Dispersion of Carbon Nanotubes Improved by Ball Milling to Prepare Functional Epoxy Nanocomposites

Abstract

1. Introduction

2. Experiment

2.1. Materials

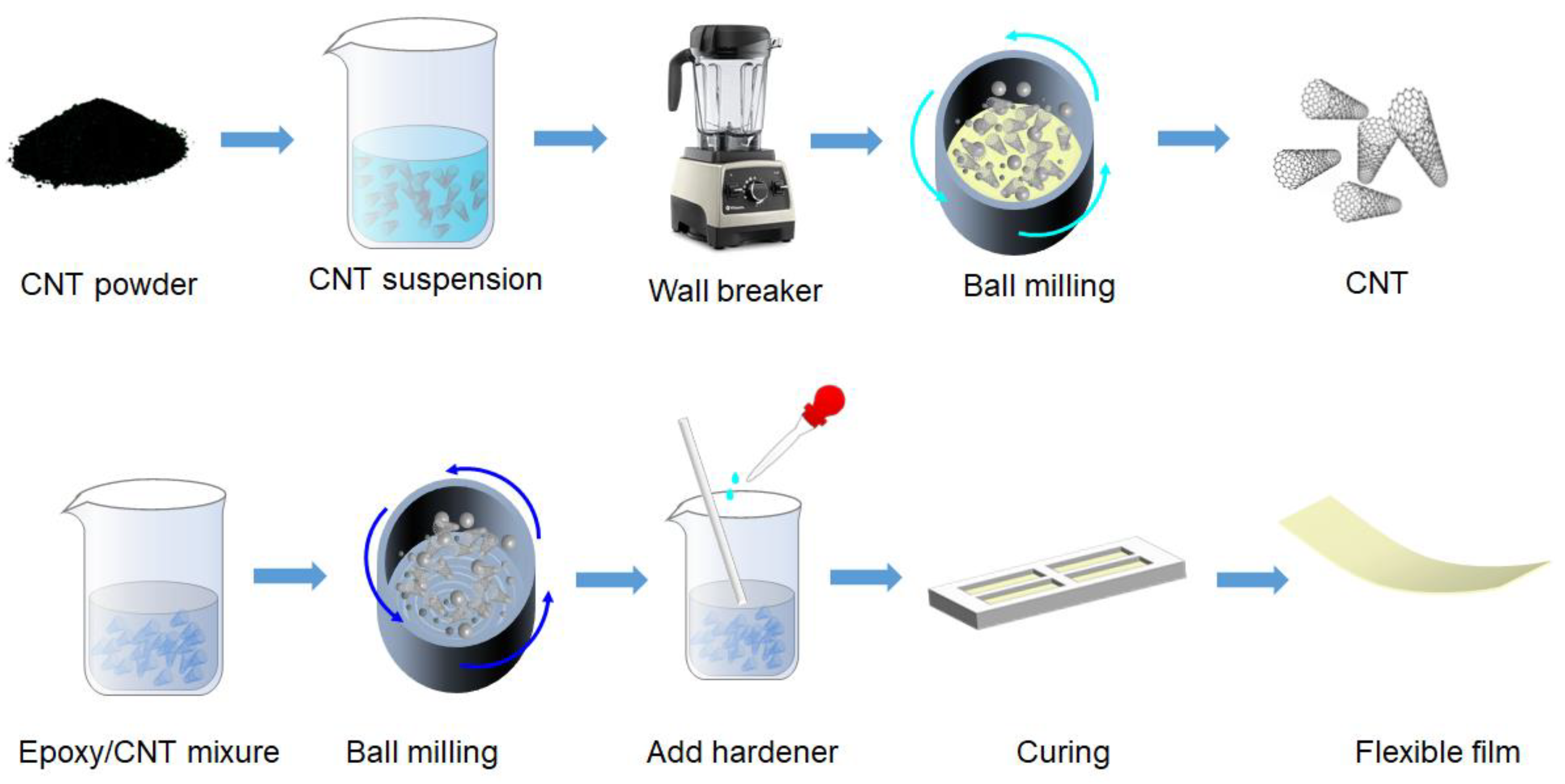

2.2. Preparation

2.3. Characterization

3. Result and Discussion

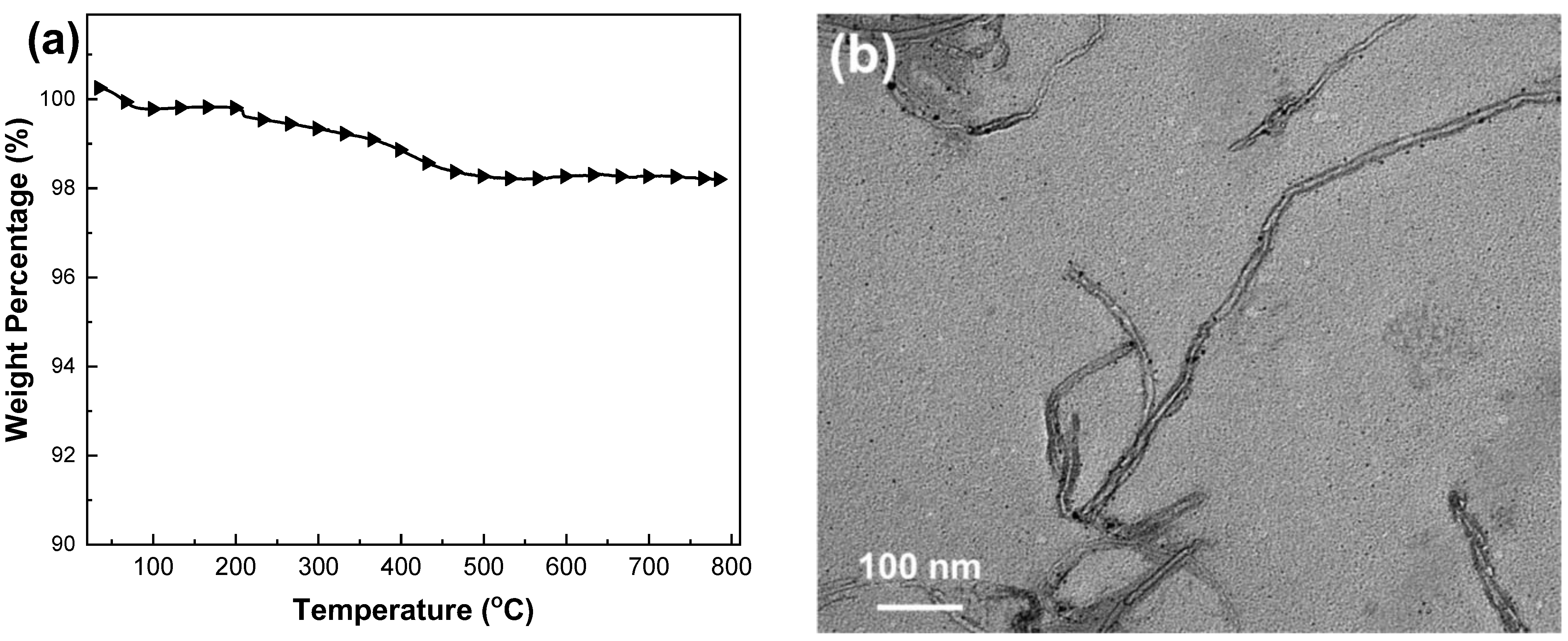

3.1. Analysis of Carbon Nanotube

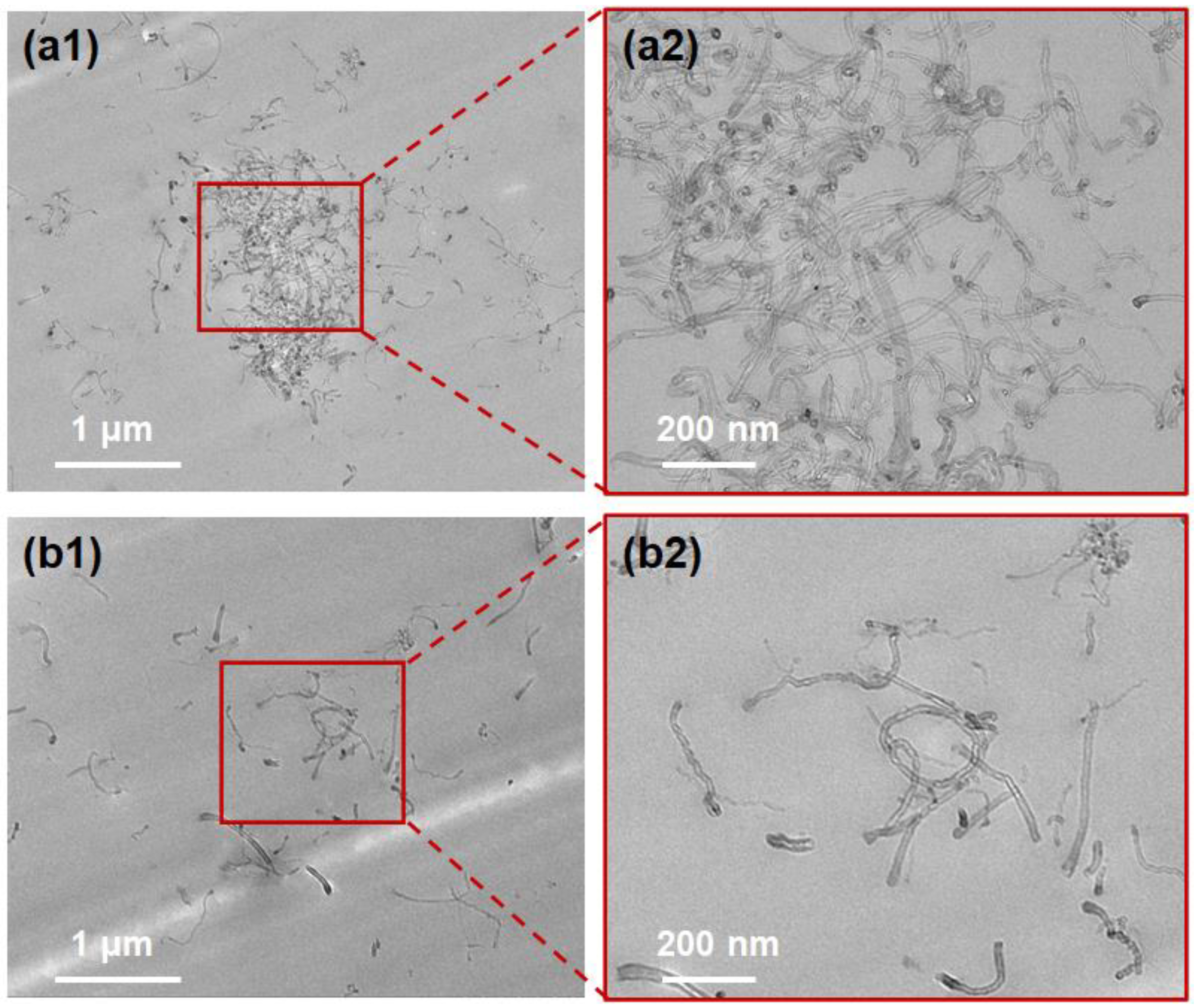

3.2. Morphologies of the Nanocomposite

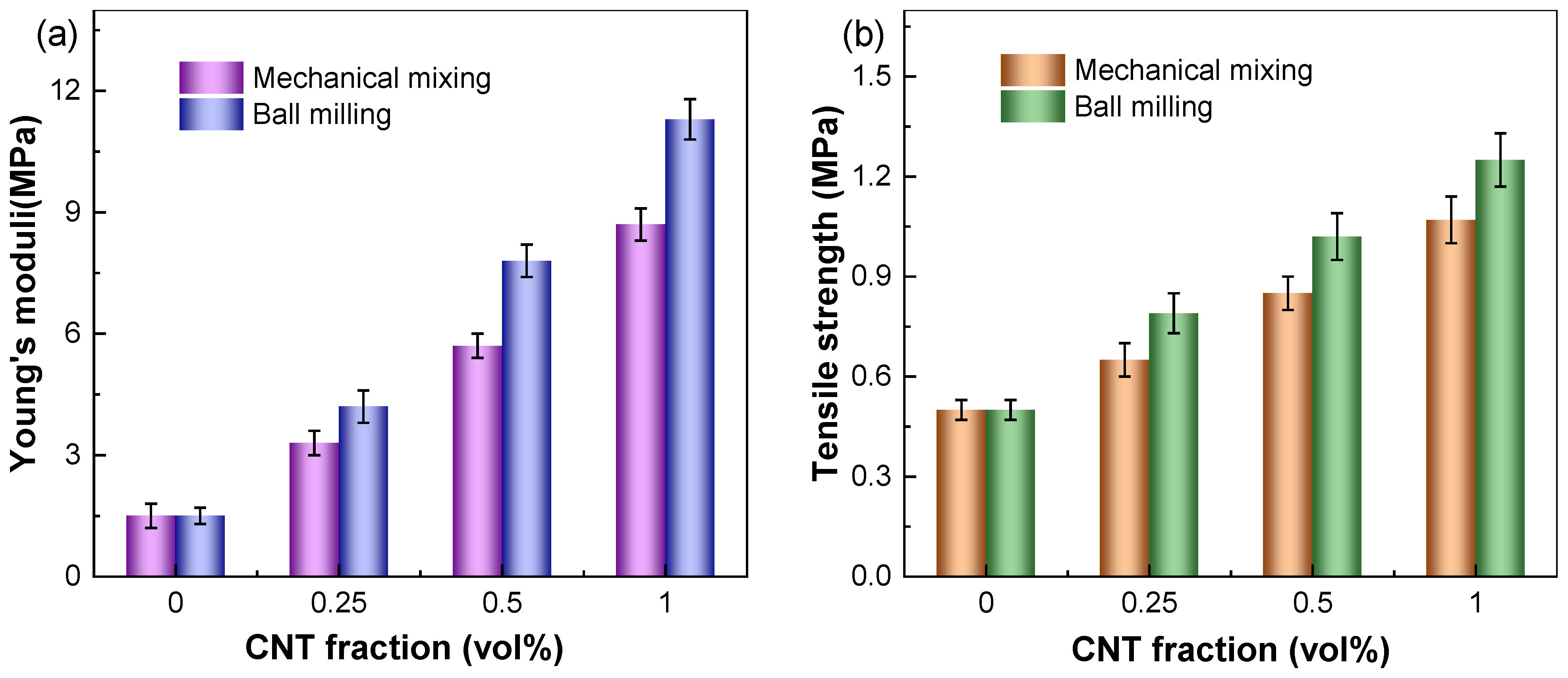

3.3. Mechanical Properties of the Nanocomposites

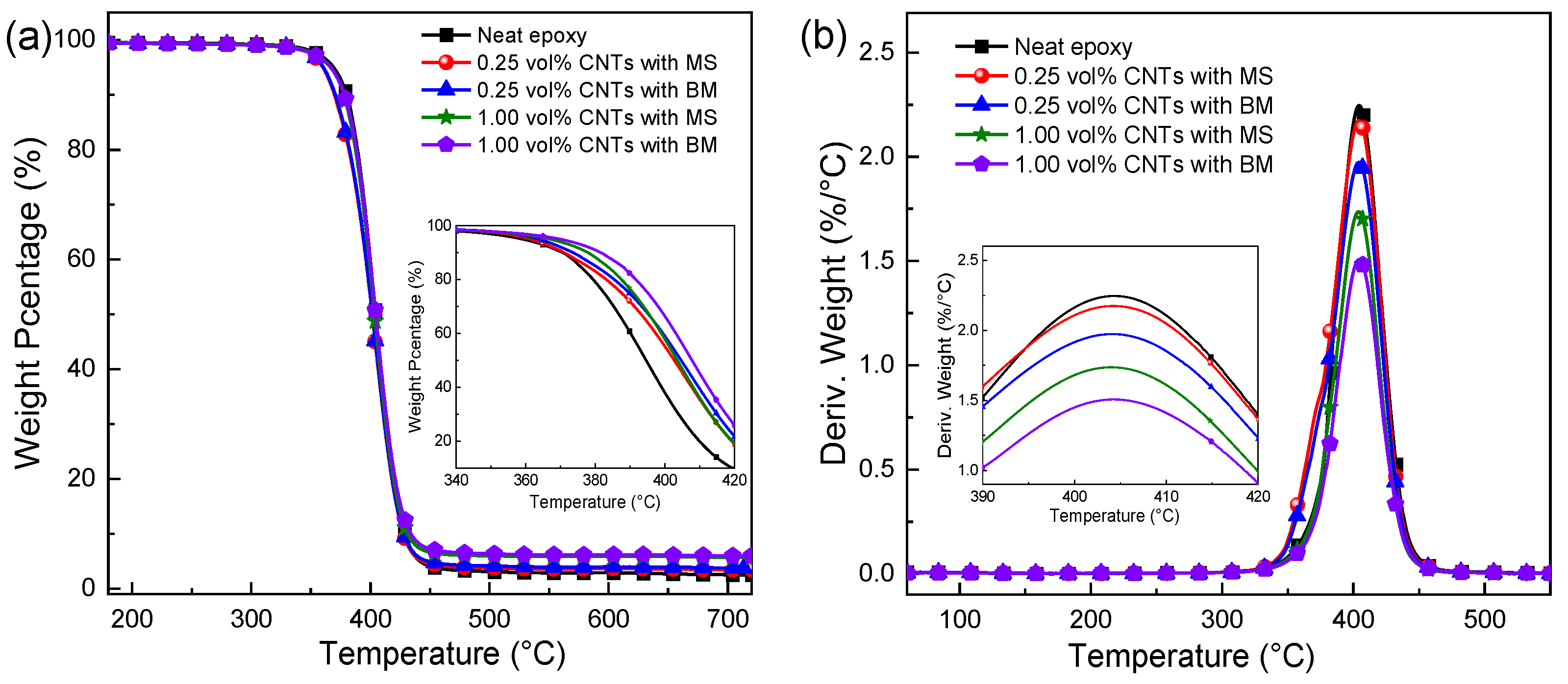

3.4. Thermal Stability

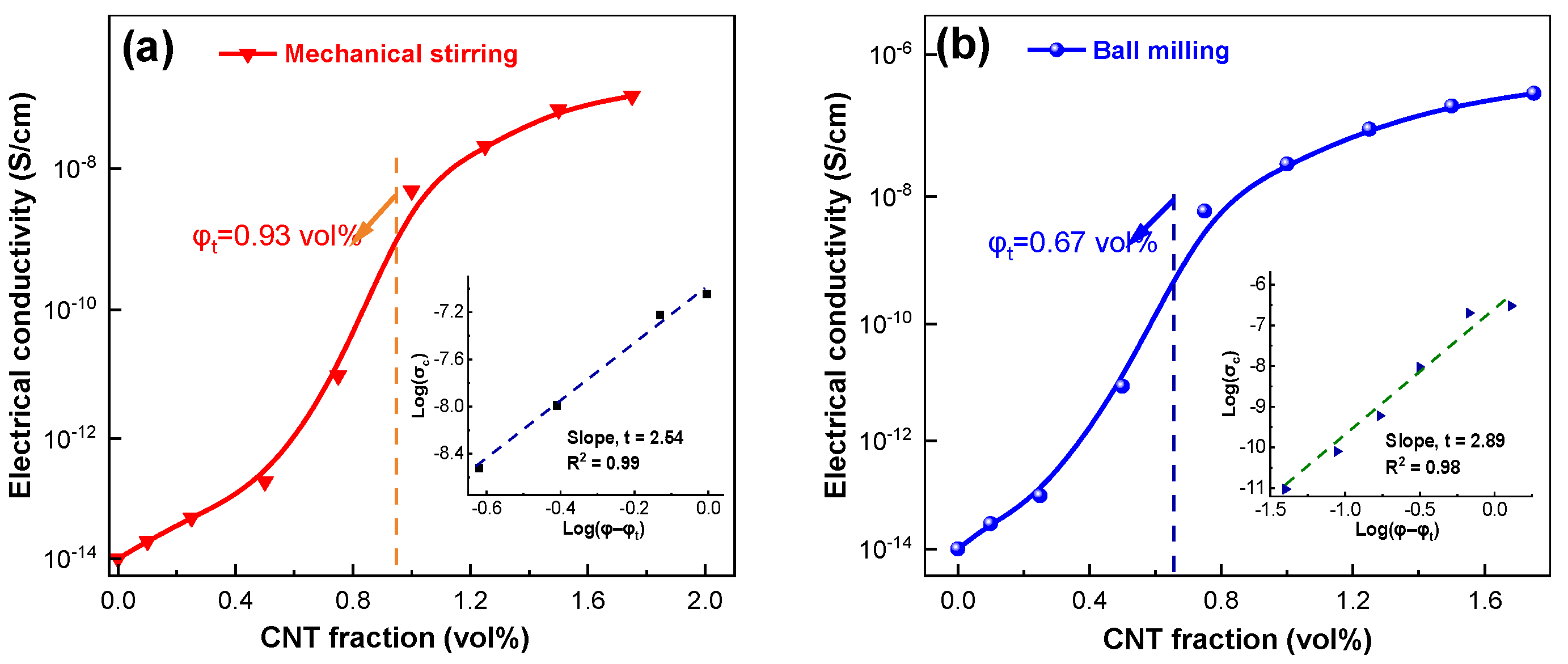

3.5. Electrical and Thermal Conductivity

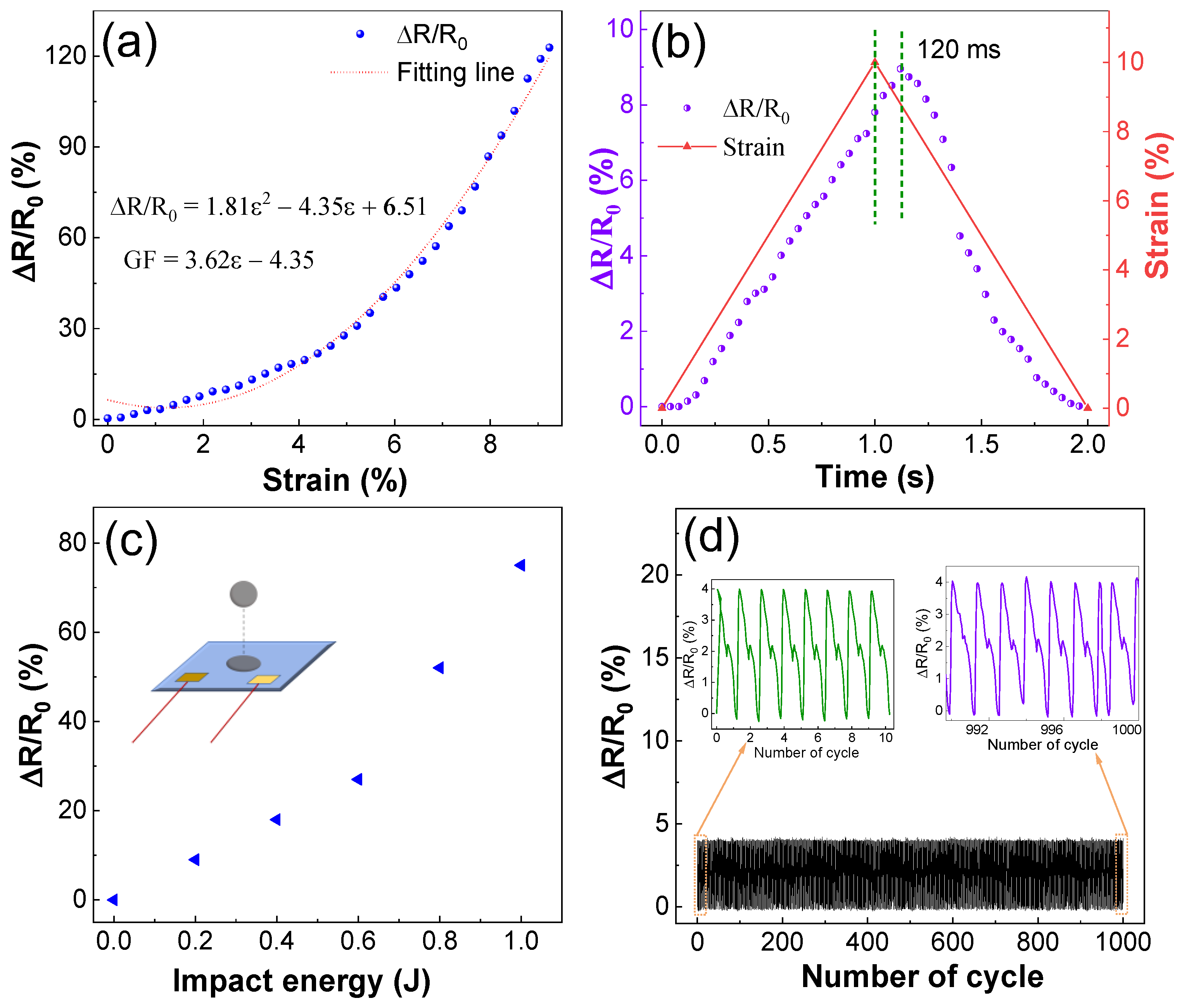

3.6. Piezoresistive Performance

3.7. Self-Sensing Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Natarajan, K. Antibiofilm Activity of Epoxy/Ag-TiO2 Polymer Nanocomposite Coatings against Staphylococcus Aureus and Escherichia Coli. Coatings 2015, 5, 95–114. [Google Scholar]

- Serra, A.; Ramis, X.; Fernández-Francos, X. Epoxy Sol-Gel Hybrid Thermosets. Coatings 2016, 6, 8. [Google Scholar] [CrossRef]

- Ibrahim, M.; Kannan, K.; Parangusan, H.; Eldeib, S.; Shehata, O.; Ismail, M.; Zarandah, R.; Sadasivuni, K.K. Enhanced Corrosion Protection of Epoxy/ZnO-NiO Nanocomposite Coatings on Steel. Coatings 2020, 10, 783. [Google Scholar] [CrossRef]

- Kim, M.I.; Kim, S.; Kim, T.; Lee, D.K.; Seo, B.; Lim, C.-S. Mechanical and Thermal Properties of Epoxy Composites Containing Zirconium Oxide Impregnated Halloysite Nanotubes. Coatings 2017, 7, 231. [Google Scholar] [CrossRef]

- Wang, N.; Gao, H.; Zhang, J.; Kang, P. Effect of Graphene Oxide/ZSM-5 Hybrid on Corrosion Resistance of Waterborne Epoxy Coating. Coatings 2018, 8, 179. [Google Scholar] [CrossRef]

- Wu, Q.; Sundborg, H.; Andersson, R.L.; Peuvot, K.; Guex, L.; Nilsson, F.; Hedenqvist, M.S.; Olsson, R.T. Conductive biofoams of wheat gluten containing carbon nanotubes, carbon black or reduced graphene oxide. RSC Adv. 2017, 7, 18260–18269. [Google Scholar] [CrossRef]

- Sam-Daliri, O.; Faller, L.-M.; Farahani, M.; Roshanghias, A.; Oberlercher, H.; Mitterer, T.; Araee, A.; Zangl, H. MWCNT–Epoxy Nanocomposite Sensors for Structural Health Monitoring. Electronics 2018, 7, 143. [Google Scholar] [CrossRef]

- Yang, S.; Zhu, S.; Hong, R. Graphene Oxide/Polyaniline Nanocomposites Used in Anticorrosive Coatings for Environmental Protection. Coatings 2020, 10, 1215. [Google Scholar] [CrossRef]

- Yan, X.; Qian, X.; Chang, Y. Preparation and Characterization of Urea Formaldehyde @ Epoxy Resin Microcapsule on Waterborne Wood Coatings. Coatings 2019, 9, 475. [Google Scholar] [CrossRef]

- Han, S.; Meng, Q.; Qiu, Z.; Osman, A.; Cai, R.; Yu, Y.; Liu, T.; Araby, S. Mechanical, toughness and thermal properties of 2D material-reinforced epoxy composites. Polymer 2019, 184, 121884. [Google Scholar] [CrossRef]

- Han, S.; Wang, P.; Zhou, Y.; Meng, Q.; Aakyiir, M.; Ma, J. Flexible, mechanically robust, multifunctional and sustainable cellulose/graphene nanocomposite films for wearable human-motion monitoring. Compos. Sci. Technol. 2022, 230, 109451. [Google Scholar] [CrossRef]

- Zhang, J.; Mi, X.; Chen, S.; Xu, Z.; Zhang, D.; Miao, M.; Wang, J. A bio-based hyperbranched flame retardant for epoxy resins. Chem. Eng. J. 2020, 381, 122719. [Google Scholar] [CrossRef]

- Yu, B.; Shi, Y.; Yuan, B.; Qiu, S.; Xing, W.; Hu, W.; Song, L.; Lo, S.; Hu, Y. Enhanced thermal and flame retardant properties of flame-retardant-wrapped graphene/epoxy resin nanocomposites. J. Mater. Chem. A 2015, 3, 8034–8044. [Google Scholar] [CrossRef]

- Zhou, K.; Gao, R.; Qian, X. Self-assembly of exfoliated molybdenum disulfide (MoS2) nanosheets and layered double hydroxide (LDH): Towards reducing fire hazards of epoxy. J. Hazard. Mater. 2017, 338, 343–355. [Google Scholar] [CrossRef] [PubMed]

- Han, S.; Meng, Q.; Pan, X.; Liu, T.; Zhang, S.; Wang, Y.; Haridy, S.; Araby, S. Synergistic effect of graphene and carbon nanotube on lap shear strength and electrical conductivity of epoxy adhesives. J. Appl. Polym. Sci. 2019, 136, 48056. [Google Scholar] [CrossRef]

- Han, S.; Chand, A.; Araby, S.; Cai, R.; Chen, S.; Kang, H.; Cheng, R.; Meng, Q. Thermally and electrically conductive multifunctional sensor based on epoxy/graphene composite. Nanotechnology 2020, 31, 075702. [Google Scholar] [CrossRef] [PubMed]

- Han, S.; Meng, Q.; Chand, A.; Wang, S.; Li, X.; Kang, H.; Liu, T. A comparative study of two graphene based elastomeric composite sensors. Polym. Test. 2019, 80, 106106. [Google Scholar] [CrossRef]

- Meng, Q.; Liu, D.; Zhou, Y.; Cai, R.; Feng, Y.; Hu, Z.; Han, S. Durable, highly sensitive conductive elastomeric nanocomposite films containing various graphene nanoplatelets and their derivatives. Polym. Adv. Technol. 2023, 34, 1170–1181. [Google Scholar] [CrossRef]

- Hicks, J.F.; Seok-Shon, Y.; Murray, R.W. Layer-by-Layer Growth of Polymer/Nanoparticle Films Containing Monolayer-Protected Gold Clusters. Langmuir 2002, 18, 2288–2294. [Google Scholar] [CrossRef]

- Meng, Q.; Liu, Z.; Han, S.; Xu, L.; Araby, S.; Cai, R.; Zhao, Y.; Lu, S.; Liu, T. A facile approach to fabricate highly sensitive, flexible strain sensor based on elastomeric/graphene platelet composite film. J. Mater. Sci. 2019, 54, 10856–10870. [Google Scholar] [CrossRef]

- Meng, Q.; Liu, Z.; Cai, R.; Han, S.; Lu, S.; Liu, T. Non-oxidized graphene/elastomer composite films for wearable strain and pressure sensors with ultra-high flexibility and sensitivity. Polym. Adv. Technol. 2020, 31, 214–225. [Google Scholar] [CrossRef]

- Meng, Q.; Kenelak, V.; Chand, A.; Kang, H.; Han, S.; Liu, T. A highly flexible, electrically conductive, and mechanically robust graphene/epoxy composite film for its self-damage detection. J Appl Polym Sci. 2020, 137, 48991. [Google Scholar] [CrossRef]

- Capezza, A.; Andersson, R.L.; Ström, V.; Wu, Q.; Sacchi, B.; Farris, S.; Hedenqvist, M.S.; Olsson, R.T. Preparation and Comparison of Reduced Graphene Oxide and Carbon Nanotubes as Fillers in Conductive Natural Rubber for Flexible Electronics. ACS Omega 2019, 4, 3458–3468. [Google Scholar] [CrossRef] [PubMed]

- Zou, B.; Qiu, S.; Ren, X.; Zhou, Y.; Zhou, F.; Xu, Z.; Zhao, Z.; Song, L.; Hu, Y.; Gong, X. Combination of black phosphorus nanosheets and MCNTs via phosphoruscarbon bonds for reducing the flammability of air stable epoxy resin nanocomposites. J. Hazard Mater. 2020, 383, 121069. [Google Scholar] [CrossRef]

- Breitwieser, A.; Siedlaczek, P.; Lichtenegger, H.; Sleytr, U.B.; Pum, D. S-Layer Protein Coated Carbon Nanotubes. Coatings 2019, 9, 492. [Google Scholar] [CrossRef]

- Kim, S.; Jeong, H.; Choi, S.-H.; Park, J.-T. Electrical Conductivity Measurement of Transparent Conductive Films Based on Carbon Nanoparticles. Coatings 2019, 9, 499. [Google Scholar] [CrossRef]

- Ma, H.; Zhao, L.; Liu, J.; Wang, J.; Xu, J. Functionalizing carbon nanotubes by grafting cyclotriphosphazene derivative to improve both mechanical strength and flame retardancy. Polym. Compos. 2014, 35, 2187–2193. [Google Scholar] [CrossRef]

- Meng, Q.; Jin, J.; Wang, R.; Kuan, H.C.; Ma, J.; Kawashima, N.; Michelmore, A.; Zhu, S.; Wang, C.H. Processable 3-nm thick graphene platelets of high electrical conductivity and their epoxy composites. Nanotechnology 2014, 25, 125707. [Google Scholar] [CrossRef]

- Ma, J.; Meng, Q.; Zaman, I.; Zhu, S.; Michelmore, A.; Kawashima, N.; Wang, C.H.; Kuan, H.C. Development of polymer composites using modified, high-structural integrity graphene platelets. Compos. Sci. Technol. 2014, 91, 82–90. [Google Scholar] [CrossRef]

- Zaman, I.; Kuan, H.C.; Dai, J.; Kawashima, N.; Michelmore, A.; Sovi, A.; Dong, S.; Luong, L.; Ma, J. From carbon nanotubes and silicate layers to graphene platelets for polymer nanocomposites. Nanoscale 2012, 4, 4578–4586. [Google Scholar] [CrossRef]

- Meng, Q.; Han, S.; Liu, T.; Ma, J.; Ji, S.; Dai, J.; Kang, H.; Ma, J. Noncovalent Modification of Boron Nitrite Nanosheets for Thermally Conductive, Mechanically Resilient Epoxy Nanocomposites. Ind. Eng. Chem. Res. 2020, 59, 20701–20710. [Google Scholar] [CrossRef]

- Meng, Q.; Song, X.; Han, S.; Abbassi, F.; Zhou, Z.; Wu, B.; Wang, X.; Araby, S. Mechanical and functional properties of polyamide/graphene nanocomposite prepared by chemicals free-approach and selective laser sintering. Compos. Commun. 2022, 36, 101396. [Google Scholar] [CrossRef]

- Deng, S.; Zhang, J.; Ye, L. Halloysite-epoxy nanocomposites with improved particle dispersion through ball mill homogenisation and chemical treatments. Compos. Sci. Technol. 2009, 69, 2497–2505. [Google Scholar] [CrossRef]

- Huang, H.-C.; Huang, S.-P.; Hsieh, T.-E.; Chen, C.-H. Characterizations of UV-curable montmorillonite/epoxy nanocomposites prepared by a hybrid of chemical dispersion and planetary mechanical milling process. J. Appl. Polym. Sci. 2012, 123, 3199–3207. [Google Scholar] [CrossRef]

- Han, S.; Meng, Q.; Araby, S.; Liu, T.; Demiral, M. Mechanical and electrical properties of graphene and carbon nanotube reinforced epoxy adhesives: Experimental and numerical analysis. Compos. Part A Appl. Sci. Manuf. 2019, 120, 116–126. [Google Scholar] [CrossRef]

- Sun, K.; Duan, W.X.; Lei, Y.H.; Wang, Z.X.; Tian, J.H.; Yang, P.T.; He, Q.F.; Chen, M.; Wu, H.K.; Zhang, Z.; et al. Flexible multi-walled carbon nanotubes/polyvinylidene fluoride membranous composites with weakly negative permittivity and low frequency dispersion. Compos. Part A Appl. Sci. Manuf. 2022, 156, 106854. [Google Scholar] [CrossRef]

- Meng, Q.; Han, S.; Araby, S.; Zhao, Y.; Liu, Z.; Lu, S. Mechanically robust, electrically and thermally conductive graphene-based epoxy adhesives. J. Adhes. Sci. Technol. 2019, 33, 1337–1356. [Google Scholar] [CrossRef]

- Meng, Q.; Zhao, Y.; Liu, Z.; Han, S.; Lu, S.; Liu, T. Flexible strain sensors based on epoxy/graphene composite film with long molecular weight curing agents. J. Appl. Polym. Sci. 2019, 136, 47906. [Google Scholar] [CrossRef]

- Wang, S.; Cai, R.; Xue, H.; Liu, T.; Han, S.; Zhou, Z.; Hu, Z.; Meng, Q. Development of high thermally conductive and electrically insulated epoxy nanocomposites with high mechanical performance. Polym. Compos. 2021, 42, 4217–4226. [Google Scholar] [CrossRef]

- Han, S.; Zhang, X.; Wang, P.; Dai, J.; Guo, G.; Meng, Q.; Ma, J. Mechanically robust, highly sensitive and superior cycling performance nanocomposite strain sensors using 3-nm thick graphene platelets. Polym. Test. 2021, 98, 107178. [Google Scholar] [CrossRef]

- Han, S.; Meng, Q.; Xing, K.; Araby, S.; Yu, Y.; Mouritz, A.; Ma, J. Epoxy/graphene film for lifecycle self-sensing and multifunctional applications. Compos. Sci. Technol. 2020, 198, 108312. [Google Scholar] [CrossRef]

- Bareia, T.; Pollak, S.; Eldar, A. Self-sensing in Bacillus subtilis quorum-sensing systems. Nat. Microbiol. 2018, 3, 83–89. [Google Scholar] [CrossRef] [PubMed]

- Lo, C.-Y.; Zhao, Y.; Kim, C.; Alsaid, Y.; Khodambashi, R.; Peet, M.; Fisher, R.; Marvi, H.; Berman, S.; Aukes, D.; et al. Highly stretchable self-sensing actuator based on conductive photothermally-responsive hydrogel. Mater. Today 2021, 50, 35–43. [Google Scholar] [CrossRef]

- Dong, L.; Ren, M.; Wang, Y.; Qiao, J.; Wu, Y.; He, J.; Wei, X.; Di, J.; Li, Q. Self-sensing coaxial muscle fibers with bi-lengthwise actuation. Mater. Horiz. 2021, 8, 2541–2552. [Google Scholar] [CrossRef] [PubMed]

- Yoo, S.J.; Kim, S.; Cho, K.-H.; Ahn, H.-J. Data-Driven Self-sensing Technique for Active Magnetic Bearing. Int. J. Precis. Eng. Manuf. 2021, 22, 1031–1038. [Google Scholar] [CrossRef]

- Birgin, H.B.; D’Alessandro, A.; Corradini, A.; Laflamme, S.; Ubertini, F. Self-sensing asphalt composite with carbon microfibers for smart weigh-in-motion. Mater. Struct. 2022, 55, 138. [Google Scholar] [CrossRef]

- Gong, Z.; Han, L.; An, Z.; Yang, L.; Ding, S.; Xiang, Y. Empowering smart buildings with self-sensing concrete for structural health monitoring. In Proceedings of the ACM SIGCOMM 2022 Conference, Amsterdam, The Netherlands, 22–26 August 2022; pp. 560–575. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Z.; Han, Q.; Liu, J.; Zhao, K.; Yu, Y.; Feng, Y.; Han, S. Dispersion of Carbon Nanotubes Improved by Ball Milling to Prepare Functional Epoxy Nanocomposites. Coatings 2023, 13, 649. https://doi.org/10.3390/coatings13030649

Gao Z, Han Q, Liu J, Zhao K, Yu Y, Feng Y, Han S. Dispersion of Carbon Nanotubes Improved by Ball Milling to Prepare Functional Epoxy Nanocomposites. Coatings. 2023; 13(3):649. https://doi.org/10.3390/coatings13030649

Chicago/Turabian StyleGao, Ziqi, Quanjiabao Han, Jianbang Liu, Kangbo Zhao, Yin Yu, Yuanyuan Feng, and Sensen Han. 2023. "Dispersion of Carbon Nanotubes Improved by Ball Milling to Prepare Functional Epoxy Nanocomposites" Coatings 13, no. 3: 649. https://doi.org/10.3390/coatings13030649

APA StyleGao, Z., Han, Q., Liu, J., Zhao, K., Yu, Y., Feng, Y., & Han, S. (2023). Dispersion of Carbon Nanotubes Improved by Ball Milling to Prepare Functional Epoxy Nanocomposites. Coatings, 13(3), 649. https://doi.org/10.3390/coatings13030649