Effect of Low Chloride and Sulfate Concentrations on Corrosion Behavior of Aluminum and Zinc Arc Thermal Sprayed Coatings

Abstract

:1. Introduction

2. Materials and Methods

- rcorr—corrosion rate (g·m−2·year−1),

- Icorr—corrosion current density (A·m−2),

- M—molar mass of metal (g·mol−1),

- n—number of electrons exchanged in dissolution reaction,

- F—Faradays constant (96,485 C·mol−1),

- t—seconds per year (31,557,600 s·year−1).

3. Results and Discussion

3.1. Structure Analysis

3.2. Electrochemical Studies of Zn, Al, and Zn-Al Coatings

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- PN-93-C-04607; Woda w Instalacjach Ogrzewania Wymagania i Badania Dotyczące Jakości Wody. PKN: Plock, Poland, 1993.

- Lee, H.-S.; Singh, J.; Ismail, M.; Bhattacharya, C.; Seikh, A.; Alharthi, N.; Hussain, R. Corrosion mechanism and kinetics of Al-Zn coating deposited by arc thermal spraying process in saline solution at prolong exposure periods. Sci. Rep. 2019, 9, 3399. [Google Scholar] [CrossRef] [PubMed]

- Bonabi, S.F.; Ashrafizadeh, F.; Sanati, A.; Nahvi, S.M. Structure and corrosion behavior of arc-sprayed Zn-Al coatings on ductile iron substrate. J. Therm. Spray Technol. 2018, 27, 524–537. [Google Scholar] [CrossRef]

- Gulec, A.; Cevher, O.; Turk, A.; Ustel, F.; Yilma, F. Accelerated corrosion behaviors of Zn, Al and Zn/15Al coatings on a steel surface. Mater. Technol. 2011, 45, 477–482. [Google Scholar]

- Thomas, S.; Birbilis, N.; Venkatraman, M.S.; Cole, I.S. Corrosion of zinc as a function of pH. Corrosion 2012, 68, 015009. [Google Scholar] [CrossRef]

- Huang, I.-W.; Hurley, B.L.; Yang, F.; Buchheit, R.G. Dependence on temperature, pH, and Cl in the uniform corrosion of aluminum alloys 2024-T3, 6061-T6, and 7075-T6. Electrochem. Act. 2016, 1992, 242–253. [Google Scholar] [CrossRef]

- Perez, V.E.P.; Alfantazi, A. Effects of oxygen and sulfate concentrations on the corrosion behavior of zinc in NaCl solutions. Corros. J. Sci. Eng. 2012, 68, 035005. [Google Scholar] [CrossRef]

- Li, S.; Church, B.C. Effects of sulfate and nitrate anions on aluminum corrosion in slightly alkaline solution. Appl. Surf. Sci. 2018, 440, 861–872. [Google Scholar] [CrossRef]

- Pritzel dos Santos, A.; Manhabosco, S.M.; Rodrigues, J.S.; Dick, L.F.P. Comparative study of the corrosion behavior of galvanized, galvannealed and Zn55Al coated interstitial free steels. Surf. Coat. Technol. 2015, 279, 150–160. [Google Scholar] [CrossRef]

- Miao, W.; Cole, I.S.; Neufeld, A.K.; Furman, S. Pitting corrosion of Zn and Zn-Al coated steels in pH 2 to 12 NaCl solutions. J. Electrochem. Soc. 2007, 154, c7–c15. [Google Scholar] [CrossRef]

- Panossian, Z.; Mariaca, L.; Morcillo, M.; Flores, S.; Rocha, J.; Peńa, J.J.; Herrera, F.; Corvo, F.; Sanchez, M.; Rincon, O.T.; et al. Steel cathodic protection afforded by zinc, aluminum and zinc/aluminum alloy coatings in the atmosphere. Surf. Coat. Technol. 2005, 190, 244–248. [Google Scholar] [CrossRef]

- Malek, M.H.A.; Saad, N.H.; Abas, S.K.; Shah, N.M. Thermal arc spray overview. IOP Conf. Ser. Mater. Sci. Eng. 2013, 46, 012028. [Google Scholar] [CrossRef]

- Li, H.Y.; Wei, D.D.; Duan, J.Y. Effect of sealing treatment on corrosion behaviours of arc sprayed zinc coatings. Corros. Eng. Sci. Technol. 2013, 48, 65–70. [Google Scholar] [CrossRef]

- Chavan, N.M.; Kiran, B.; Jyothirmayi, A.; Phani, P.S.; Sundararajan, G. The corrosion behavior of cold sprayed zinc coatings on mild steel substrate. J. Therm. Spray Technol. 2013, 22, 463–470. [Google Scholar] [CrossRef]

- Zhao, Z.; Tang, J.; Tariq, N.; Wang, J.; Cui, X.; Xiong, T. Microstructure and corrosion behavior of cold-sprayed Zn-Al composite coating. Coatings 2020, 10, 931. [Google Scholar] [CrossRef]

- Yong, W.; Timing, Z.; Weimin, Z. Sealing treatment of aluminum coating on S235 steel with thermal diffusion of zinc. J. Therm. Spray Technol. 2015, 24, 1052–1059. [Google Scholar]

- Esfahani, E.A.; Salimijazi, H.; Golozar, M.A.; Javad, M.; Pershin, L. Study of corrosion behavior of arc sprayed aluminum coating on mild steel. J. Therm. Spray Technol. 2012, 21, 1195–1202. [Google Scholar] [CrossRef]

- Bobzin, K.; Oete, M.; Linke, T.F.; Schulz, C. Corrosion of wire arc sprayed ZnMgAl. Mater. Corros. 2015, 66, 520–526. [Google Scholar] [CrossRef]

- Schuerz, S.; Fleischanderl, M.; Luckeneder, G.H.; Preis, K.; Haunschmied, T.; Mori, G.; Kneissl, A.C. Corrosion behaviour of Zn–Al–Mg coated steel sheet in sodium chloride-containing environment. Corros. Sci. 2009, 51, 2355–2363. [Google Scholar] [CrossRef]

- Adamiak, M.; Czupryński, A.; Kopyć, A.; Monica, Z.; Olender, M.; Gwiazda, A. The Properties of arc-sprayed aluminum coatings on armor-grade steel. Metals 2017, 8, 142. [Google Scholar] [CrossRef] [Green Version]

- Senderowski, C.; Chodala, M.; Bojar, Z. Corrosion behavior of detonation gas sprayed Fe-Al type intermetallic coating. Materials 2015, 8, 1108–1123. [Google Scholar] [CrossRef] [Green Version]

- Shi, X.; Wang, Y.; Li, H.; Zhang, S.; Zhao, R.; Li, G.; Zhang, R.; Sheng, Y.; Cao, S.; Zhao, Y.; et al. Corrosion resistance and biocompatibility of calcium-containing coatings developed in near-neutral solutions containing phytic acid and phosphoric acid on AZ31B alloy. J. Alloys Compd. 2020, 823, 153721. [Google Scholar] [CrossRef]

- Xu, J.L.; Tao, S.C.; Bao, L.Z.; Luo, J.M.; Zheng, Y.F. Effects of Mo contents on the microstructure, properties and cytocompatibility of the microwave sintered porous Ti-Mo alloys. Mater. Sci. Eng. C 2019, 97, 156–165. [Google Scholar] [CrossRef] [PubMed]

- Senderowski, C. Nanocomposite Fe-Al intermetallic coating obtained by gas detonation spraying of milled self-decomposing powder. J. Therm. Spray Technol. 2014, 23, 1124–1134. [Google Scholar] [CrossRef] [Green Version]

- Senderowski, C.; Bojar., Z.; Wołczyński, W.; Pawłowski, A. Microstructure characterization of D-gun sprayed Fe–Al intermetallic coatings. Intermetallics 2010, 18, 1405–1409. [Google Scholar] [CrossRef]

- Jiang, Q.; Miao, Q.; Liang, W.P.; Ying, F.; Tong, F.; Xu, Y.; Ren, B.L.; Yao, Z.J.; Zhang, P.Z. Corrosion behavior of arc sprayed Al-Zn-Si-Re coatings on mild steel in 3.5 wt% NaCl solution. Electrochim. Acta 2014, 115, 644–656. [Google Scholar] [CrossRef]

- Zaid, B.; Saidi, D.; Benzaid, A.; Hadji, S. Effects of pH and chloride concentration on pitting corrosion of AA6061 aluminum alloy. Corros. Sci. 2008, 50, 1841–1847. [Google Scholar] [CrossRef]

- Mouanga, M.; Berçot, P.; Rauch, J.Y. Comparison of corrosion behaviour of zinc in NaCl and in NaOH solutions. Part I: Corrosion layer characterization. Corros. Sci. 2010, 52, 3984–3992. [Google Scholar] [CrossRef]

- Ashassi-Sorkhabiz, H.; Asghariz, E. Effect of Solution hydrodynamics on corrosion inhibition performance of zinc sulfate in neutral solution. J. Electrochem. Soc. 2012, 159, C1–C7. [Google Scholar] [CrossRef]

- Jeong, C.; Lee, J.; Sheppard, K.; Choi, C.-H. Air-impregnated nanoporous anodic aluminum oxide layers for enhancing the corrosion resistance of aluminum. Langmuir 2015, 31, 11040–11050. [Google Scholar] [CrossRef]

- Liu, P.; Ling, X.; Zhong, C.; Deng, Y.; Han, X.; Hu, W. Porous zinc anode design for Zn-air chemistry. Front. Chem. 2019, 7, 656. [Google Scholar] [CrossRef]

- Penney, D.J.; Sullivan, J.H.; Worsley, D.A. Investigation into the effects of metallic coating thickness on the corrosion properties of Zn–Al alloy galvanizing coatings. Corros. Sci. 2007, 49, 1321–1339. [Google Scholar] [CrossRef]

| Alloying Element | C | P | S | N | Fe |

| wt.% | 0.18 | 0.013 | 0.027 | 0.009 | rem. |

| Arc Spraying Parameters | Feedstock Wire Materials Used in Thermal Arc-Spraying Experiments | ||

|---|---|---|---|

| Zn | Al | Zn-Al | |

| Atomizing gas pressure, (MPa) | 0.65 | 0.65 | 0.65 |

| Arc current, (A) | 50 | 50 | 100 |

| Arc voltage, (V) | 20 | 36 | 25 |

| Power input, (kW) | 1 | 1.8 | 2.5 |

| Distance of spraying, (mm) | 150–250 | ||

| Rate of wire, (m/min) | 3.5 | ||

| Solution Number | Concentration of Chloride Anions Cl− (mg/L) | Concentration of Sulfate Anions SO42− (mg/L) | pH |

|---|---|---|---|

| 1 | 50 | 100 | 8 |

| 2 | 0 | 100 | 8 |

| 3 | 50 | 0 | 8 |

| 4 | 0 | 0 | 8 |

| 5 | 50 | 100 | 8.5 |

| 6 | 0 | 100 | 8.5 |

| 7 | 0 | 0 | 8.5 |

| 8 | 50 | 0 | 8.5 |

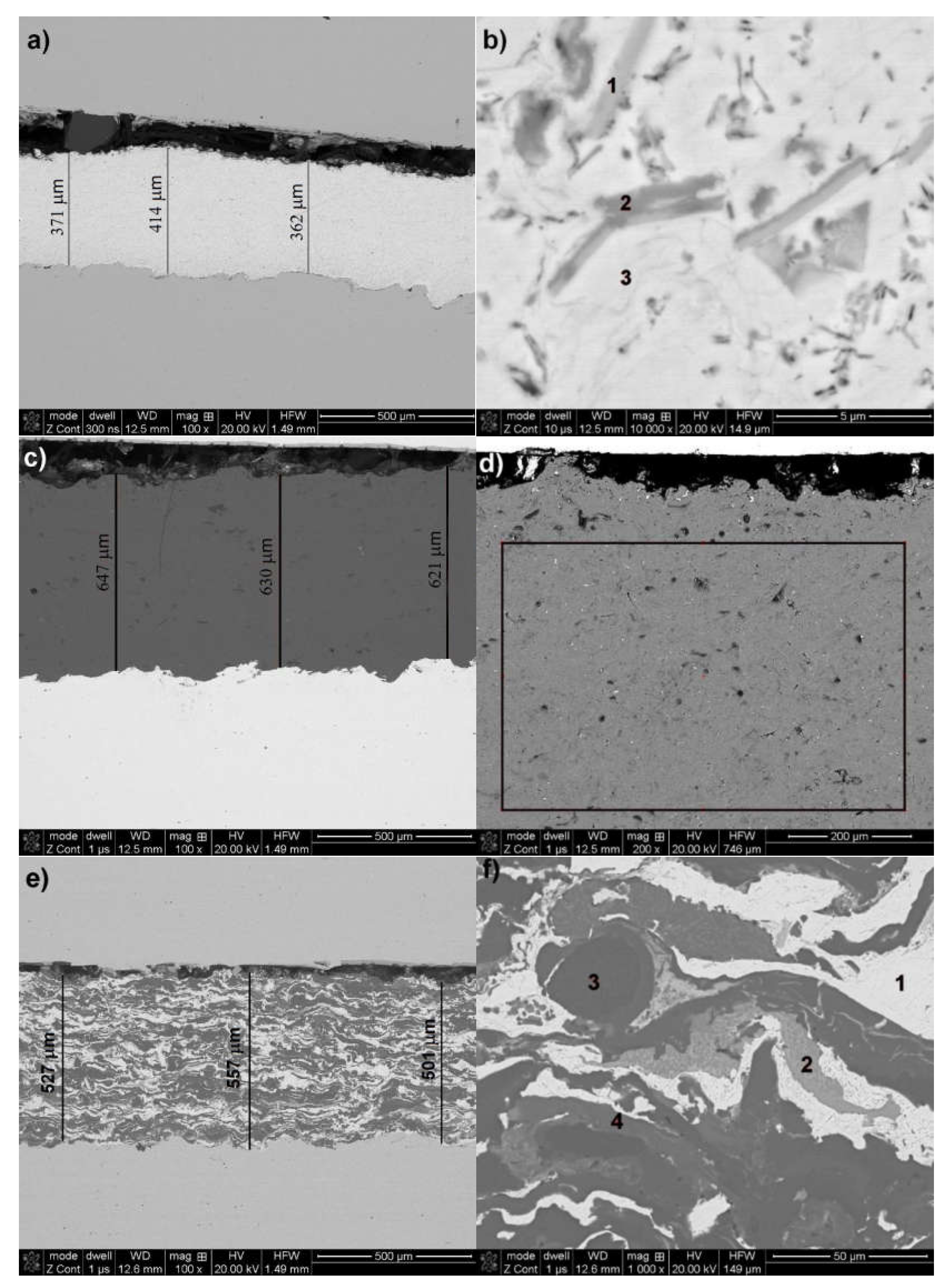

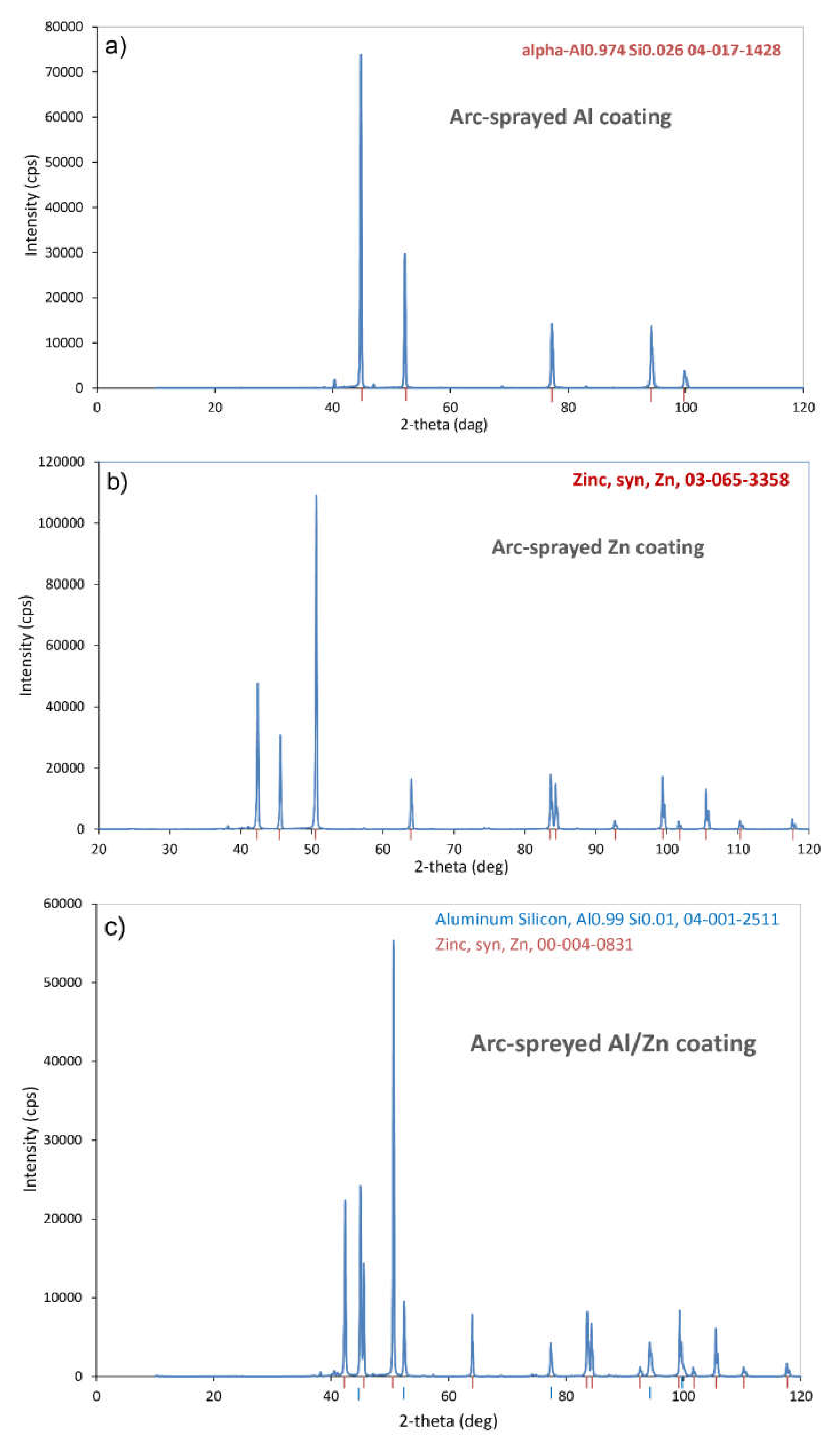

| Arc-Wire Sprayed Coatings | Thickness (µm) | Porosity (%) | Phase Composition (XRD Patterns) |

|---|---|---|---|

| Zn | 398 ± 32 | 0.2 ± 0.05 | zinc, zinc oxides (EDS) |

| Al | 648 ± 49 | 2.5 ± 0.3 | α-Al0.974Si0.026 |

| Zn-Al | 521 ± 63 | 0.25 ± 0.1 | zinc, α-Al0.99Si0.01 |

| Designation of Grain Area according to Figure 1 | Content, at.% | |||

|---|---|---|---|---|

| Zn | Al | Si | O | |

| Zn coating—Figure 1b | ||||

| 1—medium gray | 82.5 | – | – | ~17.5 |

| 2—gray | 68.6 | – | – | ~31.4 |

| 3—bright gray | 97.5 | – | – | ~2.5 |

| mapping | 85.3 | – | – | ~14.7 |

| Al coating—Figure 1d mapping | – | 97.2 | 0.2 | ~2.6 |

| Zn-Al coating | ||||

| 1—light | 96.8 | 0.7 | – | ~2.5 |

| 2—bright gray | 24.7 | 74 | – | ~1.3 |

| 3—dark gray | 2.3 | 96.7 | – | ~1.0 |

| 4—medium gray | 4.8 | 93.7 | – | ~1.5 |

| mapping | 17.1 | 80.7 | – | ~2.2 |

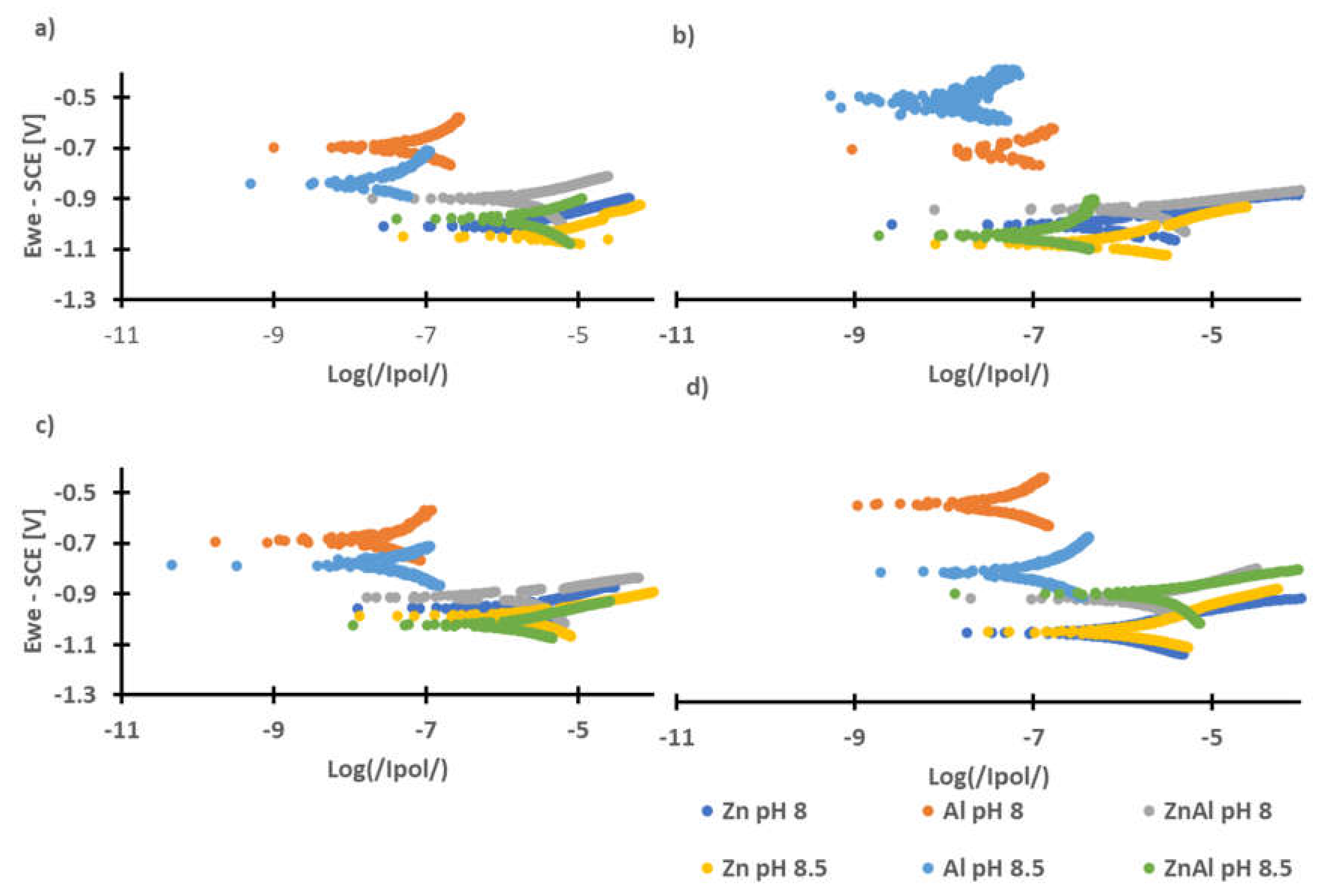

| Zn | ||||

| Solution No. | Estat (V) | Ecorr (V) | Icorr (nA·cm−2) | r (g·m−2·year−1) |

| 1 | −1.04 ± 0.002 | −1.07 ± 0.002 | 348 ± 23 | 37 ± 2.5 |

| 2 | −0.97 ± 0.01 | −0.95 ± 0.02 | 618.5 ± 15 | 65.8 ± 1.6 |

| 3 | −0.99 ± 0.003 | −1.01 ± 0.003 | 425 ± 19 | 45.25 ± 2 |

| 4 | −0.98 ± 0.01 | −1.01 ± 0.02 | 587.5 ± 62 | 73 ± 3 |

| 5 | −1.04 ± 0.002 | −1.07 ± 0.003 | 514 ± 28 | 54.6 ± 3 |

| 6 | −0.98 ± 0.01 | −0.99 ± 0.009 | 941.5 ± 137 | 99.8 ± 14 |

| 7 | −1.05 ± 0.004 | −1.05 ± 0.009 | 1505.5 ± 27 | 155.3 ± 1.7 |

| 8 | −1.03 ± 0.001 | −1.08 ± 0.002 | 339.3 ± 4 | 36.3 ± 0.5 |

| Al | ||||

| Solution No. | Estat (V) | Ecorr (V) | Icorr (nA·cm−2) | r (g·m−2·year−1) |

| 1 | −0.65 ± 0.05 | −0.66 ± 0.05 | 27.5 ± 3 | 0.8 ± 0.08 |

| 2 | −0.66 ± 0.02 | −0.69 ± 0.02 | 13.5 ± 0.2 | 0.4 ± 0.005 |

| 3 | −0.71 ± 0.03 | −0.72 ± 0.03 | 31 ± 6 | 0.9 ± 0.17 |

| 4 | −0.67 ± 0.04 | −0.7 ± 0.04 | 19.85 ± 0.4 | 0.6 ± 0.01 |

| 5 | −0.85 ± 0.08 | −0.88 ± 0.08 | 45.5 ± 11 | 1.3 ± 0.32 |

| 6 | −0.74 ± 0.05 | −0.78 ± 0.04 | 26.15 ± 3 | 0.8 ± 0.09 |

| 7 | −0.74 ± 0.007 | −0.83 ± 0.02 | 14.71 ± 3 | 0.4 ± 0.09 |

| 8 | −0.49 ± 0.02 | −0.51 ± 0.02 | 5.18 ± 0.5 | 0.15 ± 0.01 |

| Zn-Al | ||||

| Solution No. | Estat (V) | Ecorr (V) | Icorr (nA·cm−2) | r (g·m−2·year−1) |

| 1 | −0.96 ± 0.002 | −0.95 ± 0.005 | 1061 ± 3 | 92.9 ± 0.3 |

| 2 | −0.92 ± 0.002 | −0.91 ± 0.005 | 1225 ± 32 | 107.15 ± 2.8 |

| 3 | −0.98 ± 0.001 | −0.94 ± 0.005 | 367 ± 11 | 32.15 ± 1 |

| 4 | −0.91 ± 0.002 | −0.9 ± 0.002 | 604 ± 32 | 52.9 ± 2.9 |

| 5 | −0.95 ± 0.005 | −0.94 ± 0.009 | 770 ± 56 | 67.5 ± 4.9 |

| 6 | −1 ± 0.02 | −1.02 ± 0.03 | 727 ± 176 | 78.45 ± 10 |

| 7 | −0.96 ± 0.05 | −0.98 ± 0.06 | 696.3 ± 212 | 60.7 ± 11.5 |

| 8 | −1 ± 0.05 | −1.05 ± 0.04 | 60.5 ± 5 | 9.7 ± 1.1 |

| Zn | |||||

| Parameter | Estab (V) | Ecorr (V) | Icorr (nA·cm−2) | r (g·m−2·year−1) | Σ |

| Cl− | 0.71 | 9.32 | 1.58 | 1.76 | 13.37 |

| SO42− | 0.19 | 8.62 | 0.34 | 0.42 | 9.57 |

| pH | 0.73 | 7.60 | 1.03 | 1.00 | 10.36 |

| Al | |||||

| Parameter | Estab (V) | Ecorr (V) | Icorr (nA·cm−2) | r (g·m−2·year−1) | Σ |

| Cl− | 0.12 | 0.24 | 0.33 | 0.33 | 1.02 |

| SO42− | 0.32 | 0.25 | 0.39 | 0.39 | 1.35 |

| pH | 0.13 | 0.24 | 0.003 | 0.005 | 0.38 |

| Zn/Al | |||||

| Parameter | Estab (V) | Ecorr (V) | Icorr (nA·cm−2) | r (g·m−2·year−1) | Σ |

| Cl− | 0.16 | 0.12 | 0.44 | 0.55 | 1.26 |

| SO42− | 0.03 | 0.05 | 0.90 | 1.08 | 2.05 |

| pH | 0.23 | 0.42 | 0.44 | 0.39 | 1.48 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Senderowski, C.; Rejmer, W.; Bilko, P. Effect of Low Chloride and Sulfate Concentrations on Corrosion Behavior of Aluminum and Zinc Arc Thermal Sprayed Coatings. Coatings 2022, 12, 653. https://doi.org/10.3390/coatings12050653

Senderowski C, Rejmer W, Bilko P. Effect of Low Chloride and Sulfate Concentrations on Corrosion Behavior of Aluminum and Zinc Arc Thermal Sprayed Coatings. Coatings. 2022; 12(5):653. https://doi.org/10.3390/coatings12050653

Chicago/Turabian StyleSenderowski, Cezary, Wojciech Rejmer, and Piotr Bilko. 2022. "Effect of Low Chloride and Sulfate Concentrations on Corrosion Behavior of Aluminum and Zinc Arc Thermal Sprayed Coatings" Coatings 12, no. 5: 653. https://doi.org/10.3390/coatings12050653

APA StyleSenderowski, C., Rejmer, W., & Bilko, P. (2022). Effect of Low Chloride and Sulfate Concentrations on Corrosion Behavior of Aluminum and Zinc Arc Thermal Sprayed Coatings. Coatings, 12(5), 653. https://doi.org/10.3390/coatings12050653