Abstract

Pressure vessel steels are used in the manufacture of tanks for the storage of gases, chemical materials and oil. To meet the increasing production demands, high-wire-energy welding is widely used in the manufacture of pressure vessel steels. This means that the weldability of pressure vessel steels needs to be improved. Therefore, in order to reveal the microalloying effect of Ca in pressure vessel steel, this study took a commonly used pressure vessel steel as the research object, and three groups of experimental steels with different Ca mass fractions were prepared using vacuum metallurgy, controlled rolling and controlled cooling. Welding heat simulation technology was used to simulate the welding heat of experimental steel and the welding heat-affected zone (HAZ) was investigated. The inclusions of the welding HAZ in the experimental steels were observed by using a metallographic microscope and scanning electron microscope (SEM). The mechanism of intragranular acicular ferrite (IAF) nucleation induced by the inclusions containing Ca elements in the welding HAZ of pressure vessel steels was also discussed. The research results show that the addition of Ca increased the number density of effective inclusions in the welding HAZ of the experimental steel up to 535.60 pieces/mm2. The addition of the Ca element was beneficial for producing more pinning inclusions in the experimental steel welding HAZ under the experimental conditions, and the inclusions were mainly elliptical oxide complex inclusions of Ca-Si with a size of about 2 μm. Meanwhile, Al2O3 and MnS were precipitated. After the addition of Ca elements, Mn-poor regions appeared around the inclusions containing Ca in the welding HAZ. IAF nucleation was mainly induced by the local compositional change mechanism and supplemented by the stress–strain energy mechanism and inert interface energy mechanism. This study provides a valuable reference for optimizing the welding process of pressure vessel steels and is of great importance for understanding the IAF nucleation mechanism of Ca-containing inclusions in the welding HAZ of pressure vessel steels.

1. Introduction

Pressure vessel steels refer to the special steels used to make pressure vessels [1]. It includes carbon steels and low-alloy high-strength steels. It is economical and convenient. In addition, it is an indispensable and important steel [2,3,4]. Low-heat-input welding is not sufficient for the production of pressure vessel steels because of its slow speed [5,6]. However, during high-wire-energy welding of pressure vessel steels, in the coarse-grained zone of the welding HAZ, the solid base metal usually has obvious microstructure coarsening and performance deterioration due to the influence of welding thermal cycling [7]. In order to solve the problem of decreasing strength and toughness of pressure vessel steel in high-heat-input welding production, many scholars around the world have carried out research on this problem, mainly focusing on the use of microalloying elements in oxide inclusions and refining the austenite grain size to obtain good toughness of the IAF microstructure as the main way to improve the toughness of the welding HAZ [8,9,10].

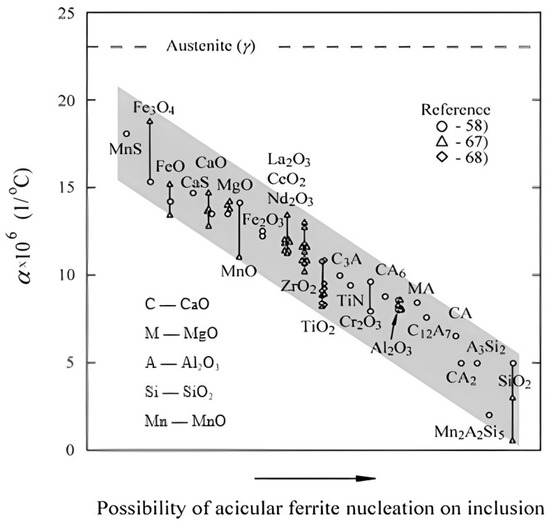

With the improvement in the welding energy input, the use of TiN and Ti oxides to improve the toughness of the welding HAZ is no longer suitable for actual production [11]. Therefore, by adding Ca elements, a sufficient number of micron-scale inclusions were introduced into the steels [12,13]. Elements such as Ca or micron-scale compound inclusions formed with other elements play a very beneficial role in inducing the nucleation and growth of the IAF microstructure in the welding HAZ. The IAF microstructure has the effect of inhibiting the rapid growth of cracks, which can improve the strength and toughness of the welding HAZ of pressure vessel steels [14,15,16]. There are four main mechanisms of IAF nucleation in the welding HAZ: minimum mismatch mechanism, stress–strain energy mechanism, local component change mechanism and inert surface mechanism [17,18]. The minimal mismatch mechanism suggests that smaller lattice mismatches between the inclusions and ferrite reduce the interfacial energy for ferrite nucleation, thus promoting IAF nucleation [19]. Wen et al. [20] found that Mg-containing inclusions have a strong ability to induce IAF nucleation. The mismatch rates for MgO and MgAl2O4 relative to ferrite were calculated to be 4.03% and 0.6%, respectively, at 1185 K. The minimal mismatch mechanism was inferred to be its nucleation mechanism. The stress–strain energy mechanism indicates that when welding with high wire energy, due to the different thermal expansion coefficients of the inclusions and the steel matrix, a large stress–strain field is easily formed around the inclusions in the HAZ, thus promoting IAF nucleation [21]. The relationship between the thermal expansion coefficient of the inclusions and the ability of the inclusions to induce IAF nucleation is shown in Figure 1, which indicates that the greater the difference in the thermal expansion coefficient between the austenite and the inclusions, the easier it is for the IAF to nucleate on the inclusions. The mechanism of local compositional changes is mainly applied to the study of titanium-containing steels at present. In the presence of Ti inclusions in steel, MnS, BN, TiN, etc., can easily precipitate on the surface of Ti2O3, forming a Mn-poor zone [22]. Mn is an austenite-forming element that enlarges the γ-phase region and increases the phase transformation driving force. Therefore, the presence of a Mn-depleted zone promotes the nucleation of IAF in the crystal [23]. The inert surface mechanism suggests that inclusions provide high-energy inert surfaces for IAF nucleation, reducing the nucleation barrier for the IAF microstructure [24]. This makes the surface of inclusions in a specific size range become the preferred site for their nucleation.

Figure 1.

Relative size of the thermal expansion coefficient of common inclusions and austenite [21].

The above four IAF nucleation mechanisms are basically inseparable from the action of inclusions. And one mechanism alone is often insufficient to fully explain the true nucleation process of IAF in the welding HAZ. Therefore, it is very unlikely that the IAF nucleation only has a separate mechanism of action, which should be the result of the combination of the above several mechanisms.

In this study, the effects of Ca elements on the inclusion characteristics (shape, composition, number density and size distribution) of the welding HAZ for pressure vessel steels were investigated. The mechanism of IAF nucleation induced by the inclusions containing Ca elements in the welding HAZ of pressure vessel steels was also investigated. Therefore, this article provides a valuable reference for optimizing the welding process of pressure vessel steels.

2. Materials and Methods

This experiment used the BJ-VIM-5 vacuum induction melting furnace (Dalunte Vaccum Technology, Shen Yang, China) to smelt experimental steel, as shown in Figure 2. The raw material was heated when the vacuum level was less than 1 × 10−2 Pa. Argon was used as a protective gas during the melting process. When the material was melted to boiling, Ca-Si alloy was added and stirred. After refining, pouring began and the casting mold was removed after 3 h of furnace cooling. The actual smelting chemical composition of the experimental steel is shown in Table 1.

Figure 2.

The BJ-VIM-5 vacuum induction melting furnace.

Table 1.

Actual melting chemical compositions of experimental steel.

In this experiment, the alkaline earth element Ca was added as a deoxidizer. According to the different mass fractions of Ca elements in the experimental steel, three groups of experimental steels were designed to be smelted, and 5 kg of each group was smelted. The designed addition amount (wt.%) of Ca for each group of experimental steels is shown in Table 2, where “R” represents the experimental steel with Ca addition amount of 0% and “C1”, “C3” and “C5” represent the experimental steels with Ca addition amounts of 1 wt.%, 3 wt.% and 5 wt.%, respectively.

Table 2.

Designed calcium contents of experimental steels.

The experimental steel billet was rolled on a hot rolling test machine with a roll diameter of 450 mm. After the rolling, the billet was placed on a self-made water-cooling equipment for cooling. In order to obtain and analyze the samples of the designated area of the welding HAZ with sufficient size, the method of welding thermal simulation was usually adopted. The dimensions of these samples were 10.5 mm × 10.5 mm × 55 mm.

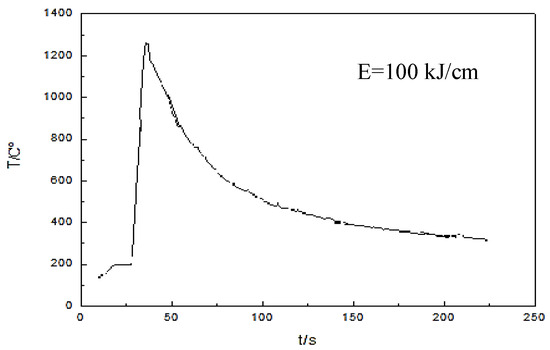

This experiment used the Gleeble-2000 welding thermal simulation test machine (DSI, St. Paul, MN, USA), as shown in Figure 3. The experimental steel was subjected to a welding heat input of 100 kJ/cm to simulate the double-wire and multi-wire welding of actual production. The welding thermal cycle curve at 100 kJ/cm is shown in Figure 4. The first step was to set the welding heat input and fix the sample. The second step was to preheat, and the temperature was set to 100 °C. The third step was to heat, and the heating speed was set to 200 °C/s. After 6 s, the peak temperature reached 1320 °C. The fourth step was to cool, the cooling time (t8/5) was set to 80 s and t8/5 represents the time required to cool from 800 °C to 500 °C. The sample was gradually cooled from 500 °C to room temperature.

Figure 3.

The Gleeble-2000 welding thermal simulation test machine.

Figure 4.

The curve of welding thermal circulation.

The HAZ inclusions were observed using a metallographic microscope. According to GB/T10561-2005 “Steel-Determination of content of nonmetallic inclusions-Micrographic method using standards diagrams”, Image-Pro Plus 6.0 professional image analysis software was used to carry out two-dimensional analysis of the number density, size and distribution of inclusions in the welding HAZ of each experimental steel. The shapes and compositions of the inclusions in the experimental steel welding HAZ were observed and analyzed using the S-4800 SEM (Hitachi, Tokyo, Japan) and the supporting energy spectrum analyzer (EDS) (Hitachi, Tokyo, Japan). The accelerating voltage of the SEM was 0.5–30 KV and it had a resolution of 1.0 nm (15 KV).

3. Results

3.1. Analysis of Inclusions in the Welding HAZ of Experimental Steel

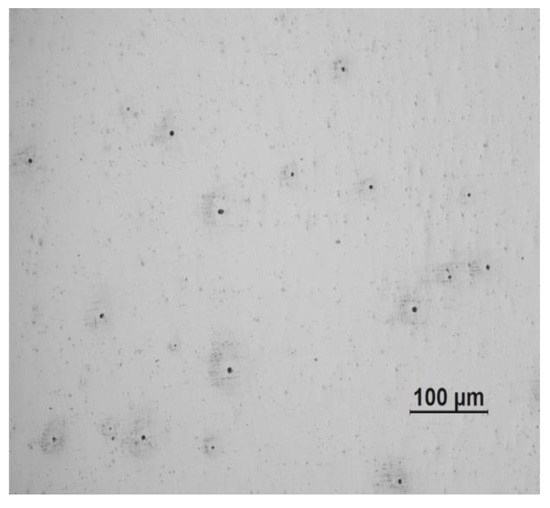

The metallographic specimens were magnified 100 times by using a metallographic microscope and the number density and distribution of inclusions were observed, the result is shown in Figure 5. Combined with the results of related studies [10,21,22], it was necessary to reduce the unavoidable statistical errors due to the shape of the inclusions in order to more accurately reflect the effect of inclusions on the welding HAZ of the material. In this experiment, the method of measuring the area of inclusions was specifically adopted and used as a basis for classifying the sizes of the inclusions. The size distribution of the inclusions in the experimental steels is shown in Table 3.

Figure 5.

Distribution of inclusions in welding HAZ of experimental steels with added Ca.

Table 3.

The number density of inclusions of different sizes in the HAZ of experimental steels.

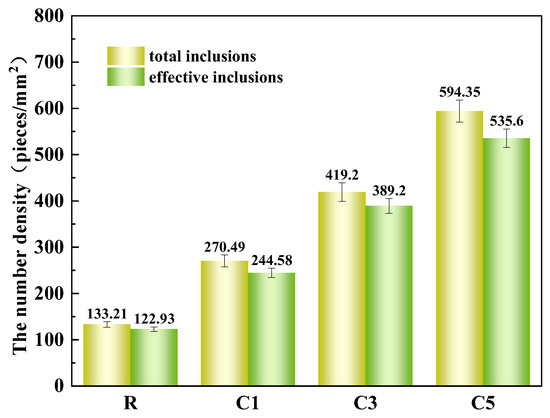

The addition of Ca promoted the formation of fine inclusions in the experimental steel welding HAZ to a certain extent. Combined with the results of related studies [25,26], it was found that when the area of the inclusion was less than 5 μm2, the diameter of the inclusion was generally less than 2.5 μm, which was the most suitable inclusion size to pin the grain boundary and induce IAF nucleation. They were called effective inclusions. The change trend of the number density of the inclusions and the effective inclusions of each experimental steel are shown in Figure 6. With the increase in Ca, the number density of inclusions and the number density of effective inclusions in the experimental steel welding HAZ increased continuously. The total number density and the number density of effective inclusions of R steel were the lowest, which were 133.21 pieces/mm2 and 122.93 pieces/mm2, respectively. In the welding HAZ of the experimental steel with 5 wt.% Ca added, the number density of inclusions was the largest, with 594.35 pieces/mm2, and the number density of effective inclusions was also the largest, with 535.60 pieces/mm2.

Figure 6.

The number density of total inclusions and effective inclusions in the experimental steel welding HAZ.

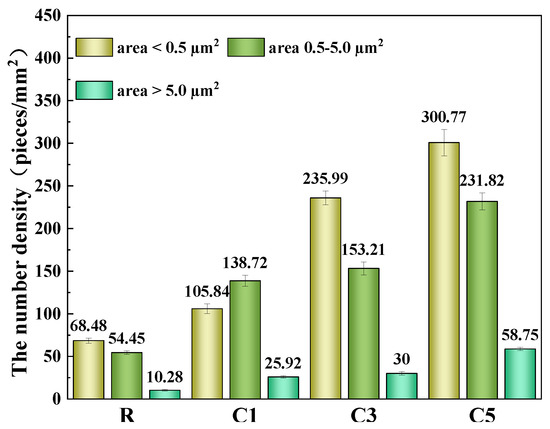

The above only discusses the number density of inclusions and effective inclusions. In order to more specifically reflect the influence of the inclusions on the welding HAZ in each experiment, the inclusions were classified according to their different effects in different size ranges. When the area of the inclusion was less than 0.5 μm2, the diameter of the inclusion was generally less than 8 nm. These nanoscale inclusions can play the role of pinning grain boundaries and inhibit grain growth and coarsening in the welding HAZ. When the area of the inclusion was 0.5~5 μm2, its diameter was generally 0.8~2.5 μm. These micron-scale inclusions were the most suitable size for inducing IAF nucleation. The more of the IAF microstructure there was in the welding HAZ, the better the strength and toughness. When the area of the inclusion was greater than 5 μm2, its diameter was generally larger than 2.5 μm. These larger-sized inclusions were not very effective at pinning the grain boundaries and inducing IAF nucleation. Therefore, the number density of the inclusions of this size in the experimental steel welding HAZ should be minimized. The distribution of inclusions with different effects per unit area in the HAZ of each experimental steel is shown in Figure 7.

Figure 7.

Distribution of inclusions with different effects per unit area in HAZ of each experimental steel.

As shown in Figure 7, since the number density of inclusions was the least in the raw material steel welding HAZ, the number density of inclusions that played the role of pinning and inducing IAF nucleation was the least, with only 68.48 pieces/mm2. As a result, the raw material steel had poor strength and toughness. In the three experimental steels with the Ca element, the number density of inclusions that played the role of pinning and inducing IAF nucleation gradually increased and was obviously higher than that of the raw steel. Among them, 105.84 pieces/mm2, 235.99 pieces/mm2 and 300.77 pieces/mm2 inclusions with an area less than 0.5 μm2 were found in the C1, C3 and C5 steels, respectively. The number density of pinning inclusions in the welded HAZ of the experimental steel with 1 wt.% Ca was less than the number density of inclusions for inducing IAF nucleation. In the other two groups of experimental steel with Ca elements, the inclusions were mainly used for pinning. In conclusion, the addition of the Ca element facilitated the production of more inclusions that acted to provide pinning in the experimental steel welding HAZ under the experimental conditions.

3.2. EDS Analysis of the Main Inclusion Composition

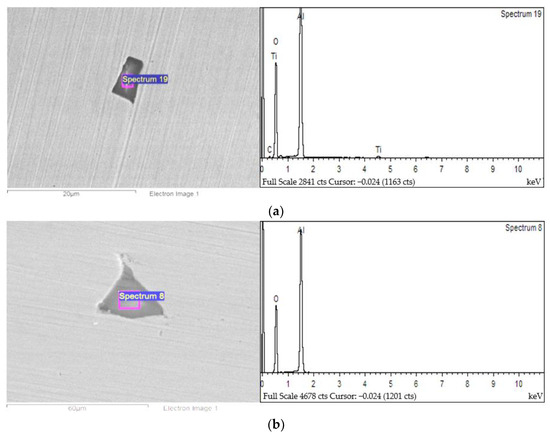

The main inclusions of the experimental steel welding HAZ with Ca were found during the shape observation and composition analysis. The results are shown in Figure 8.

Figure 8.

The main inclusion composition of HAZ in each experimental steel: (a,b) are raw steel, while (c,d) are Ca-added steels.

As shown in Figure 8a,b, the main inclusion in the welding HAZ of raw steel was the oxide inclusion of Ti or Al elements, and it had a very irregular shape, large size, and irregular quadrangles with edges or even triangular angles. The oxide of Al(Al2O3) was prone to accumulate in steel fluid to form coarse inclusions. This inclusion had no induction effect on the IAF, and it easily formed cracks during processing, which damaged the toughness of the welding HAZ of the material to a certain extent and was an undesirable inclusion. As shown in Figure 8c,d, the inclusions in the experimental steel welding HAZ with the Ca element added as a deoxidant were mainly the oxygen-sulfide inclusions of Ca and Mn. Because the Ca element of the alkaline earth metal caused a spheroidizing effect, combined with the results shown in Figure 8d, the oxygen-sulfide shape of the inclusion Ca was generally elliptical or spherical. Such a shaped inclusion was conducive to the nucleation and growth of ductile IAF microstructure.

The alkaline earth metal Ca element made the shape of the inclusion mostly spherical, with a size of about 2 μm, which was in the most suitable size range of inclusions for the IAF nucleation, as described above. Moreover, there were more inclusions of this size in the experimental steel welding HAZ, and thus, the amount of IAF nucleation was also greater.

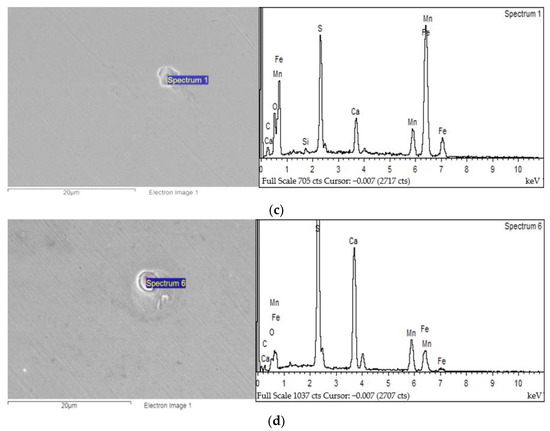

4. Discussion

4.1. The Effect of Adding Ca on the Welding HAZ of Experimental Steels

The morphology and line scan analysis of typical inclusions in the welding HAZ of experimental steels with Ca are shown in Figure 9. It was observed that the total mass fractions of the Ca and S elements were equivalent, and the contents of both elements increased significantly in the central area of the inclusion line scanning. Al and O elements were the most abundant and concentrated in the area left of the center. The change rule of Mn content was similar to that of Ca and S, and the content was more in the center of the inclusions. The content of the Si element varied little in the inclusions. Therefore, it can be seen that the basic morphology of the inclusions was as follows: the complex oxysulfide containing mainly (Ca-Mn-Si) was formed in the center, while the oxides containing Al were precipitated on the side left of the center. Under the condition of line scanning, the typical inclusions in the welding HAZ of experimental steel with the Ca element added were elliptical Ca-Si complex oxide inclusions. Meanwhile, Al2O3 and MnS were precipitated to the left and center of the inclusions, respectively.

Figure 9.

Typical inclusion morphology and line scanning results of Ca-added steel.

By observing the morphology and line scanning results of the typical inclusions in the welding HAZ of the experimental steel with the Ca addition, it was found that, first, from the morphology of the inclusions, spherical or nearly spherical inclusions were produced. The reason was that the spheroidization of alkaline earth metal Ca elements changed the morphology of the inclusions in the welding HAZ of each experimental steel. Second, from the line-scanning distribution of the elements in the inclusions, Ca elements generally compounded with other elements to form complex inclusions.

4.2. The Mechanism of IAF Nucleation Induced by Ca Elements in Welding HAZ

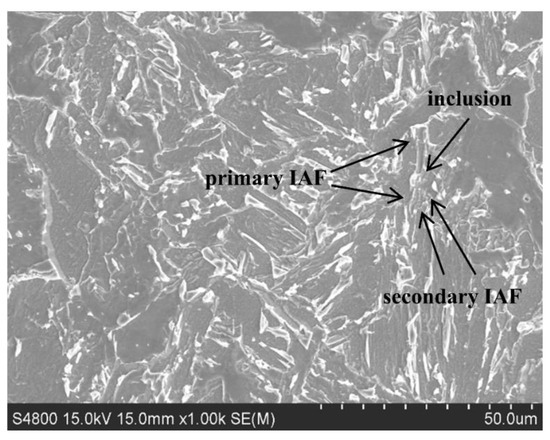

Metallographic specimens from the HAZ of the experimental steel with added calcium were corroded by the 4% alcoholic solution of nitric acid; a typical IAF microstructure induced by the fine circular inclusions is shown in Figure 10.

Figure 10.

Typical microstructure of IAF in experimental steel welding HAZ.

The addition of the Ca element could promote the spheroidization of the inclusions. The complex inclusions containing the Ca element could effectively induce the IAF nucleation. It can be clearly seen from Figure 10 that starting from the inclusion position, it radiated in both upward and downward phases, forming two “coarse” primary IAF microstructures. The figure continues to indicate the formation of a secondary IAF microstructure through an inductive nucleation mode of the primary IAF microstructure. The relatively “thick” primary IAF microstructure was the main trunk, and at the same time, many branch IAF microstructures continued to be induced on the main trunk. This was the refinement effect of the IAF microstructure itself. A large number of IAF microstructures were interlaced and firmly combined with each other, which played a role in improving the strength and toughness of experimental steel welding HAZ.

4.2.1. IAF Nucleation Mechanism Induced by Minimum Mismatch

The inclusions that promoted the IAF nucleation were affected by the interface energy of themselves or between the precipitates and the ferrite, and the interface energy between them was determined by the lattice mismatch. The study showed that the inclusions with a good coherent relationship with the IAF microstructure or the precipitates on inclusions could effectively reduce the interface energy between the inclusions and ferrite and promote the IAF nucleation [27,28,29]. The lattice mismatches between the inclusions and ferrite in the experimental steel are shown in Table 4.

Table 4.

Lattice mismatches between inclusions and ferrite in experimental steel [30,31,32].

As shown in Table 4, there was a good coherent relationship between the inclusions of some body-centered cubic microstructures, such as MnS, and the ferrite. The lattice mismatch was small, which was beneficial for becoming the core of the IAF nucleation and promoting the formation of the IAF microstructure in the welding HAZ. The lattice mismatch between the CaO inclusion and ferrite was large in this experimental steel, about 16%. The CaO inclusion itself did not have the conditions to apply the minimum mismatch mechanism to induce the IAF nucleation. Therefore, the inclusions containing the Ca element in this experiment should induce IAF nucleation via other mechanisms.

4.2.2. IAF Nucleation Mechanism Induced by Stress–Strain Energy

The average thermal expansion coefficient of the inclusions was small and the thermal expansion coefficient of the austenite matrix was relatively large during the high-heat-input welding. Thus, a stress–strain field was formed around the inclusions, causing a certain degree of distortion. The resulting distortion could provide activation energy to induce the IAF nucleation. Research data [33] show that, as shown in Table 5, the average thermal expansion coefficient of austenite is 23.0 × 10−6 K−1, while that of CaO is 13.5 × 10−6 K−1, which is close to only half that of austenite. Therefore, a large stress–strain field was generated around the inclusions to provide power for the IAF nucleation. However, it is also considered that the energy required for ferrite nucleation is often 1 to 2 orders of magnitude larger than the activation energy generated only by thermal expansion differences. Therefore, the stress–strain energy only existed as an auxiliary mechanism to induce the IAF nucleation in the welding HAZ of the experimental steel with the Ca element added.

Table 5.

Contrast of the average thermal expansion coefficients.

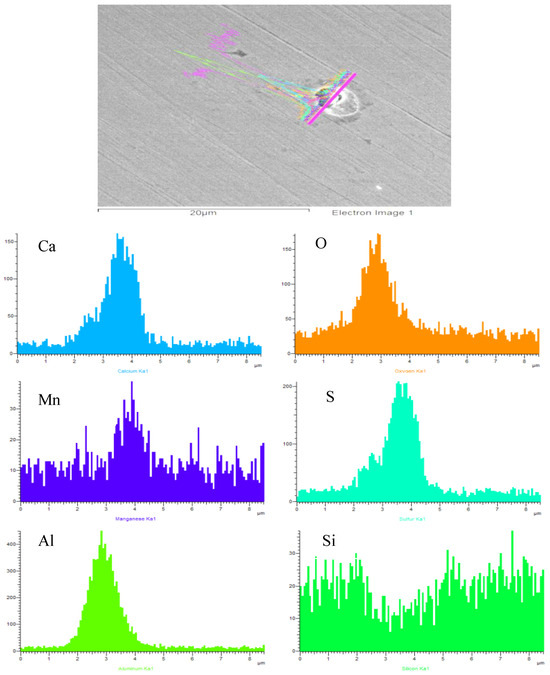

4.2.3. IAF Nucleation Mechanism Induced by Local Composition Change

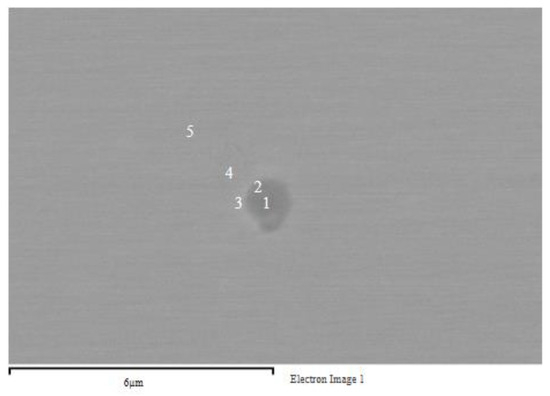

The solute elements in steel, such as Mn, were poor around the inclusions. Their contents were significantly reduced within a certain range around the inclusions and a Mn-poor zone was formed, resulting in the local composition changes and inducing the IAF nucleation [34,35,36]. The inclusion point analysis of the welding HAZ in added-Ca steel is shown in Figure 11. The chemical composition point analysis results of the inclusions in the welding HAZ in added-Ca steel are shown in Table 6.

Figure 11.

Inclusion point analysis of welding HAZ in Ca-added steels (1 is located at the center, 2 is located at the outer center, 3 is at the edge, 4 is closer to the outside, 5 is the matrix).

Table 6.

Inclusion chemical composition point analysis results of welding HAZ in Ca-added steel.

As shown in Figure 11, position 1 was located at the center of the circular inclusion and position 2 was located at the outer center. It can be seen from Table 6 that the contents of Mn at positions 1 and 2 were 4 to 5 times higher than that at position 5 of the matrix, which indicates that Mn was enriched in the inclusions. Position 3 was at the edge of the inclusion, and the content of Mn here was reduced. Position 4 was closer to the outside of the inclusion, and the Mn content here decreased significantly to only 0.82%, which was about 50% of the Mn content in the matrix. Therefore, it can be concluded that there was a Mn-poor phenomenon around the Ca-containing inclusions, which increased the driving force of the IAF nucleation. This can be used as a mechanism to induce IAF nucleation in the welding HAZ of steel containing Ca.

4.2.4. IAF Nucleation Mechanism Induced by Inert Interface Energy

Ricks et al. [37] suggested that the surface of the inclusions in steel acts as an inert interface and provides energy to induce the IAF nucleation. The interface between the inclusions and the matrix plays a role in reducing the nucleation barrier of the IAF, which is only related to the number density and size of the inclusions, and has nothing to do with their composition. In this experiment, a large number of small spherical inclusions formed by the addition of the Ca element were dispersed in the welding HAZ, which could partly provide a high-energy inert surface for the IAF nucleation to a certain extent. It could reduce the IAF nucleation barrier and promote the IAF nucleation.

Related studies [38,39] showed that the inert interface energy of complex inclusions with the diameters of 0.5–2.0 μm is about 105–106 J/mol, which is close to the minimum energy required to induce the IAF nucleation (about 106 J/mol). However, relying solely on the inert interface energy mechanism is not sufficient to fully explain the nucleation mechanism of the IAF microstructure.

5. Conclusions

- (1)

- With the increase in the Ca element, the number density of inclusions and effective inclusions in the experimental steel welding HAZ showed an increasing trend. The experimental steel welding HAZ with 5 wt.% Ca added had the highest inclusion number density of 594.35 pieces/mm2. And this steel also had the highest effective number density of inclusions, which was 535.60 pieces/mm2.

- (2)

- In the three experimental steels with Ca elements, the number density of inclusions that played the role of pinning and inducing IAF nucleation gradually increased and was obviously higher than that of the raw steel. The addition of the Ca element was beneficial to produce more pinning inclusions in the welding HAZ of the experimental steel under the experimental conditions.

- (3)

- The inclusions in the welding HAZ of experimental steel with the Ca element added were mainly elliptical oxide complex inclusions of Ca-Si with a size of about 2 μm. Meanwhile, Al2O3 and MnS were precipitated to the left and center of the inclusions, respectively. The inclusions with such shapes and sizes were conducive to the nucleation and growth of the ductile IAF microstructure.

- (4)

- After the addition of the Ca elements, a Mn-poor zone appeared around the inclusions containing Ca in the welding HAZ. IAF nucleation was induced mainly by a local compositional change mechanism, supplemented by stress–strain energy and inert interface energy mechanisms.

Author Contributions

Conceptualization, Y.L. and B.L.; methodology, Y.L., B.L. and K.W.; software, B.L., K.W. and A.D.; validation, Y.L.; formal analysis, B.L., K.W. and A.D.; investigation, Y.L., B.L. and K.W.; resources, Y.L.; data curation, B.L. and A.D.; writing—original draft preparation, Y.L. and B.L.; writing—review and editing, Y.L., B.L., K.W. and A.D.; visualization, K.W.; supervision, Y.L. and B.L.; project administration, Y.L.; funding acquisition, Y.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Support Program for Liaoning Province Natural Science Foundation Project (2023-MS-320).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

We sincerely appreciate the support provided by Shenyang University in the preparation of this manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zondi, M.C. Factors that affect welding-induced residual stress and distortions in pressure vessel steels and their mitigation techniques: A review. J. Press. Vessel. Technol. 2014, 136, 040801. [Google Scholar] [CrossRef]

- Xie, F.; Wu, X.; Zhang, H.; Zhang, X. Research on pulsed eddy current automatic detection technology for weld defects of pressure vessel cylinder. Measurement 2021, 176, 109081. [Google Scholar] [CrossRef]

- Sánchez, M.; Cicero, S.; Arroyo, B.; Arrieta, S. Master curve evaluation of ANP-5 steel using mini-CT specimens. Procedia Struct. Integr. 2022, 42, 218–223. [Google Scholar] [CrossRef]

- Vasileiou, A.N.; Smith, M.C.; Francis, J.A.; Balakrishnan, J.; Wang, Y.L.; Obasi, G.; Burke, M.G.; Pickering, E.J.; Gandy, D.; Irvine, N.M. Development of microstructure and residual stress in electron beam welds in low alloy pressure vessel steels. Mater. Design. 2021, 209, 109924. [Google Scholar] [CrossRef]

- Mesbah, M.; Fadaeifard, F.; Nasiri-Tabrizi, B.; Matori, K.A.; Basirun, W.J. The impacts of grain boundary on the scattering of intermetallics in friction-stir-welded AA6061-T6. Mater. Lett. 2021, 300, 130206. [Google Scholar] [CrossRef]

- Shen, Y.; Leng, J.; Wang, C. On the heterogeneous microstructure development in the welded joint of 12MnNiVR pressure vessel steel subjected to high heat input electrogas welding. J. Mater. Sci. Technol. 2019, 35, 1747–1752. [Google Scholar] [CrossRef]

- Liu, J.; Wang, J.; Hu, F.; Fu, K.; Zhang, Z.; Wu, Y. Effects of Ti/N Ratio on Coarse-Grain Heat-Affected Zone Microstructure Evolution and Low-Temperature Impact Toughness of High Heat Input Welding Steel. Coatings 2023, 13, 1347. [Google Scholar] [CrossRef]

- Barrick, E.J.; DuPont, J.N. The influence of martensitic microstructure and oxide inclusions on the toughness of simulated reheated 10 wt% Ni steel weld metal multi-pass fusion zones. Mat. Sci. Eng. A 2021, 801, 140336. [Google Scholar] [CrossRef]

- Šebestová, H.; Horník, P.; Mrňa, L.; Doležal, P. Microstructure and mechanical properties of hybrid LasTIG welds of HSLA steel. Procedia CIRP 2018, 74, 743–747. [Google Scholar] [CrossRef]

- Liu, C.; Yan, L.; Xiao, H.; Wang, K. Microstructure and mechanical properties of wire-fed arc-based directed energy deposition of high-strength steel after ultrasonic impact oxidation treatment. J. Manuf. Process. 2023, 85, 179–191. [Google Scholar] [CrossRef]

- Zhang, K.; Li, Z.; Wang, Z.; Sun, X.; Yong, Q. Precipitation behavior and mechanical properties of hot-rolled high strength Ti–Mo-bearing ferritic sheet steel: The great potential of nanometer-sized (Ti, Mo) C carbide. J. Mater. Res. 2016, 31, 1254–1263. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, J.; Xu, L.; Qiu, Y.; Cheng, G.; Yao, M.; Dong, J. The effect of Ca content on the formation behavior of inclusions in the heat affected zone of thick high-strength low-alloy steel plates after large heat input weldings. Metals 2019, 9, 1328. [Google Scholar] [CrossRef]

- Zhou, M.; Sun, Y.; Morisada, Y.; Shi, Q.; Fujii, H. The material flow and texture-weakening mechanism in double-sided friction stir welded Mg alloy. Sci. Technol. Weld. Join. 2023, 28, 154–161. [Google Scholar] [CrossRef]

- Mohseni, P.; Solberg, J.K.; Karlsen, M.; Akselsen, O.M.; Østby, E. Cleavage fracture initiation at M—A constituents in intercritically coarse-grained heat-affected zone of a HSLA steel. Metall. Mater. Trans. A 2014, 45, 384–394. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, J.; Du, H.; Zhang, Y.; Ma, H. Effect of Ca deoxidation on toughening of heat-affected zone in high-strength low-alloy steels after large-heat-input welding. Metals 2022, 12, 1830. [Google Scholar] [CrossRef]

- Lei, X.; Dong, S.; Huang, J.; Yang, J.; Chen, S.; Zhao, X. Phase evolution and mechanical properties of coarse-grained heat affected zone of a Cu-free high strength low alloy hull structure steel. Mater. Sci. Eng. A 2018, 718, 437–448. [Google Scholar] [CrossRef]

- Zhao, H.; Hu, S.; Wu, H.; Li, T. Research on mechanism of nucleation of intra-granular ferrite in welding heat affected zone of magnesium treated high-grade pipeline steel. Iron Steel 2010, 45, 82–85. [Google Scholar]

- Zhang, Z.; Farrar, R.A. Role of non-metallic inclusions in formation of acicular ferrite in low alloy weld metals. Mater. Sci. Technol. 2013, 12, 237–260. [Google Scholar] [CrossRef]

- Jin, H.; Shim, J.H.; Cho, Y.W.; Lee, H.C. Formation of intragranular acicular ferrite grains in a Ti-containing low carbon steel. ISIJ Int. 2003, 43, 1111–1113. [Google Scholar] [CrossRef]

- Wen, B.; Song, B. In situ observation of the evolution of intragranular acicular ferrite at Mg-containing inclusions in 16Mn steel. J. Manuf. Sci. Prod. 2013, 13, 61–72. [Google Scholar] [CrossRef]

- Sarma, D.S.; Karasev, A.V.; Jonsson, P.G. On the role of non-metallic inclusions in the nucleation of acicular ferrite in steels. ISIJ Int. 2009, 49, 1063–1074. [Google Scholar] [CrossRef]

- Xiong, Z.; Liu, S.; Wang, X.; Shang, C.; Misra, R. Relationship between crystallographic structure of the Ti2O3/MnS complex inclusion and microstructure in the heat-affected zone (HAZ) in steel processed by oxide metallurgy route and impact toughness. Mater. Charact. 2015, 106, 232–239. [Google Scholar] [CrossRef]

- Yang, J.; Cai, W. Eeffect of magnesium treatment on inclusions and HAZ microstructure and properties of steel plate. Iron Steel 2021, 56, 13–24. [Google Scholar]

- Meng, X.; Wang, W.; Bi, S.; Li, Y. Research on IAF nucleation behavior induced by Ce/Ce-Zr inclusion inhigh strength steel plate for shipbuilding. Iron Steel Vanadium Titan. 2022, 43, 146–151. [Google Scholar]

- Tanaka, Y.; Pahlevani, F.; Kitamura, S.; Privat, K.; Sahajwalla, V. Behaviour of sulphide and Non-alumina-based oxide inclusions in Ca-treated high-carbon steel. Metall. Mater. Trans. B 2020, 51, 1384–1394. [Google Scholar] [CrossRef]

- Li, X.; Wang, D.; Liu, C.; Jiang, M. Effects of Mg-Zr combined treatment on characteristics of inclusions in FH40 ship building steel ingots. J. Northeast Univ. (Nat. Sci.) 2014, 35, 529. [Google Scholar]

- Wan, X.; Wu, K.; Huang, G.; Wei, R. In Situ Observations of the Formation of Fine-Grained Mixed Microstructures of Acicular Ferrite and Bainite in the Simulated Coarse-Grained Heated-Affected Zone. Steel Res. Int. J. 2014, 85, 243–250. [Google Scholar] [CrossRef]

- Farrar, R.; Harrison, P. Acicular ferrite in carbon-manganese weld metals: An overview. J. Mater. Sci. 1987, 22, 3812–3820. [Google Scholar] [CrossRef]

- Wu, K.; Inagawa, Y.; Enomoto, M. Three-dimensional morphology of ferrite formed in association with inclusions in low-carbon steel. Mater. Charact. 2004, 52, 121–127. [Google Scholar] [CrossRef]

- Ohkita, S.; Horii, Y. Recent development in controlling the microstructure and properties of low alloy steel weld metals. ISIJ Int. 1995, 35, 1170–1182. [Google Scholar] [CrossRef]

- Huang, Q.; Wang, X.; Jiang, M.; Hu, Z.; Yang, C. Effects of Ti–Al complex deoxidization inclusions on nucleation of intragranular acicular ferrite in C–Mn steel. Steel Res. Int. 2016, 87, 445–455. [Google Scholar] [CrossRef]

- SA, D. Inclusion formation and microstructure evolution in low alloy steel welds. ISIJ Int. 2002, 42, 1344–1353. [Google Scholar]

- Zhang, S.; Hattori, N.; Enomoto, M.; Tarui, T. Ferrite nucleation at ceramic/austenite interfaces. ISIJ Int. 1996, 36, 1301–1309. [Google Scholar] [CrossRef]

- Zhou, W.; Zhu, J.; Zhang, Z. Austenite grain growth behaviors of La-microalloyed H13 steel and its effect on mechanical properties. Metall. Mater. Trans. A 2020, 51, 4662–4673. [Google Scholar] [CrossRef]

- Yuan, X.; Wang, G. Modeling interfacial evolutions at atomistic scale in the process of titanium oxide inducing ferrite nucleation in steels. Cryst. Growth Des. 2022, 22, 4059–4071. [Google Scholar] [CrossRef]

- Jia, X.; Chen, Y.; Li, H.; Yang, Y.; Wang, B.; Wang, B. Study on the mechanism of AF nucleation induced by complex oxide inclusions after LF refining in oxide metallurgical steel. Mater. Charact. 2023, 204, 113239. [Google Scholar] [CrossRef]

- Park, S.; Lee, K.; Min, K.; Kim, M.; Lee, B. Influence of the thermodynamic parameters on the temper embrittlement of SA508 Gr. 4N Ni–Cr–Mo low alloy steel with variation of Ni, Cr and Mn contents. J. Nucl. Mater. 2012, 426, 1–8. [Google Scholar] [CrossRef]

- Ricks, R.; Howell, P.; Barritte, G. The nature of acicular ferrite in HSLA steel weld metals. J. Mater. Sci. 1982, 17, 732–740. [Google Scholar] [CrossRef]

- Lee, T.; HJ, K. Effect of inclusion size on the nucleation of acicular ferrite in welds. ISIJ Int. 2000, 40, 1260–1268. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).