Friction Coefficient Dynamics of Tribological Coatings from Engine Lubricants: Analysis and Interpretation

Abstract

:1. Introduction

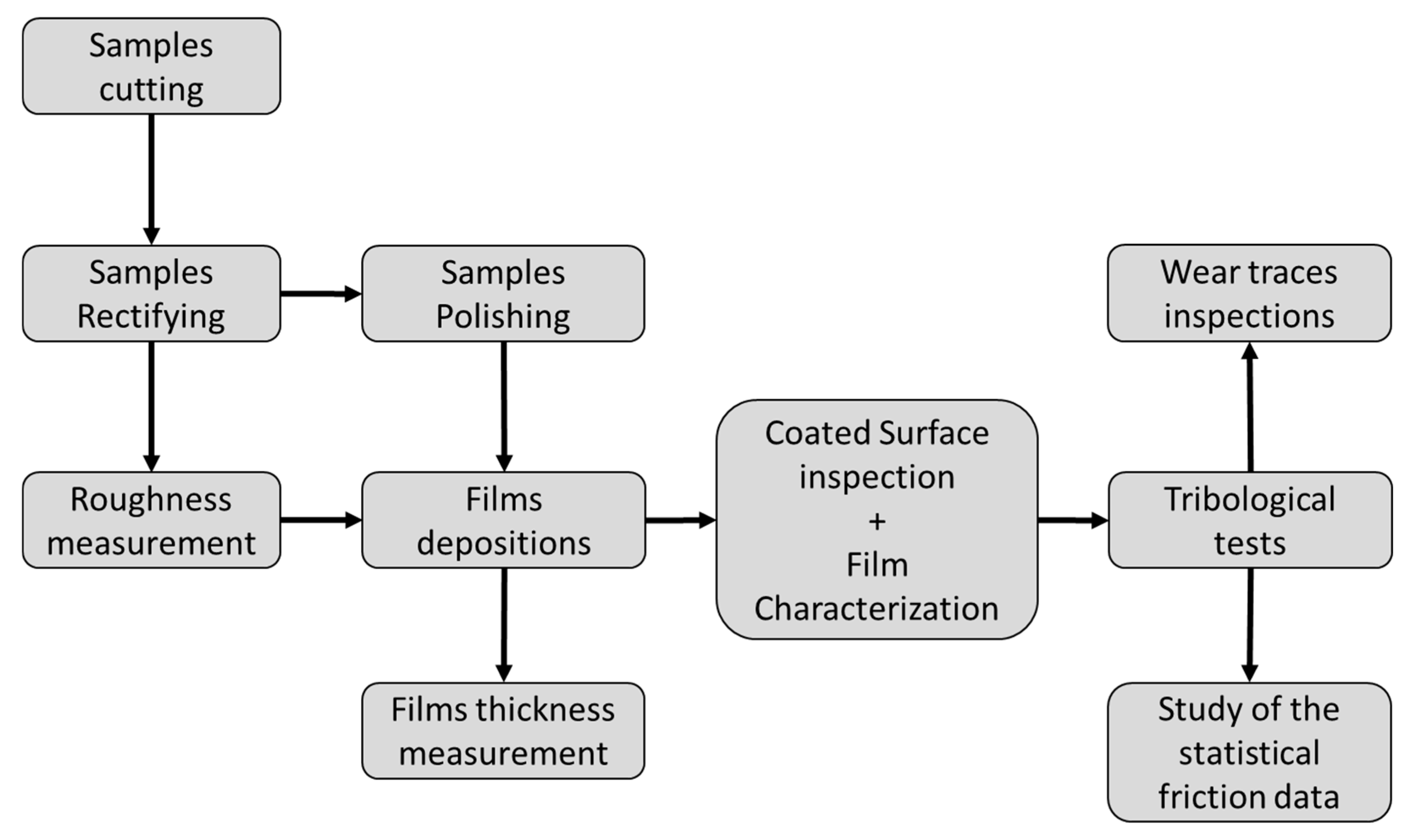

2. Materials and Methods

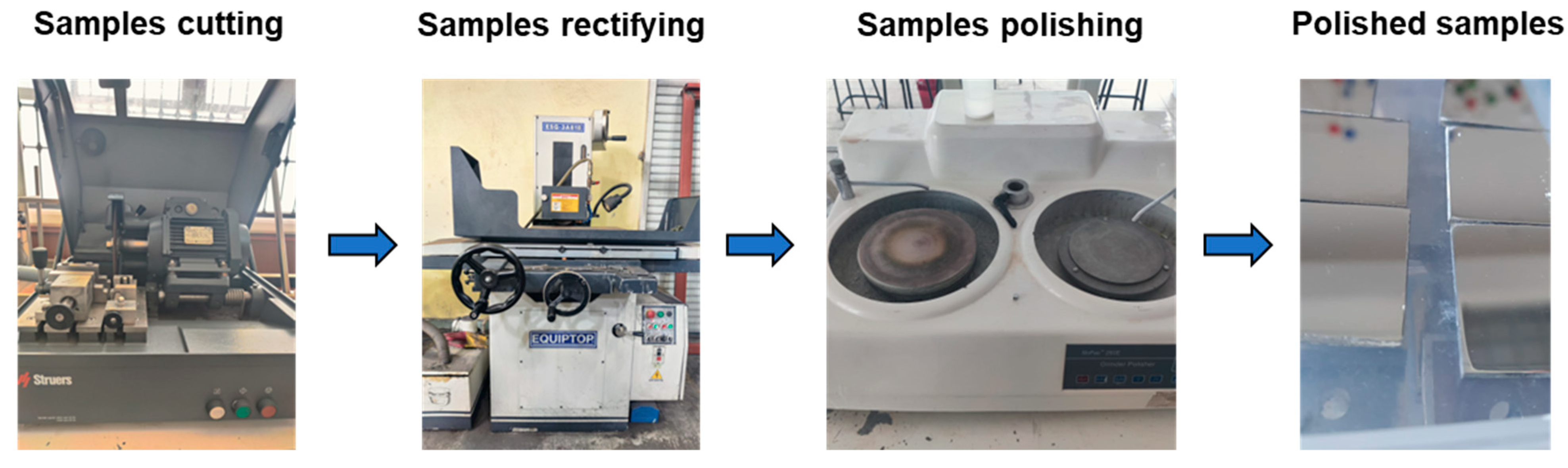

2.1. Preparation of the Metallic Samples

2.2. Deposition of Films

2.3. Morphology and Characterization of the Coated Samples

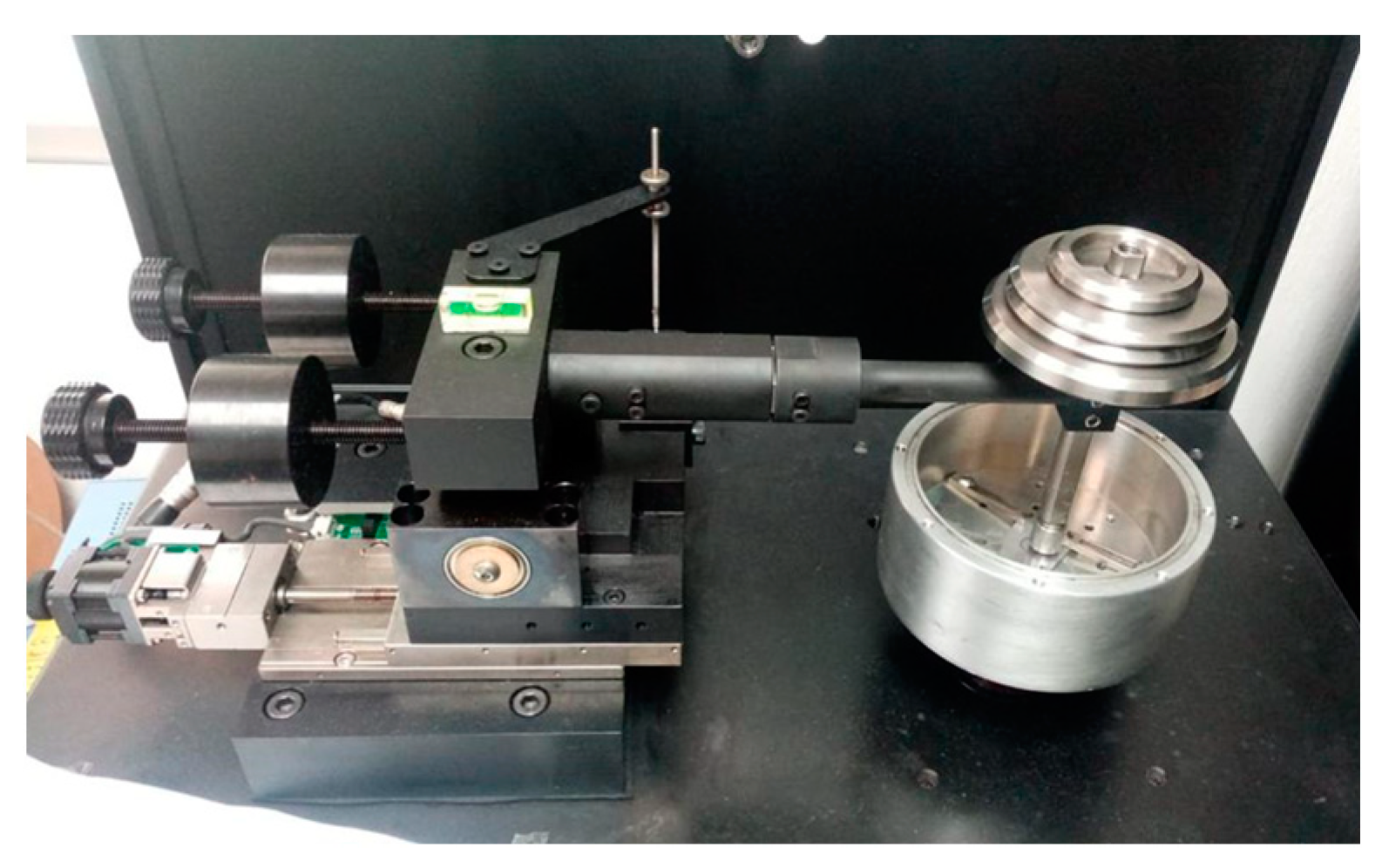

2.4. Tribological Tests

2.5. Study of the Wear Tracks

2.6. Measurement of the Film Thickness

3. Results

3.1. Topography of the Films

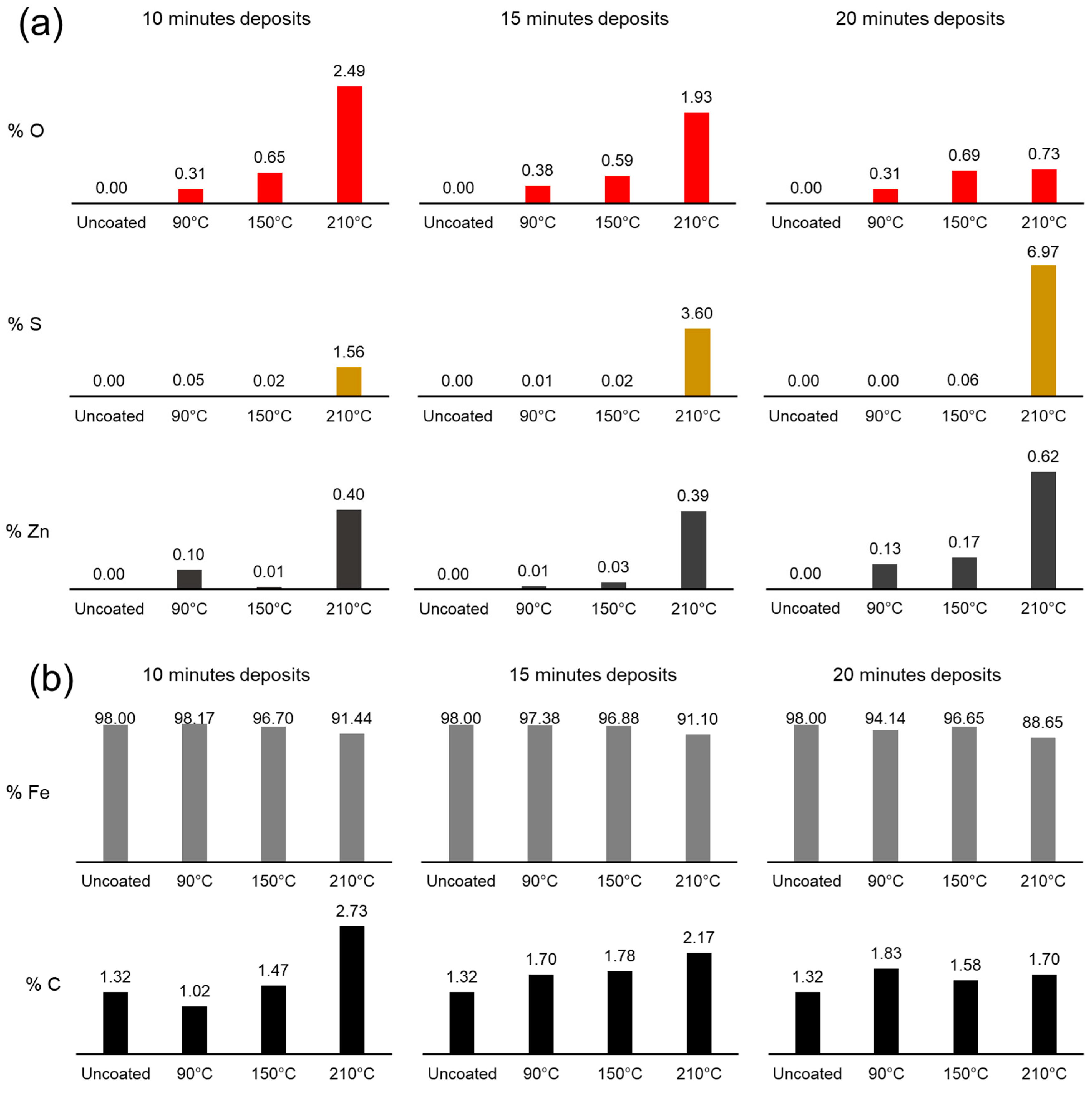

3.2. Characterization of the Films

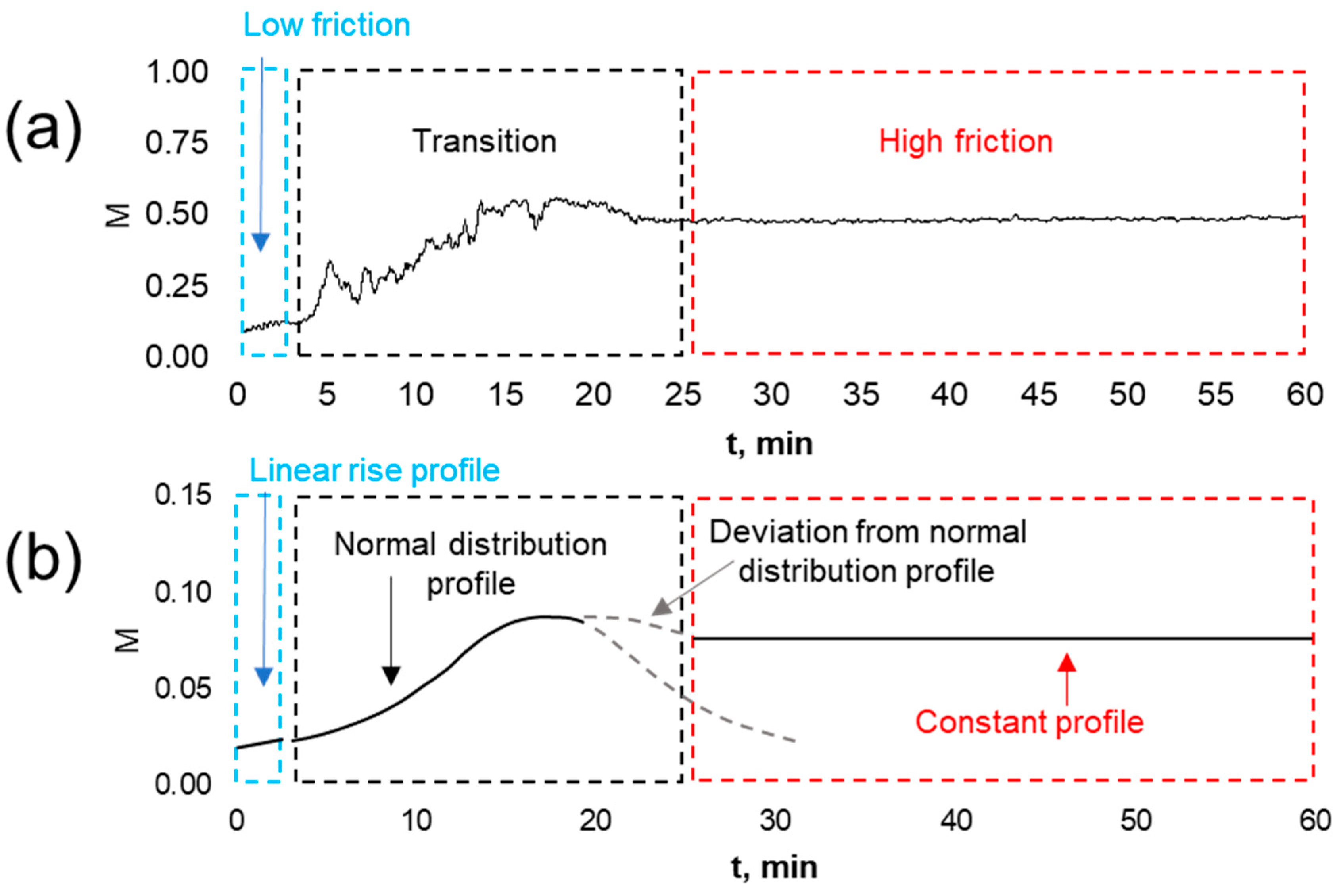

3.3. Profiles of the Coefficients of Friction

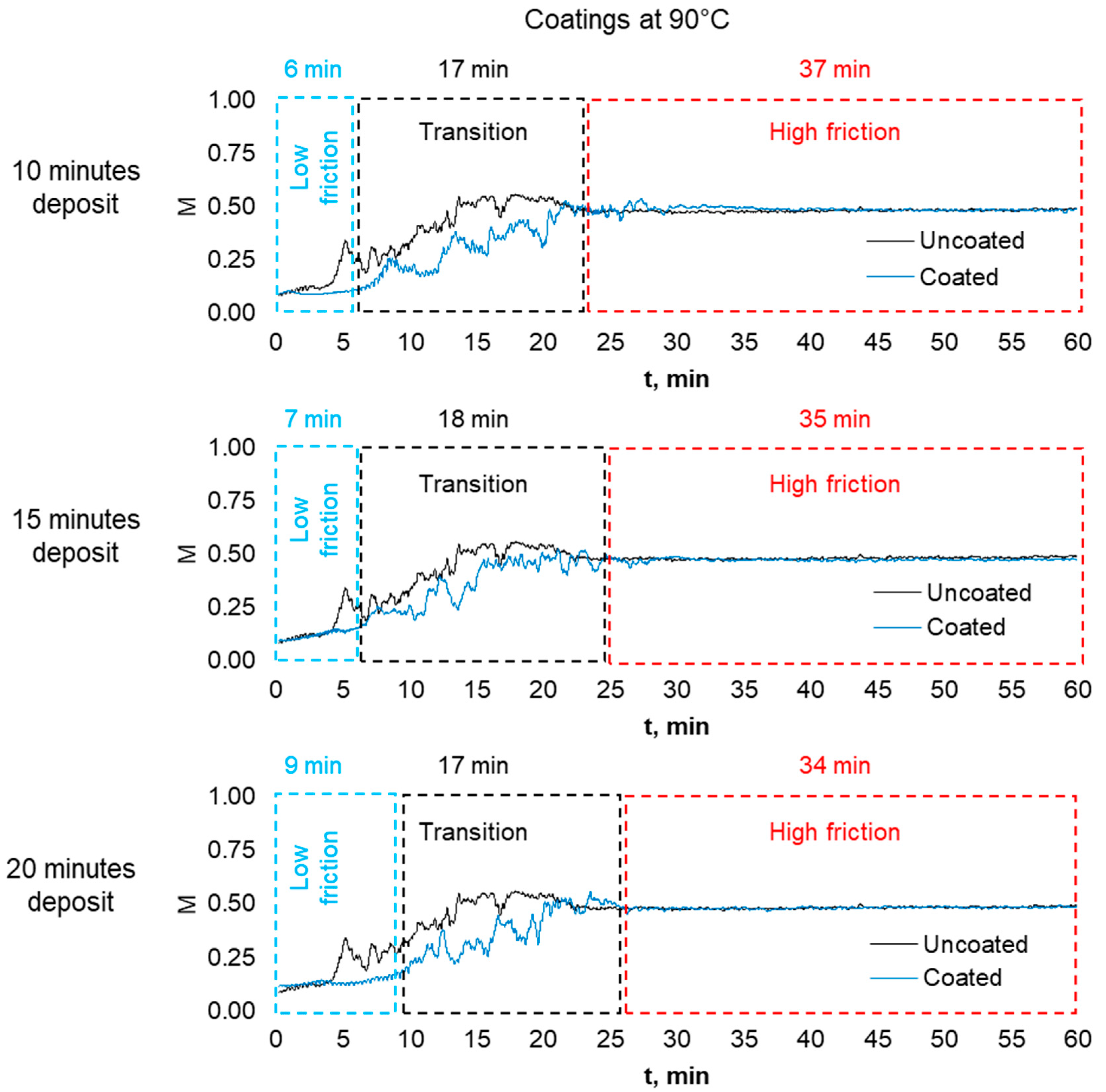

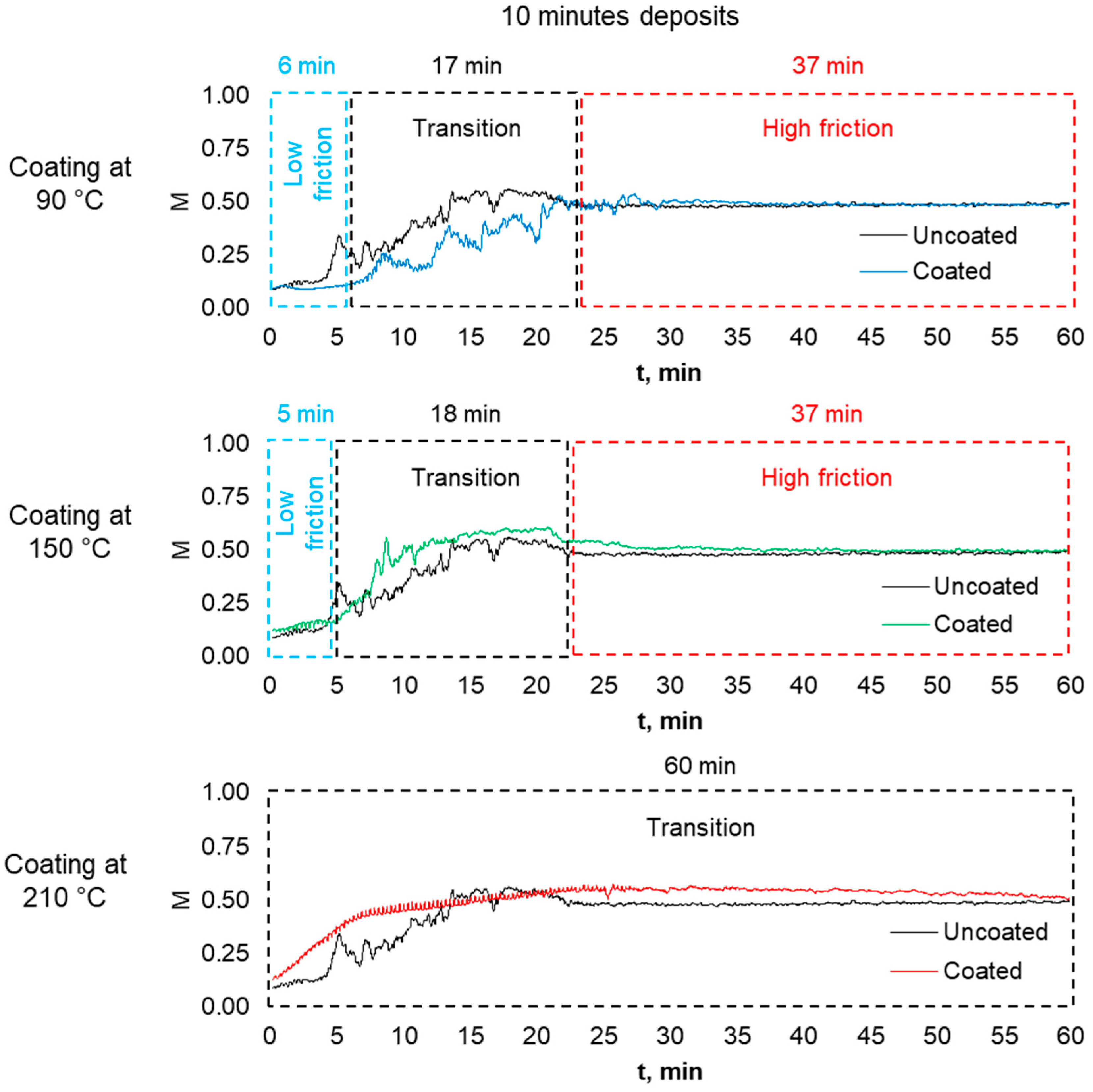

3.3.1. Profiles of the Coefficient of Friction for the Films Deposited at Low Temperature

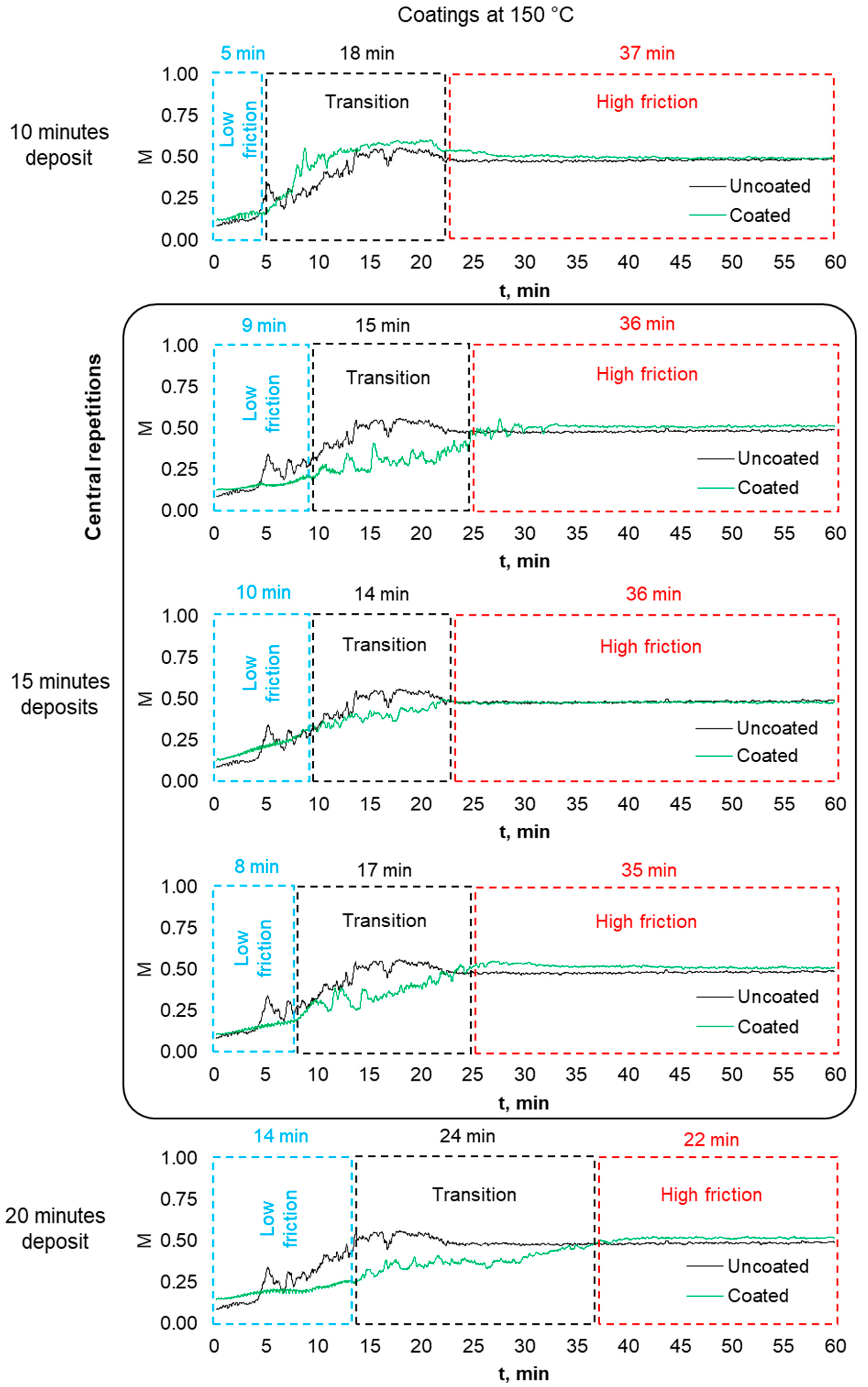

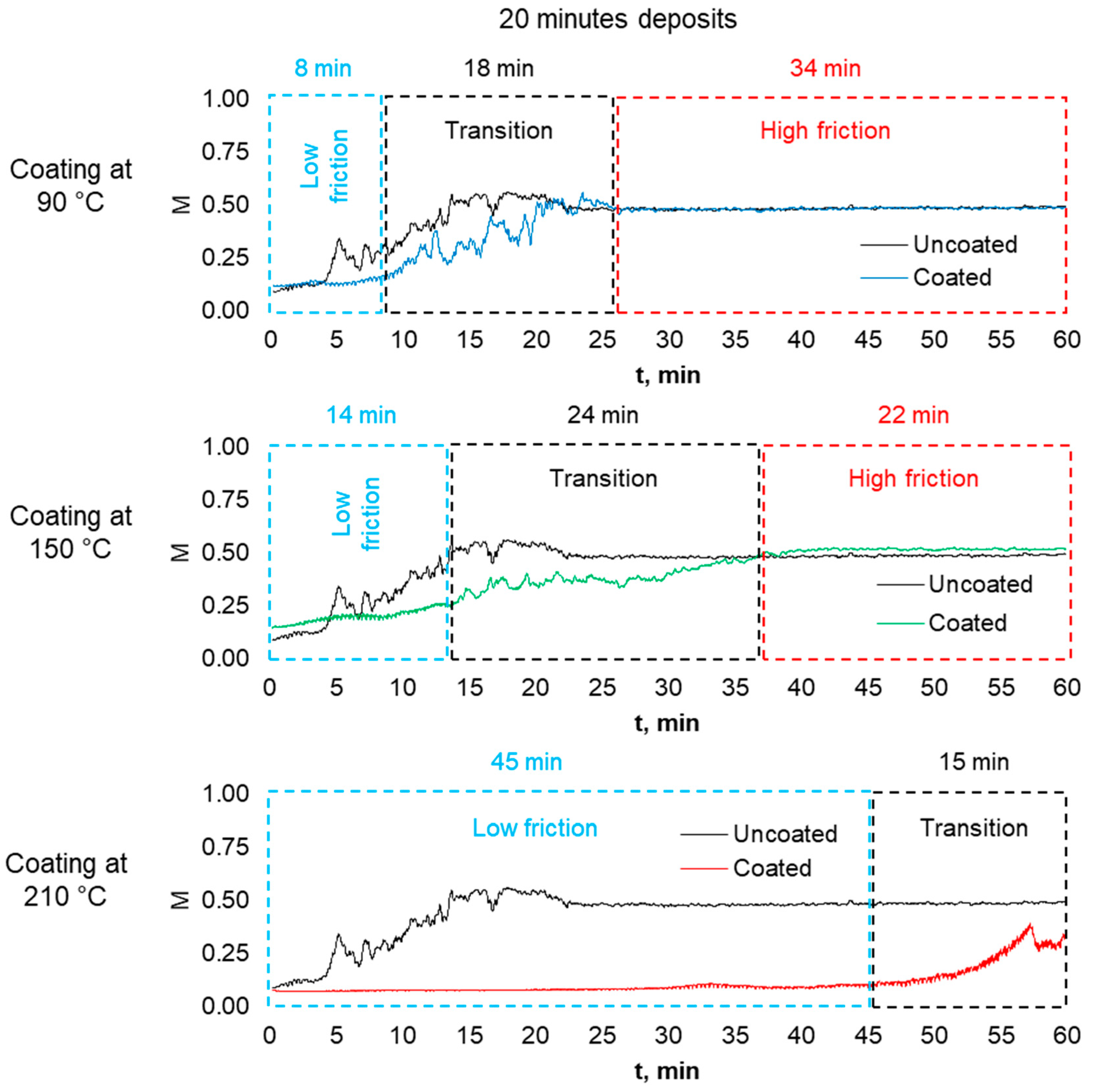

3.3.2. Profiles of the Coefficient of Friction for the Films Deposited at Medium Temperature

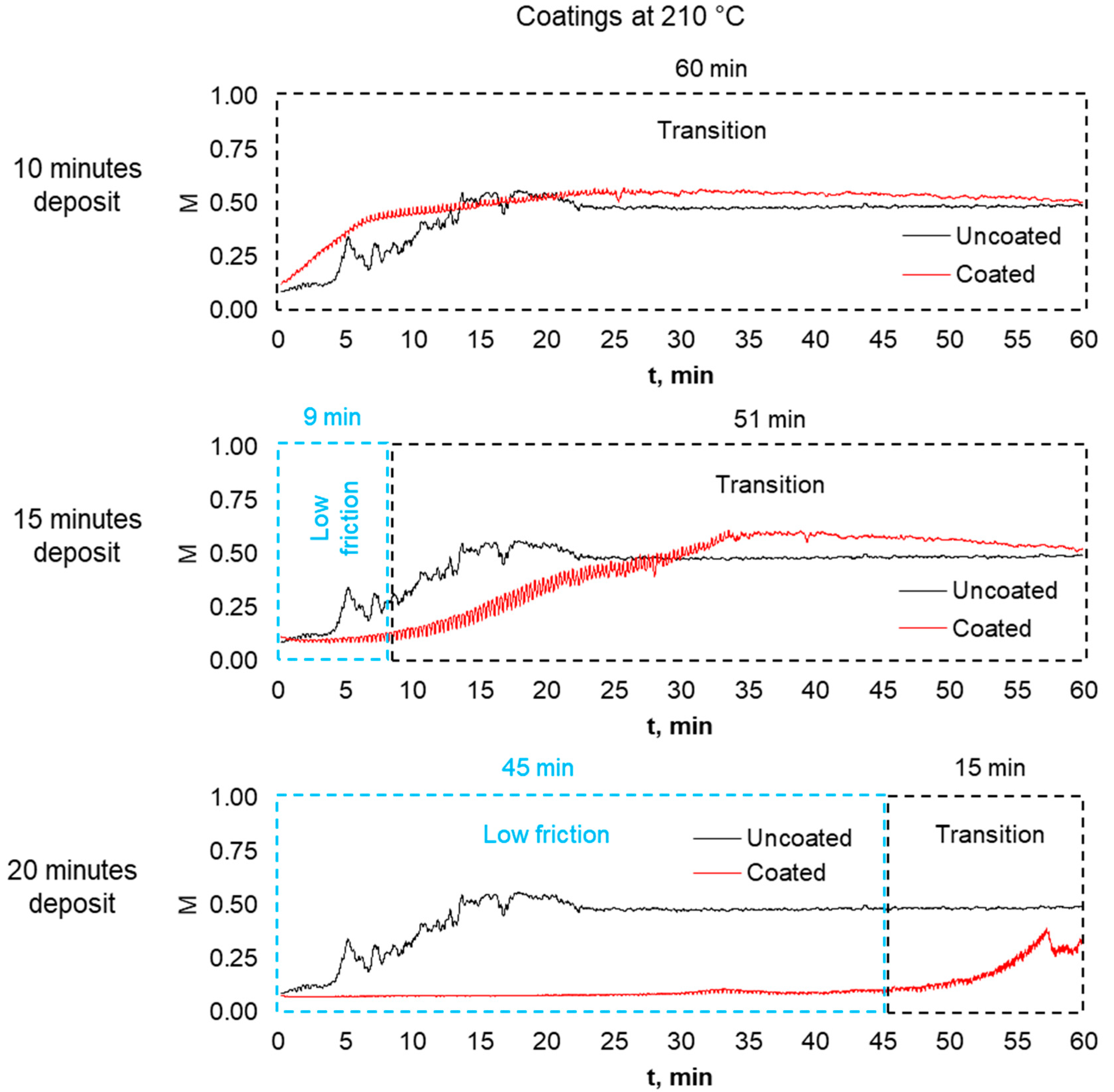

3.3.3. Profiles of the Coefficient of Friction for the Films Deposited at High Temperature

3.3.4. Effect of the Temperature in the Mobile Mean of the Coefficient of Friction

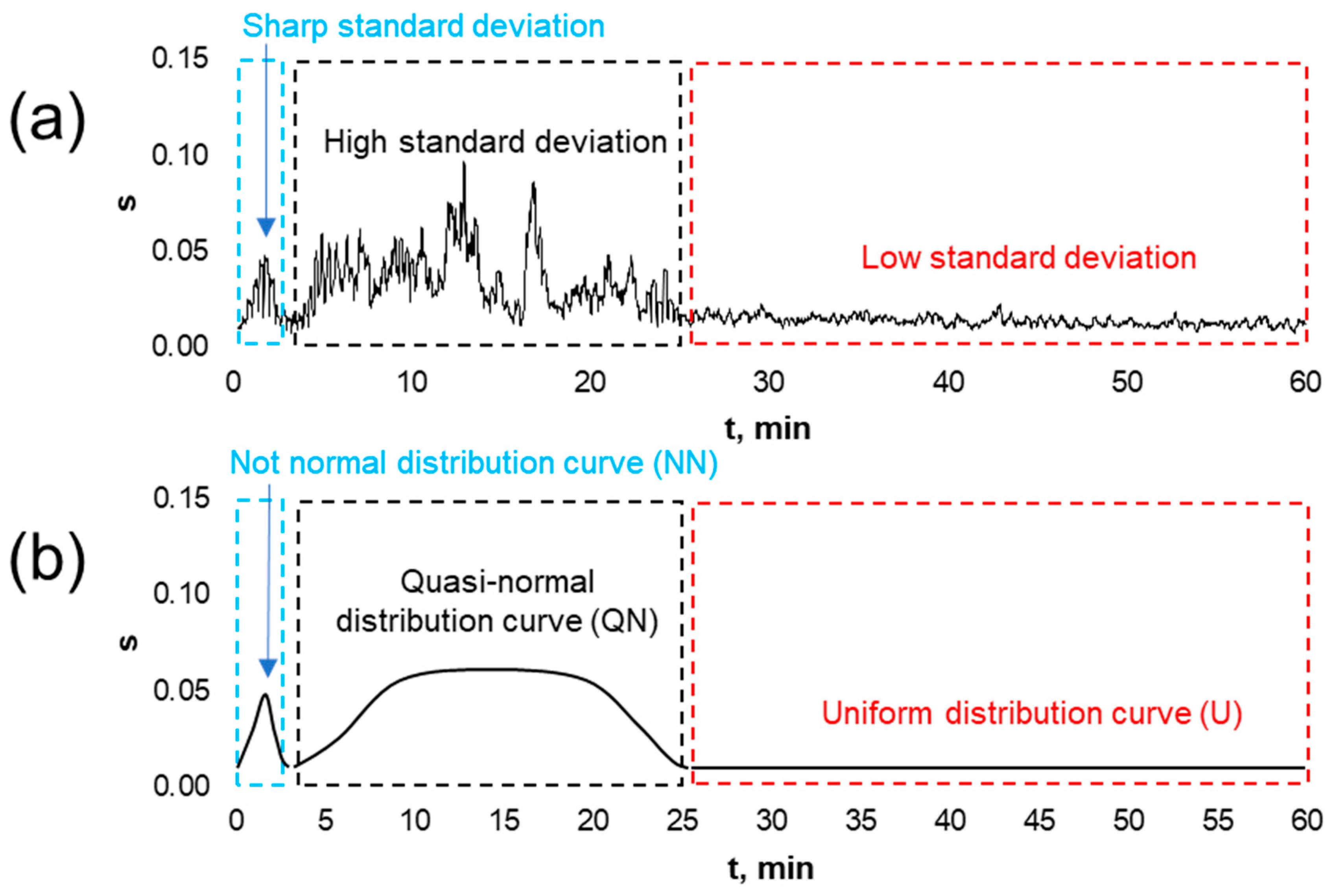

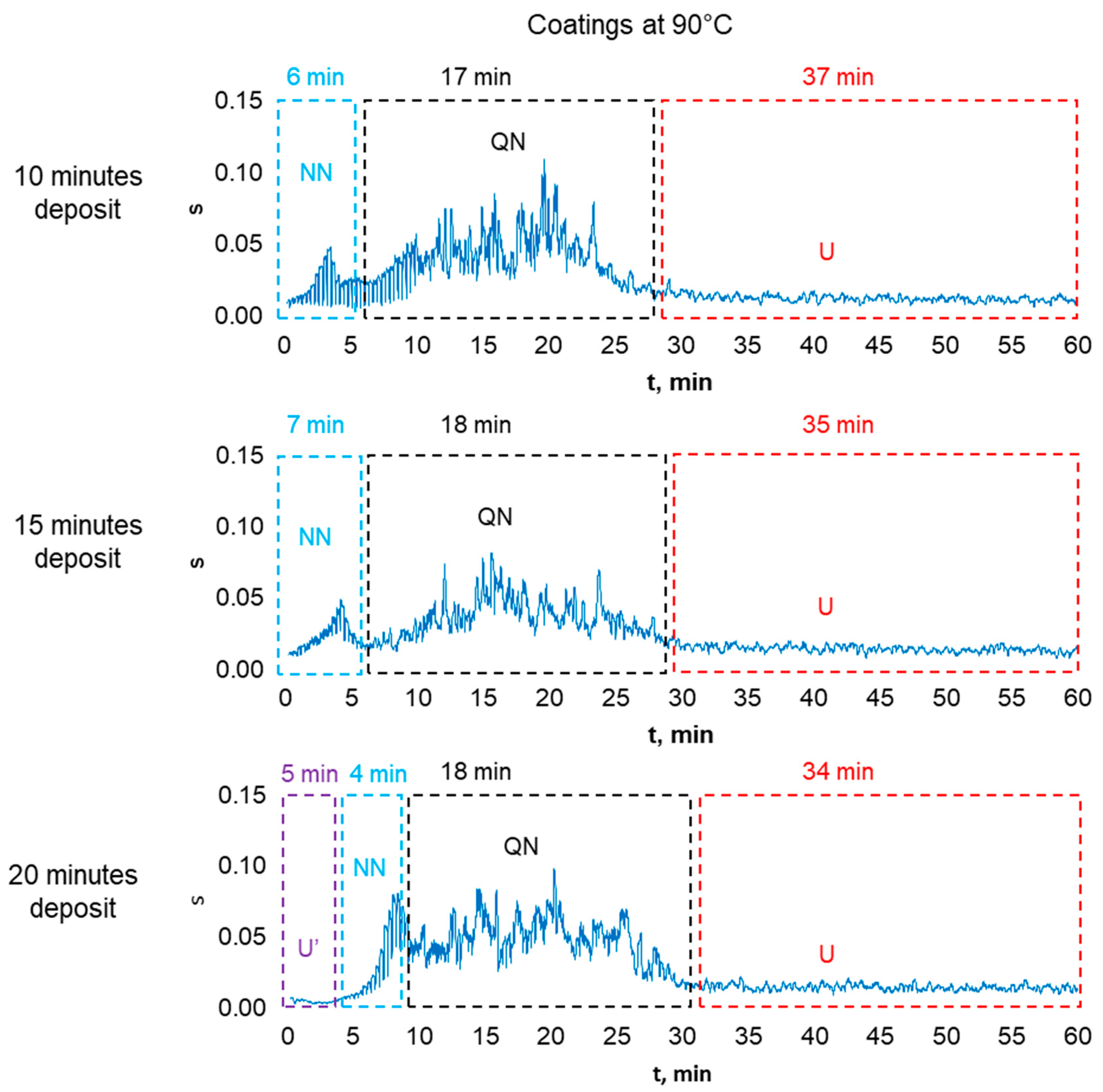

3.4. Profiles of the Standard Deviation

3.4.1. Standard Deviation for the Films Deposited at Low Temperature

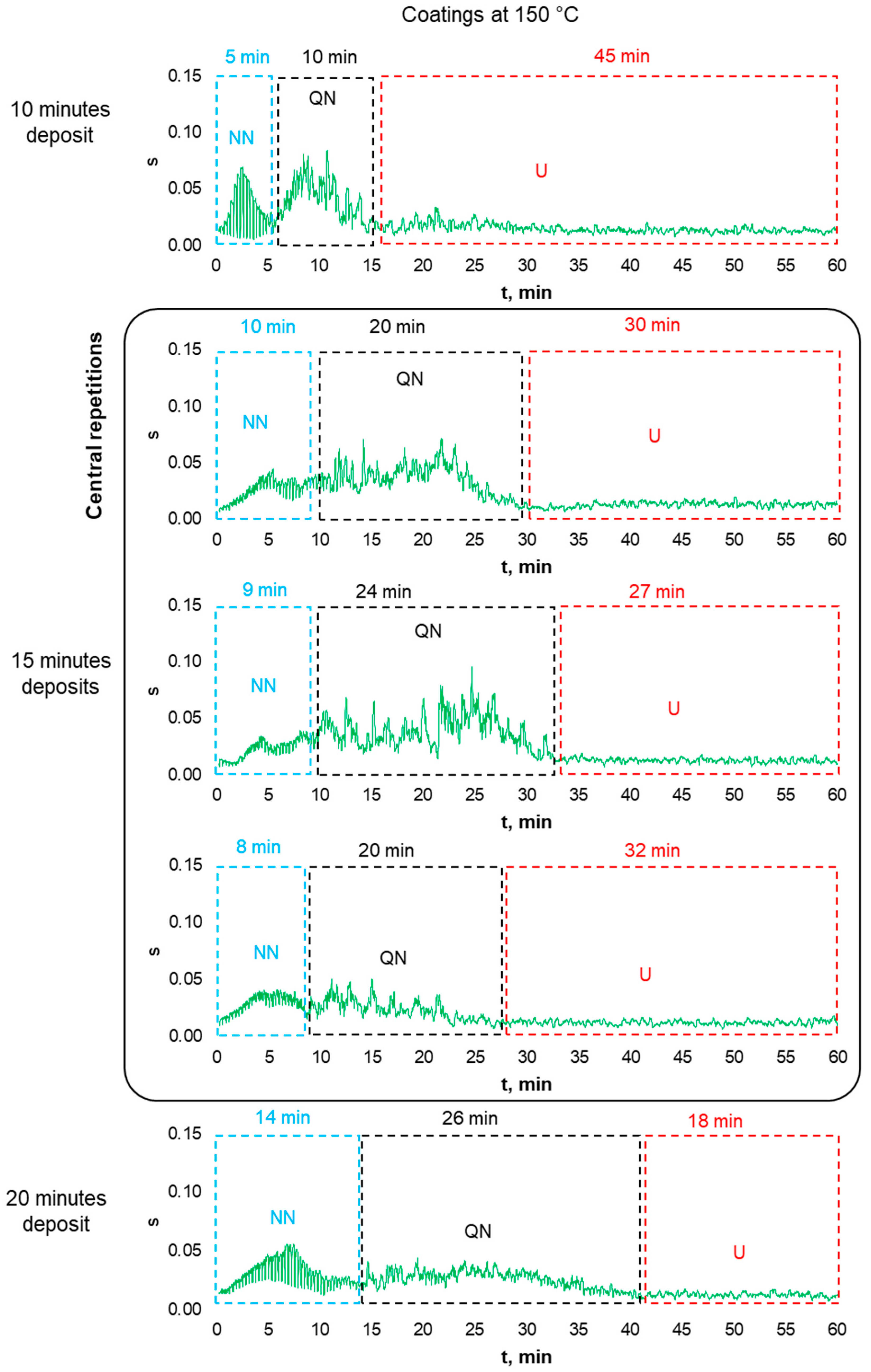

3.4.2. Standard Deviation for the Films Deposited at Medium Temperature

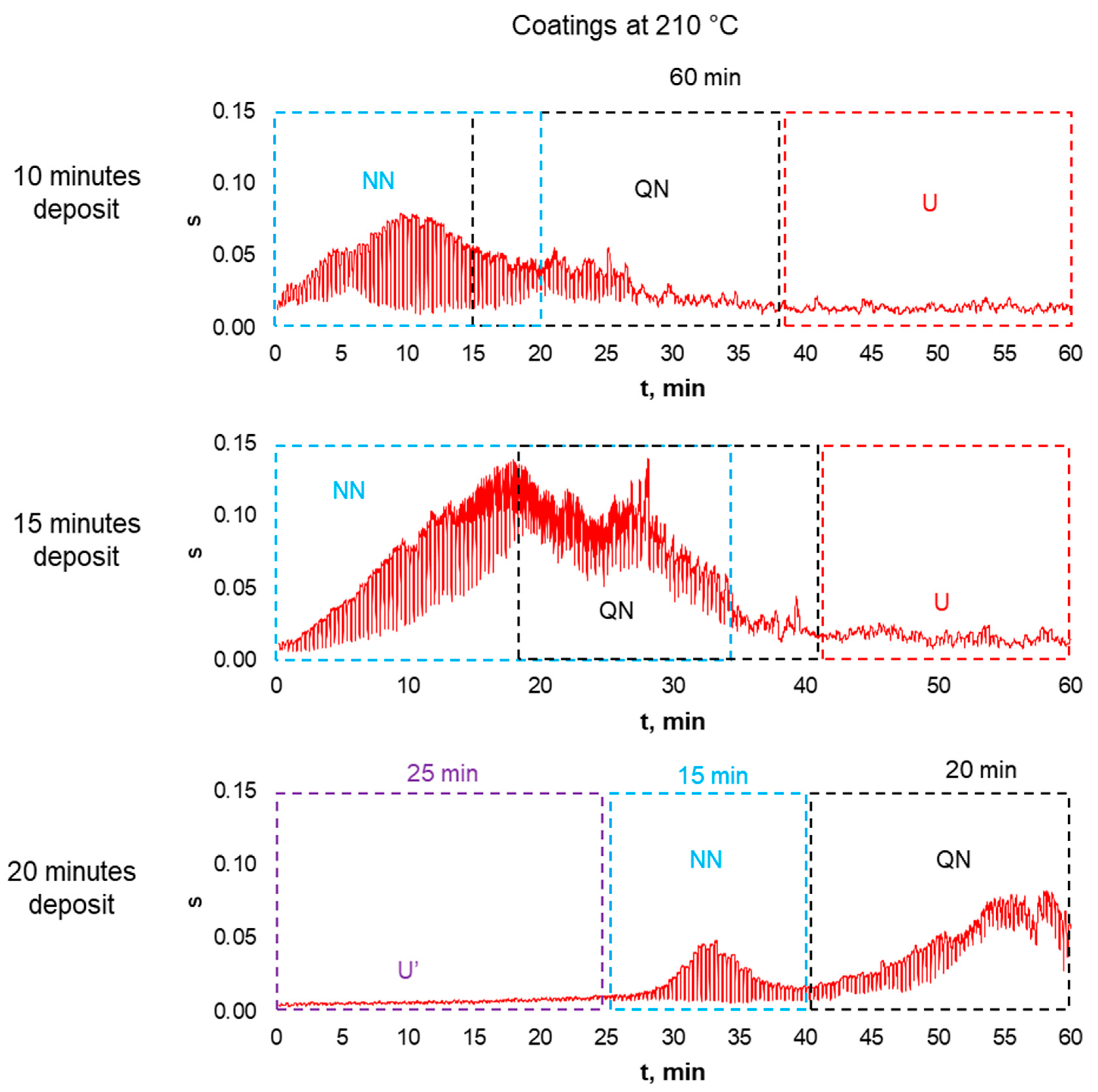

3.4.3. Standard Deviation for the Films Deposited at High Temperature

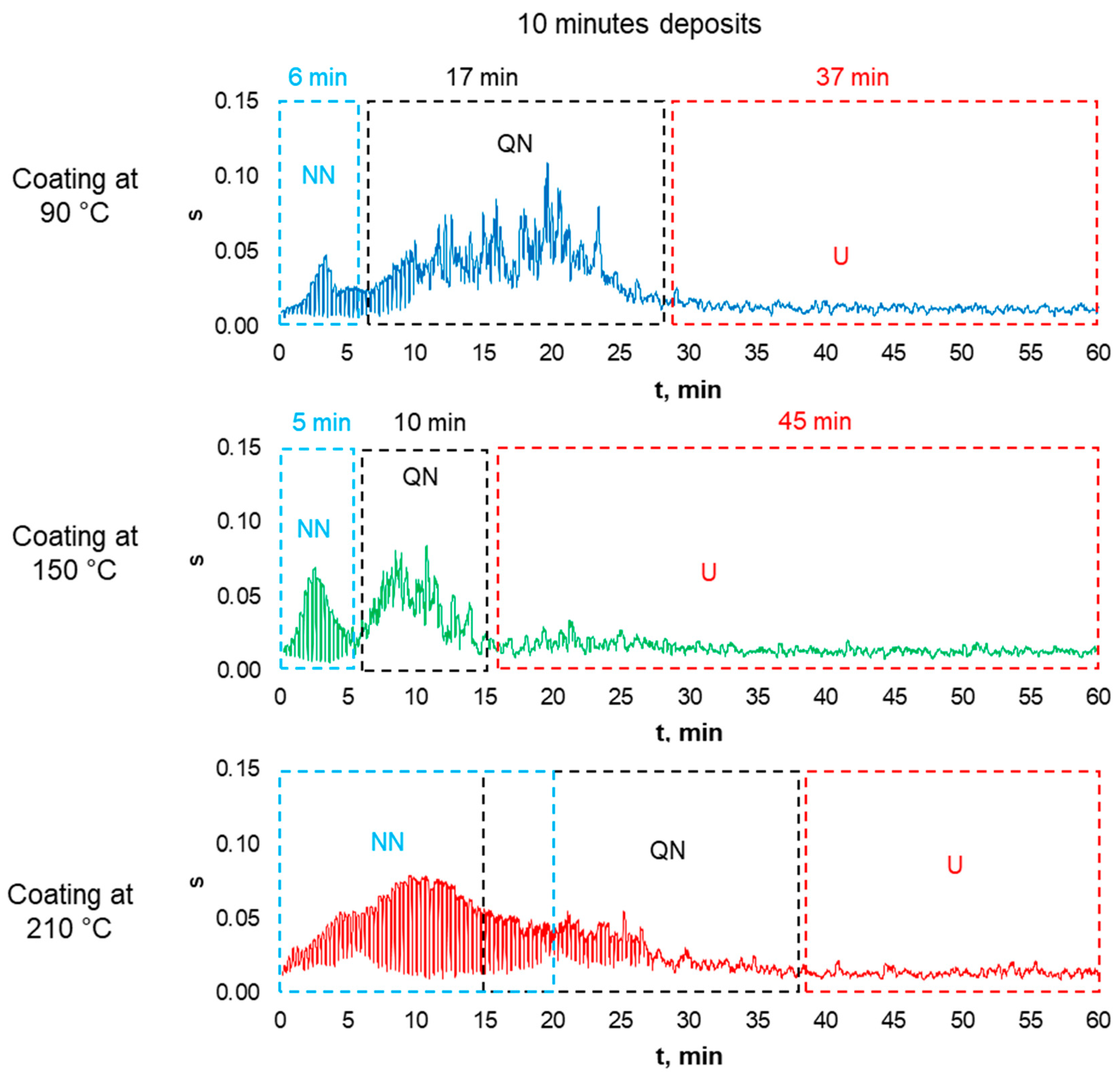

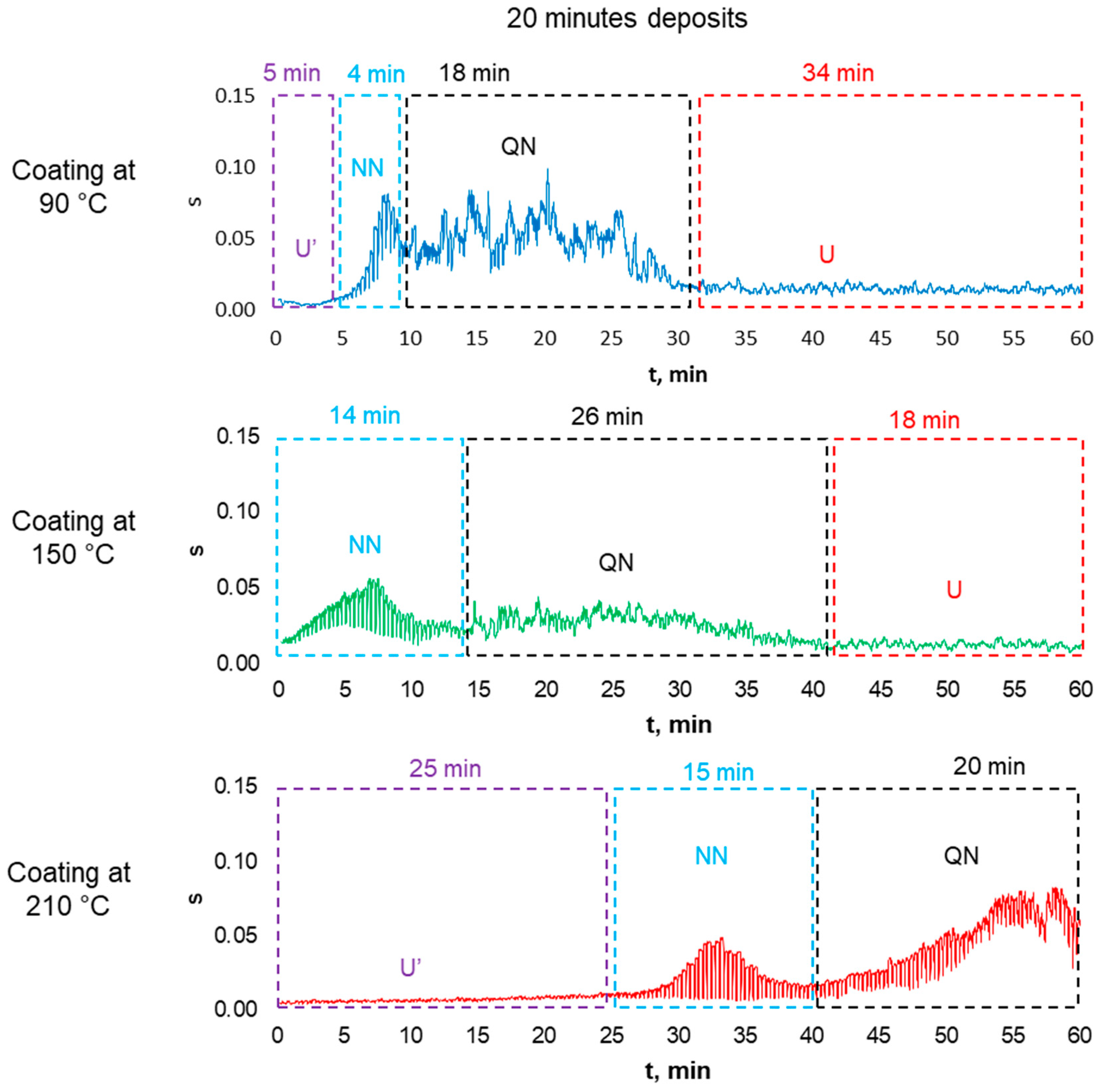

3.4.4. The Effect of the Temperature in the Mobile Standard Deviation

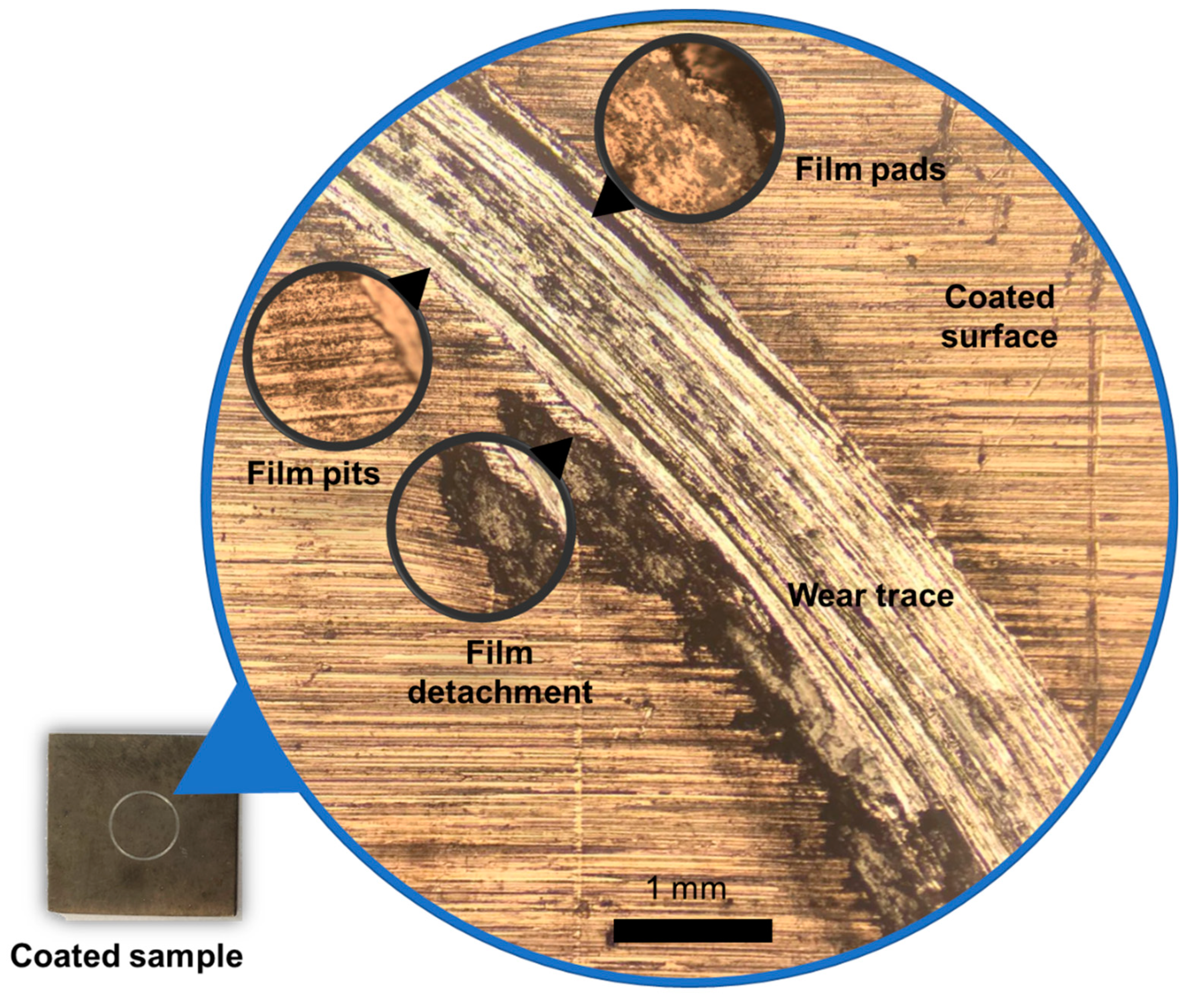

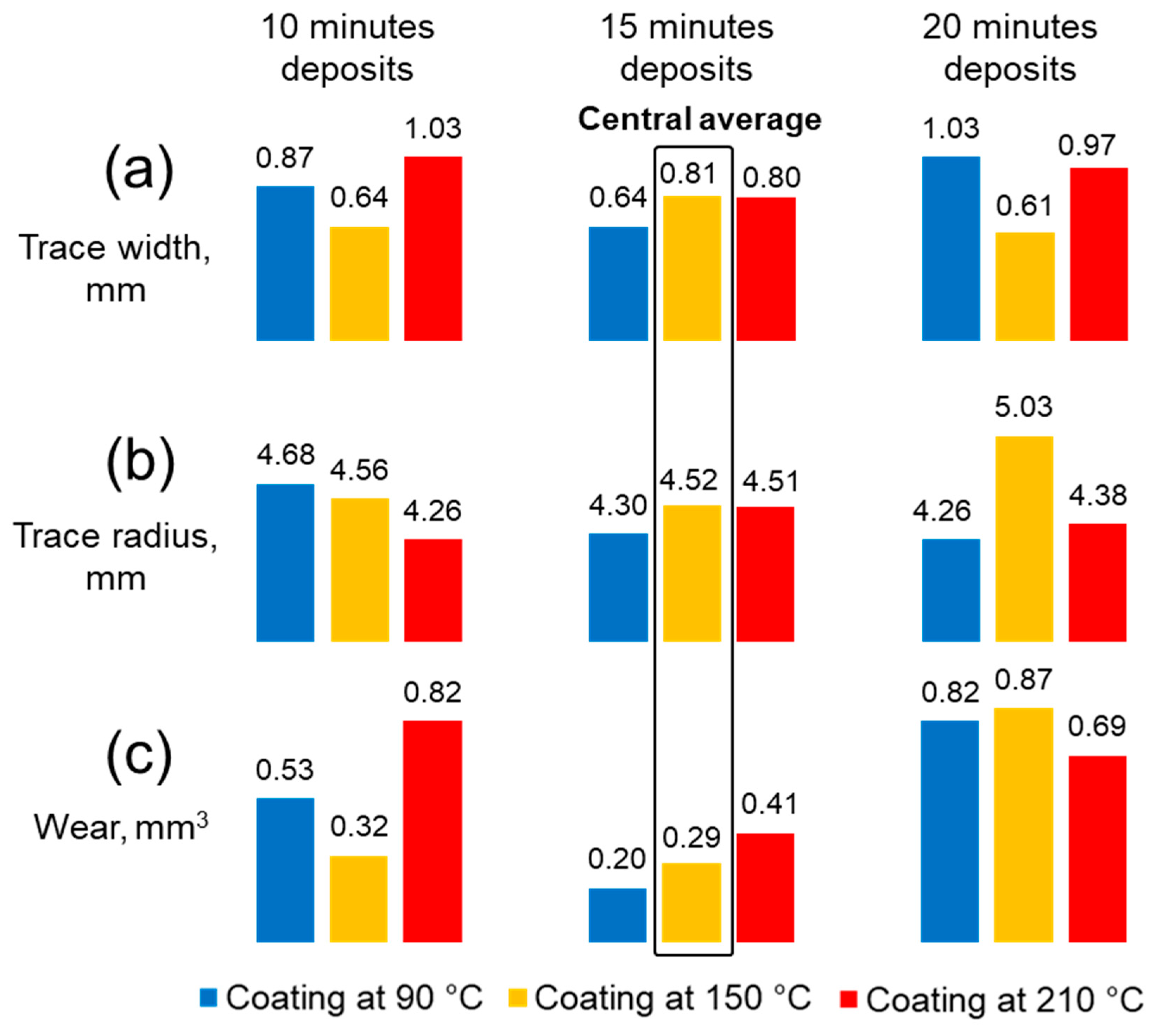

3.5. Wear Tracks Analyses

3.6. Accumulated Wear

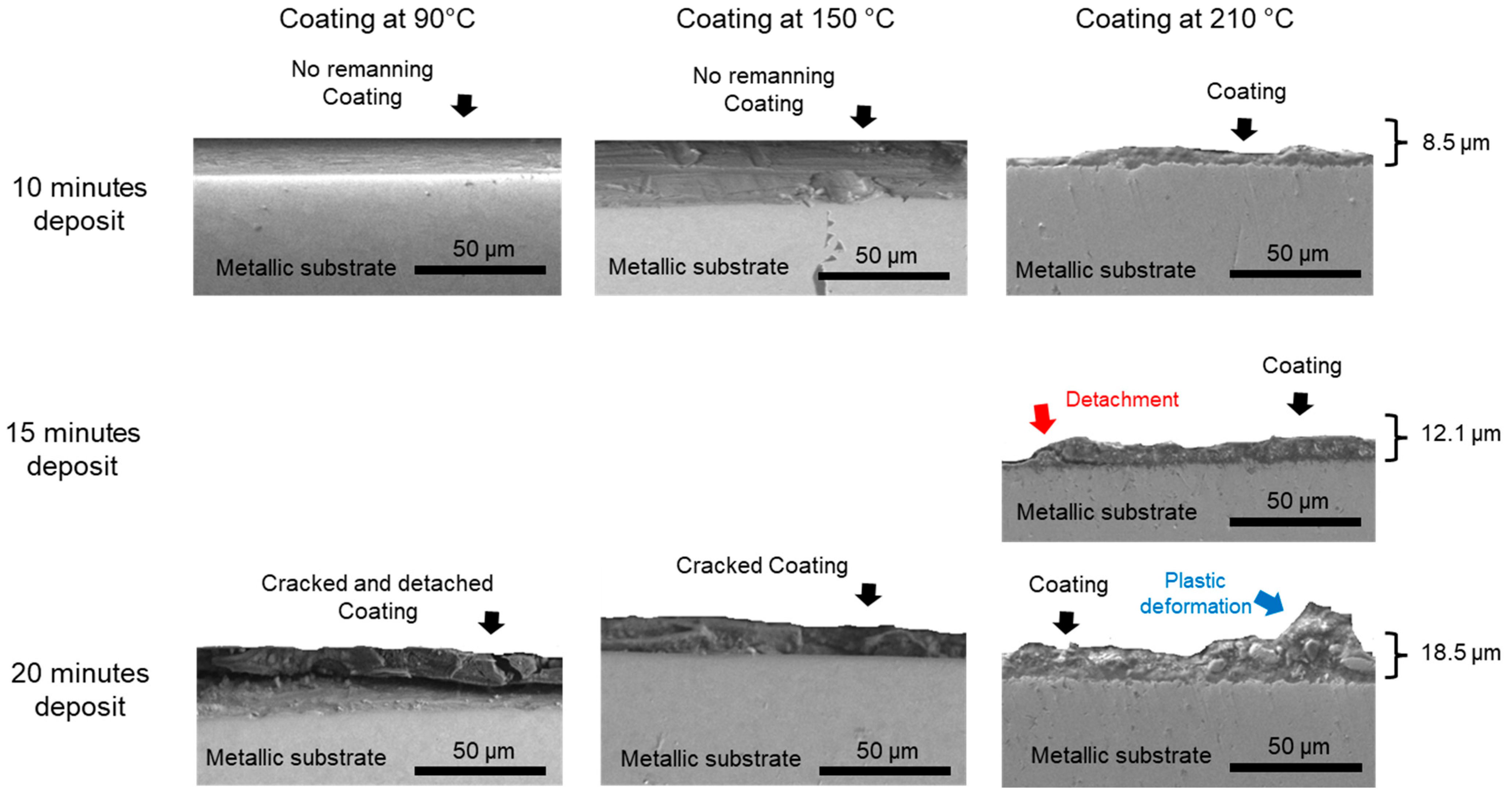

3.7. Films Thickness

4. Discussion

5. Novelty and Application

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Holmberg, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Ouyang, C.; Bai, P.; Wen, X.; Zhang, X.; Meng, Y.; Ma, L.; Tian, Y. Effects of conformational entropy on antiwear performances of organic friction modifiers. Tribol. Int. 2020, 156, 106848. [Google Scholar] [CrossRef]

- Zhang, B.; Xue, Y.; Qiang, L.; Gao, K.; Liu, Q.; Yang, B.; Liang, A.; Zhang, J. Assembling of carbon nanotubes film responding to significant reduction wear and friction on steel surface. Appl. Nanosci. 2017, 7, 835–842. [Google Scholar] [CrossRef]

- Shah, R.; Woydt, M.; Zhang, S. The Economic and Environmental Significance of Sustainable Lubricants. Lubricants 2021, 9, 21. [Google Scholar] [CrossRef]

- Attia, N.; El-Mekkawi, S.; Elardy, O.; Abdelkader, E. Chemical and rheological assessment of produced biolubricants from different vegetable oils. Fuel 2020, 271, 117578. [Google Scholar] [CrossRef]

- Alves, S.M.; Barros, B.S.; Trajano, M.F.; Ribeiro, K.S.B.; Moura, E. Tribological behavior of vegetable oil-based lubricants with nanoparticles of oxides in boundary lubrication conditions. Tribol. Int. 2013, 65, 28–36. [Google Scholar] [CrossRef]

- Cornelio, J.A.C.; Cuervo, P.A.; Hoyos-Palacio, L.M.; Lara-Romero, J.; Toro, A. Tribological properties of carbon nanotubes as lubricant additive in oil and water for a wheel–rail system. J. Mater. Res. Technol. 2016, 5, 68–76. [Google Scholar] [CrossRef]

- Otero, I.; López, E.R.; Reichelt, M.; Fernández, J. Friction and anti-wear properties of two tris(pentafluoroethyl)trifluorophosphate ionic liquids as neat lubricants. Tribol. Int. 2014, 70, 104–111. [Google Scholar] [CrossRef]

- Domínguez-García, S.; Béjar-Gómez, L.; López-Velázquez, A.; Maya-Yescas, R.; Nápoles-Rivera, F. Maximizing Lubricant Life for Internal Combustion Engines. Processes 2022, 10, 2070. [Google Scholar] [CrossRef]

- Domínguez-García, S.; Aguilar-Ramírez, C.E.; Béjar-Gómez, L.; Maya-Yescas, R. Mass balance of the tribofilm in lubricated systems. Tribol. Int. 2020, 155, 106757. [Google Scholar] [CrossRef]

- Cullen, J.M.; Allwood, J.M.; Borgstein, E.H. Reducing Energy Demand: What Are the Practical Limits? Environ. Sci. Technol. 2011, 45, 1711–1718. [Google Scholar] [CrossRef]

- Tung, S.C.; McMillan, M.L. Automotive tribology overview of current advances and challenges for the future. Tribol. Int. 2004, 37, 517–536. [Google Scholar] [CrossRef]

- Spiller, S.; Lenauer, C.; Wopelka, T.; Jech, M. Real time durability of tribofilms in the piston ring—Cylinder liner contact. Tribol. Int. 2017, 113, 92–100. [Google Scholar] [CrossRef]

- Singh, A.; Gandra, R.T.; Schneider, E.W.; Biswas, S.K. Lubricant Degradation and Related Wear of a Steel Pin in Lubricated Sliding Against a Steel Disc. ACS Appl. Mater. Interfaces 2011, 3, 2512–2521. [Google Scholar] [CrossRef] [PubMed]

- Zhao, B.; Dai, X.-D.; Zhang, Z.-N.; Xie, Y.-B. A new numerical method for piston dynamics and lubrication analysis. Tribol. Int. 2016, 94, 395–408. [Google Scholar] [CrossRef]

- Akchurin, A.; Bosman, R.; Lugt, P.M. Generation of wear particles and running-in in mixed lubricated sliding contacts. Tribol. Int. 2017, 110, 201–208. [Google Scholar] [CrossRef]

- Azam, A.; Dorgham, A.; Morina, A.; Neville, A.; Wilson, M.C. A simple deterministic plastoelastohydrodynamic lubrication (PEHL) model in mixed lubrication. Tribol. Int. 2018, 131, 520–529. [Google Scholar] [CrossRef]

- Ghanbarzadeh, A.; Wilson, M.; Morina, A.; Dowson, D.; Neville, A. Development of a new mechano-chemical model in boundary lubrication. Tribol. Int. 2016, 93, 573–582. [Google Scholar] [CrossRef]

- Azam, A.; Ghanbarzadeh, A.; Neville, A.; Morina, A.; Wilson, M.C. Modelling tribochemistry in the mixed lubrication regime. Tribol. Int. 2018, 132, 265–274. [Google Scholar] [CrossRef]

- Domínguez-García, S.; Maya-Yescas, R.; Béjar-Gómez, L. Reduction of lubricant life in lubrication systems for internal combustion engines due to high lubricant supply rates. Mater. Lett. 2022, 313, 131785. [Google Scholar] [CrossRef]

- Dörr, N.; Agocs, A.; Besser, C.; Ristić, A.; Frauscher, M. Engine Oils in the Field: A Comprehensive Chemical Assessment of Engine Oil Degradation in a Passenger Car. Tribol. Lett. 2019, 67, 68. [Google Scholar] [CrossRef]

- Okubo, H.; Tadokoro, C.; Sasaki, S. In Situ Raman-SLIM Monitoring for the Formation Processes of MoDTC and ZDDP Tribofilms at Steel/Steel Contacts under Boundary Lubrication. Tribol. Online 2020, 15, 105–116. [Google Scholar] [CrossRef]

- Acharya, B.; Seed, C.M.; Krim, J. Shear activation of ZDDP reaction films in the presence and absence of nanodiamonds. Appl. Surf. Sci. Adv. 2022, 7, 100214. [Google Scholar] [CrossRef]

- Ghanbarzadeh, A.; Parsaeian, P.; Morina, A.; Wilson, M.C.T.; van Eijk, M.C.P.; Nedelcu, I.; Dowson, D.; Neville, A. A Semi-deterministic Wear Model Considering the Effect of Zinc Dialkyl Dithiophosphate Tribofilm. Tribol. Lett. 2015, 61, 12. [Google Scholar] [CrossRef]

- Domínguez-García, S.; Béjar-Gómez, L.; Huirache-Acuna, R.; Lara-Romero, J.; Maya-Yescas, R. Delumping Strategy to Infer Lubrication Reaction Pathways in Internal Combustion Engines. Int. J. Chem. React. Eng. 2019, 18, 20190043. [Google Scholar] [CrossRef]

- Morina, A.; Neville, A.; Priest, M.; Green, J. ZDDP and MoDTC interactions and their effect on tribological performance—Tribofilm characteristics and its evolution. Tribol. Lett. 2006, 24, 243–256. [Google Scholar] [CrossRef]

- Dawczyk, J.; Morgan, N.; Russo, J.; Spikes, H. Film Thickness and Friction of ZDDP Tribofilms. Tribol. Lett. 2019, 67, 34. [Google Scholar] [CrossRef]

- Bayat, R.; Lehtovaara, A. Tribofilm Formation of Simulated Gear Contact Along the Line of Action. Tribol. Lett. 2021, 69, 126. [Google Scholar] [CrossRef]

- Yang, X.; Hu, Y.; Zhang, L.; Zheng, Y.; Politis, D.J.; Liu, X.; Wang, L.-L. Experimental and modelling study of interaction between friction and galling under contact load change conditions. Friction 2021, 10, 454–472. [Google Scholar] [CrossRef]

- Barber, J.R. Multiscale Surfaces and Amontons’ Law of Friction. Tribol. Lett. 2013, 49, 539–543. [Google Scholar] [CrossRef]

- Leibina, A.P.; Mokhnatkin, É.M. Rating engine wear by determining content of metals in oils. Chem. Technol. Fuels Oils 1976, 12, 387–390. [Google Scholar] [CrossRef]

- Vakis, A.; Yastrebov, V.; Scheibert, J.; Nicola, L.; Dini, D.; Minfray, C.; Almqvist, A.; Paggi, M.; Lee, S.; Limbert, G.; et al. Modeling and simulation in tribology across scales: An overview. Tribol. Int. 2018, 125, 169–199. [Google Scholar] [CrossRef]

- Minfray, C.; Martin, J.M.; De Barros, M.I.; Le Mogne, T.; Kersting, R.; Hagenhoff, B. Chemistry of ZDDP tribofilm by ToF-SIMS. Tribol. Lett. 2004, 17, 351–357. [Google Scholar] [CrossRef]

- Bakunin, V.N.; Kuzmina, G.N.; Kasrai, M.; Parenago, O.P.; Bancroft, G.M. Tribological behavior and tribofilm composition in lubricated systems containing surface-capped molybdenum sulfide nanoparticles. Tribol. Lett. 2006, 22, 289–296. [Google Scholar] [CrossRef]

- Özkan, D.; Sulukan, E. The anti-wear efficiency of boron succinimide on engine cylinder liner and piston ring surfaces. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 32. [Google Scholar] [CrossRef]

- Umer, J.; Morris, N.; Leighton, M.; Rahmani, R.; Balakrishnan, S.; Rahnejat, H. Nano and microscale contact characteristics of tribofilms derived from fully formulated engine oil. Tribol. Int. 2018, 131, 620–630. [Google Scholar] [CrossRef]

- Miranda-Medina, M.d.L.; Tomastik, C.; Truglas, T.; Groiss, H.; Jech, M. Effect of engine oil additives reduction on the tribofilm structure of a cylinder liner model surface. Ind. Lubr. Tribol. 2019, 72, 515–523. [Google Scholar] [CrossRef]

- Zhang, J.; Meng, Y. Boundary lubrication by adsorption film. Friction 2015, 3, 115–147. [Google Scholar] [CrossRef]

- del Río, J.M.L.; Guimarey, M.J.; Prado, J.I.; Lugo, L.; López, E.R.; Comuñas, M.J. Improving the tribological performance of a biodegradable lubricant adding graphene nanoplatelets as additives. J. Mol. Liq. 2021, 345, 117797. [Google Scholar] [CrossRef]

- Burwell, J.T. Law of Adhesive Wear. J. Appl. Phys. 1956, 27, 1561. [Google Scholar] [CrossRef]

- Burwell, J.T.; Strang, C.D. On the Empirical Law of Adhesive Wear. J. Appl. Phys. 1952, 23, 18–28. [Google Scholar] [CrossRef]

- Bhattacharyya, H.P. On the Law of Adhesive Wear. J. Appl. Phys. 1956, 27, 661–662. [Google Scholar] [CrossRef]

- Azam, A.; Dorgham, A.; Parsaeian, P.; Morina, A.; Neville, A.; Wilson, M.C. The mutual interaction between tribochemistry and lubrication: Interfacial mechanics of tribofilm. Tribol. Int. 2019, 135, 161–169. [Google Scholar] [CrossRef]

- ASTM E3-11; Standard Guide for Preparation of Metallographic Specimens. ASTM International: West Conshohocken, PA USA, 2017.

- ASTM G99-95a; Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 2000.

- Chen, C.; Wang, J.; Ge, Y.; Zhuang, M.; Ma, Z. Microstructure and Wear Resistance of High-Chromium Cast Iron with Multicomponent Carbide Coating via Laser Cladding. Coatings 2023, 13, 1474. [Google Scholar] [CrossRef]

- Masafi, M.; Palkowski, H.; Mozaffari-Jovein, H. Microstructural Properties of Particle-Reinforced Multilayer Systems of 316L and 430L Alloys on Gray Cast Iron. Coatings 2023, 13, 1450. [Google Scholar] [CrossRef]

- Saraç, E.; Özbek, N.A. Effect of tempering temperature on mechanical properties and microstructure of AISI 4140 and AISI 4340 tempered steels. Mater. Test. 2022, 64, 832–841. [Google Scholar] [CrossRef]

- Özbek, N.A. Effects of Cryogenic Treatment on the Microstructure, Hardness, and Wear Behavior of 1.2436 Steel. Gazi J. Eng. Sci. 2023, 9, 100–107. [Google Scholar] [CrossRef]

- Özbek, N.A.; Özbek, O. Effect of cryogenic treatment holding time on mechanical and microstructural properties of Sverker 21 steel. Mater. Test. 2022, 64, 1809–1817. [Google Scholar] [CrossRef]

- Maurya, A.K.; Patnaik, A.; Pandey, S.M.; Chhibber, R.; Pandey, C. Tribological Performance of Gas Tungsten Arc Welded Dissimilar Joints of sDSS 2507/N50 Steel. J. Mater. Eng. Perform. 2023, 1–15. [Google Scholar] [CrossRef]

- Thakare, J.G.; Pandey, C.; Mahapatra, M.M.; Mulik, R.S. Thermal Barrier Coatings—A State of the Art Review. Met. Mater. Int. 2020, 27, 1947–1968. [Google Scholar] [CrossRef]

- Lu, G.; Yang, Z. Tribological Performance and Model Establishment of Self-Compensating Lubrication Film Inspired by the Functional Surfaces of Scapharca subcrenata Shells. Coatings 2023, 13, 1399. [Google Scholar] [CrossRef]

| Repetitions | Temperature, °C | Deposition Time, min |

|---|---|---|

| 1 | 90 | 10 |

| 1 | 90 | 15 |

| 1 | 90 | 20 |

| 1 | 150 | 10 |

| 3 | 150 | 15 |

| 1 | 150 | 20 |

| 1 | 210 | 10 |

| 1 | 210 | 15 |

| 1 | 210 | 20 |

| Repetitions | Temperature, °C | Deposition Time, min |

|---|---|---|

| 1 | 90 | 10 |

| 1 | 150 | 10 |

| 1 | 210 | 10 |

| 1 | 210 | 15 |

| 1 | 90 | 20 |

| 1 | 150 | 20 |

| 1 | 210 | 20 |

| Element % | Disk ASTM A36 | Pin AISI 52100 |

|---|---|---|

| C | 0.25–0.29 | 0.93–1.05 |

| Mn | 0.60–1.20 | 0.25–0.45 |

| Si | 0.15–0.40 | 0.15–0.35 |

| P | 0.04 | <0.025 |

| S | 0.05 | <0.025 |

| Cr | — | 1.35–1.60 |

| Mechanical Property | Disk ASTM A36 | Pin AISI 52100 |

|---|---|---|

| Minimum yield strength, MPa | 250 | 360–560 |

| Tensile strength, MPa | 400–500 | 590–2010 |

| Elastic modulus, GPa | 200 | 190 |

| Hardness, HB | 120 | 180–210 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Domínguez García, S.; Béjar Gómez, L.; Maya Yescas, R.; Lara Romero, J.; Castro Cedeño, B.; Espinosa Medina, M.A. Friction Coefficient Dynamics of Tribological Coatings from Engine Lubricants: Analysis and Interpretation. Coatings 2023, 13, 1753. https://doi.org/10.3390/coatings13101753

Domínguez García S, Béjar Gómez L, Maya Yescas R, Lara Romero J, Castro Cedeño B, Espinosa Medina MA. Friction Coefficient Dynamics of Tribological Coatings from Engine Lubricants: Analysis and Interpretation. Coatings. 2023; 13(10):1753. https://doi.org/10.3390/coatings13101753

Chicago/Turabian StyleDomínguez García, Saúl, Luis Béjar Gómez, Rafael Maya Yescas, Javier Lara Romero, Baltazar Castro Cedeño, and Marco Antonio Espinosa Medina. 2023. "Friction Coefficient Dynamics of Tribological Coatings from Engine Lubricants: Analysis and Interpretation" Coatings 13, no. 10: 1753. https://doi.org/10.3390/coatings13101753

APA StyleDomínguez García, S., Béjar Gómez, L., Maya Yescas, R., Lara Romero, J., Castro Cedeño, B., & Espinosa Medina, M. A. (2023). Friction Coefficient Dynamics of Tribological Coatings from Engine Lubricants: Analysis and Interpretation. Coatings, 13(10), 1753. https://doi.org/10.3390/coatings13101753