Abstract

Tantalum-based films with tailored composition, density, and electrical resistivity are of interest for next generation hohlraums for magnetized indirect-drive inertial confinement fusion. Here, we use reactive direct-current magnetron sputtering to deposit tantalum suboxide films with O content in the range of 46–71 at.%. In contrast to a common approach involving varying reactive gas contents, compositional control is achieved kinetically by changing the total chamber pressure and the deposition rate, while keeping the working gas mix of Ar-5%O constant. The resultant films are X-ray amorphous with electrical resistivity varying by over seven orders of magnitude. The dominant conduction mechanism changes from metallic to activated tunneling above ∼55 at.% of O, which is characterized by a sharp increase in resistivity and a decrease in the carrier density at low temperatures.

1. Introduction

Tantalum oxide (TaO) films are used for a wide range of (opto)electronic applications due to useful properties, including a high refractive index, optical transmission, and dielectric constant [1,2,3]. Tantalum-based alloys are also attractive hohlraum materials for magnetized indirect-drive inertial confinement fusion (ICF) [4,5,6,7]. A hohlraum is a heavy-metal-based sphero-cylindrical can, typically ∼5 mm in diameter and ∼10 mm long, which hosts a hydrogen fuel capsule [8]. During the ICF implosion, laser light heats the inner wall of the hohlraum, producing an X-ray bath that compresses the fuel capsule by rocket-like ablation.

In magnetized ICF, a seed magnetic field of ∼50 Tesla is applied shortly before the implosion. During the implosion the magnetic flux density in the capsule is significantly amplified, reaching values in excess of 10 kT, positively influencing the implosion [4,5,9]. Such pulsed magnetic fields are generated by a solenoid wound around the hohlraum, which in turn necessitates that the hohlraum have a high electrical resistivity () of cm at cryogenic temperatures [4,5]. The typical hohlraum materials, pure Au and U, have rather low in these conditions, which impedes the soak in of the magnetic field flux at the microsecond time scales of magnetic field transients [4,5].

Tantalum oxides are, therefore, attractive candidates as alternative hohlraum materials due to their tunable electrical resistivity and good oxidation and corrosion resistance. Prior work on the Ta-O system has mostly focused on stoichiometric TaO films [10,11,12] or else films with oxygen content in the range of 0–60 at.% [13,14]. Films with composition corresponding to the transition from metallic conduction to insulating behavior remain comparatively unexplored.

In recent years, TaO has also received attention for optical applications due to the emergence of broad photoluminescence peaks that can be tuned through the controlled introduction of dopants [10] and as a surface protective coating with applications across materials for harsh environments and biocompatibility [15]. In light of this wide range of applications, a detailed study of reactive magnetron sputtering across a range of oxide compositions is timely, to complement existing research involving post-deposition annealing [12,16,17,18,19]. In particular, reactive sputter deposition enables much greater control of oxygen content by matching Ta and O availability during deposition and can be used to fabricate films with uniform properties through film thickness and over the substrate area.

Here, we study the TaO suboxide binary system and demonstrate a family of films with tunable composition, density, and that can be considered for ICF hohlraum fabrication. We employ a combinatorial fabrication technique where oxygen content is determined by position relative to the sputter target and the oxygen source, enabling simultaneous deposition of films with a wide range of compositions. Our results shed new light on the transition from metallic conduction to activated tunneling above ∼55 at.% of O and highlight the key role of oxygen availability in determining film growth rates in reactive sputtering and the challenges of controlling porosity in high-oxygen-content films.

2. Materials and Methods

Films were deposited by reactive direct-current magnetron sputtering (R-DCMS) in a cylindrical high-vacuum (cryo-pumped) chamber, 36 cm in height and 44 cm in diameter with a base pressure of ∼5 Torr. The substrate and chamber walls were maintained at a base temperature of ∼ 30 °C. Deposition was conducted using a 76 mm diameter planar magnetron gun (MAK series from MeiVac inc.) with a geometrical unbalance coefficient of ∼1.2 [20].

The disk-shaped Ta (99.9% purity, Plasmaterials Inc.) target had an initial total thickness of 9.5 mm, including a 3.2-mm-thick Cu backing plate. Constant power mode (100 W) was used for each of the two 15 minute runs in the sputter down configuration. An Ar/O working gas (95% Ar and 5% O, molar percent) at total pressures of 12 and 36 mTorr was used. Chamber pressure was maintained by throttling the chamber pumping speed at a constant flow rate for the working gas of 25 standard cubic centimeters per minute. The target voltage slightly decreased from 232 to 196 V with increasing pressure in this range.

Two deposition runs were conducted, using combinatorial deposition on an array of ∼10 mm (100) Si substrates with an ∼200-nm-thick thermal oxide layer. The distance between the surface of the target and the center of the array of substrates was 64 mm. The substrates were placed on glass plates that functioned as an electrically floating holder at different lateral locations, up to 140 mm from the point under the center of the target. Such a variation in the effective target-to-substrate distance allowed control of the deposition rate and, as will be shown below, O content in films.

A series of films spanning a wide stoichiometric range were thus fabricated in only two depositions runs. Oxygen content is not only affected by the target–substrate distance but also by the location of the reactive gas inlet (samples closer to the inlet receive more oxygen) and internal geometry of the chamber (samples close to chamber walls or fixturing receive a lower flux of Ta due to shadowing). The maximum temperature of the substrate holder during deposition was ∼75 °C, due to heating from the plasma.

Film thickness, measured by profilometry (KLA-Tencor, model D-100), was in the range of 100–800 nm. Film composition was determined by Rutherford backscattering spectrometry (RBS). A 2 MeV He ion beam was incident on the surface at angles between 0 and 10° to minimize the effects of ion channeling, scattering into a detector located 165° from the incident beam direction. RUMP [21] was used to simulate the spectra and determine composition, with typical precision of ≤2 at.% O. Mass density was calculated by combining the physical thickness measured by profilometry and the areal density determined by RBS.

X-ray diffraction (XRD) was performed with a Bruker-AXS Discover D8 diffractometer with Cu K radiation. Room temperature resistivity was measured with a co-linear four-point probe setup (Keithley 2002). Low temperature measurements were conducted with a Quantum Design Physical Property Measurement System (PPMS). Samples were thin strips in the conventional four-wire geometry. Electrical contact was made with Ag epoxy and 25-m Au wires.

Hall measurements to extract carrier density and mobility used a van der Pauw geometry with Ag epoxy contacts on the corners of square samples. Magnetic fields from to 100 kOe were applied out of the plane of the film. A 17 Hz pseudo-AC measurement technique was used to remove offset voltages, and field sweep data was symmetrized to correct for ordinary magnetoresistance. The surface morphology was characterized by scanning electron microscopy (SEM) in a JEOL 7401-F microscope operating at 5 kV.

3. Results

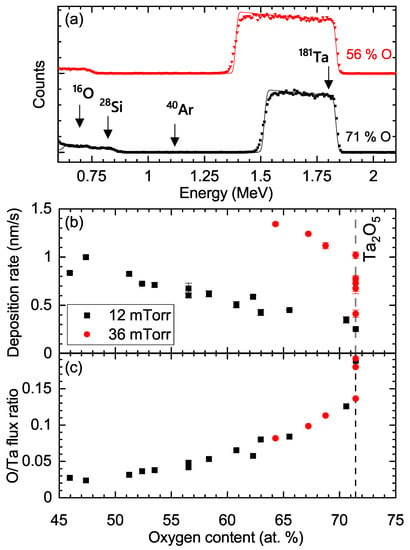

Figure 1a shows representative RBS spectra from TaO films with x of 0.56 and 0.71. A strong signal in the ∼1.5–1.8 MeV energy range originates from scattering from Ta atoms. The height of the Ta peak scales with Ta content, and the integral under the Ta peak is proportional to the areal density of Ta atoms. The signal at lower energies comes primarily from scattering from the Si substrate atoms and from O.

Figure 1.

(a) Rutherford backscattering spectra from two representative TaO films (with x of 0.56 and 0.71) on Si substrates with a 200 nm thick thermal oxide layer on top. Symbols are data points, solid lines are results of simulations using RUMP. For clarity, spectra are vertically offset, and only every fifth experimental point is depicted. The buried Si edge and surface edges of O, Ar and Ta are denoted by arrows. (b) The deposition rate versus O content in films for the two pressures of the Ar-5%O working gas mixture studied, thus, demonstrating how effective stoichiometry control can be achieved by changing the deposition rate. Error bars arise from scatter in thickness measurement across the film. (c) The ratio of O and Ta atomic flux incident upon the substrate, demonstrating that film stoichiometry is limited by O availability up to the formation of stoichiometric TaO, marked by a vertical dashed line. Due to the higher oxygen availability at 36 mTorr working gas pressure, most samples produced were stoichiometric TaO with 71.4 at.% oxygen content, and several such overlapping points are omitted for clarity.

In addition to O, working gas atoms are the main impurity expected for the present case of magnetron sputtering of a high-atomic-mass target (Ta) with a lower atomic mass gas (Ar) [22], with a previous study [23] of sputtered TaO reporting large Ar incorporation levels of up to ∼20 at.%. In contrast, our RBS measurements revealed negligible Ar incorporation (≲1 at.%) in all the films, indicating a low contribution of reflected Ar neutral atoms for the present experimental conditions, indicating that the mechanism of Ar incorporation into TaO films remains incompletely understood.

Figure 1b summarizes compositional measurements performed by RBS, confirming that O content in films monotonically scales with the deposition rate. The maximum O content of 71.4 at.% corresponds to stoichiometric TaO, while films deposited at higher rates have lower O content. A higher working gas pressure in the chamber leads to an increase in the growth rate, causing the data points for 36 mTorr to appear vertically shifted in Figure 1b. Further, most of the films deposited at this higher gas pressure are stoichiometric TaO.

These observations of the dependence of O content on the deposition rate (influenced by both the chamber pressure and the position of the substrate within the chamber) and chamber pressure indicate that film stoichiometry is determined by the availability of oxygen-containing molecules at the growing film surface, which can also be noted in the data of Waterhouse et al. [13] The impingement rate of Ta atoms onto the substrate can be determined by RBS areal density measurements, while the flux of oxygen–containing molecules onto the substrate is determined by their partial pressure and can be estimated with the Knudsen–Langmuir equation [24]:

where is incident flux of gas molecules, is the sticking coefficient (assumed to be 0.01 [25,26]), p is the partial pressure of oxygen-containing molecules, m is the molecular mass, and has the usual meaning. Figure 1c replots data from Figure 1b, with the deposition rate and chamber base pressure represented by the ratio of O and Ta atomic flux incident upon the substrate. It is seen that both data sets for 12 and 36 mTorr from Figure 1b collapse into one curve in Figure 1c, demonstrating that film stoichiometry is limited by O availability at the growing film surface, up to the formation of stoichiometric TaO. Further increasing O availability does not increase oxygen content in the films, as TaO, with 71.4 at.% O, is the Ta-O species with the lowest Ta content that is stable.

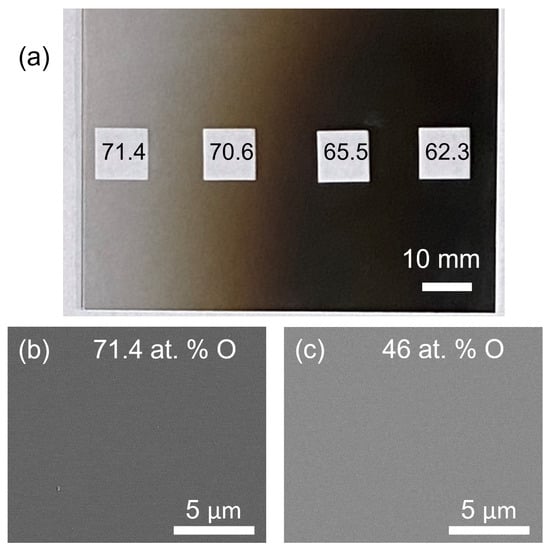

The variation of oxygen content as a function of position in the chamber (and, thus, proximity to the Ta source and chamber walls) is readily visualized by examining film color and transparency, as shown in Figure 2a. Stoichiometric TaO is transparent due to its wide bandgap, while films quickly become opaque and metallic as the oxygen content decreases. This transition is caused by a combination of the decreasing target–substrate distance (which increases the Ta flux on the substrate) and proximity to the chamber wall (which reduces the diffusive component of Ta deposition flux). Note that, because the sputter gun is mounted off-center in the chamber, samples equidistant from the target but on opposite sides can have different oxygen content due to their relative proximity to the chamber wall.

Figure 2.

(a) Photograph of a glass plate on which Si substrates were placed during deposition at 12 mTorr. Uncoated squares are the locations of substrates, and the black numbers inside indicate oxygen content as determined by RBS. A transition from opaque to transparent occurs from the right to left of the photograph as the distance from the Ta sputter gun (which is centered ∼60 mm to the right of the edge of the plate) increases and oxygen content of films increases. Plan-view SEM micrographs of films with 71.4 and 46 at.% of O are shown in (b,c), respectively, demonstrating smooth surfaces across the full range of O content.

The analysis of selected samples by SEM (Figure 2b,c) revealed the formation of smooth films with negligible variation in surface morphology across the range of O content studied here. Being free from defects, such as pinholes or significant surface roughness, the films are suitable for further characterization, such as X-ray diffraction and electrical transport.

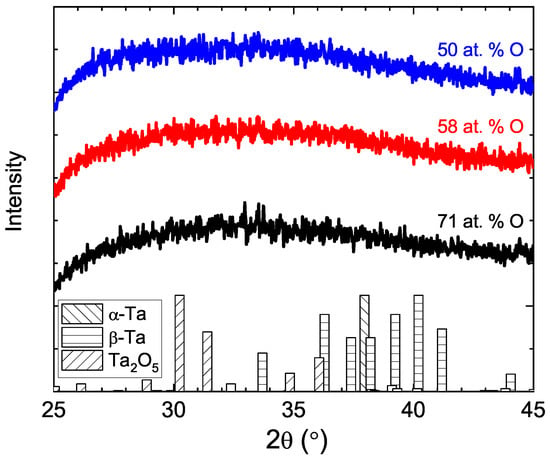

Figure 3 shows X-ray diffraction (XRD) patterns from selected films, revealing no evidence of crystallinity and indicative of a highly disordered or amorphous structure [5,27]. This observation of the lack of crystallinity is consistent across all O levels, including stoichiometric TaO, indicating that the presence of O suppresses crystallization in these films. For the limiting case of stoichiometric TaO, these findings are in agreement with previous reports that either high substrate temperatures (≳450 °C) or post-deposition annealing above ∼600–900 °C is required for crystallization of sputter-deposited TaO films [12,16,17,18]. The present work shows that crystallinity is not observed even for sub-stoichiometric TaO films with O content down to at least 46 at.%, likely as a result of the low substrate temperature during deposition.

Figure 3.

X-ray diffraction patterns for representative films with different O contents as indicated. Vertical bars denote expected peak positions and intensities for -Ta, -Ta, and TaO powder diffraction. The broad, featureless patterns indicate that the films are X-ray amorphous. The patterns are vertically offset for clarity.

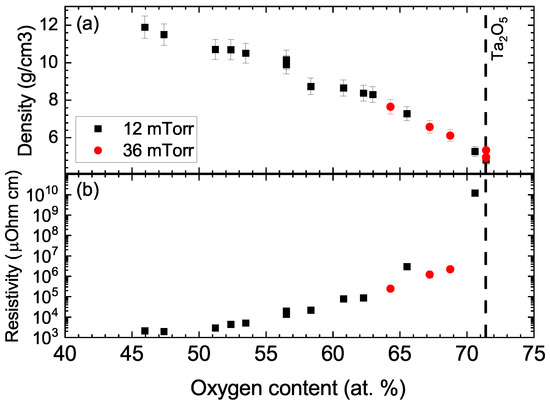

Figure 4a displays a monotonic decrease in mass density with increasing O content in films. This trend is expected since tantalum oxide has lower mass density (though larger atomic density) than Ta metal. Scatter in the data in Figure 4a primarily arises from uncertainty in film thickness measurements due to thickness gradients inherent to the combinatorial approach used in this study. The fact that the density of films with the largest O concentration drops below the theoretical maximum density of TaO (8.2 g cm) indicates the presence of porosity. A similar phenomenon was previously observed by Ngaruiya et al. [23] for sputter-deposited TaO where the density decreased below the bulk value with increasing O flow rates.

Figure 4.

Oxygen content dependence of (a) mass density and (b) room-temperature electrical resistivity for TaO films, showing how increasing presence of the less-dense TaO phase leads to a decrease in mass density and an increase in electrical resistivity over seven orders of magnitude. The vertical dashed line corresponds to stoichiometric TaO (with 71.4 at.% of O), marked by a dramatic increase in resistivity. The resistivity of stoichiometric TaO films was too high to be measured with the methods employed in this study. Error bars arise from uncertainty in areal density as determined by RBS and scatter in resistance measurements (however, in this case, the error bars are smaller than the symbols).

The dependence of room-temperature on O content is plotted in Figure 4b, demonstrating a monotonic increase in with increasing O content. Data points for films made by deposition at two different Ar working gas pressures fall on the same curve, indicating that is determined primarily by O content and is largely insensitive to the deposition pressure and hence landing atom energetics.

The dependence from Figure 4b displays three distinct regions. The first region for O content of at.% is characterized by a weak dependence of on O content. This corresponds to the so-called “plateau” region wherein is approximately linear with O content, which has previously been observed for TaO films made by the “triode” sputtering technique [13,14]. The dependence becomes strong, close-to-exponential in the second region of O content within ∼50–70 at.%, consistent with previous reports [13,28,29]. The third region is for O content of ≳70 at.%, when the film composition approaches that of stoichiometric TaO and experiences a rapid increase, where most films with O content above ∼70 at.% had values that were too high to be measured with our (direct-current) setup.

This is consistent with the formation of stoichiometric TaO, which is an excellent dielectric at room temperature. These films with O content of ∼70 at.% were also close to transparent in the visible spectrum (Figure 2a). The results of Figure 4b suggest that films undergo a transition from metallic conduction at a low O content (≲50 at.% of O) to an activated tunneling through intergranular oxides at higher O content values (50–70 at.% of O), with fully insulating behavior present for stoichiometric TaO. The presence of pores further increased due to the increased tortuosity of the current path as these films also exhibited a density lower than the theoretical maximum density of TaO (Figure 4a).

The change in the conduction mechanism is more readily examined through temperature-dependent measurements of , which are presented in Figure 5a for a range of film compositions. The data can be divided into two groups according to O content. Films with at.% of O display metallic conducting behavior, albeit with a slightly negative temperature coefficient of resistivity (TCR) for low O content films. Such a negative TCR is common for sputter deposited Ta films due to the high degree of disorder or the presence of the -phase [30,31]. In these films with O content of at.%, the main conduction channel is through the metallic Ta-rich phase.

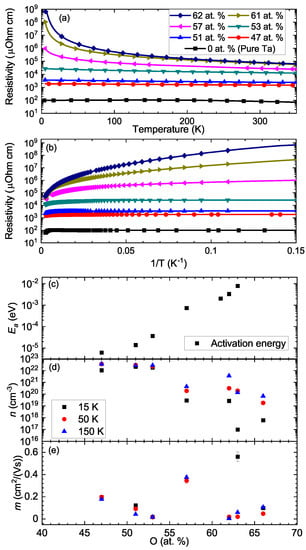

Figure 5.

(a) Temperature dependence of the electrical resistivity of TaO films with different O content, including a reference film of pure Ta. Above ∼55 at.% of O, the films start exhibiting semiconductor–like behavior (i.e., a decrease in resistivity with increasing temperature), consistent with conduction dominated by activated tunneling and defect states in the oxide phase. An Arrhenius plot used to extract activation energy () is presented in (b), while resulting energies are shown as a function of O content in (c). For clarity, only every 100th data point is marked with a symbol in (a,b), and the legend in (a) applies to (b) also. The carrier density (n) and mobility () extracted from Hall effect measurements are plotted in (d,e), respectively, with temperature of the measurement indicated in the legend in (d), which applies to both panels (d,e). The carrier density is largely independent of temperature for low O content films but exhibits pronounced variations with temperature as O content increases. Error bars arise from uncertainty in fits to the high–field Hall data. In most cases, error bars are comparable to the size of the symbols due to multiple scans being averaged to improve data quality.

Films with O content above ∼55 at.% display the characteristics of activated tunneling with strongly negative TCR values. This behavior could be understood by considering that, with increasing TaO content in films, the conducting regions become more isolated. In this case, electronic transport can be described by activation or tunneling type models, such as that developed by Neugebauer [32,33]. Figure 5b shows an Arrhenius plot of as a function of temperature, while Figure 5c plots O content dependence of the the activation energy () obtained by fitting these curves [32,33].

The transition away from metallic conduction at ∼55 at.% is not as sharply marked in Figure 5b; however, the exponential relationship between O content and is clear. An increase in the oxide phase fraction may also result in a tortuous path for conduction, which changes the effective path length for carriers. These observations suggest that, after a certain point of ∼55 at.% of O in these films, electrical current no longer flows in the metallic conduction pathways, even at low temperatures, and activated tunneling through the oxide becomes the dominant conduction mechanism.

Further evidence for this change in the conduction mechanism comes from examining the carrier density from Hall effect measurements shown in Figure 5d. Films with O content of at.% exhibit a relatively high carrier density of ∼5 cm (comparable with the atomic density) that is largely independent of temperature and composition. In this region, the Hall effect measurements are probing the metallic component. As O content increases, the number of free carriers rapidly drops, particularly at low temperatures where thermal energy is not sufficient to promote many carriers, and the effect of defect states within the band gap of the insulating oxide phase becomes more prominent.

A recent report for amorphous TaO found a carrier density of ∼7 cm at room temperature [34], which is consistent with the trend observed here. The carrier mobility, by contrast, is relatively low and does not display a systematic trend with the O content or temperature (Figure 5e), consistent with a highly disordered (amorphous) state of these films.

4. Conclusions

This work demonstrated the deposition of TaO films by reactive direct-current magnetron sputtering onto planar substrates held at ∼30–75 °C using a combinatorial approach that allows for a rapid assessment of a wide range of compositions. This was achieved by controlled O content in the films kinetically in a regime where the oxide formation is limited by the oxygen availability at the growing film surface rather than by the common route of modifying O partial pressure in the chamber.

With this method, films with a range of O content of ∼46–71 at.% were demonstrated. These films were X-ray amorphous, suggesting that the presence of oxygen suppressed film crystallization. Their electrical resistivity spanned over seven orders of magnitude. They exhibited a transition from metallic conduction to activated tunneling through the oxide phase at ∼55 at.% of O. The results of this work can be used to select a combination of O content, density, and electrical resistivity desired for the specific design of inertial confinement fusion hohlraums.

Author Contributions

Conceptualization, S.O.K. and J.D.M.; Data curation, A.A.B. and L.B.B.-A.; Formal analysis, A.A.B., A.M.E., L.B.B.-A., S.J.S. and S.O.K.; Funding acquisition, J.D.M. and S.O.K.; Investigation, A.A.B., A.M.E., L.B.B.-A. and S.J.S.; Methodology, A.M.E. and J.H.B.; Resources, S.O.K.; Supervision, J.D.M. and S.O.K.; Writing—original draft, A.A.B. and A.M.E.; Writing—review and editing, A.A.B. and S.O.K. All authors have read and agreed to the published version of the manuscript.

Funding

This work was performed under the auspices of the U.S. DOE by LLNL under Contract DE-AC52-07NA27344 and by General Atomics under Contract 89233119CNA000063 and was supported by the LLNL-LDRD program under Projects No. 19-FS-062 and 20-SI-002.

Data Availability Statement

Data are available from the authors upon reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chaneliere, C.; Autran, J.L.; Devine, R.A.B.; Balland, B. Tantalum pentoxide (Ta2O5) thin films for advanced dielectric applications. Mater. Sci. Eng. R 1998, 22, 269. [Google Scholar] [CrossRef]

- Wilk, G.D.; Wallace, R.M.; Anthony, J.M. High-kappa gate dielectrics: Current status and materials properties considerations. J. Appl. Phys. 2001, 89, 5243. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, J.; Gong, J. Tantalum-based semiconductors for solar water splitting. Chem. Soc. Rev. 2014, 43, 4395–4422. [Google Scholar] [CrossRef]

- Moody, J.D.; Johnson, A.; Javedani, J.; Carroll, E.; Fry, J.; Kozioziemski, B.; Kucheyev, S.O.; Logan, B.G.; Pollock, B.B.; Sio, H.; et al. Transient magnetic field diffusion considerations relevant to magnetically assisted indirect drive inertial confinement fusion. Phys. Plasmas 2020, 27, 112711. [Google Scholar] [CrossRef]

- Aji, L.B.B.; Engwall, A.M.; Bae, J.H.; Baker, A.A.; Beckham, J.L.; Shin, S.J.; Chavez, X.L.; McCall, S.K.; Moody, J.D.; Kucheyev, S.O. Sputtered Au–Ta films with tunable electrical resistivity. J. Phys. D Appl. Phys. 2021, 54, 075303. [Google Scholar]

- Engwall, A.M.; Aji, L.B.B.; Baker, A.A.; Shin, S.J.; Bae, J.H.; McCall, S.K.; Moody, J.D.; Kucheyev, S.O. Effect of substrate tilt on sputter-deposited AuTa films. Appl. Surf. Sci. 2021, 547, 149010. [Google Scholar] [CrossRef]

- Bae, J.H.; Aji, L.B.B.; Shin, S.J.; Engwall, A.M.; Nielsen, M.H.; Baker, A.A.; McCall, S.K.; Moody, J.D.; Kucheyev, S.O. Gold–tantalum alloy films deposited by high-density-plasma magnetron sputtering. J. Appl. Phys. 2021, 130, 165301. [Google Scholar] [CrossRef]

- Rosen, M.D. Fundamentals of ICF Hohlraums. In Lectures in the Scottish Universities Summer School in Physics, 2005, on High Energy Laser Matter Interactions; Jaroszynski, D.A., Bingham, R., Cairns, R.A., Eds.; CRC Press: Boca Raton, FL, USA, 2009; pp. 253–325. [Google Scholar]

- Perkins, L.J.; Ho, D.D.-M.; Logan, B.G.; Zimmerman, G.B.; Rhodes, M.A.; Strozzi, D.J.; Blackfield, D.T.; Hawkins, S.A. The potential of imposed magnetic fields for enhancing ignition probability and fusion energy yield in indirect-drive inertial confinement fusion. Phys. Plasmas 2017, 24, 062708. [Google Scholar] [CrossRef]

- Miura, K.; Osawa, T.; Yokota, Y.; Suzuki, T.; Hanaizumi, O. Fabrication of Tm-doped Ta2O5 thin films using a co-sputtering method. Results Phys. 2014, 4, 148. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.; Bai, R.; Huang, M. Optical properties of amorphous Ta2O5 thin films deposited by RF magnetron sputtering. Opt. Mater. 2019, 97, 109404. [Google Scholar] [CrossRef]

- Beckage, P.J.; Knorr, D.B.; Wu, X.M.; Lu, T.-M.; Rymaszewski, E.J. Discrete β-Ta2O5 crystallite formation in reactively sputtered amorphous thin films. J. Mat. Sci. 1998, 33, 4375. [Google Scholar] [CrossRef]

- Waterhouse, N.; Wilcox, P.S.; Willmott, D.J. Effect of oxygen on the electrical and structural properties of triode-sputtered tantalum films. J. Appl. Phys. 1971, 42, 5649. [Google Scholar] [CrossRef]

- Waterhouse, N.; Westwood, W.D. Effect of oxygen on the temperature dependence of electrical properties of reactively sputtered tantalum films. Can. J. Phys. 1971, 49, 2250. [Google Scholar] [CrossRef]

- Xu, G.; Shen, X.; Hu, Y.; Ma, P.; Cai, K. Fabrication of tantalum oxide layers onto titanium substrates for improved corrosion resistance and cytocompatibility. Surf. Coat. Tech. 2015, 272, 58. [Google Scholar] [CrossRef]

- Guoping, C.; Lingzhen, L.; Suixin, Z.; Haokang, Z. Structures and properties of a Ta2O5 thin film deposited by dc magnetron reactive sputtering in a pure O2 atmosphere. Vacuum 1990, 41, 1204. [Google Scholar] [CrossRef]

- Felten, F.; Senateur, J.P.; Labeau, M.; Yu-Zhang, K.; Abrutis, A. Deposition of Ta2O5/SiO2 multilayer films by a new process “injection mocvd”. Thin Solid Films 1997, 296, 79. [Google Scholar] [CrossRef]

- Grüger, H.; Kunath, C.; Kurth, E.; Sorge, S.; Pufe, W.; Pechstein, T. High quality rf sputtered metal oxides (Ta2O5, HfO2) and their properties after annealing. Thin Solid Films 2004, 447, 509. [Google Scholar] [CrossRef]

- Paolone, A.; Placidi, E.; Stellino, E.; Betti, M.G.; Majorana, E.; Mariani, C.; Nucara, A.; Palumbo, O.; Postorino, P.; Rago, I.; et al. Effects of the annealing of amorphous Ta2O5 coatings produced by ion beam sputtering concerning the effusion of argon and the chemical composition. J. Non Cryst. Solids 2021, 557, 120651. [Google Scholar] [CrossRef]

- Golosov, D.A. Balanced magnetic field in magnetron sputtering systems. Vacuum 2017, 139, 109. [Google Scholar] [CrossRef]

- Doolittle, L.R. Algorithms for the rapid simulation of rutherford backscattering spectra. Nucl. Instrum. Methods Phys. Res. B 1985, 9, 344. [Google Scholar] [CrossRef]

- Westwood, W.D. Sputter Deposition; AVS Education Committee: Chico, CA, USA, 2003. [Google Scholar]

- Ngaruiya, J.M.; Venkataraj, S.; Drese, R.; Kappertz, O.; Leervad-Pedersen, T.P.; Wuttig, M. Preparation and characterization of tantalum oxide films produced by reactive dc magnetron sputtering. Phys. Status Solidi A 2003, 198, 99. [Google Scholar] [CrossRef]

- Kolasinski, K.W. Surface Science: Foundations of Catalysis and Nanoscience; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Gerstenberg, D.; Calbick, C.J. Effects of nitrogen, methane, and oxygen on structure and electrical properties of thin tantalum films. J. Appl. Phys. 1964, 35, 402. [Google Scholar] [CrossRef]

- Knepper, R.; Stevens, B.; Baker, S.P. Effect of oxygen on the thermomechanical behavior of tantalum thin films during the β–α phase transformation. J. Appl. Phys. 2006, 100, 123508. [Google Scholar] [CrossRef]

- Howson, M.A.; Greig, D. Temperature dependence of conductivity arising from electron-electron interaction effects in amorphous metals. Phys. Rev. B 1984, 30, 4805. [Google Scholar] [CrossRef]

- Krikorian, E.; Sneed, R.J. Deposition of Tantalum, Tantalum Oxide, and Tantalum Nitride with Controlled Electrical Characteristics. J. Appl. Phys. 1966, 37, 3674. [Google Scholar] [CrossRef]

- Li, Y.; Sanna, S.; Norrman, K.; Christensen, D.V.; Pedersen, C.S.; Lastra, J.M.G.; Traulsen, M.L.; Esposito, V.; Pryds, N. Tuning the stoichiometry and electrical properties of tantalum oxide thin films. Appl. Surf. Sci. 2019, 470, 1071. [Google Scholar] [CrossRef]

- Zhou, Y.M.; Xie, Z.; Xiao, H.N.; Hu, P.F.; He, J. Effects of deposition parameters on tantalum films deposited by direct current magnetron sputtering. J. Vac. Sci. Technol. Vacuum Surfaces Films 2009, 27, 109. [Google Scholar] [CrossRef]

- Schwartz, N.; Reed, W.A.; Polash, P.; Read, M.H. Temperature coefficient of resistance of beta-tantalum films and mixtures with b.c.c.-tantalum. Thin Solid Films 1972, 14, 333. [Google Scholar] [CrossRef]

- Neugebauer, C.A.; Webb, M.B. Electrical conduction mechanism in ultrathin, evaporated metal films. J. Appl. Phys. 1962, 33, 74. [Google Scholar] [CrossRef]

- Neugebauer, C.A. Structural disorder phenomena in thin metal films. Phys. Thin Films 1964, 2, 1. [Google Scholar]

- Eo, M.D.; Mollmann, A.; Haddad, J.; Unlu, F.; Kulkarni, A.; Liu, M.; Tachibana, Y.; Stadler, D.; Bhardwaj, A.; Ludwig, T.; et al. Tantalum Oxide as an Efficient Alternative Electron Transporting Layer for Perovskite Solar Cells. Nanomaterials 2022, 12, 780. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).