Abstract

Among the different nanostructures involved in the improvement of material properties, carbon nanotubes occupy a specific place because of their small refractive index, extended surface, and large Young’s module, which can all provoke dramatic change in basic matrix material characteristics. Inorganic crystals, semiconductors, metals, conductive compounds, and some polymer structures whose surfaces are treated with carbon nanotubes demonstrate better features than the ones obtained before carbon nanotubes deposition. Thus, the areas of application for these unique nanostructure materials can be effectively extended, e.g., for optoelectronic use, in biomedicine, and display applications. In the current paper, the advantages of the laser-oriented deposition technique are shown in order to demonstrate how the main material parameters change drastically through the incorporation of carbon nanotubes.

1. Introduction

It is well known that after the discovery of carbon nanotubes (CNTs) in 1991, many scientific and technical research teams in the world have revealed novel ways to improve classical material properties through adding these nanostructures to the body of matrix compounds or by the deposition of CNTs on the material’s surface. PVD, CVD, and pulse laser vaporization methods, among others, have all been applied to grow and use CNTs [1,2,3,4,5]. Analytical and quantum chemical calculations support the experimental results obtained. The focus has mainly been on theoretical simulation, as shown, for example, in papers [6,7,8,9], where an appropriative relationship with the experimental results was mentioned. CNTs, as promising nano-objects used for the improvement of material properties, have branched surfaces, high conductivity, strong C–C bonds, a small value of refractive index, and complicated and unique mechanisms of charge carrier movement. Moreover, CNTs have a diameter on the nanometric scale and a length measured in micrometers. These features extend the areas of CNT application and provide them with significant advantages [10,11,12,13,14,15,16,17,18,19,20,21,22].

Analyzing previously observed data from different papers and taking into account discussions at different scientific conferences, it can be postulated that the laser-oriented deposition (LOD) approach has some advantage in improving material characteristics. This is due to the fact that the LOD technique can be applied without high temperatures, it can be used with a small amount of CNTs (connected to the low loss of the oriented carbon material), and can reveal covalent bonding between carbon atoms and the material matrix surface atoms. The peculiarity of this method is the use of a grid under tension in a vacuum cap during laser deposition of the CNTs. This permits variation of the electric field from 100 to 600 V/cm and orients the CNTs in a vertical position under the deposition process.

To reveal these advantages of CNTs via the use of the LOD approach, different types of optical materials, such as metals Al and Cu [23,24], semiconductors ZnSe and ZnS [25,26], and optical crystals KBr, LiF, and MgF2 [27,28,29], ITO conductive layers [30,31] are treated to vertically deposit the nano-objects mentioned above in order to change the refractivity, the spectral and mechanical characteristics, and the wetting phenomena of the materials.

In the current paper, the comparative parameters of the different materials treated are shown, analyzed, and explained. Additional novel data for the materials treated are also shown.

2. Materials and Methods

The CNTs used in this work were single-wall carbon nanotubes (SWCNTs), type #704121, with a diameter in the range of 0.7–1.1 nm (Aldrich Co., Karlsruhe, Germany). These possess good structures to treat all types of materials.

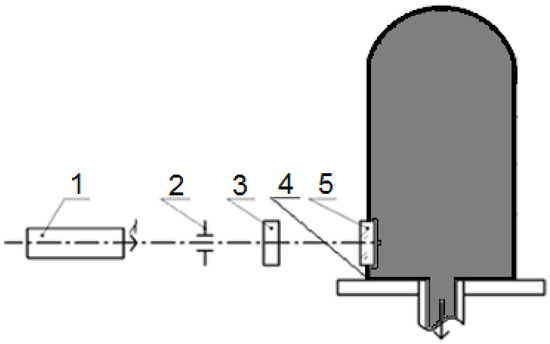

The method of the LOD technique has been explained in patents [32,33]. The principle block-scheme of the laser-deposition technique is shown in paper [27]; the actual scheme to deposit CNTs in the vertical position is presented in paper [24]. In order to explain the principle of the LOD technique more clearly, a short version of the scheme is shown in Figure 1.

Figure 1.

Short presentation of the used setup: 1—CO2-laser (λ = 10.6 microns); 2—diaphragm, 3—prison; 4—vacuum post (inside which the CNTs are deposited in the vertical position on the chosen samples when using a grid with a voltage); 5—a panel of KCl single crystal.

In order to structure the material’s surface, an IR CO2-laser with p-polarized irradiation at a wavelength of 10.6 μm and power of 30 W was applied. The laser system was connected to a vacuum hood containing the fixing unit samples and the device for placing substances deposited on the substrate. CNTs were placed at the material’s interface under an additional electric field of 100–600 V/cm−1 in order to orient the nanotubes in the vertical position during the deposition process. Thus, the laser-oriented deposition (LOD) method was realized.

The spectra were collected using a VIS spectrophotometer SF-26, IR Furrier FSM-1202 device (Nica-Garant+, Saint-Petersburg, Russia). Microhardness Vickers tests were carried out by a PMT-3M tester (LOMO Ltd., Saint-Petersburg, Russia). The microhardness values illustrated in the work are the average of five points on each sample. The contact angle (CA) was determined using a OCA 15EC device (LabTech Co., Saint-Petersburg-Moscow, Russia). The contact angle values presented in this work are the average of five points on each sample. Both pure and modified surface analysis were performed using Solver Next AFM (purchased from NT MDT Co., Zelenograd, Moscow region, Russia).

3. Results

The basic results of this comparative analysis are shown in Table 1 and Table 2. The data presented in Table 1 demonstrate the increase of the micro-hardness of the treated materials under the value of the chosen indenters. The values of the used indenter are also shown.

Table 1.

Micro-hardness increases of the materials.

Table 2.

Wetting angle increases of the materials.

To explain the mechanical parameter improvements, high Young’s module values were used, and the covalent bonding formed between the carbon atoms and the material’s surfaces were taken into account, which is supported via quantum-chemical calculation for all materials treated [23,24,25,26,27,28,29,30,31].

The data shown in Table 2 visualize the change of contact angle (wetting angle) when a drop of water was placed on the material’s surface. In order to explain the increase of the wetting angle, the diameter of the CNTs and the value of the lattice parameters of the studied materials were chosen carefully.

Regarding spectral improvement, it is possible to see that the KBr have shown an increase in transparency from 70% to 78% at a wavelength of 350–400 nm, and from 87% to 89% in the range of 1000–1300 nm. The increase of the tested transparency for KBr was from 88.3% to 89.8% in the spectral range of 1400–2400 nm [27]. In the spectral range of 1400–2400 nm the change of the transparency for the ZnS and ZnSe structures was established as 0.5% [25]; at the wavelength of 2.3 microns, the change of the transmittance spectra of the ZnS materials was found to be close to 1.5% [26]. The transmittance of the MgF2 systems was increased up to 15% at a wavelength of 125 nm [26]. The transparency of the NaCl structure increased by more than 10% in the range of 2–16 microns [29]. The transmittance was increase for the LiF materials by ~5% in the range of 225–350 nm [28].

To explain the spectral increase, the small value of the CNTs refractive index (n close to 1.1) and the lager value of the refractive parameters for all materials shown in this study were all taken into account. For example, one important KBr material (used as the main element in a Furrier spectrometer) has a refractive index change from n = 1.594 (at a wavelength of λ = 0.391 microns) to n = 1.461 (at a wavelength of 25.140 microns), which is more than the one for the CNTs structure used. MgF2 crustal (used as the output window in UV lamps for the disinfection of hospital rooms) has a refractive index change from n = 1.4376 (at a wavelength of λ = 0.200 microns) to n = 1.3101 (at a wavelength of 7.0 microns), which is also more than the one for the CNTs. Other materials treated and shown in this article also have larger values of refractive index in comparison to that for the CNTs. Thus, Fresnel losses were minimized dramatically.

Of course, it can also be seen from the data shown that the materials have not been studied by spectral parameters at all wavelengths, where they exhibit features. This may give rise to a new study on the extended spectral range and on an explanation of the manifested features, not only at specific wavelengths.

It should be mentioned that, for the ITO conductive structure, a drastic decrease of resistivity was found, which can be explained by graphene-quasi-layers forming [31]. It has been shown that the resistance may change by 3–5 times or more.

It should be noted that some materials shown in Table 1 and Table 2 have been investigated in order to check their roughness. For example, for the MgF2 model crystal, the main parameters of the roughness are presented in Table 3.

Table 3.

Roughness parameters for the MgF2 structure.

For the MgF2 materials, it can be seen that the maximum (Rmax), average (Ra), and root-mean-square change in roughness (Sq) is improved during surface treatment due to the directional deposition of the CNTs. The roughness was analyzed by atomic force microscopy at the surface area of 5000 nm × 5000 nm. The same tendency has been observed for the other treated systems shown in this summarized data.

4. Conclusions

Comparative data regarding the optical, mechanical, and wetting properties of large groups of material are shown. The advantage of the LOD technique has been demonstrated, and details of CNTs nano-objects regarding their material investigations and modifications has been presented.

Indeed, it should be remarked that other approaches can be applied to form novel coatings in order to protect materials from corrosion, bacterial activity, and solvent impact, etc. Experiments and mathematical models have been shown in recently published papers [34,35,36,37,38,39,40,41,42,43] and have demonstrated their various advantages. However, the LOD technique has certain unique advantage that allows treatment of all types of the materials, such as inorganic crystals, semiconductors, metals, and some high-temperature polyimide structures, etc.

As a forecast for the further use of this technology (LOD approach), it is worth stating the following. It is possible that, due to the small diameter of nanotubes, along with their dense placement on the surface of materials and their very high mechanical hardness, it is possible to use the resulting lotus effect to protect against bacteria and viruses on both medical instruments and auxiliary medical devices in hospitals and polyclinics. Indeed, this direction is very important for human life; therefore, future experiments should be made with great care and attention.

Moreover, changing the angle of suspension of water molecules on a number of materials allows for the potential application of this effect in modulating technology (electrically- or optically-addressed light modulators with a modulating layer on liquid crystals), when it will be possible to dispense with the use of direct orienting layers and use the modified surface of the material to record information, for example, based on a photo layer from ZnS or ZnSe, etc.

Author Contributions

Conceptualization, investigation, formal analysis, writing—original draft preparation, writing—review and editing, N.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The results shown coincide with scientific research at the Photophysics Lab at Vavilov State Optical Institute over more than 10 years via some Russian and International projects. The author would like to thank her young researcher in the Lab, PhD-students, and students from Saint-Petersburg State Electrotechnical University “LETI”, which were partially involved in this researche at different stages.

Conflicts of Interest

The author declares no conflict of interest.

References

- Krzysztof, K.; Boskovic, B.O.; Noorhana, Y. Synthesis of Carbon Nanostructures by CVD Method. In Carbon and Oxide Nanostructures. Advanced Structured Materials; Springer: Berlin/Heidelberg, Germany, 2010; Volume 5, pp. 23–49. [Google Scholar] [CrossRef]

- Nishide, D.; Kataura, H.; Suzuki, S.; Okubo, S.; Achiba, Y. Growth of single-wall carbon nanotubes from ethanol vapor on cobalt particles produced by pulsed laser vaporization. Chem. Phys. Lett. 2004, 392, 309–313. [Google Scholar] [CrossRef]

- Rui, S.; Lu, J.; Chunxu, P. A Single-Step Process for Preparing Supercapacitor Electrodes from Carbon Nanotubes. Soft Nanosci. Lett. 2011, 1, 11–15. [Google Scholar] [CrossRef]

- Ángel, P.d.P.; Enikö, G.; Laura, C.; Belén, B.; Gerard, T. Deposition of functionalized single wall carbon nanotubes through matrix assisted pulsed laser evaporation. Carbon 2012, 50, 4450–4458. [Google Scholar] [CrossRef]

- Watanabe, T.; Yamazaki, S.; Yamashita, S.; Inaba, T.; Muroga, S.; Morimoto, T.; Kobashi, K.; Okazaki, T. Comprehensive Characterization of Structural, Electrical, and Mechanical Properties of Carbon Nanotube Yarns Produced by Various Spinning Methods. Nanomaterials 2022, 12, 593. [Google Scholar] [CrossRef]

- Jean-Christophe, C.; Xavier, B.; Stephan, R. Electronic and transport properties of nanotubes. Rev. Mod. Phys. 2007, 79, 677–732. [Google Scholar] [CrossRef]

- Hua, B.; Xiulin, R.; Timothy, S.F. Optical properties of ordered vertical arrays of multi-walled carbon nanotubes from FDTD simulations. Opt. Express 2010, 18, 6347–6359. [Google Scholar]

- Clancy, A.J.; Bayazit, M.K.; Hodge, S.A.; Skipper, N.T.; Howard, C.A.; Shaffer, M.S.P. Charged Carbon Nanomaterials: Redox Chemistries of Fullerenes, Carbon Nanotubes, and Graphenes. Chem. Rev. 2018, 118, 7363–7408. [Google Scholar] [CrossRef]

- Belonenko, M.B.; Dvuzhilov, I.S.; Dvuzhilova, Y.V.; Boroznin, S.V. Light Bullets in a Periodically Inhomogeneous Medium of Oriented Carbon Nanotubes in an Optical Cavity. Opt. Spectrosc. 2019, 126, 394–399. [Google Scholar] [CrossRef]

- Robertson, J. Realistic applications of CNTs. Mater. Today 2004, 7, 46–52. [Google Scholar] [CrossRef]

- Namilae, S.; Chandra, N.; Shet, C. Mechanical behavior of functionalized nanotubes. Chem. Phys. Lett. 2004, 387, 247–252. [Google Scholar] [CrossRef]

- Alexander, D.P.; Beresnev, V.M. Nanocoatings Nanosystems Nanotechnologies; Bentham Science Publishers: Sharjah, United Arab Emirates, 2012. [Google Scholar] [CrossRef]

- Ferriera, M.; Martino, A.D.; Kasumov, A.; Guéron, S.; Kociak, M.; Egger, R.; Bouchiat, H. Superconductivity in ropes of carbon nanotubes. Solid State Commun. 2004, 131, 615–623. [Google Scholar] [CrossRef]

- Santos, A.; Amorim, L.; Nunes, J.P.; Rocha, L.A.; Silva, A.F.; Viana, J.C. A Comparative Study between Knocked-Down Aligned Carbon Nanotubes and Buckypaper-Based Strain Sensors. Materials 2019, 12, 2013. [Google Scholar] [CrossRef]

- Hazarika, M.; Chinnamuthu, P.; Borgohain, C.; Borah, J.P. Role of MWCNT concentration in MWCNT/ZnFe2O4 nanocomposites for enhanced photocatalytic performance. J. Mater. Sci. Mater. Electron. 2020, 31, 10783–10794. [Google Scholar] [CrossRef]

- Bonegardt, D.; Klyamer, D.; Kuksoy, B.; Durmuş, M.; Basova, T. Hybrid materials of carbon nanotubes with fluoroalkyl- and alkylsubstituted zinc phthalocyanines. J. Mater. Sci. Mater. Electron. 2020, 31, 11021–11028. [Google Scholar] [CrossRef]

- Ibrahim, S.O.; Isah, K.U.; Abdulkareem, A.S.; Ahmadu, U.; Tijani, J.O.; Roos, W.D. Synthesis and characterization of platinum multi-walled carbon nanotubes nanocomposite film electrode. J. Mater. Sci. Mater. Electron. 2021, 32, 12800–12811. [Google Scholar] [CrossRef]

- Rossella, A.; Giulio, M. Rheological Behavior of Polymer/Carbon Nanotube Composites: An Overview. Materials 2020, 13, 2771. [Google Scholar] [CrossRef]

- Shafique, S.; Karimov, K.S.; Abid, M.; Ahmed, M.M.; Akhmedov, K.M.; Aziz-ur-Rehman. Carbon nanotubes, orange dye, and graphene powder based multifunctional temperature, pressure, and displacement sensors. J. Mater. Sci. Mater. Electron. 2020, 31, 8893–8899. [Google Scholar] [CrossRef]

- Andreev, A.S.; Kazakova, M.A.; Ishchenko, A.V.; Selyutin, A.G.; Lapina, O.B.; Kuznetsov, V.L.; de Lacaillerie, J.-B.d.E. Magnetic and dielectric properties of carbon nanotubes with embedded cobalt nanoparticles. Carbon 2017, 114, 39–49. [Google Scholar] [CrossRef]

- Valadão, D.R.B.; Pires, D.G.; Alencar, M.A.R.C.; Hickmann, J.M.; Fantini, C.; Pimenta, M.A.; Fonseca, E.J.S. Investigation of the electronic nonlinear refraction index of single-wall carbon nanotubes wrapped with different surfactants. Opt. Mater. Express 2012, 2, 749–756. [Google Scholar] [CrossRef]

- Srivastava, A.K.; Pozhidaev, E.P.; Chigrinov, V.G.; Manohar, R. Single walled carbon nano-tube, ferroelectric liquid crystal composites: Excellent diffractive tool. Appl. Phys. Lett. 2011, 99, 201106. [Google Scholar] [CrossRef]

- Kamanina, N.; Borodianskiy, K.; Kvashnin, D. Surface Heterostructure of Aluminum with Carbon Nanotubes Obtained by Laser-Oriented Deposition. Coatings 2021, 11, 674. [Google Scholar] [CrossRef]

- Kamanina, N.; Toikka, A.; Kvashnin, D. Nanostructuration Impact on the Basic Properties of the Materials: Novel Composite Carbon Nanotubes on a Copper Surface. J. Compos. Sci. 2022, 6, 181. [Google Scholar] [CrossRef]

- Kamanina, N.; Toikka, A.; Valeev, B.; Kvashnin, D. Carbon Nanotubes Use for the Semiconductors ZnSe and ZnS Material Surface Modification via the Laser-Oriented Deposition Technique. C 2021, 7, 84. [Google Scholar] [CrossRef]

- Kamanina, N.; Toikka, A.; Barnash, Y.; Kuzhakov, P.; Kvashnin, D. Advanced and Functional Structured Ceramics: MgF2 and ZnS. Materials 2022, 15, 4780. [Google Scholar] [CrossRef]

- Kamanina, N.V.; Likhomanova, S.V.; Kuzhakov, P.V. Advantages of the Surface Structuration of KBr Materials for Spectrometry and Sensors. Sensors 2018, 18, 3013. [Google Scholar] [CrossRef]

- Kamanina, N.; Kuzhakov, P.; Kukharchik, A.; Kvashnin, D. A nanostructuring approach for modification of the features of optical materials: Lithium fluoride. IOP Conf. Ser. Mater. Sci. Eng. 2019, 693, 012008. [Google Scholar] [CrossRef]

- Kuzhakov, P.V.; Kamanina, N.V. Spectral Investigations and Wettability of Nanostructured Potassium Bromide, Sodium Chloride, and Magnesium Fluoride Single Crystals. Opt. Spectrosc. 2014, 117, 643–646. [Google Scholar] [CrossRef]

- Kamanina, N.V.; Kukharchik, A.A.; Kuzhakov, P.V.; Zubtcova, Y.A.; Stepanov, R.O.; Baryshnikov, N.V. Modification of the conductive ITO layer by carbon nanotubes for orientation of liquid crystals in electro-optical optical information conversion devices. Liq. Cryst. Appl. 2015, 15, 109–118. [Google Scholar] [CrossRef]

- Kamanina, N.; Toikka, A.; Gladysheva, I. ITO conducting coatings properties improvement via nanotechnology approach. Nano Express 2021, 2, 010006. [Google Scholar] [CrossRef]

- Kamanina, N.V.; Vasilyev, P.Y. Optical Coatings Based on CNTs for the Optical Devises and Nanoelectronics. Patent RU 2007, 2, 1. [Google Scholar]

- Kamanina, N.V.; Vasilyev, P.Y.; Studeonov, V.I. Optical Coating Based on Oriented in the Electric Field CNTs for the Optical Devises, Micro- and Nanoelectronics under the Conditions When the Interface: Solid Substrate-Coating Can Be Eliminated. Patent RU 2008, 2, 177. [Google Scholar]

- Beake, B.D. Nano- and Micro-Scale Impact Testing of Hard Coatings: A Review. Coatings 2022, 12, 793. [Google Scholar] [CrossRef]

- Piperopoulos, E.; Grifò, G.; Scionti, G.; Atria, M.; Calabrese, L.; Consolo, G.; Proverbio, E. Study of Intumescent Coatings Growth for Fire Retardant Systems in Naval Applications: Experimental Test and Mathematical Model. Coatings 2022, 12, 1180. [Google Scholar] [CrossRef]

- Vereschaka, A.; Seleznev, A.; Gaponov, V. Wear Resistance, Patterns of Wear and Plastic Properties of Cr,Mo-(Cr,Mo,)N-(Cr,Mo,Al)N Composite Coating with a Nanolayer Structure. Coatings 2022, 12, 758. [Google Scholar] [CrossRef]

- Botas, A.M.P. New Frontiers in Novel Optical Materials and Devices. Coatings 2022, 12, 856. [Google Scholar] [CrossRef]

- Drozda, M.; Miszczyk, A. Selection of Organic Coating Systems for Corrosion Protection of Industrial Equipment. Coatings 2022, 12, 523. [Google Scholar] [CrossRef]

- Laube, T.; Weisser, J.; Sachse, S.; Seemann, T.; Wyrwa, R.; Schnabelrauch, M. Comparable Studies on Nanoscale Antibacterial Polymer Coatings Based on Different Coating Procedures. Nanomaterials. 2022, 12, 614. [Google Scholar] [CrossRef]

- Bulatova, M.I.; Shatsova, A.A. Strength and Fracture Resistance of Quartz Fibers with Polyimide Coatings. Russ. J. Non-Ferr. Met. 2021, 62, 756–762. [Google Scholar] [CrossRef]

- Atta, A.M.; El-Newehy, M.H.; Abdulhameed, M.M.; Wahby, M.H.; Hashem, A.I. Seawater Absorption and Adhesion Properties of Hydrophobic and Superhydrophobic Thermoset EpoxyNanocomposite. Coatings. Nanomaterials 2021, 11, 272. [Google Scholar] [CrossRef]

- Ress, J.; Martin, U.; Bastidas, D.M. Improved Corrosion Protection of Acrylic Waterborne Coating by Doping with Microencapsulated Corrosion Inhibitors. Coatings 2021, 11, 1134. [Google Scholar] [CrossRef]

- Qi, Y.; Weicheng, N.; Chaofan, L.; Ping, C.; Hanlin, C.; Yiyi, W. Synthesis of reduced graphene oxides with magnetic Co nanocrystals coating for electromagnetic absorption properties. J. Mater. Sci. Mater. Electron. 2020, 31, 22616–22628. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).