Abstract

In this study, we explored the effects of a laser cleaning process on the surface properties of an aerospace aluminum alloy. We performed surface cleaning on an AA2024 aluminum alloy. Through SEM and EDS analyses on the surface of the aluminum alloy samples after cleaning, the cleaning effect on the aluminum alloy under different laser energy densities was studied. After laser cleaning, residual stress, hardness, friction, and wear tests were performed on the aluminum alloy samples. The experimental results demonstrated that the oxides on the surface of AA2024 could be effectively removed when the laser energy density was 10.5 J/cm2. With an increase in the laser energy density, the friction and wear properties of the AA2024 surface could be improved. Laser cleaning could also generate a new hardened layer and residual tensile stress on the surface of AA2024. This article provides a reference for applying laser cleaning in the aerospace field by studying the structure and mechanical properties of an aluminum alloy after laser cleaning.

1. Introduction

As the primary structural material of space shuttles, aluminum alloys are widely used in the critical parts of spacecraft skins, propellers, fuel tanks, and landing gear struts [1,2,3]. The 2XXX aluminum alloy has copper as the main alloy element. Due to its high strength, strong heat resistance, and good processing performance, it is mainly used to produce significant space shuttle skin components [4]. 2XXX aluminum materials exposed to the air for an extended period will form an uneven and non-continuous surface oxide film that must be thoroughly removed before the components are welded and repainted [5,6] or it will significantly impact the bonding force of the coating and the welding quality [7,8]. At present, 2XXX aluminum alloys generally use a mixture of chromic acid, sulfuric acid, and hydrofluoric acid to remove the oxide film on the surface [9,10]. This chemical cleaning method requires a substantial workforce and pollutes the environment; the cleaning quality is also difficult to guarantee [11]. Laser cleaning technology has the advantages of a high processing accuracy and a proficient cleaning effect, as well as greater environmental protection from the cleaning process [12]. It has become one of the mainstream research directions of cleaning technology and has been widely used in industrial links such as pre-welding pretreatments and coating removals [13,14,15]. The 2024 aluminum alloy is a kind of high-strength hard aluminum, which is mainly used to make various high-load parts and components. At present, most spacecraft shells and parts are made of this material. In this study, we used a laser cleaning method to conduct 2024 aluminum alloy spraying and pre-welding treatments. The research results provide a basis for applying laser cleaning in the aerospace industry.

Since the 1980s, laser cleaning technology has been applied to repair and maintain artworks and sculptures [16]. After years of technological development, it has been applied to the surface treatment process of various metal materials [17,18]. In this study, an Nd:YAG solid-state laser was used to clean the surface of AA2024 [19]. By SEM and EDS analyses of the surface of the aluminum alloy sample after cleaning, the cleaning effect on the aluminum alloy surface under different laser energy densities was studied. Since aerospace equipment has strict requirements on the mechanical properties of materials, residual stress and hardness tests were performed on the cleaned aluminum alloy samples, and friction and wear experiments were also performed. The research on the microstructure and mechanical properties of the aluminum alloy after laser cleaning provides a theoretical basis for applying laser cleaning in the aerospace field.

2. Materials and Experimental Methods

2.1. Experimental Materials

The experimental material was the AA2024 aluminum alloy used in aerospace. Its chemical composition is shown in Table 1. The sample size was 40 mm × 40 mm × 5 mm.

Table 1.

Chemical composition of the AA2024 aluminum alloy [9].

2.2. Laser Cleaning Experiment

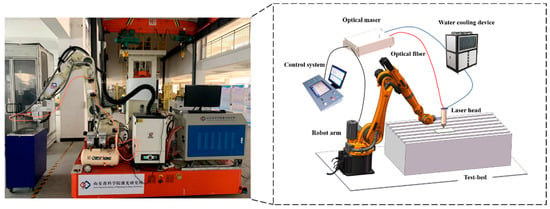

The experimental equipment used Nd:YAG pulsed solid-state laser cleaning equipment (SC200 W–350 KW, Laser Institute of Shandong Academy of Sciences, Jinan, China). A schematic diagram of the laser cleaning equipment is shown in Figure 1, and the main parameters of the laser are shown in Table 2. The laser emitted by the Nd:YAG pulsed solid-state laser is transmitted to the laser cleaning head through an optical fiber. The control system controls the laser, mechanical arm, and laser head parameters so that the laser acts on the workpiece and completes the cleaning through a set path. A cooling water device completes the heat dissipation of the equipment in the whole process. In this experiment, the cleaning speed was set to 5 mm/s, the pulse frequency was 8 kHz, and the spot overlap rate was 30%. The energy density of the laser was proportional to the average power of the laser, and the laser energy density was changed by controlling the average power of the laser. The energy density was set to 8.5, 10.5, and 12.5 J/cm2. After the experiment, SEM and EDS analyses (JSM-7610F, JEOL, Tokyo, Japan) were used to analyze the cleaned sample to study the effect of cleaning.

Figure 1.

Schematic diagram of the laser cleaning equipment.

Table 2.

The main parameters of the laser.

2.3. Friction and Wear Experiments

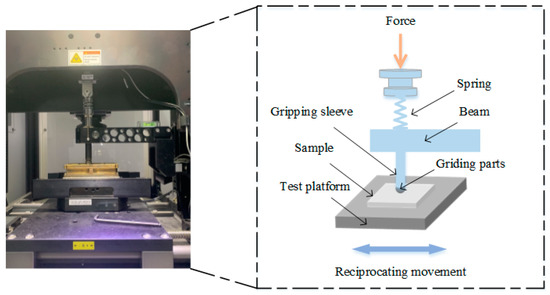

An RTEC friction and wear tester (MFT-50, San Jose, CA, USA) was used to analyze the friction and wear characteristics of the laser-cleaned samples. The principle of the friction and wear experiment is shown in Figure 2. The friction method was the dry reciprocating friction of the ball and the plate. A GCr15 steel ball-bearing (Ra < 0.1 μm) with a diameter of 6.35 mm and a hardness of 750 HV was selected as the counter-grinding ball. The load force of the wear test was 10 N, the wear time was 30 min, the displacement amplitude was 4.5 mm, and the working frequency was 2 Hz. After the friction and wear experiment was completed, a white light interferometer (MFT-4000, Lanzhou Huahui Instrument Technology Co., Ltd., Lanzhou, China) was used to collect the wear scar morphology of the sample and measure the friction coefficient.

Figure 2.

Schematic diagram of the friction and wear test.

2.4. Microhardness and Residual Stress Experiments

A Vickers microhardness tester (402-MVD, Wilson, Norwood, MA, USA) was used to test the microhardness of the sample surface after laser cleaning. The test method was a 4-point measurement; the loading force was 100 g, and the average value of the same sample was measured 3 times. An X-ray residual stress analyzer (IXRDCOMBO, Promo, Canada) was used to test the residual stress on the surface of the cleaned sample.

3. Results and Discussion

3.1. Surface Morphology of the Aluminum Alloy after Laser Cleaning

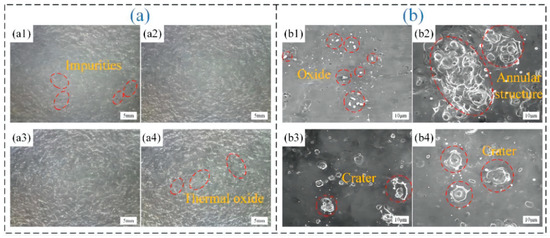

Figure 3 shows the surface morphology of the AA2024 alloy laser-cleaned at different energy densities. It was observed from the macroscopic morphology that there were obvious black impurity particles on the surface of the uncleaned aluminum alloy. With a continuous increase in the laser energy density, the impurities were gradually removed, and the surface of the aluminum alloy became significantly brighter, proving that a large number of surface contaminants had been removed.

Figure 3.

Surface morphology of an aluminum alloy cleaned by a laser with different loading energy densities. (a) Macromorphology: (a1): not cleaned; (a2): 8.5 J/cm2; (a3): 10.5 J/cm2; (a4): 12.5 J/cm2. (b) Micromorphology: (b1): not cleaned; (b2): 8.5 J/cm2; (b3): 10.5 J/cm2; (b4): 12.5 J/cm2.

From the microscopic morphology, it could be seen that there were many white oxides on the surface of the uncleaned aluminum alloy. When the energy density reached 8.5 J/cm2, white spots—suspected to be thermal oxidation—appeared on the surface of the aluminum alloy. According to the analysis, the impact and vibration of the laser pulse could not remove the surface impurities due to the low energy density. At this time, the contaminants on the surface of the workpiece were only affected by heat, forming many white oxides. When the energy density reached 10.5 J/cm2, the white oxide on the surface of the aluminum alloy was reduced, due to the increase in the heat input, the rapid growth of the thermal expansion coefficient difference between the contaminants and the substrate, the rapid expansion of the contaminants and oxides, and the shock and vibration of the pulsed laser so that the contaminants were detached from the substrate. Due to the combined action of the impact force of the laser pulse and the recoil force of the aluminum alloy surface, a small number of inconspicuous crater structures remained on the surface of the material [20]. When the energy density continued to increase to 12.5 J/cm2, the shock vibration effect and heat input of the pulse increased, and small white spots appeared around the pits. The analysis concluded that this was due to the increased heat input causing new oxides to form around the holes.

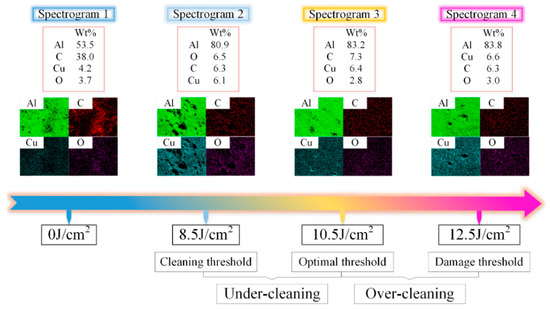

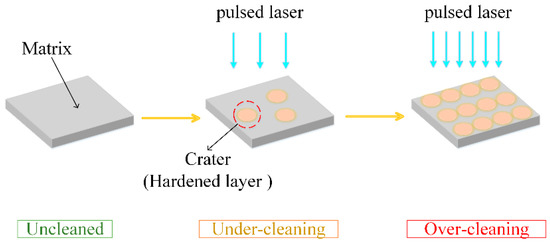

Figure 4 is a flow chart of the entire cleaning process, combining the surface topography and flow chart to analyze the cleaning process further. When the aluminum alloy surface was not cleaned, the aluminum element content was 53.5%, the carbon element content was 38.0%, and the oxygen element content was 3.7%. At this time, the surface contained a greater number of impurities. When the energy density reached 8.5 J/cm2, the aluminum element content increased to 80.9%, the carbon element dropped to 6.3%, and the oxygen element rose to 6.5%. At this time, most of the impurities on the surface of the aluminum alloy were removed, but there were a greater number of oxides around the ring structure on the surface, causing the oxygen content to rise. At this time, it was in a state of under-cleaning. When the energy density reached 10.5 J/cm2, the range of the aluminum was further increased to 83.2%, and the oxygen content dropped to the lowest point of 2.8%. At this time, the annular structure on the surface of the aluminum alloy disappeared, and the cover was the smoothest, indicating the most effective cleaning state. When the energy density was increased to 12.5 J/cm2, there was no noticeable change in the elements on the surface, and the oxygen content was slightly increased. At this time, the surface of the aluminum alloy was thermally oxidized around the crater due to the action of the laser spot, causing the oxygen content to increase again, which was a state of over-cleaning.

Figure 4.

Flow chart of the cleaning process.

3.2. Friction and Wear Properties after Laser Cleaning

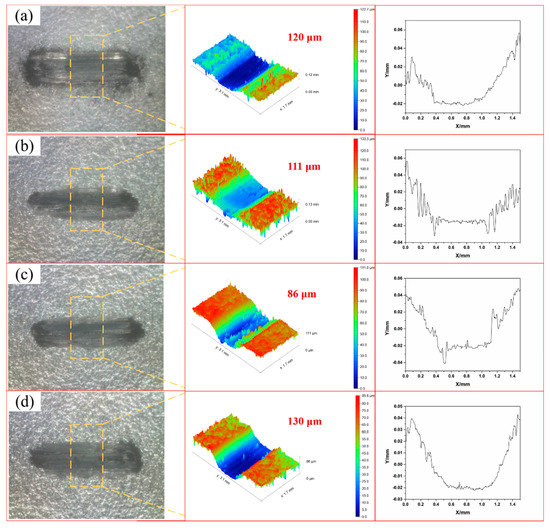

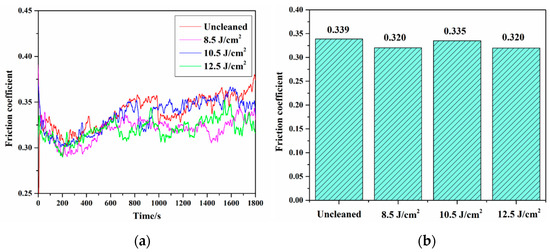

Figure 5 shows the wear scar morphology of each sample under different energy densities. Figure 6 shows the friction coefficient of each sample under different energy densities. From Figure 5 and Figure 6, we observed that the wear scar depth of each sample was 120, 111, 86, and 130 μm when the energy density was 0, 8.5, 10.5, and 12.5 J/cm2, respectively. The average friction coefficient of each sample was 0.3388, 0.3201, 0.3349, and 0.3197, respectively. Impurities and oxides adhered to the surface of the sample when it was not cleaned, and the surface was rough, so the depth of the wear scar and the average friction coefficient were both at a maximum. When the energy density was 8.5 J/cm2, the impurities and oxides on the sample’s surface were removed. The ring structure on the surface increased the friction resistance, resulting in a slight decrease in the friction coefficient and a decrease in the depth of the wear scar. The abrasion resistance of the aluminum alloy surface was improved. When the energy density reached 10.5 J/cm2, the surface of the aluminum alloy was the smoothest, there were the fewest oxides, and the cleaning effect was the most noticeable. At this time, the average wear scar of the sample is the shallowest, and the friction coefficient is slightly higher than that of the energy density of 8.5 J/cm2, which may be caused by the decrease of the surface hardness of the substrate. When the energy density reached 12.5 J/cm2, the wear scar depth of the sample increased, whereas the average friction coefficient decreased. The aluminum alloy underwent thermal oxidation, and there was a new oxide film on the surface. The low adhesion of the film led to an increase in the depth of the wear scar [21]. The decrease in the average friction coefficient was due to the increase in hardness, which is explained in the subsequent experimental discussion. In summary, laser cleaning could improve the wear resistance of the aluminum alloy surface, and the effect was greatest at 12.5 J/cm2.

Figure 5.

Wear scar morphology of each sample under different loading energy densities: (a) not cleaned; (b) 8.5 J/cm2; (c) 10.5 J/cm2; (d) 12.5 J/cm2.

Figure 6.

The friction coefficient of each sample under different loading energy densities: (a) friction coefficient; (b) average friction coefficient.

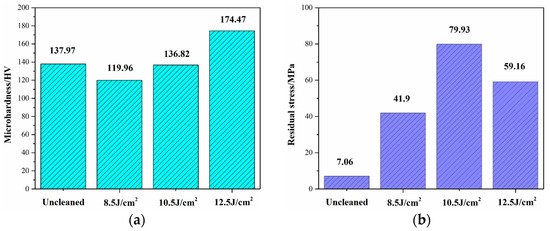

3.3. Mechanical Properties after Laser Cleaning

Changes in the surface microstructure of metal materials will affect their mechanical properties, so we studied the effect of laser cleaning on the surface microhardness and residual stress of the aluminum alloy. Figure 7a shows the microhardness value of each sample under different energy densities, and Figure 7b shows the residual stress value of each piece under different energy densities. As shown in Figure 7a, the microhardness value of the aluminum alloy surface was 137.97 HV without cleaning. When the laser energy density was 8.5, 10.5, and 12.5 J/cm2, the microhardness of the surface was 119.96, 136.82, and 174.47 HV, respectively. When the energy density was 8.5 and 10.5 J/cm2, the surface hardness of the aluminum alloy was lower than that without cleaning. When the energy density reached 12.5 J/cm2 (over-cleaning), the surface hardness significantly increased. Figure 8 is a diagram of the principal hardness strengthening of the aluminum alloy surface after laser cleaning. When the laser spot acted on the aluminum alloy surface, pits were formed on the surface due to the impact effect of the pulsed laser. Affected by the impact pressure, the insides of the holes were microstrengthened. In an under-cleaned state, the surface of the aluminum alloy was mainly ring-shaped, with a slight decrease in hardness. When a state of excessive cleaning was reached, many pits were formed on the surface of the aluminum alloy. The uniform distribution of the holes included a layer of strengthened film on the character of the sample, which significantly increased the hardness.

Figure 7.

(a) Vickers microhardness of each sample under different loading energy densities; (b) residual stress of each sample under different loading energy densities.

Figure 8.

Principal surface hardness strengthening of the aluminum alloy.

Residual stress on a metal surface is one of the indicators that can reflect the fundamental strength and plasticity of the material. It can be seen in Figure 7b that the residual stress value on the surface of the aluminum alloy when it was not cleaned was 7.06 MPa. The laser energy density was 8.5, 10.5, and 12.5 J/cm2, and the residual stress values of the aluminum alloy surface after cleaning were 41.9, 79.93, and 59.16 MPa, respectively. After laser cleaning, the residual tensile stress on the surface of the aluminum alloy significantly increased. According to the analysis of the structural changes on the surface of the aluminum alloy, when the high-energy laser spot was irradiated to the aluminum alloy substrate, the oxide film on the surface cracked and thermally oxidized. At this time, the residual stress on the surface was reorganized, resulting in the generation of residual tensile stress [22]. In summary, under appropriate laser process parameters, laser cleaning could slightly increase the surface hardness of the aluminum alloys, but it caused residual tensile stress.

4. Conclusions

Laser cleaning could effectively remove impurities and oxides on the surface of AA2024. The most effective laser energy density was 10.5 J/cm2. When the energy density was lower than the optimal energy density, a ring structure formed on the surface of the aluminum alloy. When the energy density was higher than the optimal energy density, the surface of the aluminum alloy was thermally oxidized.

Laser cleaning could enhance the friction and wear performance of the AA2024 surface by changing the microstructure. It was most noticeable when the laser energy density was 12.5 J/cm2 and increased with the energy density.

Laser cleaning could produce a hardened layer on the surface of AA2024 and increase the microhardness of the aluminum alloy surface. Laser cleaning could also reorganize the residual stress on the aluminum alloy surface, resulting in the generation of residual tensile stress.

Author Contributions

Conceptualization, Y.R. and X.M.; methodology, L.W.; validation, J.L. and W.C.; formal analysis, X.M.; investigation, Y.R.; data curation, Y.R.; writing—original draft preparation, Y.R.; writing—review and editing, L.W.; project administration, J.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the National Key R&D Program of China (Grant No. 2020YFB1711603), the National Natural Science Foundation of China (Grant No. 51805297), the Key Technology R&D Program of Shandong (Grant No. 2020CXGC011004), Innovation Team of Colleges and Universities Program of JiNan (Grant No. 2019GXRC029), The Province Key R&D Program of ShanDong (Grant No. 2020JMRH0504).

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki and approved by the Institutional Review Board of Shandong University.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Song, M.; Wu, L.; Liu, J.; Hu, Y. Effects of laser cladding on crack resistance improvement for aluminum alloy used in aircraft skin. Opt. Laser Technol. 2020, 133, 106531. [Google Scholar] [CrossRef]

- Manjunath, M.A.; Vinod, P.; Balashanmugam, N.; Sankar, M.R. Abrasive flow finishing for surface roughness improvement of aluminum propeller: A case study. Mater. Today Proc. 2020, 26, 1113–1118. [Google Scholar] [CrossRef]

- Vasanthakumar, P.; Sekar, K.; Venkatesh, K. Recent developments in powder metallurgy based aluminium alloy composite for aerospace applications. Mater. Today Proc. 2019, 18, 5400–5409. [Google Scholar] [CrossRef]

- Huda, Z.; Taib, N.I.; Zaharinie, T. Characterization of AA2024-T3: An aerospace aluminum alloy. Mater. Chem. Phys. 2009, 113, 515–517. [Google Scholar] [CrossRef]

- Aamir, M.; Giasin, K.; Tolouei-Rad, M.; Vafadar, A. Drilling performance and hole quality of aluminium alloys for aerospace applications. J. Mater. Res. Technol. 2020, 9, 12484–12500. [Google Scholar] [CrossRef]

- Llavori, I.; Zabala, A.; Urchegui, M.; Tato, W.; Gómez, X. A coupled crack initiation and propagation numerical procedure for combined fretting wear and fretting fatigue lifetime assessment. Theor. Appl. Fract. Mech. 2019, 101, 294–305. [Google Scholar] [CrossRef]

- Moutarlier, V.; Viennet, R.; Gigandet, M.P.; Hihn, J.Y. Use of ultrasound irradiation during acid etching of the AA2024: Effect on corrosion resistance after anodization. Ultrason. Sonochem. 2020, 64, 104879. [Google Scholar] [CrossRef]

- Gomes, V.; Dionísio, A.; Antonio, J.S.P.; Rivas, T.; Ramil, A. Mechanical and laser cleaning of spray graffiti paints on a granite subjected to a SO2-rich atmosphere. Constr. Build. Mater. 2018, 188, 621–632. [Google Scholar] [CrossRef]

- Aamir, M.; Tolouei-Rad, M.; Giasin, K.; Vafadar, A. Machinability of Al2024, Al6061, and Al5083 alloys using multi-hole simultaneous drilling approach. J. Mater. Res. Technol. 2020, 9, 10991–11002. [Google Scholar] [CrossRef]

- Aamir, M.; Tolouei-Rad, M.; Giasin, K.; Vafadar, A. Feasibility of tool configuration and the effect of tool material, and tool geometry in multi-hole simultaneous drilling of Al2024. Int. J. Adv. Manuf. Technol. 2020, 111, 1–19. [Google Scholar] [CrossRef]

- American Society for Metals. Properties Selection: Nonferrous Alloys and Pure Metals; American Society for Metals: Geauga County, OH, USA, 1979. [Google Scholar]

- Derose, J.A.; Suter, T.; Balkowiec, A.; Schmutz, P. Localised corrosion initiation and microstructural characterisation of an Al 2024 alloy with a higher Cu to Mg ratio. Corros. Sci. 2012, 55, 313–325. [Google Scholar] [CrossRef]

- Li, X.; Huang, T.; Chong, A.W.; Hong, M.; Choo, Y.S. Laser cleaning of steel structure surface for paint removal and repaint adhesion. Opto-Electron. Eng. 2017, 44, 340–344. [Google Scholar]

- Razab, M.K.A.A.; Mohamed Noor, A.; Suhaimi Jaafar, M.; Abdullah, N.H. A review of incorporating Nd: YAG laser cleaning principal in automotive industry. J. Radiat. Res. Appl. Sci. 2018, 11, 393–402. [Google Scholar] [CrossRef] [Green Version]

- Zhao, W.; Yu, Z. Self-cleaning effect in high quality percussion ablating of cooling hole by picosecond ultra-short pulse laser. Opt. Lasers Eng. 2018, 105, 125–131. [Google Scholar] [CrossRef]

- Mallets, T. Laser paint removal. NASA STI/Recon Tech. Rep. N 1983, 85, 368–371. [Google Scholar]

- Tsunemi, A.; Hagiwara, K.; Saito, N.; Nagasaka, K. Complete removal of paint from metal surface by ablation with a TEA CO2 laser. Appl. Phys. A 1996, 63, 435–439. [Google Scholar] [CrossRef]

- Chen, G.X.; Kwee, T.J.; Tan, K.P.; Choo, Y.S. Laser cleaning of steel for paint removal. Appl. Phys. A 2010, 101, 249–253. [Google Scholar] [CrossRef]

- Madhukar, Y.K.; Mullick, S.; Shukla, D.K.; Kumar, S.; Nath, A.K. Effect of laser operating mode in paint removal with a fiber laser. Appl. Surf. Sci. 2013, 264, 892–901. [Google Scholar] [CrossRef]

- Zhu, G.; Wang, S.; Cheng, W.; Wang, G.; Liu, W.; Ren, Y. Investigation on the Surface Properties of 5A12 Aluminum Alloy after Nd: YAG Laser Cleaning. Coatings 2019, 9, 578. [Google Scholar] [CrossRef] [Green Version]

- Zhu, G.; Wang, S.; Zhang, M.; Yang, X.; Liu, W.; Wang, G. Application of laser cleaning in postwelding treatment of aluminum alloy. Appl. Opt. 2020, 59, 10967–10972. [Google Scholar] [CrossRef]

- Zhu, G.; Wang, S.; Cheng, W.; Ren, Y.; Wen, D. Corrosion and Wear Performance of Aircraft Skin after Laser Cleaning. Opt. Laser Technol. 2020, 132, 106475. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).