A Review on Modelling and Simulation of Laser Additive Manufacturing: Heat Transfer, Microstructure Evolutions and Mechanical Properties

Abstract

:1. Introduction

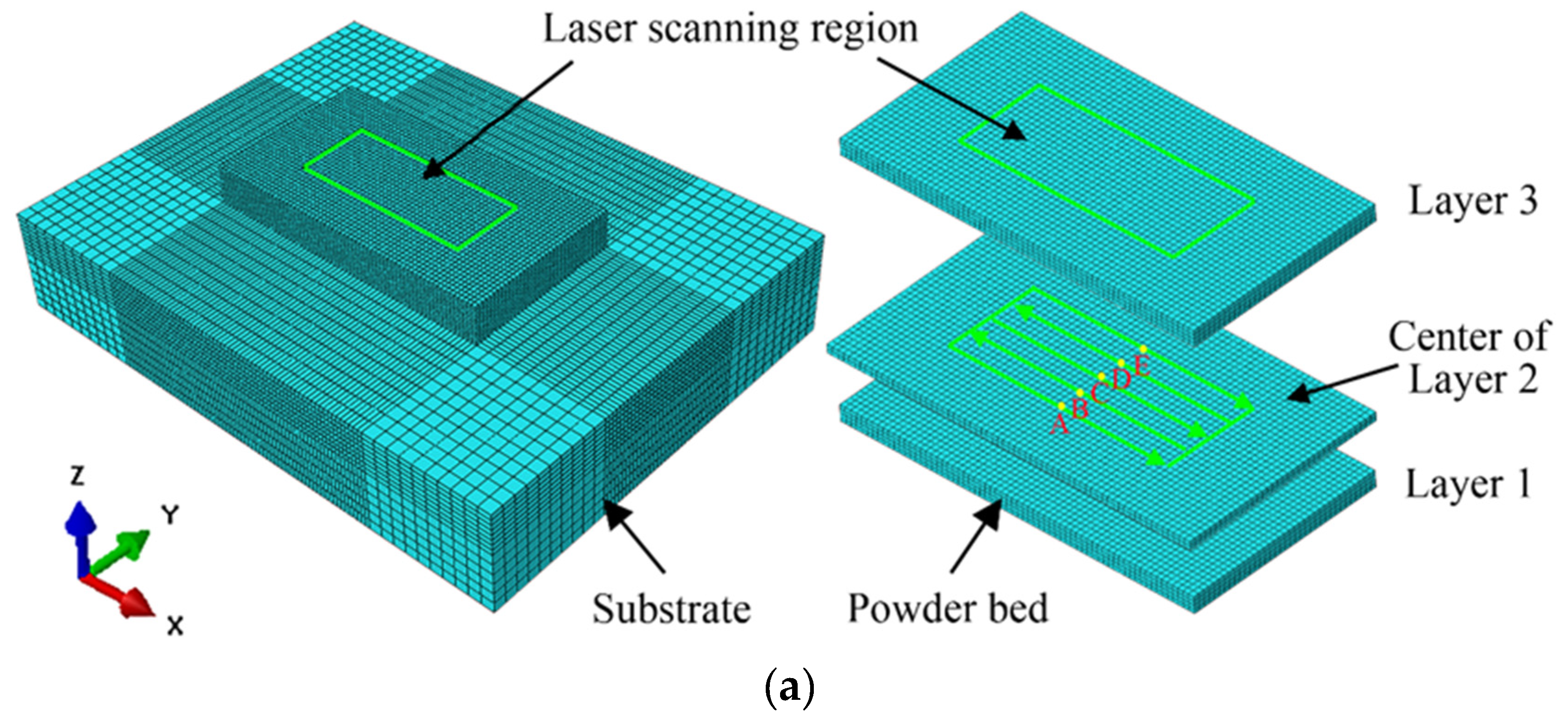

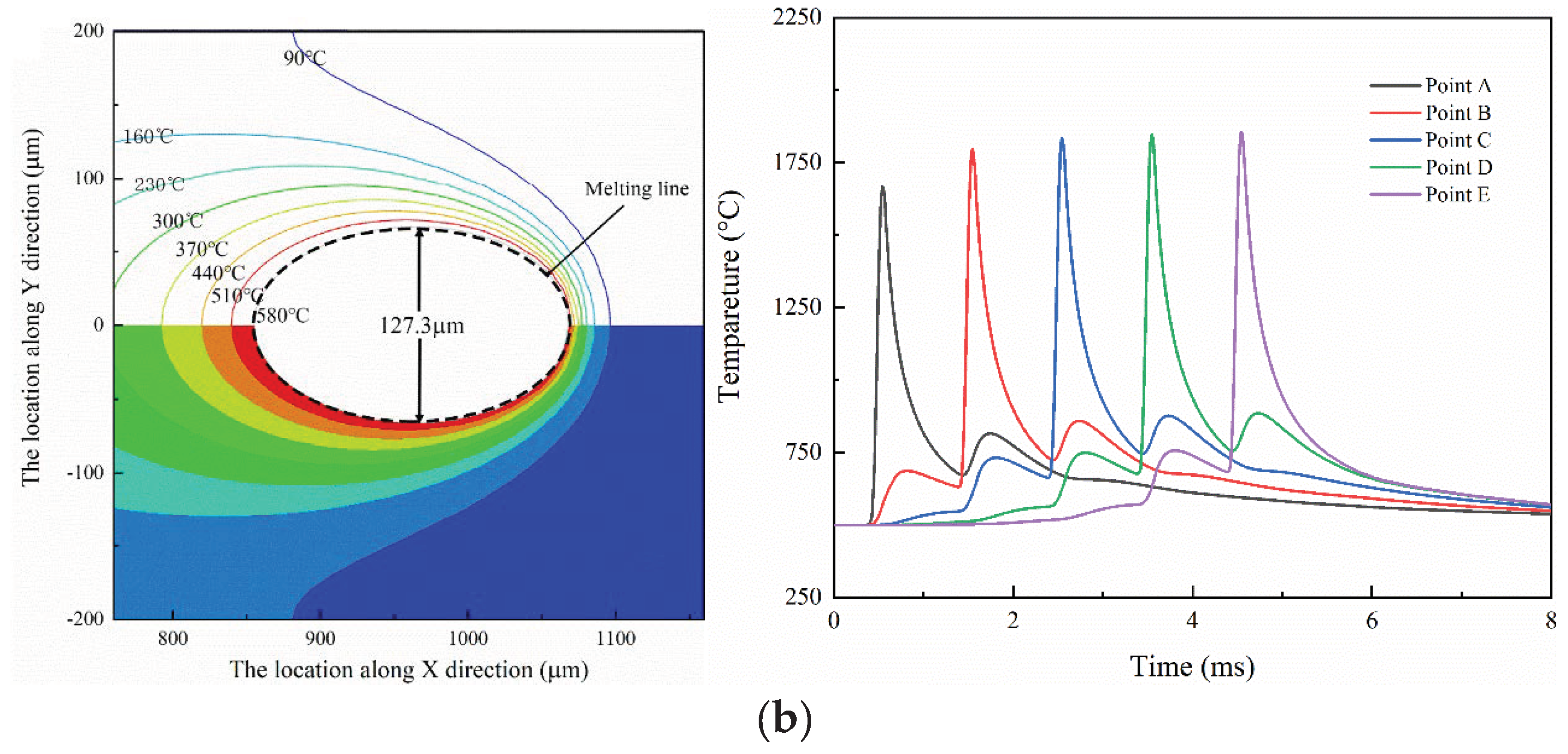

2. Thermal Modelling

2.1. Volumetric Heat Source Model

2.1.1. Gaussian Heat Source Model

2.1.2. Double Ellipsoid Heat Source Model

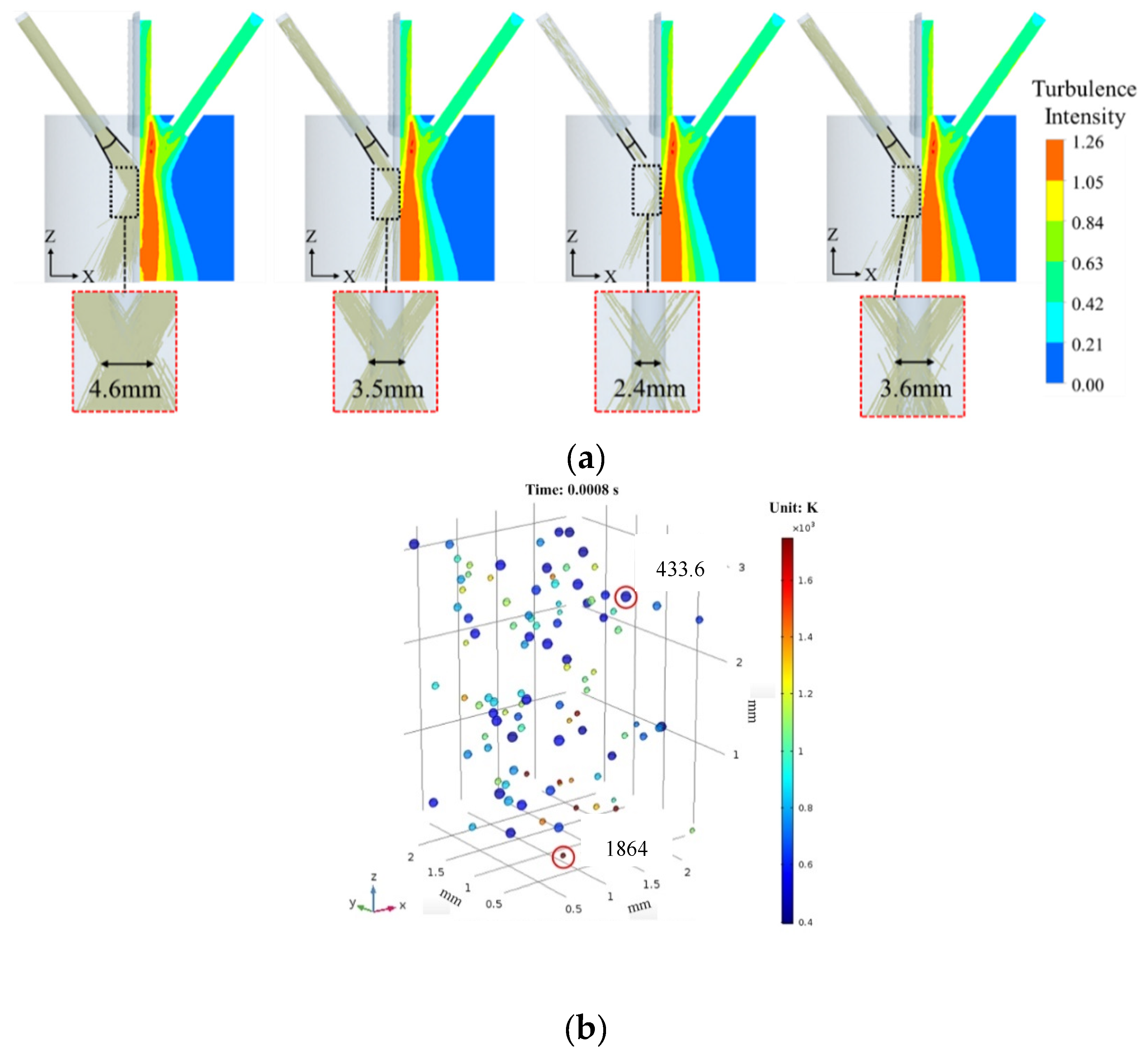

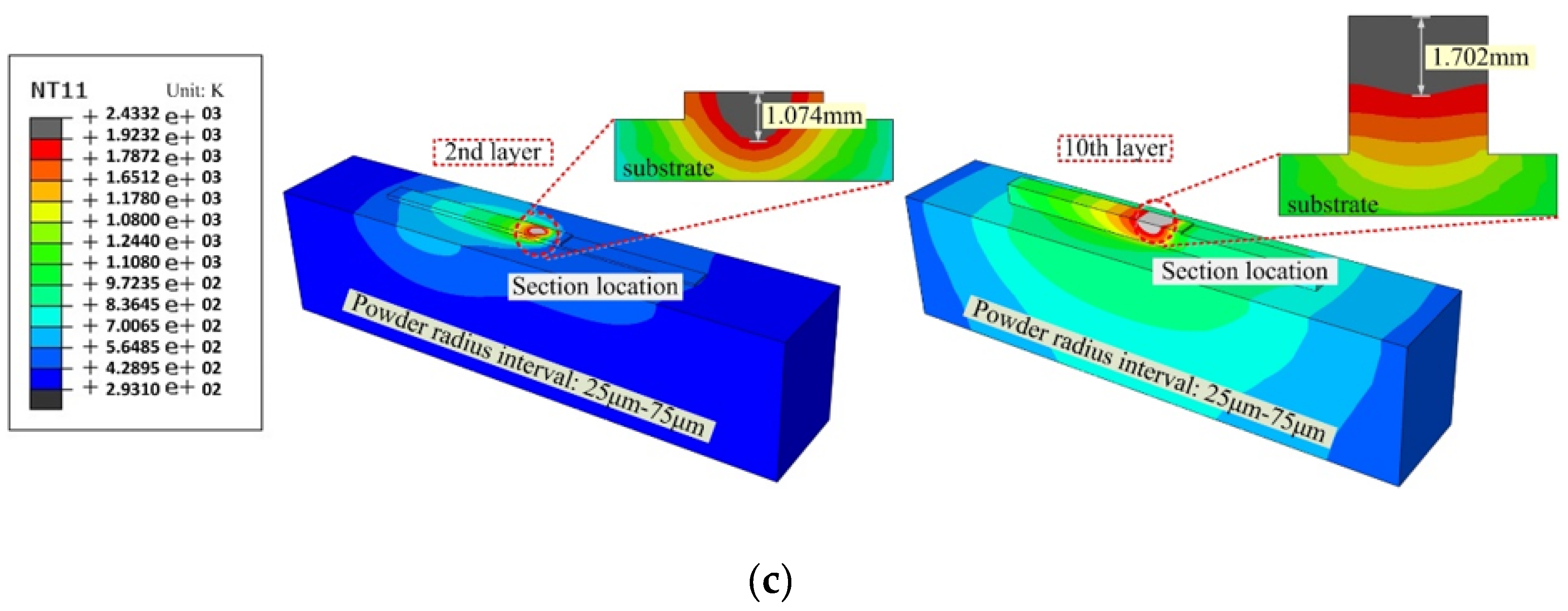

2.2. Heat Source Model Considering Laser-Particle Interactions

| Heat Source Model | AM Type | AM Material | AM Parameters | Temperature | Reference |

|---|---|---|---|---|---|

| Gaussian heat source | PBF | Ti6Al4V | P = 3 W d = 0.1 mm v = 1 mm/s dp = 30 μm | 2425–2450 K | [75] |

| Gaussian heat source | DED | 316L | P = 600 W d = 1.2 mm v = 6 mm/s dp = 80–120 μm | 2000 °C | [76] |

| Surface heat source | DED | Ti-22Al-25Nb | P = 1000 W d = 4 mm v = 3 mm/s dp = 38–160 μm | ~2300–2800 °C | [77] |

| Surface heat source | DED | Ti6Al4V | P = 400–600 W d = 1.74 mm v = 0.2–0.4 m/min | 2139–2390 K | [78] |

| Double ellipsoid heat source | DED | Ti6Al4V | P = 1000 W d = 3 mm v = 5 mm/s dp = 45–150 μm | ~2950 °C | [79] |

| Gaussian heat source | SLS | AlSi10Mg | P = 100 W d = 0.2 mm v = 100 mm/s | 1761 °C | [80] |

| Semi-spherical power distribution model | SLS | Ti6Al4V | P = 270 W d = 0.2 mm v = 1 m/s | 4000–7000 K | [81] |

| Gaussian heat source | PBF | Inconel 625 | P = 2 W d = 0.025 mm v = 1 mm/s dp = 30 μm | ~2000 °C | [82] |

| Gaussian heat source | PBF | Ti6Al4V | P = 3 W d = 0.1 mm v = 1 mm/s dp = 30 μm | 2500–3000 K | [83] |

| Gaussian heat source | PBF | Hastelloy X | P = 150 W d = 0.1 mm v = 1–1.6 mm/s | ~2700–3300 K | [84] |

| Gaussian heat source | PBF | Mg2Si with nanoparticles (Si) | P = 6.5–25 W d = 0.6 mm v = 4.23 mm/s | 1200–2500 K | [85] |

| Surface heat source | SLS | Ti6Al4V | P = 170 W d = 0.1 mm v = 1.25 m/s | 1650 °C | [86] |

| Gaussian heat source | SLS | AlSi10Mg | P = 700–1900 J/m d = 0.1 mm v = 0.1 m/s | 731–2672 °C | [87] |

| Gaussian heat source | - | Ti6Al4V SS316L Al7075 | P = 100 W d = 0.2 mm v = 4 m/s | 2369 °C 1790 °C 969 °C | [88] |

| Different heat source models | PBF | SS17-4PH | P = 170–220 W d = 0.1 mm v = 0.6–1.3 m/s dp = 16–64 μm | ~4500–6500 K | [89] |

| Gaussian heat source | PBF | Ti-6Al-4V | P = 100 W d = 0.2 mm v = 0.2 m/s | 2311–2474 °C (depending on layer thickness) | [90] |

3. Microstructure Evolutions

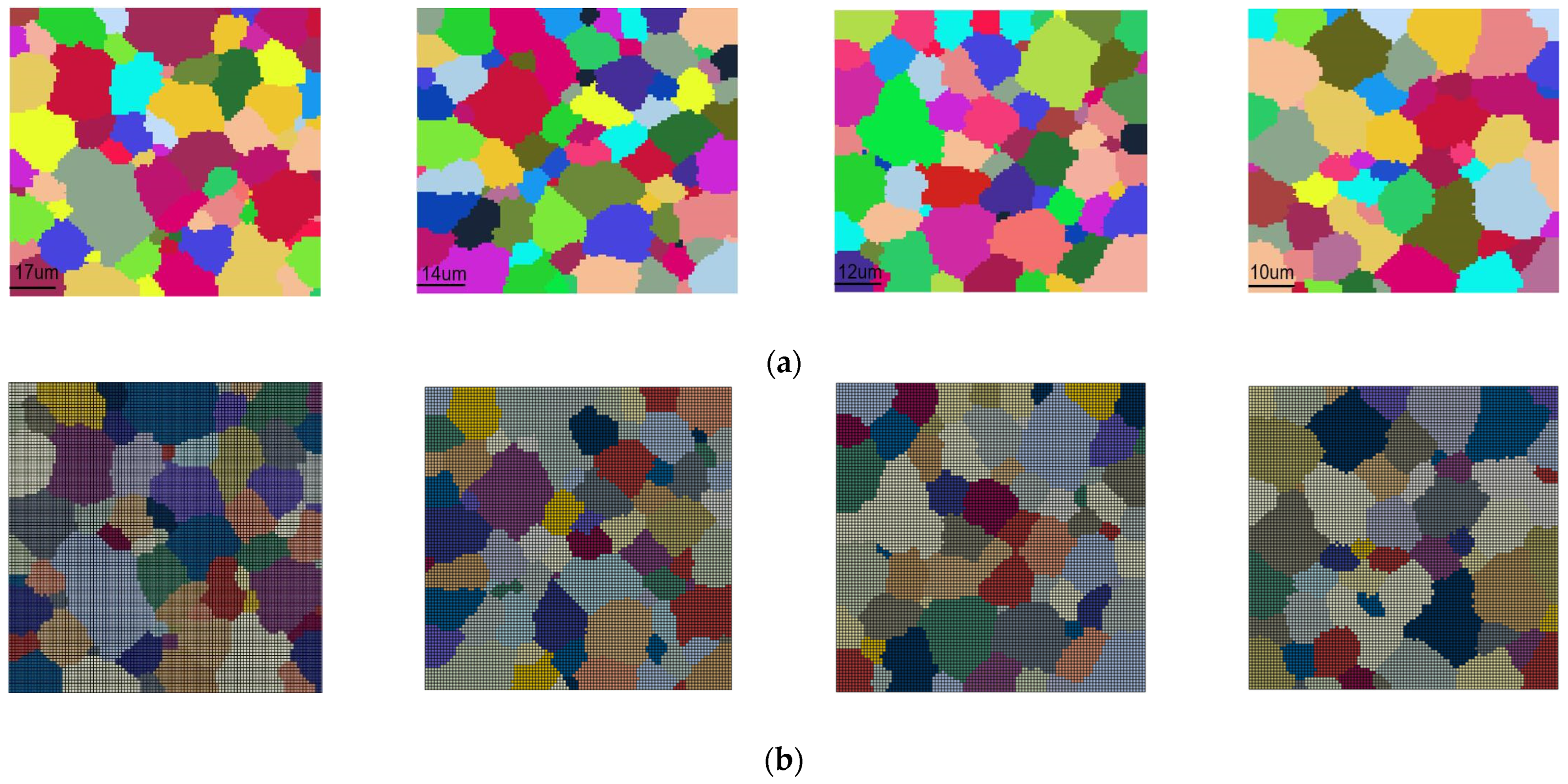

3.1. Monte Carlo Model

3.2. Cellular Automaton Model

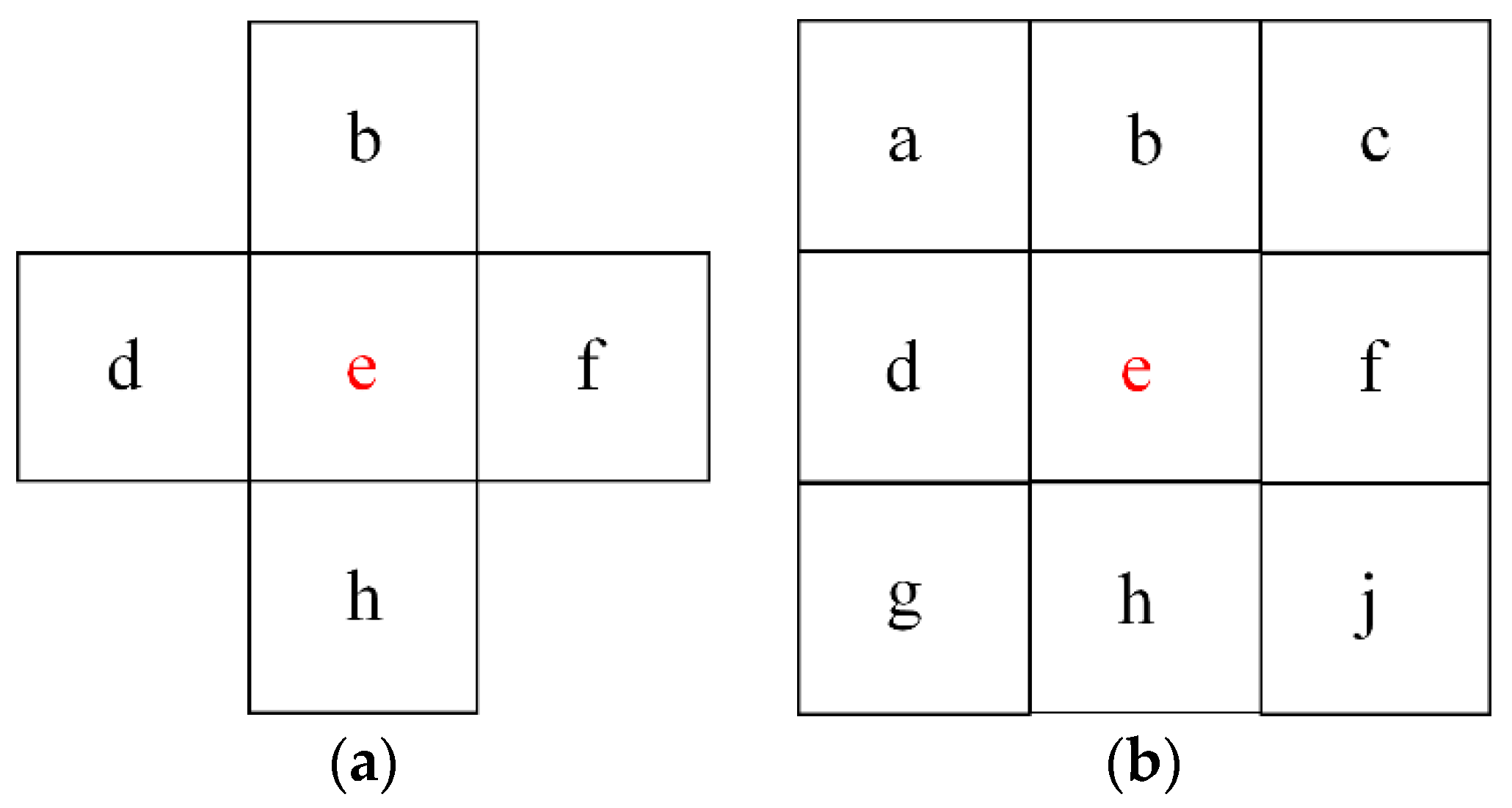

- If the state value of a cells e is the same as that of the eight adjacent neighbors, then the state value of the next step is constant;

- (a) If any 3 of the cell b, d, f, and h is A States, the state of the cell e is converted to A at the next CAS;(b) If any 3 of the cell a, c, g, and j are A States, the state of the cell e is converted to A at the next CAS;

- If the above conditions are not satisfied, each cell overcomes the energy barriers to change randomly into 8 adjacent cells, calculate the grain boundary energy change ΔE, the GBE for each site can be calculated by the Hamiltonian,

- If the state value of a cells e is the same as that of the four adjacent neighbors, then the state value of the next step is constant;

- If any 3 of the cell b, d, f, and h is A States, the state of the cell e is converted to A at the next CAS. It can be expressed as (1);

- If the above conditions are not satisfied, each cell overcomes the energy barriers to change randomly into 4 adjacent cells, the rules of calculation are the same as formulas (3) and (4);

- If the above conditions are not satisfied, randomly changes to the value of a neighbor cell.

3.3. Phase Field Model

3.4. Precipitate Evolution Model

4. Mechanical Properties

4.1. Physics Based Model

4.1.1. Precipitate Evolution Based Model of Mechanical Property

4.1.2. Dislocation Density Evolution Based Model of Mechanical Property

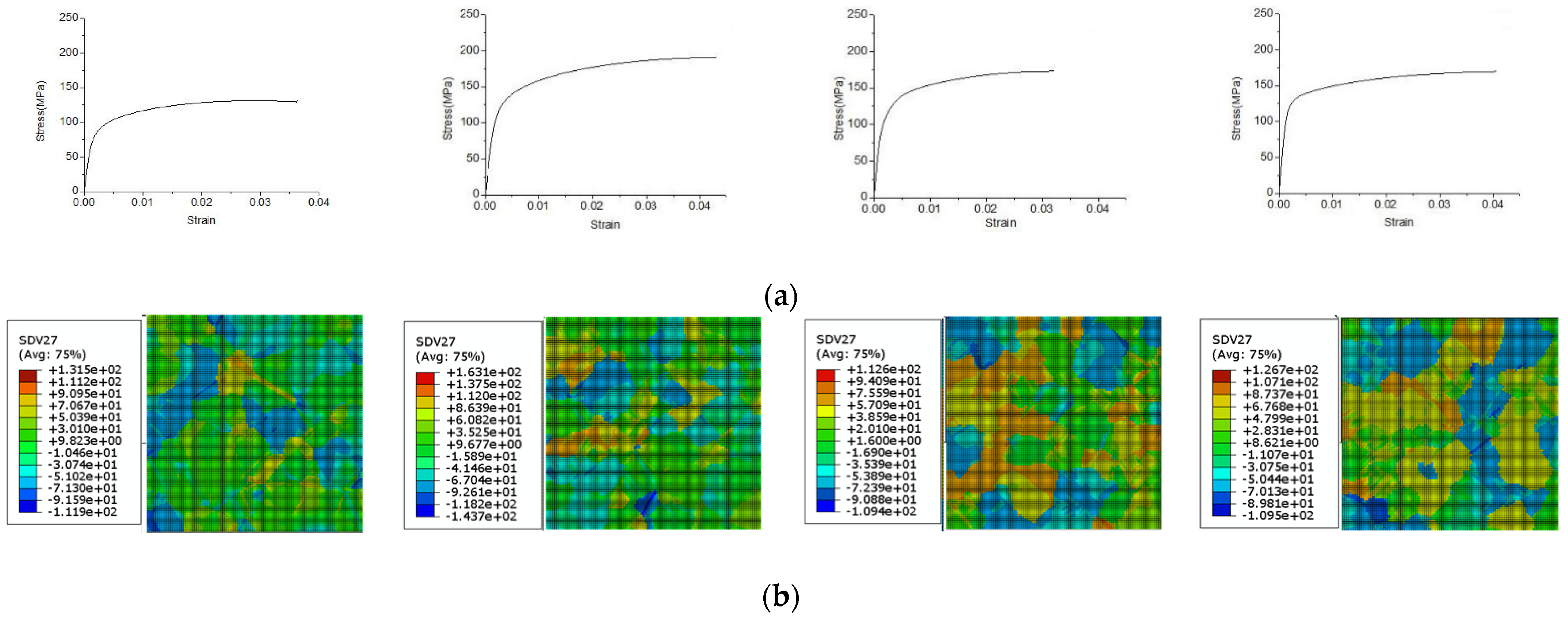

4.2. Crystal Plasticity Model

5. Summaries and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Du Plessis, A.; Razavi, S.M.J.; Benedetti, M.; Murchio, S.; Leary, M.; Watson, M.; Bhate, D.; Berto, F. Properties and applications of additively manufactured metallic cellular materials: A review. Prog. Mater. Sci. 2022, 125, 100918. [Google Scholar] [CrossRef]

- Zhang, X.Q.; Zhang, K.Q.; Zhang, L.; Wang, W.Q.; Li, Y.; He, R.J. Additive manufacturing of cellular ceramic structures: From structure to structure-function integration. Mater. Des. 2022, 215, 110470. [Google Scholar] [CrossRef]

- Gu, D.D.; Shi, X.Y.; Poprawe, R.; Bourell, D.L.; Setchi, R.; Zhu, J.H. Material-structure-performance integrated laser-metal additive manufacturing. Science 2021, 372, abg1487. [Google Scholar] [CrossRef]

- Samodurova, M.; Logachev, I.; Shaburova, N.; Samoilova, O.; Radionova, L.; Zakirov, R.; Pashkeev, K.; Myasoedov, V.; Trofimov, E. A study of the structural characteristics of titanium alloy products manufactured using additive technologies by combining the selective laser melting and direct metal deposition methods. Materials 2019, 12, 3269. [Google Scholar] [CrossRef]

- Samodurova, M.; Shaburova, N.; Samoilova, O.; Radionova, L.; Zakirov, R.; Pashkeev, K.; Myasoedov, V.; Erdakov, I.; Trofimov, E. A study of characteristics of aluminum bronze coatings applied to steel using additive technologies. Materials 2020, 13, 461. [Google Scholar] [CrossRef]

- Erdakov, I.; Glebov, L.; Pashkeev, K.; Bykov, V.; Bryk, A.; Lezin, V.; Radionova, L. Effect of the Ti6Al4V alloy track trajectories on mechanical properties in direct metal deposition. Machines 2020, 8, 79. [Google Scholar] [CrossRef]

- Baitimerov, R.; Lykov, P.; Zherebtsov, D.; Radionova, L.; Shultc, A.; Prashanth, K.G. Influence of powder characteristics on processability of AlSi12 alloy fabricated by selective laser melting. Materials 2018, 11, 742. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Uriondo, A.; Esperon-Miguez, M.; Perinpanayagam, S. The present and future of additive manufacturing in the aerospace sector: A review of important aspects. Proc. Inst. Mech. Eng. Part G—J. Aerosp. Eng. 2015, 229, 2132–2147. [Google Scholar] [CrossRef]

- Fasel, U.; Keidel, D.; Baumann, L.; Cavolina, G.; Eichenhofer, M.; Ermanni, P. Composite additive manufacturing of morphing aerospace structures. Manuf. Lett. 2020, 23, 85–88. [Google Scholar] [CrossRef]

- Leal, R.; Barreiros, F.M.; Alves, L.; Romeiro, F.; Vasco, J.C.; Santos, M.; Marto, C. Additive manufacturing tooling for the automotive industry. Int. J. Adv. Manuf. Technol. 2017, 92, 1671–1676. [Google Scholar] [CrossRef]

- Ituarte, I.F.; Chekurov, S.; Tuomi, J.; Mascolo, J.E.; Zanella, A.; Springer, P.; Partanen, J. Digital manufacturing applicability of a laser sintered component for automotive industry: A case study. Rapid Prototyp. J. 2018, 24, 1203–1211. [Google Scholar] [CrossRef]

- Borrelli, A.; D’Errico, G.; Borrelli, C.; Citarella, R. Assessment of crash performance of an automotive component made through additive manufacturing. Appl. Sci. 2020, 10, 9106. [Google Scholar] [CrossRef]

- Segonds, F. Design by additive manufacturing: An application in aeronautics and defence. Virtual Phys. Prototyp. 2018, 13, 237–245. [Google Scholar] [CrossRef]

- Saccone, G.; Andreutti, G.; Lucariello, D.; Pirozzi, C.; Franchitti, S.; Borrelli, R.; Toscano, C.; Pascarella, C.; Caso, P.; Caiazzo, F. Performance improvement of piston engine in aeronautics by means of additive manufacturing technologies. J. Aerosp. Eng. 2021, 34, 04021065. [Google Scholar] [CrossRef]

- Zhang, Y.C.; Wang, Z.P.; Zhang, Y.C.; Gomes, S.; Bernard, A. Bio-inspired generative design for support structure generation and optimization in Additive Manufacturing (AM). CIRP Ann. -Manuf. Technol. 2020, 69, 117–120. [Google Scholar] [CrossRef]

- Basalah, A.; Esmaeili, S.; Toyserkani, E. Mechanical properties of additive-manufactured porous titanium bio-structures with oriented macro-scale channels. Int. J. Adv. Manuf. Technol. 2016, 84, 2239–2246. [Google Scholar] [CrossRef]

- Budholiya, S.; Bhat, A.; Raj, S.A.; Sultan, M.T.H.; Shah, A.U.M.; Basri, A.A. State of the art review about bio-inspired design and applications: An aerospace perspective. Appl. Sci. 2021, 11, 5054. [Google Scholar] [CrossRef]

- Tan, Z.J.; Zhang, Z. Band gap characteristics of friction stir additive manufactured phononic crystals. Phys. Scr. 2022, 97, 025702. [Google Scholar] [CrossRef]

- Guo, J.C.; Li, J.R.; Zhang, L.; Zhang, Z. Wide range of wave attenuation in beam-supported stepped hybrid phononic crystals. Wave Motion 2021, 108, 102827. [Google Scholar] [CrossRef]

- Hu, Y.; Guo, Z.P.; Ragonese, A.; Zhu, T.S.; Khuje, S.; Li, C.N.; Grossman, J.C.; Zhou, C.; Nouh, M.; Ren, S.Q. A 3D-printed molecular ferroelectric metamaterial. Proc. Natl. Acad. Sci. USA 2020, 117, 27204–27210. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.C.; Zhang, Z. Mass inertia moment-based design of band gap characteristics in zigzag beam-supported stepped phononic crystals. Appl. Phys. A 2022, 128, 126. [Google Scholar] [CrossRef]

- Guo, J.C.; Li, J.R.; Zhang, Z. Interface design of low-frequency band gap characteristics in stepped hybrid phononic crystals. Appl. Acoust. 2021, 182, 108209. [Google Scholar] [CrossRef]

- Calleja-Ochoa, A.; Gonzalez-Barrio, H.; de Lacalle, N.L.; Martinez, S.; Albizuri, J.; Lamikiz, A. A new approach in the design of microstructured ultralight components to achieve maximum functional performance. Materials 2021, 14, 1588. [Google Scholar] [CrossRef]

- Perez-Ruiz, J.D.; Marin, F.; Martinez, S.; Lamikiz, A.; Urbikain, G.; de Lacalle, L.N.L. Stiffening near-net-shape functional parts of Inconel 718 LPBF considering material anisotropy and subsequent machining issues. Mech. Syst. Signal Process. 2022, 168, 108675. [Google Scholar] [CrossRef]

- Liu, P.W.; Wang, Z.; Xiao, Y.H.; Lebensohn, R.A.; Liu, Y.C.; Horstemeyer, M.F.; Cui, X.Y.; Chen, L. Integration of phase-field model and crystal plasticity for the prediction of process-structure-property relation of additively manufactured metallic materials. Int. J. Plast. 2020, 128, 102670. [Google Scholar] [CrossRef]

- Wang, X.; Liu, P.W.; Ji, Y.; Liu, Y.; Horstemeyer, M.H.; Chen, L. Investigation on microsegregation of IN718 alloy during additive manufacturing via integrated phase-field and finite-element modeling. J. Mater. Eng. Perform. 2019, 28, 657–665. [Google Scholar] [CrossRef]

- Zhang, Z.; Tan, Z.J.; Yao, X.X.; Hu, C.P.; Ge, P.; Wan, Z.Y.; Li, J.Y.; Wu, Q. Numerical methods for microstructural evolutions in laser additive manufacturing. Comput. Math. Appl. 2019, 78, 2296–2307. [Google Scholar] [CrossRef]

- McNamara, K.; Ji, Y.Z.; Lia, F.; Promoppatum, P.; Yao, S.C.; Zhou, H.L.; Wang, Y.; Chen, L.Q.; Martukanitz, R.P.P. Predicting phase transformation kinetics during metal additive manufacturing using non-isothermal Johnson-Mehl-Avrami models: Application to Inconel 718 and Ti-6Al-4V. Addit. Manuf. 2022, 49, 102478. [Google Scholar] [CrossRef]

- Kirka, M.M.; Nandwana, P.; Lee, Y.; Dehoff, R.R. Solidification and solid-state transformation sciences in metals additive manufacturing. Scr. Mater. 2017, 135, 130–134. [Google Scholar] [CrossRef]

- Zhang, Z.; Ge, P.; Li, J.Y.; Ren, D.X.; Wu, T. Monte Carlo simulations of solidification and solid-state phase transformation during directed energy deposition additive manufacturing. Prog. Addit. Manuf. 2022, 7, 671–682. [Google Scholar] [CrossRef]

- Papazoglou, E.L.; Karkalos, N.E.; Karmiris-Obratanski, P.; Markopoulos, A.P. On the modeling and simulation of SLM and SLS for metal and polymer powders: A review. Arch. Comput. Methods Eng. 2022, 29, 941–973. [Google Scholar] [CrossRef]

- Bayat, M.; Dong, W.; Thorborg, J. A review of multi-scale and multi-physics simulations of metal additive manufacturing processes with focus on modeling strategies. Addit. Manuf. 2021, 47, 102278. [Google Scholar] [CrossRef]

- Xie, R.S.; Chen, G.Q.; Zhao, Y.; Zhang, S.; Yan, W.T.; Lin, X.; Shi, Q.Y. In-situ observation and numerical simulation on the transient strain and distortion prediction during additive manufacturing. J. Manuf. Processes 2019, 38, 494–501. [Google Scholar] [CrossRef]

- Lian, Y.P.; Lin, S.; Yan, W.T.; Liu, W.K.; Wagner, G.J. A parallelized three-dimensional cellular automaton model for grain growth during additive manufacturing. Comput. Mech. 2018, 61, 543–558. [Google Scholar] [CrossRef]

- Yu, Y.F.; Yan, W.T.; Lin, F. Understanding the formation process of shrinkage pores with a 3D dendrite growth model: From casting to additive manufacturing. Comput. Mech. 2022, 69, 133–149. [Google Scholar] [CrossRef]

- Yan, Z.R.; Liu, W.W.; Tang, Z.J.; Liu, X.Y.; Zhang, N.; Li, M.Z.; Zhang, H.C. Review on thermal analysis in laser-based additive manufacturing. Opt. Laser Technol. 2018, 106, 427–441. [Google Scholar] [CrossRef]

- Tang, Z.J.; Liu, W.W.; Wang, Y.W.; Saleheen, K.M.; Liu, Z.C.; Peng, S.T.; Zhang, Z.; Zhang, H.C. A review on in situ monitoring technology for directed energy deposition of metals. Int. J. Adv. Manuf. Technol. 2020, 108, 3437–3463. [Google Scholar] [CrossRef]

- DebRoy, T.; Mukherjee, T.; Wei, H.L.; Elmer, J.W.; Milewski, J.O. Metallurgy, mechanistic models and machine learning in metal printing. Nat. Rev. Mater. 2020, 6, 48–68. [Google Scholar] [CrossRef]

- Joe, J.; Barber, J.R.; Raeymaekers, B. A general load-displacement relationship between random rough surfaces in elastic, non-adhesive contact, with application in metal additive manufacturing. Tribol. Lett. 2022, 70, 77. [Google Scholar] [CrossRef]

- Li, J.Y.; Yao, X.X.; Wang, Y.F.; Gao, X.; Zhang, Z. The simulation of post-heat treatment in selective laser melting additive manufacturing. Integr. Mater. Manuf. Innov. 2021, 10, 413–428. [Google Scholar] [CrossRef]

- Siao, Y.H.; Wen, C.D. Examination of molten pool with Marangoni flow and evaporation effect by simulation and experiment in selective laser melting. Int. Commun. Heat Mass Transf. 2021, 125, 105325. [Google Scholar] [CrossRef]

- Taylor, S.; Wright, J.B.; Forrest, E.C.; Jared, B.; Koepke, J.; Beaman, J. Investigating relationship between surface topography and emissivity of metallic additively manufactured parts. Int. Commun. Heat Mass Transf. 2020, 115, 104614. [Google Scholar] [CrossRef]

- Hagqvist, P.; Sikstrom, F.; Christiansson, A.K. Emissivity estimation for high temperature radiation pyrometry on Ti-6Al-4V. Measurement 2013, 46, 871–880. [Google Scholar] [CrossRef]

- Qu, D.X.; Berry, J.; Calta, N.P.; Crumb, M.F.; Guss, G.; Matthews, M.J. Temperature measurement of laser-irradiated metals using hyperspectral imaging. Phys. Rev. Appl. 2020, 14, 014031. [Google Scholar] [CrossRef]

- Ren, C.G.; Lo, Y.L.; Tran, H.C.; Lee, M.H. Emissivity calibration method for pyrometer measurement of melting pool temperature in selective laser melting of stainless steel 316L. Int. J. Adv. Manuf. Technol. 2019, 105, 637–649. [Google Scholar] [CrossRef]

- Goldak, J.; Chakravarti, A.; Bibby, M. A new finite-element model for welding heat-sources. Metall. Trans. B 1984, 15, 299–305. [Google Scholar] [CrossRef]

- Heinze, C.; Schwenk, C.; Rethmeier, M. Effect of heat source configuration on the result quality of numerical calculation of welding-induced distortion. Simul. Model. Pract. Theory 2012, 20, 112–123. [Google Scholar] [CrossRef]

- Zhang, Z.; Ge, P.; Zhao, G.Z. Numerical studies of post weld heat treatment on residual stresses in welded impeller. Int. J. Press. Vessel Pip. 2017, 153, 1–14. [Google Scholar] [CrossRef]

- Zhou, X.F.; Cao, X.B.; Zhang, F.; Duan, J.A. Numerical and experimental investigation of thermal stress distribution in laser lap welding of Ti6Al4V and 2024 alloy plates. Int. J. Adv. Manuf. Technol. 2022, 118, 1427–1440. [Google Scholar] [CrossRef]

- Sripriyan, K.; Ramu, M.; Thyla, P.R.; Anantharuban, K. Weld bead characterization of flat wire electrode in gmaw process part II: A numerical study. J. Mech. Sci. Technol. 2021, 35, 2615–2622. [Google Scholar] [CrossRef]

- Liu, P.W.; Cui, X.Y.; Deng, J.S.; Li, S.; Li, Z.C.; Chen, L. Investigation of thermal responses during metallic additive manufacturing using a “Tri-Prism” finite element method. Int. J. Therm. Sci. 2019, 136, 217–229. [Google Scholar] [CrossRef]

- Giarollo, D.F.; Mazzaferro, C.C.P.; Mazzaferro, J.A.E. Comparison between two heat source models for wire-arc additive manufacturing using GMAW process. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 7. [Google Scholar] [CrossRef]

- Jing, H.; Ge, P.; Zhang, Z.; Chen, J.Q.; Liu, Z.M.; Liu, W.W. Numerical studies of the effects of the substrate structure on the residual stress in laser directed energy additive manufacturing of thin-walled products. Metals 2022, 12, 462. [Google Scholar] [CrossRef]

- Anca, A.; Fachinotti, V.D.; Escobar-Palafox, G.; Cardona, A. Computational modelling of shaped metal deposition. Int. J. Numer. Methods Eng. 2011, 85, 84–106. [Google Scholar] [CrossRef]

- Mi, G.Y.; Wei, Y.H.; Zhan, X.H.; Gu, C.; Yu, F.Y. A coupled thermal and metallurgical model for welding simulation of Ti–6Al–4V alloy. J. Mater. Process. Technol. 2014, 214, 2434–2443. [Google Scholar] [CrossRef]

- Gao, X.; Yao, X.X.; Niu, F.Y.; Zhang, Z. The influence of nozzle geometry on powder flow behaviors in directed energy deposition additive manufacturing. Adv. Powder Technol. 2022, 33, 103487. [Google Scholar] [CrossRef]

- Yao, X.X.; Li, J.Y.; Wang, Y.F.; Gao, X.; Li, T.; Zhang, Z. Experimental and numerical studies of nozzle effect on powder flow behaviors in directed energy deposition additive manufacturing. Int. J. Mech. Sci. 2021, 210, 106740. [Google Scholar] [CrossRef]

- Barros, F.M.F.; Duc, E.; Nedelec, J.M.; Falk, V.; Marchal, P. Characterization of flow properties of gas-atomized powder alloys used for additive manufacturing: Comparison between traditional methods and vibrated rheology. Part. Part. Syst. Charact. 2022, 153, 2100151. [Google Scholar] [CrossRef]

- Jiang, S.; Zheng, B.L.; Schoenung, J.M. Directed energy deposition of metal matrix composites: Computational and experimental comparison of powder particle flow behavior. J. Mater. Res. Technol. 2021, 16, 516–529. [Google Scholar] [CrossRef]

- Kroeger, J.; Poirie, T.; Moghimian, P.; Marion, F.; Larouche, F. Flow rate ranges for spherical metallic powders for additive manufacturing. Prog. Addit. Manuf. 2022, 7, 411–418. [Google Scholar] [CrossRef]

- Iams, A.D.; Gao, M.Z.; Shetty, A.; Palmer, T.A. Influence of particle size on powder rheology and effects on mass flow during directed energy deposition additive manufacturing. Powder Technol. 2022, 396, 316–326. [Google Scholar] [CrossRef]

- Zhang, Z.; Ge, P.; Li, T.; Lindgren, L.E.; Liu, W.W.; Zhao, G.Z.; Guo, X. Electromagnetic wave-based analysis of laser–particle interactions in directed energy deposition additive manufacturing. Addit. Manuf. 2020, 34, 101284. [Google Scholar] [CrossRef]

- Manvatkar, V.; De, A.; DebRoy, T. Heat transfer and material flow during laser assisted multi-layer additive manufacturing. J. Appl. Phys. 2014, 116, 124905. [Google Scholar] [CrossRef]

- Ge, P.; Zhang, Z.; Tan, Z.J.; Hu, C.P.; Zhao, G.Z.; Guo, X. An integrated modeling of process-structure-property relationship in laser additive manufacturing of duplex titanium alloy. Int. J. Therm. Sci. 2019, 140, 329–343. [Google Scholar] [CrossRef]

- Yan, W.; Ge, W.; Qian, Y.; Lin, S.; Zhou, B.; Liu, W.K.; Lin, F.; Wagner, G.J. Multi-physics modeling of single/multiple-track defect mechanisms in electron beam selective melting. Acta Mater. 2017, 134, 324–333. [Google Scholar] [CrossRef]

- Yang, M.; Wang, L.; Yan, W.T. Phase-field modeling of grain evolution in additive manufacturing with addition of reinforcing particles. Addit. Manuf. 2021, 47, 102286. [Google Scholar] [CrossRef]

- Tyagi, S.A.; Manjaiah, M. Laser additive manufacturing of titanium-based functionally graded materials: A review. J. Mater. Eng. Perform. 2022, 31, 6131–6148. [Google Scholar] [CrossRef]

- Schoinochoritis, B.; Chantzis, D.; Salonitis, K. Simulation of metallic powder bed additive manufacturing processes with the finite element method: A critical review. Proc. Inst. Mech. Eng. Part B -J. Eng. Manuf. 2017, 231, 96–117. [Google Scholar] [CrossRef]

- Guan, X.Y.; Zhao, Y.F. Modeling of the laser powder-based directed energy deposition process for additive manufacturing: A review. Int. J. Adv. Manuf. Technol. 2020, 107, 1959–1982. [Google Scholar] [CrossRef]

- Al Hamahmy, M.I.; Deiab, I. Review and analysis of heat source models for additive manufacturing. Int. J. Adv. Manuf. Technol. 2020, 106, 1223–1238. [Google Scholar] [CrossRef]

- Liu, C.M.; Gao, H.B.; Li, L.Y.; Wang, J.D.; Guo, C.H.; Jiang, F.C. A review on metal additive manufacturing: Modeling and application of numerical simulation for heat and mass transfer and microstructure evolution. China Foundry 2021, 18, 317–334. [Google Scholar] [CrossRef]

- Kundakcioglu, E.; Lazoglu, I.; Rawal, S. Transient thermal modeling of laser-based additive manufacturing for 3D freeform structures. Int. J. Adv. Manuf. Technol. 2016, 85, 493–501. [Google Scholar] [CrossRef]

- Yan, Z.; Song, L.J.; Liu, W.Y.; Zou, X.; Zhou, Z.P. Numerical analysis of thermal stress evolution of pulsed-wave laser direct energy deposition. Int. J. Adv. Manuf. Technol. 2021, 115, 1399–1410. [Google Scholar] [CrossRef]

- Tang, Y.J.; Zhang, Y.Z.; Liu, Y.T. Numerical and experimental investigation of laser additive manufactured Ti2AlNb-based alloy. J. Alloy. Compd. 2017, 727, 196–204. [Google Scholar] [CrossRef]

- Peyre, P.; Dal, M.; Pouzet, S.; Castelnau, O. Simplified numerical model for the laser metal deposition additive manufacturing process. J. Laser Appl. 2017, 29, 022304. [Google Scholar] [CrossRef]

- Zhang, Z.; Ge, P.; Li, J.Y.; Wang, Y.F.; Gao, X.; Yao, X.X. Laser-particle interaction-based analysis of powder particle effects on temperatures and distortions in directed energy deposition additive manufacturing. J. Therm. Stresses 2021, 44, 1068–1095. [Google Scholar] [CrossRef]

- Panda, B.K.; Sahoo, S. Thermo-mechanical modeling and validation of stress field during laser powder bed fusion of AlSi10Mg built part. Results Phys. 2019, 12, 1372–1381. [Google Scholar] [CrossRef]

- Zhao, X.R.; Iyer, A.; Promoppatum, P.; Yao, S.C. Numerical modeling of the thermal behavior and residual stress in the direct metal laser sintering process of titanium alloy products. Addit. Manuf. 2017, 14, 126–136. [Google Scholar] [CrossRef]

- Kundakcioglu, E.; Lazoglu, I.; Poyraz, O.; Yasa, E.; Cizicioglu, N. Thermal and molten pool model in selective laser melting process of Inconel 625. Int. J. Adv. Manuf. Technol. 2018, 95, 3977–3984. [Google Scholar] [CrossRef]

- Roberts, I.A.; Wang, C.J.; Esterlein, R.; Stanford, M.; Mynors, D.J. A three-dimensional finite element analysis of the temperature field during laser melting of metal powders in additive layer manufacturing. Int. J. Mach. Tools Manuf. 2009, 49, 916–923. [Google Scholar] [CrossRef]

- Shahabad, S.I.; Zhang, Z.D.; Keshavarzkermani, A.; Ali, U.; Mahmoodkhani, Y.; Esmaeilizadeh, R.; Bonakdar, A.; Toyserkani, E. Heat source model calibration for thermal analysis of laser powder-bed fusion. Int. J. Adv. Manuf. Technol. 2020, 106, 3367–3379. [Google Scholar] [CrossRef]

- Wu, Y.J.; Sun, K.; Yu, S.F.; Zuo, L. Modeling the selective laser melting-based additive manufacturing of thermoelectric powders. Addit. Manuf. 2021, 37, 101666. [Google Scholar] [CrossRef]

- Novotny, L.; Beres, M.; de Abreu, H.F.G.; Zajac, J.; Bleck, W. Thermal analysis and phase transformation behaviour during additive manufacturing of Ti-6Al-4V alloy. Mater. Sci. Technol. 2019, 35, 846–855. [Google Scholar] [CrossRef]

- Samantaray, M.; Sahoo, S.; Thatoi, D. Modeling of thermal and solidification behavior during laser additive manufacturing of AlSi10Mg alloy powders and its experimental validation. J. Laser Appl. 2019, 31, 032019. [Google Scholar] [CrossRef]

- Romano, J.; Ladani, L.; Sadowski, M. Thermal modeling of laser based additive manufacturing processes within common materials. Procedia Manuf. 2015, 5, 238–250. [Google Scholar] [CrossRef]

- Zhang, Z.D.; Huang, Y.; Kasinathan, A.R.; Shahabad, S.I.; Ali, U.; Mahmoodkhani, Y.; Toyserkani, E. 3-Dimensional heat transfer modeling for laser powder-bed fusion additive manufacturing with volumetric heat sources based on varied thermal conductivity and absorptivity. Opt. Laser Technol. 2019, 109, 297–312. [Google Scholar] [CrossRef]

- Yao, X.X.; Zhang, Z. Laser-particle interaction-based heat source model of laser powder bed fusion additive manufacturing. Opt. Laser Technol. 2022, 155, 108402. [Google Scholar] [CrossRef]

- Zhang, Z.; Wu, Q.; Grujicic, M.; Wan, Z.Y. Monte Carlo simulation of grain growth and welding zones in friction stir welding of AA6082-T6. J. Mater. Sci. 2016, 51, 1882–1895. [Google Scholar] [CrossRef]

- Grujicic, M.; Ramaswami, S.; Snipes, J.S.; Avuthu, V.; Galgalikar, R.; Zhang, Z. Prediction of the grain-microstructure evolution within a Friction Stir Welding (FSW) joint via the use of the Monte Carlo simulation method. J. Mater. Eng. Perform. 2015, 24, 3471–3486. [Google Scholar] [CrossRef]

- Zhang, Z.; Hu, C.P. 3D Monte Carlo simulation of grain growth in friction stir welding. J. Mech. Sci. Technol. 2018, 32, 1287–1296. [Google Scholar] [CrossRef]

- Xiao, Y.H.; Wan, Z.X.; Liu, P.W.; Wang, Z.; Li, J.J.; Chen, L. Quantitative simulations of grain nucleation and growth at additively manufactured bimetallic interfaces of SS316L and IN625. J. Mater. Process. Technol. 2022, 302, 117506. [Google Scholar] [CrossRef]

- Rodgers, T.M.; Madison, J.D.; Tikare, V. Simulation of metal additive manufacturing microstructures using kinetic Monte Carlo. Comput. Mater. Sci. 2017, 135, 78–89. [Google Scholar] [CrossRef]

- Rodgers, T.M.; Moser, D.; Abdeljawad, F.; Jackson, O.D.U.; Carroll, J.D.; Jared, B.H.; Bolintineanu, D.S.; Mitchell, J.A.; Madison, J.D. Simulation of powder bed metal additive manufacturing microstructures with coupled finite difference-Monte Carlo method. Addit. Manuf. 2021, 41, 101953. [Google Scholar] [CrossRef]

- Zhou, X.W.; Karnesky, R.A.; Yang, N.; Yee, J.K. Kinetic Monte Carlo simulations of structural evolution during anneal of additively manufactured materials. Comput. Mater. Sci. 2020, 179, 109605. [Google Scholar] [CrossRef]

- Zinoviev, A.; Zinovieva, O.; PLoshikhin, V.; Romanova, V.; Balokhonov, R. Evolution of grain structure during laser additive manufacturing: Simulation by a cellular automata method. Mater. Des. 2016, 106, 321–329. [Google Scholar] [CrossRef]

- Teferra, K.; Rowenhorst, D.J. Optimizing the cellular automata finite element model for additive manufacturing to simulate large microstructures. Acta Mater. 2021, 213, 116930. [Google Scholar] [CrossRef]

- Sun, W.Z.; Shan, F.H.; Zong, N.F.; Dong, H.B.; Jing, T. Simulation of solidified beta grain for Ti-6Al-4V during wire laser additive manufacturing by three-dimensional cellular automaton method. Model. Simul. Mater. Sci. Eng. 2021, 29, 065006. [Google Scholar] [CrossRef]

- Bailey, N.S.; Shin, Y.C. Multi-track, multi-layer dendrite growth and solid phase transformation analysis during additive manufacturing of H13 tool steel using a combined hybrid cellular automata/phase field, solid-state phase prediction models. Int. J. Adv. Manuf. Technol. 2022, 120, 2089–2108. [Google Scholar] [CrossRef]

- Wu, L.M.; Zhang, J. Phase field simulation of dendritic solidification of Ti-6Al-4V during additive manufacturing process. JOM 2018, 70, 2392–2399. [Google Scholar] [CrossRef]

- Rappaz, M.; Gandin, C.A. Probabilistic modeling of microstructure formation in solidification processes. Acta Metall. Mater. 1993, 41, 345–360. [Google Scholar] [CrossRef]

- Provatas, N.; Dantzig, J.A.; Athreya, B. Using the phase-field crystal method in the multi-scale modeling of microstructure evolution. JOM 2007, 59, 83–90. [Google Scholar] [CrossRef]

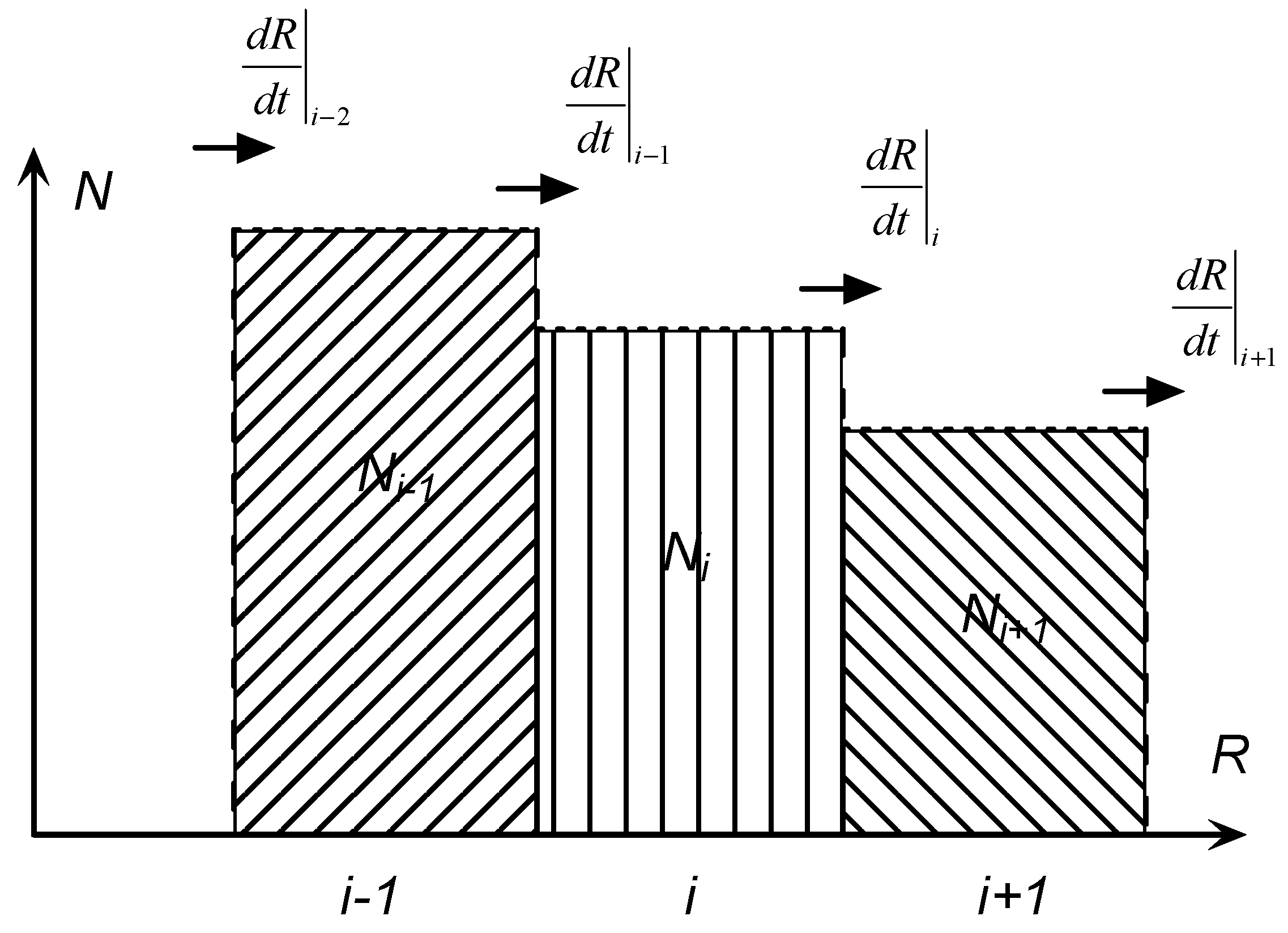

- Yao, X.X.; Li, J.Y.; Wang, Y.F.; Gao, X.; Zhang, Z. Numerical simulation of powder effect on solidification in directed energy deposition additive manufacturing. Trans. Nonferrous Soc. China 2021, 31, 2871–2884. [Google Scholar] [CrossRef]

- Yao, X.X.; Ge, P.; Li, J.Y.; Wang, Y.F.; Li, T.; Liu, W.W.; Zhang, Z. Controlling the solidification process parameters of direct energy deposition additive manufacturing considering laser and powder properties. Comput. Mater. Sci. 2020, 182, 109788. [Google Scholar] [CrossRef]

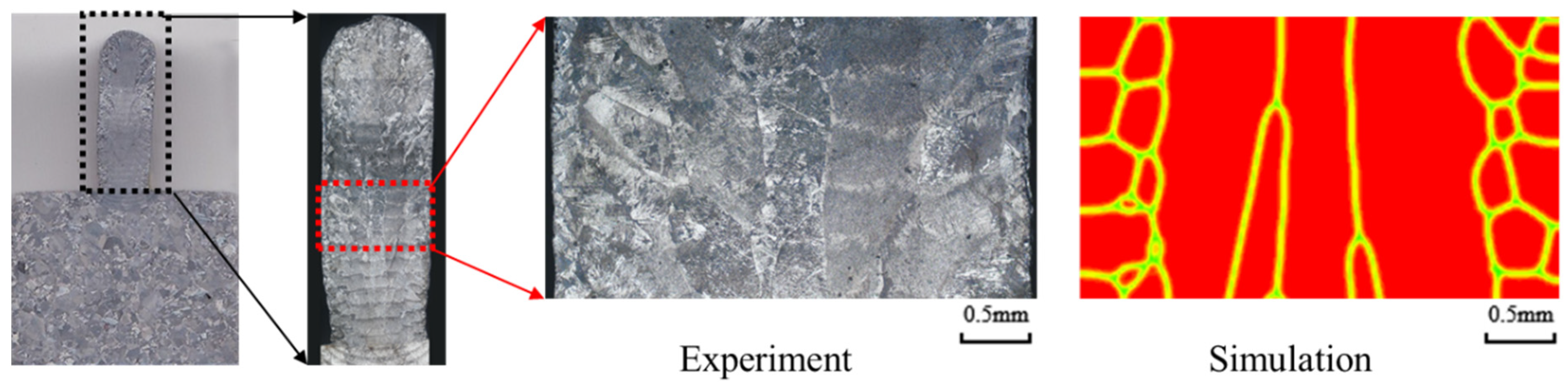

- Zhang, Z.; Yao, X.X.; Ge, P. Phase-field-model-based analysis of the effects of powder particle on porosities and densities in selective laser sintering additive manufacturing. Int. J. Mech. Sci. 2020, 166, 105230. [Google Scholar] [CrossRef]

- Li, L.; Li, J.Q.; Fan, T.H. Phase-field modeling of wetting and balling dynamics in powder bed fusion process. Phys. Fluids 2021, 33, 042116. [Google Scholar] [CrossRef]

- Boussinot, G.; Doring, M.; Hemes, S.; Stryzhyboroda, O.; Apel, M.; Schmidt, M. Laser powder bed fusion of eutectic Al-Ni alloys: Experimental and phase-field studies. Mater. Des. 2021, 198, 109299. [Google Scholar] [CrossRef]

- Keller, T.; Lindwall, G.; Ghosh, S.; Ma, L.; Lane, B.M.; Zhang, F.; Kattner, U.R.; Lass, E.A.; Heigel, J.C.; Idell, Y.; et al. Application of finite element, phase-field, and CALPHAD-based methods to additive manufacturing of Ni-based superalloys. Acta Mater. 2017, 139, 244–253. [Google Scholar] [CrossRef]

- Sahoo, S.; Chou, K. Phase-field simulation of microstructure evolution of Ti-6Al-4V in electron beam additive manufacturing process. Addit. Manuf. 2016, 9, 14–24. [Google Scholar] [CrossRef]

- Lu, L.X.; Sridhar, N.; Zhang, Y.W. Phase field simulation of powder bed-based additive manufacturing. Acta Mater. 2018, 144, 801–809. [Google Scholar] [CrossRef]

- Li, Z.; Wang, T.; Chu, D.Y.; Liu, Z.; Cui, Y. A coupled crystal-plasticity and phase-field model for understanding fracture behaviors of single crystal tungsten. Int. J. Plast. 2022, 157, 103375. [Google Scholar] [CrossRef]

- Agius, D.; O’Toole, P.; Wallbrink, C.; Sterjovski, Z.; Wang, C.H.; Schaffer, G.B. Integrating phase field and crystal plasticity finite element models for simulations of titanium alloy Ti-5553. J. Phys.-Mater. 2021, 4, 044014. [Google Scholar] [CrossRef]

- Wu, R.H.; Zhang, Y.F. Phase-field, dislocation based plasticity and damage coupled model: Modelling and application to single crystal superalloys. Int. J. Plast. 2022, 157, 103376. [Google Scholar] [CrossRef]

- Carron, D.; Bastid, P.; Yin, Y.; Faulkner, R.G. Modelling of precipitation during friction stir welding of anAl-Mg-Si alloy. Tech. Mech. 2010, 30, 29–44. [Google Scholar]

- Myhr, O.R.; Grong, Ø.; Andersen, S.J. Modelling of the age hardening behaviour of Al–Mg–Si alloys. Acta Mater. 2001, 49, 65–75. [Google Scholar] [CrossRef]

- Myhr, O.R.; Grong, Ø. Modelling of non-isothermal transformations in alloys containing a particle distribution. Acta Mater. 2000, 48, 1605–1615. [Google Scholar] [CrossRef]

- Simar, A.; Bréchet, Y.; de Meester, B.; Denquin, A.; Gallais, C.; Pardoen, T. Integrated modeling of friction stir welding of 6xxx series Al alloys: Process, microstructure and properties. Prog. Mater. Sci. 2012, 57, 95–183. [Google Scholar] [CrossRef]

- Zhang, Z.; Tan, Z.J.; Li, J.Y.; Zu, Y.F.; Sha, J.J. Integrated modeling of process-microstructure-property relations in friction stir additive manufacturing. Acta Metall. Sin. 2020, 33, 75–87. [Google Scholar] [CrossRef]

- Zhang, Z.; Tan, Z.J.; Li, J.Y.; Zu, Y.F.; Liu, W.W.; Sha, J.J. Experimental and numerical studies of re-stirring and re-heating effects on mechanical properties in friction stir additive manufacturing. Int. J. Adv. Manuf. Technol. 2019, 104, 767–784. [Google Scholar] [CrossRef]

- Tan, Z.J.; Li, J.Y.; Zhang, Z. Experimental and numerical studies on fabrication of nanoparticle reinforced aluminum matrix composites by friction stir additive manufacturing. J. Mater. Res. Technol. 2021, 12, 1898–1912. [Google Scholar] [CrossRef]

- Bergstrom, Y. A dislocation model for the stress-strain behaviour of polycrystalline alpha-Fe with special emphasis on the variation of the densities of mobile and immobile dislocations. Mater. Sci. Eng. 1970, 5, 193–200. [Google Scholar] [CrossRef]

- Kocks, U.F. Laws for work-hardening and low-temperature creep. J. Eng. Mater. Technol. 1976, 98, 76–85. [Google Scholar] [CrossRef]

- Babu, B.; Lindgren, L.E. Dislocation density based model for plastic deformation and globularization of Ti-6Al-4V. Int. J. Plast. 2013, 50, 94–108. [Google Scholar] [CrossRef]

- Malmelov, A.; Fisk, M.; Lundback, A.; Lindgren, L.E. Mechanism based flow stress model for alloy 625 and alloy 718. Materials 2020, 13, 5620. [Google Scholar] [CrossRef]

- Holt, D.L. Dislocation cell formation in metals. J. Appl. Phys. 1970, 41, 3197–3201. [Google Scholar] [CrossRef]

- Lindgren, L.E.; Domkin, K.; Hansson, S. Dislocations, vacancies and solute diffusion in physical based plasticity model for AISI 316L. Mech. Mater. 2008, 40, 907–919. [Google Scholar] [CrossRef]

- Sargent, G.A.; Zane, A.P.; Fagin, P.N.; Ghosh, A.K.; Semiatin, S.L. Low-temperature coarsening and plastic flow behavior of an alpha/beta titanium billet material with an ultrafine microstructure. Metall. Mater. Trans. A 2008, 39, 2949–2964. [Google Scholar] [CrossRef]

- Dalai, B.; Moretti, M.A.; Akerstrom, P.; Arvieu, C.; Jacquin, D.; Lindgren, L.E. Mechanical behavior and microstructure evolution during deformation of AA7075-T651. Mater. Sci. Eng. A 2021, 822, 141615. [Google Scholar] [CrossRef]

- Pietrzyk, M. Identification of parameters in the history dependent constitutive model for steels. CIRP Ann.-Manuf. Technol. 2001, 50, 161–164. [Google Scholar] [CrossRef]

- Babu, B.; Lundback, A.; Lindgren, L.E. Simulation of Ti-6Al-4V additive manufacturing using coupled physically based flow stress and metallurgical model. Materials 2019, 12, 3844. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.X.; Lutz, A.; Andra, H.; Lahres, M.; Sittig, D.; Maawad, E.; Gan, W.M.; Knoop, D. An additively manufactured and direct-aged AlSi3.5Mg2.5 alloy with superior strength and ductility: Micromechanical mechanisms. Int. J. Plast. 2021, 146, 103083. [Google Scholar] [CrossRef]

- Zhang, X.X.; Andrä, H. Crystal plasticity simulation of the macroscale and microscale stress–strain relations of additively manufactured AlSi10Mg alloy. Comput. Mater. Sci. 2021, 200, 110832. [Google Scholar] [CrossRef]

- Peirce, D.; Asaro, R.J.; Needleman, A. An analysis of nonuniform and localized deformation in ductile single crystals. Acta Metall. 1982, 30, 1087–1119. [Google Scholar] [CrossRef]

- Lim, H.; Abdeljawad, F.; Owen, S.J.; Hanks, B.W.; Foulk, J.W.; Battaile, C.C. Incorporating physically-based microstructures in materials modeling: Bridging phase field and crystal plasticity frameworks. Model. Simul. Mater. Sci. Eng. 2016, 24, 045016. [Google Scholar] [CrossRef]

- Lim, H.; Hale, L.M.; Zimmerman, Z.A.; Battaile, C.C.; Weinberger, C.R. A multi-scale model of dislocation plasticity in α-Fe: Incorporating temperature, strain rate and non-Schmid effects. Int. J. Plast. 2015, 73, 100–118. [Google Scholar] [CrossRef]

- Yuan, H.L.; Tan, Z.J.; Zhang, Z. Numerical simulation of friction stir welding based on microstructure mechanical behavior integration calculation. J. Plast. Eng. 2020, 27, 182–191. (In Chinese) [Google Scholar]

- Pinomaa, T.; Yashchuk, I.; Lindroos, M.; Andersson, T.; Provatas, N.; Laukkanen, A. Process-structure-properties-performance modeling for selective laser melting. Metals 2019, 9, 1138. [Google Scholar] [CrossRef]

- Zhang, J.H.; Li, X.X.; Xu, D.S.; Yang, R. Recent progress in the simulation of microstructure evolution in titanium alloys. Prog. Nat. Sci. -Mater. Int. 2019, 29, 295–304. [Google Scholar] [CrossRef]

- Casuso, M.; Veiga, F.; Suarez, A.; Bhujangrao, T.; Aldalur, E.; Artaza, T.; Amondarain, J.; Lamikiz, A. Model for the Prediction of Deformations in the Manufacture of Thin-Walled Parts by Wire Arc Additive Manufacturing Technology. Metals 2021, 11, 678. [Google Scholar] [CrossRef]

- Perez-Ruiz, J.D.; de Lacalle, L.N.L.; Urbikain, G.; Pereira, O.; Martinez, S.; Bris, J. On the relationship between cutting forces and anisotropy features in the milling of LPBF Inconel 718 for near net shape parts. Int. J. Mach. Tools Manuf. 2021, 170, 103801. [Google Scholar] [CrossRef]

- Xu, S.Z.; Liu, J.K.; Ma, Y.S. Residual stress constrained self-support topology optimization for metal additive manufacturing. Comput. Methods Appl. Mech. Eng. 2022, 389, 114380. [Google Scholar] [CrossRef]

- Setien, I.; Chiumenti, M.; van der Veen, S.; San Sebastian, M.; Garciandia, F.; Echeverria, A. Empirical methodology to determine inherent strains in additive manufacturing. Comput. Math. Appl. 2019, 78, 2282–2295. [Google Scholar] [CrossRef]

- Liang, X.; Cheng, L.; Chen, Q.; Yang, Q.C.; To, A.C. A modified method for estimating inherent strains from detailed process simulation for fast residual distortion prediction of single-walled structures fabricated by directed energy deposition. Addit. Manuf. 2018, 23, 471–486. [Google Scholar] [CrossRef]

- Wang, Y.F.; Li, Q.; Qian, L.Y.; Yang, Y.B. A modified inherent strain model with consideration of the variance of mechanical properties in metal additive manufacturing. J. Manuf. Processes 2021, 72, 115–125. [Google Scholar] [CrossRef]

- Lyu, D.D.; Hu, W.; Ren, B.; Pan, X.F.; Wu, C.T. Numerical Prediction of Residual Deformation and Failure for Powder Bed Fusion Additive Manufacturing of Metal Parts. J. Mech. 2020, 36, 623–636. [Google Scholar] [CrossRef]

- Bugatti, M.; Semeraro, Q. Limitations of the inherent strain method in simulating powder bed fusion processes. Addit. Manuf. 2018, 23, 329–346. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, Y.; Chen, H.; Wu, Y.; Chen, J.Q.; Xiong, J.; Ren, L.S.; Qian, J. Multi-scale residual stress prediction for selective laser melting of high strength steel considering solid-state phase transformation. Opt. Laser Technol. 2022, 146, 107578. [Google Scholar] [CrossRef]

- Zhang, Z.; Ge, P.; Yao, X.X.; Li, T.; Liu, W.W. Numerical studies of residual states and scaling effects in laser-directed energy deposition additive manufacturing. Int. J. Adv. Manuf. Technol. 2020, 108, 1233–1247. [Google Scholar] [CrossRef]

- Wang, Y.F.; Guo, J.C.; Zhang, Z. The deformation induced tunable topology in controlling of band gap characteristics for stepped phononic crystals. Solid State Commun. 2022, 351, 114809. [Google Scholar] [CrossRef]

- Hashemi, S.M.; Parvizi, S.; Baghbanijavid, H.; Tan, A.T.L.; Nematollahi, M.; Ramazani, A.; Fang, N.I.X.; Elahinia, M. Computational modelling of process-structure-property-performance relationships in metal additive manufacturing: A review. Int. Mater. Rev. 2022, 67, 1–46. [Google Scholar] [CrossRef]

- Goh, G.D.; Yap, Y.L.; Tan, H.K.J.; Sing, S.L.; Goh, G.L.; Yeong, W.Y. Process-structure-properties in polymer additive manufacturing via material extrusion: A review. Crit. Rev. Solid State Mater. Sci. 2020, 45, 113–133. [Google Scholar] [CrossRef]

- Papon, E.A.; Haque, A. Review on process model, structure-property relationship of composites and future needs in fused filament fabrication. J. Reinf. Plast. Compos. 2020, 39, 758–789. [Google Scholar] [CrossRef]

- Kouraytem, N.; Li, X.X.; Tan, W.D.; Kappes, B.; Spear, A.D. Modeling process-structure-property relationships in metal additive manufacturing: A review on physics-driven versus data-driven approaches. J. Phys.-Mater. 2021, 4, 032002. [Google Scholar] [CrossRef]

- Yao, X.X.; Gao, X.; Zhang, Z. Three-dimensional microstructure evolution of Ti–6Al–4V during multi-layer printing = a phase-field simulation. J. Mater. Res. Technol. 2022, 20, 934–949. [Google Scholar] [CrossRef]

- Kumar, P.; Chandran, K. Strength-ductility property maps of powder metallurgy (PM) Ti-6Al-4V alloy: A critical review of processing-structure-property relationships. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2017, 48, 2301–2319. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Wang, Y.; Ge, P.; Wu, T. A Review on Modelling and Simulation of Laser Additive Manufacturing: Heat Transfer, Microstructure Evolutions and Mechanical Properties. Coatings 2022, 12, 1277. https://doi.org/10.3390/coatings12091277

Zhang Z, Wang Y, Ge P, Wu T. A Review on Modelling and Simulation of Laser Additive Manufacturing: Heat Transfer, Microstructure Evolutions and Mechanical Properties. Coatings. 2022; 12(9):1277. https://doi.org/10.3390/coatings12091277

Chicago/Turabian StyleZhang, Zhao, Yifei Wang, Peng Ge, and Tao Wu. 2022. "A Review on Modelling and Simulation of Laser Additive Manufacturing: Heat Transfer, Microstructure Evolutions and Mechanical Properties" Coatings 12, no. 9: 1277. https://doi.org/10.3390/coatings12091277

APA StyleZhang, Z., Wang, Y., Ge, P., & Wu, T. (2022). A Review on Modelling and Simulation of Laser Additive Manufacturing: Heat Transfer, Microstructure Evolutions and Mechanical Properties. Coatings, 12(9), 1277. https://doi.org/10.3390/coatings12091277