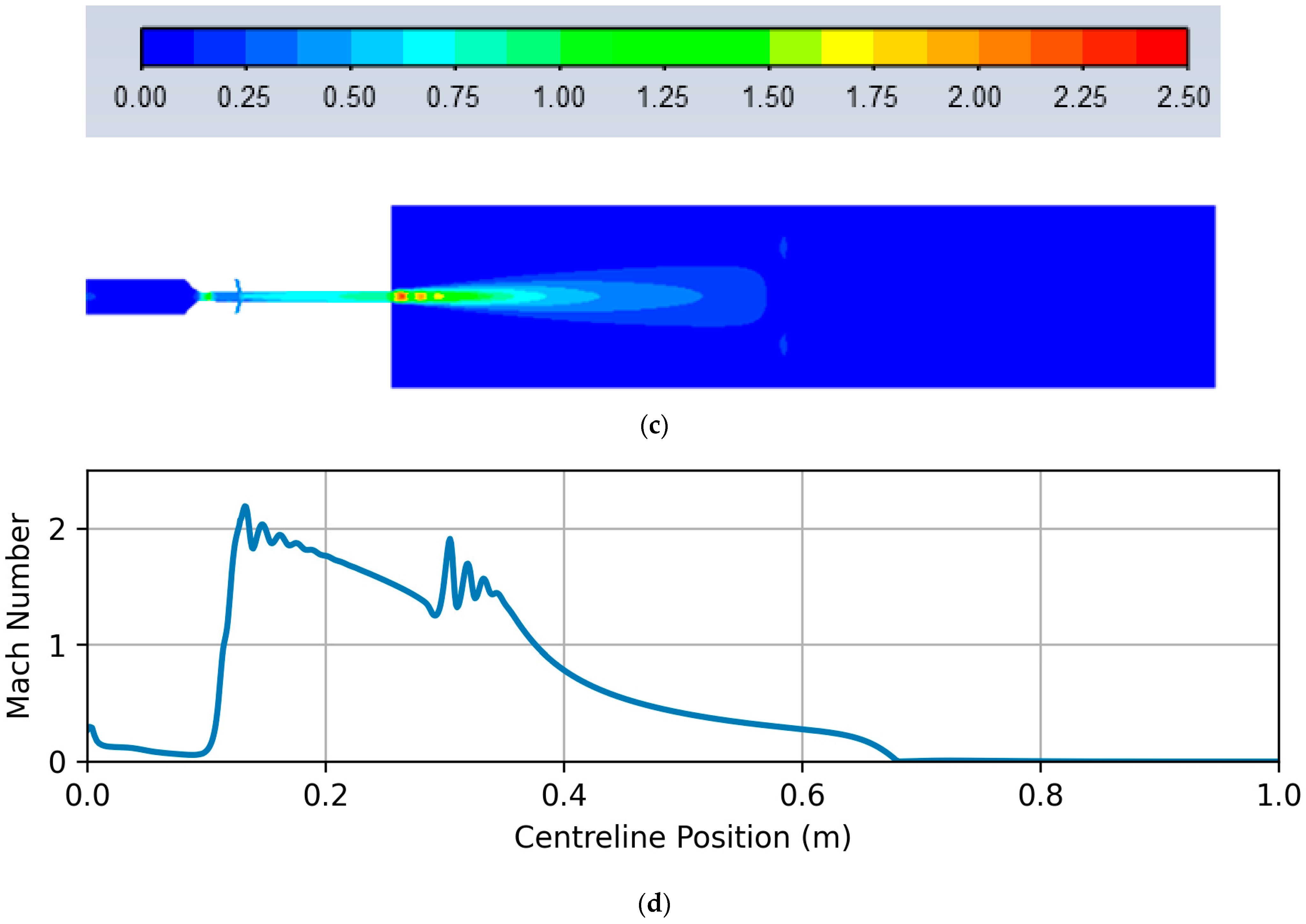

The centreline velocity of the fuel mixture is shown in

Figure 10 for both continuum and discrete fuel droplet models. It is found that both continuum and discrete fuel droplet models result in similar velocity predictions throughout the entire HVOF system, from the combustion chamber to the barrel exit. Unlike the centreline temperature, we hardly notice any difference in the velocity profiles between continuum and discrete fuel models. This may be attributed to the fact that the velocity regimes throughout the HVOF system are less sensitive to unburnt gaseous fuel, especially for smaller droplet sizes less than 5µm. However, there is a reduction of ~100 m/s throughout for the 10 μm droplet size. This reduction, in turn, does not influence the particle velocity significantly—this will be discussed shortly.

In spray processes (both cold and thermal), the compressed gases under high pressure are forced through the CD nozzle, and, hence, a rapid rise in velocity occurs. At the throat, the flow is chocked to Mach one. However, two small shocks in the HVOF sprays tend to occur as the gas expands and accelerates through the divergent section, marked by slight increases in the velocity the centreline (

Figure 10). This characteristic is different from that of the cold spray process [

22], as no shocks were observed in the CD nozzle throat region there, which is purely attributed to the CD nozzle throat diameter. In the case of cold spray CD nozzle, the throat diameter is half (50% smaller) that of HVOF nozzles, leading to no shocks in the flow characteristics at the throat. Whereas several shocks occur at the exit of the CD nozzle due to the expansion of the supersonic gas and strong reflections at the solid internal surface of the barrel, which are characterized by fluctuations in temperature along the centreline,

Figure 10.

Having carried out detailed investigations and validation of the HVOF models using literature data, we now discuss the CFD simulation results of the flow characteristics resulting from in-house-designed laboratory HVOF particle spray conditions. A complete picture of the fuel mixture characteristics is shown below, based on the assumption that the fuel mixture is continuum. The continuum assumption for fuel mixture will be employed in the rest of the paper instead of discrete powder particle dynamics due to the difference in the gas characteristics between continuum and discrete fuel droplet model being insignificant, as discussed earlier.

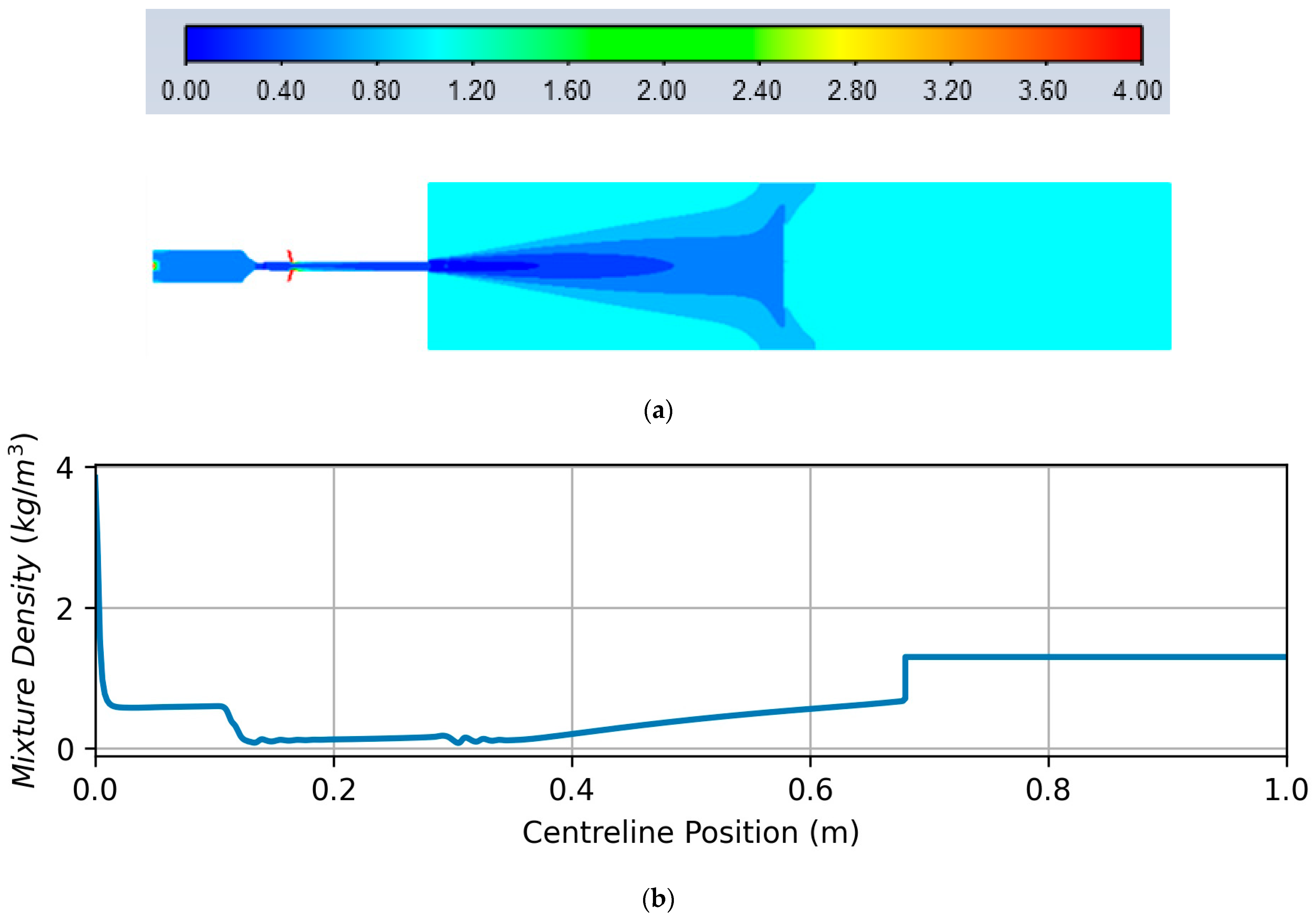

Simulated contours of density, axial velocity, temperature, and Mach number are shown in

Figure 11a–d, respectively. High pressure and temperature field are maintained inside the combustion chamber due to the reaction kinetics. Temperature and static pressure are found to reach their respective maximums, viz., 3000 K and 6 × 10

5 Pa. Pressure starts to decrease continuously from the CD nozzle throat as the burnt fuel expands, resulting in an increase of the fuel mixture velocity. Density contours depicted in

Figure 11a,b clearly reveal the gas expansion from the CD nozzle throat to the ambient domain. As anticipated at the throat of the nozzle, the Mach number reaches unity (

Figure 11d) and increases further, to around 2.3, immediately after the throat, before starting to decline. This peak in the Mach number plot is unique, unlike in the case of the cold spray systems or in the Diamond jet hybrid gun (Sulzer Metco) HOVF system reported earlier by Li and Christofides [

9]. This characteristic may be attributed to the system design, as discussed earlier. Following the local maximum after the CD nozzle throat, there occur multiple diamond shocks, as reflected in the Mach number plots, that are caused due to the under-expansion of the burnt fuel. Analysing the nozzle exit flow pressure data reveals that the burnout fuel from the nozzle exit is over-expanded, leading to multiple diamond shocks. The resulting peak pressure at the exit was noted to be around 7 × 10

4 Pa. As we don’t have an in-house pressure measurement facility, we correlated this simulated exit pressure data with that of the measurements reported earlier by Li and Christofides [

9] under similar operating conditions but in a different HVOF system (Diamond jet hybrid gun, Sulzer Metco). The comparison is found be in good agreement and is not presented here for brevity. It should be noted that although HVOF system reported by Li and Christofides [

9] is different from that considered in the present study, the CD nozzle and barrel dimensions are nearly the same as of the present model. Hence, the above crude comparison is still worth considering as we already validated the radial temperature profiles at the nozzle exit (

Figure 4).

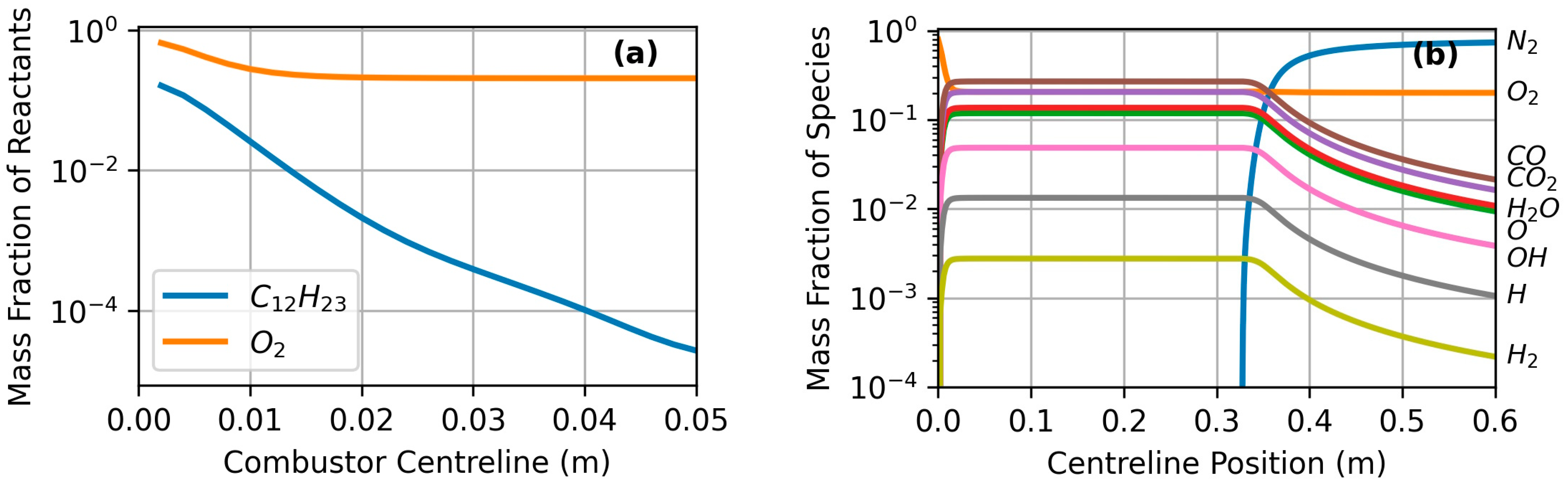

The solved mass fraction of each gas component of the reactants and products is shown in

Figure 12a,b.

Figure 12a is limited to the combustion chamber only, and we see that the liquid fuel gets burnt completely within this region; thus, the resulting mass fraction of liquid kerosene drops to zero at the end of the combustion chamber located roughly at the mid combustor, viz.,

x = 0.04 m. Consequently, the mass fraction of all species appearing in the RHS of chemical reaction, Equation (4), increases as the gas mixture passes through the CD nozzle and remains steady till the barrel exit. As the supersonic burnt fuel mixture exits the barrel, the mass fraction of N

2 species increases to 0.8, leaving O

2 at 0.2 because of the entrainment of the air from the ambient environment. However, the presence of oxygen composition at this level may influence the particle oxidation, which in turn may affect the coating characteristics. Therefore, one way to reduce the oxygen concentration is to introduce N

2 gas at the fuel inlet, but this may in turn reduce the flame temperature. However, this subject is beyond the scope of the present study and, hence, no details are presented here.

3.2. Analysis of Discrete Particle Dynamics

The powder particle flight characteristics play a vital role in the coating microstructure formation. In general, to achieve good coating metrics, it is important to maintain high particle temperatures, without superheating/melting, at the point of impact on the substrate. This is because the small grain sizes, after impacting the melting particles, can lead to the superior qualities of coatings, especially nanostructured coatings [

15]. It is also of great importance to maintain high particle velocity at the point of impact on the substrate since the higher the particle velocity, the denser the coating. All these critical parameters form a deposition window that must be calculated and understood. In the present simulations, a circular substrate 100 mm in diameter is assumed to be placed at a stand-off distance of 300 mm from the torch barrel exit to mimic the in-house experimental conditions. The substrate is given a wall boundary condition so that the gas flow and particles impinging on it will get altered greatly. Also, the presence of the substrate will retard the flow velocity, thus affecting the particle flight dynamics as well. However, it was understood from a previous in-house study that particles of smaller sizes (<10 μm) generally follow the gas contours, thus gliding down gently towards the wall, whereas larger particles (>10 μm) propel at their own momentum and are not affected by the presence of a substrate. Also, it is to be noted here that the substrate in the present simulations is located farther away, 300 mm, from the barrel exit, unlike in the cold spray, where the substrate is placed relatively closer to the barrel exit, approximately 30 mm. Hence, we may expect, at longer spray distances, such as 300 mm in HVOF, that the substrate should have a minimal influence on both the thermal and the flow field. This is because the impinging gas velocity and temperature are relatively low when the spray distance is long. Having calculated the gas flow characteristics, the particle inflight behaviour is then calculated (particle thermo-physical and flow data are given in

Table 2) using the discrete phase modelling (DPM) described earlier by applying suitable boundary conditions. Two particle injection ports inclined at angle of 77° are in the y direction after the CD nozzle,

Figure 2a.

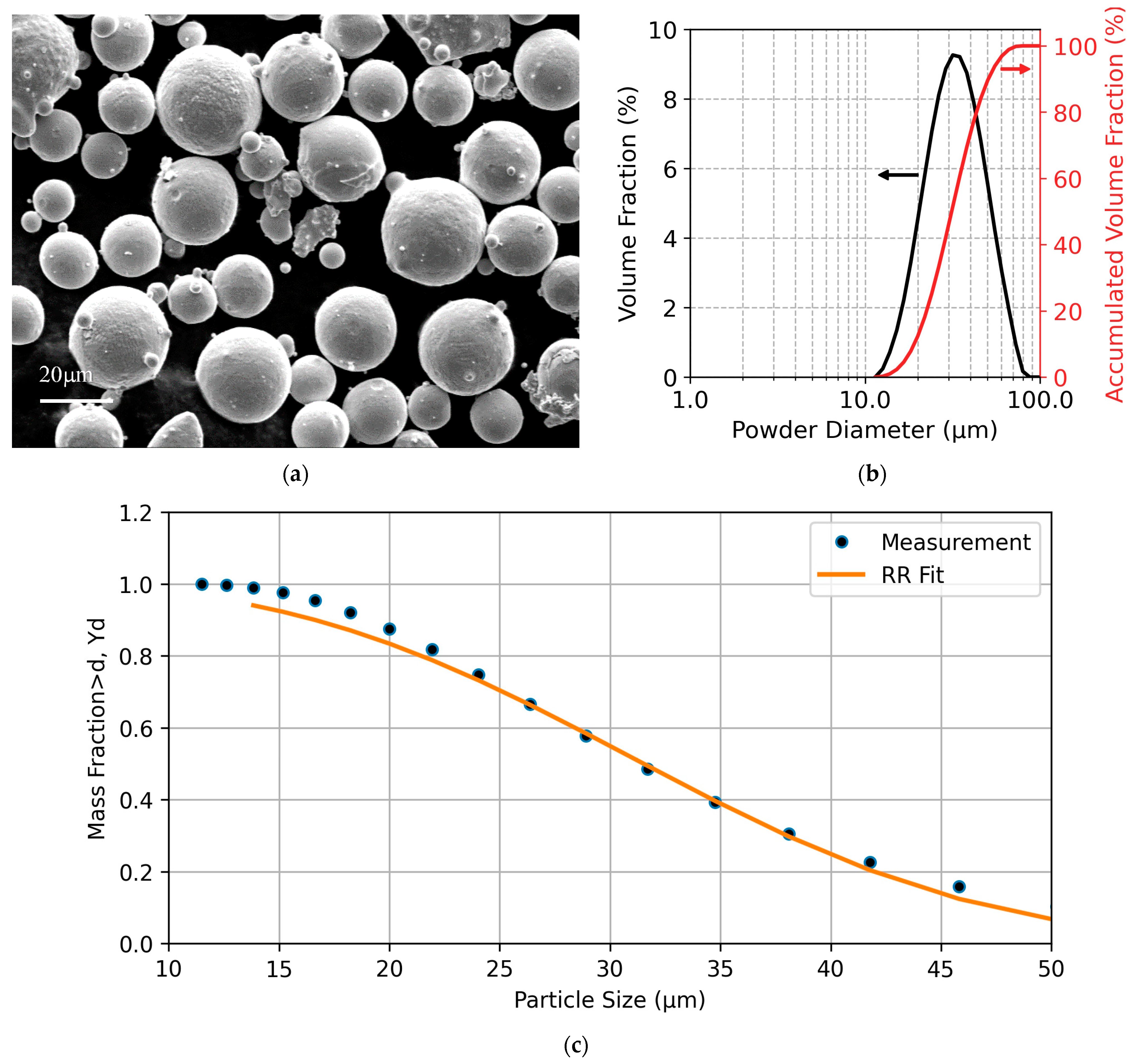

The particle morphology and size distribution of the CoNiCrAlY (Diamalloy 4700, manufactured by Oerlikon Metco) particles are shown in

Figure 13 below. The SEM image shows that the powders have a spherical shape with smaller satellite particles attached to the main powders (

Figure 13a). The D

10, D

50, and D

90 size of particles were measured by the Malvern Mastersizer 2000 and found to be 19.1, 31.2, and 50.6 μm, respectively (

Figure 13b). The black curve in

Figure 13b represents the volume fraction against the corresponding powder size. Each point represents the proportion of particles within a specific size range, which could help in understanding the dominant particle sizes and the spread of the distribution. The red curve in

Figure 13b depicts the accumulated volume fraction against the powder size with each point here signifying the proportion of particles with sizes equal to or smaller than the certain powder size. This is useful for determining the proportion of particles below a certain size and thus identifying specific percentiles, such as D

10, D

50 and D

90. The size distribution is modelled using logarithmic Rosin-Rammler (RR) distribution in the CFD code [

19]. The RR fit against the measured cumulative fraction is shown in

Figure 13c and found to be in good agreement.

Before we move on to discuss particle dynamics, it is to be noted that the turbulent dispersion model is activated through the discrete random walk model to ensure turbulent dispersion is well accounted. The particle shape is assumed to be spherical and, hence, a spherical drag law is applied to model the drag force term in the Lagrangian particle velocity model. Although agglomerations are seen in the particle morphology shown above (

Figure 13a), some agglomerations can be removed when the particles are heated up and, hence, the particles remain spherical in shape. For the given particle loading rate, and with the other random walk particle settings, we could track about 10

4 particles in total from the point of injection until their impact on the substrate. Once particles hit the substrate located 300 mm from the barrel exit, they are assumed to deposited in the present model.

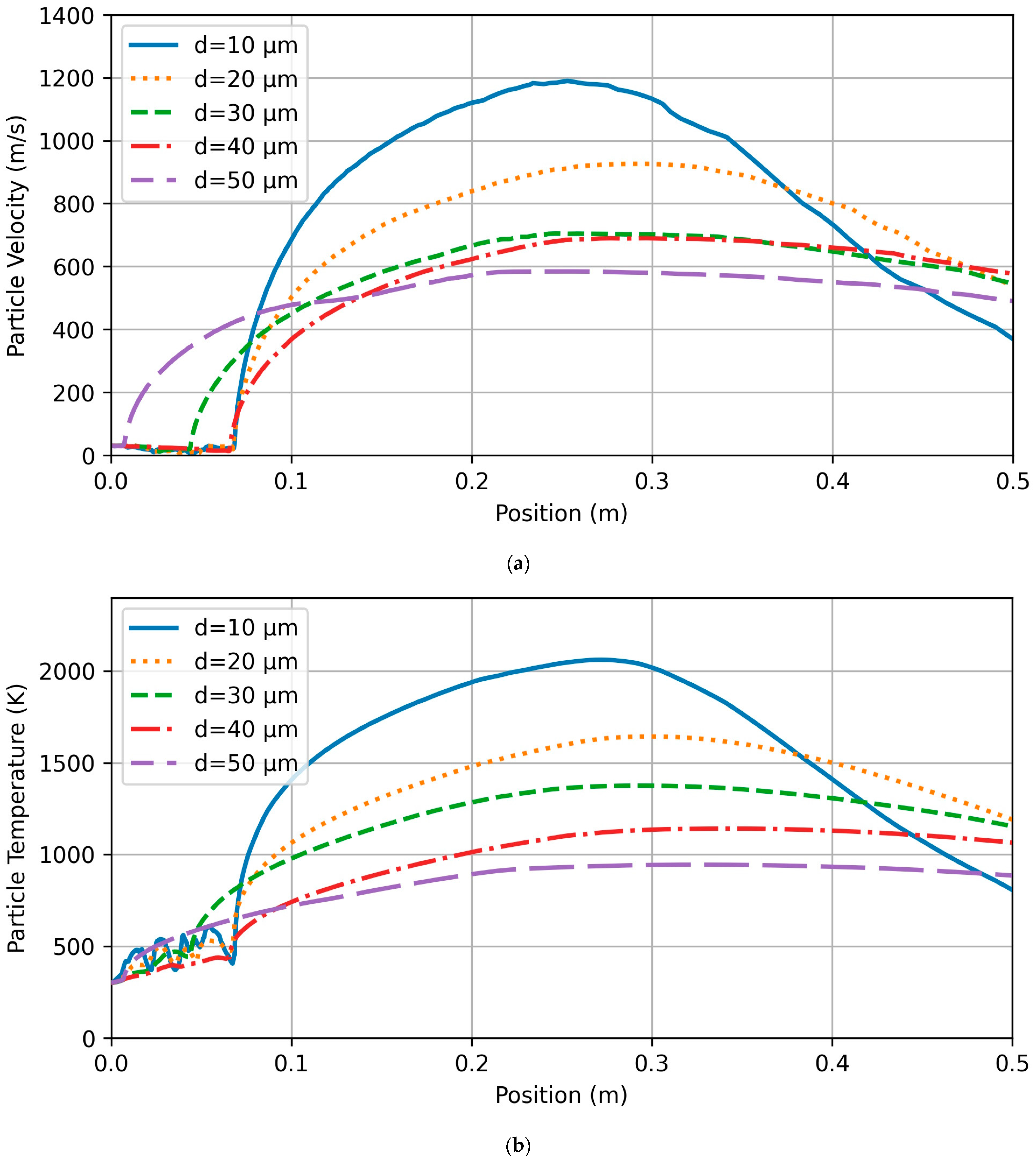

The results of the particle dynamics in terms of flight velocities and temperature are shown in

Figure 14a,b.

Torch working conditions for simulating the inflight particle characteristics are provided in

Table 1. These conditions are similar to Li et al. [

23], in which the baseline mixture flow rate was assumed to be 0.018 kg/s and the carrier gas flow rate to be 28.5

scfh. Although the torch model used in [

23] is different from the present study, the gas and particle flow characteristics in both the studies are still comparable as they exhibit similar dynamics. A detailed comparison and discussion of the results between the present study and Li et al. [

23] are provided below.

Although particles of small sizes reach very high velocities during the flight, their velocities drop more sharply after a critical flight distance than those of larger particles because of their smaller momentum inertias. In the diamond shock waves present at the nozzle exit, gas flow characteristics oscillate sharply, whereas particle velocity and temperature profiles do not exhibit any significant oscillations. The phenomenon is attributed to significantly larger mass inertia, and, hence, the particle velocity can exceed the gas velocity in the ambient domain throughout their entire flight, before impacting the substrate. However, if the particle sizes are too small (<5 μm), one may expect the particle flow oscillations like that of gas phase oscillations as reported in Li et al. [

23]. This also depends on the particle density; for e.g., in the case of lighter particles such as aluminium, even larger particles may also exhibit flow oscillations like the gas phase oscillations. As anticipated, particle velocities drop with an increase in their size due to increased drag force associated with the increased particle surface area. However, as the gas jet approaches the solid substrate, the velocity of the gas flow gets retarded, and the smaller particles tend to follow gas behaviour, resulting in a sharp decrease in their velocities, even below the velocity of the large particles considered here. This inference is unique and is different from previous observations reported by Li et al. [

23], where it was reported that smaller particles in the range 10 μm <

dp < 60 μm, like the present range, always resulted in higher velocity, and large particles resulted in lower velocity magnitudes. This may be attributed to the fact that in the previous investigation, the presence of a solid substrate is not modelled and, therefore, the gas flow does not experience any flow retardation effect, which results in different particle impact velocities. Also, their computational domain is 2D axisymmetric, which might not be a correct assumption for the study of turbulent particle dynamics. This serves as a novelty of our study. It is interesting to infer from the particle velocity profiles that larger particles experience an almost constant velocity after exiting the nozzle into the ambient atmosphere, for reasons described earlier.

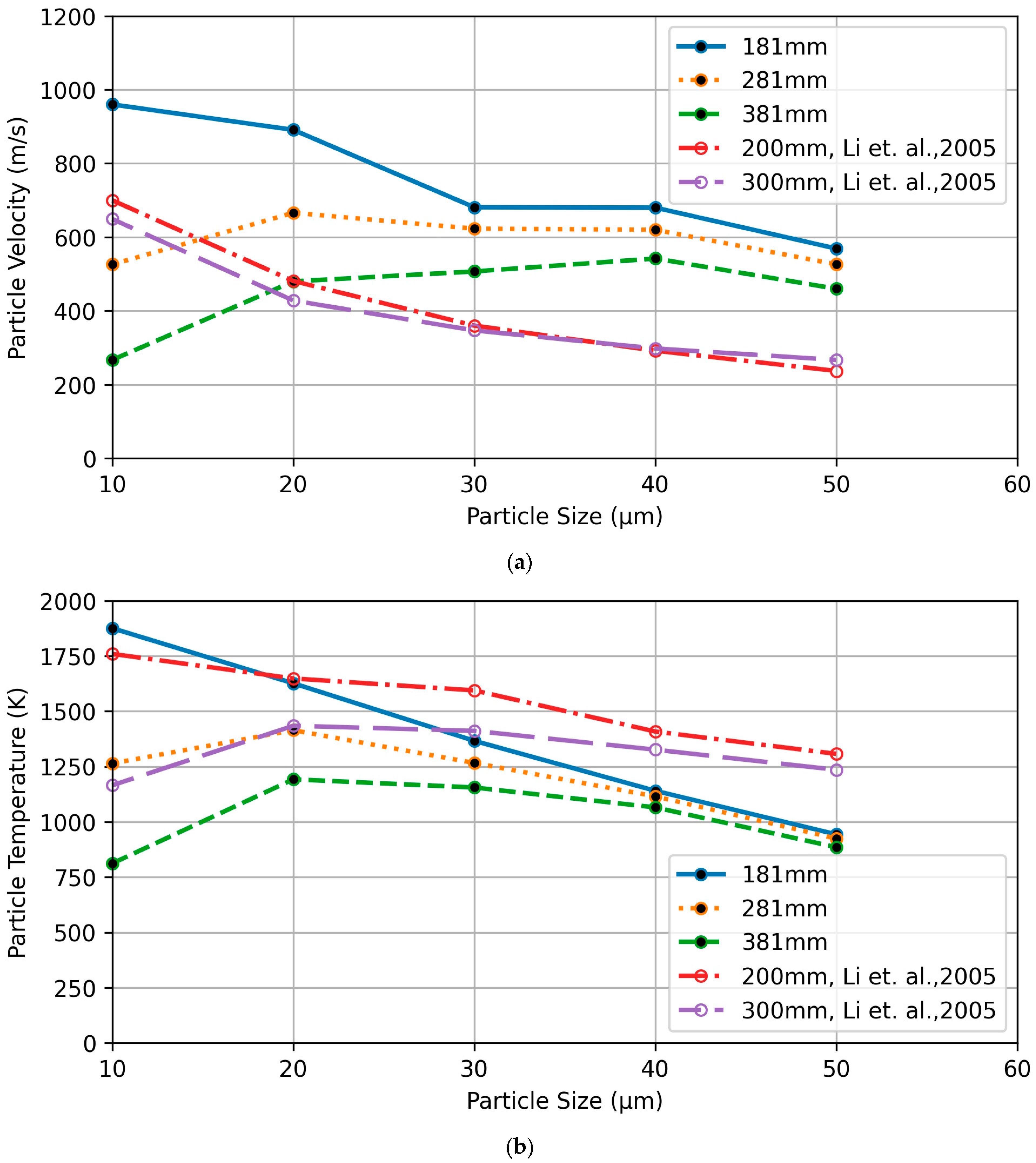

Particle impact velocities at different stand-off distances are shown in

Figure 15a. In the above figure, a solid physical substrate was modelled at a stand-off distance of 381 mm. In addition to the particles impacting on the substrate, two other virtual substrates were created at 181 mm and 281 mm, respectively, and then the mean particle velocities were computed at these stand-off distances. It is observed from

Figure 15a that when the stand-off distance is 181 mm, the particle impact velocity decreases with increase in particle size, as previously reported by Li et al. [

23] and shown in

Figure 15a. However, when the stand-off distance is increased to 281 mm and 381 mm, it is found that the smallest particles (10 μm here) have the lowest velocity compared to larger-sized particles (>10 μm). This observation is interesting and different from previous observations made by Li et al. [

23]. This may be attributed to two reasons: (i) longer stand-off distances and (ii) lower particle mass compared to previous observations by Li et al. [

23]. As the particle mass decreases, smaller particles tend to get trapped into the gas stream, the velocity of which is reduced at longer stand-off distances, resulting in lower particle velocity.

The particles at the injection inlets are assumed to be at ambient temperature, whereas their velocities are determined by the given flow rate. However, as particles travel in the supersonic gas flow inside the barrel, they acquire thermal energy from hot gas and, as a result, smaller particles are heated even beyond the melting point in a short duration (

Figure 15b). Very small particles (<10 μm) get fully melted during their flight within the barrel, while particles of 10 μm <

dp < 20 μm are melted after issuing from the nozzle; particles of sizes greater than 20 μm stay below the melting point but get softened. Although smaller particles are melted quickly, they also eventually turn into a semi-molten state by losing their temperature to the low temperature ambient air through convection before impacting the substrate. Due to small thermal inertias, smaller particles change their temperatures easily. However, larger particles undergo longer periods of acceleration and heating due to their larger surface area, and, hence, their velocity (or temperature) profiles become nearly plateau (

Figure 15b). It is observed that particle temperature profiles tend to follow the same trend as their velocities. From the particle size analysis, we found that the mean diameter of the particle population used in the experimental spraying conditions is 38 µm. The impact mean velocity and temperature of this mean-sized particle, obtained from the numerical simulations, are around 700 m/s and 1350 K. Further, if the characteristic time scales of particle velocity and temperature are

respectively, then the time scale ratio of particle temperature to particle velocity is calculated to be

This ratio is usually less than one (Li et al. [

23]) and, therefore, it can be inferred that the particle temperature is more easily varied than the particle velocity. That is, by adjusting particle heating residence time by altering the stand-off distance, we may vary the particle temperature independent of the particle velocity. However, varying particle velocity independent of particle temperature may be attained by maintaining the equivalence ratio (fuel/oxygen ratio divided by its stoichiometric value) of close to but less 1, as per Li et al. [

23]. Note that in the industrial HVOF processing environment, it is important to independently control the particle velocity and the particle temperature (or melting degree) to achieve the desired coating properties.

The particle’s impact temperature with stand-off distance is observed to have a similar trend as that of the particle’s impact velocities (

Figure 15b). Also, it is observed from

Figure 15b that good agreement between the present study and Li et al. [

23] exits in terms of the particle impact temperature.

3.3. Particle Deposit Formation on Substrate

Particle locations on the substrate were tracked, and splat formation was determined numerically and compared against that of observed in-house measurements.

In the above splat analyses, it was assumed that all the particles impacting the substrate adhered to the substrate and formed a coating. Such an assumption is valid, especially in warm sprays, as most particles get partially melted/softened so that they will eventually stick to the substrate. Hence, based on this assumption, particle locations on the substrate were captured through simulations and qualitatively compared to the deposit observed and measured from experiments. Particle splats at different stand-off distances, viz., 381 mm, 281 mm, 181 mm, and 81 mm, are shown in

Figure 16. It is evident that the splat diameter increases with the substrate stand-off distance. This is attributed to the increased particle turbulent dispersion with increasing stand-off distance. There also exist two islands or butterfly-like deposits/footprints a little away from the substrate centre, especially with the increase in the stand-off distance (

Figure 16a–c). At the shortest stand-off distance of 81 mm, this butterfly-like footprint is least pronounced (

Figure 16d).

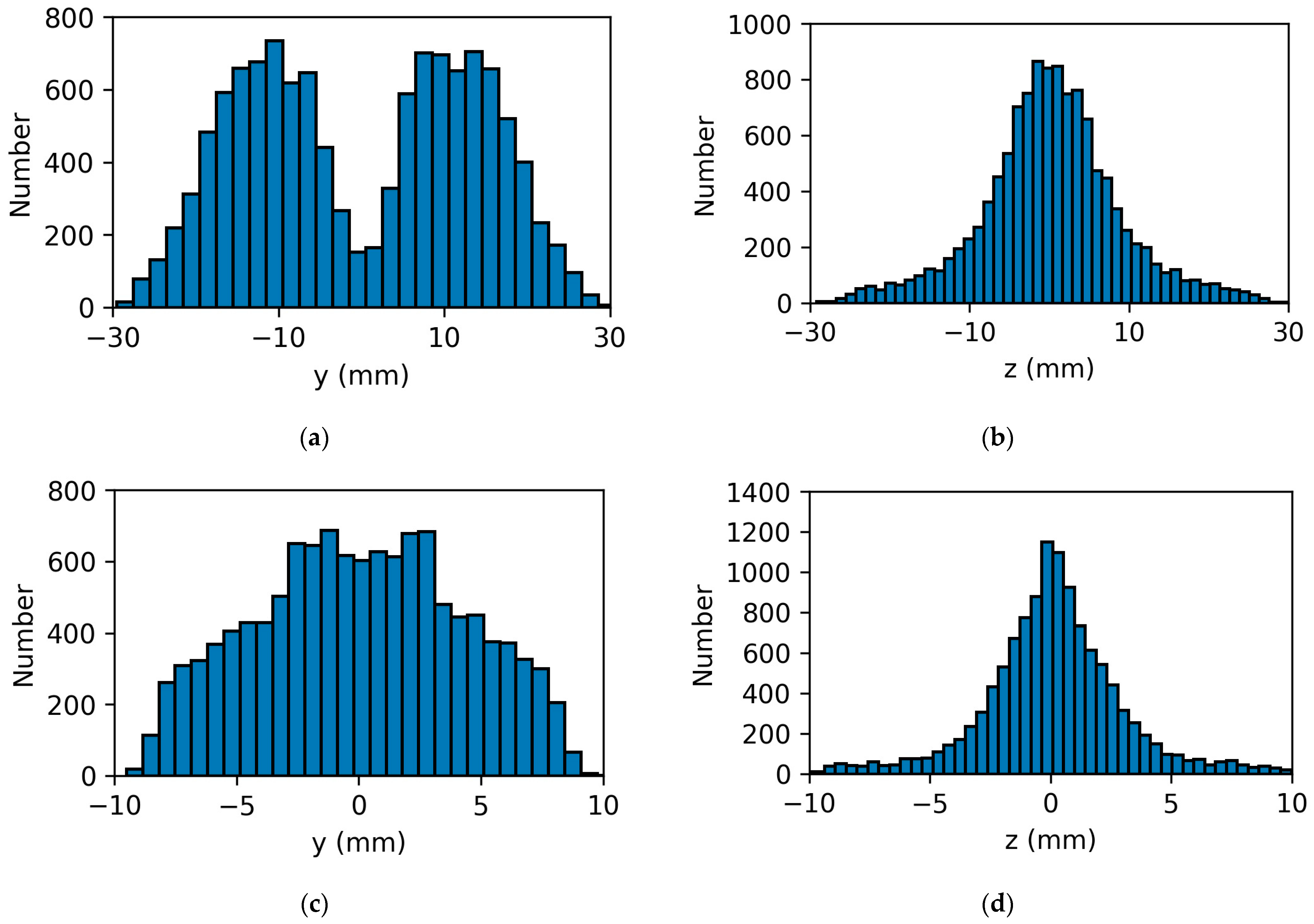

These island formations can be clearly seen from their respective horizontal histogram plots, depicted in

Figure 17. For the sake of simplicity, the histograms are plotted only for two stand-off distances, viz., 381 mm (

Figure 17a,b) and 81 mm (

Figure 17c,d).

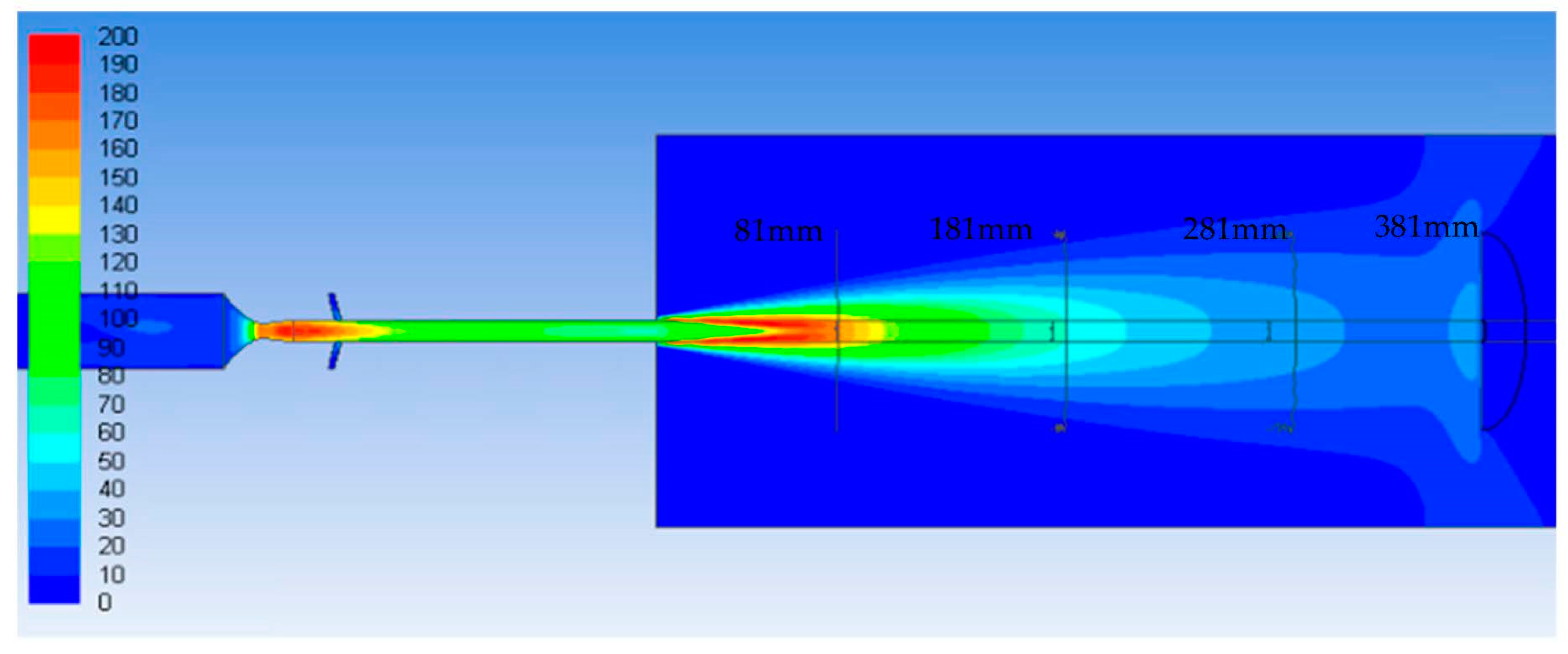

The turbulent component of gas velocity magnitude contours obtained from turbulent kinetic energy is shown in

Figure 18. This is essentially a

x-y centreplane sliced in the direction of the powder injection (we can see the injection ports immediately after the CD nozzle). It is evident from this figure that turbulent velocity is stronger and concentrated in the gas core immediately after the barrel exit, up to a short axial distance (i.e., ~81 mm). After this distance, the turbulent velocity component spreads away from the gas core, viz., at stand-off distances of 281 mm and 381 mm, respectively. This spread in turn disperses particles to a larger radius on the substrate and creates island/butterfly-like particle deposits, as shown in

Figure 16.

Histogram plots of the particle deposits along the

y (parallel to injection direction) and

z (normal to injection direction) axes are shown in

Figure 17a–d. These plots further substantiate the island formation in the particle splats in the

y direction but not in the

z direction, although the turbulent velocity magnitude contours plotted in the

x-z plane have similar characteristics to those of the

x-y plane. This may be attributed to the influence of powder injection directions that are present in the

x-y plane rather than in

x-z plane.

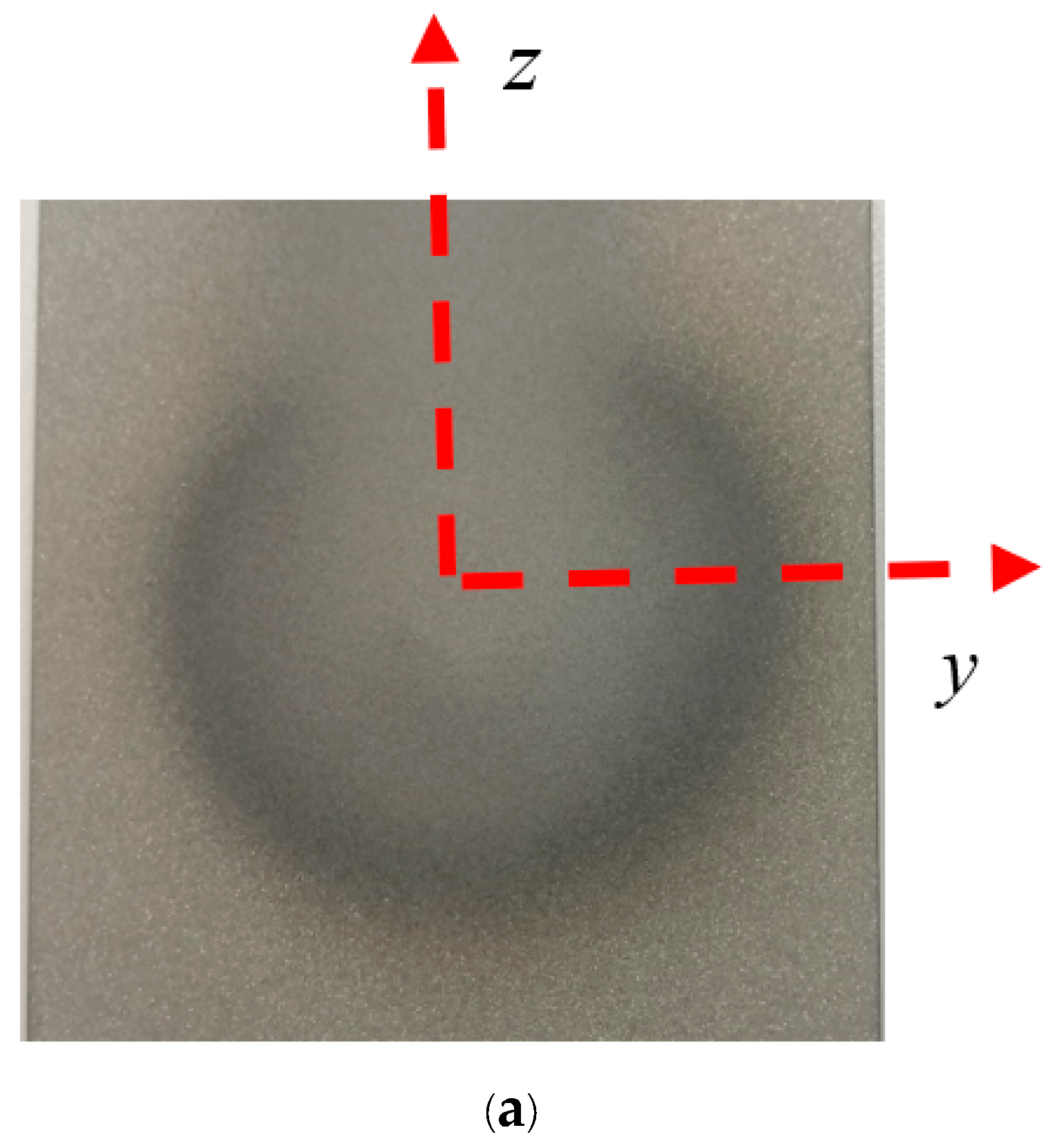

To validate the numerical prediction of particle splat dynamics, we carried out a stagnation spot spray test by spraying CoNiCrAlY particles onto a nickel alloy (AMS 5536 Hastelloy X) substrate (7 × 14 cm

2) located at a stand-off distance of 381 mm for about 20 s. The HVOF spray was performed using a Praxair JP-5000

® HVOF system [

24]. CoNiCrAlY powders were dried in an oven at 60 °C for a minimum of 2 h and fed into the centre of a JP5220 gun with 15.2 cm (or 6″) barrel by a GTV PF2/1 powder feeder. The substrate was cleaned using acetone and sand blasted using Al

2O

3 grit 60 at a pressure of 1.7–2.1 × 10

5 Pa prior to the spray. The spray parameters are listed in

Table 3. The image of the spraying spot is shown in

Figure 19a, while the

y and

z line profiles of spot height were measured by the Prismo Ultra high accuracy coordinate measuring machine (CMM) from Carl Zeiss and are shown in

Figure 19b and

Figure 19c, respectively.

Visual inspection suggests that the spot shape was nearly circular. However, the corresponding line profiles reveal double peaks existing along the

y direction and a single peak in the

z direction, located at the substrate centre. These line plots correspond to the particle density along the

y and

z directions. The existence of a double peak in the y direction is attributed to the two particle injectors located in the y direction. The diameter of the splat is found to be around 60 mm and the maximum height of the spray at the centre is found to be around 20 mm. Numerical predictions of the particle splat, together with their line profiles in

y and

z direction, are shown in

Figure 17a and

Figure 20 for the experimental stand-off distance of 381 mm. It is inferred that the general character of the numerical particle splat is like that of the experimental observations. Line profiles of particle number distributions along

y and

z directions obtained from the numerical simulations are found to replicate experimental observations with single and double peaks in the

z and

y directions. In the double peak feature of the

y line profile, the dip at the centre is found to be significant when compared to that of the measurements. This may be attributed to the fact that, in measurements, the

y profile reflects the deposit height, whereas in simulations, the particle-impacting probability is plotted in the

y direction. Also, the peening effect may damp the bumps/peaks region, resulting in making the drop at the centre less severe. In the case of the

z profile, it is more bell-shaped with a slight shift to one direction that may be due to slanted particle injectors. Further, it is clear from the numerical predictions that the splat diameter is in close agreement with that of measurements, viz., ~56 mm. The height/thickness of the splat profile was not investigated in the present numerical study and will be carried out in future with a detailed finite element model. Nevertheless, the splat profile agrees with the measurements reasonably well, as the particle density is higher at the central region of the substrate and decreases with increasing radial distance.