Effect of Ultrasonic Vibration Frequency on Ni-Based Alloy Cladding Layer

Abstract

:1. Introduction

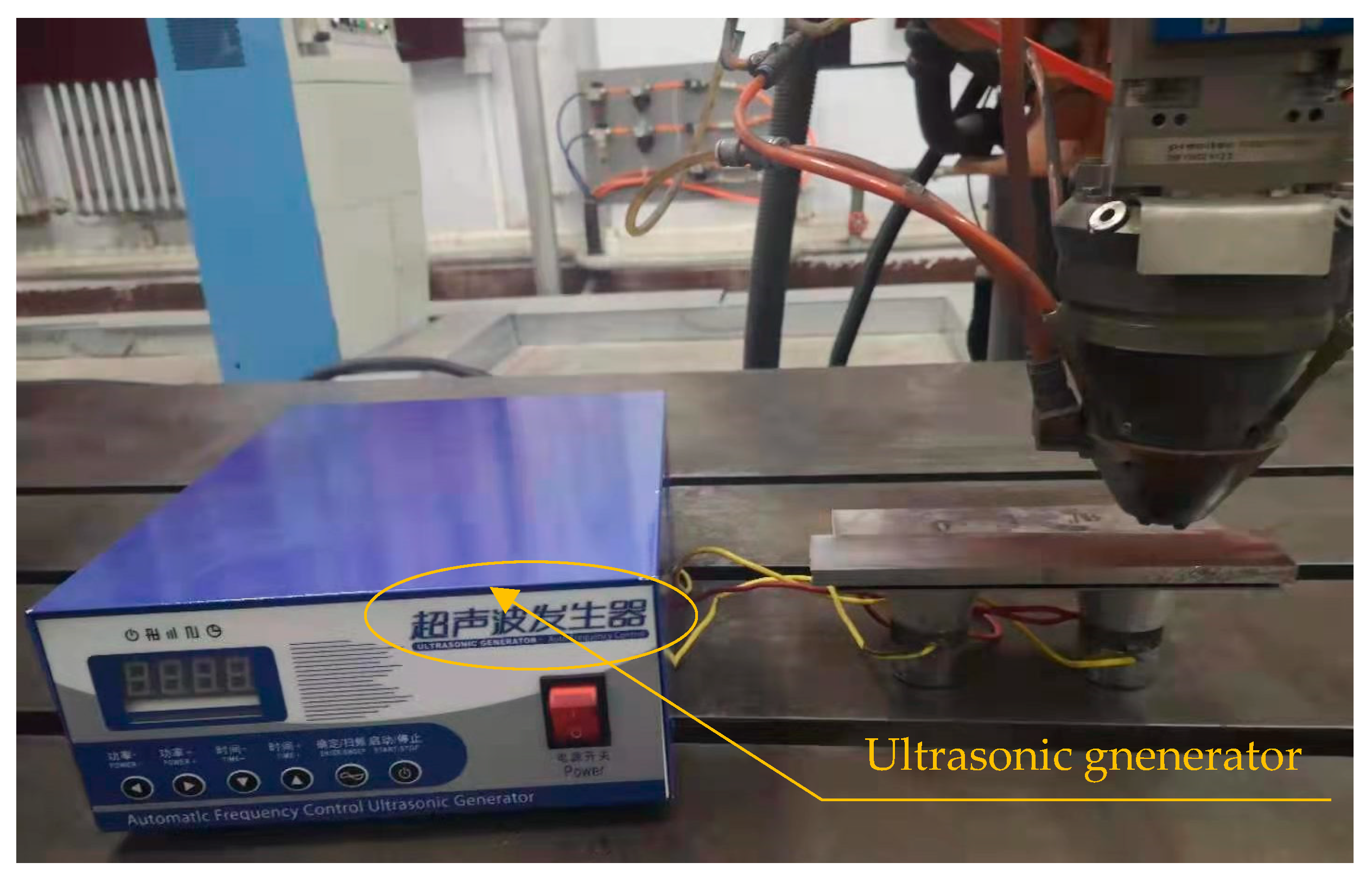

2. Experimental Materials and Methods

2.1. Experimental Materials

2.2. Experimental Methods

3. Experiment Results and Analysis

3.1. Morphology Analysis of the Cladding Layer

3.2. Microstructure Analysis of the Cladding Layer

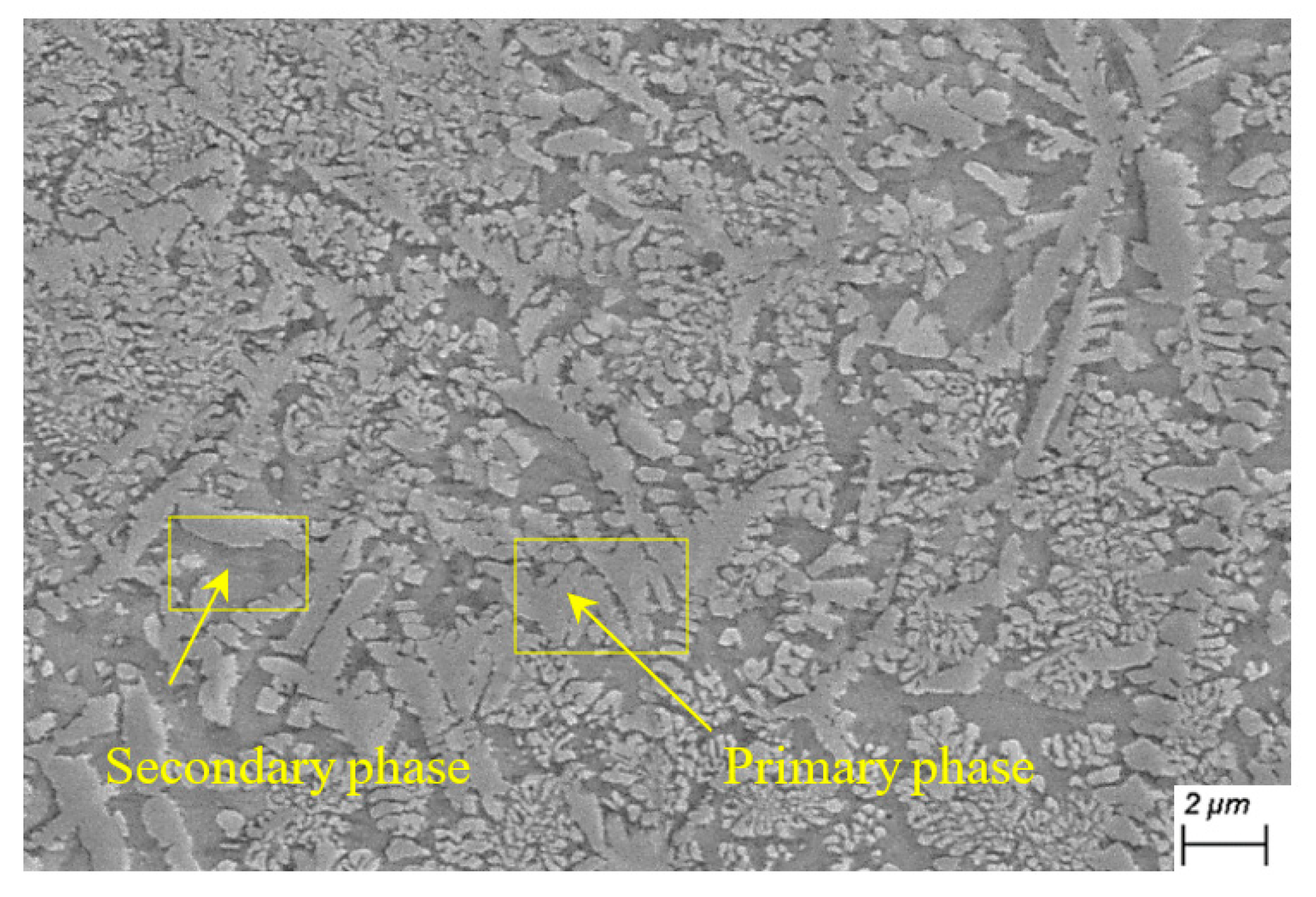

3.2.1. Microstructure of Cladding Layer

3.2.2. Segregation of Elements in the Cladding Layer

3.3. Microhardness of the Cladding Layer

3.4. Friction and Wear Properties of the Cladding Layer

3.4.1. Wear Rate of Cladding Layer

3.4.2. Friction and Wear Behavior of Cladding Layer

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.; Zhao, S.; Gao, W.; Zhou, C.; Liu, F.; Lin, X. Microstructure and properties of laser cladding FeCrBSi composite powder coatings with higher Cr content. J. Mater. Process. Technol. 2014, 214, 899–905. [Google Scholar] [CrossRef]

- Williamson, E.H.; Gee, M.; Robertson, D.; Watts, J.F.; Whiting, M.J.; Yeomans, J.A. A comparative study of the wear performance of hard coatings for nuclear applications. Wear 2022, 488–489, 204124. [Google Scholar] [CrossRef]

- Ramirez, A.; Qian, M.; Davis, B.; Wilks, T.; StJohn, D.H. Potency of high-intensity ultrasonic treatment for grain refinement of magnesium alloys. Scr. Mater. 2008, 59, 19–22. [Google Scholar] [CrossRef]

- Ma, G.; Yan, S.; Wu, D.; Miao, Q.; Liu, M.; Niu, F. Microstructure evolution and mechanical properties of ultrasonic assisted laser clad yttria stabilized zirconia coating. Ceram. Int. 2017, 43, 9622–9629. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, S.; Zhang, X.; Liu, W.; Li, R. Experiments and Analysis of 3450Fe/CeO2 Coatings by Ultrasonic Vibration Assisted Laser Claddin. China Mech. Eng. 2018, 29, 2600–2605. [Google Scholar]

- Li, M.; Zhang, Q.; Han, B.; Song, L. Microstructure and property of Ni/WC/La2O3 coatings by ultrasonic vibration-assisted laser cladding treatment. Opt. Lasers Eng. 2020, 125, 10548. [Google Scholar] [CrossRef]

- Zhan, W. Research on Technology and Properties of Ni60 Coating by Ultrasound-Assisted Laser Cladding. Master’s Thesis, Xinjiang University, Ürümqi, China, 2020. [Google Scholar]

- Du, S. Study on the Effect of Mechanical Vibration on the Properties of Induction Cladding Ni60+WC Coatings. Ph.D. Thesis, Qingdao University of Technology, Qingdao, China, 2018. [Google Scholar]

- Gao, G.; Guo, Z.; Li, K. Ultrasonic vibration assisted Ni60WC25 powder laser cladding technology. Heat Treat. Met. 2019, 44, 172–175. [Google Scholar]

- Fengxiao, H. An Investigation on Microstructure and Properties of Ni-Based Alloy by Laser Cladding and Laser Cladding Forming; Jilin University: Changchun, China, 2011. [Google Scholar]

- Bartsch, H.J. Handbook of Mathematical Formulas; Academic Press: New York, NY, USA, 1974. [Google Scholar]

- Li, M.; Han, B.; Wang, Y.; Song, L.; Guo, L. Investigation on lasercladding high-hardness nano-ceramic coating assisted by ultrasonic vibration processing. Opt. Int. Light Electron Opt. 2016, 304, 262. [Google Scholar]

- Shen, J.; Lin, C.; Yao, Y.; Xu, H.; Liu, J. Effect of Ultrasound Vibration on Microstructure and Propertise of Laser Cladding. Surf. Technol. 2019, 48, 226–232. [Google Scholar]

- Fan, Z.; Wang, K.; Dong, X.; Duan, W.; Wang, R.; Mei, X.; Wang, W.; Cui, J.; Zhang, S.; Xu, C. Evaluation of microstructural evolution and corrosion types in ultrasonic assisted laser re-melted thermal barrier coatings underexposure to molten salts. Mater. Lett. 2017, 188, 145–148. [Google Scholar] [CrossRef]

- Liu, H.; Xu, Q.; Wang, C.; Zhang, X. Corrosion and wear behavior of Ni60CuMoW coatings fabricated by combination of laser cladding and mechanical vibration processing. J. Alloys Compd. 2015, 621, 357–363. [Google Scholar] [CrossRef]

- Liu, X.; Osawa, Y.; Takamori, S.; Mukai, T. Microstructure and mechanical properties of AZ91 alloy produced with ultrasonic vibration. Mater. Sci. Eng. A 2008, 487, 120–123. [Google Scholar] [CrossRef]

- Cui, Z.Q.; Qin, Y.C. Metallurgy and Heat Treatment, 2nd ed.; China Machine Press: Beijing, China, 2007. [Google Scholar]

- Shao, X. Prepariation and Properties of Ultrasonic Vibration Assisted Laser Clad Strengthened Coating on High-Speed Wheel/Rail Steel. Ph.D. Thesis, East China Jiaotong University, Nanchang, China, 2017. [Google Scholar]

- Wang, Y.; Li, C.; Jiang, F.; Zhang, J.; An, X. Effect of Ultrasonic Assistance on Mechanical Properties of Laser Cladding Al2O3-ZrO2 Ceramic Coating. Surf. Technol. 2020, 49, 309–319. [Google Scholar]

| Elments | C | Si | Mn | Cr | Mo | V | P | S | Fe | B | W | Ni |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H13 | 0.38 | 0.92 | 0.28 | 5 | 1.2 | 0.95 | 0.02 | 0.03 | Bal. | -- | -- | -- |

| Ni60 | 0.65 | 4.0 | -- | 15 | -- | -- | -- | -- | 15 | 3.5 | 3 | Bal. |

| f/kHz | W/mm | H/mm | h/mm | Dilution Rate η (%) | Wetting Angle θ (°) |

|---|---|---|---|---|---|

| 0 | 3.93 | 0.98 | 0.45 | 31.46 | 50.25 |

| 26 | 4.05 | 0.84 | 0.24 | 22.12 | 44.92 |

| 30 | 4.21 | 0.76 | 0.21 | 21.83 | 43.50 |

| 34 | 4.36 | 0.69 | 0.18 | 20.05 | 34.08 |

| 38 | 4.03 | 0.71 | 0.20 | 21.17 | 36.12 |

| Area | Element | B | C | Si | Cr | Fe | Ni | W |

|---|---|---|---|---|---|---|---|---|

| Primary phase | wt% | 10.17 | 10.25 | 2.33 | 16.09 | 12.74 | 47.38 | 1.04 |

| at% | 29.14 | 26.45 | 2.57 | 9.59 | 7.07 | 25.01 | 0.18 | |

| Secondary phase | wt% | 8.61 | 6.86 | 3.65 | 9.91 | 15.25 | 55.71 | -- |

| at% | 27.37 | 19.63 | 4.47 | 6.55 | 9.38 | 32.60 | -- |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, F.; Li, J.; Fang, L.; Ming, Z. Effect of Ultrasonic Vibration Frequency on Ni-Based Alloy Cladding Layer. Coatings 2022, 12, 1305. https://doi.org/10.3390/coatings12091305

Yao F, Li J, Fang L, Ming Z. Effect of Ultrasonic Vibration Frequency on Ni-Based Alloy Cladding Layer. Coatings. 2022; 12(9):1305. https://doi.org/10.3390/coatings12091305

Chicago/Turabian StyleYao, Fangping, Jinhua Li, Lijin Fang, and Zhi Ming. 2022. "Effect of Ultrasonic Vibration Frequency on Ni-Based Alloy Cladding Layer" Coatings 12, no. 9: 1305. https://doi.org/10.3390/coatings12091305

APA StyleYao, F., Li, J., Fang, L., & Ming, Z. (2022). Effect of Ultrasonic Vibration Frequency on Ni-Based Alloy Cladding Layer. Coatings, 12(9), 1305. https://doi.org/10.3390/coatings12091305