Weathering and Material Characterization of ZTO/Ag/ZTO Coatings on Polyethylene Terephthalate Substrates for the Application of Flexible Transparent Conductors

Abstract

:1. Introduction

2. Experimental Methods

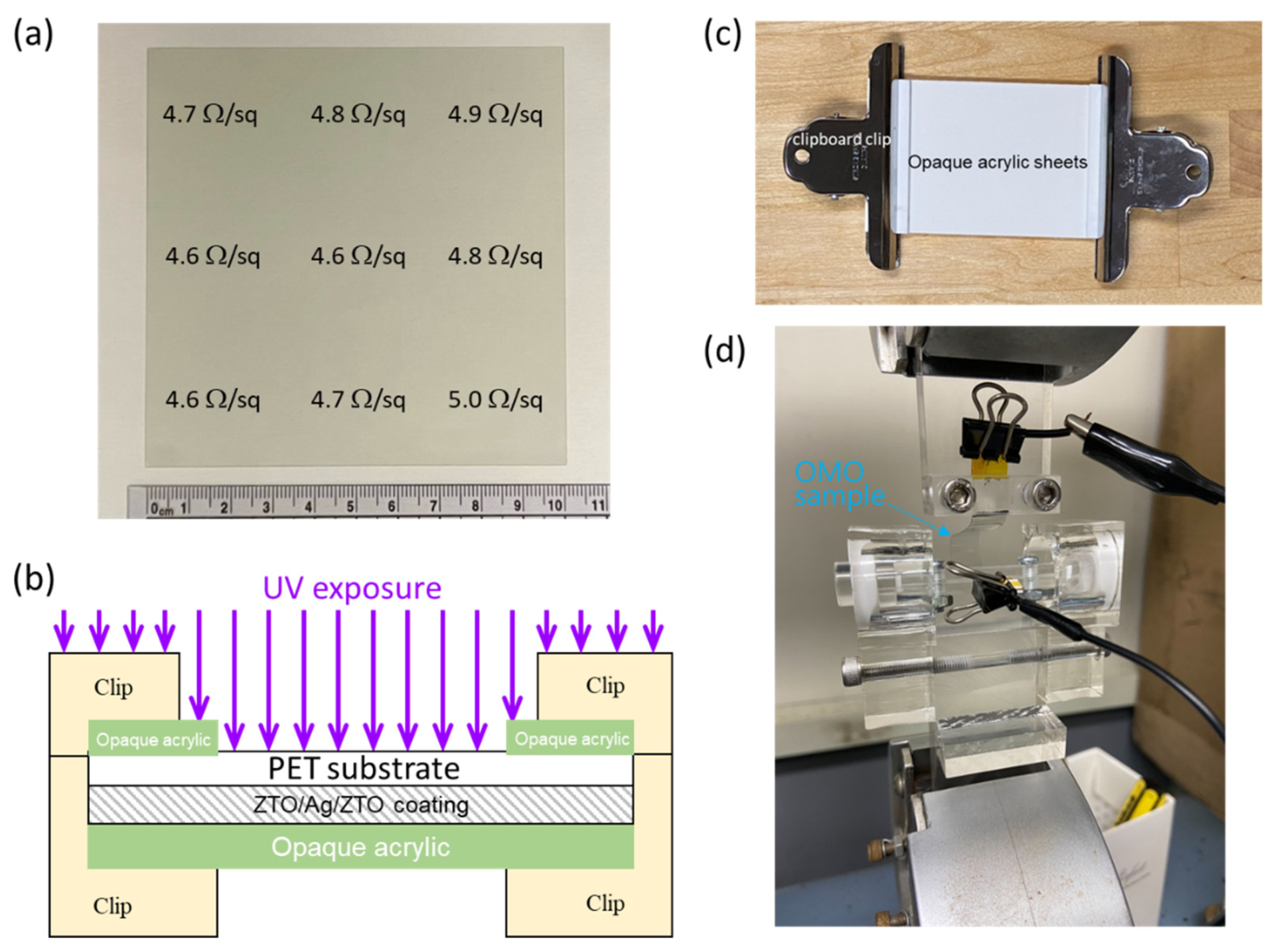

2.1. OMO Samples and Weathering Tests

2.2. Materials’ Characterization

2.3. Real-Time Resistance Measurement under Cyclic Bending

3. Results and Discussion

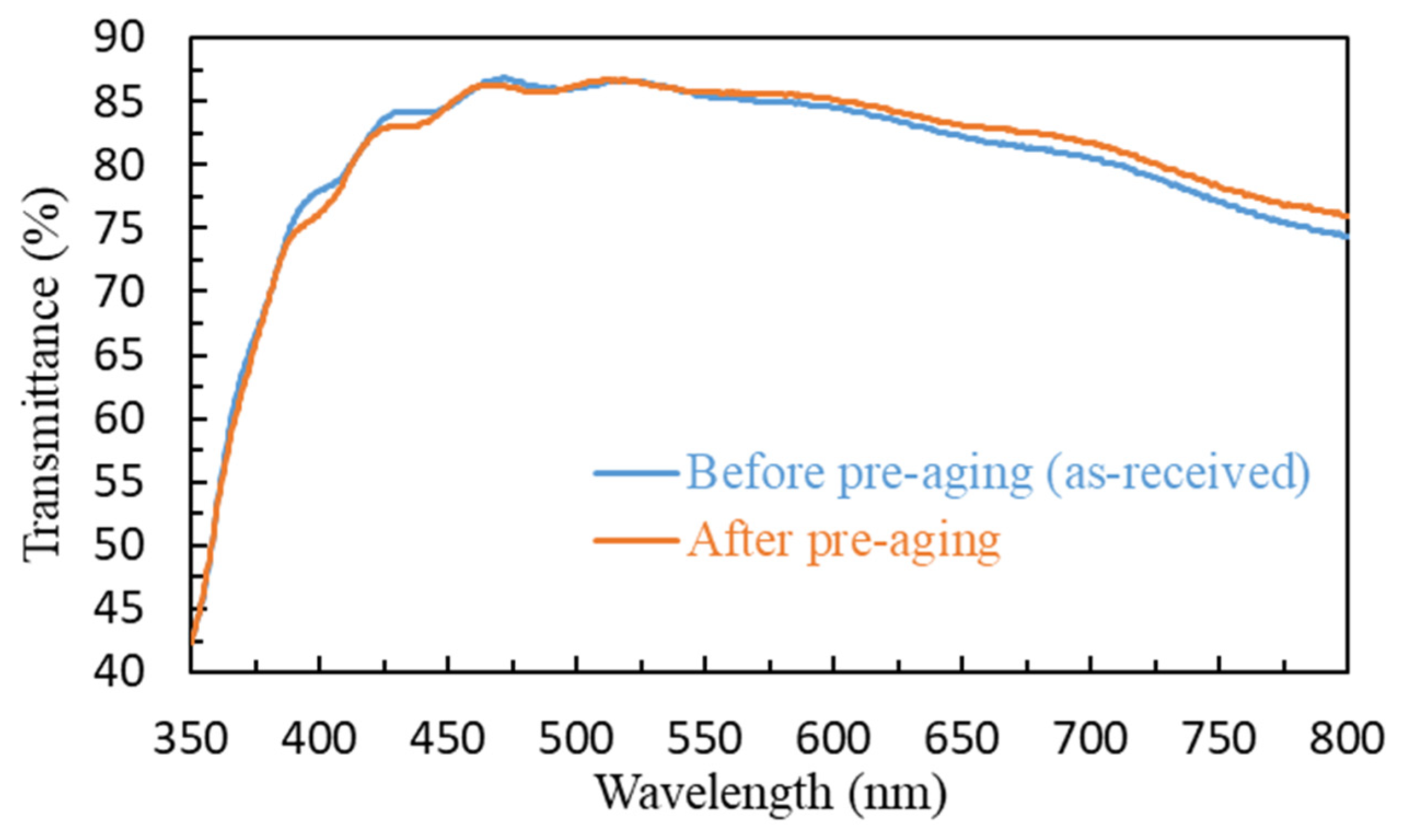

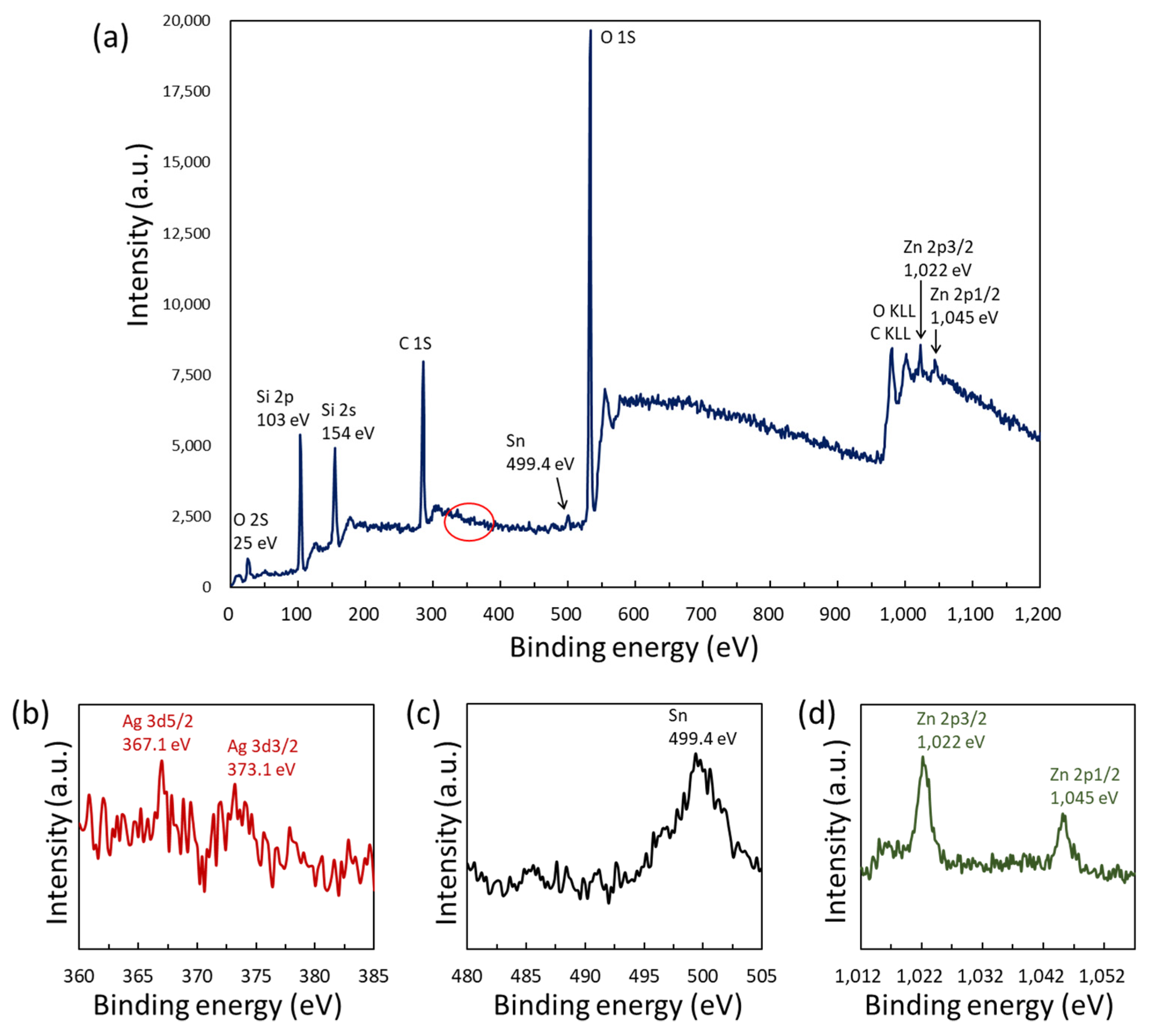

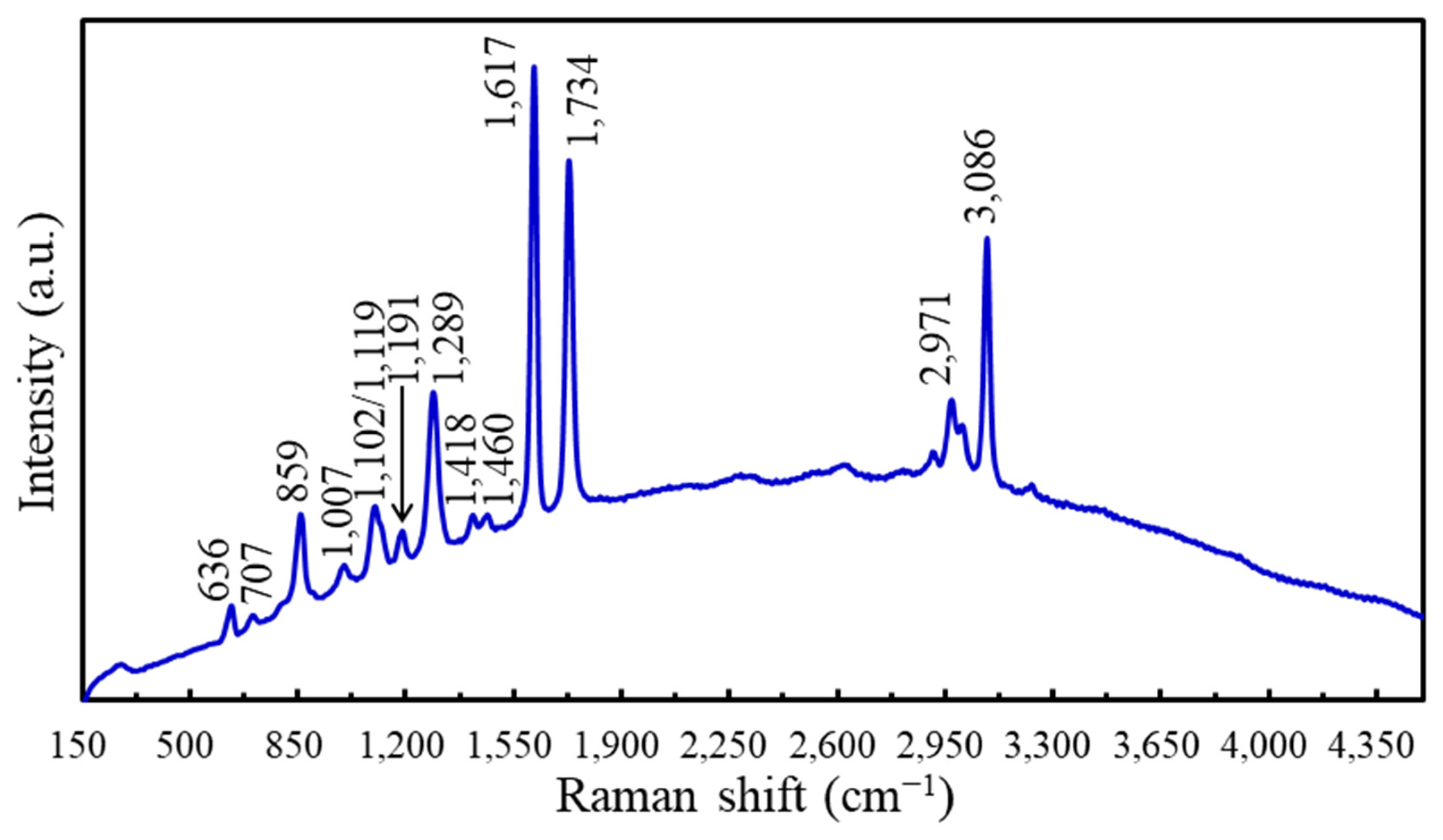

3.1. Unaged OMO Samples

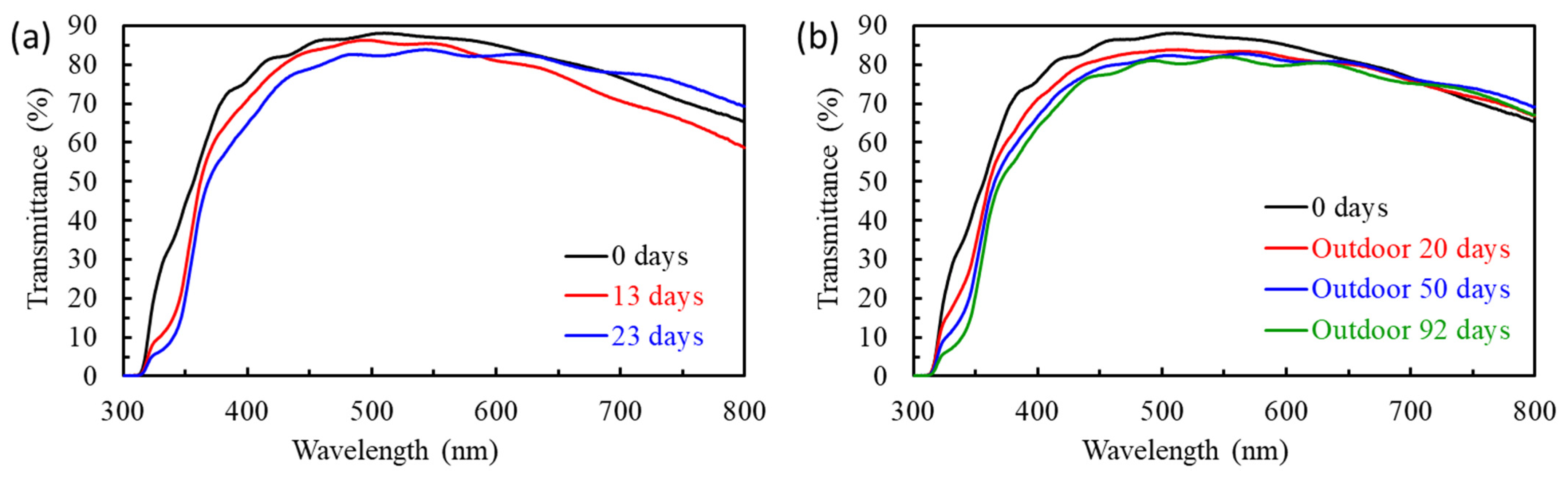

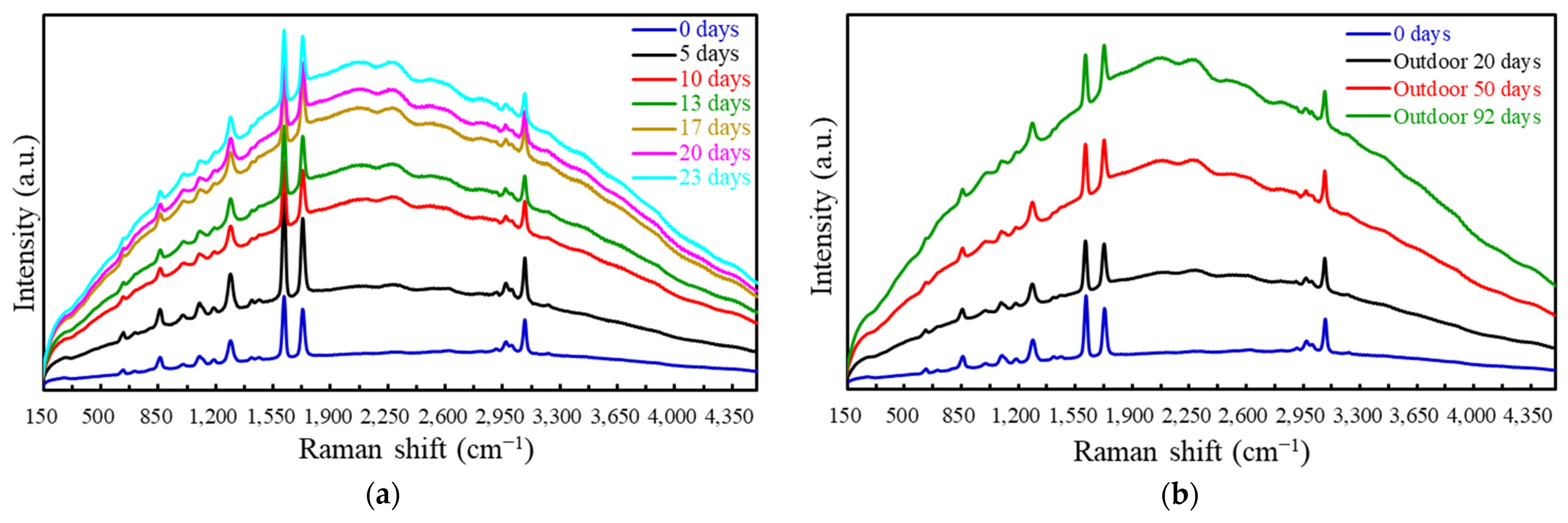

3.2. Degradation of OMO Coatings and PET Substrates

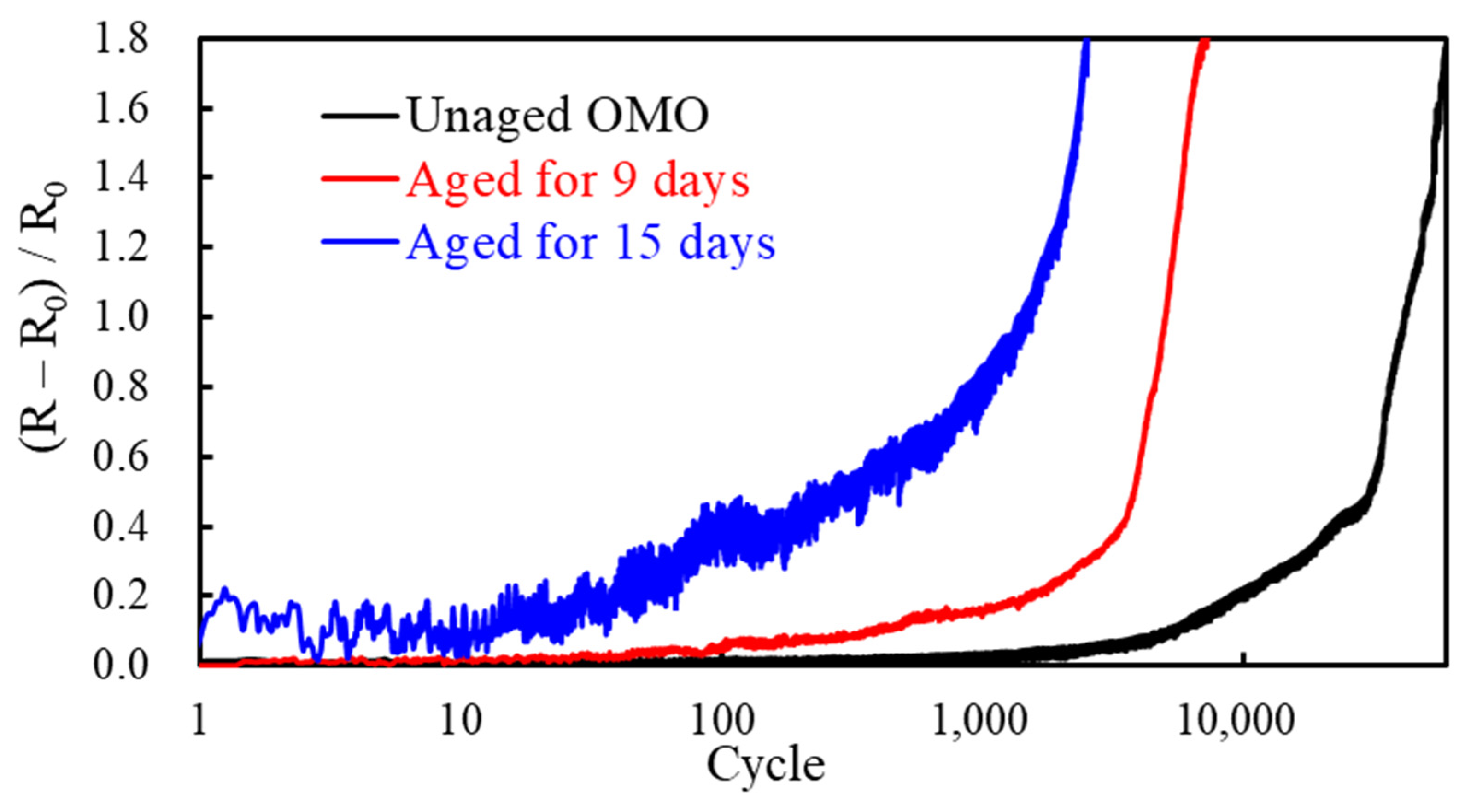

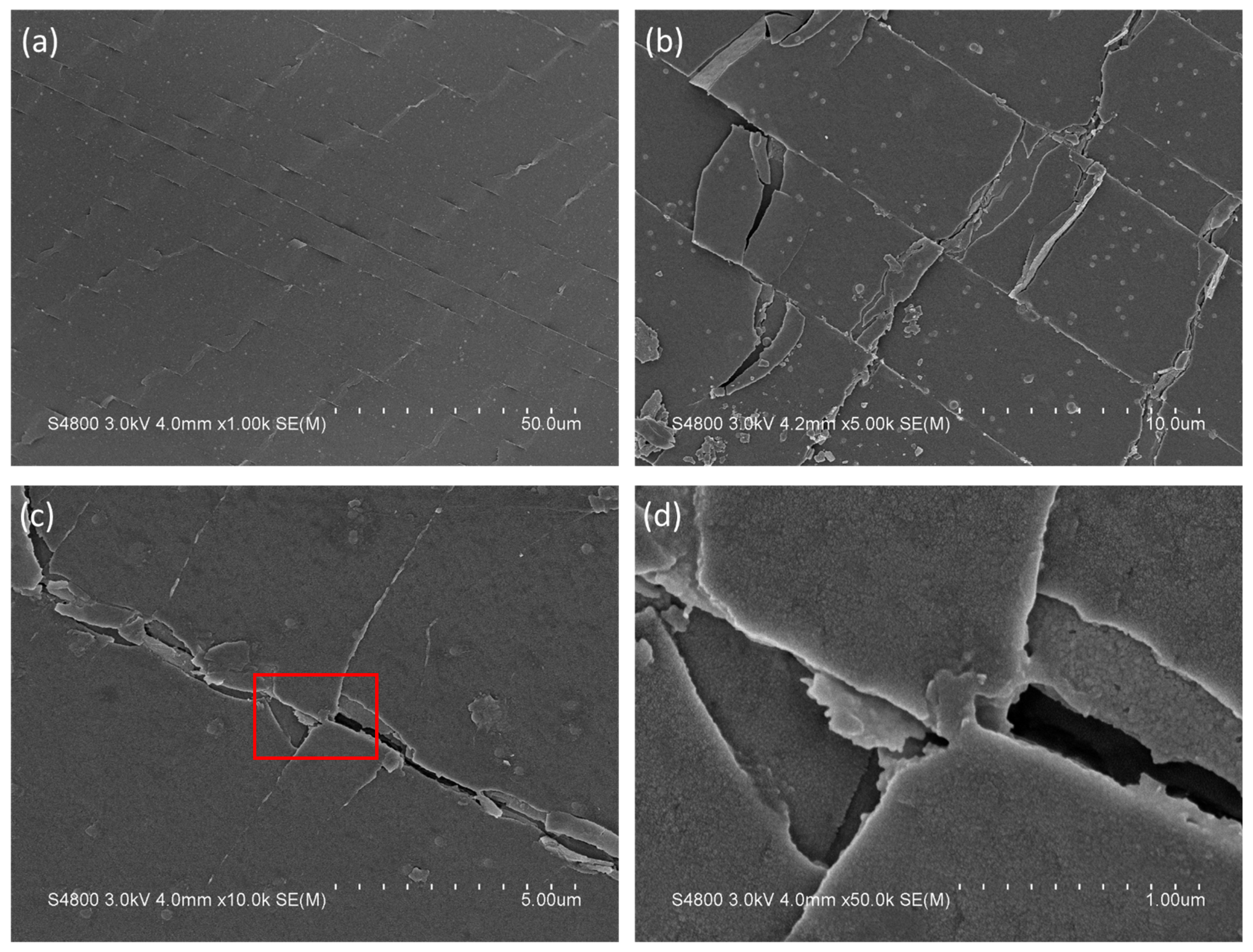

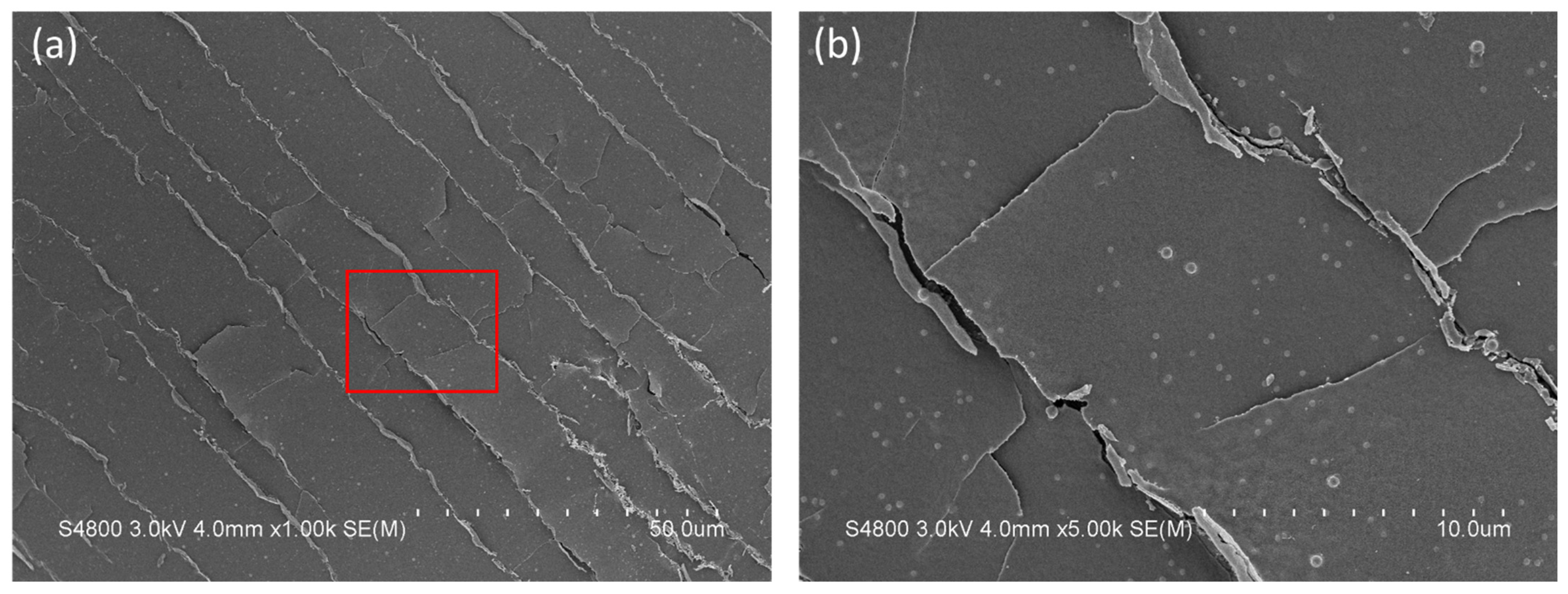

3.3. Bending Mechanical Properties of OMO Samples

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yun, J. Ultrathin metal films for transparent electrodes of flexible optoelectronic devices. Adv. Funct. Mater. 2017, 27, 1606641. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, J.; Li, Q.; Li, G.; Tian, X.; Luo, Z.; Qiao, F.; Wu, X.; Zhang, J. Review of printed electrodes for flexible devices. Front. Mater. 2017, 5, 77. [Google Scholar] [CrossRef]

- Nguyen, V.H.; Papanastasiou, D.T.; Resende, J.; Bardet, L.; Sannicolo, T.; Jiménez, C.; Muñoz-Rojas, D.; Nguyen, N.D.; Bellet, D. Advances in flexible metallic transparent electrodes. Small 2022, 18, 2106006. [Google Scholar] [CrossRef] [PubMed]

- Sarma, B.; Sarma, B.K. Role of residual stress and texture of ZnO nanocrystals on electro-optical properties of ZnO/Ag/ZnO multilayer transparent conductors. J. Alloys Compd. 2018, 734, 210–219. [Google Scholar] [CrossRef]

- Winkler, T.; Schmidt, H.; Flügge, H.; Nikolayzik, F.; Baumann, I.; Schmale, S.; Johannes, H.H.; Rabe, T.; Hamwi, S.; Riedl, T.; et al. Realization of ultrathin silver layers in highly conductive and transparent zinc tin oxide/silver/zinc tin oxide multilayer electrodes deposited at room temperature for transparent organic devices. Thin Solid Films 2012, 520, 4669–4673. [Google Scholar] [CrossRef]

- Behrendt, A.; Friedenberger, C.; Gahlmann, T.; Trost, S.; Becker, T.; Zilberberg, K.; Polywka, A.; Gorrn, P.; Riedl, T. Highly robust transparent and conductive gas diffusion barriers based on tin oxide. Adv. Mater. 2015, 27, 5961–5967. [Google Scholar] [CrossRef]

- Jeong, E.; Lee, S.G.; Yu, S.M.; Bae, J.S.; Lee, G.H.; Choi, D.; Yun, J. Thermal stability enhancement of ultrathin Ag film electrodes by incorporating atomic oxygen. Appl. Surf. Sci. 2021, 546, 149149. [Google Scholar] [CrossRef]

- Choo, D.C.; Kim, T.W. Degradation mechanisms of silver nanowire electrodes under ultraviolet irradiation and heat treatment. Sci. Rep. 2017, 7, 1696. [Google Scholar] [CrossRef]

- Chang, H.S.; Feng, P.; Lyu, Y.; Lin, C.C. Accelerated and outdoor weathering of silver nanowire transparent conductors under electrical stress in pseudo-modules. Nanotechnology 2022, 33, 15LT01. [Google Scholar] [CrossRef]

- Sanga, T.; Wallisb, C.J.; Hillb, G.; Britovsek, G.J.P. Polyethylene terephthalate degradation under natural and accelerated weathering conditions. Eur. Polym. J. 2020, 136, 109873. [Google Scholar] [CrossRef]

- Horne, F.J.; Liggat, J.J.; MacDonald, W.A.; Sankey, S.W. Photo-oxidation of poly(ethylene terephthalate) films intended for photovoltaic backsheet. J. Appl. Polym. Sci. 2020, 137, 48623. [Google Scholar] [CrossRef]

- Gok, A.; Gordon, D.A.; Burns, D.M.; Fowler, S.P.; French, R.H.; Bruckman, L.S. Reciprocity and spectral effects of the degradation of poly(ethylene-terephthalate) under accelerated weathering exposures. J. Appl. Polym. 2019, 136, 47589. [Google Scholar] [CrossRef]

- Park, S.I.; Ahn, J.H.; Feng, X.; Wang, S.; Huang, Y.; Rogers, J.A. Theoretical and experimental studies of bending of inorganic electronic materials on plastic substrates. Adv. Funct. Mater. 2008, 18, 2673–2684. [Google Scholar] [CrossRef]

- Seo, Y.; Ha, H.; Matteinind, P.; Hwang, B. A review on the deformation behavior of silver nanowire networks under many bending cycles. Appl. Sci. 2021, 11, 4515. [Google Scholar] [CrossRef]

- Mohammed, D.W.; Ameen, R.B.; Sierros, K.A.; Bowen, J.; Kukureka, S.N. Twisting fatigue in multilayer films of Ag-alloy with indium tin oxide on polyethylene terephthalate for flexible electronics devices. Thin Solid Films 2018, 645, 241–252. [Google Scholar] [CrossRef]

- Lee, J.E.; Kim, H.K. Highly transparent and flexible TiN doped In2O3 (ITON)/Ag-Ti/ITON multilayer electrodes coated on polyethylene terephthalate substrate. Thin Solid Films 2018, 666, 1–5. [Google Scholar] [CrossRef]

- Ruoho, M.; Tarasiuk, N.; Rohbeck, N.; Kapusta, C.; Michler, J.; Utke, I. Stability of mechanical properties of molecular layer–deposited alucone. Mater. Today Chem. 2018, 10, 187–194. [Google Scholar] [CrossRef]

- ASTM D6287-09; Standard Practice for Cutting Film and Sheeting Test Specimens. ASTM: West Conshohocken, PA, USA, 2009.

- Lin, C.C.; Chang, H.S. Degradation of silver nanowire transparent conductors by module-level weathering under electrical stress. In Proceedings of the 2021 IEEE 71st Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 1 June–4 July 2021. [Google Scholar]

- Lin, C.C.; Krommenhoek, P.J.; Watson, S.S.; Gu, X. Depth profiling of degradation of multilayer photovoltaic backsheets after accelerated laboratory weathering: Cross-sectional Raman imaging. Sol. Energy Mater. Sol. Cells 2016, 144, 289–299. [Google Scholar] [CrossRef]

- Pern, F.J. Luminescence and absorption characterization of ethylene-vinyl acetate encapsulant for PV modules before and after weathering degradation. Polym. Degrad. Stab. 1993, 41, 125–139. [Google Scholar] [CrossRef]

- Lippert, T.H.; Zimmermann, F.; Wokaun, A. Surface analysis of excimer-laser-treated polyethylene-terephthalate by surface-enhanced Raman scattering and X-ray photoelectron spectroscopy. Appl. Spectrosc. 1993, 47, 1931–1942. [Google Scholar] [CrossRef]

- Adar, F.; Noether, H. Raman microprobe spectra of spin-oriented and drawn filaments of poly(ethylene terephthalate). Polymer 1985, 26, 1935–1943. [Google Scholar] [CrossRef]

- Larenaa, A.; Millánb, F.; Pérezc, G.; Pintoa, G. Effect of surface roughness on the optical properties of multilayer polymer films. Appl. Surf. Sci. 2002, 187, 339–346. [Google Scholar] [CrossRef]

- Bauch, M.; Dimopoulos, T.; Trassl, S. Nanostructured, ultrathin silver-based transparent electrode with broadband near-infrared plasmonic resonance. Nanotechnology 2019, 30, 265201. [Google Scholar] [CrossRef] [PubMed]

- Ward, I.M.; Wilding, M.A. Infra-red and Raman spectra of poly(m-methylene terephthalate) polymers. Polymer 1977, 18, 327–335. [Google Scholar] [CrossRef]

- Štokr, J.; Schneider, B.; Doskočilová, D.; Lövy, J.; Sedláček, P. Conformational structure of poly(ethylene terephthalate). Infra-red, Raman and N.M.R. spectra. Polymer 1982, 23, 714–721. [Google Scholar] [CrossRef]

- Davis, R.; Chin, J.; Lin, C.C.; Petit, S. Accelerated weathering of polyaramid and polybenzimidazole firefighter protective clothing fabrics. Polym. Degrad. Stab. 2010, 95, 1642–1654. [Google Scholar] [CrossRef]

- Musil, J. Flexible hard nanocomposite coatings. RSC Adv. 2015, 5, 60482. [Google Scholar] [CrossRef]

- Kempe, M.D.; Lyu, Y.; Kim, J.H.; Felder, T.; Gu, X. Fragmentation of photovoltaic backsheets after accelerated weathering exposure. Sol. Energy Mater. Sol. Cells 2021, 226, 111044. [Google Scholar] [CrossRef]

- Yoon, Y.; Angel, J.D.; Hansen, D.C. Atmospheric corrosion of silver in outdoor environments and modified accelerated corrosion chambers. Corrosion 2016, 72, 1424–1432. [Google Scholar] [CrossRef]

- Kim, C.; Kim, C.H. Universal testing apparatus implementing various repetitive mechanical deformations to evaluate the reliability of flexible electronic devices. Micromachines 2018, 9, 492. [Google Scholar] [CrossRef] [Green Version]

- Hsueh, C.H.; Yanaka, M. Multiple film cracking in film/substrate systems with residual stresses and unidirectional loading. J. Mater. Sci. 2003, 38, 1809–1817. [Google Scholar] [CrossRef]

| Raman Shift (cm−1) | Assignment |

|---|---|

| 636 | Ring C–C–C in-plane bend |

| 707 | Ring C–C–C out-of-plane bend |

| 859 | Ring C–C breathing |

| 1007 | Glycol C–C stretch/O–CH2 stretch/ring torsion |

| 1102 | Ring CH in-plane bend/glycol C–O stretch/COC and CCO bending/C–C stretch |

| 1191 | Ring CH in-plane bend |

| 1289 | Ring-carbonyl stretch/O–C stretch/ring CH in-plane bend |

| 1418 | Ring C–C stretch |

| 1460 | Glycol C–C deformation |

| 1617 | Ring C=C stretch |

| 1734 | C=O stretch |

| 2971 | Amorphous aliphatic CH2 stretching |

| 3086 | Aromatic C─H stretching |

| Indoor Accelerated Weathering | ||||||

|---|---|---|---|---|---|---|

| Exposure Time (Day) | 0 | 5 | 10 | 13 | 17 | 23 |

| Rsq (Ω/Square) | 4.7 ± 0.1 | 4.8 ± 0.2 | 5.3 ± 0.3 | 5.0 ± 0.2 | 4.9 ± 0.2 | 4.9 ± 0.5 |

| Outdoor Weathering | ||||

|---|---|---|---|---|

| Exposure Time (Day) | 0 | 20 | 50 | 92 |

| Rsq (Ω/Square) | 4.7 ± 0.1 | 6.3 ± 1.0 | 7.8 ± 1.9 | 9.9 ± 1.5 |

| Exposure Time (Days) | Ultimate Tensile Strength (MPa) | Elongation at Break (%) | Yield Strength (MPa) |

|---|---|---|---|

| 0 | 174.7 ± 5.9 | 83.1 ± 3.5 | 110.2 ± 4.4 |

| 5 | 170.2 ± 10.1 | 66.0 ± 8.5 | 105.9 ± 7.4 |

| 10 | 112.8 ± 6.9 | 17.0 ± 3.1 | 99.0 ± 3.4 |

| 13 | 91.6 ± 6.0 | 2.2 ± 0.1 | N/A |

| 17 | 79.7 ± 7.8 | 1.7 ± 0.1 | N/A |

| 20 | 71.9 ± 7.9 | 1.5 ± 0.1 | N/A |

| 23 | 72.8 ± 6.4 | 1.4 ± 0.2 | N/A |

| Outdoor 50 days | 71.3 ± 9.0 | 2.0 ± 0.2 | N/A |

| UV Testing (d) | Continuous Sun (d) | Equivalent Outdoor Conditions (d) |

|---|---|---|

| UVT | CS = 1.5 × UVT | EOC = 3 × UVT |

| 5 | 7.5 | 15 |

| 10 | 15 | 30 |

| 13 | 19.5 | 39 |

| 17 | 25.5 | 51 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kao, Y.-H.; Chang, H.-S.; Wang, C.-C.; Lin, C.-C. Weathering and Material Characterization of ZTO/Ag/ZTO Coatings on Polyethylene Terephthalate Substrates for the Application of Flexible Transparent Conductors. Coatings 2022, 12, 1249. https://doi.org/10.3390/coatings12091249

Kao Y-H, Chang H-S, Wang C-C, Lin C-C. Weathering and Material Characterization of ZTO/Ag/ZTO Coatings on Polyethylene Terephthalate Substrates for the Application of Flexible Transparent Conductors. Coatings. 2022; 12(9):1249. https://doi.org/10.3390/coatings12091249

Chicago/Turabian StyleKao, Yu-Han, Hung-Shuo Chang, Chih-Chieh Wang, and Chiao-Chi Lin. 2022. "Weathering and Material Characterization of ZTO/Ag/ZTO Coatings on Polyethylene Terephthalate Substrates for the Application of Flexible Transparent Conductors" Coatings 12, no. 9: 1249. https://doi.org/10.3390/coatings12091249

APA StyleKao, Y.-H., Chang, H.-S., Wang, C.-C., & Lin, C.-C. (2022). Weathering and Material Characterization of ZTO/Ag/ZTO Coatings on Polyethylene Terephthalate Substrates for the Application of Flexible Transparent Conductors. Coatings, 12(9), 1249. https://doi.org/10.3390/coatings12091249