Cold Spray Coatings of Complex Concentrated Alloys: Critical Assessment of Milestones, Challenges, and Opportunities

Abstract

1. Introduction

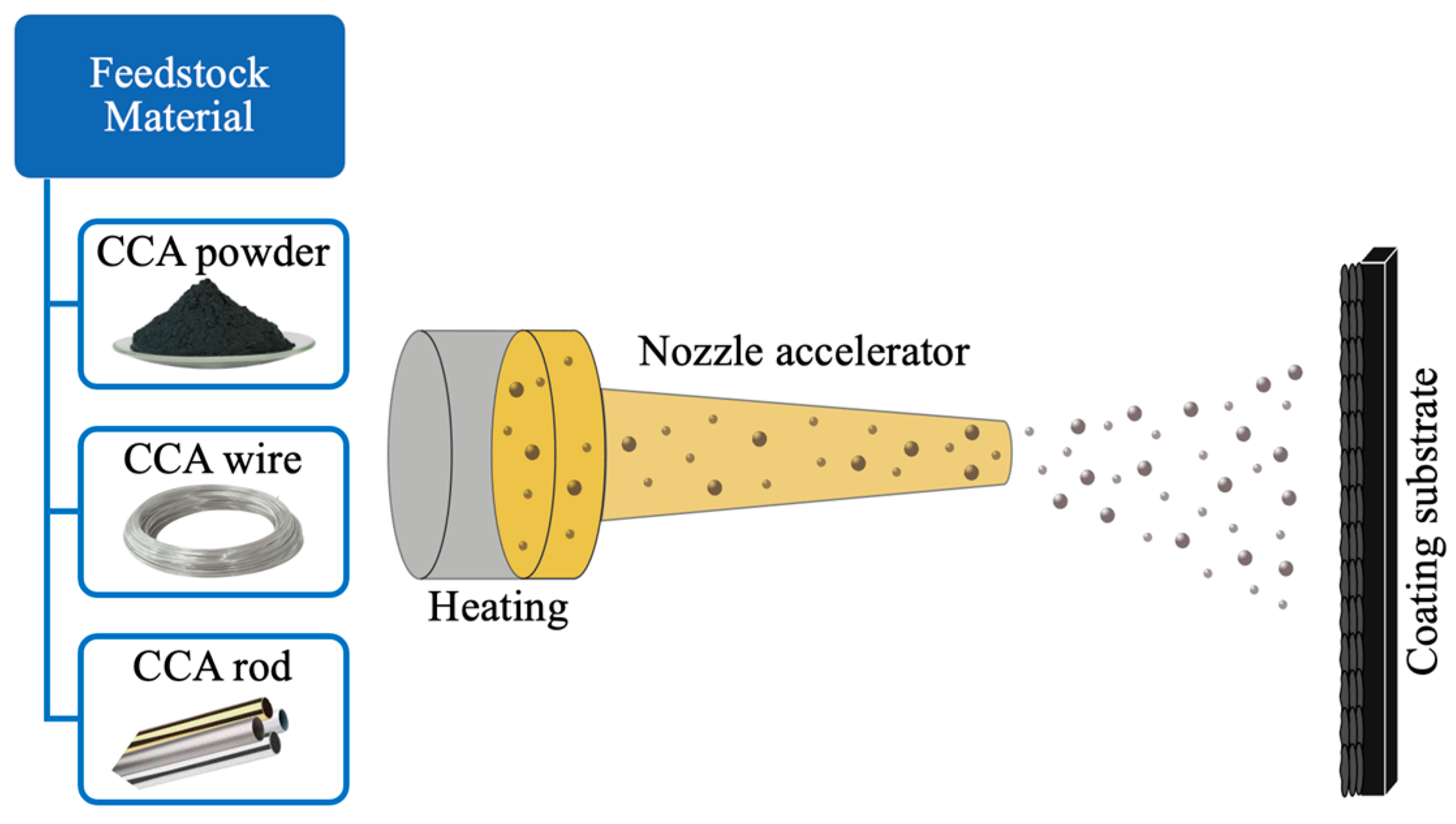

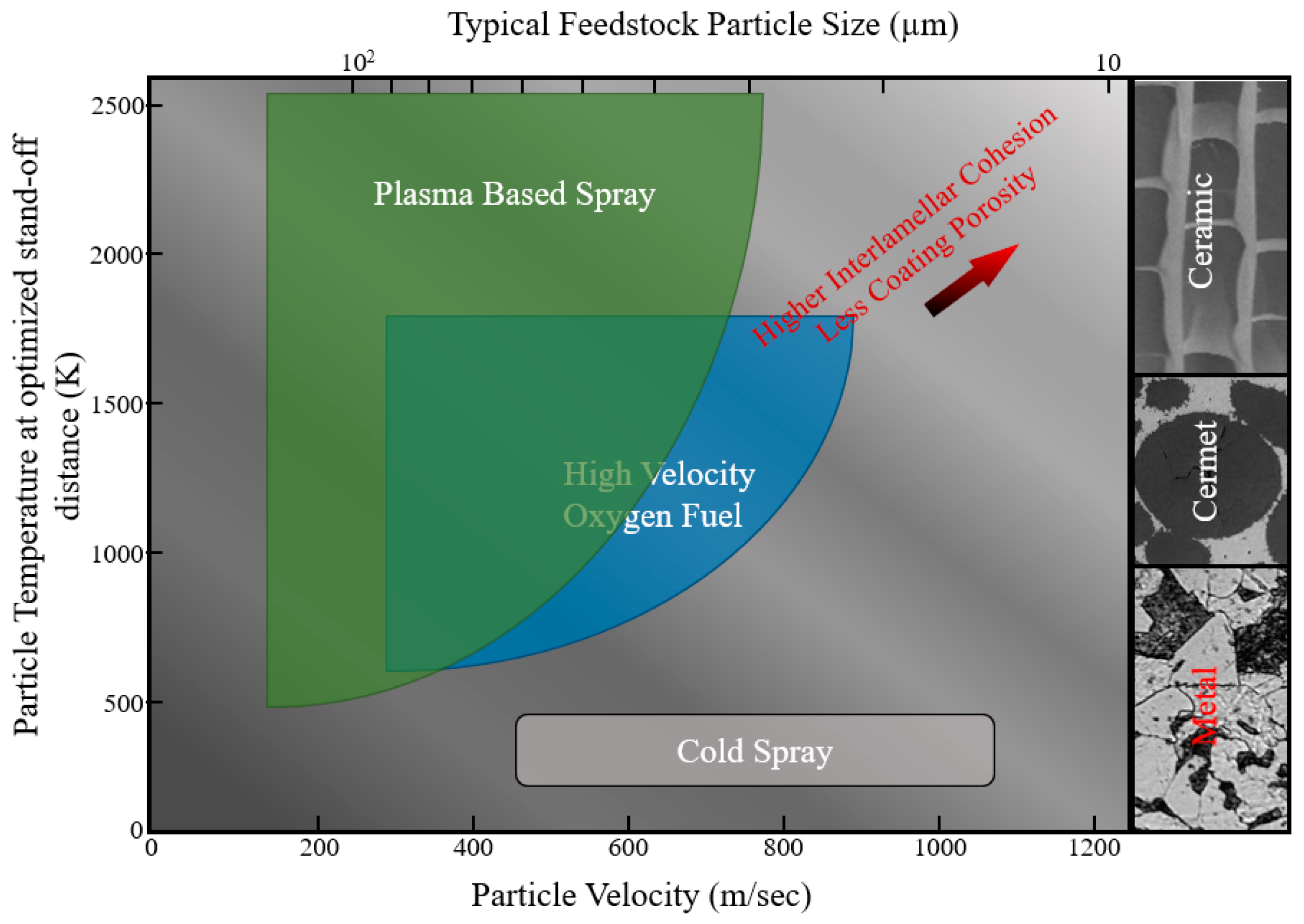

2. Thermal Spray Technology—Brief Overview

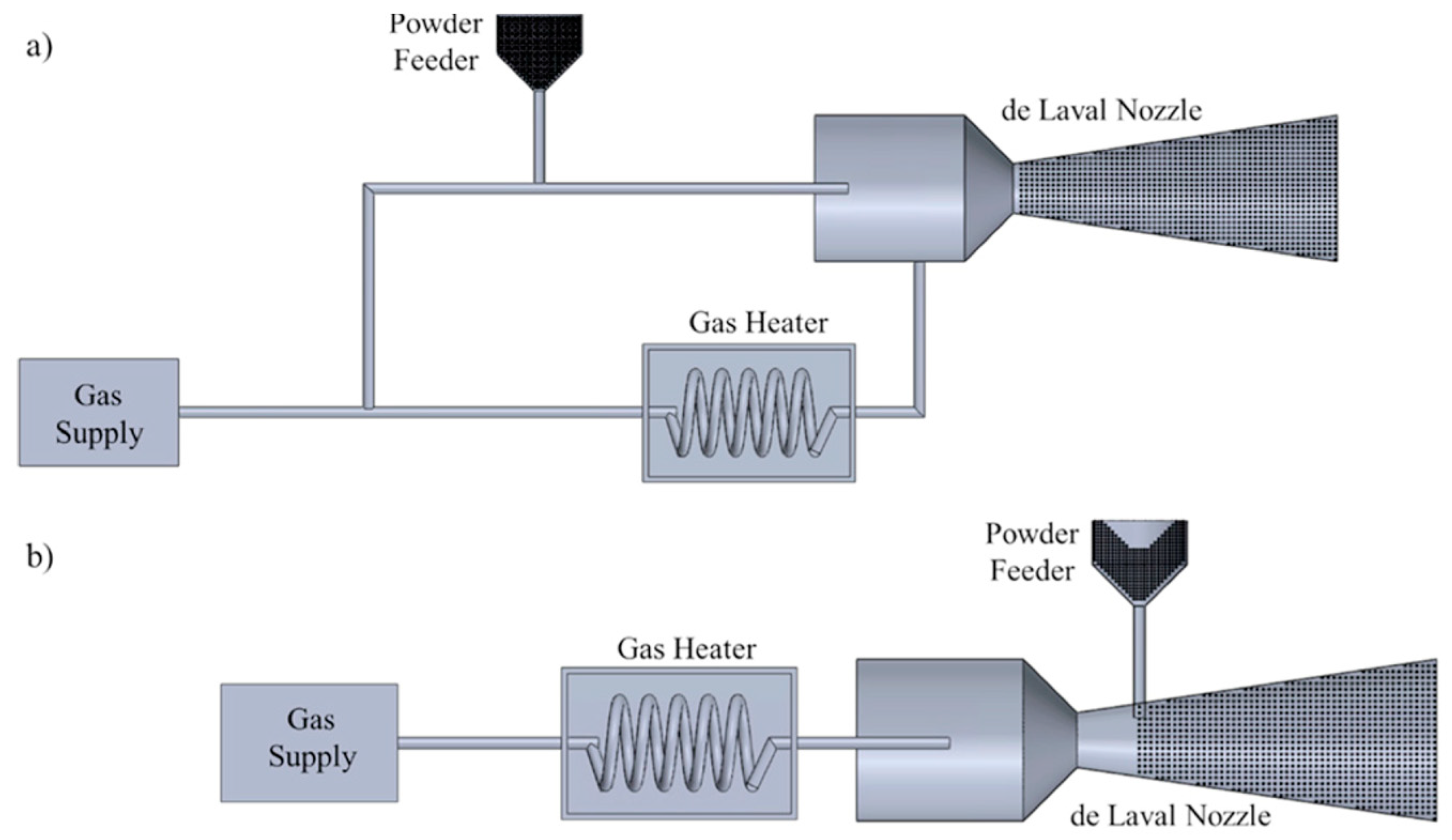

3. Cold Spray Technology: An Overview

3.1. Introduction and General Concepts

3.2. Processing Parameters of Cold Spray Coatings

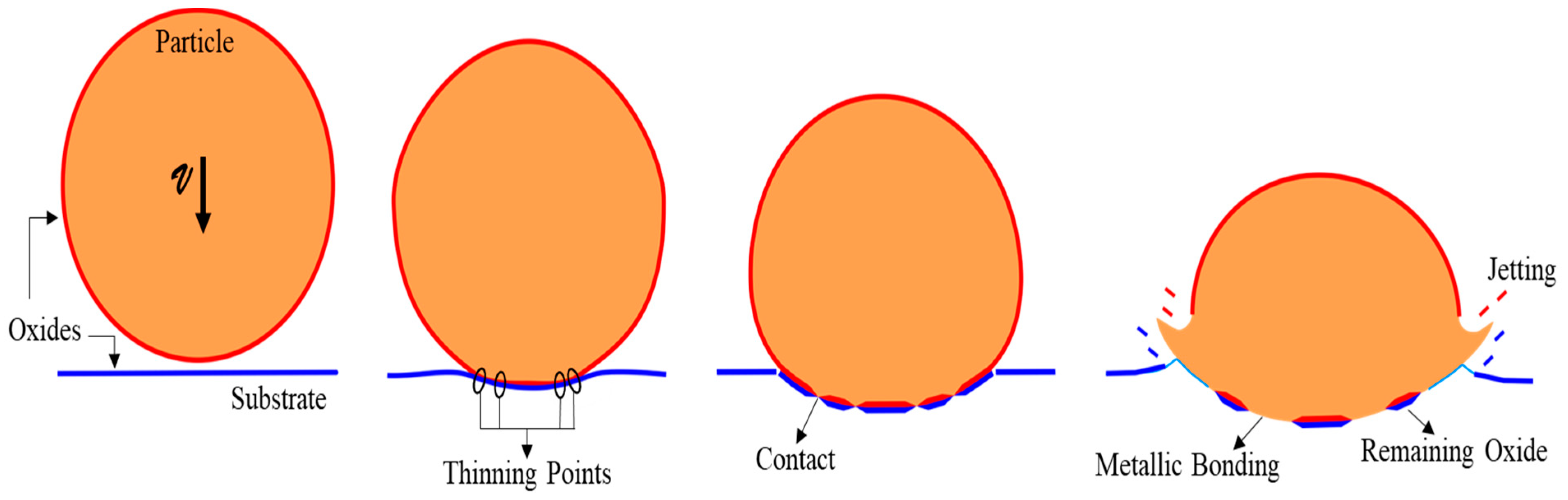

3.3. Bonding Mechanisms of Cold Spray of Metallic Materials

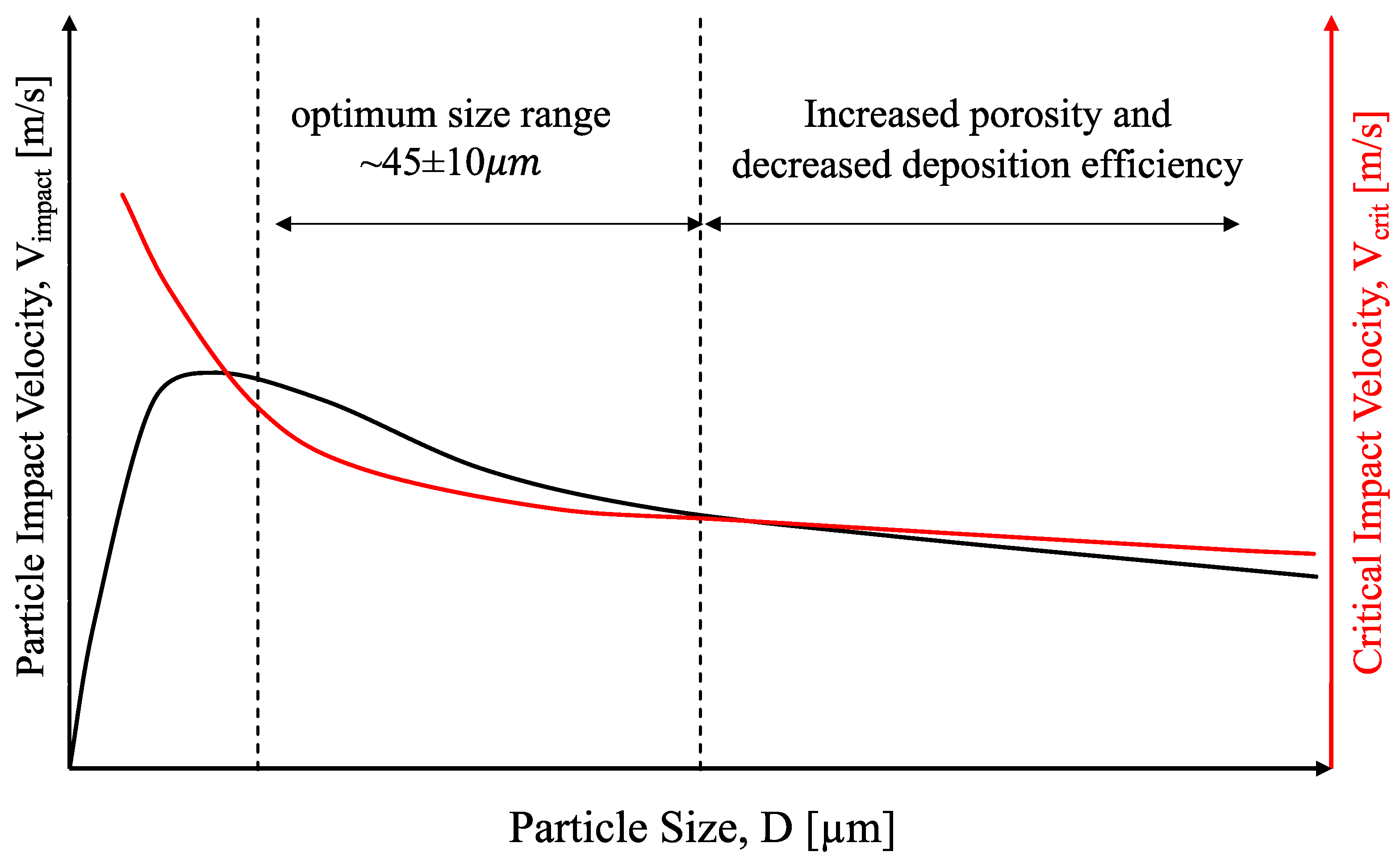

- The velocity of the particles should be higher than a critical nominal velocity (critical velocity) to induce sufficient kinetic energy, a characteristic of velocity for enough plastic deformation to initiate the interaction between the particle and oxide films on substrate. There are instances where there are no oxide layers, but the particle critical velocity is crucial for cold spray.

4. Computational and Numerical Simulation Models—An Overview

4.1. Modeling Approaches Using Numerical Simulations

4.1.1. Lagrangian Approach

4.1.2. Eulerian Approach

4.1.3. Combined (Coupled) Eulerian–Lagrangian Approach

4.1.4. Particle-Based Approach

- The SPH, being a particle-based method, allows for the handling of large deformations. This is because connections between the particles are generated as part of the computations and changes with time, especially for the high-velocity impact phenomenon which underpins cold spray technology.

- The SPH method has been successfully applied to conceptualized problems with deformable boundaries with extremely large deformations, free surface, and moving interfaces.

- The SPH is a particle approach of the Lagrangian kind with the Galilean invariant algorithm. It can easily estimate time history of the particles of the material, which are relevant for determining the transport and advection of the system.

- The SPH method, being one of the oldest mesh-free particle methods, has approached maturation and been successfully integrated into commercial software packages for practical applications.

- The SPH is ideal for free surface and interfacial flow modeling characteristics with the cold spray process. The specific location of the particles prior to the commencement of any analysis is critical. This leads to accurate and easily traceable material interfaces and free surfaces by the SPH simulation irrespective of the complexity of the particle movement and interaction, which may be challenging for mesh-based methods.

- The SPH approach is extensively used in applications ranging from the microscale to macroscale and even astronomical scale, and in discrete to continuum systems. It is easy to combine with other methods such as classical molecular dynamics and dissipative particle dynamic methods for various applications.

- Numerical simulations associated with SPH have the objects not under continuum, which is vital for bio- and nanoengineering across the nano- to the microscale.

- The SPH method is comparatively easy to implement and to use to develop 3D numerical models than the mesh-based approaches. It has also gained an acceptable level of accuracy for practical engineering applications.

4.2. Finite Element-Based Numerical Models for Cold Spray Processes

4.2.1. Johnson–Cook Model

4.2.2. Preston–Tonk–Wallace (PTW) Model

4.2.3. The Zerilli–Armstrong (ZA) Model

4.2.4. The Voyiadjis–Abed (VA) Model

4.2.5. The Other Types of Models

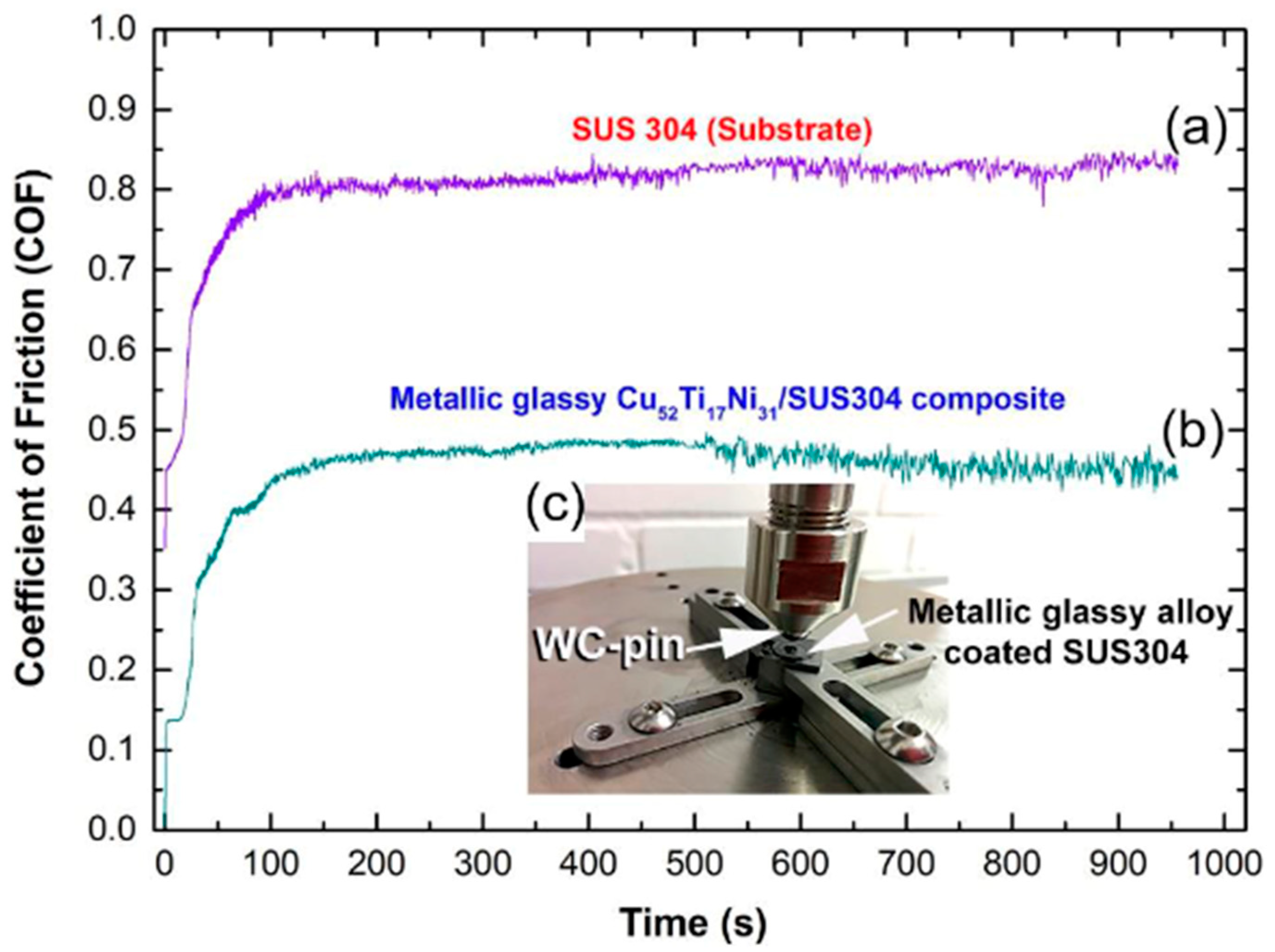

5. Bulk Metallic Glass Cold Spray Coatings

- High hardness, high strength, and wear resistance: BMG coatings exhibit high hardness and wear resistance, making them suitable for use in harsh environments where traditional coatings may fail.

- Corrosion resistance: BMG coatings have excellent corrosion resistance, making them perfect for use in marine, aerospace, and other corrosive environments.

- Low porosity: BMG coatings have a low porosity, lowering the chance of corrosion and enhancing substrate adhesion.

- High bonding strength: BMG coatings have a strong bond to their substrate, reducing the chance of delamination or cracking.

- Low thermal conductivity: BMG coatings have a low thermal conductivity, making them suitable for use in high-temperature environments where thermal insulation is needed.

- Tailored properties: BMG coatings possess specific properties such as electrical conductivity, magnetic properties, or optical properties, making them useful in a variety of applications.

- Cost effectiveness: As a cost-effective substitute for conventional coating techniques, BMG cold spray coatings can be applied using a relatively inexpensive procedure.

5.1. Aluminum-Based BMG Cold Spray Coatings

5.2. Copper-Based BMG Cold Spray Coatings

5.3. Iron-Based BMG Cold Spray Coatings

5.4. Nickel-Based BMG Cold Spray Coatings

5.5. Zirconium-Based BMG Cold Spray Coatings

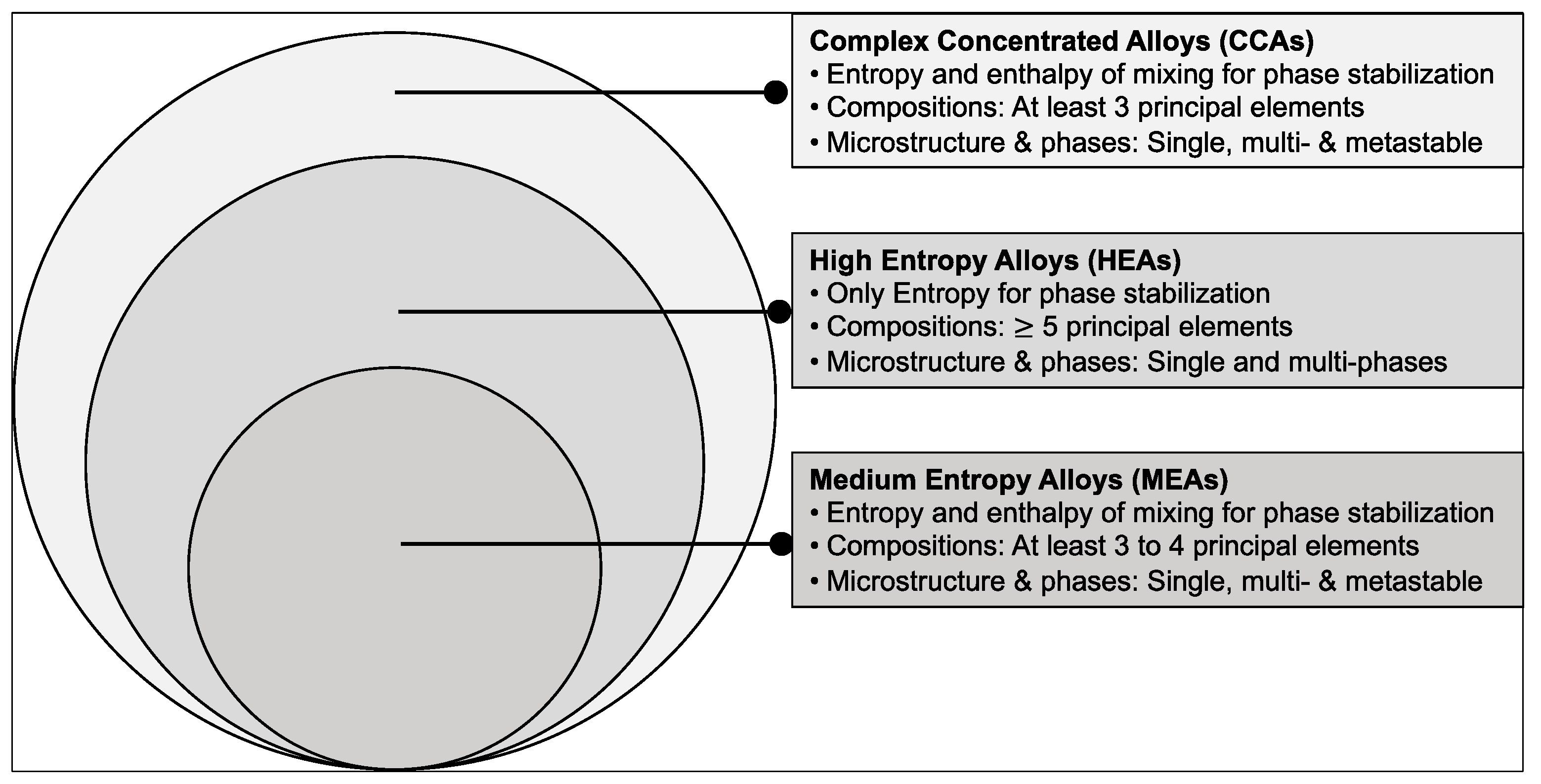

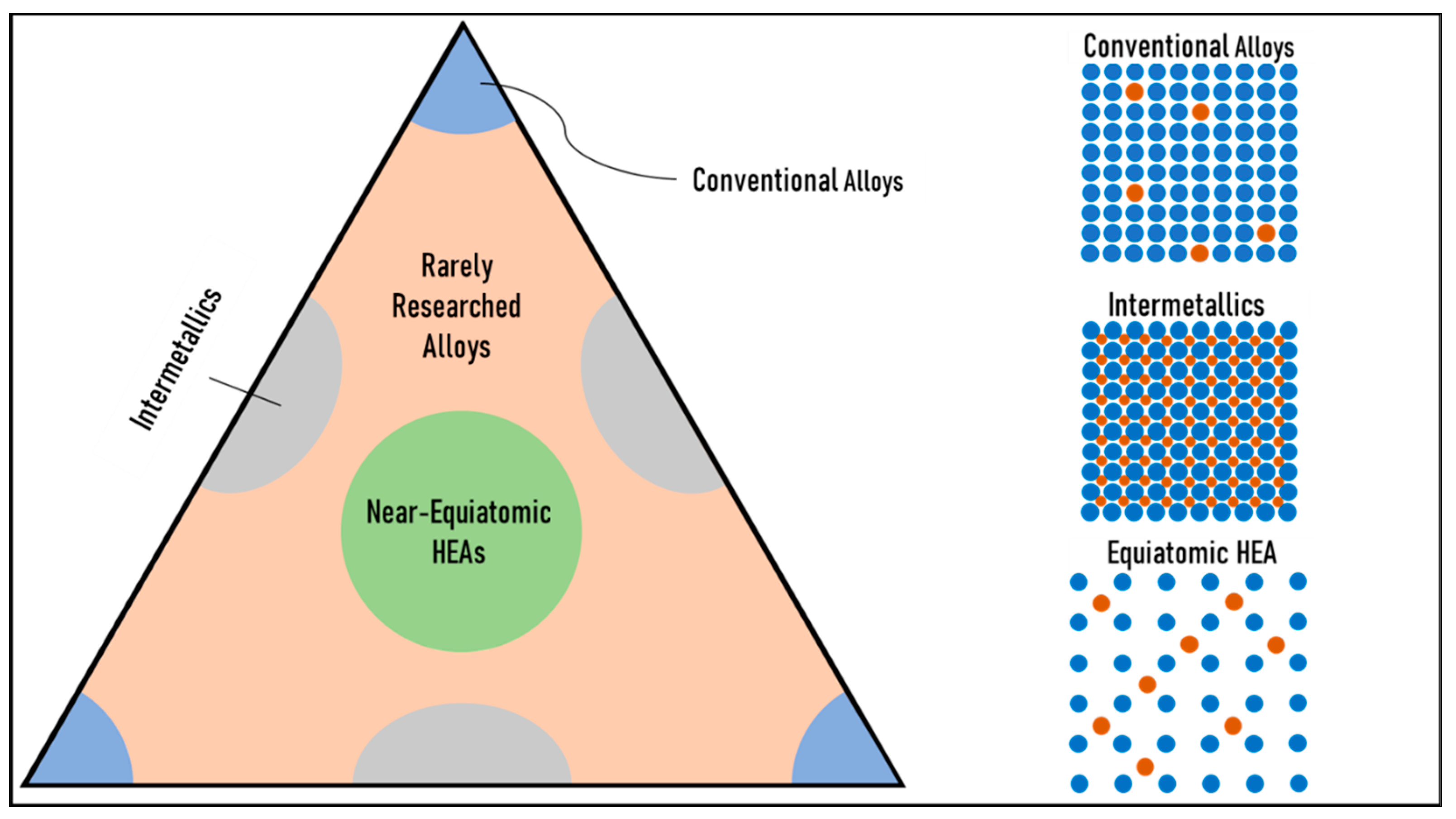

6. Complex Concentrated Alloys—Brief Overview

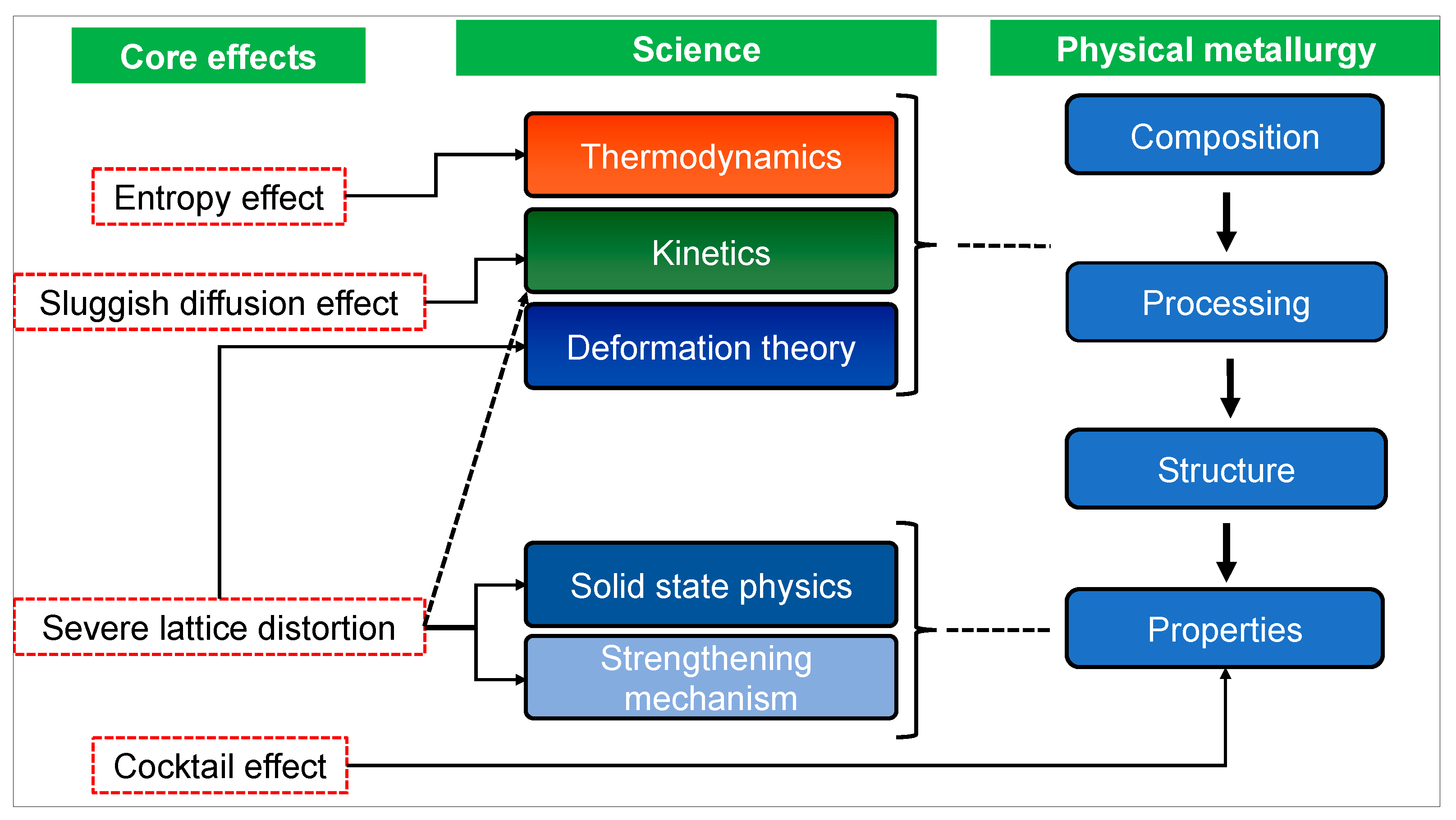

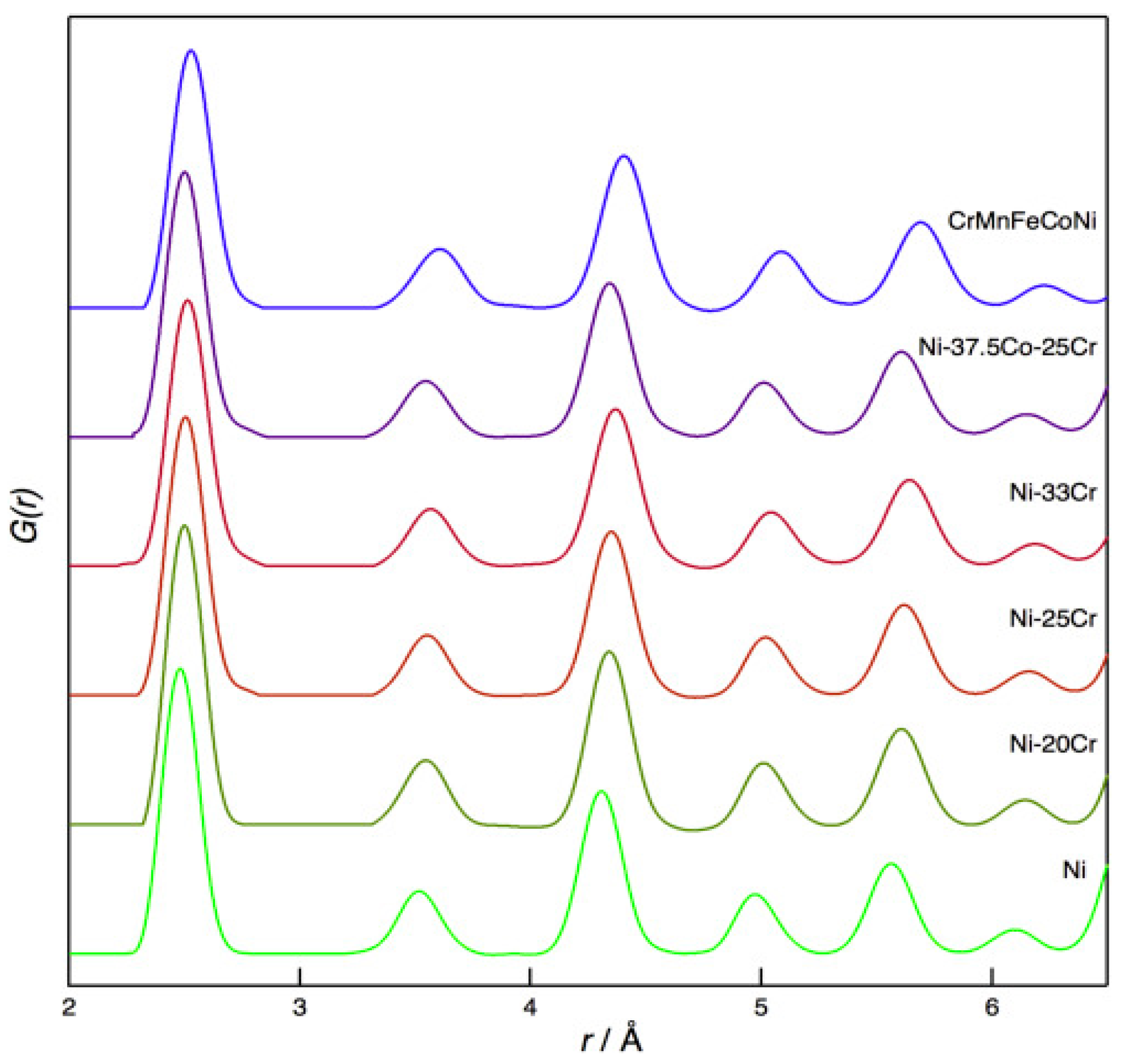

6.1. Core Effects of Complex Concentrated Alloys

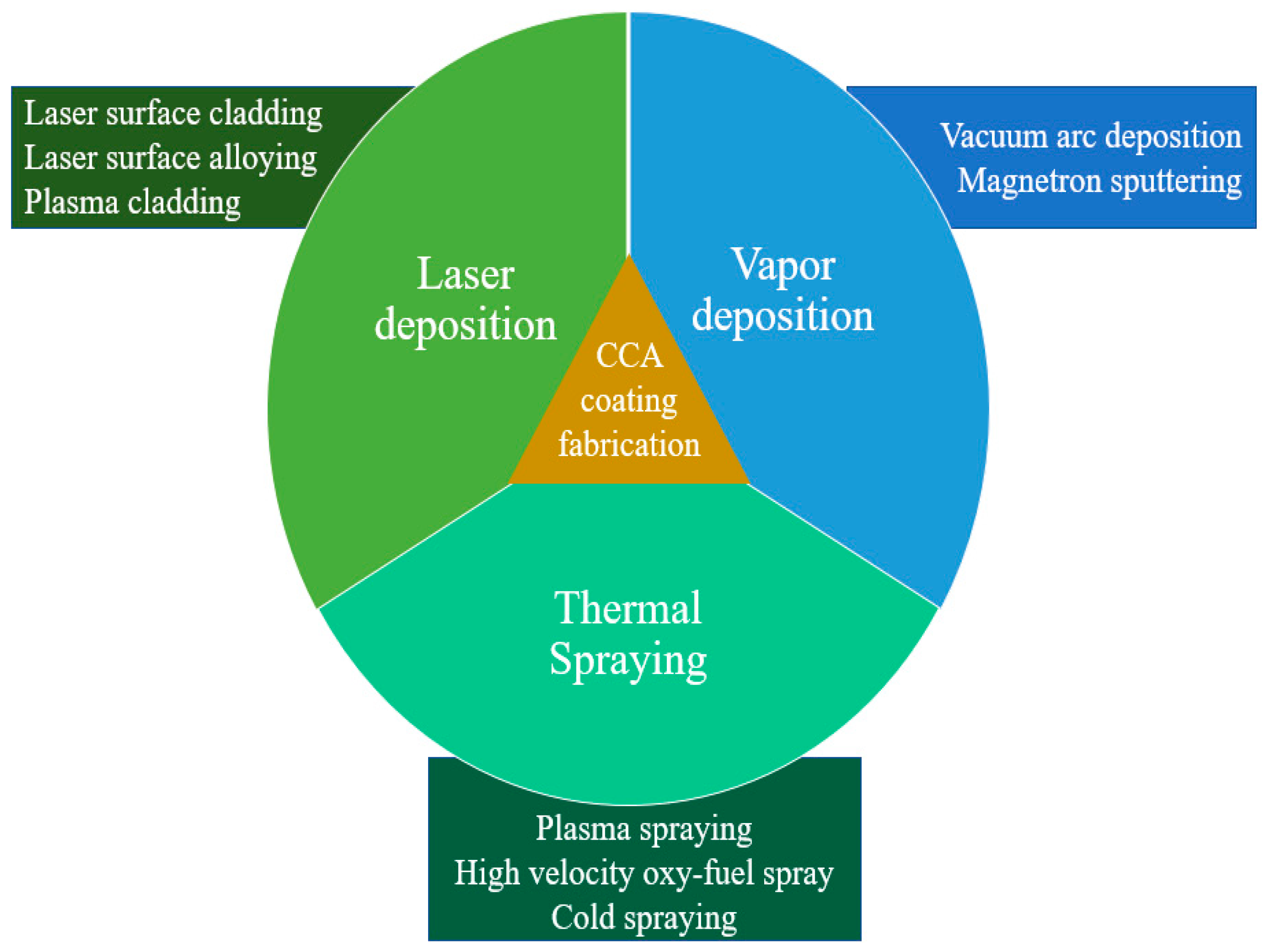

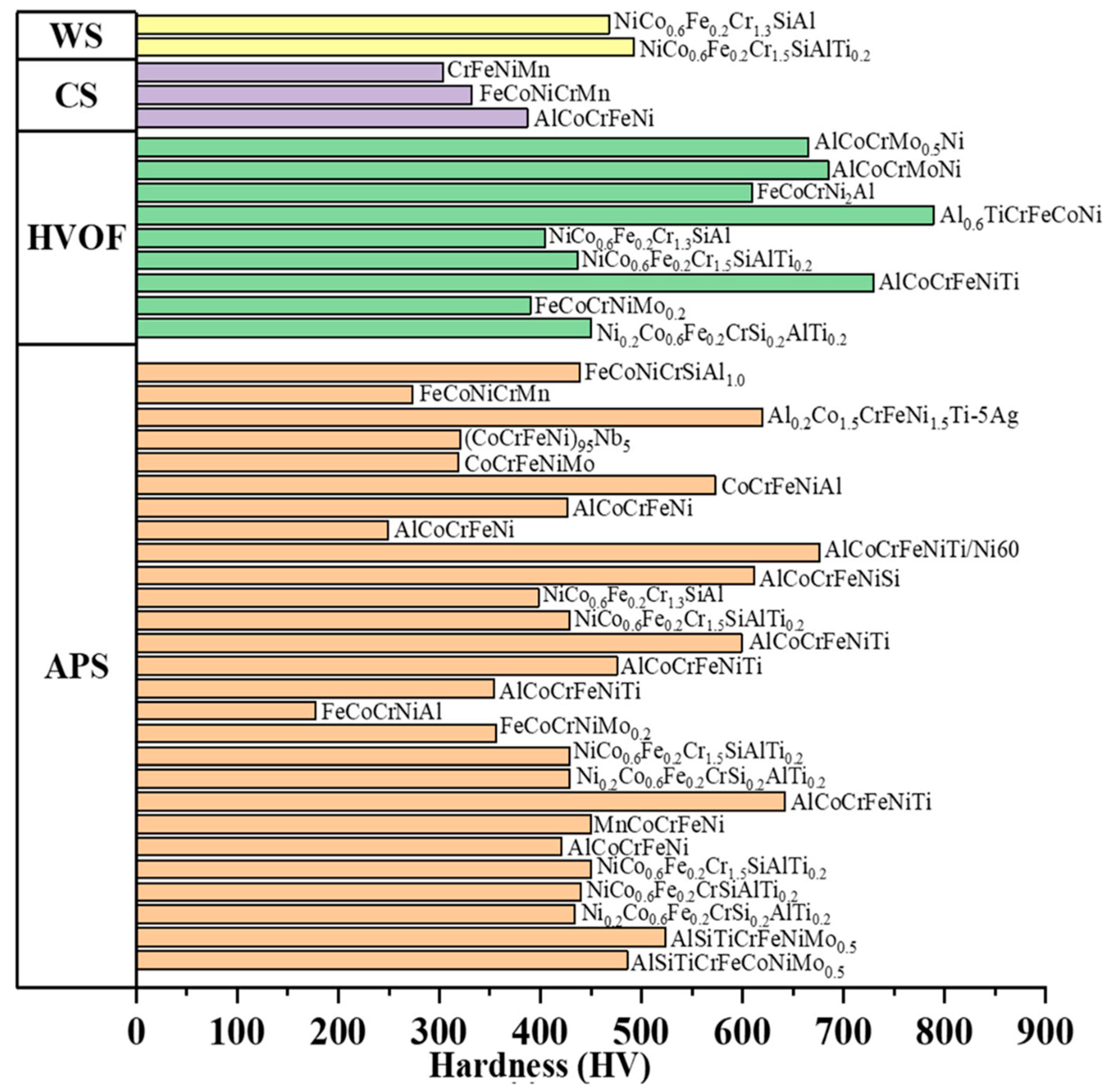

6.2. Complex Concentrated Alloy Coatings

6.2.1. Complex Concentrated Alloy Cold Spray Coatings—An Outlook

6.2.2. Mechanical Properties of Cold Sprayed CCAs on Different Metallic Substrates

| Method | Substrate | CCA/HEA Coating | Structure | Thickness (µm) | References |

|---|---|---|---|---|---|

| Laser deposition techniques | |||||

| Plasma transferred arc cladding | Q 235 | CoCrCuFeNiNb | FCC + Laves | ~2000 | [208] |

| TiC–TiB2/CoCrCuFeNi | FCC + BCC + TiC + TiB2 | [209] | |||

| CoNiCuFeCr | FCC | [210] | |||

| Plasma cladding | CrCuFexNiTi | FCC + BCC + Fe2Ti | ~2500 | [211] | |

| AISI 1045 steel | FeCoNiAlCu | FCC + BCC | ~1000 | [212] | |

| Pure Ti | FeCoCrNiNbx | ~1500 | [213] | ||

| Laser cladding | CoCrFeNiNb | BCC + Cr2Ti+ Cr2Nb | ~500–600 | [214] | |

| Ti6Al4V | AlTiVMoNb | BCC | [215] | ||

| CoCrFeNi2V0.5Ti0.75 | BCC + (Co, Ni)Ti2 + Ti rich | ~800 | [216] | ||

| Stainless steel | Al2CrFeNiMox | BCC | - | [217] | |

| Q 235 steel | 6FeNiCoSiCrAlTi | 1200 | [218] | ||

| MgMoNbFeTi2Yx | FCC + BCC | ~1300 | [219] | ||

| Al2CrFeNiCoCuTix | ~600 | [220] | |||

| AlCoCrFeNi/NbC | FCC + BCC + NbC | 1200 | [221] | ||

| Al2CoCrCuFeNiTix | - | 500 | [222] | ||

| FeCoNiCrCu(SiMnMo) | FCC | ~2000 | [223] | ||

| Al 5083 | Al0.5FeCu0.7NiCoCr | FCC + BCC | ~600 | [224] | |

| H13 steel | Co34Cr29B14Fe8Ni8Si7 | Amorphous + FeNi3 | ~450 | [225,226] | |

| 45# steel | AlCoCrxFeNi | FCC + FeAl3 | - | [227] | |

| AZ31 Mg | AlCoCrCuFeNiSi0.5/Y2O3 | FCC + BCC | 1500 | [228] | |

| 904L SS | CoCr2FeNiTix/TiNi | FCC + TiN | 1500 | [229] | |

| M2 steel | MoFeCrTiWAlNb | BCC + (Nb, Ti)C + Fe2Nb | 1400 | [230] | |

| 253MA steel | AlxCoCrFeNi | FCC + BCC | ~900 | [231] | |

| 45 # steel | FeCrCoNiAlMox | BCC | ~640 | [232] | |

| H13 steel | FeCoCrBNiSi | Amorphous + FCC | ~200 | [233] | |

| Laser alloying | Ti6Al4V | CrCoNiTiVAl | BCC + (Ni, Co)Ti2 | [234] | |

| BCC + (Ni, Co)Ti2 + HCP | [235] | ||||

| 304 SS | FeCoCrAlNi | BCC | ~600 | [236] | |

| Q235 | FeCoCrAlCu | 800 | [237] | ||

| A36 steel | CrMnFeCoNi | FCC | 2000 | [238] | |

| Ni201 | FeCoCrAlCuVxNi | FCC + BCC | 400 | [239] | |

| Pure Cu | FeCoCrAlCuNix | 500 | [240] | ||

| Vapor deposition techniques | |||||

| Vacuum arc deposition | Stainless steel | (TiZrNbAlYCr)N | FCC + BCC | ~7 | [241] |

| C35 steel | (TiZrHfVNbTa)N | Amorphous + FCC + BCC | - | [242] | |

| C45 steel | (TiZrHfVNb)N | FCC | ~4.78 | [243] | |

| Magnetron sputtering | 304 | FeCoCrNiMo0.1 | FCC | ~0.85 | [199] |

| CrNbTiMoZr | Amorphous | ~1.2 | [244] | ||

| CuMoTaWV | FCC + BCC | ~0.9 | [245] | ||

| 201 | FeAlCuCrCoMn | FCC | ~1.8 | [246] | |

| M2 steel | CoCrNi/Ti | FCC + BCC + CoTi2 | 3.5 | [247] | |

| (TiZrNbHfTa)C | FCC | 2.0 | [248] | ||

| C45 steel | (TiZrNbHfTa)N | FCC | 2.0 | ||

| N36 Zr | AlCoMoNbZr | Amorphous + BCC | 3.0 | [249] | |

| Mild steel | (TiAlCrSiV)xNy | Amorphous + FCC | 1.7 | [250] | |

| Si (100) wafer | (AlCrNbSiTiV)N | 1.0 | [251] | ||

| (AlCrMnMoNiZr)Nx | FCC | 1.5 | [252] | ||

| (AlCrMoTaTi)SixN | 1.0 | [253] | |||

| Si (100); SiO2; Al2O3 | (HfNbTiVr)N | 1.2 | [254] | ||

| Ti6Al4V | TiTaHfNbZr | Amorphous | ~0.8 | [255] | |

| Ag doped TiZrTaNbW | ~1.1 | [256] | |||

| Thermal spray techniques | |||||

| High-velocity oxygen-fuel spraying | ASTM A572 | Al0.6TiCrFeCoNi | BCC | ~300 | [257] |

| 304/316 | AlCoCrFeNiTi0.5 | ~500 | [258] | ||

| 304L | TiNbMoMnFe | - | [259] | ||

| Incoloy 800H | Ni0.2Co0.6Fe0.2CrSi0.2AlTi0.2 | BCC + Cr3Si | ~1500 | [260] | |

| Plasma spray | 316 | AlCoCrFeNiTi/TiNi60 | FCC + BCC | [261] | |

| Q235 steel | (CoCrFeNi)95Nb5 | FCC + Laves | 500 | [262] | |

| Mild steel | CoCrMnFeNi | FCC + BCC + Fe3O4 | - | [263] | |

| AlCoCrFeNi | FCC + BCC + Al2(Cr, Fe)O4 | - | |||

| 304 | FeCoNiCrMn | FCC | ~195 | [264] | |

| FeCoNiCrSiAlx | BCC + FCC | ~160 | [265] | ||

| Mild steel | AlCoCrFeNi | BCC + FCC | [266] | ||

| Q 235 | (CoCrFeNi)95Nb5 | BCC | ~500 | [262] | |

| Atmospheric plasma spraying | 304 SS | NiCo0.6Fe0.2Cr1.5SiAlTi0.2 | FCC + BCC + Cr3Si | - | [204] |

| NixCo0.6Fe0.2CrySi2AlTi0.2 | BCC + Cr3Si | - | [267] | ||

| 316 SS | AlCoCrFeNiTi | BCC + FCC | 240 | [268] | |

| Database | Year | Title of the Published Paper | Refs |

|---|---|---|---|

| Web of Science | 2019 | Deposition of FeCoNiCrMn high entropy alloy (HEA) coating via cold spraying | [200] |

| First report on cold-sprayed AlCoCrFeNi high-entropy alloy and its isothermal oxidation | [269] | ||

| 2020 | Cold Gas Spraying of a High-Entropy CrFeNiMn Equiatomic Alloy | [207] | |

| Nanostructured AlNiCoFeCrTi high-entropy coating performed by cold spray | [270] | ||

| 2021 | Cold Spray Additive Manufacturing: Microstructure Evolution and Bonding Features | [271] | |

| Cold spray deposition characteristic and bonding of CrMnCoFeNi high entropy alloy | [272] | ||

| Microstructure and properties of CuFeCrAlNiTi high entropy alloy coating prepared by cold spray assisted in-situ synthesis | |||

| Nanostructural AlNiCoFeCrTi High-Entropy Coatings Performed by Cold Spraying | [270] | ||

| Solid-state cold spraying of FeCoCrNiMn high-entropy alloy: an insight into microstructure evolution and oxidation behavior at 700–900 °C | [273] | ||

| Synthesis of High-Entropy AlNiCoFeCrTi Coating by Cold Spraying | [274] | ||

| Tuning the Microstructure and Mechanical Properties of Cold Sprayed Equiatomic CoCrFeMnNi High-Entropy Alloy Coating Layer | [275] | ||

| 2022 | An inclusive numerical framework to assess the role of feedstock features on the quality of cold spray deposits | [276] | |

| Cold Spray Additive Manufacturing of CoCrFeNiMn High-Entropy Alloy: Process Development, Microstructure, and Mechanical Properties | [206] | ||

| Cold Spray and Laser-Assisted Cold Spray of CrMnCoFeNi High Entropy Alloy Using Nitrogen as the Propelling Gas | [277] | ||

| Cold Spray: Over 30 Years of Development Toward a Hot Future | [9] | ||

| Deposition of High-Entropy Alloy Coating by Cold Spray Combined with Laser Melting: Feasibility Tests | [278] | ||

| Effect of Microstructure on Wear and Corrosion Performance of Thermally Sprayed AlCoCrFeMo High-Entropy Alloy Coatings | [202] | ||

| Fatigue Bending of V-Notched Cold-Sprayed FeCoCrNiMn Coatings | [201] | ||

| Friction Stir Processing of Cold-Sprayed High-Entropy Alloy Particles Reinforced Aluminum Matrix Composites: Corrosion and Wear Properties | [279] | ||

| Scopus | Mechanical and microstructural properties of a CoCrFe0.75NiMo0.3Nb0.125 high-entropy alloy additively manufactured via cold-spray | [169] | |

| Web of Science | Microstructural, Mechanical and Wear Behavior of HVOF and Cold-Sprayed High-Entropy Alloys (HEAs) Coatings | [280] | |

| Microstructure and Mechanical Properties of the Plasma-Sprayed and Cold-Sprayed Al0.5CoCrFeNi2Ti0.5 High-Entropy Alloy Coatings | [197] | ||

| Microstructure and Properties of Cold Spraying AlCoCrCuFeNix HEA Coatings Synthesized by Induction Remelting | [281] | ||

| Web of Science | Microstructure and tribological properties of Al2O3 reinforced FeCoNiCrMn high entropy alloy composite coatings by cold spray | [282] | |

| Scopus | Microstructure evolution and composition redistribution of FeCoNiCrMn high entropy alloy under extreme plastic deformation | [283] | |

| Web of Science | Microstructures, wear resistance and corrosion resistance of CoCrFeNi high entropy alloys coating on AZ91 Mg alloy prepared by cold spray | [284] | |

| Modification of cold-sprayed high-entropy alloy particles reinforced aluminum matrix composites via friction stir processing | [170] | ||

| Scopus | Numerical and Experimental Analysis of the Deformation Behavior of CoCrFeNiMn High Entropy Alloy Particles onto Various Substrates During Cold Spraying | [285] | |

| Web of Science | Numerical Simulation of Cold Spray Bonding for CrFeNi Medium-Entropy Alloy | [286] | |

| Structure Evolution and Corrosion Performance of CoCrFeMnNi High Entropy Alloy Coatings Produced Via Plasma Spray and Cold Spray | [287] | ||

| 2023 | Cyclic behavior of FeCoCrNiMn high entropy alloy coatings produced through cold spray | [18] | |

| Scopus | Sliding wear behavior of high entropy alloy coatings deposited through cold spraying and flame spraying: A comparative assessment | [288] |

6.2.3. Microstructural Characterization of Cold Sprayed CCAs

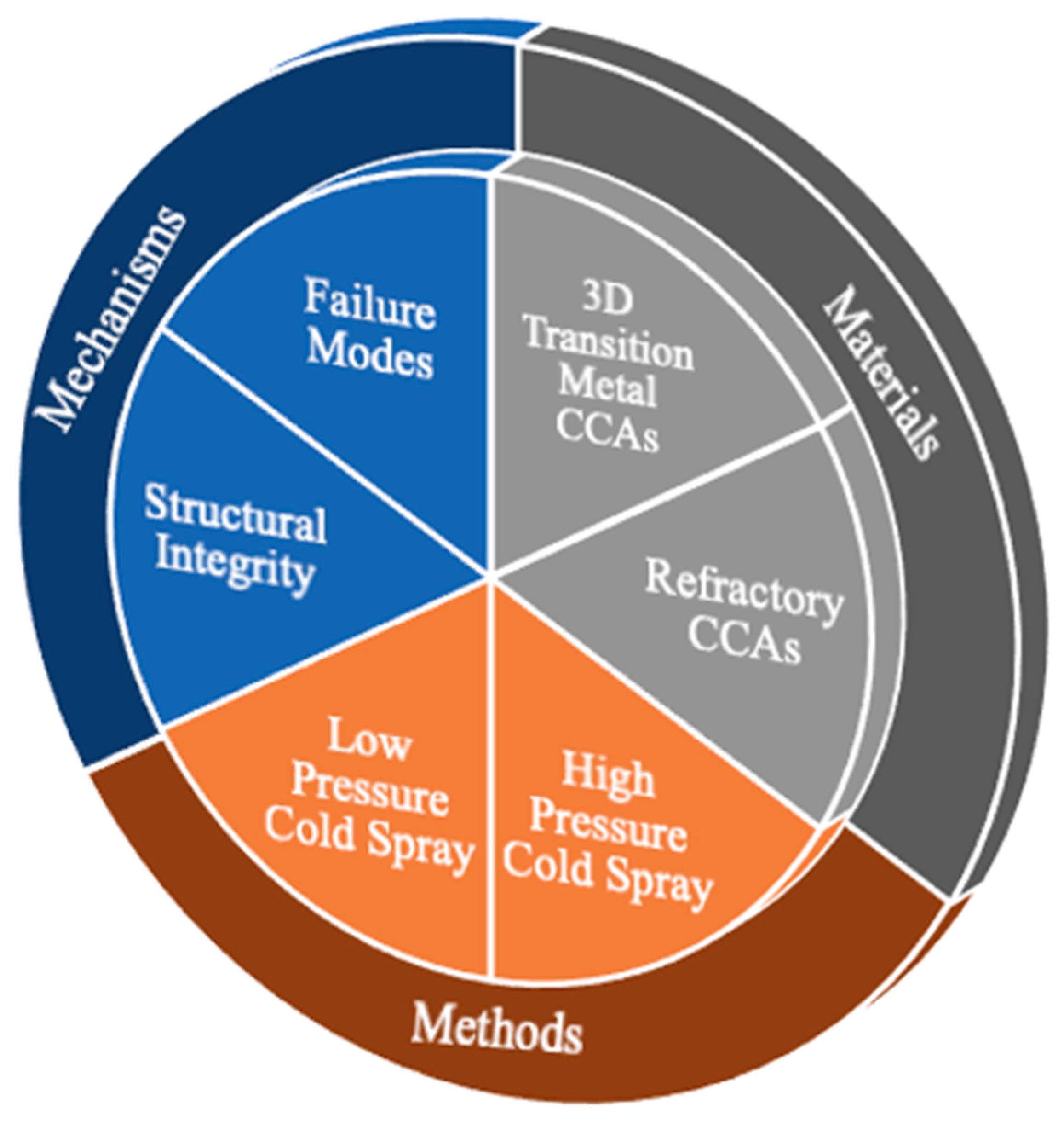

7. Areas for Future Research Direction and Implications

7.1. Materials

7.2. Methods

7.3. Mechanisms

8. Summary and Concluding Remarks

- Cold spray involves feedstock produced from CCAs with relatively low particle size distribution. This is true for CCAs with single, metastable, and multiple phases, a critical parameter which enhances the overall mechanical properties at the coating–substrate interface.

- There is a correlation between processing parameters (e.g., critical velocity, spray angle, stand-off distance, gas pressure, and temperature), bonding mechanism, deposition efficiency, adhesion, and cohesion strength of the coating.

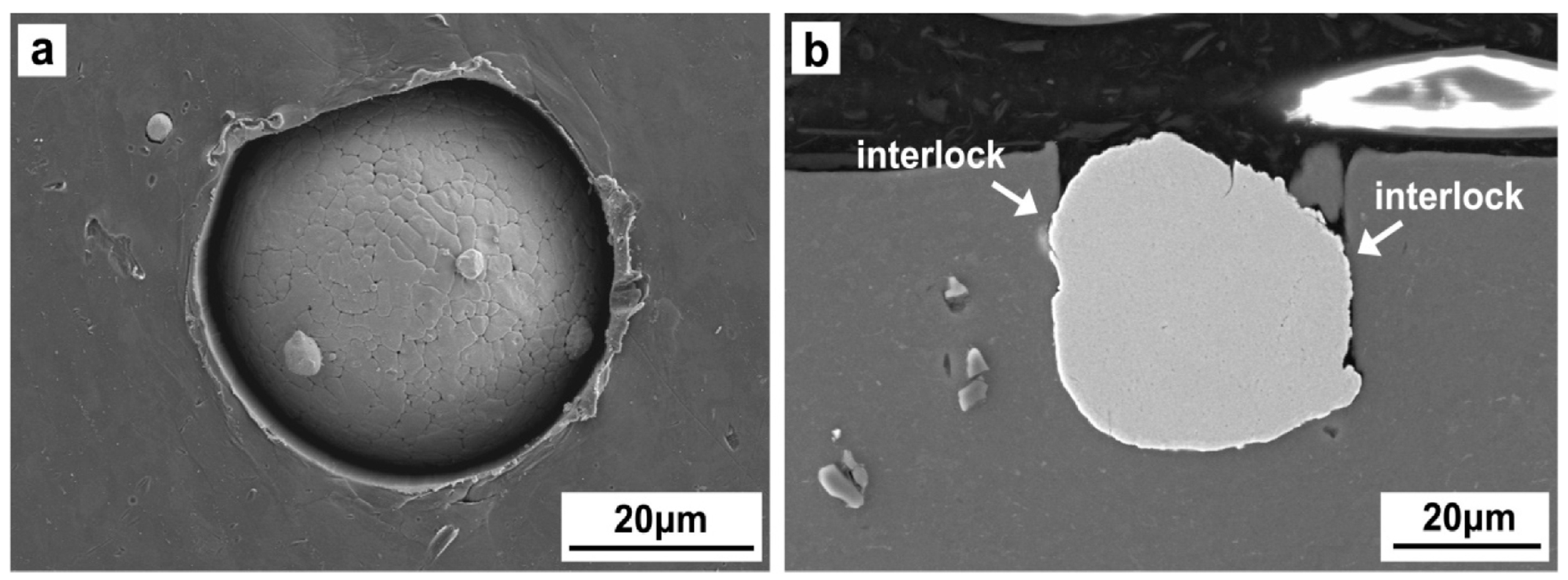

- Although the bonding mechanism has been a bone of contention regarding the particle–substrate and particle–particle interaction, metallurgical bonding is the main mechanism. For the CCA-based feedstock on ductile substrate, mechanical interlocking was observed.

- The computational and numerical simulations employed for cold spray processes are reviewed. The challenges associated with the mesh-based and mesh-free finite element methods are highlighted. Although the Johnson–Cook plasticity model is widely used, its inefficiency at relatively high strains was highlighted. Modifications to the JC model as well as others were discussed considering current research applications. Emphasis was on PTW, VA, and ZA models and how they have been applied to dilute alloy designs.

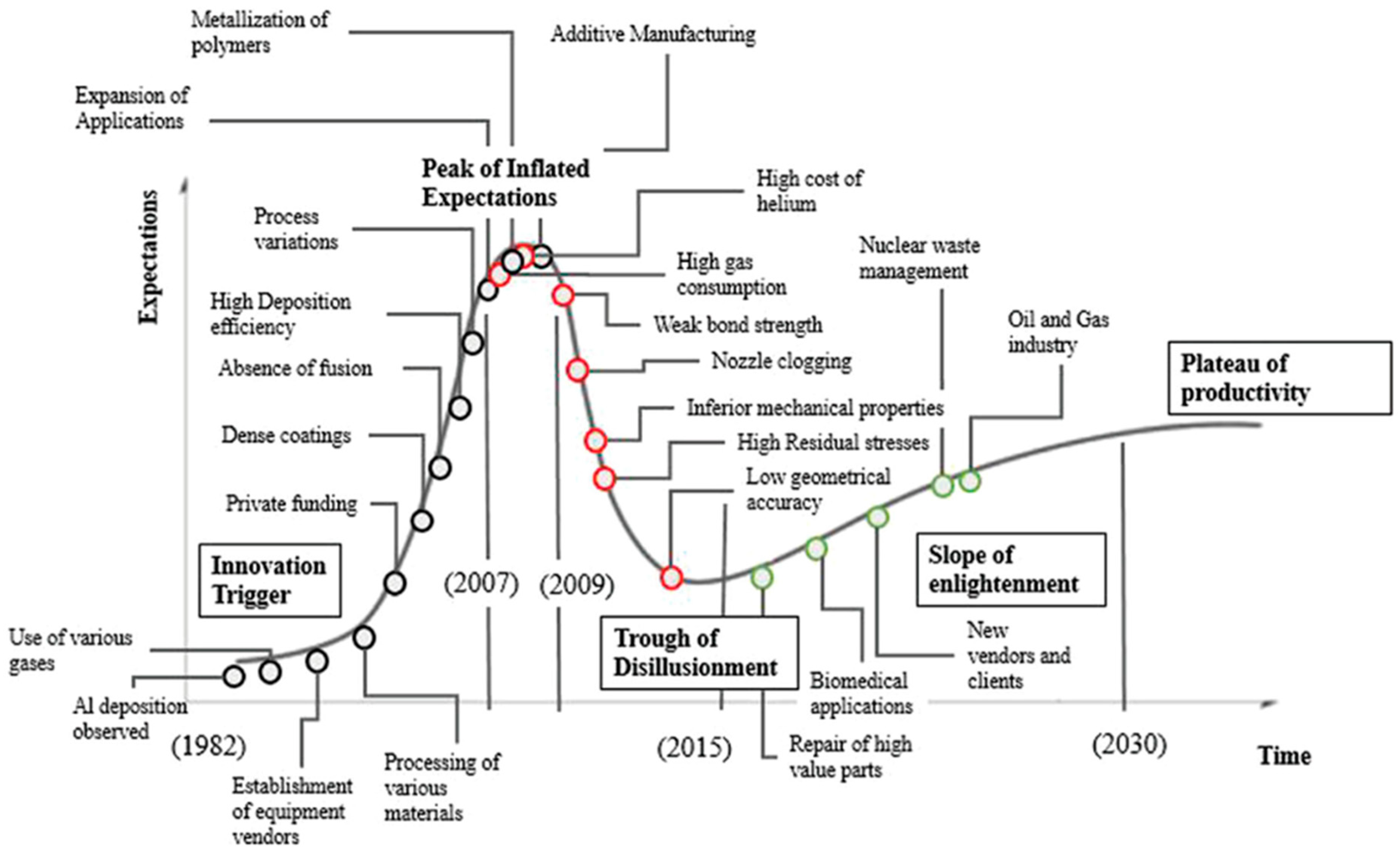

- The fundamental concepts of bulk and coating based on complex concentrated alloys are highlighted. The influence of the core effects of the CCAs and their contributing factors to enhancing the mechanical and microstructural characterization are discussed. The mechanical, chemical, and physical properties are comparable to those of the conventional bulk and coating materials. According to the technology and innovation maturation timeline of CCA-based coatings, the estimated plateau of productivity is expected by 2030.

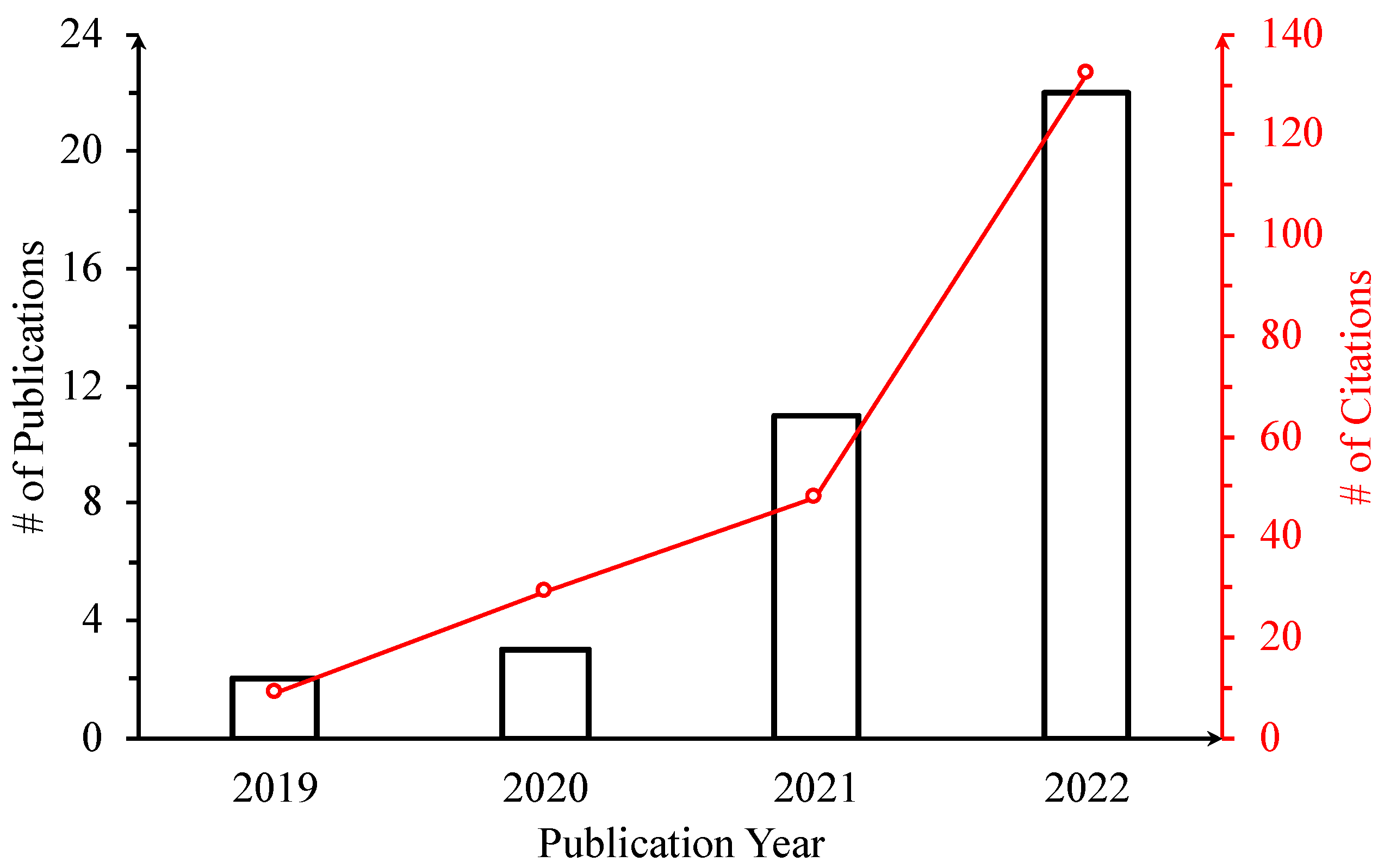

- Trend analyses of the CCA-based cold spray coatings on various metallic substrates showed less than 40 publications between 2019 and 2023. The major themes in these publications focused on alloy systems for efficient deposition and tuning of microstructural features to induce desirable mechanical properties. Some have looked at wear resistance, post-processing treatments coupled with other manufacturing routes such as friction stir welding, and other forms of additive manufacturing. The main elements which are constantly being explored for cold spray and other thermal spray coatings are C, Cr, Co, Mn, Fe, Ni, Mo, Nb, Si, and Ti. These elements are the base for Cantor alloys and derivatives, and refractory CCAs.

- The strengthening and hardening mechanisms of the CCA-based cold spray coatings are due to work hardening, grain refinement, and dispersion strengthening. This is because of the severe plastic deformation associated with the high-impact velocity resulting from the bombardment of the feedstock particles onto the substrate. These mechanisms are different from the precipitation hardening, solid solution strengthening, dislocation strengthening, and oxide formation associated with other forms of thermal spray coating techniques. The deformation mechanisms, which are dependent on the energy density, result in localized adiabatic shear as a function of properties of the particles and the process parameters.

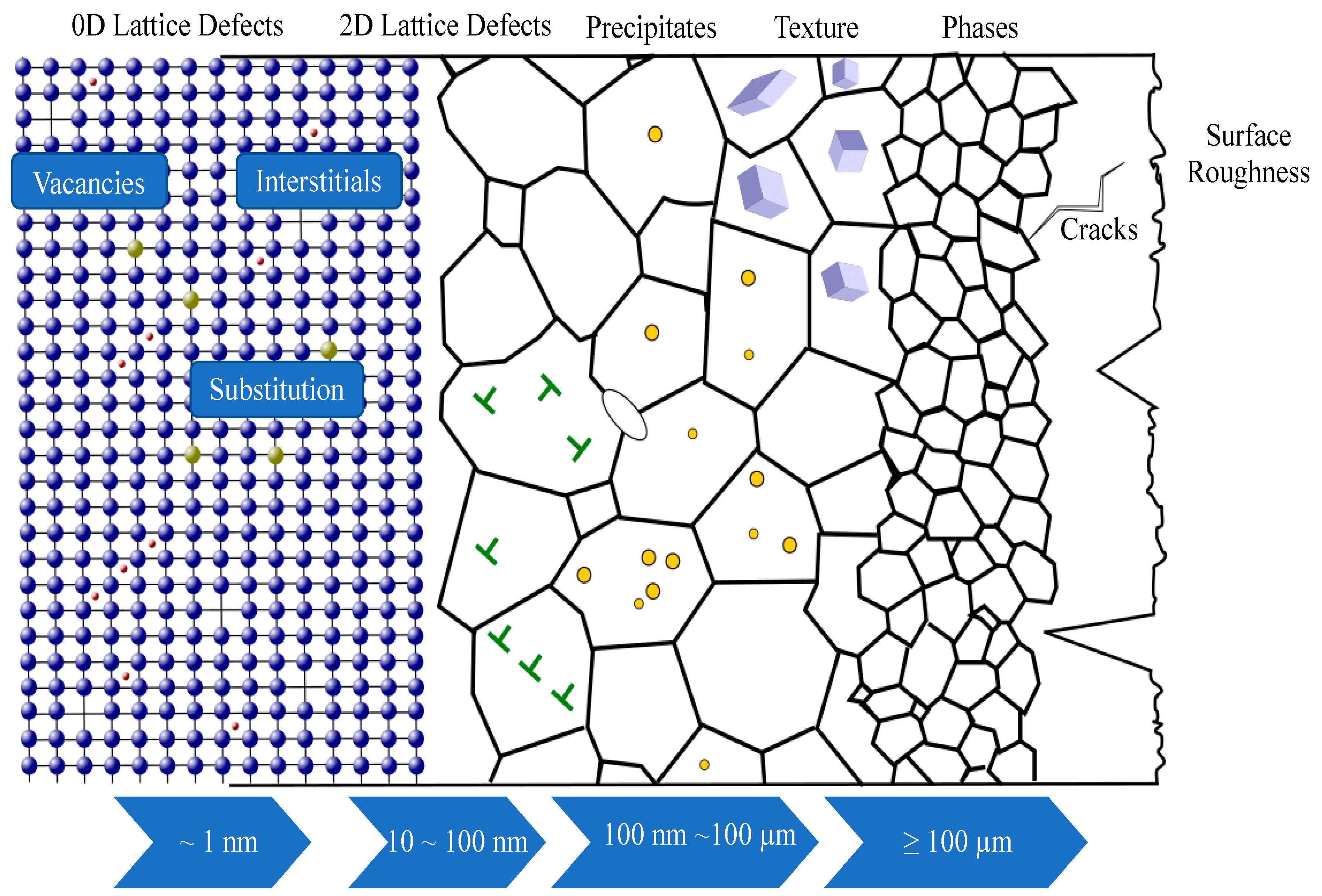

- Microstructural defects across different length scales associated with cold spray mechanisms are highlighted. These defects include intergranular cracks, voids, porosities, delamination, transverse cracks, pull-outs, and metallic inclusions. The effects of these defects on structural and functional properties have been discussed.

- The need for rational alloy and coating design approaches is highlighted. The application of computational, numerical, simulation, and experimental approaches for the design of next generation CCA and BMG coatings is required. By using simulations, the processing parameters can be optimized to ensure the designed and desired mechanical properties, while inducing the required microstructural features.

- This overview provides the theoretical framework for new frontiers in developing and accelerating the next generation of CCA-based cold spray coatings. Furthermore, it highlights challenges and open-ended questions that require future research efforts focusing on materials systems (3D transition and refractory metals), cold spray methods (low- and high-pressure cold spray approaches), and mechanisms underlying structural integrity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Klenam, D.; Rahbar, N.; Soboyejo, W. Mechanical Properties of Complex Concentrated Alloys: Implications for Structural Integrity. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar] [CrossRef]

- Klenam, D.; Rahbar, N.; Soboyejo, W. Critical Review of Limitations of Equiatomic Composition Alloying Strategy of Complex Concentrated Alloys. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar] [CrossRef]

- Vandadi, M.; Klenam, D.; Rahbar, N.; Soboyejo, W. Advances in the Structural Integrity of Cold Sprayed Alloys—A Critical Review of Process Models and Mechanical Properties. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar] [CrossRef]

- Cantor, B. Multicomponent high-entropy Cantor alloys. Prog. Mater. Sci. 2021, 120, 100754. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Yin, S.; Cavaliere, P.; Aldwell, B.; Jenkins, R.; Liao, H.; Li, W.; Lupoi, R. Cold spray additive manufacturing and repair: Fundamentals and applications. Addit. Manuf. 2018, 21, 628–650. [Google Scholar] [CrossRef]

- Luo, X.-T.; Li, C.-X.; Shang, F.-L.; Yang, G.-J.; Wang, Y.-Y.; Li, C.-J. High velocity impact induced microstructure evolution during deposition of cold spray coatings: A review. Surf. Coat. Technol. 2014, 254, 11–20. [Google Scholar] [CrossRef]

- Cavaliere, P.; Silvello, A. Crack Repair in Aerospace Aluminum Alloy Panels by Cold Spray. J. Therm. Spray Technol. 2017, 26, 661–670. [Google Scholar] [CrossRef]

- Guo, D.; Kazasidis, M.; Hawkins, A.; Fan, N.; Leclerc, Z.; MacDonald, D.; Nastic, A.; Nikbakht, R.; Ortiz-Fernandez, R.; Rahmati, S.; et al. Cold Spray: Over 30 Years of Development Toward a Hot Future. J. Therm. Spray Technol. 2022, 31, 866–907. [Google Scholar] [CrossRef]

- Vaz, R.F.; Garfias, A.; Albaladejo, V.; Sanchez, J.; Cano, I.G. A Review of Advances in Cold Spray Additive Manufacturing. Coatings 2023, 13, 267. [Google Scholar] [CrossRef]

- Kumar, A.; Goyal, D.K.; Kant, R.; Singh, H. Enhancing Corrosion Performance of Cold-Sprayed Titanium/Baghdadite (Ti/BAG) Bio-Composite Coatings via Laser Treatment. Coatings 2022, 12, 1010. [Google Scholar] [CrossRef]

- Dzhurinskiy, D.; Babu, A.; Dautov, S.; Lama, A.; Mangrulkar, M. Modification of Cold-Sprayed Cu-Al-Ni-Al2O3 Composite Coatings by Friction Stir Technique to Enhance Wear Resistance Performance. Coatings 2022, 12, 1113. [Google Scholar] [CrossRef]

- Chen, X.; Li, C.; Gao, Q.; Duan, X.; Liu, H. Comparison of Microstructure, Microhardness, Fracture Toughness, and Abrasive Wear of WC-17Co Coatings Formed in Various Spraying Ways. Coatings 2022, 12, 814. [Google Scholar] [CrossRef]

- Cinca, N.; Lavigne, O.; Peres, R.N.; Conze, S.; Hoehn, S.; Dosta, S.; Koivuluoto, H.; Kim, C.; da Silva, F.S.; Matikainen, V.; et al. Electrochemical Corrosion Characterization of Submicron WC-12Co Coatings Produced by CGS and HVAF Compared with Sintered Bulks. Coatings 2022, 12, 620. [Google Scholar] [CrossRef]

- Manap, A.; Afandi, N.; Mahalingam, S.; Yusof, S.N.A.; Rosli, Z.M. Mechanical and Tribological Study on Aluminum Coatings with High-Pressure and Low-Pressure Cold-Spray Processes. Coatings 2022, 12, 1792. [Google Scholar] [CrossRef]

- Maev, R.G.; Tjong, J.; Leshchinsky, E.; Pantea, M.; Leshchynsky, V. Cold-Sprayed Multilayer Thermal Barrier–Catalytic Coatings for Engine Pistons: Coatings Design and Properties. Coatings 2022, 12, 1332. [Google Scholar] [CrossRef]

- Adaan-Nyiak, M.A.; Tiamiyu, A.A. Recent advances on bonding mechanism in cold spray process: A review of single-particle impact methods. J. Mater. Res. 2022, 38, 69–95. [Google Scholar] [CrossRef] [PubMed]

- Cavaliere, P.; Perrone, A.; Silvello, A.; Laska, A.; Blasi, G.; Cano, I.; Sadeghi, B.; Nagy, S. Cyclic behavior of FeCoCrNiMn high entropy alloy coatings produced through cold spray. J. Alloys Compd. 2023, 931, 167550. [Google Scholar] [CrossRef]

- Champagne, V.; Helfritch, D. Critical Assessment 11: Structural repairs by cold spray. Mater. Sci. Technol. 2015, 31, 627–634. [Google Scholar] [CrossRef]

- Klenam, D.; Rahbar, N.; Soboyejo, W. Critical Review of Factors Hindering Scalability of Complex Concentrated Alloys. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar] [CrossRef]

- Lu, K.; Zhu, J.; Guo, D.; Yang, M.; Sun, H.; Wang, Z.; Hui, X.; Wu, Y. Microstructures, Corrosion Resistance and Wear Resistance of High-Entropy Alloys Coatings with Various Compositions Prepared by Laser Cladding: A Review. Coatings 2022, 12, 1023. [Google Scholar] [CrossRef]

- Li, J.; Huang, Y.; Meng, X.; Xie, Y. A Review on High Entropy Alloys Coatings: Fabrication Processes and Property Assessment. Adv. Eng. Mater. 2019, 21, 1900343. [Google Scholar] [CrossRef]

- Bagherifard, S.; Guagliano, M. Fatigue performance of cold spray deposits: Coating, repair and additive manufacturing cases. Int. J. Fatigue 2020, 139, 105744. [Google Scholar] [CrossRef]

- Raoelison, R.N.; Verdy, C.; Liao, H. Cold gas dynamic spray additive manufacturing today: Deposit possibilities, technological solutions and viable applications. Mater. Des. 2017, 133, 266–287. [Google Scholar] [CrossRef]

- Blose, R.; Walker, B.; Walker, R.; Froes, S. New opportunities to use cold spray process for applying additive features to titanium alloys. Met. Powder Rep. 2006, 61, 30–37. [Google Scholar] [CrossRef]

- Srikanth, A.; Basha, G.M.T.; Venkateshwarlu, B. A Brief Review on Cold Spray Coating Process. Mater. Today Proc. 2020, 22, 1390–1397. [Google Scholar] [CrossRef]

- Assadi, H.; Gärtner, F.; Stoltenhoff, T.; Kreye, H. Bonding mechanism in cold gas spraying. Acta Mater. 2003, 51, 4379–4394. [Google Scholar] [CrossRef]

- Meghwal, A.; Anupam, A.; Murty, B.S.; Berndt, C.C.; Kottada, R.S.; Ang, A.S.M. Thermal spray high-entropy alloy coatings: A review. J. Therm. Spray Technol. 2020, 29, 857–893. [Google Scholar] [CrossRef]

- Ang, A.S.; Berndt, C. A review of testing methods for thermal spray coatings. Int. Mater. Rev. 2014, 59, 179–223. [Google Scholar] [CrossRef]

- Ahmed, R.; Yu, H.; Stoica, V.; Edwards, L.; Santisteban, J. Neutron diffraction residual strain measurements in post-treated thermal spray cermet coatings. Mater. Sci. Eng. A 2008, 498, 191–202. [Google Scholar] [CrossRef]

- Suhonen, T.; Varis, T.; Dosta, S.; Torrell, M.; Guilemany, J.M. Residual stress development in cold sprayed Al, Cu and Ti coatings. Acta Mater. 2013, 61, 6329–6337. [Google Scholar] [CrossRef]

- Valarezo, A.; Sampath, S. An Integrated Assessment of Process-Microstructure-Property Relationships for Thermal-Sprayed NiCr Coatings. J. Therm. Spray Technol. 2011, 20, 1244–1258. [Google Scholar] [CrossRef]

- Yildirim, B.; Muftu, S.; Gouldstone, A. Modeling of high velocity impact of spherical particles. Wear 2011, 270, 703–713. [Google Scholar] [CrossRef]

- Shayegan, G.; Mahmoudi, H.; Ghelichi, R.; Villafuerte, J.; Wang, J.; Guagliano, M.; Jahed, H. Residual stress induced by cold spray coating of magnesium AZ31B extrusion. Mater. Des. 2014, 60, 72–84. [Google Scholar] [CrossRef]

- Li, W.; Yang, K.; Zhang, D.; Zhou, X. Residual Stress Analysis of Cold-Sprayed Copper Coatings by Numerical Simulation. J. Therm. Spray Technol. 2016, 25, 131–142. [Google Scholar] [CrossRef]

- Lin, E.; Chen, Q.; Ozdemir, O.C.; Champagne, V.K.; Müftü, S. Effects of Interface Bonding on the Residual Stresses in Cold-Sprayed Al-6061: A Numerical Investigation. J. Therm. Spray Technol. 2019, 28, 472–483. [Google Scholar] [CrossRef]

- Oviedo, F.; Valarezo, A. Residual Stress in High-Velocity Impact Coatings: Parametric Finite Element Analysis Approach. J. Therm. Spray Technol. 2020, 29, 1268–1288. [Google Scholar] [CrossRef]

- Fardan, A.; Berndt, C.C.; Ahmed, R. Numerical modelling of particle impact and residual stresses in cold sprayed coatings: A review. Surf. Coat. Technol. 2021, 409, 126835. [Google Scholar] [CrossRef]

- Zhang, K.; Song, Y.; Cai, S.; Wang, Z.; Chen, W.; Xie, L. Multiscale Simulation of Shot-Peening-Assisted Low-Pressure Cold Spraying Based on Al-Zn-Al2O3 Coatings. Coatings 2022, 12, 1490. [Google Scholar] [CrossRef]

- Wang, S.; Li, Y.; Yao, M.; Wang, R. Compressive residual stress introduced by shot peening. J. Mater. Process. Technol. 1998, 73, 64–73. [Google Scholar] [CrossRef]

- Wei, Y.-K.; Luo, X.-T.; Li, C.-X.; Li, C.-J. Optimization of In-Situ Shot-Peening-Assisted Cold Spraying Parameters for Full Corrosion Protection of Mg Alloy by Fully Dense Al-Based Alloy Coating. J. Therm. Spray Technol. 2017, 26, 173–183. [Google Scholar] [CrossRef]

- Kobayashi, M.; Matsui, T.; Murakami, Y. Mechanism of creation of compressive residual stress by shot peening. Int. J. Fatigue 1998, 20, 351–357. [Google Scholar] [CrossRef]

- Hammersley, G.; Hackel, L.A.; Harris, F. Surface prestressing to improve fatigue strength of components by laser shot peening. Opt. Lasers Eng. 2000, 34, 327–337. [Google Scholar] [CrossRef]

- Torres, M.A.S.; Voorwald, H.J.C. An evaluation of shot peening, residual stress and stress relaxation on the fatigue life of AISI 4340 steel. Int. J. Fatigue 2002, 24, 877–886. [Google Scholar] [CrossRef]

- Kendall, O.; Paradowska, A.; Abrahams, R.; Reid, M.; Qiu, C.; Mutton, P.; Yan, W. Residual Stress Measurement Techniques for Metal Joints, Metallic Coatings and Components in the Railway Industry: A Review. Materials 2023, 16, 232. [Google Scholar] [CrossRef] [PubMed]

- Song, X.; Everaerts, J.; Zhai, W.; Zheng, H.; Tan, A.W.Y.; Sun, W.; Li, F.; Marinescu, I.; Liu, E.; Korsunsky, A.M. Residual stresses in single particle splat of metal cold spray process—Numerical simulation and direct measurement. Mater. Lett. 2018, 230, 152–156. [Google Scholar] [CrossRef]

- Li, W.; Cao, C.; Yin, S. Solid-state cold spraying of Ti and its alloys: A literature review. Prog. Mater. Sci. 2020, 110, 100633. [Google Scholar] [CrossRef]

- Schmidt, T.; Gärtner, F.; Assadi, H.; Kreye, H. Development of a generalized parameter window for cold spray deposition. Acta Mater. 2006, 54, 729–742. [Google Scholar] [CrossRef]

- Schmidt, T.; Assadi, H.; Gärtner, F.; Richter, H.; Stoltenhoff, T.; Kreye, H.; Klassen, T. From Particle Acceleration to Impact and Bonding in Cold Spraying. J. Therm. Spray Technol. 2009, 18, 794–808. [Google Scholar] [CrossRef]

- Klinkov, S.V.; Kosarev, V.F.; Rein, M. Cold spray deposition: Significance of particle impact phenomena. Aerosp. Sci. Technol. 2005, 9, 582–591. [Google Scholar] [CrossRef]

- Champagne, V.; Nardi, A.; Cote, D. Materials characterization of advanced cold-spray aluminum alloys. Int. J. Powder Metall. 2015, 51, 37–47. [Google Scholar]

- Walker, M. Microstructure and bonding mechanisms in cold spray coatings. Mater. Sci. Technol. 2018, 34, 2057–2077. [Google Scholar] [CrossRef]

- Viscusi, A.; Astarita, A.; Della Gatta, R.; Rubino, F. A perspective review on the bonding mechanisms in cold gas dynamic spray. Surf. Eng. 2019, 35, 743–771. [Google Scholar] [CrossRef]

- Champagne, V.; Helfritch, D. The unique abilities of cold spray deposition. Int. Mater. Rev. 2016, 61, 437–455. [Google Scholar] [CrossRef]

- Hussain, T.; McCartney, D.G.; Shipway, P.H.; Zhang, D. Bonding Mechanisms in Cold Spraying: The Contributions of Metallurgical and Mechanical Components. J. Therm. Spray Technol. 2009, 18, 364–379. [Google Scholar] [CrossRef]

- Grujicic, M.; Saylor, J.; Beasley, D.; DeRosset, W.; Helfritch, D. Computational analysis of the interfacial bonding between feed-powder particles and the substrate in the cold-gas dynamic-spray process. Appl. Surf. Sci. 2003, 219, 211–227. [Google Scholar] [CrossRef]

- Li, W.-Y.; Gao, W. Some aspects on 3D numerical modeling of high velocity impact of particles in cold spraying by explicit finite element analysis. Appl. Surf. Sci. 2009, 255, 7878–7892. [Google Scholar] [CrossRef]

- Aleksieieva, O.; Dereviankina, L.; Breuninger, P.; Bozoglu, M.; Tretiakov, P.; Toporov, A.; Antonyuk, S. Simulation of Particle Interaction with Surface Microdefects during Cold Gas-Dynamic Spraying. Coatings 2022, 12, 1297. [Google Scholar] [CrossRef]

- Nélias, D.; Xie, J.; Walter-Le Berre, H.; Ichikawa, Y.; Ogawa, K. Simulation of the Cold Spray Deposition Process for Aluminum and Copper using Lagrangian, ALE and CEL Methods. In Thermomechanical Industrial Processes: Modeling and Numerical Simulation; Bergheau, J.-M., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2014; pp. 321–358. [Google Scholar]

- Xie, J.; Nelias, D.; Berre, H.W.-L.; Ogawa, K.; Ichikawa, Y. Simulation of the Cold Spray Particle Deposition Process. J. Tribol. 2015, 137, 041101. [Google Scholar] [CrossRef]

- Li, W.-Y.; Liao, H.; Li, C.-J.; Li, G.; Coddet, C.; Wang, X. On high velocity impact of micro-sized metallic particles in cold spraying. Appl. Surf. Sci. 2006, 253, 2852–2862. [Google Scholar] [CrossRef]

- Li, W.-Y.; Zhang, C.; Li, C.-J.; Liao, H. Modeling Aspects of High Velocity Impact of Particles in Cold Spraying by Explicit Finite Element Analysis. J. Therm. Spray Technol. 2009, 18, 921–933. [Google Scholar] [CrossRef]

- Panfilov, P.; Gornostyrev, Y.N.; Kuznetsov, A.R. Breakdown of relationship between chemical bonding and deformation behavior of crystalline materials. TMS Annu. Meet. 2010, 2, 13–24. [Google Scholar]

- Li, W.Y.; Yang, K.; Yin, S.; Guo, X.P. Numerical Analysis of Cold Spray Particles Impacting Behavior by the Eulerian Method: A Review. J. Therm. Spray Technol. 2016, 25, 1441–1460. [Google Scholar] [CrossRef]

- Hemeda, A.; Zhang, C.; Hu, X.; Fukuda, D.; Cote, D.; Nault, I.; Nardi, A.; Champagne, V.; Ma, Y.; Palko, J. Particle-based simulation of cold spray: Influence of oxide layer on impact process. Addit. Manuf. 2021, 37, 101517. [Google Scholar] [CrossRef]

- Liu, M.B.; Liu, G.R. Smoothed Particle Hydrodynamics (SPH): An Overview and Recent Developments. Arch. Comput. Methods Eng. 2010, 17, 25–76. [Google Scholar] [CrossRef]

- Hoover, W.; Hoover, C.; Kum, O.; Castillo, V. Smooth particle applied mechanics. Comput. Methods Sci. Technol. 1996, 2, 65–72. [Google Scholar] [CrossRef]

- Liu, G.R.; Liu, M.B. Smoothed Particle Hydrodynamics—A Meshfree Particle Method; World Scientific Publishing Company: Singapore, 2003. [Google Scholar]

- Shadloo, M.; Oger, G.; Le Touzé, D. Smoothed particle hydrodynamics method for fluid flows, towards industrial applications: Motivations, current state, and challenges. Comput. Fluids 2016, 136, 11–34. [Google Scholar] [CrossRef]

- Lemiale, V.; King, P.; Rudman, M.; Prakash, M.; Cleary, P.; Jahedi, M.; Gulizia, S. Temperature and strain rate effects in cold spray investigated by smoothed particle hydrodynamics. Surf. Coat. Technol. 2014, 254, 121–130. [Google Scholar] [CrossRef]

- Gnanasekaran, B.; Liu, G.-R.; Fu, Y.; Wang, G.; Niu, W.; Lin, T. A Smoothed Particle Hydrodynamics (SPH) procedure for simulating cold spray process—A study using particles. Surf. Coat. Technol. 2019, 377, 124812. [Google Scholar] [CrossRef]

- Li, W.-Y.; Yin, S.; Wang, X.-F. Numerical investigations of the effect of oblique impact on particle deformation in cold spraying by the SPH method. Appl. Surf. Sci. 2010, 256, 3725–3734. [Google Scholar] [CrossRef]

- Yin, S.; Wang, X.-F.; Xu, B.-P.; Li, W.-Y. Examination on the Calculation Method for Modeling the Multi-Particle Impact Process in Cold Spraying. J. Therm. Spray Technol. 2010, 19, 1032–1041. [Google Scholar] [CrossRef]

- King, P.C.; Bae, G.; Zahiri, S.H.; Jahedi, M.; Lee, C. An Experimental and Finite Element Study of Cold Spray Copper Impact onto Two Aluminum Substrates. J. Therm. Spray Technol. 2010, 19, 620–634. [Google Scholar] [CrossRef]

- Yin, S.; Wang, X.-F.; Li, W.-Y.; Xu, B.-P. Numerical Investigation on Effects of Interactions Between Particles on Coating Formation in Cold Spraying. J. Therm. Spray Technol. 2009, 18, 686–693. [Google Scholar] [CrossRef]

- Bolelli, G.; Dosta, S.; Lusvarghi, L.; Manfredini, T.; Guilemany, J.; Cano, I. Building up WC-Co coatings by cold spray: A finite element simulation. Surf. Coat. Technol. 2019, 374, 674–689. [Google Scholar] [CrossRef]

- Song, X.; Ng, K.L.; Chea, J.M.-K.; Sun, W.; Tan, A.W.-Y.; Zhai, W.; Li, F.; Marinescu, I.; Liu, E. Coupled Eulerian-Lagrangian (CEL) simulation of multiple particle impact during Metal Cold Spray process for coating porosity prediction. Surf. Coat. Technol. 2020, 385, 125433. [Google Scholar] [CrossRef]

- Li, Y.; Wang, X.-F.; Yin, S.; Xu, S.-L. Influence of Particle Initial Temperature on High Velocity Impact Process in Cold Spraying. Procedia Environ. Sci. 2012, 12, 298–304. [Google Scholar] [CrossRef]

- Morris, J.P.; Fox, P.J.; Zhu, Y. Modeling Low Reynolds Number Incompressible Flows Using SPH. J. Comput. Phys. 1997, 136, 214–226. [Google Scholar] [CrossRef]

- Liu, M.; Liu, G.; Lam, K. Constructing smoothing functions in smoothed particle hydrodynamics with applications. J. Comput. Appl. Math. 2003, 155, 263–284. [Google Scholar] [CrossRef]

- Lucy, L.B. A numerical approach to the testing of the fission hypothesis. Astron. J. 1977, 82, 1013–1024. [Google Scholar] [CrossRef]

- Chun, D.-M.; Ahn, S.-H. Deposition mechanism of dry sprayed ceramic particles at room temperature using a nano-particle deposition system. Acta Mater. 2011, 59, 2693–2703. [Google Scholar] [CrossRef]

- Park, H.; Kwon, J.; Lee, I.; Lee, C. Shock-induced plasticity and fragmentation phenomena during alumina deposition in the vacuum kinetic spraying process. Scr. Mater. 2015, 100, 44–47. [Google Scholar] [CrossRef]

- Manap, A.; Nooririnah, O.; Misran, H.; Okabe, T.; Ogawa, K. Experimental and SPH study of cold spray impact between similar and dissimilar metals. Surf. Eng. 2014, 30, 335–341. [Google Scholar] [CrossRef]

- Vural, M.; Ravichandran, G.; Rittel, D. Large strain mechanical behavior of 1018 cold-rolled steel over a wide range of strain rates. Met. Mater. Trans. A 2003, 34, 2873–2885. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 1985, 21, 31–48. [Google Scholar] [CrossRef]

- Preston, D.L.; Tonks, D.L.; Wallace, D.C. Model of plastic deformation for extreme loading conditions. J. Appl. Phys. 2003, 93, 211–220. [Google Scholar] [CrossRef]

- Grujicic, M.; Zhao, C.; DeRosset, W.; Helfritch, D. Adiabatic shear instability based mechanism for particles/substrate bonding in the cold-gas dynamic-spray process. Mater. Des. 2004, 25, 681–688. [Google Scholar] [CrossRef]

- Rahmati, S.; Ghaei, A. The Use of Particle/Substrate Material Models in Simulation of Cold-Gas Dynamic-Spray Process. J. Therm. Spray Technol. 2014, 23, 530–540. [Google Scholar] [CrossRef]

- Bae, G.; Xiong, Y.; Kumar, S.; Kang, K.; Lee, C. General aspects of interface bonding in kinetic sprayed coatings. Acta Mater. 2008, 56, 4858–4868. [Google Scholar] [CrossRef]

- Guetta, D.; Berger, M.-H.; Borit, F.; Guipont, V.; Jeandin, M.; Boustie, M.; Ichikawa, Y.; Sakaguchi, K.; Ogawa, K. Influence of Particle Velocity on Adhesion of Cold-Sprayed Splats. J. Therm. Spray Technol. 2009, 18, 331–342. [Google Scholar] [CrossRef]

- Hassani-Gangaraj, M.; Veysset, D.; Champagne, V.K.; Nelson, K.A.; Schuh, C.A. Adiabatic shear instability is not necessary for adhesion in cold spray. Acta Mater. 2018, 158, 430–439. [Google Scholar] [CrossRef]

- Ahmed, R.A.; Rahneshin, V.; Bond, T.; Vandadi, M.; Oghenevweta, J.E.; Navabi, A.; Oyewole, O.K.; Obayemi, J.D.; Rahbar, N.; Soboyejo, W.O. On the Role of Deformation and Cracking in the Cold Spray Processing of Refractory Ta Powders onto Ta or 4340 Steel Substrates: Effects of Topical Oxide Layers and Spray Velocity. Met. Mater. Trans. A 2022, 53, 3381–3391. [Google Scholar] [CrossRef]

- Navabi, A.; Vandadi, M.; Bond, T.; Rahneshin, V.; Obayemi, J.; Ahmed, R.; Oghenevweta, J.; Champagne, V.; Rahbar, N.; Soboyejo, W. Deformation and cracking phenomena in cold sprayed 6061 Al alloy powders with nanoscale aluminum oxide films. Mater. Sci. Eng. A 2022, 841, 143036. [Google Scholar] [CrossRef]

- Bansal, P.; Shipway, P.; Leen, S. A hybrid implicit—Explicit finite element methodology for coating formation in the high-velocity oxy-fuel spraying process. Proc. Inst. Mech. Eng. L J. Mater. Des. Appl. 2007, 221, 285–297. [Google Scholar] [CrossRef]

- Micunovic, M.; Albertini, C.; Montagnani, M. High Strain Rate Thermo-Inelasticity of Damaged AISI 316H. Int. J. Damage Mech. 2003, 12, 267–303. [Google Scholar] [CrossRef]

- Ghelichi, R.; Bagherifard, S.; Guagliano, M.; Verani, M. Numerical simulation of cold spray coating. Surf. Coat. Technol. 2011, 205, 5294–5301. [Google Scholar] [CrossRef]

- Zhang, D.-N.; Shangguan, Q.-Q.; Xie, C.-J.; Liu, F. A modified Johnson–Cook model of dynamic tensile behaviors for 7075-T6 aluminum alloy. J. Alloys Compd. 2015, 619, 186–194. [Google Scholar] [CrossRef]

- Lin, Y.; Chen, X.-M.; Liu, G. A modified Johnson–Cook model for tensile behaviors of typical high-strength alloy steel. Mater. Sci. Eng. A 2010, 527, 6980–6986. [Google Scholar] [CrossRef]

- Chakrabarty, R.; Song, J. A modified Johnson-Cook material model with strain gradient plasticity consideration for numerical simulation of cold spray process. Surf. Coat. Technol. 2020, 397, 125981. [Google Scholar] [CrossRef]

- Zhao, Y.; Sun, J.; Li, J.; Yan, Y.; Wang, P. A comparative study on Johnson-Cook and modified Johnson-Cook constitutive material model to predict the dynamic behavior laser additive manufacturing FeCr alloy. J. Alloys Compd. 2017, 723, 179–187. [Google Scholar] [CrossRef]

- Rahmati, S.; Jodoin, B. Physically Based Finite Element Modeling Method to Predict Metallic Bonding in Cold Spray. J. Therm. Spray Technol. 2020, 29, 611–629. [Google Scholar] [CrossRef]

- Su, J.; Kang, J.-J.; Yue, W.; Ma, G.-Z.; Fu, Z.-Q.; Zhu, L.-N.; She, D.-S.; Wang, H.-D.; Wang, C.-B. Review of cold spraying and its use for metallic glass coatings. Mater. Sci. Technol. 2019, 35, 1908–1923. [Google Scholar] [CrossRef]

- Jočbalis, G.; Kačianauskas, R.; Borodinas, S.; Rojek, J. Comparative numerical study of rate-dependent continuum-based plasticity models for high-velocity impacts of copper particles against a substrate. Int. J. Impact Eng. 2023, 172, 104394. [Google Scholar] [CrossRef]

- Henao, J.; Bolelli, G.; Concustell, A.; Lusvarghi, L.; Dosta, S.; Cano, I.; Guilemany, J. Deposition behavior of cold-sprayed metallic glass particles onto different substrates. Surf. Coat. Technol. 2018, 349, 13–23. [Google Scholar] [CrossRef]

- Grujicic, M.; Pandurangan, B.; Yen, C.-F.; Cheeseman, B.A. Modifications in the AA5083 Johnson-Cook Material Model for Use in Friction Stir Welding Computational Analyses. J. Mater. Eng. Perform. 2012, 21, 2207–2217. [Google Scholar] [CrossRef]

- Chen, Q.; Alizadeh, A.; Xie, W.; Wang, X.; Champagne, V.; Gouldstone, A.; Lee, J.-H.; Müftü, S. High-Strain-Rate Material Behavior and Adiabatic Material Instability in Impact of Micron-Scale Al-6061 Particles. J. Therm. Spray Technol. 2018, 27, 641–653. [Google Scholar] [CrossRef]

- Schreiber, J.; Smid, I.; Eden, T.; Koudela, K.; Cote, D.; Champagne, V. Cold spray particle impact simulation using the Preston-Tonks-Wallace plasticity model. Finite Elem. Anal. Des. 2021, 191, 103557. [Google Scholar] [CrossRef]

- Banerjee, B. An evaluation of plastic flow stress models for the simulation of high-temperature and high-strain-rate deformation of metals. arXiv 2005, arXiv:cond-mat/0512466. [Google Scholar]

- Fraser, K.; Kiss, L.I.; St-Georges, L.; Drolet, D. Optimization of Friction Stir Weld Joint Quality Using a Meshfree Fully-Coupled Thermo-Mechanics Approach. Metals 2018, 8, 101. [Google Scholar] [CrossRef]

- Weiller, S.; Delloro, F. A numerical study of pore formation mechanisms in aluminium cold spray coatings. Addit. Manuf. 2022, 60, 103193. [Google Scholar] [CrossRef]

- Henao, J.; Concustell, A.; Dosta, S.; Cinca, N.; Cano, I.G.; Guilemany, J.M. Influence of the Substrate on the Formation of Metallic Glass Coatings by Cold Gas Spraying. J. Therm. Spray Technol. 2016, 25, 992–1008. [Google Scholar] [CrossRef]

- Voyiadjis, G.Z.; Abed, F.H. Microstructural based models for bcc and fcc metals with temperature and strain rate dependency. Mech. Mater. 2005, 37, 355–378. [Google Scholar] [CrossRef]

- Abed, F.H.; Voyiadjis, G.Z. A consistent modified Zerilli-Armstrong flow stress model for BCC and FCC metals for elevated temperatures. Acta Mech. 2005, 175, 1–18. [Google Scholar] [CrossRef]

- Khan, A.S.; Liang, R. Behaviors of three BCC metal over a wide range of strain rates and temperatures: Experiments and modeling. Int. J. Plast. 1999, 15, 1089–1109. [Google Scholar] [CrossRef]

- Khan, A.S.; Liang, R. Behaviors of three BCC metals during non-proportional multi-axial loadings: Experiments and modeling. Int. J. Plast. 2000, 16, 1443–1458. [Google Scholar] [CrossRef]

- Gao, C.; Zhang, L. Constitutive modelling of plasticity of fcc metals under extremely high strain rates. Int. J. Plast. 2012, 32–33, 121–133. [Google Scholar] [CrossRef]

- Telford, M. The base for bulk metallic glass. Mater. Today 2003, 7, 36–43. [Google Scholar] [CrossRef]

- Suryanarayana, C.; Inoue, A. Iron-based bulk metallic glasses. Int. Mater. Rev. 2013, 58, 131–166. [Google Scholar] [CrossRef]

- Wang, Q.; Han, P.; Yin, S.; Niu, W.-J.; Zhai, L.; Li, X.; Mao, X.; Han, Y. Current Research Status on Cold Sprayed Amorphous Alloy Coatings: A Review. Coatings 2021, 11, 206. [Google Scholar] [CrossRef]

- Miracle, D.B. A structural model for metallic glasses. Nat. Mater. 2004, 3, 697–702. [Google Scholar] [CrossRef] [PubMed]

- Miracle, D.B. A Structural Model for Metallic Glasses. Microsc. Microanal. 2004, 10 (Suppl. 2), 786–787. [Google Scholar] [CrossRef]

- Inoue, A.; Takeuchi, A. Recent development and application products of bulk glassy alloys. Acta Mater. 2011, 59, 2243–2267. [Google Scholar] [CrossRef]

- Das, J.; Tang, M.B.; Kim, K.B.; Theissmann, R.; Baier, F.; Wang, W.H.; Eckert, J. “Work-Hardenable” Ductile Bulk Metallic Glass. Phys. Rev. Lett. 2005, 94, 205501. [Google Scholar] [CrossRef]

- Greer, J.R.; De Hosson, J.T. Plasticity in small-sized metallic systems: Intrinsic versus extrinsic size effect. Prog. Mater. Sci. 2011, 56, 654–724. [Google Scholar] [CrossRef]

- Greer, A.; Cheng, Y.; Ma, E. Shear bands in metallic glasses. Mater. Sci. Eng. R Rep. 2013, 74, 71–132. [Google Scholar] [CrossRef]

- Gao, M.; Lu, W.; Yang, B.; Zhang, S.; Wang, J. High corrosion and wear resistance of Al-based amorphous metallic coating synthesized by HVAF spraying. J. Alloys Compd. 2018, 735, 1363–1373. [Google Scholar] [CrossRef]

- Shen, Y.; Perepezko, J. Al-based amorphous alloys: Glass-forming ability, crystallization behavior and effects of minor alloying additions. J. Alloys Compd. 2017, 707, 3–11. [Google Scholar] [CrossRef]

- Goldman, M.E.; Ünlü, N.; Shiflet, G.J.; Scully, J.R. Selected Corrosion Properties of a Novel Amorphous Al-Co-Ce Alloy System. Electrochem. Solid-State Lett. 2005, 8, B1. [Google Scholar] [CrossRef]

- Wang, D.; Li, P. Thermodynamic and mechanical properties of Cu–Zr–Al–Ti bulk metallic glasses. AIP Adv. 2018, 8, 125003. [Google Scholar] [CrossRef]

- Wang, Y.; Li, M.; Sun, L.; Zhang, X.; Shen, J. Environmentally assisted fracture behavior of Fe-based amorphous coatings in chloride-containing solutions. J. Alloys Compd. 2018, 738, 37–48. [Google Scholar] [CrossRef]

- Lin, J.; Wang, Z.; Cheng, J.; Kang, M.; Fu, X.; Hong, S. Effect of Initial Surface Roughness on Cavitation Erosion Resistance of Arc-Sprayed Fe-Based Amorphous/Nanocrystalline Coatings. Coatings 2017, 7, 200. [Google Scholar] [CrossRef]

- Yasir, M.; Zhang, C.; Wang, W.; Xu, P.; Liu, L. Wear behaviors of Fe-based amorphous composite coatings reinforced by Al2O3 particles in air and in NaCl solution. Mater. Des. 2015, 88, 207–213. [Google Scholar] [CrossRef]

- Qiao, J.-H.; Jin, X.; Qin, J.-H.; Liu, H.-T.; Luo, Y.; Zhang, D.-K. A super-hard superhydrophobic Fe-based amorphous alloy coating. Surf. Coat. Technol. 2018, 334, 286–291. [Google Scholar] [CrossRef]

- Zhou, H.; Zhang, C.; Wang, W.; Yasir, M.; Liu, L. Microstructure and Mechanical Properties of Fe-based Amorphous Composite Coatings Reinforced by Stainless Steel Powders. J. Mater. Sci. Technol. 2015, 31, 43–47. [Google Scholar] [CrossRef]

- Bahrami, F.; Amini, R.; Taghvaei, A.H. Microstructure and corrosion behavior of electrodeposited Ni-based nanocomposite coatings reinforced with Ni 60 Cr 10 Ta 10 P 16 B 4 metallic glass particles. J. Alloys Compd. 2017, 714, 530–536. [Google Scholar] [CrossRef]

- Suresh, K.; Yugeswaran, S.; Rao, K.; Kobayashi, A.; Shum, P. Sliding wear behavior of gas tunnel type plasma sprayed Ni-based metallic glass composite coatings. Vacuum 2013, 88, 114–117. [Google Scholar] [CrossRef]

- Wang, B.; Xu, K.; Shi, X.; Zhang, M.; Qiao, J.; Gao, C.; Wu, Y. Electrochemical and chemical corrosion behaviors of the in-situ Zr-based metallic glass matrix composites in chloride-containing solutions. J. Alloys Compd. 2019, 770, 679–685. [Google Scholar] [CrossRef]

- Zhang, Y.; Yan, L.; Zhao, X.; Ma, L. Enhanced chloride ion corrosion resistance of Zr-based bulk metallic glasses with cobalt substitution. J. Non-Cryst. Solids 2018, 496, 18–23. [Google Scholar] [CrossRef]

- Astarita, A.; Coticelli, F.; Prisco, U. Repairing of an Engine Block Through the Cold Gas Dynamic Spray Technology. Mater. Res. 2016, 19, 1226–1231. [Google Scholar] [CrossRef]

- Concustell, A.; Henao, J.; Dosta, S.; Cinca, N.; Cano, I.; Guilemany, J. On the formation of metallic glass coatings by means of Cold Gas Spray technology. J. Alloys Compd. 2015, 651, 764–772. [Google Scholar] [CrossRef]

- Moridi, A.; Hassani-Gangaraj, S.M.; Guagliano, M.; Dao, M. Cold spray coating: Review of material systems and future perspectives. Surf. Eng. 2014, 30, 369–395. [Google Scholar] [CrossRef]

- Su, J.; Kang, J.-J.; Yue, W.; Ma, G.-Z.; Fu, Z.-Q.; Zhu, L.-N.; She, D.-S.; Wang, H.-D.; Wang, C.-B. Comparison of tribological behavior of Fe-based metallic glass coatings fabricated by cold spraying and high velocity air fuel spraying. J. Non-Cryst. Solids 2019, 522, 119582. [Google Scholar] [CrossRef]

- Henao, J.; Concustell, A.; Cano, I.G.; Dosta, S.; Cinca, N.; Guilemany, J.M.; Suhonen, T. Novel Al-based metallic glass coatings by Cold Gas Spray. Mater. Des. 2016, 94, 253–261. [Google Scholar] [CrossRef]

- Lahiri, D.; Gill, P.K.; Scudino, S.; Zhang, C.; Singh, V.; Karthikeyan, J.; Munroe, N.; Seal, S.; Agarwal, A. Cold sprayed aluminum based glassy coating: Synthesis, wear and corrosion properties. Surf. Coat. Technol. 2013, 232, 33–40. [Google Scholar] [CrossRef]

- List, A.; Gärtner, F.; Mori, T.; Schulze, M.; Assadi, H.; Kuroda, S.; Klassen, T. Cold Spraying of Amorphous Cu50Zr50 Alloys. J. Therm. Spray Technol. 2014, 24, 108–118. [Google Scholar] [CrossRef]

- Yoon, S.; Bae, G.; Xiong, Y.; Kumar, S.; Kang, K.; Kim, J.-J.; Lee, C. Strain-enhanced nanocrystallization of a CuNiTiZr bulk metallic glass coating by a kinetic spraying process. Acta Mater. 2009, 57, 6191–6199. [Google Scholar] [CrossRef]

- Ajdelsztajn, L.; Jodoin, B.; Richer, P.; Sansoucy, E.; Lavernia, E.J. Cold Gas Dynamic Spraying of Iron-Base Amorphous Alloy. J. Therm. Spray Technol. 2006, 15, 495–500. [Google Scholar] [CrossRef]

- Yoon, S.; Kim, J.; Bae, G.; Kim, B.; Lee, C. Formation of coating and tribological behavior of kinetic sprayed Fe-based bulk metallic glass. J. Alloys Compd. 2011, 509, 347–353. [Google Scholar] [CrossRef]

- List, A.; Gärtner, F.; Schmidt, T.; Klassen, T. Impact Conditions for Cold Spraying of Hard Metallic Glasses. J. Therm. Spray Technol. 2012, 21, 531–540. [Google Scholar] [CrossRef]

- Choi, H.; Yoon, S.; Kim, G.; Jo, H.; Lee, C. Phase evolutions of bulk amorphous NiTiZrSiSn feedstock during thermal and kinetic spraying processes. Scr. Mater. 2005, 53, 125–130. [Google Scholar] [CrossRef]

- Yoon, S.; Lee, C.; Choi, H.; Jo, H. Kinetic spraying deposition behavior of bulk amorphous NiTiZrSiSn feedstock. Mater. Sci. Eng. A 2006, 415, 45–52. [Google Scholar] [CrossRef]

- Kang, N.; Coddet, P.; Liao, H.; Coddet, C. The effect of heat treatment on microstructure and tensile properties of cold spray Zr base metal glass/Cu composite. Surf. Coat. Technol. 2015, 280, 64–71. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, Z.; Chang, X.; Hou, W.; Wang, J. Identifying the role of nanoscale heterogeneities in pitting behaviour of Al-based metallic glass. Corros. Sci. 2011, 53, 3007–3015. [Google Scholar] [CrossRef]

- Jeong, J.I.; Lee, S.H.; Jeon, J.-B.; Kim, S.J. Excessively High Vapor Pressure of Al-Based Amorphous Alloys. Metals 2015, 5, 1878–1886. [Google Scholar] [CrossRef]

- Sansoucy, E.; Kim, G.; Moran, A.; Jodoin, B. Mechanical Characteristics of Al-Co-Ce Coatings Produced by the Cold Spray Process. J. Therm. Spray Technol. 2007, 16, 651–660. [Google Scholar] [CrossRef]

- Xueqing, W.; Mo, M.; Chaogui, T.; Xiufeng, W.; Jianguo, L. Comparative Study on Thermodynamical and Electrochemical Behavior of Al88Ni6La6 and Al86Ni6La6Cu2 Amorphous Alloys. J. Rare Earths 2007, 25, 381–384. [Google Scholar] [CrossRef]

- Wang, X.; Wu, X.; Lin, J.; Ma, M. The influence of heat treatment on the corrosion behaviour of as-spun amorphous Al88Ni6La6 alloy in 0.01 M NaCl solution. Mater. Lett. 2007, 61, 1715–1717. [Google Scholar] [CrossRef]

- Wu, J.; Peng, Z. Effects of microadditions on glass transition and hardness of Cu-based bulk metallic glasses. Appl. Phys. A 2018, 124, 632. [Google Scholar] [CrossRef]

- Kim, J.; Kang, K.; Yoon, S.; Lee, C. Enhancement of metallic glass properties of Cu-based BMG coating by shroud plasma spraying. Surf. Coat. Technol. 2011, 205, 3020–3026. [Google Scholar] [CrossRef]

- Lee, K.-A.; Jung, D.J.; Park, D.Y.; Kang, W.G.; Lee, J.K.; Kim, H.J. Study on the fabrication and physical properties of cold-sprayed, Cu-based amorphous coating. J. Phys. Conf. Ser. 2009, 144, 012113. [Google Scholar] [CrossRef]

- Kim, K.-H.; Lee, S.-W.; Ahn, J.-P.; Fleury, E.; Kim, Y.-C.; Lee, J.-C. A Cu-based amorphous alloy with a simultaneous improvement in its glass forming ability and plasticity. Met. Mater. Int. 2007, 13, 21–24. [Google Scholar] [CrossRef]

- Aldhameer, A.; El-Eskandarany, M.S.; Kishk, M.; Alajmi, F.; Banyan, M. Mechanical Alloying Integrated with Cold Spray Coating for Fabrication Cu50(Ti50−xNix), x; 10, 20, 30, and 40 at.% Antibiofilm Metallic Glass Coated/SUS304 Sheets. Nanomaterials 2022, 12, 1681. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, C.; Zhang, Z.-W.; Li, Y.-C.; Yasir, M.; Wang, H.-T.; Liu, L. Toughening Fe-based Amorphous Coatings by Reinforcement of Amorphous Carbon. Sci. Rep. 2017, 7, 4084. [Google Scholar] [CrossRef]

- Tian, W.-P.; Yang, H.-W.; Zhang, S.-D. Synergistic Effect of Mo, W, Mn and Cr on the Passivation Behavior of a Fe-Based Amorphous Alloy Coating. Acta Met. Sin. (Engl. Lett.) 2018, 31, 308–320. [Google Scholar] [CrossRef]

- Jiao, J.; Luo, Q.; Wei, X.; Wang, Y.; Shen, J. Influence of sealing treatment on the corrosion resistance of Fe-based amorphous coatings in HCl solution. J. Alloys Compd. 2017, 714, 356–362. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, S.; Sun, W.; Gao, Y.; Wang, J. Enhanced corrosion resistance in Fe-based amorphous coatings through eliminating Cr-depleted zones. Corros. Sci. 2018, 136, 161–173. [Google Scholar] [CrossRef]

- Cinca, N.; Drehmann, R.; Dietrich, D.; Gaertner, F.; Klassen, T.; Lampke, T.; Guilemany, J.M. Mechanically induced grain refinement, recovery and recrystallization of cold-sprayed iron aluminide coatings. Surf. Coat. Technol. 2019, 380, 125069. [Google Scholar] [CrossRef]

- Rojas, D.F.; Li, H.; Orhan, O.K.; Shao, C.; Hogan, J.D.; Ponga, M. Mechanical and microstructural properties of a CoCrFe0.75NiMo0.3Nb0.125 high-entropy alloy additively manufactured via cold-spray. J. Alloys Compd. 2022, 893, 162309. [Google Scholar] [CrossRef]

- Han, P.; Wang, W.; Liu, Z.; Zhang, T.; Liu, Q.; Guan, X.; Qiao, K.; Ye, D.; Cai, J.; Xie, Y.; et al. Modification of cold-sprayed high-entropy alloy particles reinforced aluminum matrix composites via friction stir processing. J. Alloys Compd. 2022, 907, 164426. [Google Scholar] [CrossRef]

- Kwon, J.; Park, H.; Lee, I.; Lee, C. Effect of gas flow rate on deposition behavior of Fe-based amorphous alloys in vacuum kinetic spray process. Surf. Coat. Technol. 2014, 259, 585–593. [Google Scholar] [CrossRef]

- White, B.; Story, W.A.; Brewer, L.; Jordon, J. Fracture mechanics methods for evaluating the adhesion of cold spray deposits. Eng. Fract. Mech. 2019, 205, 57–69. [Google Scholar] [CrossRef]

- Cavaliere, P.; Perrone, A.; Silvello, A. Crystallization Evolution of Cold-Sprayed Pure Ni Coatings. J. Therm. Spray Technol. 2016, 25, 1158–1167. [Google Scholar] [CrossRef]

- Sample, C.M.; Champagne, V.K.; Nardi, A.T.; Lados, D.A. Factors governing static properties and fatigue, fatigue crack growth, and fracture mechanisms in cold spray alloys and coatings/repairs: A review. Addit. Manuf. 2020, 36, 101371. [Google Scholar] [CrossRef]

- Singh, R.; Schruefer, S.; Wilson, S.; Gibmeier, J.; Vassen, R. Influence of coating thickness on residual stress and adhesion-strength of cold-sprayed Inconel 718 coatings. Surf. Coat. Technol. 2018, 350, 64–73. [Google Scholar] [CrossRef]

- Shi, H.; Liu, M.; Cong, L.; Wang, L. A study on preparation and mechanism of Ni based ternary alloy. Mater. Express 2019, 9, 681–685. [Google Scholar] [CrossRef]

- Wang, A.P.; Zhang, T.; Wang, J.Q. Ni-based fully amorphous metallic coating with high corrosion resistance. Philos. Mag. Lett. 2006, 86, 5–11. [Google Scholar] [CrossRef]

- Yoon, S.; Kim, H.J.; Lee, C. Deposition behavior of bulk amorphous NiTiZrSiSn according to the kinetic and thermal energy levels in the kinetic spraying process. Surf. Coat. Technol. 2006, 200, 6022–6029. [Google Scholar] [CrossRef]

- Wang, A.; Chang, X.; Hou, W.; Wang, J. Preparation and corrosion behaviour of amorphous Ni-based alloy coatings. Mater. Sci. Eng. A 2007, 449–451, 277–280. [Google Scholar] [CrossRef]

- Yoon, S.; Lee, C.; Choi, H. Evaluation of the effects of the crystallinity of kinetically sprayed Ni–Ti–Zr–Si–Sn bulk metallic glass on the scratch response. Mater. Sci. Eng. A 2007, 449–451, 285–289. [Google Scholar] [CrossRef]

- Sugita, K.; Matsumoto, M.; Mizuno, M.; Araki, H.; Shirai, Y. Electron irradiation damage and the recovery in a Zr-based bulk amorphous alloy Zr55Cu30Al10Ni5. J. Phys. Conf. Ser. 2008, 106, 012024. [Google Scholar] [CrossRef]

- Sun, Y.-S.; Zhang, W.; Kai, W.; Liaw, P.K.; Huang, H.-H. Evaluation of Ni-free Zr–Cu–Fe–Al bulk metallic glass for biomedical implant applications. J. Alloys Compd. 2014, 586, S539–S543. [Google Scholar] [CrossRef]

- Liu, L.; Qiu, C.; Huang, C.; Yu, Y.; Huang, H.; Zhang, S. Biocompatibility of Ni-free Zr-based bulk metallic glasses. Intermetallics 2009, 17, 235–240. [Google Scholar] [CrossRef]

- Yeh, J.-W.; Chen, S.K.; Lin, S.-J.; Gan, J.-Y.; Chin, T.-S.; Shun, T.-T.; Tsau, C.-H.; Chang, S.-Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Akinbami, O.; Mohlala, L.M.; Klenam, D.; van der Merwe, J.; Bodunrin, M. The Status of High Entropy Alloys Studies in Africa: An Overview. Key Eng. Mater. 2022, 917, 41–53. [Google Scholar] [CrossRef]

- Owen, L.; Jones, N. Quantifying local lattice distortions in alloys. Scr. Mater. 2020, 187, 428–433. [Google Scholar] [CrossRef]

- Chen, H.; Kauffmann, A.; Laube, S.; Choi, I.-C.; Schwaiger, R.; Huang, Y.; Lichtenberg, K.; Müller, F.; Gorr, B.; Christ, H.-J.; et al. Contribution of Lattice Distortion to Solid Solution Strengthening in a Series of Refractory High Entropy Alloys. Met. Mater. Trans. A 2018, 49, 772–781. [Google Scholar] [CrossRef]

- Owen, L.R.; Jones, N.G. Lattice distortions in high-entropy alloys. J. Mater. Res. 2018, 33, 2954–2969. [Google Scholar] [CrossRef]

- Owen, L.; Pickering, E.; Playford, H.; Stone, H.; Tucker, M.; Jones, N. An assessment of the lattice strain in the CrMnFeCoNi high-entropy alloy. Acta Mater. 2017, 122, 11–18. [Google Scholar] [CrossRef]

- Diao, H.; Santodonato, L.J.; Tang, Z.; Egami, T.; Liaw, P.K. Local Structures of High-Entropy Alloys (HEAs) on Atomic Scales: An Overview. Jom 2015, 67, 2321–2325. [Google Scholar] [CrossRef]

- Guo, W.; Dmowski, W.; Noh, J.-Y.; Rack, P.; Liaw, P.K.; Egami, T. Local Atomic Structure of a High-Entropy Alloy: An X-Ray and Neutron Scattering Study. Met. Mater. Trans. A 2013, 44, 1994–1997. [Google Scholar] [CrossRef]

- Santodonato, L.J.; Zhang, Y.; Feygenson, M.; Parish, C.M.; Gao, M.C.; Weber, R.J.; Neuefeind, J.C.; Tang, Z.; Liaw, P.K. Deviation from high-entropy configurations in the atomic distributions of a multi-principal-element alloy. Nat. Commun. 2015, 6, 5964. [Google Scholar] [CrossRef]

- Abbasi, E.; Luo, Q.; Owens, D. A comparison of microstructure and mechanical properties of low-alloy-medium-carbon steels after quench-hardening. Mater. Sci. Eng. A 2018, 725, 65–75. [Google Scholar] [CrossRef]

- Ahmady, A.R.; Ekhlasi, A.; Nouri, A.; Nazarpak, M.H.; Gong, P.; Solouk, A. High entropy alloy coatings for biomedical applications: A review. Smart Mater. Manuf. 2023, 1, 100009. [Google Scholar] [CrossRef]

- Assadi, H.; Kreye, H.; Gärtner, F.; Klassen, T. Cold spraying—A materials perspective. Acta Mater. 2016, 116, 382–407. [Google Scholar] [CrossRef]

- Ren, Y.; King, P.; Yang, Y.; Xiao, T.; Chu, C.; Gulizia, S.; Murphy, A. Characterization of heat treatment-induced pore structure changes in cold-sprayed titanium. Mater. Charact. 2017, 132, 69–75. [Google Scholar] [CrossRef]

- Kiplangat, R.S.; Lin, T.-T.; Kipkirui, N.G.; Chen, S.-H. Microstructure and Mechanical Properties of the Plasma-Sprayed and Cold-Sprayed Al0.5CoCrFeNi2Ti0.5 High-Entropy Alloy Coatings. J. Therm. Spray Technol. 2022, 31, 1207–1221. [Google Scholar] [CrossRef]

- Nikbakht, R.; Assadi, H.; Jodoin, B. Intermetallic Phase Evolution of Cold-Sprayed Ni-Ti Composite Coatings: Influence of As-Sprayed Chemical Composition. J. Therm. Spray Technol. 2021, 30, 119–130. [Google Scholar] [CrossRef]

- Dai, C.-D.; Fu, Y.; Guo, J.-X.; Du, C.-W. Effects of substrate temperature and deposition time on the morphology and corrosion resistance of FeCoCrNiMo0.3 high-entropy alloy coating fabricated by magnetron sputtering. Int. J. Miner. Met. Mater. 2020, 27, 1388–1397. [Google Scholar] [CrossRef]

- Yin, S.; Li, W.; Song, B.; Yan, X.; Kuang, M.; Xu, Y.; Wen, K.; Lupoi, R. Deposition of FeCoNiCrMn high entropy alloy (HEA) coating via cold spraying. J. Mater. Sci. Technol. 2019, 35, 1003–1007. [Google Scholar] [CrossRef]

- Cavaliere, P.; Perrone, A.; Silvello, A.; Laska, A.; Blasi, G.; Cano, I.G. Fatigue Bending of V-Notched Cold-Sprayed FeCoCrNiMn Coatings. Metals 2022, 12, 780. [Google Scholar] [CrossRef]

- Nair, R.B.; Perumal, G.; McDonald, A. Effect of Microstructure on Wear and Corrosion Performance of Thermally Sprayed AlCoCrFeMo High-Entropy Alloy Coatings. Adv. Eng. Mater. 2022, 24, 2101713. [Google Scholar] [CrossRef]

- Rokni, M.R.; Widener, C.; Champagne, V.R. Microstructural Evolution of 6061 Aluminum Gas-Atomized Powder and High-Pressure Cold-Sprayed Deposition. J. Therm. Spray Technol. 2014, 23, 514–524. [Google Scholar] [CrossRef]

- Hsu, W.-L.; Yang, Y.-C.; Chen, C.-Y.; Yeh, J.-W. Thermal sprayed high-entropy NiCo 0.6 Fe 0.2 Cr 1.5 SiAlTi 0.2 coating with improved mechanical properties and oxidation resistance. Intermetallics 2017, 89, 105–110. [Google Scholar] [CrossRef]

- Ma, X.; Ruggiero, P.; Bhattacharya, R.; Senkov, O.N.; Rai, A.K. Evaluation of New High Entropy Alloy as Thermal Sprayed Bondcoat in Thermal Barrier Coatings. J. Therm. Spray Technol. 2022, 31, 1011–1020. [Google Scholar] [CrossRef]

- Feng, S.; Guan, S.; Story, W.A.; Ren, J.; Zhang, S.; Te, A.; Gleason, M.A.; Heelan, J.; Walde, C.; Birt, A.; et al. Cold Spray Additive Manufacturing of CoCrFeNiMn High-Entropy Alloy: Process Development, Microstructure, and Mechanical Properties. J. Therm. Spray Technol. 2022, 31, 1222–1231. [Google Scholar] [CrossRef]

- Lehtonen, J.; Koivuluoto, H.; Ge, Y.; Juselius, A.; Hannula, S.-P. Cold Gas Spraying of a High-Entropy CrFeNiMn Equiatomic Alloy. Coatings 2020, 10, 53. [Google Scholar] [CrossRef]

- Cheng, J.; Liang, X.; Xu, B. Effect of Nb addition on the structure and mechanical behaviors of CoCrCuFeNi high-entropy alloy coatings. Surf. Coat. Technol. 2014, 240, 184–190. [Google Scholar] [CrossRef]

- Cheng, J.; Liu, D.; Liang, X.; Chen, Y. Evolution of microstructure and mechanical properties of in situ synthesized TiC–TiB2/CoCrCuFeNi high entropy alloy coatings. Surf. Coat. Technol. 2015, 281, 109–116. [Google Scholar] [CrossRef]

- Cheng, J.B.; Liang, X.B.; Wang, Z.H.; Xu, B.S. Formation and Mechanical Properties of CoNiCuFeCr High-Entropy Alloys Coatings Prepared by Plasma Transferred Arc Cladding Process. Plasma Chem. Plasma Process. 2013, 33, 979–992. [Google Scholar] [CrossRef]

- Lu, J.; Wang, B.; Qiu, X.; Peng, Z.; Ma, M. Microstructure evolution and properties of CrCuFe x NiTi high-entropy alloy coating by plasma cladding on Q235. Surf. Coat. Technol. 2017, 328, 313–318. [Google Scholar] [CrossRef]

- Cai, Z.; Wang, Y.; Cui, X.; Jin, G.; Li, Y.; Liu, Z.; Dong, M. Design and microstructure characterization of FeCoNiAlCu high-entropy alloy coating by plasma cladding: In comparison with thermodynamic calculation. Surf. Coat. Technol. 2017, 330, 163–169. [Google Scholar] [CrossRef]

- Fang, Q.; Chen, Y.; Li, J.; Liu, Y.; Liu, Y. Microstructure and mechanical properties of FeCoCrNiNb high-entropy alloy coatings. Phys. B Condens. Matter 2018, 550, 112–116. [Google Scholar] [CrossRef]

- Xiang, K.; Chen, L.-Y.; Chai, L.; Guo, N.; Wang, H. Microstructural characteristics and properties of CoCrFeNiNbx high-entropy alloy coatings on pure titanium substrate by pulsed laser cladding. Appl. Surf. Sci. 2020, 517, 146214. [Google Scholar] [CrossRef]

- Chen, L.; Wang, Y.; Hao, X.; Zhang, X.; Liu, H. Lightweight refractory high entropy alloy coating by laser cladding on Ti–6Al–4V surface. Vacuum 2021, 183, 109823. [Google Scholar] [CrossRef]

- Li, Y.; Liang, H.; Nie, Q.; Qi, Z.; Deng, D.; Jiang, H.; Cao, Z. Microstructures and Wear Resistance of CoCrFeNi2V0.5Tix High-Entropy Alloy Coatings Prepared by Laser Cladding. Crystals 2020, 10, 352. [Google Scholar] [CrossRef]

- Wu, W.; Jiang, L.; Jiang, H.; Pan, X.; Cao, Z.; Deng, D.; Wang, T.; Li, T. Phase Evolution and Properties of Al2CrFeNiMo x High-Entropy Alloys Coatings by Laser Cladding. J. Therm. Spray Technol. 2015, 24, 1333–1340. [Google Scholar] [CrossRef]

- Zhang, H.; Pan, Y.; He, Y.; Jiao, H. Microstructure and properties of 6FeNiCoSiCrAlTi high-entropy alloy coating prepared by laser cladding. Appl. Surf. Sci. 2011, 257, 2259–2263. [Google Scholar] [CrossRef]

- Gu, Z.; Mao, P.; Gou, Y.; Chao, Y.; Xi, S. Microstructure and properties of MgMoNbFeTi2Yx high entropy alloy coatings by laser cladding. Surf. Coat. Technol. 2020, 402, 126303. [Google Scholar] [CrossRef]

- Qiu, X.; Zhang, Y.; Liu, C. Effect of Ti content on structure and properties of Al2CrFeNiCoCuTix high-entropy alloy coatings. J. Alloys Compd. 2014, 585, 282–286. [Google Scholar] [CrossRef]

- Li, X.; Feng, Y.; Liu, B.; Yi, D.; Yang, X.; Zhang, W.; Chen, G.; Liu, Y.; Bai, P. Influence of NbC particles on microstructure and mechanical properties of AlCoCrFeNi high-entropy alloy coatings prepared by laser cladding. J. Alloys Compd. 2019, 788, 485–494. [Google Scholar] [CrossRef]

- Qiu, X. Microstructure, hardness and corrosion resistance of Al2CoCrCuFeNiTix high-entropy alloy coatings prepared by rapid solidification. J. Alloys Compd. 2018, 735, 359–364. [Google Scholar] [CrossRef]

- Zhang, H.; Pan, Y.; He, Y.-Z. Synthesis and characterization of FeCoNiCrCu high-entropy alloy coating by laser cladding. Mater. Des. 2011, 32, 1910–1915. [Google Scholar] [CrossRef]

- Ni, C.; Shi, Y.; Liu, J.; Huang, G. Characterization of Al0.5FeCu0.7NiCoCr high-entropy alloy coating on aluminum alloy by laser cladding. Opt. Laser Technol. 2018, 105, 257–263. [Google Scholar] [CrossRef]

- Shu, F.; Wu, L.; Zhao, H.; Sui, S.; Zhou, L.; Zhang, J.; He, W.; He, P.; Xu, B. Microstructure and high-temperature wear mechanism of laser cladded CoCrBFeNiSi high-entropy alloy amorphous coating. Mater. Lett. 2018, 211, 235–238. [Google Scholar] [CrossRef]

- Shu, F.; Zhang, B.; Liu, T.; Sui, S.; Liu, Y.; He, P.; Liu, B.; Xu, B. Effects of laser power on microstructure and properties of laser cladded CoCrBFeNiSi high-entropy alloy amorphous coatings. Surf. Coat. Technol. 2019, 358, 667–675. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, J.; Juan, Y.; Lu, Z.; Jia, W. Evolution in microstructure and corrosion behavior of AlCoCrxFeNi high-entropy alloy coatings fabricated by laser cladding. J. Alloys Compd. 2019, 775, 1–14. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, W.; He, Y.; Li, M.; Guo, S. Formation of core–shell structure in high entropy alloy coating by laser cladding. Appl. Surf. Sci. 2016, 363, 543–547. [Google Scholar] [CrossRef]

- Guo, Y.; Shang, X.; Liu, Q. Microstructure and properties of in-situ TiN reinforced laser cladding CoCr2FeNiTi high-entropy alloy composite coatings. Surf. Coat. Technol. 2018, 344, 353–358. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, Q. MoFeCrTiWAlNb refractory high-entropy alloy coating fabricated by rectangular-spot laser cladding. Intermetallics 2018, 102, 78–87. [Google Scholar] [CrossRef]

- Chao, Q.; Guo, T.; Jarvis, T.; Wu, X.; Hodgson, P.; Fabijanic, D. Direct laser deposition cladding of Al CoCrFeNi high entropy alloys on a high-temperature stainless steel. Surf. Coat. Technol. 2017, 332, 440–451. [Google Scholar] [CrossRef]

- Juan, Y.; Li, J.; Jiang, Y.; Jia, W.; Lu, Z. Modified criterions for phase prediction in the multi-component laser-clad coatings and investigations into microstructural evolution/wear resistance of FeCrCoNiAlMox laser-clad coatings. Appl. Surf. Sci. 2019, 465, 700–714. [Google Scholar] [CrossRef]

- Shu, F.; Yang, B.; Dong, S.; Zhao, H.; Xu, B.; Xu, F.; Liu, B.; He, P.; Feng, J. Effects of Fe-to-Co ratio on microstructure and mechanical properties of laser cladded FeCoCrBNiSi high-entropy alloy coatings. Appl. Surf. Sci. 2018, 450, 538–544. [Google Scholar] [CrossRef]

- Cai, Z.; Cui, X.; Jin, G.; Liu, Z.; Zheng, W.; Li, Y.; Wang, L. Microstructure and thermal stability of a Ni-Cr-Co-Ti-V-Al high-entropy alloy coating by laser surface alloying. Met. Mater. Int. 2017, 23, 1012–1018. [Google Scholar] [CrossRef]

- Cai, Z.; Jin, G.; Cui, X.; Liu, Z.; Zheng, W.; Li, Y.; Wang, L. Synthesis and microstructure characterization of Ni-Cr-Co-Ti-V-Al high entropy alloy coating on Ti-6Al-4V substrate by laser surface alloying. Mater. Charact. 2016, 120, 229–233. [Google Scholar] [CrossRef]

- Zhang, S.; Wu, C.; Zhang, C.; Guan, M.; Tan, J. Laser surface alloying of FeCoCrAlNi high-entropy alloy on 304 stainless steel to enhance corrosion and cavitation erosion resistance. Opt. Laser Technol. 2016, 84, 23–31. [Google Scholar] [CrossRef]

- Zhang, S.; Wu, C.; Yi, J.; Zhang, C. Synthesis and characterization of FeCoCrAlCu high-entropy alloy coating by laser surface alloying. Surf. Coat. Technol. 2015, 262, 64–69. [Google Scholar] [CrossRef]

- Ye, Q.; Feng, K.; Li, Z.; Lu, F.; Li, R.; Huang, J.; Wu, Y. Microstructure and corrosion properties of CrMnFeCoNi high entropy alloy coating. Appl. Surf. Sci. 2017, 396, 1420–1426. [Google Scholar] [CrossRef]

- Zhang, S.; Wu, C.; Zhang, C. Phase evolution characteristics of FeCoCrAlCuVxNi high entropy alloy coatings by laser high-entropy alloying. Mater. Lett. 2015, 141, 7–9. [Google Scholar] [CrossRef]

- Wu, C.; Zhang, S.; Zhang, C.; Zhang, H.; Dong, S. Phase evolution and properties in laser surface alloying of FeCoCrAlCuNi high-entropy alloy on copper substrate. Surf. Coat. Technol. 2017, 315, 368–376. [Google Scholar] [CrossRef]

- Smyrnova, K.V.; Pogrebnjak, A.D.; Beresnev, V.M.; Litovchenko, S.V.; Borba-Pogrebnjak, S.O.; Manokhin, A.S.; Klimenko, S.A.; Zhollybekov, B.; Kupchishin, A.I.; Kravchenko, Y.O.; et al. Microstructure and Physical–Mechanical Properties of (TiAlSiY)N Nanostructured Coatings Under Different Energy Conditions. Met. Mater. Int. 2018, 24, 1024–1035. [Google Scholar] [CrossRef]

- Pogrebnjak, A.; Yakushchenko, I.V.; Bondar, O.; Beresnev, V.M.; Oyoshi, K.; Ivasishin, O.M.; Amekura, H.; Takeda, Y.; Opielak, M.; Kozak, C. Irradiation resistance, microstructure and mechanical properties of nanostructured (TiZrHfVNbTa)N coatings. J. Alloys Compd. 2016, 679, 155–163. [Google Scholar] [CrossRef]

- Yu, X.; Wang, J.; Wang, L.; Huang, W. Fabrication and characterization of CrNbSiTiZr high-entropy alloy films by radio-frequency magnetron sputtering via tuning substrate bias. Surf. Coat. Technol. 2021, 412, 127074. [Google Scholar] [CrossRef]

- Wang, J.; Kuang, S.; Yu, X.; Wang, L.; Huang, W. Tribo-mechanical properties of CrNbTiMoZr high-entropy alloy film synthesized by direct current magnetron sputtering. Surf. Coat. Technol. 2020, 403, 126374. [Google Scholar] [CrossRef]

- Alvi, S.; Jarzabek, D.M.; Kohan, M.G.; Hedman, D.; Jenczyk, P.; Natile, M.M.; Vomiero, A.; Akhtar, F. Synthesis and Mechanical Characterization of a CuMoTaWV High-Entropy Film by Magnetron Sputtering. ACS Appl. Mater. Interfaces 2020, 12, 21070–21079. [Google Scholar] [CrossRef]

- Li, X.; Zheng, Z.; Dou, D.; Li, J. Microstructure and Properties of Coating of FeAlCuCrCoMn High Entropy Alloy Deposited by Direct Current Magnetron Sputtering. Mater. Res. 2016, 19, 802–806. [Google Scholar] [CrossRef]

- Cao, F.; Munroe, P.; Zhou, Z.; Xie, Z. Microstructure and mechanical properties of a multilayered CoCrNi/Ti coating with varying crystal structure. Surf. Coat. Technol. 2018, 350, 596–602. [Google Scholar] [CrossRef]

- Braic, V.; Vladescu, A.; Balaceanu, M.; Luculescu, C.; Braic, M. Nanostructured multi-element (TiZrNbHfTa)N and (TiZrNbHfTa)C hard coatings. Surf. Coat. Technol. 2012, 211, 117–121. [Google Scholar] [CrossRef]

- Zhang, W.; Tang, R.; Yang, Z.; Liu, C.; Chang, H.; Yang, J.; Liao, J.; Yang, Y.; Liu, N. Preparation, structure, and properties of an AlCrMoNbZr high-entropy alloy coating for accident-tolerant fuel cladding. Surf. Coat. Technol. 2018, 347, 13–19. [Google Scholar] [CrossRef]

- Lin, C.; Duh, J. Corrosion behavior of (Ti–Al–Cr–Si–V)xNy coatings on mild steels derived from RF magnetron sputtering. Surf. Coat. Technol. 2008, 203, 558–561. [Google Scholar] [CrossRef]

- Huang, P.-K.; Yeh, J.-W. Effects of nitrogen content on structure and mechanical properties of multi-element (AlCrNbSiTiV)N coating. Surf. Coat. Technol. 2009, 203, 1891–1896. [Google Scholar] [CrossRef]

- Ren, B.; Shen, Z.; Liu, Z. Structure and mechanical properties of multi-element (AlCrMnMoNiZr)Nx coatings by reactive magnetron sputtering. J. Alloys Compd. 2013, 560, 171–176. [Google Scholar] [CrossRef]

- Tsai, D.-C.; Deng, M.-J.; Chang, Z.-C.; Kuo, B.-H.; Chen, E.-C.; Chang, S.-Y.; Shieu, F.-S. Oxidation resistance and characterization of (AlCrMoTaTi)-Six-N coating deposited via magnetron sputtering. J. Alloys Compd. 2015, 647, 179–188. [Google Scholar] [CrossRef]

- Johansson, K.; Riekehr, L.; Fritze, S.; Lewin, E. Multicomponent Hf-Nb-Ti-V-Zr nitride coatings by reactive magnetron sputter deposition. Surf. Coat. Technol. 2018, 349, 529–539. [Google Scholar] [CrossRef]

- Tüten, N.; Canadinc, D.; Motallebzadeh, A.; Bal, B. Microstructure and tribological properties of TiTaHfNbZr high entropy alloy coatings deposited on Ti 6Al 4V substrates. Intermetallics 2019, 105, 99–106. [Google Scholar] [CrossRef]

- Alamdari, A.A.; Unal, U.; Motallebzadeh, A. Investigation of microstructure, mechanical properties, and biocorrosion behavior of Ti1.5ZrTa0.5Nb0.5W0.5 refractory high-entropy alloy film doped with Ag nanoparticles. Surf. Interfaces 2022, 28, 101617. [Google Scholar] [CrossRef]

- Chen, L.; Bobzin, K.; Zhou, Z.; Zhao, L.; Öte, M.; Königstein, T.; Tan, Z.; He, D. Wear behavior of HVOF-sprayed Al0.6TiCrFeCoNi high entropy alloy coatings at different temperatures. Surf. Coat. Technol. 2019, 358, 215–222. [Google Scholar] [CrossRef]

- Löbel, M.; Lindner, T.; Lampke, T. High-temperature wear behaviour of AlCoCrFeNiTi0.5 coatings produced by HVOF. Surf. Coat. Technol. 2020, 403, 126379. [Google Scholar] [CrossRef]

- Abhijith, N.V.; Kumar, D.; Kalyansundaram, D. Development of Single-Stage TiNbMoMnFe High-Entropy Alloy Coating on 304L Stainless Steel Using HVOF Thermal Spray. J. Therm. Spray Technol. 2022, 31, 1032–1044. [Google Scholar] [CrossRef]

- Hsu, W.-L.; Murakami, H.; Yeh, J.-W.; Yeh, A.-C.; Shimoda, K. On the study of thermal-sprayed Ni 0.2 Co 0.6 Fe 0.2 CrSi 0.2 AlTi 0.2 HEA overlay coating. Surf. Coat. Technol. 2017, 316, 71–74. [Google Scholar] [CrossRef]

- Tian, L.; Feng, Z.; Xiong, W. Microstructure, Microhardness, and Wear Resistance of AlCoCrFeNiTi/Ni60 Coating by Plasma Spraying. Coatings 2018, 8, 112. [Google Scholar] [CrossRef]

- Wang, W.; Qi, W.; Xie, L.; Yang, X.; Li, J.; Zhang, Y. Microstructure and Corrosion Behavior of (CoCrFeNi)95Nb5 High-Entropy Alloy Coating Fabricated by Plasma Spraying. Materials 2019, 12, 694. [Google Scholar] [CrossRef]

- Ang, A.S.M.; Berndt, C.C.; Sesso, M.L.; Anupam, A.; Praveen, S.; Kottada, R.S.; Murty, B.S. Plasma-Sprayed High Entropy Alloys: Microstructure and Properties of AlCoCrFeNi and MnCoCrFeNi. Metall. Mater. Trans. A 2015, 46, 791–800. [Google Scholar] [CrossRef]

- Xiao, J.-K.; Tan, H.; Wu, Y.-Q.; Chen, J.; Zhang, C. Microstructure and wear behavior of FeCoNiCrMn high entropy alloy coating deposited by plasma spraying. Surf. Coat. Technol. 2020, 385, 125430. [Google Scholar] [CrossRef]

- Xiao, J.-K.; Wu, Y.-Q.; Chen, J.; Zhang, C. Microstructure and tribological properties of plasma sprayed FeCoNiCrSiAlx high entropy alloy coatings. Wear 2020, 448–449, 203209. [Google Scholar] [CrossRef]

- Anupam, A.; Kottada, R.S.; Kashyap, S.; Meghwal, A.; Murty, B.; Berndt, C.; Ang, A. Understanding the microstructural evolution of high entropy alloy coatings manufactured by atmospheric plasma spray processing. Appl. Surf. Sci. 2020, 505, 144117. [Google Scholar] [CrossRef]

- Wang, L.; Chen, C.; Yeh, J.; Ke, S. The microstructure and strengthening mechanism of thermal spray coating NixCo0.6Fe0.2CrySizAlTi0.2 high-entropy alloys. Mater. Chem. Phys. 2011, 126, 880–885. [Google Scholar] [CrossRef]

- Tian, L.-H.; Xiong, W.; Liu, C.; Lu, S.; Fu, M. Microstructure and Wear Behavior of Atmospheric Plasma-Sprayed AlCoCrFeNiTi High-Entropy Alloy Coating. J. Mater. Eng. Perform. 2016, 25, 5513–5521. [Google Scholar] [CrossRef]

- Anupam, A.; Kumar, S.; Chavan, N.M.; Murty, B.S.; Kottada, R.S. First report on cold-sprayed AlCoCrFeNi high-entropy alloy and its isothermal oxidation. J. Mater. Res. 2019, 34, 796–806. [Google Scholar] [CrossRef]

- Hushchyk, D.V.; Yurkova, A.I.; Cherniavsky, V.V.; Bilyk, I.I.; Nakonechnyy, S.O. Nanostructured AlNiCoFeCrTi high-entropy coating performed by cold spray. Appl. Nanosci. 2020, 10, 4879–4890. [Google Scholar] [CrossRef]

- Zou, Y. Cold Spray Additive Manufacturing: Microstructure Evolution and Bonding Features. Acc. Mater. Res. 2021, 2, 1071–1081. [Google Scholar] [CrossRef]

- Nikbakht, R.; Saadati, M.; Kim, T.-S.; Jahazi, M.; Kim, H.S.; Jodoin, B. Cold spray deposition characteristic and bonding of CrMnCoFeNi high entropy alloy. Surf. Coat. Technol. 2021, 425, 127748. [Google Scholar] [CrossRef]