Erosion Effect in the Degradation of Coated and Uncoated Glass Solar Mirrors Highlighted by Coupled Accelerated Erosion/Aging Tests

Abstract

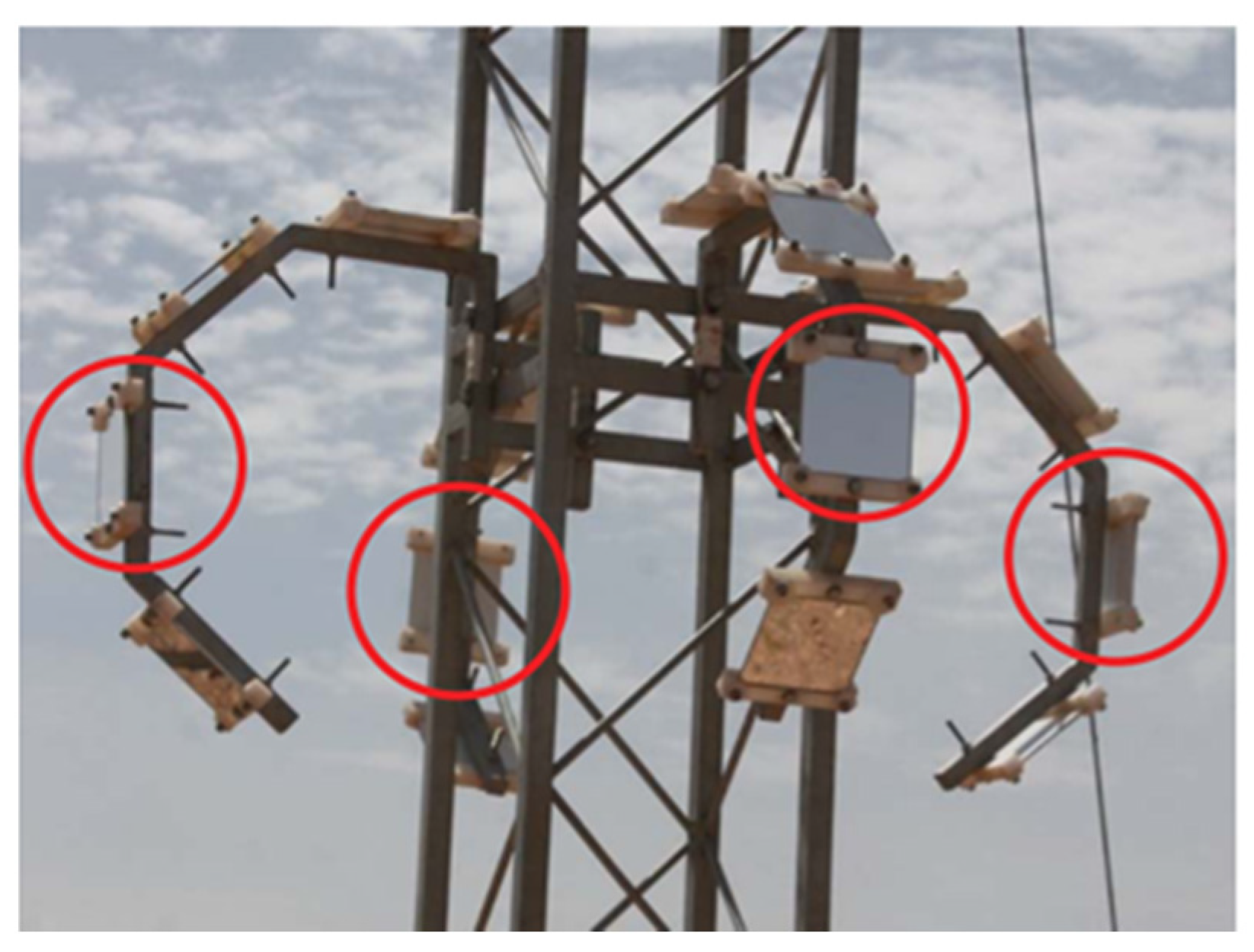

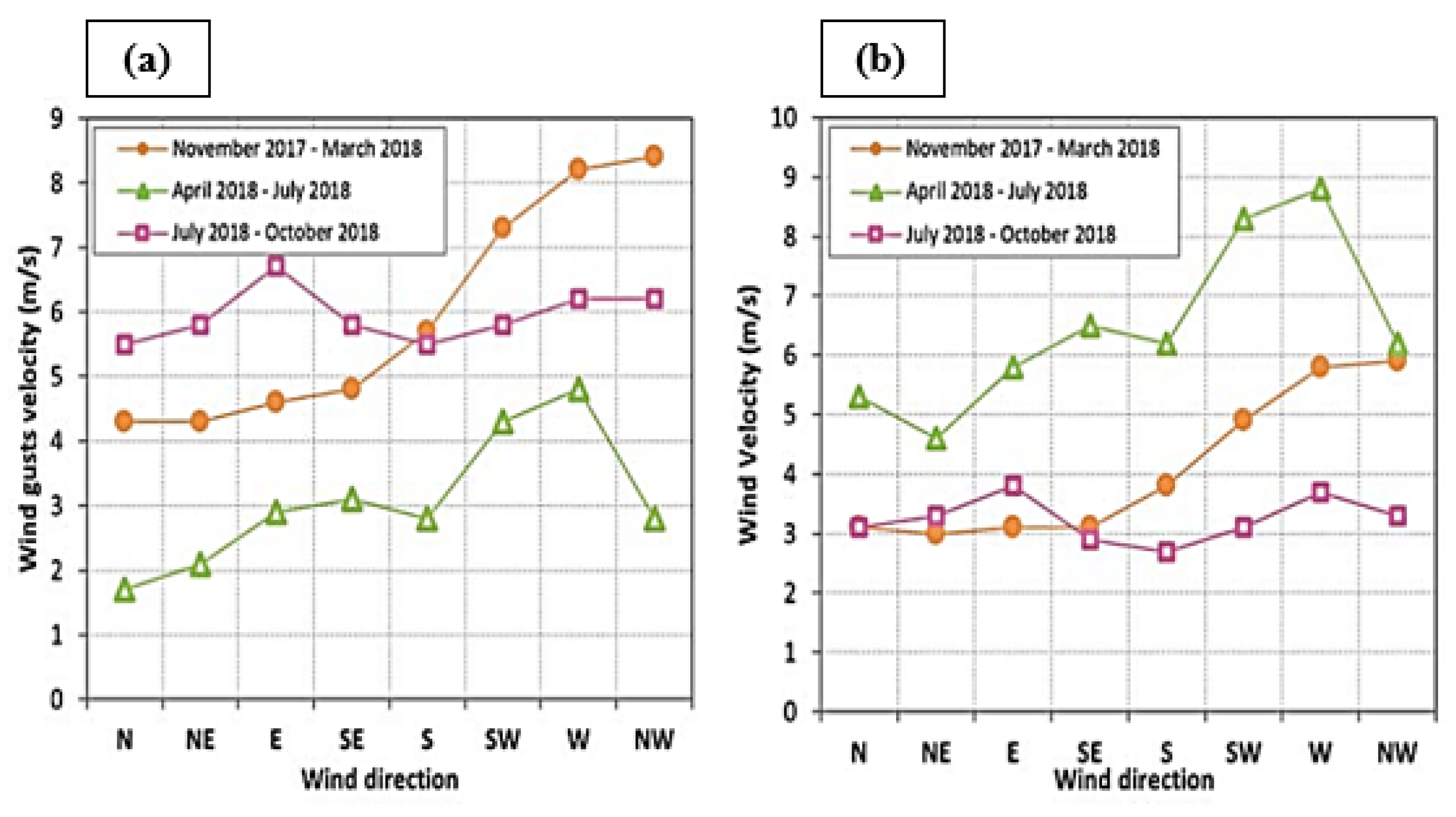

:1. Introduction

- -

- Uncoated, the frontal protection is made by a soda-lime glass with a thickness of 4 mm. The back protection is ensured by two paint layers.

- -

- Coated, the frontal protection is ensured by the same soda-lime glass in addition to an anti-soiling SiO2 coating.

- -

- High temperature humidity and pressure aging stress test named HAST

- -

- Cyclic UV/water spray test named SUNTEST

2. Materials and Methods

2.1. Aging Procedure

- -

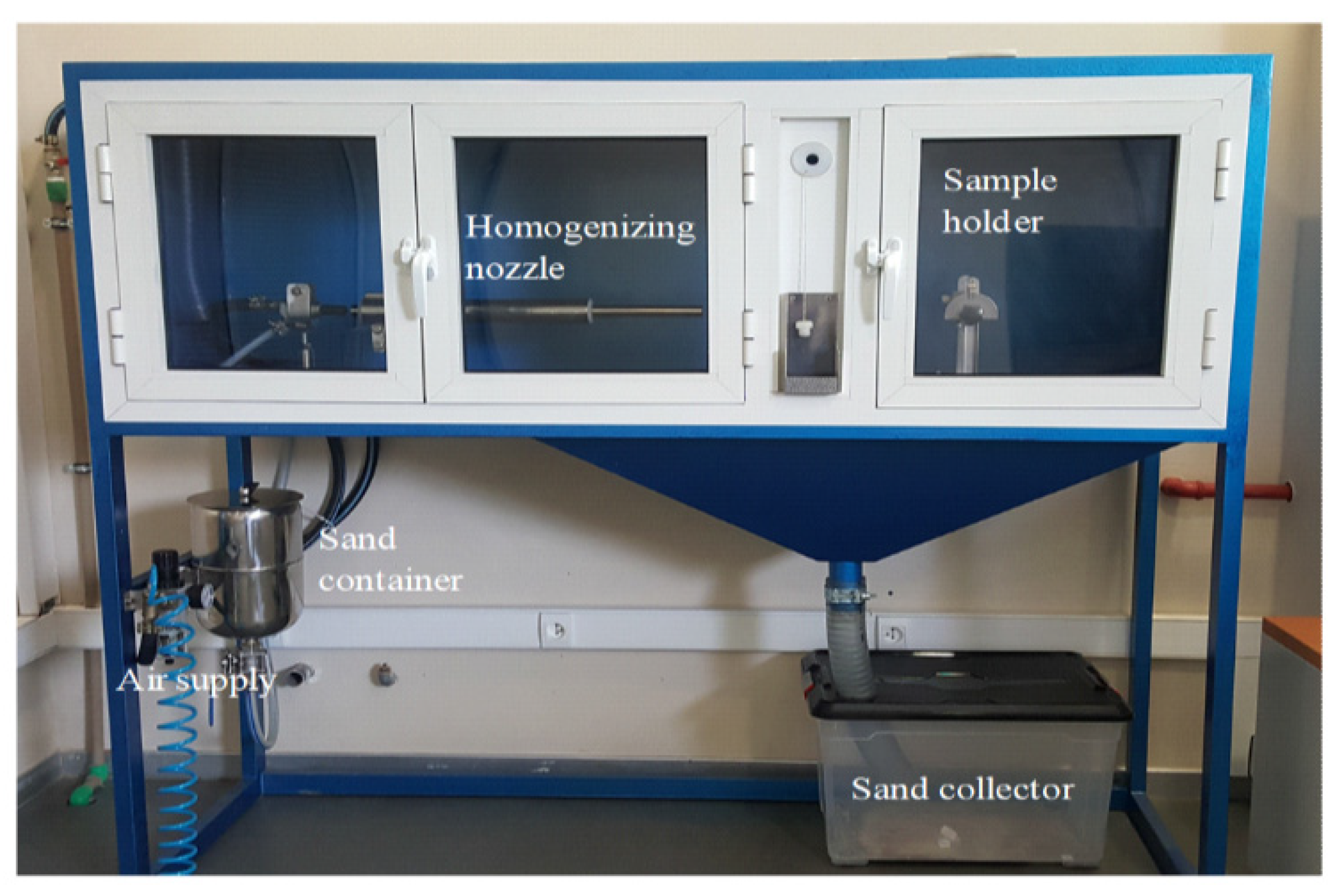

- Step 1: the first step of this work is to expose tested samples to an accelerated erosion damage. The test bench used to simulate the erosion degradation caused by sand particles is a horizontal ejection system (Figure 6). The pressurized air and sand particles are homogenized and mixed through a horizontal tube. After the mixture, the particles are propelled and ejected towards the target surface with a fixed air speed and a controlled inclination angle.

- -

- Step 2: the second step of this work is to couple erosion and aging tests by exposing the eroded samples and intact samples in a climatic chamber. Two aging tests were chosen:

- -

- High accelerated aging stress test (HAST): this test aims to study the resistance of materials against humidity. The water pressure inside the chamber is increased until it exceeds the water vapor pressure inside the tested samples. As the water vapor moves from higher pressures to lower pressures, it favors the penetration of moisture into tested samples. This test was performed in an Espec EHS211M climatic chamber according to IEC60068-2-66 in exposing the samples to a constant climate of 2 bars, 110 ± 0.5 °C and 85 ± 3% relative humidity. Samples were positioned in the chamber with an inclination of around 25° to the vertical, front side up.

- -

- Cyclic UV/water spray test: Though this combined test, we want to study the effect of liquid water that evaporate under UV and to check if eroded samples will retain more water. The Xenon radiation with water spray test, according to ISO 16474-2 [16] consists of the following cycle: in the beginning, samples are exposed to a water spray during 3 min. Afterwards, samples are exposed during 27 min to a xenon radiation (irradiation xenon lamp with filter, 65 W/m2 between 300–400 nm). The total duration of one cycle is 30 min. Samples are tested with the coated/uncoated side facing the Xenon lamps. Tests were led in an ATLAS SUNTEST XXL+ climatic chamber.

- -

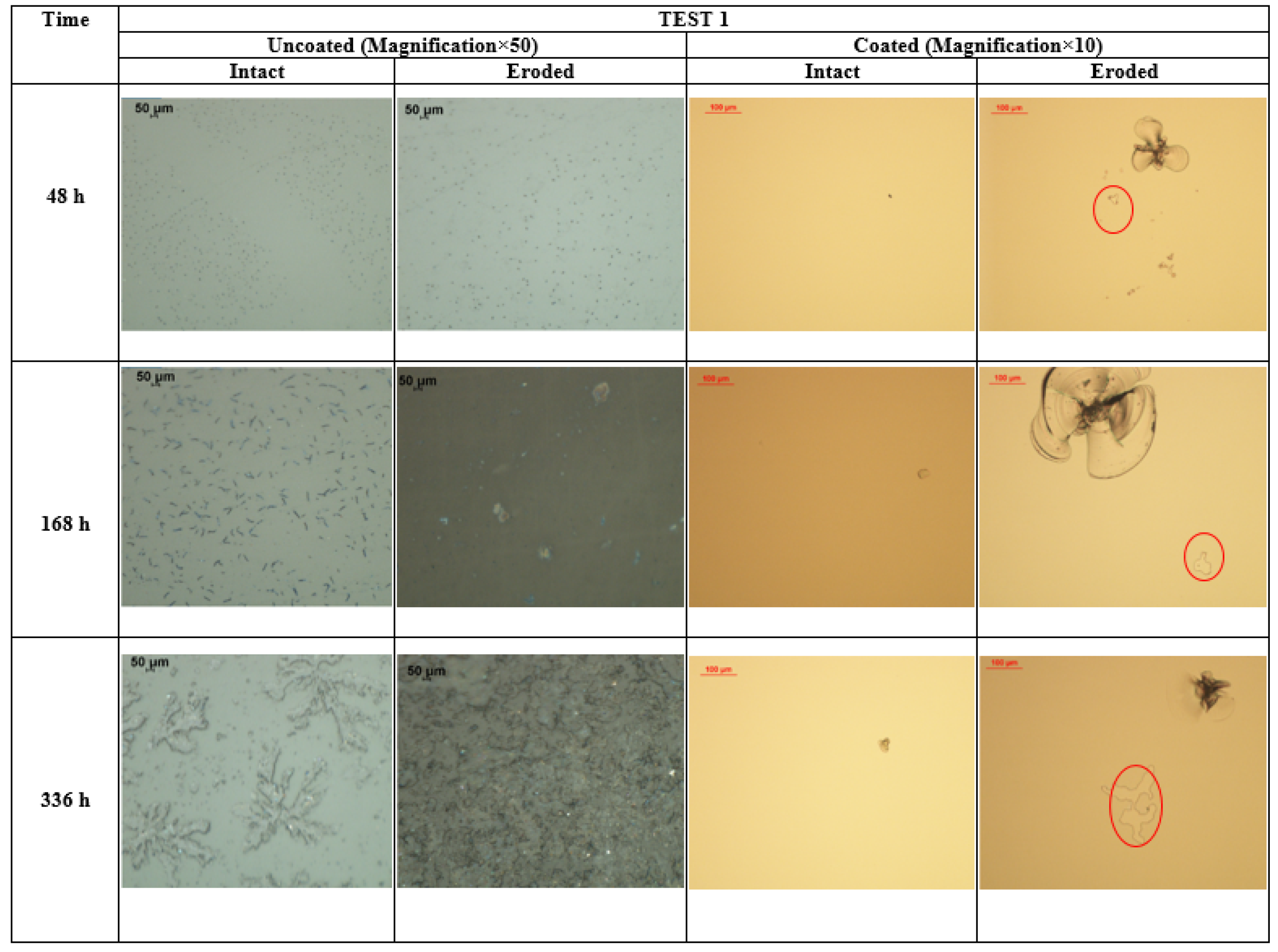

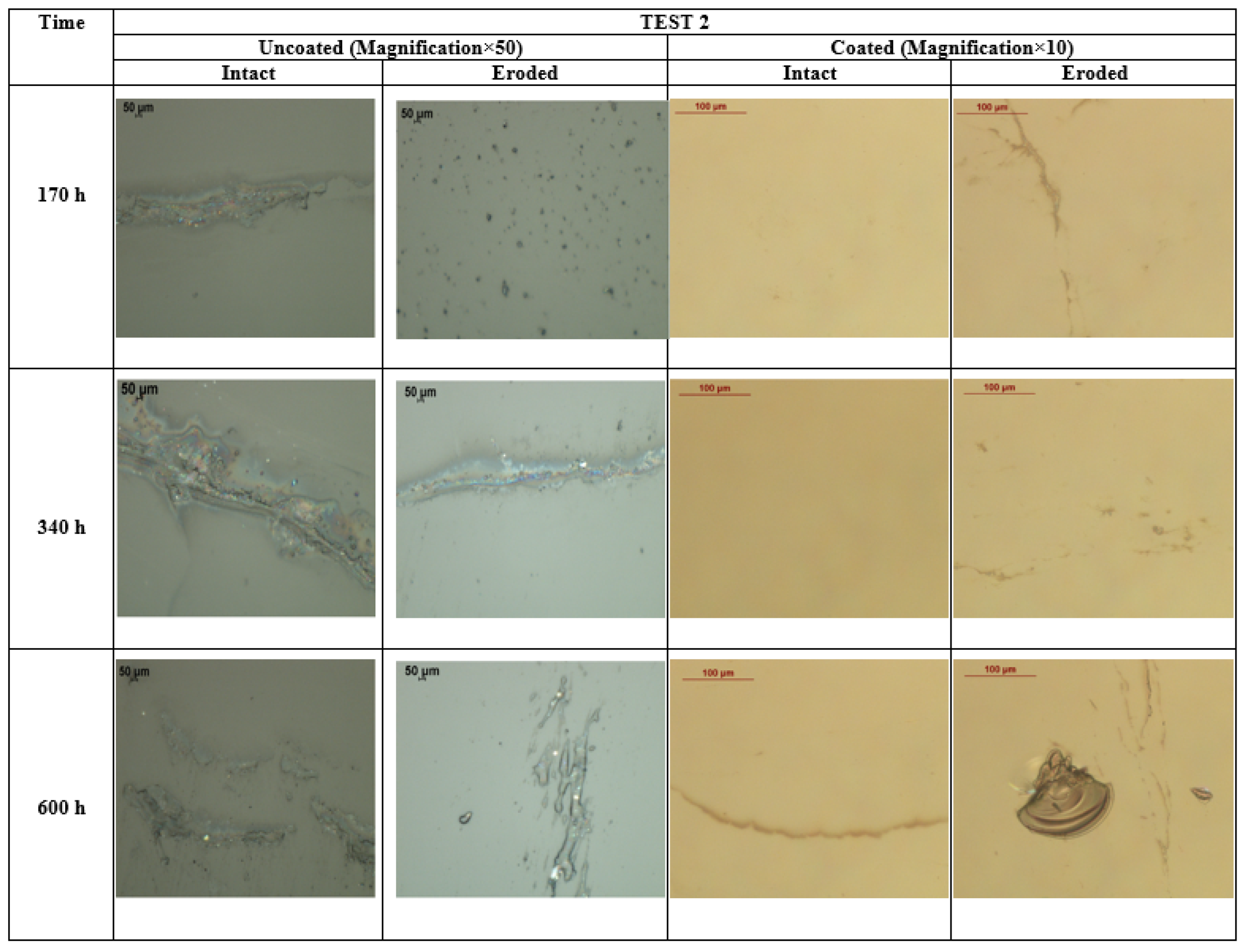

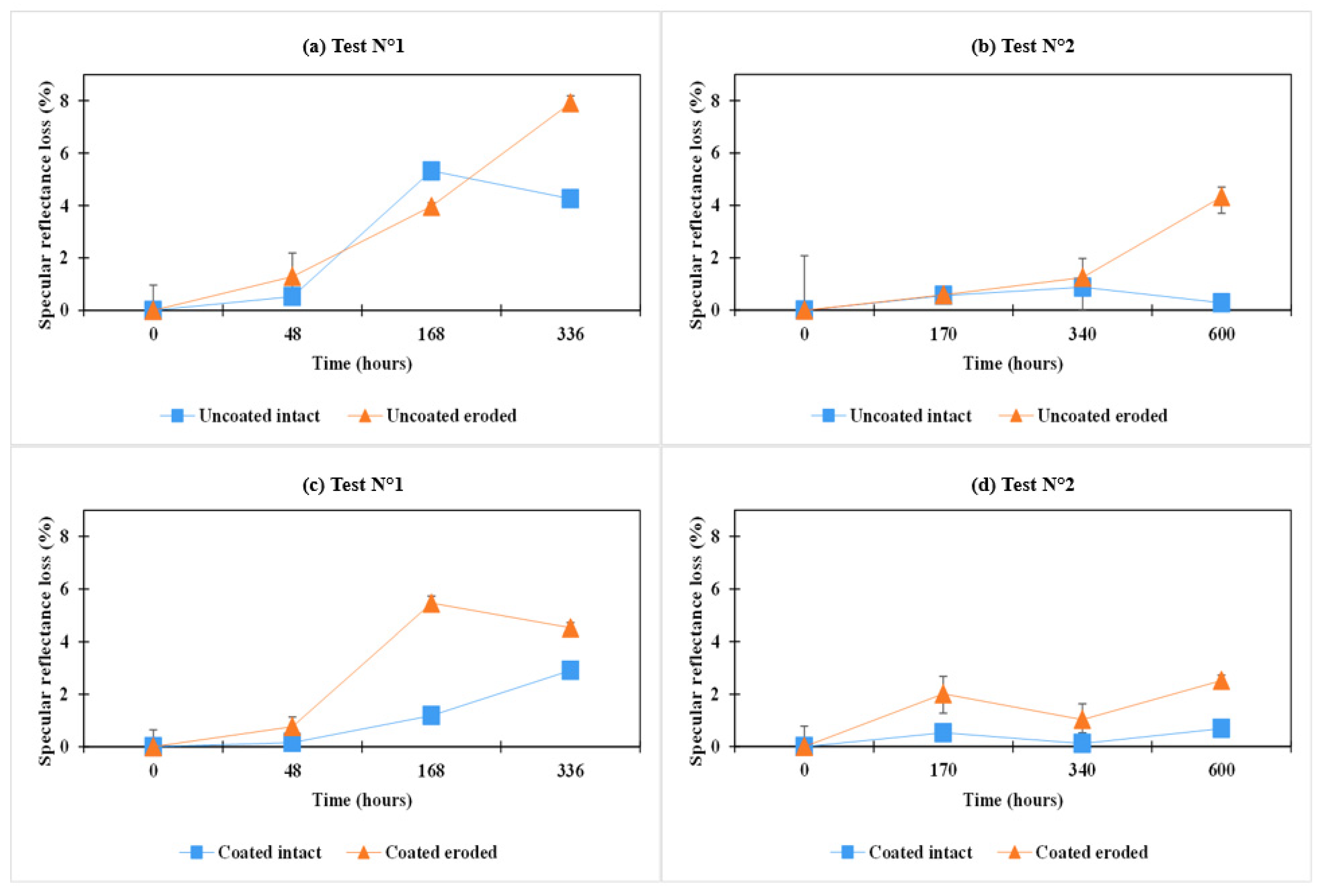

- Step 3: after introducing tested samples into the climatic chambers, the weathering will be provided for the entire period (336 h for HAST test and 600 h for SUNTEST test). Three follow-ups are planned, and 4 samples were removed (uncoated intact—uncoated eroded—coated intact—coated eroded) from every follow-up for laboratory analysis. For HAST test N°1, the follow-ups are planned respectively after 48 h, 168 h and 336 h. For SUNTEST test N°2, the samples are analyzed after 170 h, 340 h and 600 h.

2.2. Measured Parameters

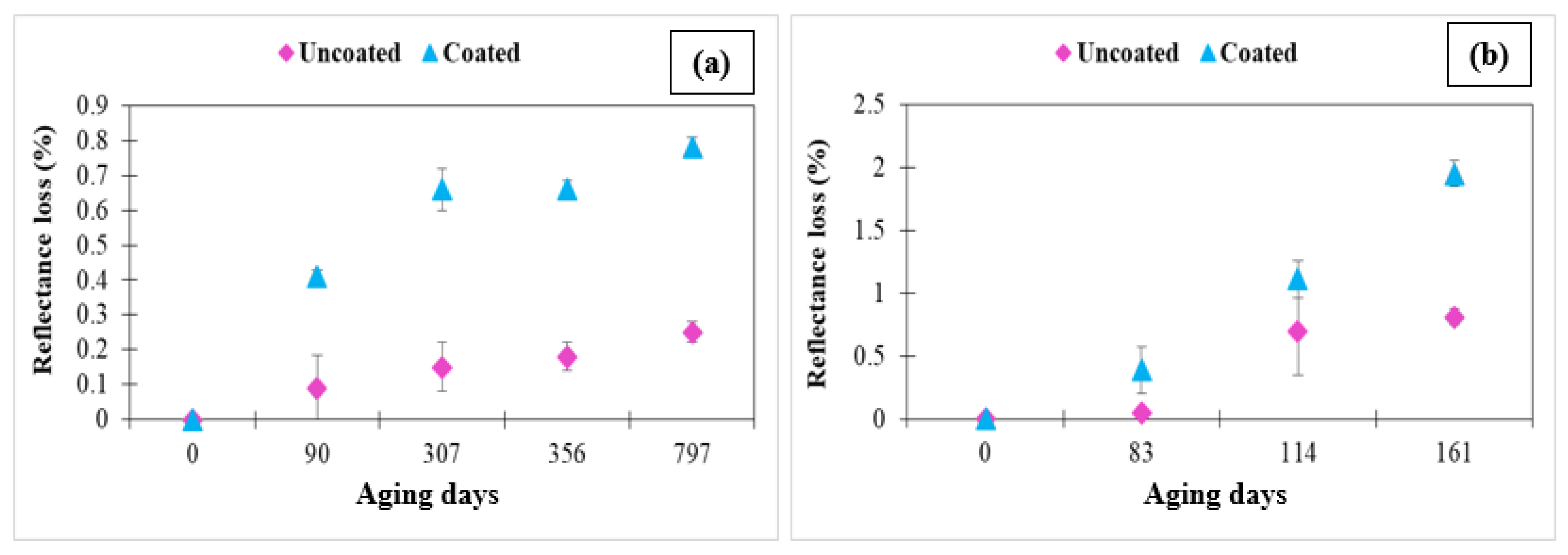

2.2.1. Reflectance Loss

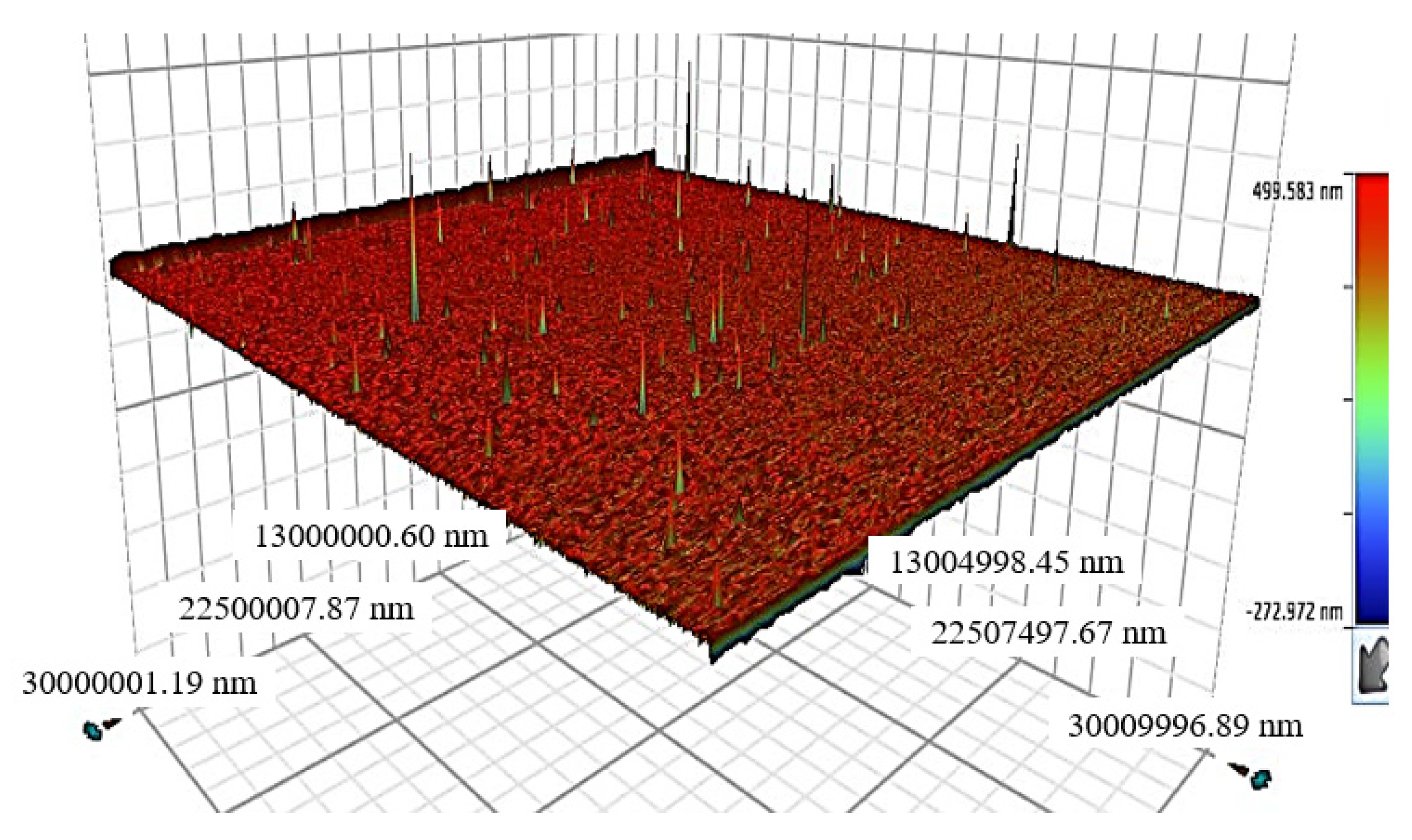

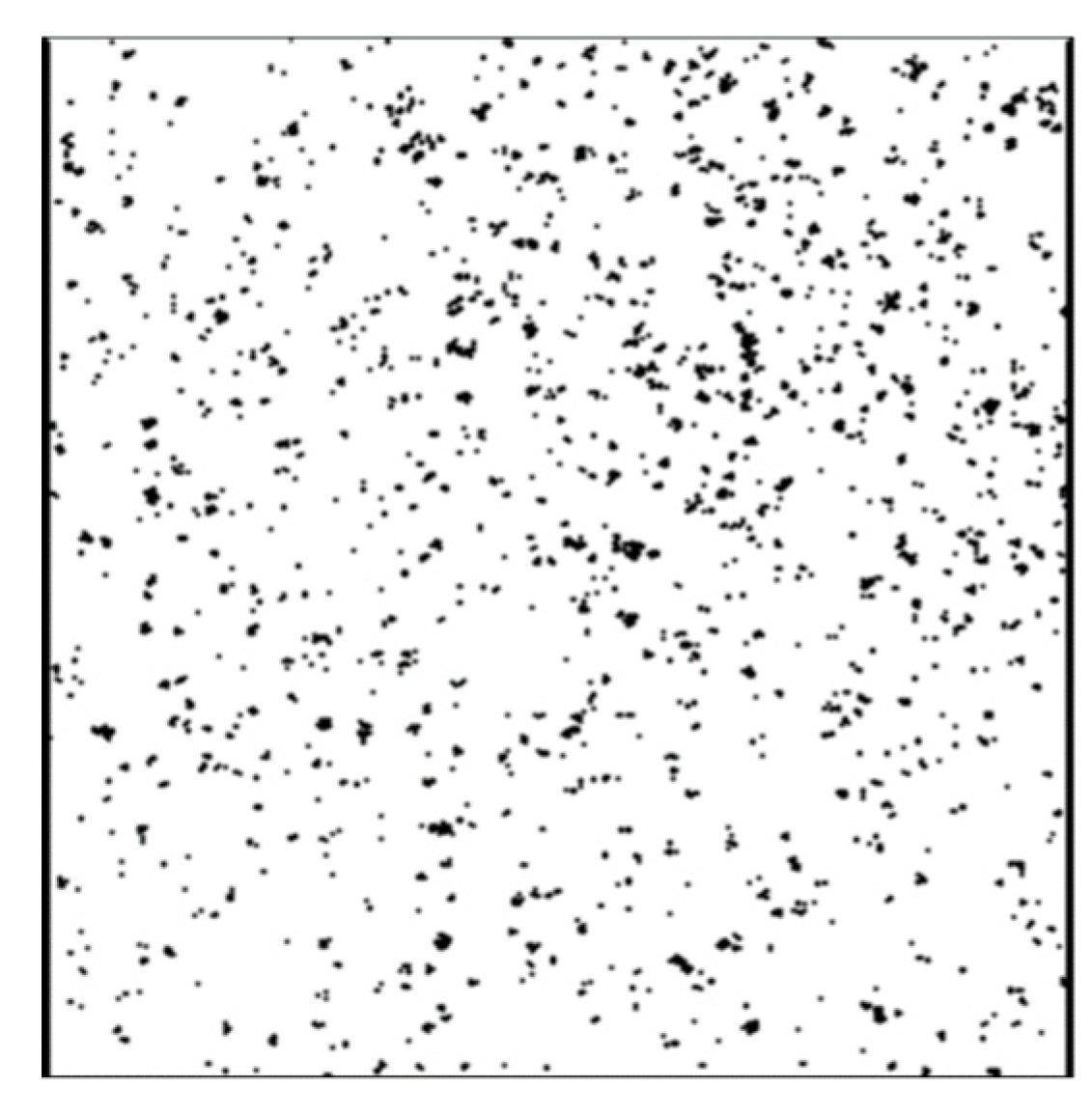

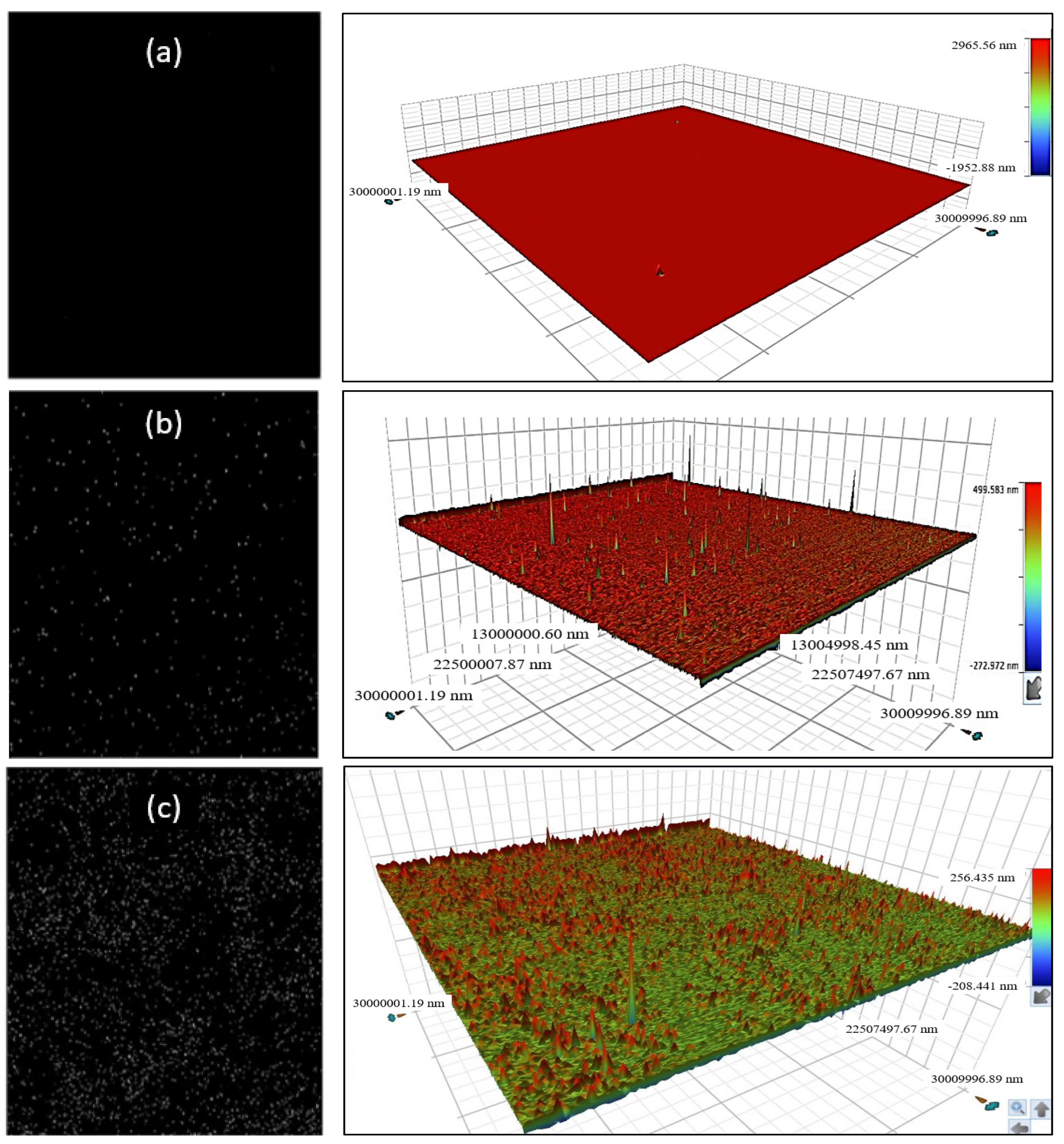

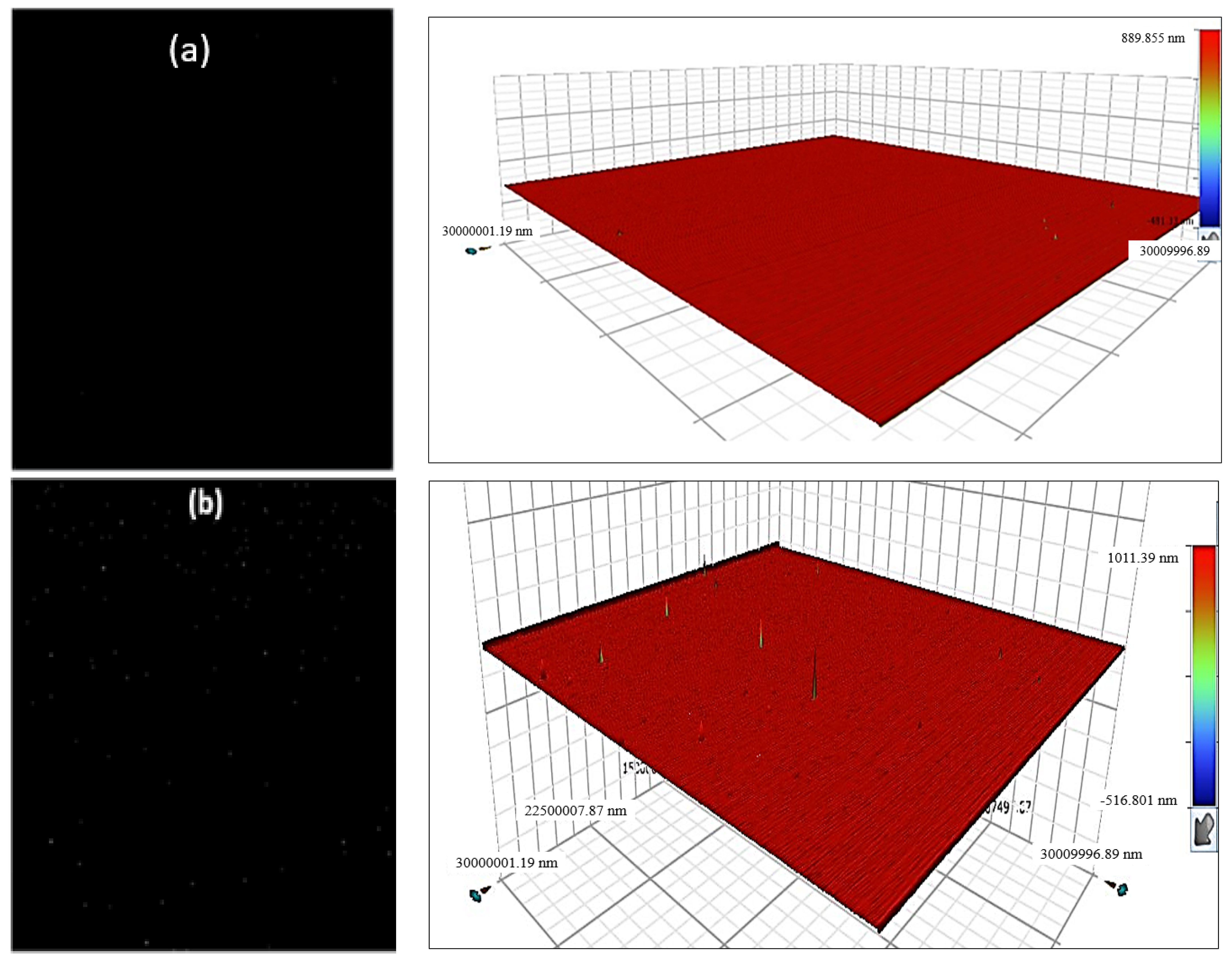

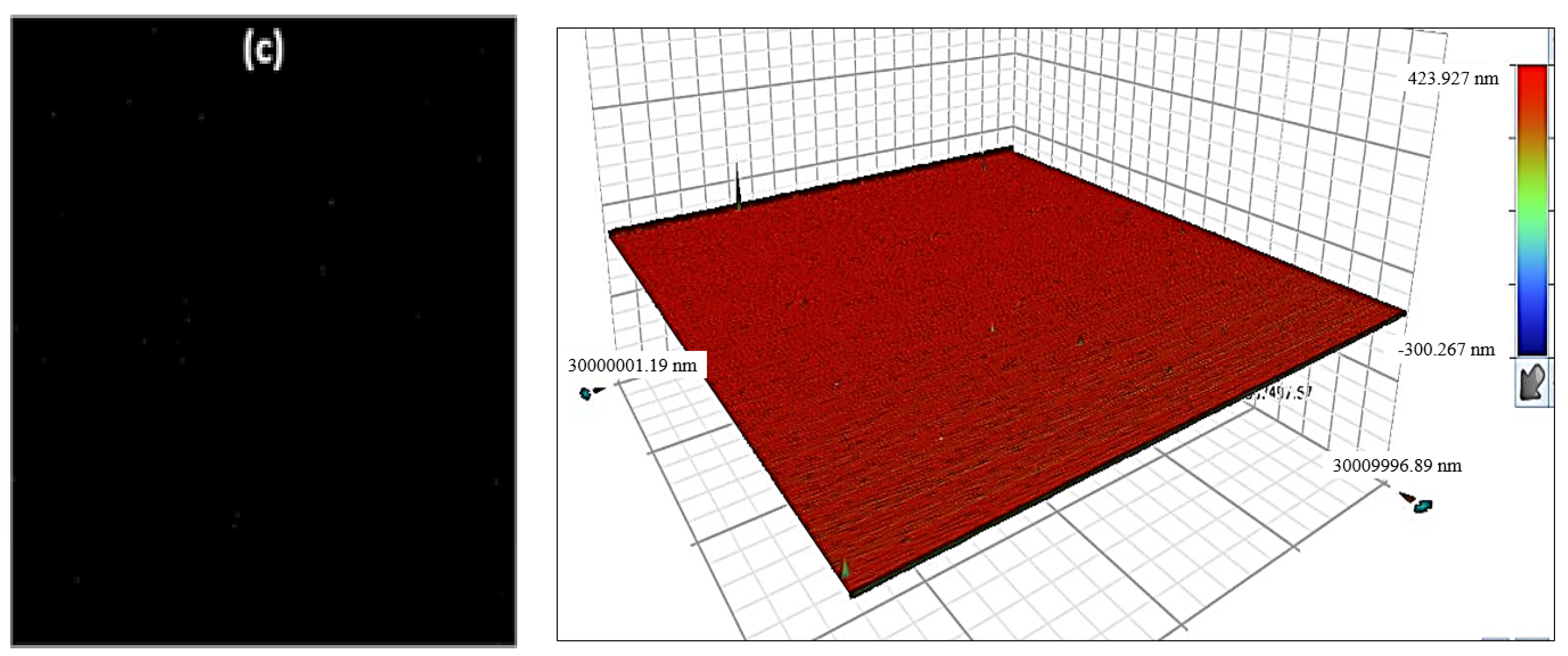

2.2.2. 3D Surface Profiling

3. Results

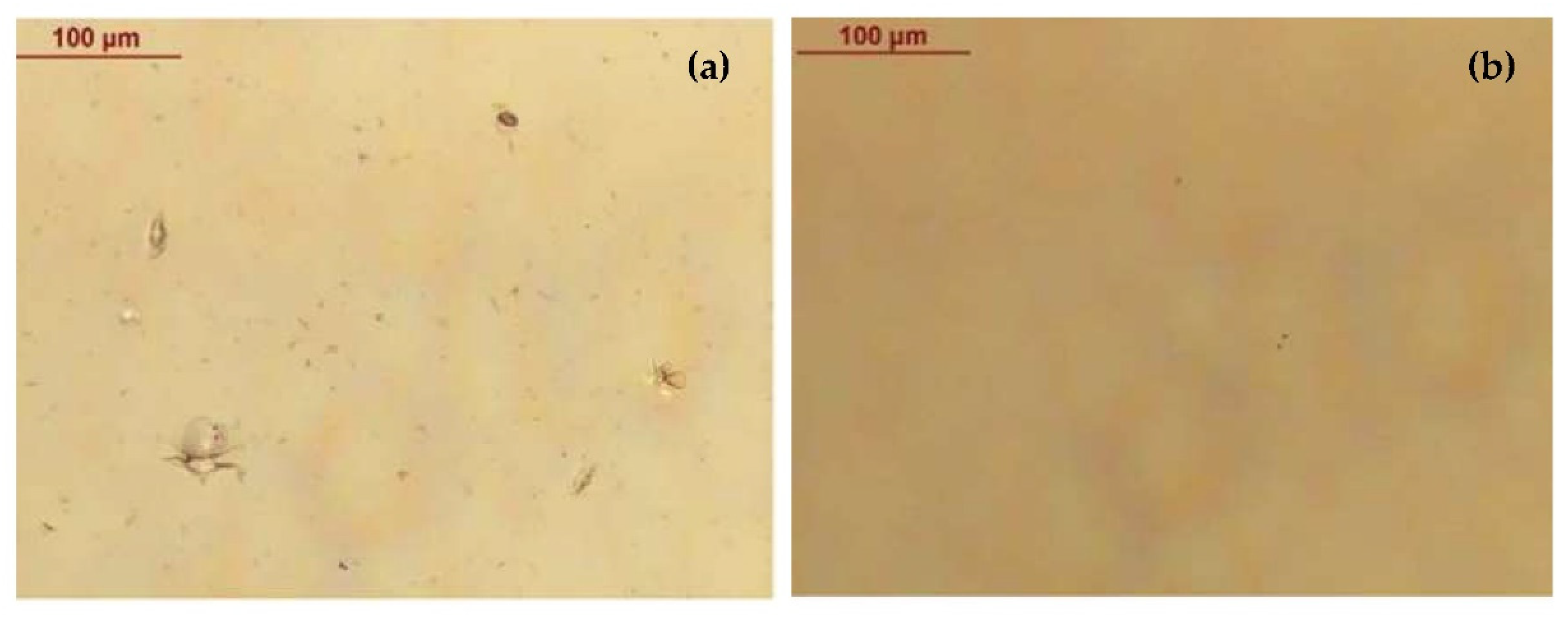

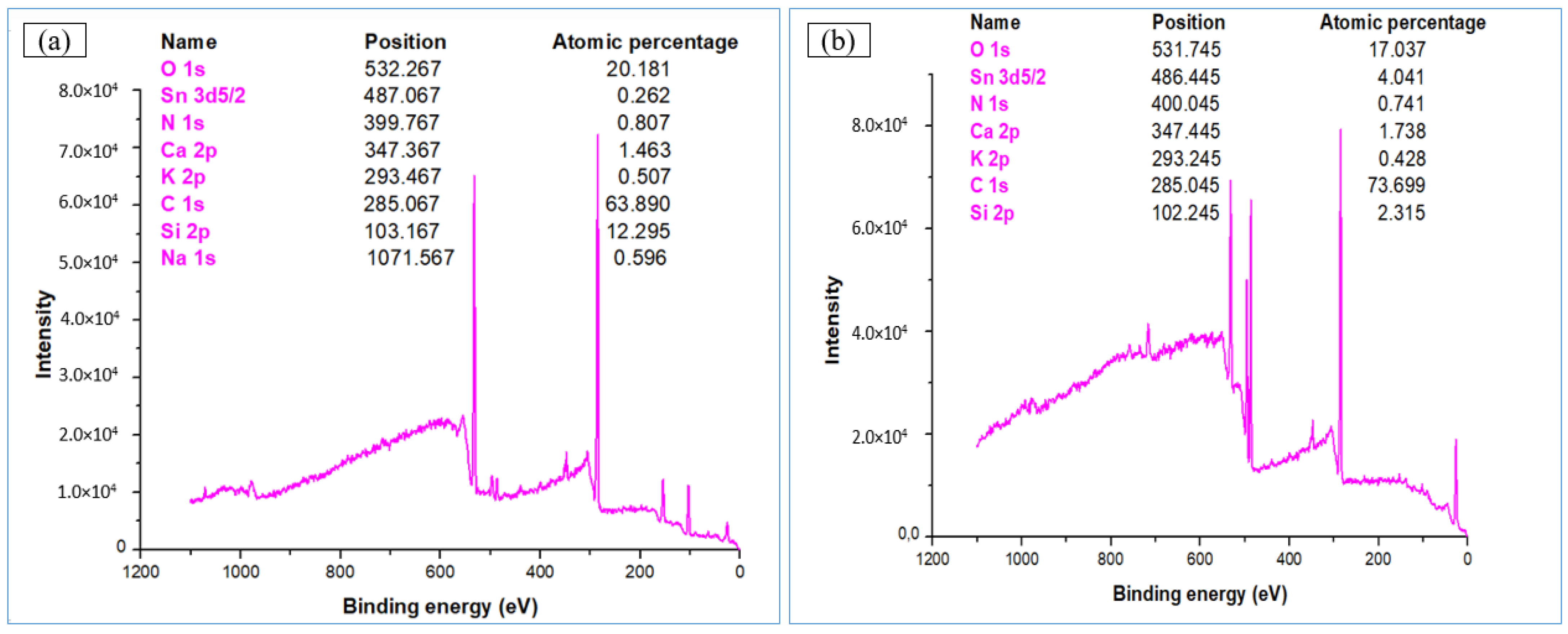

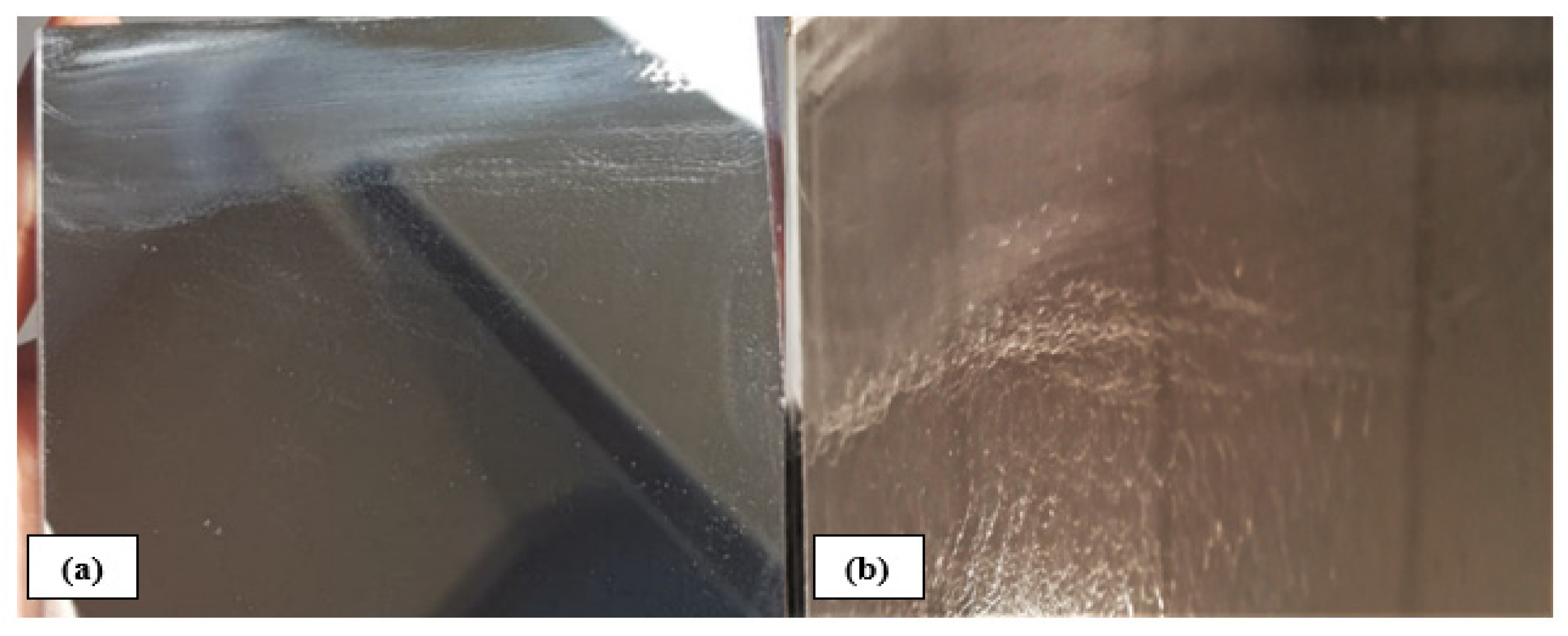

3.1. General Degradation Aspects

3.2. Optical Degradation

3D Surface Scan

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Paraillous, M. Traitement de Surface et Revêtement Transparent sur Verre Sodo-Calcique. Matériaux. Ph.D. Thesis, Université de Bordeaux, Bordeaux, France, 2016. [Google Scholar]

- Leboeuf, V. Caractérisation Cinétique et Structurale de Verres Sodo-Silicatés Soumis à un Echange Ionique au Potassium. Science des matériaux. Ph.D. Thesis, Université d’Orléans, Orléans, France, 2015. [Google Scholar]

- Garoli, D.; Rodriguez De Marcos, L.V.; Larruquert, J.I.; Corso, A.J.; Proietti Zaccaria, R.; Pelizzo, M.G. Mirrors for Space Telescopes: Degradation Issues. Appl. Sci. 2020, 10, 7538. [Google Scholar] [CrossRef]

- Kottek, M.; Grieser, J.; Beck, C.; Rudolf, B.; Rubel, F. World map of the Köppen-Geiger climate classification updated. Meteorol. Zeitschrift 2006, 15, 259–263. [Google Scholar] [CrossRef]

- ISE. Task 27 Solar Building Facade Components Subtask B: Durability Performance, Durability and Sustainability of Advanced Windows and Solar Components for Building Envelopes Final Report Subtask B: Durability PROJECT B3: Durability and Reliability Assessment; ISE: Freiburg, Germany, 2007. [Google Scholar]

- Karim, M. Etude de L’endommagement par Erosion et Par Encrassement des Surfaces de Miroirs Réflecteurs Utilisés dans les Centrales Solaires Thermodynamiques. Ph.D. Thesis, Université Cadi Ayyad, Marrakesh, Morocco, 2016. [Google Scholar]

- Wiesinger, F.; Sutter, F.; Fernández-García, A.; Wette, J.; Hanrieder, N. Sandstorm erosion on solar reflectors: A field study on height and orientation dependence. Energy 2021, 217, 119351. [Google Scholar] [CrossRef]

- Matal, A.; Naamane, S. Accelerated erosion of coated solar glass reflectors. AIP Conf. Proc. 2020, 2303, 150012. [Google Scholar] [CrossRef]

- Wiesinger, F.; Sutter, F.; Fernandez-García, A.; Wette, J.; Wolfertstetter, F.; Hanrieder, N.; Martin, S.; Pitz-Paald, R. Sandstorm erosion on solar reflectors: Highly realistic modeling of artificial aging tests based on advanced site assessment. Appl. Energy 2020, 268, 114925. [Google Scholar] [CrossRef]

- Finnie, I. Erosion of surfaces by solid particles. Wear 1960, 3, 87–103. [Google Scholar] [CrossRef]

- Pescheux, A.-C.; Le Baron, E.; Raccurt, O. Characterization of different Moroccan sands to explain their potential negative impacts on CSP solar mirrors. Sol. Energy 2019, 194, 959–968. [Google Scholar] [CrossRef]

- Avenel, C. Durabilité des Miroirs Pour L’énergie Solaire à Concentration: Étude des Modes de Vieillissement. Ph.D. Thesis, Clermont Auvergne University, Clermont-Ferrand, France, 2018. [Google Scholar]

- Boukheir, S.; Abdelouahed, C.; Amal, M.; Sara, L.; Naamane, S.; Mustapha, M.; Moulay, H.B. Physical and chemical reactivity of mechanically primed glass surfaces of CSP reflectors. AIP Conf. Proc. 2020, 2303, 150005. [Google Scholar] [CrossRef]

- Fuseini, M.; Zaghloul, M.M.Y.; Elkady, M.F.; El-Shazly, A.H. Evaluation of synthesized polyaniline nanofibres as corrosion protection film coating on copper substrate by electrophoretic deposition. J. Mater. Sci. 2022, 57, 6085–6101. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.; Steel, K.; Veidt, M.; Heitzmann, M.T. Wear behaviour of polymeric materials reinforced with man-made fibres: A comprehensive review about fibre volume fraction influence on wear performance. J. Reinf. Plast. Compos. 2022, 41, 215–241. [Google Scholar] [CrossRef]

- ISO 16474-2 Paints and Varnishes—Methods of Exposure to Laboratory Light Sources—Part 2: Xenon-Arc Lamps International Organization for Standardization. 2013. Available online: https://www.iso.org/standard/56830.html (accessed on 12 January 2022).

- Portal, S. Corrosion de Verres de Silicate Analyse Texturale de La Couche D’alteration. 2001. Available online: https://tel.archives-ouvertes.fr/tel-00449855 (accessed on 12 January 2022).

- Vienna, J.D.; Neeway, J.J.; Ryan, J.V.; Kerisit, S.N. Impacts of glass composition, pH, and temperature on glass forward dissolution rate. npj Mater. Degrad. 2018, 2, 22. [Google Scholar] [CrossRef]

- Martínez-Arcos, L.; Fernández-García, A.; Sutter, F.; Reche-Navarro, T.; Wette, J.; Carvalho, M.J.; Diamantino, T.; Sallaberry, F.; Erice, R.; Imbuluzqueta, G.; et al. Round Robin Test for Solar Reflectors Durability. 2018. STAGE-STE Project. Project Deliverable R 8.1.3-2. Available online: https://aip.scitation.org/doi/abs/10.1063/1.5067231 (accessed on 12 January 2022).

- Sutter, F.; Fernandez-García, A.; Wette, J.; Heller, P. Comparison and evaluation of accelerated aging tests for reflectors. Energy Procedia 2014, 49, 1718–1727. [Google Scholar] [CrossRef]

| Erosion Parameters | |

| Ejection Speed | 25 m/s |

| Impact Angle | 90° |

| Ejected Particles | Standardized sand MIL-STD810G |

| Ejected Particles Size | 180 < Φ < 250 |

| Particles Composition | 90% of quartz |

| Particles Hardness (Mohs Scale) | 7 |

| Particles Shape | Sharp |

| Test | Conditions | Duration |

|---|---|---|

| Test N°1: HAST | P: 2 bars T: 110 °C RH: 85% | 336 h |

| Test N°2: SUNTEST | 1 Cycle = 30 min Water spray = 3 min Irradiation xenon lamp (65 W/m2 between 300–400 nm) = 27 min T Air = 70 °C T sample = 85 °C | 600 h |

| Time (h) | Surface Roughness (nm) | Impacts Number | Impacts Diameter (µm) | Circularity | |

|---|---|---|---|---|---|

| Uncoated intact (N°1 HAST) | 0 | 1.21 | 0.00 | 0.00 | - |

| 48 | 1.597 | 308.00 | 10.02 ± 0.01 | 0.83 ± 0.2 | |

| 168 | 1.74 | 297.00 | 10.95 ± 0.01 | 0.78 ± 0.2 | |

| 336 | 1.541 | 173.00 | 11.59 ± 0.01 | 0.84 ± 0.2 | |

| Uncoated eroded (N°1 HAST) | 0 | 21.33 | 1453 | 9.32 ± 0.01 | 0.91 ± 0.1 |

| 48 | 22.053 | 1602 | 12.57 ± 0.02 | 0.83 ± 0.2 | |

| 168 | 23.326 | 1642 | 11.56 ± 0.03 | 0.89 ± 0.2 | |

| 336 | 24.479 | 2810 | 13.37 ± 0.04 | 0.87 ± 0.2 | |

| Uncoated intact (N°2 SUNTEST) | 0 | 1.2 | 0.00 | 0.00 | - |

| 170 | 2.684 | 5108 | 5.02 ± 0.1 | 0.97 ± 0.09 | |

| 340 | 2.045 | 4767 | 12.06 ± 0.04 | 0.89 ± 0.2 | |

| 600 | 1.39 | 52 | 42.40 ± 0.7 | 0.92 ± 0.2 | |

| Uncoated eroded (N°2 SUNTEST) | 0 | 21.11 | 1409 | 8.72 ± 0.01 | 0.93 ± 0.1 |

| 170 | 22.1 | 1528.00 | 12.08 ± 0.03 | 0.84 ± 0.2 | |

| 340 | 23.52 | 1699.00 | 12.16 ± 0.02 | 0.77 ± 0.2 | |

| 600 | 27.53 | 2169.00 | 14.7 ± 0.04 | 0.84 ± 0.2 |

| Time (h) | Surface Roughness (nm) | Impacts Number | Impacts Diameter (µm) | Circularity | |

|---|---|---|---|---|---|

| Coated intact (N°1 HAST) | 0 | 1.22 | 0.00 | 0.00 | - |

| 48 | 1.16 | 122.00 | 7.15 ± 0.01 | 1 ± 0.01 | |

| 168 | 1.21 | 92.00 | 8.25 ± 0.01 | 0.99 ± 0.06 | |

| 336 | 1.21 | 63.00 | 13 ± 0.01 | 0.79 ± 0.2 | |

| Coated eroded (N°1 HAST) | 0 | 21.04 | 1526 | 10.63 ± 0.02 | 0.88 ± 0.2 |

| 48 | 21.28 | 1614 | 15.01 ± 0.03 | 0.83 ± 0.3 | |

| 168 | 22.70 | 1678 | 11.58 ± 0.03 | 0.88 ± 0.2 | |

| 336 | 24.35 | 2027 | 9.36 ± 0.03 | 0.91 ± 0.2 | |

| Coated intact (N°2 SUNTEST) | 0 | 1.21 | 0.00 | 0.00 | - |

| 170 | 1.19 | 31.00 | 8.96 ± 0.01 | 0.86 ± 0.1 | |

| 340 | 1.29 | 1244 | 7.11 ± 0.01 | 0.92 ± 0.1 | |

| 600 | 1.15 | 932 | 8.33 ± 0.01 | 0.95 ± 0.1 | |

| Coated eroded (N°2 SUNTEST) | 0 | 21.10 | 1498 | 10.61 ± 0.02 | 0.88 ± 0.2 |

| 170 | 23.37 | 1510.00 | 13.03 ± 0.03 | 0.85 ± 0.2 | |

| 340 | 22.48 | 1630.00 | 18.52 ± 0.06 | 0.79 ± 0.2 | |

| 600 | 23.16 | 1636.00 | 20.13 ± 0.06 | 0.76 ± 0.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lakhouil, S.; Boukheir, S.; Bouaouine, H.; Baron, E.L.; Disdier, A.; Vuillerme, V.; Naamane, S. Erosion Effect in the Degradation of Coated and Uncoated Glass Solar Mirrors Highlighted by Coupled Accelerated Erosion/Aging Tests. Coatings 2022, 12, 1087. https://doi.org/10.3390/coatings12081087

Lakhouil S, Boukheir S, Bouaouine H, Baron EL, Disdier A, Vuillerme V, Naamane S. Erosion Effect in the Degradation of Coated and Uncoated Glass Solar Mirrors Highlighted by Coupled Accelerated Erosion/Aging Tests. Coatings. 2022; 12(8):1087. https://doi.org/10.3390/coatings12081087

Chicago/Turabian StyleLakhouil, Sara, Sofia Boukheir, Hassane Bouaouine, Estelle Le Baron, Angela Disdier, Valery Vuillerme, and Sanae Naamane. 2022. "Erosion Effect in the Degradation of Coated and Uncoated Glass Solar Mirrors Highlighted by Coupled Accelerated Erosion/Aging Tests" Coatings 12, no. 8: 1087. https://doi.org/10.3390/coatings12081087

APA StyleLakhouil, S., Boukheir, S., Bouaouine, H., Baron, E. L., Disdier, A., Vuillerme, V., & Naamane, S. (2022). Erosion Effect in the Degradation of Coated and Uncoated Glass Solar Mirrors Highlighted by Coupled Accelerated Erosion/Aging Tests. Coatings, 12(8), 1087. https://doi.org/10.3390/coatings12081087