Improvement of Monitoring Technology for Corrosive Pollution of Marine Environment under Cloud Computing Platform

Abstract

:1. Introduction

2. Corrosive Pollution of the Marine Environment

2.1. Influencing Factors of Steel Corrosion in Marine Environment

- (1)

- Dissolved oxygen: Oxygen is a depolarizer for the seawater corrosion of steel. If there is no dissolved oxygen in the seawater, steel will not corrode. Therefore, dissolved oxygen in seawater is one of the important factors affecting the corrosion of steel in the sea. It continuously reacts in the cathode area of the microbattery corroded by steel and produces strong cathode depolarization. The metal in the anode area of the microbattery continuously dissolves to form ferrous hydroxide, which causes the metal to be corroded. On the other hand, for those metals that rely on surface passivation film to improve corrosion resistance, such as stainless steel, the formation, and repair of the metal surface oxide film can inhibit the corrosion reaction to a certain extent.

- (2)

- Salinity: A large number of neutral salts such as NaCI, KCI, and Na2SO4 are dissolved in seawater, of which NaCl accounts for 78%. The concentration of NaCl in seawater is generally about 3%. The corrosion rate is at its maximum near this concentration. When the salt concentration is low, the corrosion rate increases rapidly as the salt content increases. This is mainly due to the increase in cl-promoting the anode reaction. In addition, since the solubility of oxygen decreases with the increase of salt concentration, the corrosion rate decreases significantly when the salinity in the solution continues to increase.

- (3)

- Temperature: The oxidation reaction of iron and steel occurs in seawater. Generally speaking, the reaction speed increases when the temperature rises. However, this mutual relationship is very complicated, and the corrosion rate does not increase proportionally with the increase in temperature. It is also related to other factors such as oxygen diffusion. The corrosion rate is dominated by oxygen diffusion. At a temperature of 1.2 L, the solubility of oxygen in the solution is reduced, which slows down the reaction process of the cathode. In a closed system, when the temperature rises, the oxygen in the solution does not decrease, and the corrosion rate increases linearly with the rise of the temperature; but in an open system, the oxygen content in the water gradually decreases as the temperature rises. When the water temperature is between 80 and 90 °C, the corrosion rate is significantly reduced. When the temperature reaches the boiling point of 100 °C, the corrosion rate drops to the lowest value.

- (4)

- pH value: Generally speaking, the increase of the pH value of seawater is beneficial to inhibiting the corrosion of steel by seawater. However, the pH value of seawater has a small change, which will not have a significant impact on the corrosion of steel and seawater (far from it with a large oxygen content). Although the pH value of surface seawater is higher than that of deep seawater, surface seawater has higher oxygen content than deep seawater, so surface seawater is more corrosive to steel than deep seawater. The pH value of seawater mainly affects the deposition of calcareous scale, which affects the corrosiveness of seawater. Under the condition of the pH value of seawater, the carbonate in the seawater is generally saturated, so even if the pH value does not change much, it will affect the deposition of the calcium carbonate scale. As the pH value increases, calcium deposits are easily formed, and seawater is less corrosive. When applying cathodic protection, this deposited layer is beneficial to cathodic protection.

- (5)

- Flow rate: The flow of liquid on the metal surface can promote the circulation of corrosion products in the solution, accelerate the diffusion of oxygen, and also remove the corrosion products attached to the metal surface, thereby promoting metal corrosion. However, this refers to steel that is difficult to form a passivation film on the surface. The steel that easily forms a passive film on the surface is different, such as stainless steel. Due to the flow of seawater, a passive film is easily formed on the surface, and the corrosion rate will decrease instead. In a nearly neutral aqueous solution, since the corrosion reaction of the metal is controlled by the reduction of oxygen, the higher the flow rate, the more severe the corrosion. No matter what the situation, a thin water film will always adhere to the metal surface. When the flow rate becomes larger, at this time, the thickness of the film will be reduced, making it easier to diffuse oxygen through the film to the metal surface.

- (6)

- Marine life: The impact of marine life on steel corrosion is complex. Sometimes the attachment of some organisms can reduce the corrosion rate of steel, but soon it will accelerate the corrosion, produce pitting corrosion, or damage the coating. First of all, the surface of steel: the part covered by the organism becomes the anode because the supply of oxygen is controlled, and the part not covered by the organism becomes the cathode, which will cause local corrosion, or the inside and outside of the adhesion layer may produce oxygen concentration cell corrosion; secondly, due to biological life activities, the composition of the seawater on the surface of the steel is changed, which changes the nature of the water and accelerates the corrosion of the steel. In addition, certain sea creatures can penetrate the protective layer when they grow, and directly destroy the protection. The adhesion of certain marine organisms to the protective layer is even greater than the adhesion of the protective layer to the metal. Therefore, under the action of mechanical loads such as seawater impact, the marine organisms peel off with the protective layer, causing the protective layer to be damaged, and the corrosion of steel is changed.

2.2. Corrosion Mechanism of Steel in Various Corrosion Zones in the Marine Environment

- (1)

- Corrosion of steel in the marine atmosphere: the marine atmosphere refers to the atmosphere above the splash zone and the coastal atmosphere. For steel structures in the ocean, it refers to the parts that are not in contact with seawater all year round. The ocean atmosphere has high humidity, and water vapor easily adheres to the surface of the steel to form a water film invisible to the naked eye. The standard electrode potential of the main element of steel and the trace element carbon is different. They form when they are in the electrolyte solution (water film) at the same time. In galvanic cells, iron is oxidized as an anode and loses electrons, turning into rust. This is basically the same as the corrosion in the inland atmosphere. However, due to the high relative humidity of the ocean atmosphere, the thick water film, the high salt content, and the strong electrolytic capacity of the water film, the corrosion of steel is accelerated. At the same time, the steel in the ocean atmosphere is exposed to sunlight during the day and the water evaporation increases the surface salinity. With the formation of a wet surface, this dry-wet cycle makes the corrosion rate greatly accelerated;

- (2)

- Corrosion of steel in the splash zone: the splash zone refers to the marine environment. Seawater can splash on the surface of the structure, which is the part of the section that cannot be submerged by the seawater when the seawater is at high tide. For many metal materials, the splash zone is the most corroded part of all marine environments. Foreign scholars believe that the reason the splash zone has become the most severely corroded part of all marine environments, is due to sea water splashingasit is difficult to form a protective rust layer on the surface of steel with a short drying time; and compared with the marine atmosphere, its sunlight exposure is the same. This is due to the movement and evaporation of seawater so that the accumulation of sea salt particles within a certain range of the average high tide level is far greater than the accumulation in the ocean atmosphere. In general, the large number of salt particles, the long water film retention time, and the high frequency of dry and wet alternates are external factors that cause severe corrosion of steel in the splash zone. The internal factor is that the steel in the splash zone is corroded due to surface rust during the corrosion process.

- (3)

- The corrosion of steel in the tidal range refers to the area between the average high tide level and the average low tide level of seawater. There are two main types of steel corrosion in the tidal range. One is the corrosion of steel components that are isolated in the tidal range, for example, the corrosion of the sewage gate in the tidal range; the other is the steel pile type. The corrosion + experiment proved that the corrosion rate of the respective tufted pieces in the tidal range is much greater than that of the long-length coupons. Through the corrosion current measurement experiment, the main reason for the above phenomenon is that the macroscopic battery is formed between the underwater part and the tidal range of the long-length coupon. The tidal range is the cathode area where oxygen is fully supplied to form the macro battery, and the underwater part becomes the anode area of the macro battery. The anode area provides protection current to the cathode area to reduce corrosion in the tidal range. It should be pointed out that although the specimens in the tidal range are protected to a certain extent, they still corrode. Although all the specimens in the tidal range get the protection current of the specimens in the seawater full immersion zone, the upper part of the specimens has a short immersion time in the seawater, and the time to obtain the current is short, plus the time in the air. Longer immersion timemeans the free corrosion time is also longer; while the corrosion of the lower part of the specimen is just the opposite. Therefore, the corrosion rate of the upper part of the specimen in the tidal range is greater than that of the lower part of the specimen.

- (4)

- Corrosion of steel in the seawater full immersion zone: the seawater full immersion zone refers to the area below the low tide level all year-round to the seabed. According to different sea depths, it is divided into shallow water area (within 20 m–30 m below the low tide level), continental shelf full immersion area (in the water depth area of 30 m to 200 m), and the deep sea area (>200 m water depth area): the three areas affect the corrosion of steel structures. The elements of this water are different due to the water depth. In the shallow sea area, the seawater velocity is relatively high, and there is offshore chemical and sediment pollution. Steel corrosion is mainly electrochemical, and the physical and chemical corrosion is supplemented. The corrosion in this water area is lighter than that in the shallow sea area; the pressure increases with the depth of the water, the dissolved mineral salt decreases, the water flow, and the temperature aeration are low, and the steel corrosion is mainly electrochemical corrosion and stress corrosion, and chemical corrosion is the second. Therefore, generally speaking, due to the high content of oxygen in seawater and the almost neutral pH, the corrosion mechanism of metals in seawater is mainly controlled by the cathodic reaction produced by the reduction of oxygen.

- (5)

- Corrosion of iron and steel in the submarine soil zone. The sea cement soil zone refers to the part below the seawater flooding zone, which is mainly composed of seabed sediments. The physical, chemical, and biological properties of seabed sediments vary with the sea area and sea depth. Compared with terrestrial soil, the submarine mud area has high salt content and low resistivity. The submarine mud is a good electrolyte and corrodes steel more strongly than in terrestrial soil. In addition, the bottom soil area usually contains bacteria, mainly anaerobic sulfate-reducing bacteria, which can grow and multiply under anoxic environmental conditions. The static pressure of seawater will increase the activity of bacteria.

2.3. Intelligent Image Monitoring Technology for Corrosive Pollution in the Marine Environment

3. Improvement of Monitoring Technology for Corrosive Pollution in the Marine Environment Based on Cloud Computing Platform

3.1. Functional Modules of the Marine Environment Corrosive Pollution Monitoring System

- (1)

- System management. Including system management and task management, it can realize the addition and deletion of the overall system functions.

- (2)

- Data recruitment and processing. Including data collection, recruitment, classification, and processing, it is the core of the entire system.

- (3)

- Data encoding and encryption. Since the marine environmental monitoring systems of various countries may contain secret level information, the collected data needs to be encrypted and the data must be encoded at the same time.

- (4)

- Data synchronization function. Keep the data of the monitoring system synchronized with the data of the marine ship information center and storage server.

3.2. Design of a Monitoring System for Corrosive Pollution in the Marine Environment Based on a Cloud Computing Platform

3.2.1. System Total Module

3.2.2. Jump to Each Activity Task on the Mobile Terminal

- (1)

- Action: Used to identify the specific jump type, such as the jump initiate Action_Call, data synchronization Action_Sync.

- (2)

- Category: Activity behavior type of this UI, formulate specific Intent type.

- (3)

- Data: The data to be transmitted.

- (4)

- Component: Various components are included in the action behavior. The Intent process parses the jump behavior, all data is packaged in the Manifest.xml file, and all actions are registered during initialization. The Intent then parses out the type of Action and makes a response jump, while data transmission is performed.

3.2.3. Data Synchronization

- (1)

- Message: The specific message object has a unique ID and is managed by Message Queue.

- (2)

- Message Queue: Message queue, which receives the message sent by the Handler and saves it; at the same time, the Looper polls, and if it is not processed, the Handler is notified to process it, otherwise it is deleted.

- (3)

- Handler: The process of sending and receiving messages.

- (4)

- Looper: The polling process of messages. In the marine environment, each activity data needs to be synchronized with the central server. This article uses a WIFI network for data transmission. First, turn on the WIFI, and the client process sends a 0 × 0000 confirmation command to the server to confirm whether the server program is ready; if it is ready, the client process subpackages the collected data process and performs MD5 verification. The subpackage package needs to include the synchronization number.

4. Experimental Analysis

4.1. The Purpose of the Experiment

4.2. Experimental Parameters

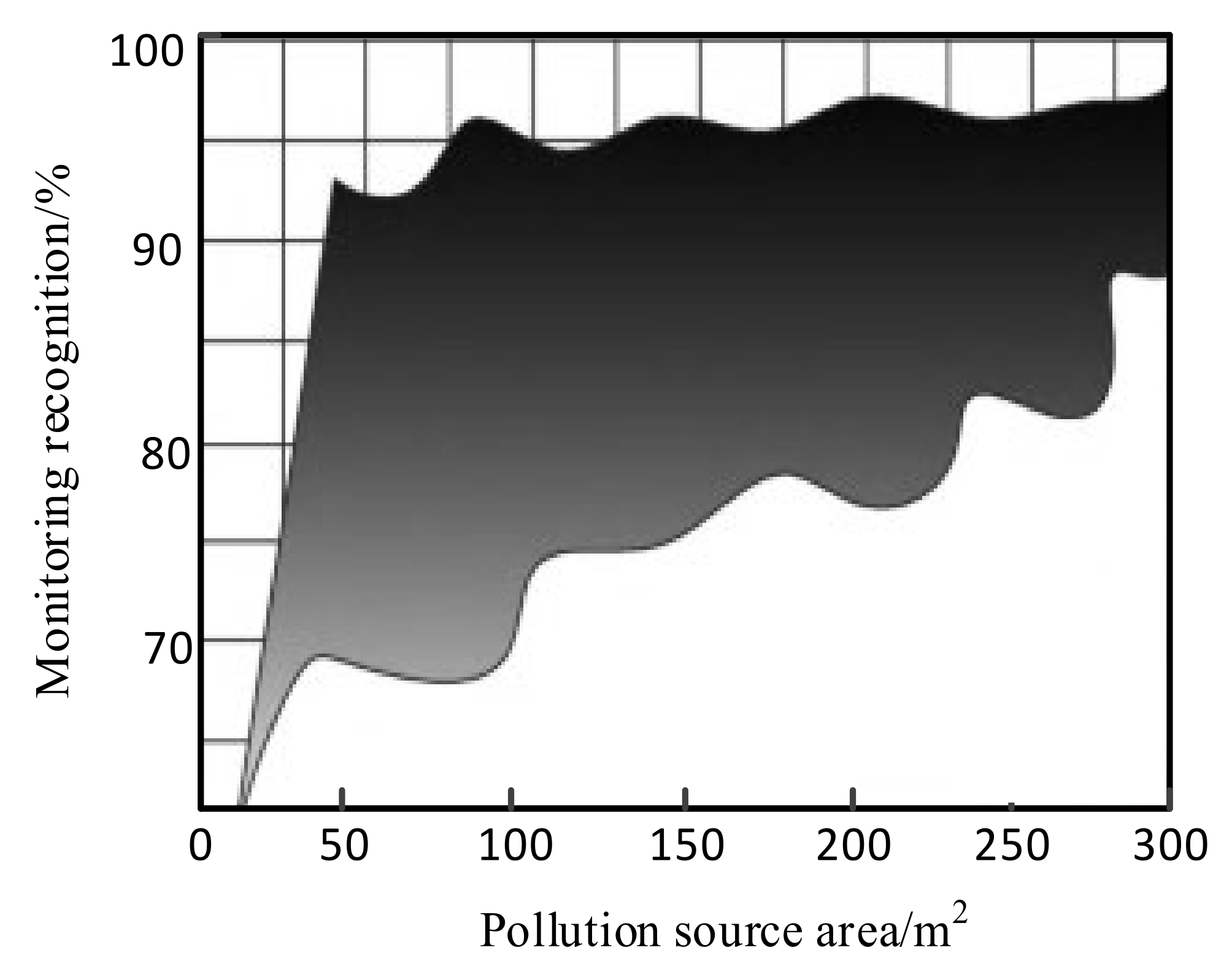

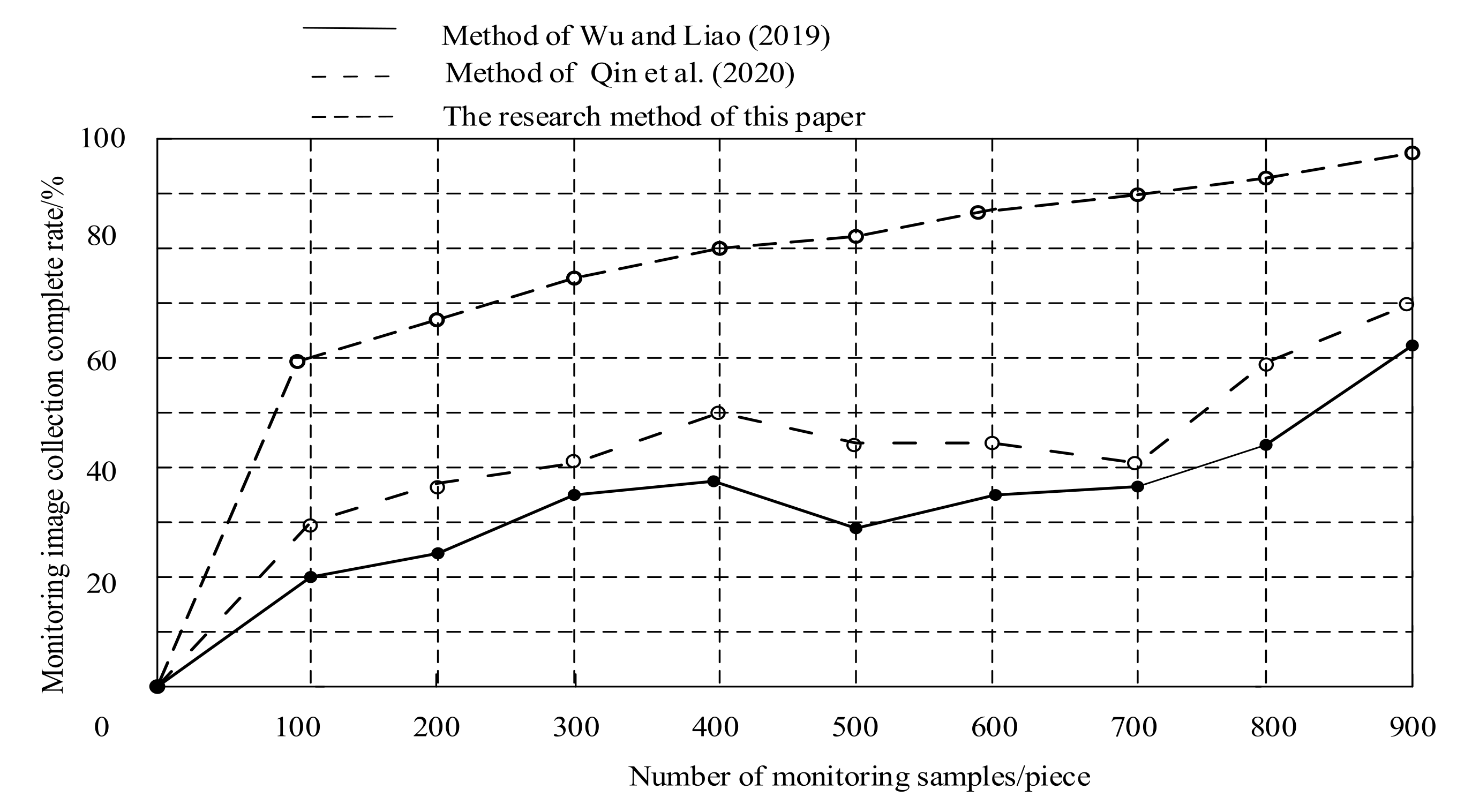

4.3. Experimental Results and Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, H.T.; Shao, Z.D. Marines ediment quality evaluation based on IGWO and BP neural network. Comput. Simul. 2020, 37, 350–353. [Google Scholar]

- Barua, P.; Rahman, S.H. Aquatic health index of coastal aquaculture activities at South-Eastern coast of Bangladesh. Water Conserv. Manag. 2020, 4, 51–57. [Google Scholar] [CrossRef]

- Peng, D.; Yang, Q.; Yang, H.J.; Liu, H.; Zhu, Y.; Mu, Y. Analysis on the relationship between fisheries economic growth and marine environmental pollution in China’s coastal regions. Sci. Total Environ. 2020, 713, 136641. [Google Scholar] [CrossRef] [PubMed]

- Celis-Hernández, O.; Enrique, V.; Ward, R.D.; Amparo, R.S.M.; Alberto, A.T.J. Microplastic distribution in urban vs pristine mangroves: Using marine sponges as bioindicators of environmental pollution. Environ. Pollut. 2021, 284, 117391. [Google Scholar] [CrossRef]

- Wang, L.; Yang, T.; Wang, B.Q.; Lin, Q.L.; Zhu, S.R.; Li, C.Y.; Ma, Y.C.; Tang, J.; Xing, J.J.; Li, X.S.; et al. RALF1-FERONIA complex affects splicing dynamics to modulate stress responses and growth in plants. Sci. Adv. 2020, 6, eaaz1622. [Google Scholar] [CrossRef]

- Wu, W.F.; Liao, Q.L. The application of laser induced technology in marine pollution detection. Laser J. 2019, 10, 36–39. [Google Scholar]

- Qin, X.G.; Lin, X.R.; Gong, W.Q.; Yang, T. Status of hazardous chemical classification system and its application in marine environmental emergency monitoring. Adm. Tech. Environ. Monit. 2020, 32, 5–9. [Google Scholar]

- Xu, D.; Liu, J.; Ma, T.; Zhao, X.; Ma, H.; Li, J. Coupling of sponge fillers and two-zone clarifiers for granular sludge in an integrated oxidation ditch. Environ. Technol. Innov. 2022, 26, 102264. [Google Scholar] [CrossRef]

- Yu, C.; Chen, X.; Li, N.; Zhang, Y.; Li, S.; Chen, J.; Yao, L.; Lin, K.; Lai, Y.; Deng, X. Ag3PO4-based photocatalysts and their application in organic-polluted wastewater treatment. Environ. Sci. Pollut. Res. 2022, 29, 18423–18439. [Google Scholar] [CrossRef]

- Ma, Z.; Zheng, W.; Chen, X.; Yin, L. Joint embedding VQA model based on dynamic word vector. PeerJ Comput. Sci. 2021, 7, e353. [Google Scholar] [CrossRef]

- Yin, L.; Wang, L.; Keim, B.D.; Konsoer, K.; Zheng, W. Wavelet Analysis of Dam Injection and Discharge in Three Gorges Dam and Reservoir with Precipitation and River Discharge. Water 2022, 14, 567. [Google Scholar] [CrossRef]

- Shi, D.; Chen, Y.; Li, Z.; Dong, S.; Li, L.; Hou, M.; Liu, H.; Zhao, S.; Chen, X.; Wong, C.; et al. Anisotropic Charge Transport Enabling High-Throughput and High-Aspect-Ratio Wet Etching of Silicon Carbide. Small Methods 2022, 2022, 2200329. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, X.J.; Jia, J.H.; Cheng, X.Q.; Xiao, K.; Li, X. Effect of Sb and Sn on the corrosion behavior of low alloy steel in simulated polluted marine atmosphere. Surf. Technol. 2021, 50, 224–237. [Google Scholar]

- Guo, H.C.; Wei, H.H.; Yang, D.X.; Liu, Y.H.; Wang, Z.S.; Tian, J.B. Experimental research on fatigue performance of Q690 high strength steel in marine corrosive environment. J. Civ. Eng. 2021, 54, 36–45. [Google Scholar]

- Zhang, X.; Hu, H.Y.; Gong, L.; Wang, Z.Y.; Peng, D.; Zhu, C.J.; Wei, W.Z.; Wu, K.M. Study on the corrosion behavior of rare earth/niobium microalloyed steels in marine atmospheric environments. Mater. Prot. 2021, 54, 7–15+33. [Google Scholar]

- Li, Z.Y.; Wang, G.; Luo, S.W.; Deng, P.C.; Hu, J.Z.; Deng, J.h.; Xu, J.M. Early corrosion behavior of eh36 ship plate steel in tropical marine atmosphere. J. Chin. Soc. Corros. Prot. 2020, 40, 463–468. [Google Scholar]

- Xu, S.H.; Song, C.M.; Li, H. Difference in surface characteristics of corroded steel under simulated marine and general atmosphere environment. Mater. Rev. 2021, 35, 125–132. [Google Scholar]

- Fang, X.; Wang, Q.; Wang, J.; Xiang, Y.; Wu, Y.; Zhang, Y. Employing extreme value theory to establish nutrient criteria in bay waters: A case study of Xiangshan Bay. J. Hydrol. 2021, 603, 127146. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, H.; Zhou, B.; Fu, H. Multi-dimensional prediction method based on Bi-LSTMC for ship roll. Ocean. Eng. 2021, 242, 110106. [Google Scholar] [CrossRef]

- Dai, L.; Wang, Z.; Guo, T.; Hu, L.; Chen, Y.; Chen, C.; Yu, G.; Ma, Q.; Chen, J. Pollution characteristics and source analysis of microplastics in the Qiantang River in southeastern China. Chemosphere 2022, 293, 133576. [Google Scholar] [CrossRef]

- Sanahuja, A.B.; Casado-Coy, N.; Simó-Cabrera, L.; Sanz-Lázaro, C. Monitoring polymer degradation under different conditions in the marine environment. Environ. Pollut. 2020, 259, 113836. [Google Scholar] [CrossRef]

- Ha, M.G.; Jeon, S.H.; Jeong, Y.S.; Mha, H.S.; Ahn, J.H. Corrosion environment monitoring of local structural members of a steel truss bridge under a marine environment. Int. J. Steel Struct. 2021, 21, 167–177. [Google Scholar] [CrossRef]

- Mousavi, A.A.; Zhang, C.; Masri, S.F.; Gholipour, G. Damage detection and characterization of a scaled model steel truss bridge using combined complete ensemble empirical mode decomposition with adaptive noise and multiple signal classification approach. Struct. Health Monit. 2021, 2021, 84049285. [Google Scholar] [CrossRef]

- Bai, B.; Rao, D.; Chang, T.; Guo, Z. A nonlinear attachment-detachment model with adsorption hysteresis for suspension-colloidal transport in porous media. J. Hydrol. 2019, 578, 124080. [Google Scholar] [CrossRef]

- Zheng, W.; Liu, X.; Yin, L. Research on image classification method based on improved multi-scale relational network. PeerJ Comput. Sci. 2021, 7, e613. [Google Scholar] [CrossRef]

- Montrucchio, B.; Giusto, E.; Vakili, M.G.; Quer, S.; Fornaro, C. A densely-deployed, high sampling rate, open-source air pollution monitoring WSN. IEEE Trans. Veh. Technol. 2020, 69, 15786–15799. [Google Scholar] [CrossRef]

- Jo, J.; Jo, B.W.; Khan, R.; Kim, J.H. A cloud computing-based damage prevention system for marine structures during berthing. Ocean. Eng. 2019, 180, 23–28. [Google Scholar] [CrossRef]

- Saxena, D.; Singh, A.K. Security embedded dynamic resource allocation model for cloud data centre. Electron. Lett. 2020, 56, 1062–1065. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, Y.; Dong, J.; Qi, X.; Wang, F. Improvement of Monitoring Technology for Corrosive Pollution of Marine Environment under Cloud Computing Platform. Coatings 2022, 12, 938. https://doi.org/10.3390/coatings12070938

Jiang Y, Dong J, Qi X, Wang F. Improvement of Monitoring Technology for Corrosive Pollution of Marine Environment under Cloud Computing Platform. Coatings. 2022; 12(7):938. https://doi.org/10.3390/coatings12070938

Chicago/Turabian StyleJiang, Yongzeng, Jing Dong, Xiaoyu Qi, and Fazhi Wang. 2022. "Improvement of Monitoring Technology for Corrosive Pollution of Marine Environment under Cloud Computing Platform" Coatings 12, no. 7: 938. https://doi.org/10.3390/coatings12070938

APA StyleJiang, Y., Dong, J., Qi, X., & Wang, F. (2022). Improvement of Monitoring Technology for Corrosive Pollution of Marine Environment under Cloud Computing Platform. Coatings, 12(7), 938. https://doi.org/10.3390/coatings12070938