Abstract

Contact fatigue is the main failure model for bearing systems in steel rolling mills. Characterizing the degree of contact fatigue damage is important for predicting its operating life. In this paper, the X-ray diffraction method (XRD) is used to measure the residual stress state and the diffraction peak width (FWHM, full width at half maximum) of six samples with different degrees of contact fatigue failure. The results show that surface residual stress values increased by more than 70% compared with the original state, while the diffraction peak width values decreased by more than 7% and were strongly correlated with the degree of contact fatigue damage. The XRD measurement of the bearing inner ring enables the characterization of the evolution of the residual stress state and grain distortion due to damage development. FWHM values may be considered an indicator for predicting the degree of contact fatigue.

1. Introduction

High-precision plate and strip rolling mills with four-row cylindrical roller bearing systems are widely used in the modern steel industry [,]. Contact fatigue is the main failure model for the roller bearing system. One of the most prominent locations for failure of the bearing system is the bearing inner ring that supports the heavily loaded bearings. Even when installed and maintained very carefully, the bearing system still has a limited service life due to tribological effects. In the operation of a rolling mill, cyclic contact stress is transferred to the bearing system, causing rolling contact fatigue (RCF) [,]. In theory, under uniaxial loading, the highly localized stress exerted between the bearing and inner ring can be analyzed by the Hertz contact theory without considering lubrication. However, the RCF failure of a rolling bearing system is a multi-axial condition; it is much more complicated than failure with a uni-axial condition.

In the study of contact fatigue failure, there are two main contact fatigue failure models: one is surface pitting and the other is spalling from the subsurface [,]. Surface pitting is closely related to surface finish, lubricating oil pollution, etc., while subsurface spalling is related to metallurgical inclusion and residual stress distribution in metal materials. For example, in carburized bearings, the composition and microstructure of the hardened layer will affect its strength, and it is generally necessary to control the martensite, carbide, residual austenite content, etc. []. RCF life is largely dependent on the maximum size of the non-metal inclusion. In terms of chemical composition, a previous study showed that the contact fatigue life of bearings was determined by the total oxygen content of the bearings. Because oxygen atoms mostly exist in the form of oxides, when the oxygen content is high, the inclusion particles tend to be large, so controlling the oxygen content is effective. In terms of theoretical analysis, Lundberg and Palmgren [] developed a life prediction model based on the subsurface spalling failure of bearings and found that service life conforms to the Weibull statistical distribution model. Zaretsky and Tallian et al. [] have proposed a similar model for predicting bearing contact fatigue life. The above models mainly considered the influence of size, shape, depth, and hardness of non-metal inclusions on bearing contact fatigue life and gave a theoretical prediction model of bearing life []. In addition to non-metal inclusions, bearings are accompanied by damage and variation in the residual stress state during rolling operation []. In many cases, damage due to rolling contact fatigue under cyclic loading gradually increases. However, the question of how to measure the degree of contact fatigue with non-destructive methods remains a key issue [].

The X-ray diffraction method is widely applied to characterize the phase, texture, and residual stress of crystalline materials [,,,]. Regarding diffraction peaks, peak intensity is related to the preferred orientation, residual stress can be calculated from the shift of the diffraction peak, and peak width (FWHM, full width at half maximum) is related to micro-structure (crystal diffraction domain size, micro-strain, and dislocation density) []. The diffraction crystal size, micro-strain, and dislocation density can be calculated with the line profile analysis method. Many researchers have attempted to characterize the damage evolution of materials under external loading using the X-ray diffraction line profile analysis method []. SATO reported using the X-ray diffraction line profile analysis method to quantitatively evaluate dislocations in austenitic and ferritic stainless steels under cyclic loading; it revealed that the dislocation density normalized by the maximum work hardening for both stainless steels exhibited a log-log linear relationship with the low-cycle fatigue life []. In the gear and bearing industry, the German SKF research team established a low-cycle fatigue life prediction model based on FWHM distribution and obtained the critical threshold of its value under different failure modes []. Scholars have also used the finite element simulation method to analyze the equivalent relationship between the deformation hardening layer and the evolution of diffraction peak width for TORKA high-strength steel during the rolling process []. Similarly, it has also been reported that a white bright layer on the surface of GCr15 steel samples can be formed under contact loading and that the thickness of this white bright layer shows a certain equivalent relationship with the change in diffraction peak width of the surface layer []. The Politecnico di Milano [] investigated the evolution of FWHM at the tooth surface of a carburized steel 16CrNi4 gear during contact fatigue failure. However, FWHM evolution during contact fatigue testing was not accompanied by obvious surface damage, which requires further investigation. Therefore, can we use the FWHM values as a critical parameter to predict the degree of surface contact fatigue damage for practical application with an X-ray diffraction analyzer? In addition, if the bearing inner ring is improperly ground during the production process, it will cause substantial grinding residual stress, and cracks will be caused when this residual stress is too large [,,,]. At the same time, during contact fatigue, the evolution of residual stress changes the state of surface shear stress [,,]. It is necessary to study the relationship between the surface FWHM values, or residual stress, and the degree of surface damage to samples under cyclic contact loading using X-ray diffraction analysis.

Therefore, in this paper, G10CrNi3Mo steel bearing inner rings with different degrees of contact fatigue damage were selected. Residual stress and FWHM values were measured by X-ray diffraction. We combined this with other experimental analyses (SEM observation, micro-hardness measurements) to assess if it is possible to find a relationship between the evolution of rolling contact fatigue damage, the residual stress state, and the diffraction peak width.

2. Materials and Methods

2.1. Materials

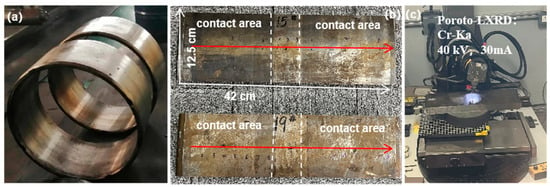

In this work, bearing inner rings with different degrees of contact fatigue are shown in Figure 1a. They were made of G10CrNi3Mo steel, with an original surface hardness of about HV 680. Six test samples(namely 3#, 8#, 9#, 10#, 15#, 19#) with different degrees of contact fatigue were cut into rectangles (42 cm × 12.5 cm), as shown in Figure 1b. The samples contained contact fatigue areas on both ends of the sample and a middle area without contact rolling. The chemical composition of the materials is listed in Table 1; the main alloying elements are Cr, Ni, and Mo. These alloying elements are used to improve the strength and toughness of the materials. Comparing the composition of the surface and substrate, it can be seen that the carbon at the surface is much higher than that at the substrate, indicating that the surface has been carburized.

Figure 1.

(a) Bearing inner ring samples. (b) Test samples cut from the bearing inner ring. (c) X-ray stress testing.

Table 1.

Surface and substrate chemical compositions of bearing inner rings.

2.2. Characterization Method

The microstructure of the samples was observed by SEM, and the carbide was characterized by TEM. The phase was determined using X-ray diffraction equipment (Bruker D8 Advance) with Bragg-Brentano geometry. The surface hardness was tested using a Richter hardness tester, while the hardness distribution along the depth was measured by a micro-hardness tester. The residual stress and the full width at half maximum (FWHM) were measured using an X-ray stress analyzer (LXRD, Proto, LaSalle, ON, Canada) with Cr-Ka radiation at a voltage of 30 kV, 25 mA. For the residual stress measurement, the sin2Ψ method was used to calculate the residual stress with Ψ in the range of −35°~+35°. There were 20 measurement points along the longitudinal direction of the surface, as shown by the red line in Figure 1b. To obtain the depth distribution of residual stress, the thin top surface layers were removed one by one via the method of electrolyte-etching with a voltage of 15 V in saturated NaCl solution.

3. Results and Discussion

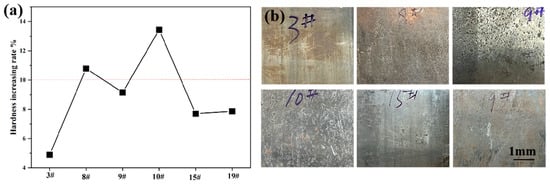

Generally, the surface hardness increasing rate is often used to characterize the degree of contact fatigue []. For the six samples tested, the surface hardness of the contact areas increased to different degrees compared to the original area without contact, as shown in Figure 2a. In terms of the surface hardness increasing rate, it reached approximately 10% for samples 8#, 9#, and 10# but was only 4.89% for sample 3#, indicating that the damage to 10# was the most serious in all samples. The surface images of the six samples are also displayed in Figure 2b. There is obvious contact fatigue pitting on the surfaces of samples 8#, 9#, and 10#, while there is no obvious pitting on the surface of sample 3#. In the case of contact fatigue, even though external loading does not exceed the yield strength, localized damage still occurs, possibly due to uneven localized strength. The results also further confirm that surface damage is related with surface hardness enhancement.

Figure 2.

(a) Increase in hardness in the contact area. (3#, 8#, 9#, 10#, 15#, 19# sample numbers, orange dotted line is the 10% hardness increasing rate) (b) Typical surface morphology of six samples.

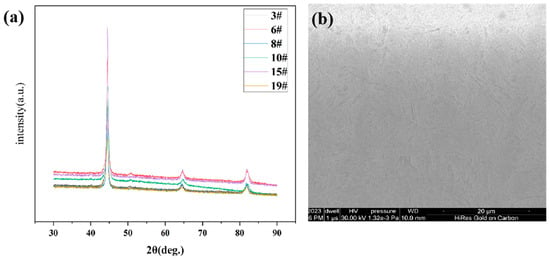

Figure 3 shows the X-ray diffraction patterns of the six samples. Three main diffraction peaks of the martensite phase at 44.43°, 64.56°, and 81.96° are detected, which correspond to the crystallographic planes of Fe(110), Fe(200), and Fe(211), respectively. Meanwhile, the diffraction peaks are broad, indicating grain refinement during the rolling. Figure 3b shows the microstructure of a typical sample. The martensite, which appears as needle-like structures, contributed to its high hardness.

Figure 3.

(a) X-ray patterns of six samples; (b) SEM image of the microstructure.

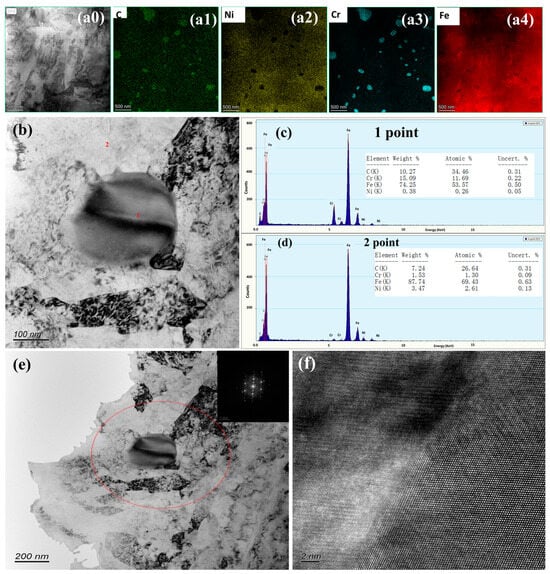

For the bearing inner ring, in order to improve its strength and toughness, strong carbide-forming elements are often added []. Figure 4 shows the TEM characterization of carbide in a typical, original sample. Carbide spheres (100 to 200 nm in diameter) are observed in Figure 4a0. The element maps are shown in Figure 4a1–a4, and the C and Cr are enriched at the carbide, indicating a Cr-riching carbide formed in the steel. Figure 4b shows a typical carbide image with large magnification; it is a spherical shape inlaid in the matrix. The element distributions at the carbide and matrix are shown in Figure 4c,d. The Cr content of the carbide is 15.09 wt%, which is much higher than the Ni content; however, in the matrix, the Ni content reaches 3.47 wt%, while the Cr content is only 1.53 wt%. This may be because Cr is a strong carbide-forming element, while Ni is a non-carbide-forming element []. Figure 4e shows the TEM morphology of the carbide, with a dark-field image of the micro-diffraction pattern in the upper-right corner. This is a M3C-type carbide with (Fe,Cr)3C, according to the elemental distribution. The interface between the matrix and carbide shown in Figure 4f indicates that the interface is likely coherent or semi-coherent.

Figure 4.

TEM and elemental distributions (a0–a4); (b) TEM image of carbide (1, 2 are the testing points for element distribution); (c,d) elemental distributions of the matrix and carbide; (e) image of carbide and micro-diffraction pattern; (f) interface between the carbide and matrix.

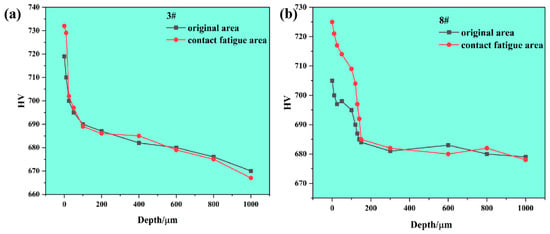

Figure 5 shows the hardness distribution of the contact fatigue area and the original area for typical samples 3# and 8#. For both samples with different damage degrees, it shows a similar change tendency. The hardness value gradually decreases along the depth, and the hardness at the near surface layer increases after contact rolling, which indicates that work hardening occurred on the surface during operation. The relative change in hardness in the contact fatigue area compared to the original area is greater for sample 8# than for sample 3#. Sample 8# underwent greater work hardening than sample 3#, which is consistent with the degree of hardness enhancement shown in Figure 2a.

Figure 5.

Hardness distribution of typical samples (a) 3# and (b) 8#.

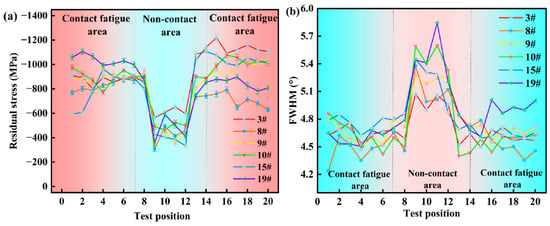

The surface residual stress and FWHM value distributions on the surface are shown in Figure 6. The residual stress in the original area is in the range of −300 MPa~−600 MPa. However, in the contact area, the compressive residual stress values have significantly increased. The six samples illustrate similar tendencies, with compressive residual stress being much higher in contact fatigue areas than in the original area for all six testing samples, as shown in Figure 6a. The FWHM values on the surface of the six samples are displayed in Figure 6b. It can be seen that FWHM values in the contact areas decrease compared to the values in the original areas. FWHM is often used to characterize micro stresses due to annealing or work hardening of the material. This quantity is related to grain distortion, dislocation density, and so-called type II micro residual stresses. In metals after surface work hardening, FWHM values often increase due to the refinement of grain and increased dislocation density. It is interesting that, in this study, FWHM values in the contact fatigue areas decreased compared to the original areas. Previous papers have also reported similar results, especially for high-strength steel []. The decrease in FWHM values for this G10CrNi3Mo steel may be due to its high dislocation density. It is possible that, during the rolling operation, the dislocations are rearranged into structures with lower distortion, resulting in lower FWHM values. This indicates that, during the contact fatigue testing, inhomogeneous microstructures are formed in the surface layer.

Figure 6.

(a) Surface residual stress distributions; (b) FWHM distributions of six samples.

Table 2 shows the percent change in residual stress, FWHM, and hardness of the six samples tested. It can be seen that, for all six samples, the change in residual stress was higher than 60%. The change in residual stress was weakly correlated with the surface damage degree and percent change in surface hardness. However, the percent change in FWHM was found to be strongly correlated with the percent change in hardness and surface damage degree. This result indicates that the percent change in FWHM may be used as a parameter to characterize surface damage degree in contact fatigue testing.

Table 2.

The change in residual stress, FWHM, and hardness for six samples.

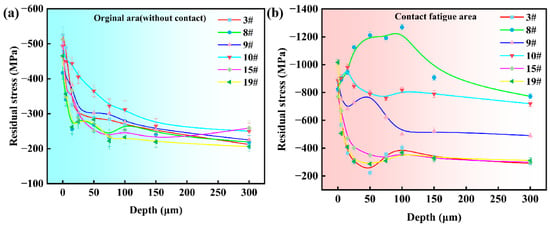

The residual stress distributions along the depth for the original area and contact fatigue areas are shown in Figure 7. For original areas without contact, the compressive residual stress gradually decreases, and the residual stress is almost the same with a value of −300 MPa at a depth beyond 25 μm. However, the residual stress depth distributions were substantially different for samples (8#, 9#, and 10#) with serious contact fatigue, in which residual stress maxima occurred in subsurface layers. This large residual stress may promote pitting formation during the rolling operation.

Figure 7.

Residual stress distribution along the depth. (a) Original area. (b) Contact fatigue area.

For residual stress, it is generally recognized that compressive residual stress can inhibit the propagation of cracks. In the case of contact fatigue, the increased compressive residual stress may move the maximum shear stress caused by Hertz contact stress from the subsurface to the surface and, in so doing, promote surface pitting. For the FWHM, according to the theoretical analysis of metal, the residual distortion energy can account for a few percent to more than ten percent of the total deformation work and it is determined by the type of materials, the degree of the deformation, the deformation temperature, and the speed. The distortion energy is mainly stored in microscopic distortion. This microscopic distortion causes diffraction line broadening, which plays an important role in determining the amount of fatigue. The changing rate of FWHM values is strongly correlated with the degree of contact fatigue. Therefore, it is expected that variation in FWHM may be used as an indicator to characterize the degree of contact fatigue for bearing systems.

4. Conclusions

The fatigue damage occurring near the surface of bearing inner rings was studied using the X-ray diffraction method. Hardness testing indicated that the hardness of contact fatigue areas increased in the range of 4.83%~13.44% compared to the original areas without rolling. Residual stress was measured in the contact and non-contact areas. However, the compressive residual stress values in the contact fatigue areas significantly increased by more than 70% compared to the non-contact areas and showed a weak linear correlation with the degree of contact fatigue. In terms of FWHM values, they decreased after rolling contact fatigue, and the degree of fatigue damage is more sensitive to the FHWM variation. The surface value of FWHM could be proposed as a damage indicator of rolling contact fatigue for bearing systems.

Author Contributions

Conceptualization, H.Q. and K.Z.; methodology, L.Y. and H.Q.; investigation, K.Z.; data curation, L.Y.; writing-original draft preparation, H.Q. and K.Z.; writing-review and editing, K.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to company’s rules.

Conflicts of Interest

Author Qu H. and Yao L. was employed by the company Baoshan Iron & Steel company. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Hirani, H. Root Cause Failure Analysis of Outer Ring Fracture of Four-Row Cylindrical Roller Bearing. Tribol. Trans. 2009, 52, 180–190. [Google Scholar] [CrossRef]

- Liu, Y.-J.; Wang, S.; Qi, J.-B.; Yan, X.-Q. Vibrations of tandem cold rolling mill: Coupled excitation of rolling force and variable stiffness of fault-free back-up roll bearing. J. Iron Steel Res. Int. 2023, 30, 1792–1802. [Google Scholar] [CrossRef]

- Ghaffari, M.A.; Zhang, Y.; Xiao, S. Multiscale modeling and simulation of rolling contact fatigue. Int. J. Fatigue 2018, 108, 9–17. [Google Scholar] [CrossRef]

- El Laithy, M.; Wang, L.; Harvey, T.J.; Vierneusel, B.; Correns, M.; Blass, T. Further understanding of rolling contact fatigue in rolling element bearings—A review. Tribol. Int. 2019, 140, 105849. [Google Scholar] [CrossRef]

- Lorenz, S.J.; Sadeghi, F.; Trivedi, H.K.; Rosado, L.; Kirsch, M.S.; Wang, C. An approach for predicting failure mechanism in rough surface rolling contact fatigue. Tribol. Int. 2021, 158, 106923. [Google Scholar] [CrossRef]

- Liu, H.; Liu, H.; Zhu, C.; Tang, J. Study on gear contact fatigue failure competition mechanism considering tooth wear evolution. Tribol. Int. 2020, 147, 106277. [Google Scholar] [CrossRef]

- Paulson, N.R.; Golmohammadi, Z.; Walvekar, A.A.; Sadeghi, F.; Mistry, K. Rolling contact fatigue in refurbished case carburized bearings. Tribol. Int. 2017, 115, 348–364. [Google Scholar] [CrossRef]

- Palmgren, A.J.P.S.I.I. Ball and Roller Bearing Engineering; S.H. Burbank & Co. Press: Philadelphia, PA, USA, 1959. [Google Scholar]

- Zaretsky, E.V.; Anderson, W.J. Rolling-Contact Fatigue Studies with Four Tool Steels and a Crystallized Glass Ceramic. J. Basic Eng. 1961, 83, 603–610. [Google Scholar] [CrossRef]

- Wang, H.; Chen, J.; Qu, J.; Ni, G. A new approach for safety life prediction of industrial rolling bearing based on state recognition and similarity analysis. Saf. Sci. 2020, 122, 104530. [Google Scholar] [CrossRef]

- Al-Tameemi, H.A.; Long, H. Finite element simulation of subsurface initiated damage from non-metallic inclusions in wind turbine gearbox bearings. Int. J. Fatigue 2020, 131, 105347. [Google Scholar] [CrossRef]

- Reid, A.; Marshall, M.; Martinez, I.; Moorby, S.; Connolley, T.; Mostafavi, M.; Kabra, S. Measurement of strain evolution in overloaded roller bearings using time-of-flight neutron diffraction. Mater. Des. 2020, 190, 108571. [Google Scholar] [CrossRef]

- Cao, J.; Yang, Q.; Zhou, L.; Chen, H.; Zhan, K.; Liu, J.; Ding, R.; You, S.; Zhao, B.; Ji, V. Microstructure, properties and synergetic effect of graphene oxide-functionalized carbon nanotubes hybrid reinforced copper matrix composites prepared by DC electrodeposition. Carbon 2023, 212, 118157. [Google Scholar] [CrossRef]

- Zhan, K.; Wang, W.; Li, F.; Cao, J.; Liu, J.; Yang, Z.; Wang, Z.; Zhao, B. Microstructure and properties of graphene oxide reinforced copper-matrix composite foils fabricated by ultrasonic assisted electrodeposition. Mater. Sci. Eng. A 2023, 872, 144995. [Google Scholar] [CrossRef]

- Bao, L.; Li, K.; Zheng, J.; Zhang, Y.; Zhan, K.; Yang, Z.; Zhao, B.; Ji, V. Surface characteristics and stress corrosion behavior of AA 7075-T6 aluminum alloys after different shot peening processes. Surf. Coat. Technol. 2022, 440, 128481. [Google Scholar] [CrossRef]

- Zhan, K.; Zhang, Y.; Bao, L.; Yang, Z.; Zhao, B.; Ji, V. Surface characteristic and wear resistance of QT-700-2 nodular cast iron after laser quenching combing with shot peening treatment. Surf. Coat. Technol. 2021, 423, 127589. [Google Scholar] [CrossRef]

- Li, C.; Si, X.; Cao, J.; Qi, J.; Dong, Z.; Feng, J. Residual stress distribution as a function of depth in graphite/copper brazing joints via X-ray diffraction. J. Mater. Sci. Technol. 2019, 35, 2470–2476. [Google Scholar] [CrossRef]

- Muro, H.; Tsushima, N.; Nunome, K. Failure analysis of rolling bearings by X-ray measurement of residual stress. Wear 1973, 25, 345–356. [Google Scholar] [CrossRef]

- Moshtaghi, M.; Sato, S. Characterization of Dislocation Evolution in Cyclically Loaded Austenitic and Ferritic Stainless Steels via XRD Line-profile Analysis. ISIJ Int. 2019, 59, 1591–1598. [Google Scholar] [CrossRef]

- Epp, J. 4—X-ray diffraction (XRD) techniques for materials characterization. In Materials Characterization Using Nondestructive Evaluation (NDE) Methods; Hübschen, G., Altpeter, I., Tschuncky, R., Herrmann, H.-G., Eds.; Woodhead Publishing: Sawston, UK, 2016; pp. 81–124. [Google Scholar]

- Akopyan, T.K.; Gamin, Y.V.; Galkin, S.P.; Prosviryakov, A.S.; Aleshchenko, A.S.; Noshin, M.A.; Koshmin, A.N.; Fomin, A.V. Radial-shear rolling of high-strength aluminum alloys: Finite element simulation and analysis of microstructure and mechanical properties. Mater. Sci. Eng. A 2020, 786, 139424. [Google Scholar] [CrossRef]

- Fu, P.; Chu, R.; Xu, Z.; Ding, G.; Jiang, C. Relation of hardness with FWHM and residual stress of GCr15 steel after shot peening. Appl. Surf. Sci. 2018, 431, 165–169. [Google Scholar] [CrossRef]

- Fernández Pariente, I.; Guagliano, M. Contact fatigue damage analysis of shot peened gears by means of X-ray measurements. Eng. Fail. Anal. 2009, 16, 964–971. [Google Scholar] [CrossRef]

- Krishna, V.V.; Hossein-Nia, S.; Casanueva, C.; Stichel, S.; Trummer, G.; Six, K. Rail RCF damage quantification and comparison for different dam-age models. Railw. Eng. Sci. 2022, 30, 23–40. [Google Scholar] [CrossRef]

- Zhang, S.Y.; Spiryagin, M.; Ding, H.H.; Wu, Q.; Guo, J.; Liu, Q.Y.; Wang, W.J. Rail rolling contact fatigue formation and evolution with surface defects. Int. J. Fatigue 2022, 158, 106762. [Google Scholar] [CrossRef]

- Seo, J.; Kwon, S.; Lee, D. Effects of surface defects on rolling contact fatigue of rail. Procedia Eng. 2011, 10, 1274–1278. [Google Scholar] [CrossRef]

- Zeng, D.; Xu, T.; Liu, W.; Lu, L.; Zhang, J.; Gong, Y. Investigation on rolling contact fatigue of railway wheel steel with surface defect. Wear 2020, 446–447, 203207. [Google Scholar] [CrossRef]

- Jin, G.; Gao, Y.; Huang, P.; Zhou, J.; Tang, Y. Surface roughness in grinding outer ring inner raceway of tapered roller bearing. Int. J. Adv. Manuf. Technol. 2023, 16, 964–971. [Google Scholar] [CrossRef]

- Chang, Z.; Jia, Q. Optimization of grinding efficiency considering surface integrity of bearing raceway. SN Appl. Sci. 2019, 1, 679. [Google Scholar] [CrossRef]

- Wang, W.; Liu, H.; Zhu, C.; Du, X.; Tang, J. Effect of the residual stress on contact fatigue of a wind turbine carburized gear with multiaxial fatigue criteria. Int. J. Mech. Sci. 2019, 151, 263–273. [Google Scholar] [CrossRef]

- Zhang, S.Y.; Zhao, H.Y.; Ding, H.H.; Lin, Q.; Wang, W.J.; Guo, J.; Wang, P.; Zhou, Z.R. Effect of vibration amplitude and axle load on the rail rolling contact fatigue under water condition. Int. J. Fatigue 2023, 167, 107329. [Google Scholar] [CrossRef]

- Yao, Z.; Chen, Z.; Ouyang, M.; Chen, X.; Yang, M.; Li, Z.; Wang, C.; Yang, T.; Shi, R.; Zhong, Z.; et al. Accelerated discovery of composition-carbide-hardness linkage of Stellite alloys assisted by image recognition. Scr. Mater. 2023, 234, 115539. [Google Scholar] [CrossRef]

- Sushko, M.L.; Schreiber, D.K.; Rosso, K.M.; Bruemmer, S.M. Role of Cr-rich carbide precipitates in the intergranular oxidation of Ni-Cr alloys. Scr. Mater. 2018, 156, 51–54. [Google Scholar] [CrossRef]

- Jasenko, P.; Jovan, T.; Andrej, Z.; Ivan, P. Residual stresses after deep rolling of a torsion bar made from high strength steel. J. Mater. Proces. Technol. 2015, 218, 89–98. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).