Structural Transformations on the Surface of Al-Ti Cathodes Subjected to Vacuum Arc Heating

Abstract

:1. Introduction

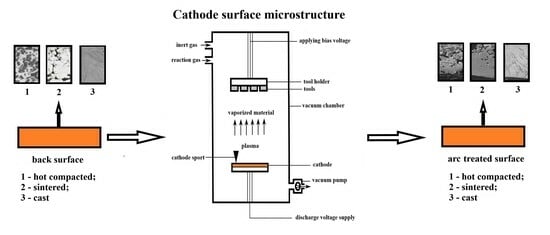

2. Materials and Experimental Technique

3. Results

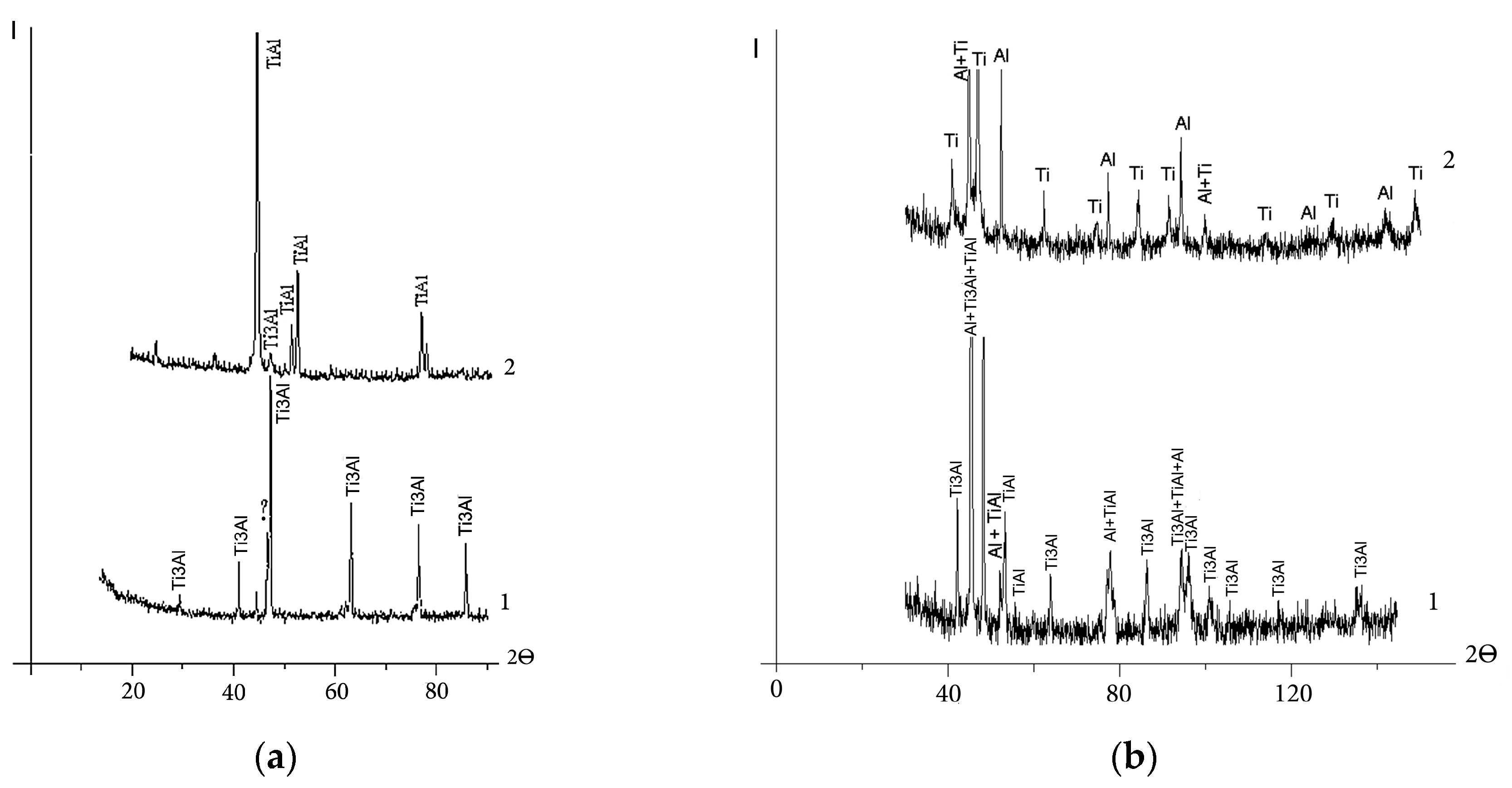

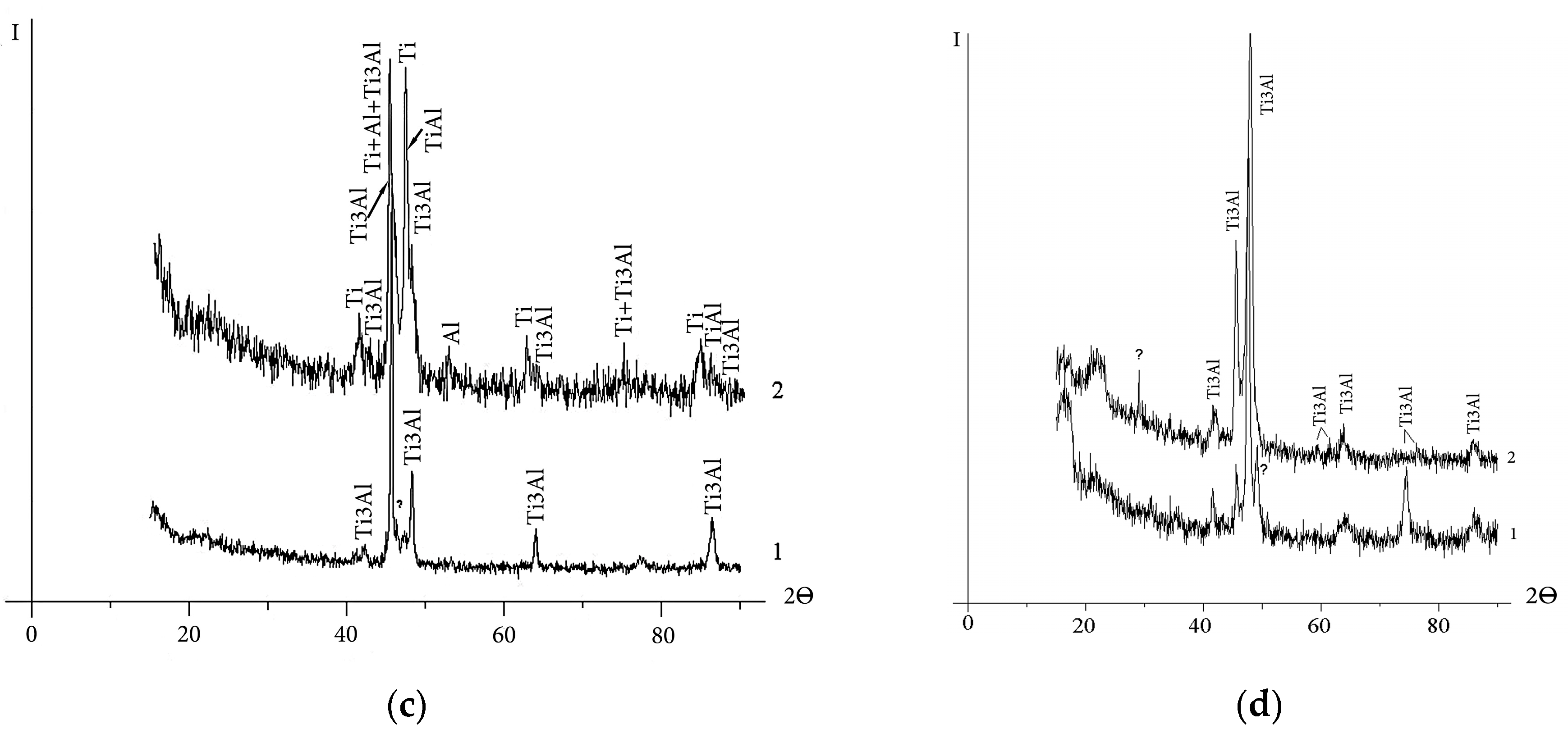

3.1. Starting Structural State of Cathodes

3.2. Structural-Phase State of Arc Modified Surface Layer of the Cathodes

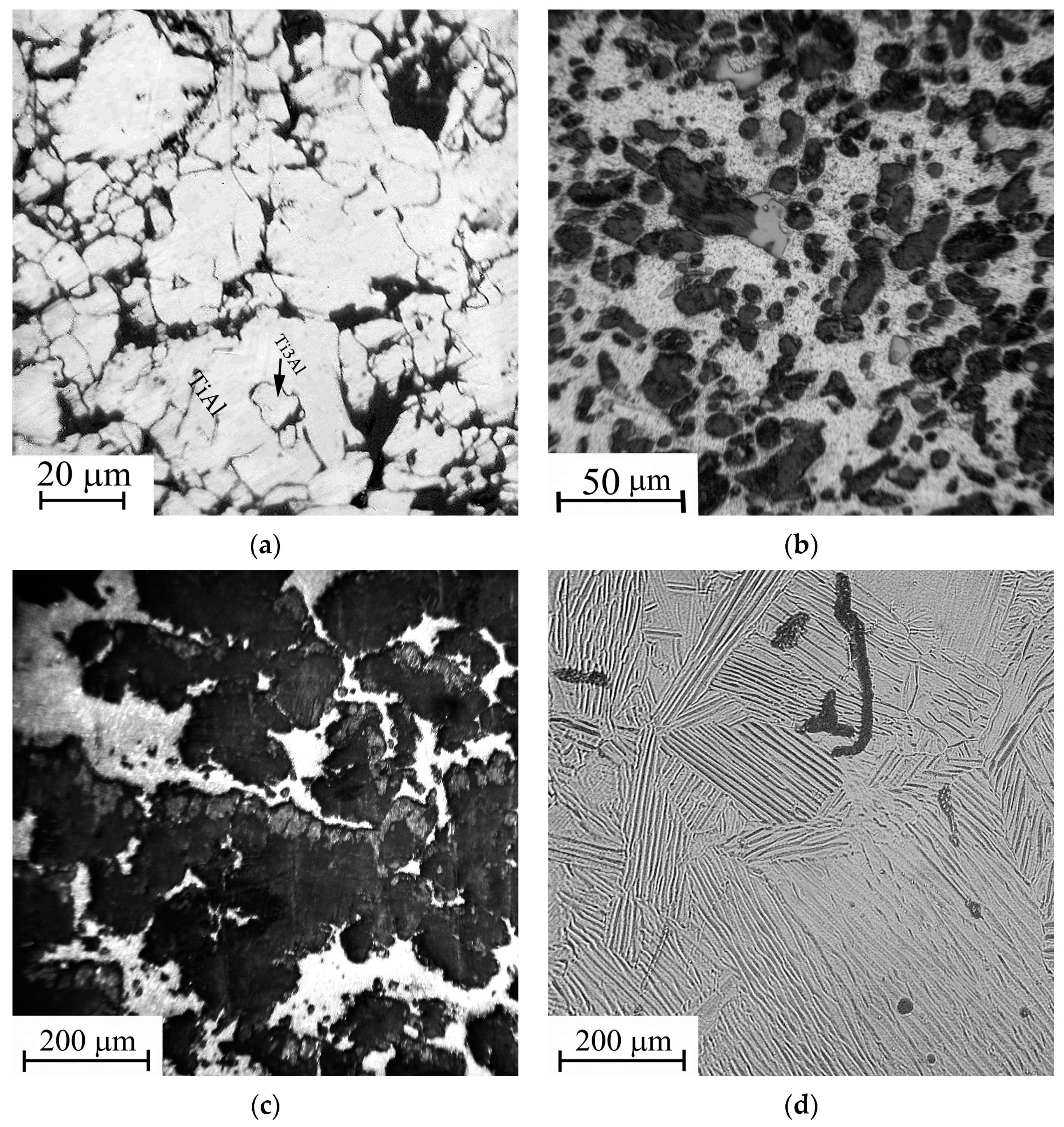

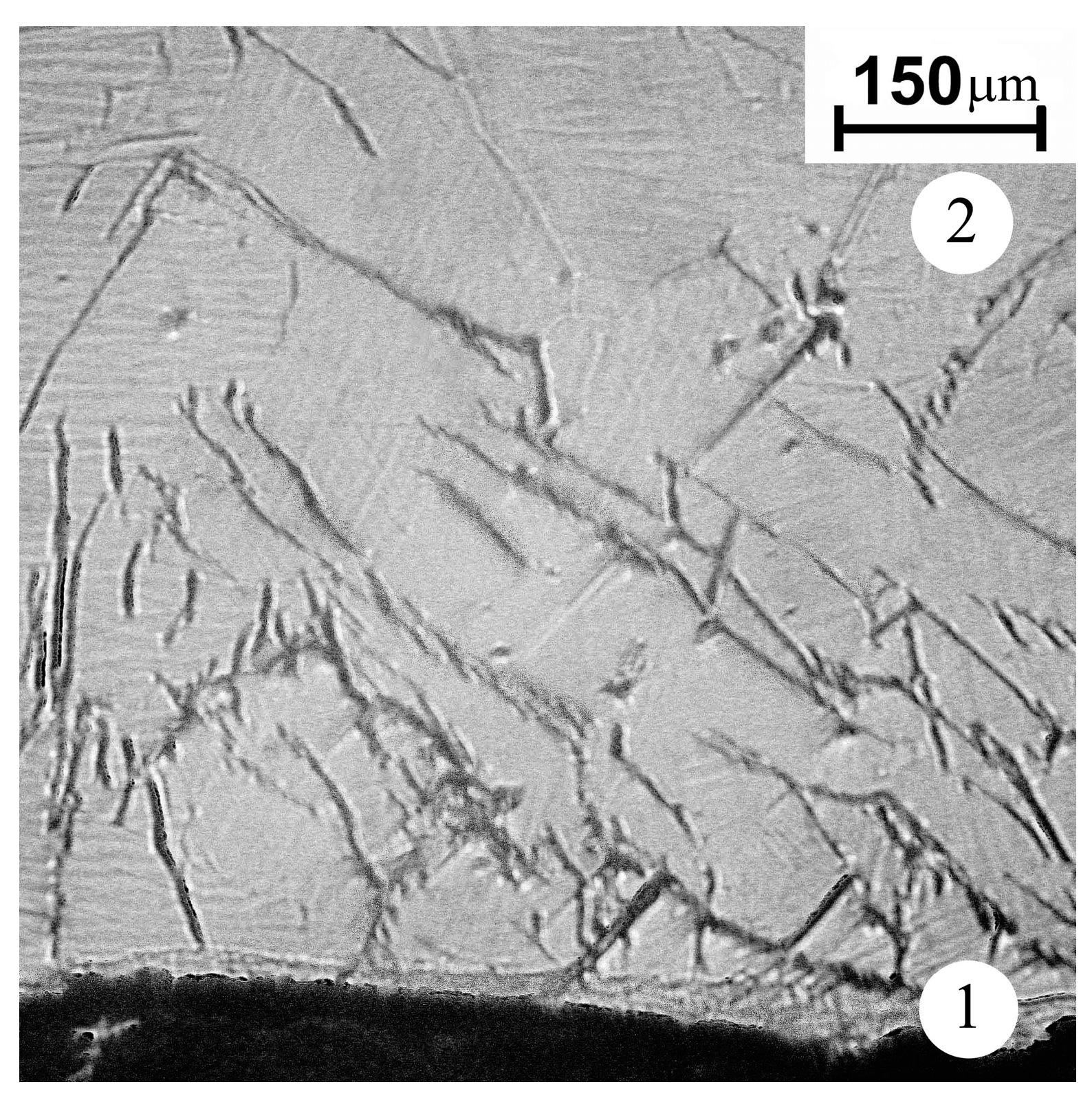

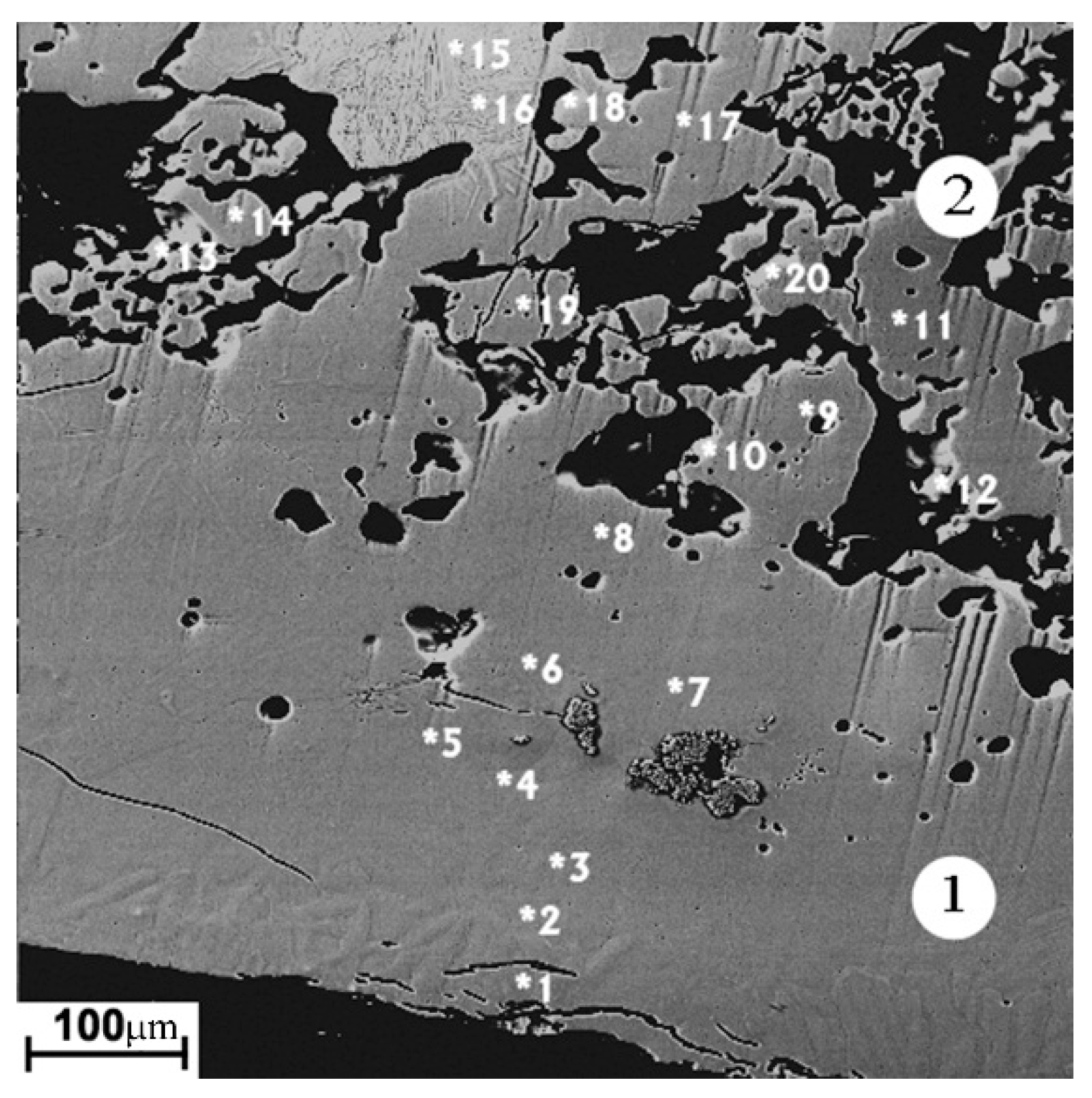

3.2.1. Cast Cathode No. 4

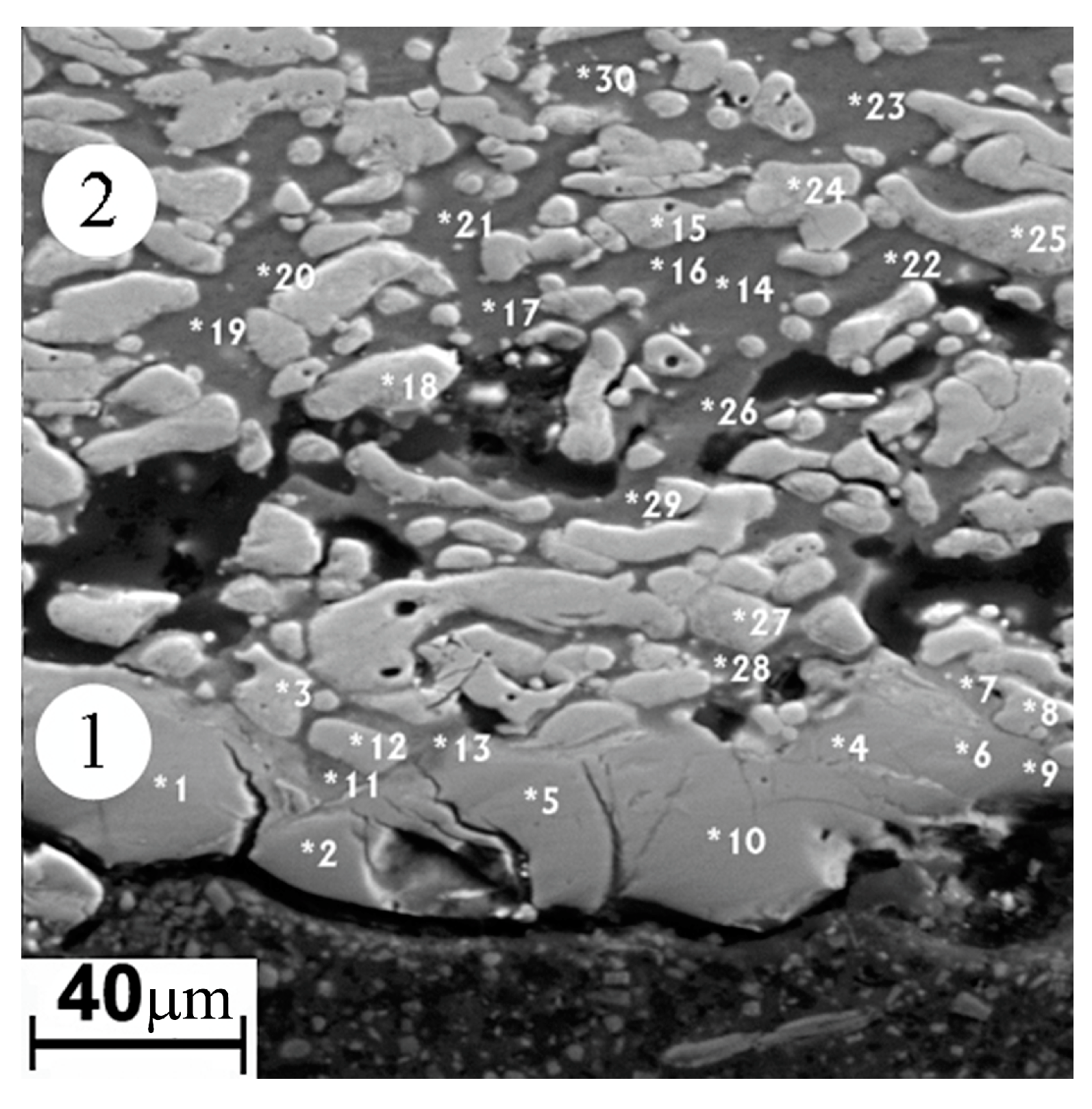

3.2.2. Sintered Cathode No. 1

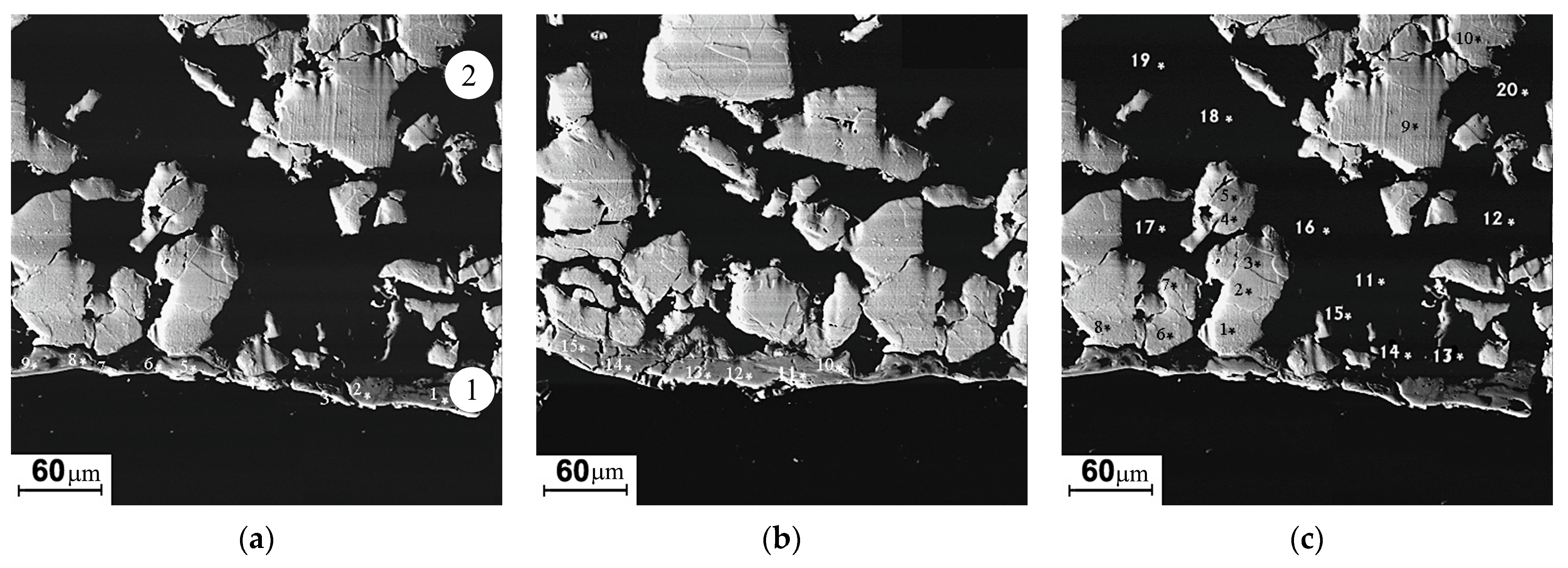

3.2.3. Cathode No. 2, “Polema”

3.2.4. Cathode No. 3, “Umicore”

4. The Discussion of the Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Coll, B.F.; Sanders, D.M. Design of vacuum arc-based sources. Surf. Coat. Technol. 1996, 81, 42–51. [Google Scholar] [CrossRef]

- Sanchette, F.; Ducros, C.; Schmitt, T.; Steyer, P.; Billard, A. Nanostructured hard coatings deposited by cathodic arc deposition: From concepts to applications. Surf. Coat. Technol. 2011, 205, 5444–5453. [Google Scholar] [CrossRef]

- Veprek, S.; Veprek-Heijman, M.G.J.; Karvankova, P.; Prochazka, J. Different approaches to superhard coatings and nanocomposites. Thin Solid Films 2005, 476, 1–29. [Google Scholar] [CrossRef]

- Nurnberg, A.W.; Fang, D.Y.; Bauder, U.H. Temperature dependence of the erosion of Al and TiC by vacuum arcs in a magnetic field. J. Nucl. Mater. 1981, 103–104, 305–308. [Google Scholar] [CrossRef]

- Pribytkov, G.; Korzhova, V.; Korosteleva, E.; Krinitcyn, M. Effect of Silicon on the Surface Modification of Al-Cr Powder Cathodes Subjected to Vacuum Arc Treatment. Coatings 2022, 12, 958. [Google Scholar] [CrossRef]

- Rafaja, D.; Polzer, C.; Schreiber, G.; Polcic, P.; Kathrein, M. Surface modification of Ti-Al targets during cathodic arc evaporation. Surf. Coat. Technol. 2011, 205, 5116–5123. [Google Scholar] [CrossRef]

- Syed, B.; Zhu, J.; Polcik, P.; Kolozsvari, S.; Hakansson, G.; Johnson, L.; Ahlgren, M.; Joesaar, M.; Oden, M. Morphology and microstructure evolution of Ti-50 at.% Al cathodes during cathodic arc deposition of Ti-Al-N coatings. J. Appl. Phys. 2017, 121, 245309. [Google Scholar] [CrossRef]

- Zhu, J.Q.; Johansson-Jöesaar, M.P.; Polcik, P.; Jensen, J.; Greczynski, G.; Hultman, L.; Odén, M. Influence of Ti–Si cathode grain size on the cathodic arc process and resulting Ti–Si–N coatings. Surf. Coat. Technol. 2013, 235, 637–647. [Google Scholar] [CrossRef]

- Koller, C.M.; Hahn, R.; Ramm, J.; Kolozsvári, S.; Mayrhofer, P.H. Microstructural modifications in powder-metallurgically produced Al0.675Cr0.275Fe0.05 targets during cathodic arc evaporation. J. Vac. Sci. Technol. A 2016, 34, 021603. [Google Scholar] [CrossRef]

- Zöhrer, S.; Golizadeh, M.; Koutná, N.; Holec, D.; Anders, A.; Franz, R. Erosion and cathodic arc plasma of Nb-Al cathodes: Composite versus intermetallic. Plasma Sources Sci. Technol. 2020, 29, 025022. [Google Scholar] [CrossRef]

- Anders, A.; Yotsombat, B.; Binder, R. Correlation between cathode properties, burning voltage and plasma parameters of vacuum arcs. J. Appl. Phys. 2001, 89, 7764. [Google Scholar] [CrossRef]

- Eriksson, A.O.; Zhirkov, I.; Dahlqvist, M.; Jensen, J.; Hultman, L.; Rosen, J. Characterization of plasma chemistry and ion energy in cathodic arc plasma from Ti-Si cathodes of different compositions. J. Appl. Phys. 2013, 113, 163304. [Google Scholar] [CrossRef]

- Syed, B.; Joesaar, M.J.; Polcek, P.; Kolozsvari, S.; Hakansson, G.; Johnson, L.; Ahlgren, M.; Oden, M. Effect of work function and cohesive energy of the constituent phases of Ti-50 at.% Al cathode during arc deposition of Ti-Al-N coatings. Surf. Coat. Technol. 2019, 357, 393–401. [Google Scholar] [CrossRef]

- Rosen, J.; Anders, A.; Hultman, L.; Schneider, J.M. Temporal development of the composition of Zr and Cr cathodic arc plasma streams in a N2 environment. J. Appl. Phys. 2003, 94, 1414–1419. [Google Scholar] [CrossRef]

- Franz, R.; Polcik, P.; Anders, A. Element- and charge-state-resolved ion energies in the cathodic arc plasma from composite AlCr cathodes in argon, nitrogen and oxygen atmospheres. Surf. Coat. Technol. 2015, 272, 309–321. [Google Scholar] [CrossRef]

- Zhirkov, I.; Landalv, L.; Gothelid, E.; Ahlgren, M.; Eklund, P.; Rosen, J. Effect of Si on DC arc plasma generation from Al-Cr and Al-Cr-Si cathodes used in oxygen. J. Appl. Phys. 2017, 121, 083303. [Google Scholar] [CrossRef]

- Zhirkov, I.; Petruhins, A.; Polcik, P.; Kolozsvári, S.; Rosen, J. Effect of Ti-Al cathode grain size on plasma generation and thin film synthesis from a direct current vacuum arc plasma source. AIP Adv. 2019, 9, 045008. [Google Scholar] [CrossRef]

- Zhirkov, I.; Oks, E.; Rosen, J. Effect of N2 and Ar gas on DC arc plasma generation and film composition from Ti-Al compound cathodes. J. Appl. Phys. 2015, 117, 213301. [Google Scholar] [CrossRef]

- Zhirkov, I.; Eriksson, A.O.; Petruhins, A.; Dahlqvist, M.; Ingason, A.S.; Rosen, J. Effect of Ti-Al cathode composition on plasma generation and plasma transport in direct current vacuum arc. J. Appl. Phys. 2014, 115, 123301. [Google Scholar] [CrossRef]

- Zhu, J.; Eriksson, A.; Ghafoor, N.; Johansson, M.P.; Sjolen, J.; Hultman, L.; Rosén, J.; Odén, M. Characterization of worn Ti-Si cathodes used for reactive cathodic arc evaporation. J. Vac. Sci. Technol. A 2010, 28, 347–353. [Google Scholar] [CrossRef]

- Franz, R.; Mendez-Martin, F.; Hawranek, G.; Polcik, P. Erosion behavior of composite Al-Cr cathodes in cathodic arc plasmas in inert and reactive atmospheres. J. Vac. Sci. Technol. A 2016, 34, 021304. [Google Scholar] [CrossRef]

- Pohler, M.; Franz, R.; Ramm, J.; Polcik, P.; Mitterer, C. Cathodic arc deposition of (Al,Cr)2O3: Macroparticles and cathode surface modifications. Surf. Coat. Technol. 2011, 206, 1454–1460. [Google Scholar] [CrossRef]

- Kameneva, A.; Antonova, N.; Pesin, M.; Makarov, V.; Nikitin, S.; Bublik, N. Structural and phase transformations control in Ti and Al cathode materials, WC-Co substrate, and Ti1−xAlxN coating to improve their physico-mechanical and wear properties. Int. J. Refract. Met. Hard Mater. 2022, 102, 105726. [Google Scholar] [CrossRef]

- Holzapfel, D.M.; Music, D.; Hans, M.; Wolff-Goodrich, S.; Holec, D.; Bogdanovski, D.; Arndt, M.; Eriksson, A.O.; Yalamanchili, K.; Primetzhofer, D.; et al. Enhanced thermal stability of (Ti,Al)N coatings by oxygen incorporation. Acta Mater. 2021, 218, 117204. [Google Scholar] [CrossRef]

- Koller, C.M.; Glatz, S.A.; Kolozsvári, S.; Bolvardi, H.; Mayrhofer, P.H. Thermal stability and oxidation resistance of architecturally designed Ti–Al–N- and Ti–Al–Ta–N-based multilayers. Surf. Coat. Technol. 2020, 385, 125444. [Google Scholar] [CrossRef]

- Schalk, N.; Weirather, T.; Polzer, C.; Polcik, P.; Mitterer, C. A comparative study on Ti1−xAlxN coatings reactively sputtered from compound and from mosaic targets. Surf. Coat. Technol. 2011, 25, 4705–4710. [Google Scholar] [CrossRef]

- Pribytkov, G.A.; Andreeva, I.A.; Korjova, V.V. Bulk changes and structure formation in solid phase sintering of Ti–TiAl3 powder mixtures. Powder Metall. Met. Ceram. 2008, 47, 687–692. [Google Scholar] [CrossRef]

- Phase Equilibrium Diagrams, Datebase, Version 3.1; American Ceramic Society: Columbus, OH, USA, 2006.

- Binnewies, M.; Milke, E. Thermochemical Data of Elements and Compounds; Wiley-VCH Verlag GmbH: Weinheim, Germany, 2002; 919p. [Google Scholar]

| Cathode | Supplier | Production Technology |

|---|---|---|

| No. 1, sintered | ISPMS SB RAS, Tomsk, Russia | Sintering |

| No. 2, “Polema” | JSC “Polema”, Tula, Russia | Hot pressing of Al + Ti mixture |

| No. 3, “Umicore” | “Umicore Materials AG”, Hanau-Wolfgang, Germany | Hot pressing of Al + Ti mixture |

| No. 4, cast | - | Casting |

| Cathode | Analyzed Site | Content of Phases, Vol.% | |

|---|---|---|---|

| Major Constituents | Other Phases | ||

| No. 1. Sintered | Arc exposed surface layer | 95% Ti3Al | 5% unidentified |

| Back surface layer | 72%–82% γ-TiAl | 21%–12% Ti3Al, traces of Al2O3, 7% unidentified | |

| No. 2. “Polema” | Arc exposed surface layer | 59%–78% Ti3Al | 21%–41% TiAl |

| Back surface layer | 41% Ti, 57% Al | 2% Ti3Al, 2% unidentified | |

| No. 3. “Umicore” | Arc exposed surface layer | 89% Ti3Al | 11% TiAl + traces of TiH0.71 |

| Back surface layer | 47%–74% Ti | 23%–12% Ti3Al, 24%–12% TiAl, 7%–8% Al | |

| No. 4. Cast | Arc exposed surface layer | 81% Ti3Al | 11% TiH0.71, 8% unidentified |

| Back surface layer | 99% Ti3Al | 1% unidentified | |

| Cathode | Analyzed Site | Composition, at.% | No. of Points in Figure 3 | Phase | Hμ, MPa | |

|---|---|---|---|---|---|---|

| Ti | Al | |||||

| No. 1, sintered | Core | 70.9 ± 5.8 | 29.1 ± 5.8 | 1, 5–12, 15, 16 (Figure 3a) | Ti3Al | 5188 ± 794 |

| Periphery | 52.1 ± 1.3 | 48.4 ± 0.8 | 2–4 (Figure 3a) | TiAl | 3333 ± 172 | |

| No. 2, “Polema” | Light grains | 100.0 | 0.0 | 1–15 (Figure 3b) | α-Ti | 2385 ± 191 |

| Gray matrix | 1.8 ± 0.7 | 97.5 ± 1.1 | 16–30 (Figure 3b) | Al(Ti) | 555 ± 24 | |

| No. 3, “Umicore” | Inclusions in the gray phase | 77.65 ± 6.65 | 22.35 ± 6.65 | 4–6, 11–13 (Figure 3c), 18, 19,22, 24, 25, 32 (Figure 3d) | Ti3Al | 1287 ± 126 |

| Gray phase | 100.0 | 0.0 | 2, 7–9, 14, 17 (Figure 3c), 20, 26, 31, 33 (Figure 3d) | α-Ti | 2163 ± 319 | |

| Black phase | 0.74 ± 0.67 | 99.25 ± 0.65 | 3 (Figure 3c), 27, 29, 34, 35, 36 (Figure 3d) | Al(Ti) | 440 ± 4 | |

| At the border of gray phases and inclusions | 91.95 ± 5.45 | 8.5 ± 5.45 | 1, 10, 15, 16 (Figure 3c), 21, 23, 37 (Figure 3d) | Ti(Al) | - | |

| No. 4, cast | Zone 2 (Figure 4) | - | - | - | - | 4640 ± 1 |

| Zones | Description of Structural Components (Figure 5) | Composition, at.% | No. of Points in Figure 5 | Phases | |

|---|---|---|---|---|---|

| Ti | Al | ||||

| 1 | Continuous grey layer | 64.82 ± 1 | 35.18 ± 1 | 1–8 | Ti3Al |

| 2 | Base | 66.28 ± 1.5 | 33.44 ± 1.5 | 9, 11, 14–19 | Ti3Al |

| Light grey spots | 57.26 ± 1.4 | 42.5 ± 1.4 | 10, 12, 13, 18, 20 | Ti3Al + TiAl | |

| Zones | Description of Structural Components (Figure 6) | Composition, at.% | No. of Points in Figure 6 | Phases | |

|---|---|---|---|---|---|

| Ti | Al | ||||

| 1 | Continuous grey layer | 57.56 ± 1.77 | 42.44 ± 1.77 | 1–10 | Ti3Al + TiAl |

| Light gray inclusions | 27.0 ± 7.75 | 73.0 ± 7.75 | 7, 11, 13 | TiAl3 | |

| 2 | Light grains | 100.0 | 0.0 | 3, 8, 12, 15, 18, 24, 25, 27 | α-Ti |

| Taupe matrix | 8.31 ± 6.02 | 91.69 ± 6.02 | 14, 16, 17, 19–23, 26, 28–30 | Al(Ti) | |

| Zones | Description of Structural Components | Composition, at.% | No. of Points in Figure 7a,b | Phases | |

|---|---|---|---|---|---|

| Ti | Al | ||||

| 1 | Surface layer | 71.09 ± 5.11 | 28.91 ± 5.11 | 5 (Figure 7a), 12, 15 (Figure 7b) | Ti3Al |

| 49.9 ± 0.5 | 50.1 ± 0.5 | 1, 3 (Figure 7a) | TiAl | ||

| 57.28 ± 3.25 | 42.72 ± 3.25 | 2, 4–6, 8, 9 (Figure 7a), 11, 13, 14 (Figure 7b) | Ti3Al + TiAl | ||

| 2 | Light gray grains | 100.0 | 0.0 | 10 (Figure 7b), 1–10 (Figure 7c) | α-Ti |

| Black matrix | 0.22 ± 0.25 | 99.78 ± 0.25 | 11–20 (Figure 7) | Al(Ti) | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pribytkov, G.; Firsina, I.; Korzhova, V. Structural Transformations on the Surface of Al-Ti Cathodes Subjected to Vacuum Arc Heating. Coatings 2023, 13, 1906. https://doi.org/10.3390/coatings13111906

Pribytkov G, Firsina I, Korzhova V. Structural Transformations on the Surface of Al-Ti Cathodes Subjected to Vacuum Arc Heating. Coatings. 2023; 13(11):1906. https://doi.org/10.3390/coatings13111906

Chicago/Turabian StylePribytkov, Gennady, Irina Firsina, and Victoria Korzhova. 2023. "Structural Transformations on the Surface of Al-Ti Cathodes Subjected to Vacuum Arc Heating" Coatings 13, no. 11: 1906. https://doi.org/10.3390/coatings13111906

APA StylePribytkov, G., Firsina, I., & Korzhova, V. (2023). Structural Transformations on the Surface of Al-Ti Cathodes Subjected to Vacuum Arc Heating. Coatings, 13(11), 1906. https://doi.org/10.3390/coatings13111906