Assessment of Modulus Attenuation of Cement and Lime-Fly Ash Semi-Rigid Road Base Materials

Abstract

:1. Introduction

2. Materials and Experimental

2.1. Materials

2.1.1. Cement

2.1.2. Lime

2.1.3. Fly Ash

2.1.4. Aggregate

2.2. Mix Design

2.2.1. Aggregate Gradation

2.2.2. Cement Dosage and Optimum Moisture Content

2.3. Test Methods

2.3.1. Dynamic Modulus Test

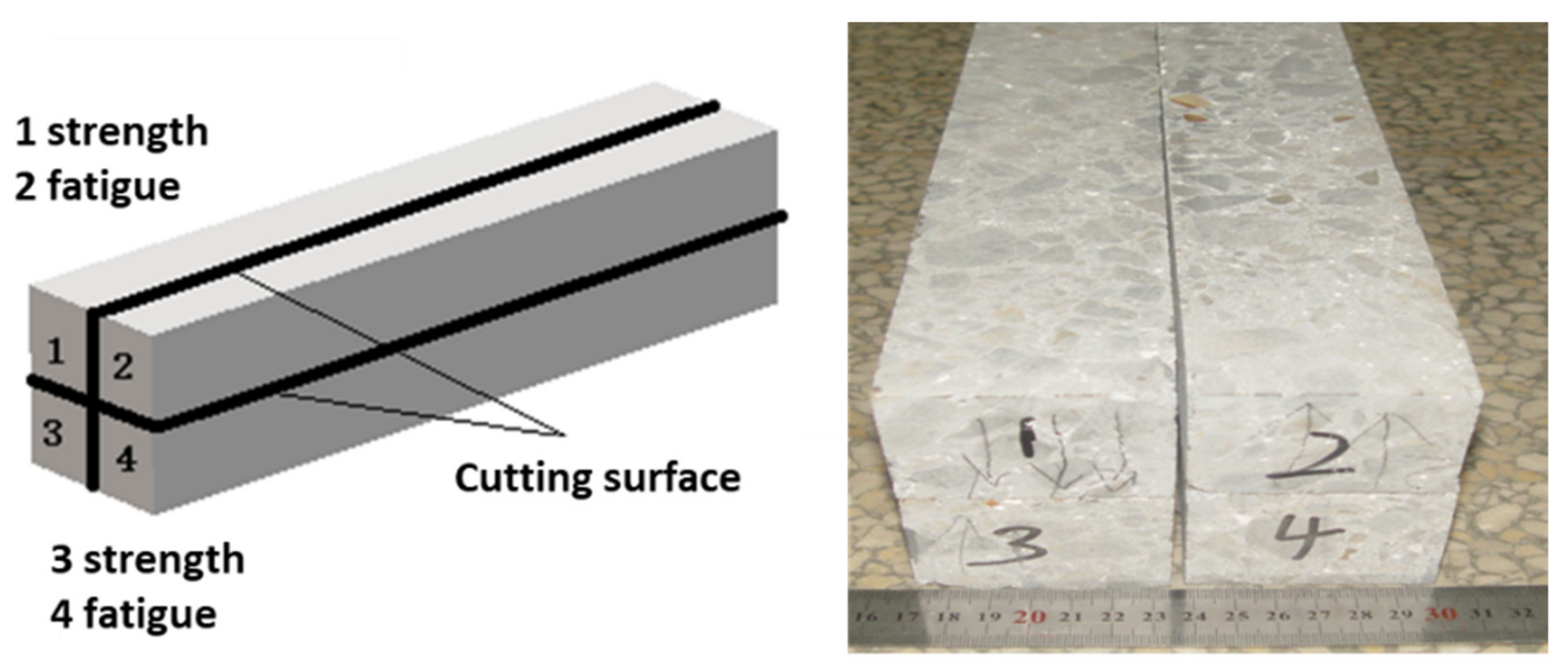

2.3.2. Four-Point Bending Fatigue Test

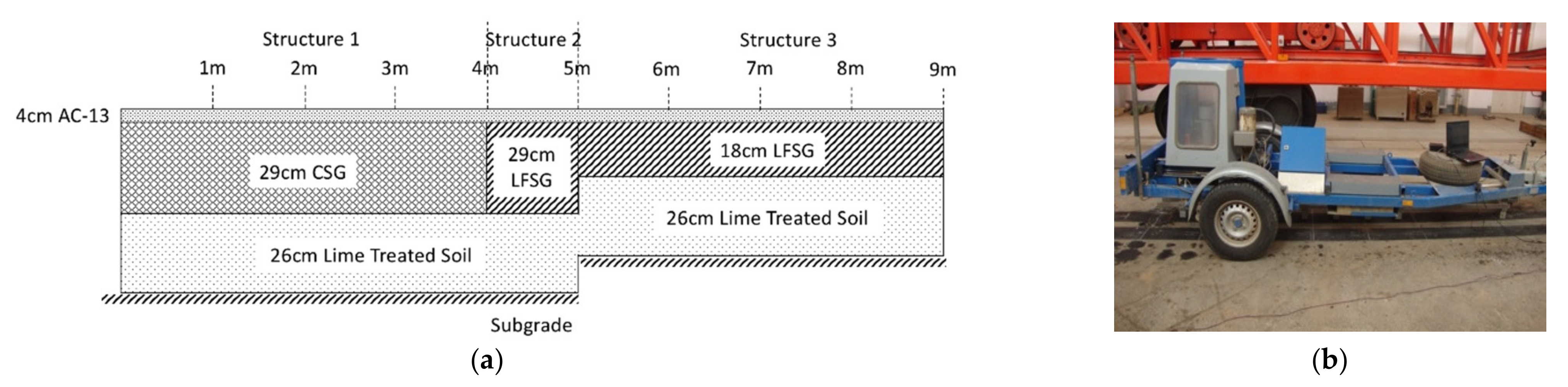

2.3.3. Full-Scale Accelerated Loading Test

3. Results and Discussion

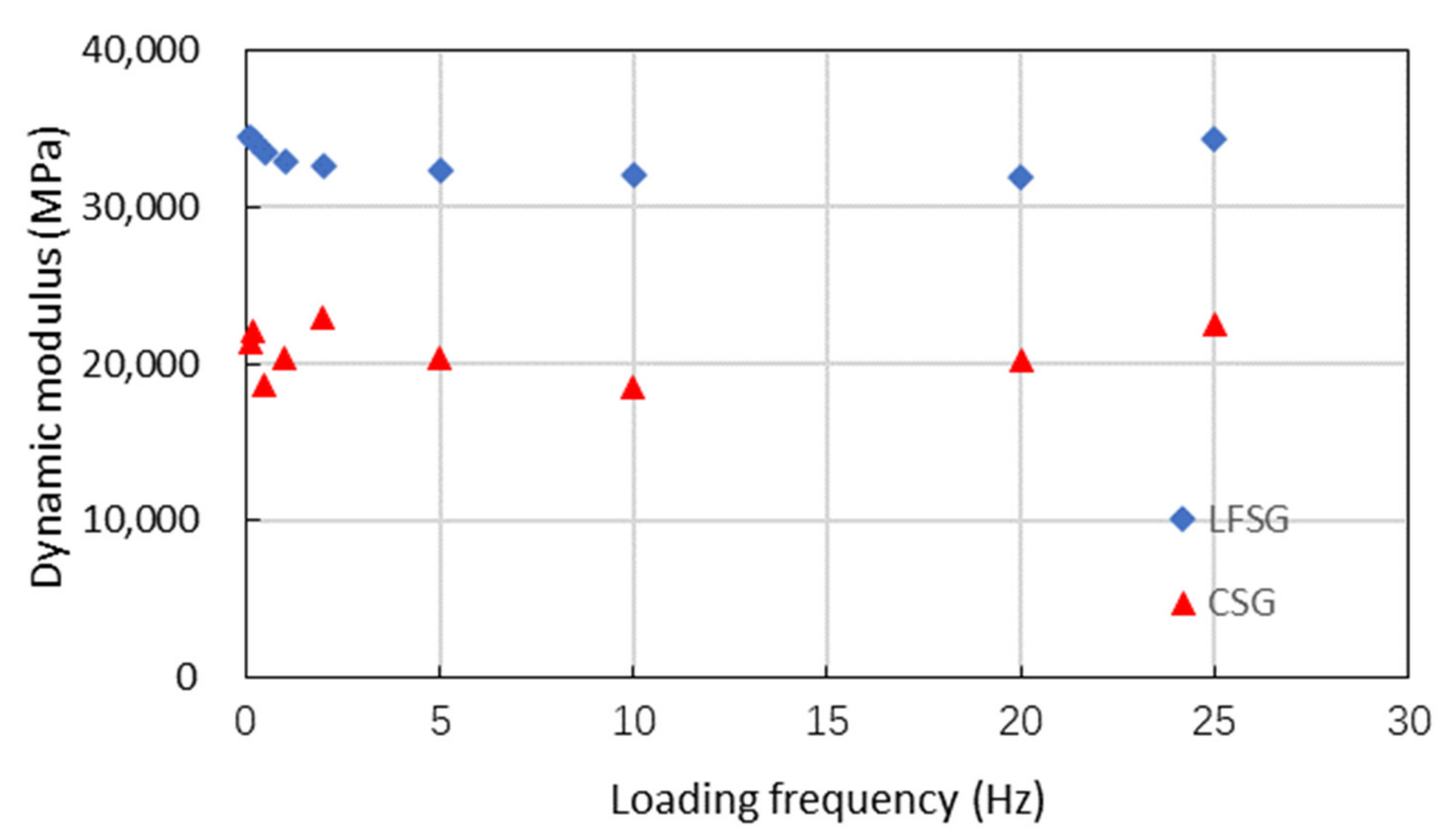

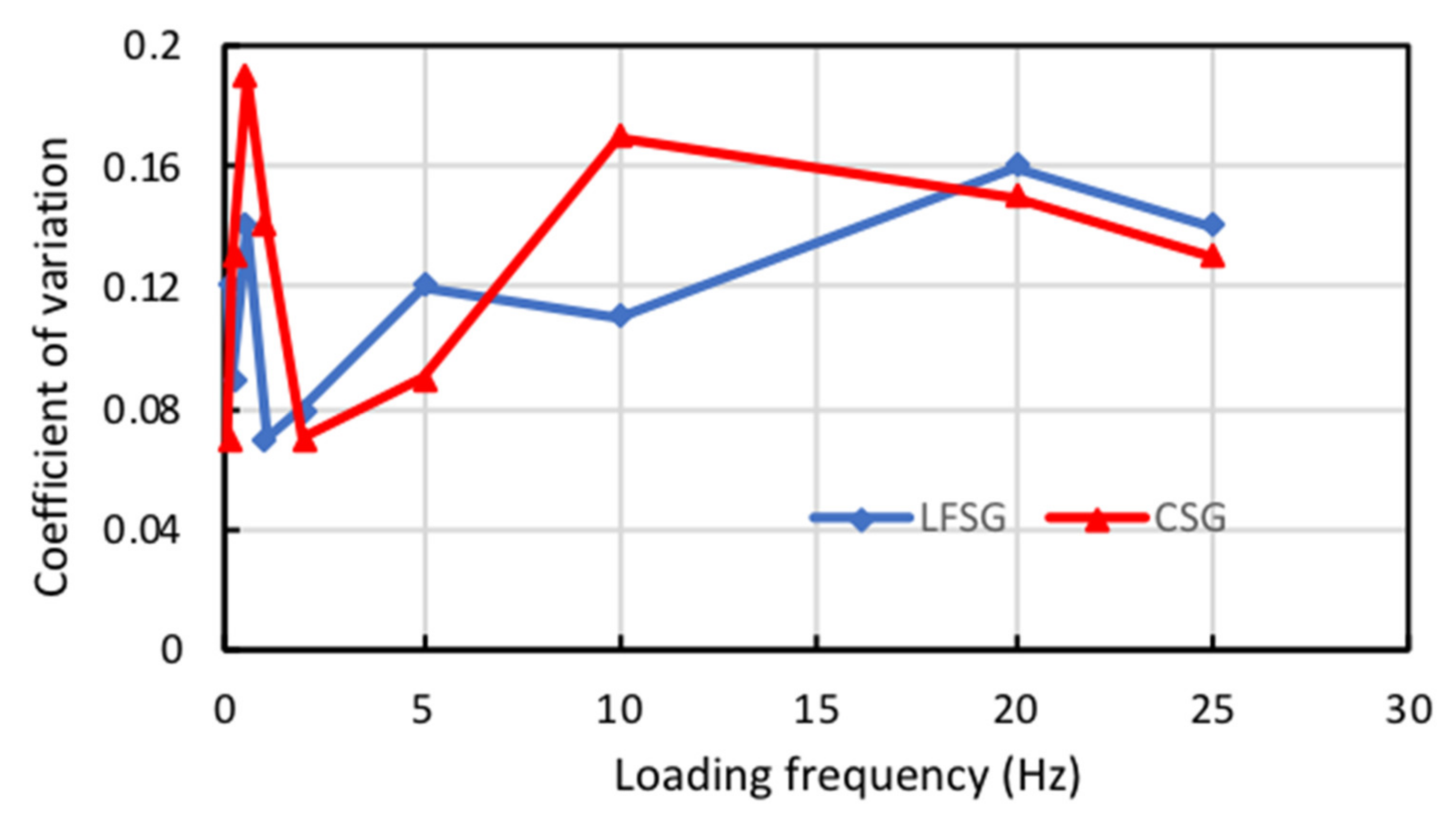

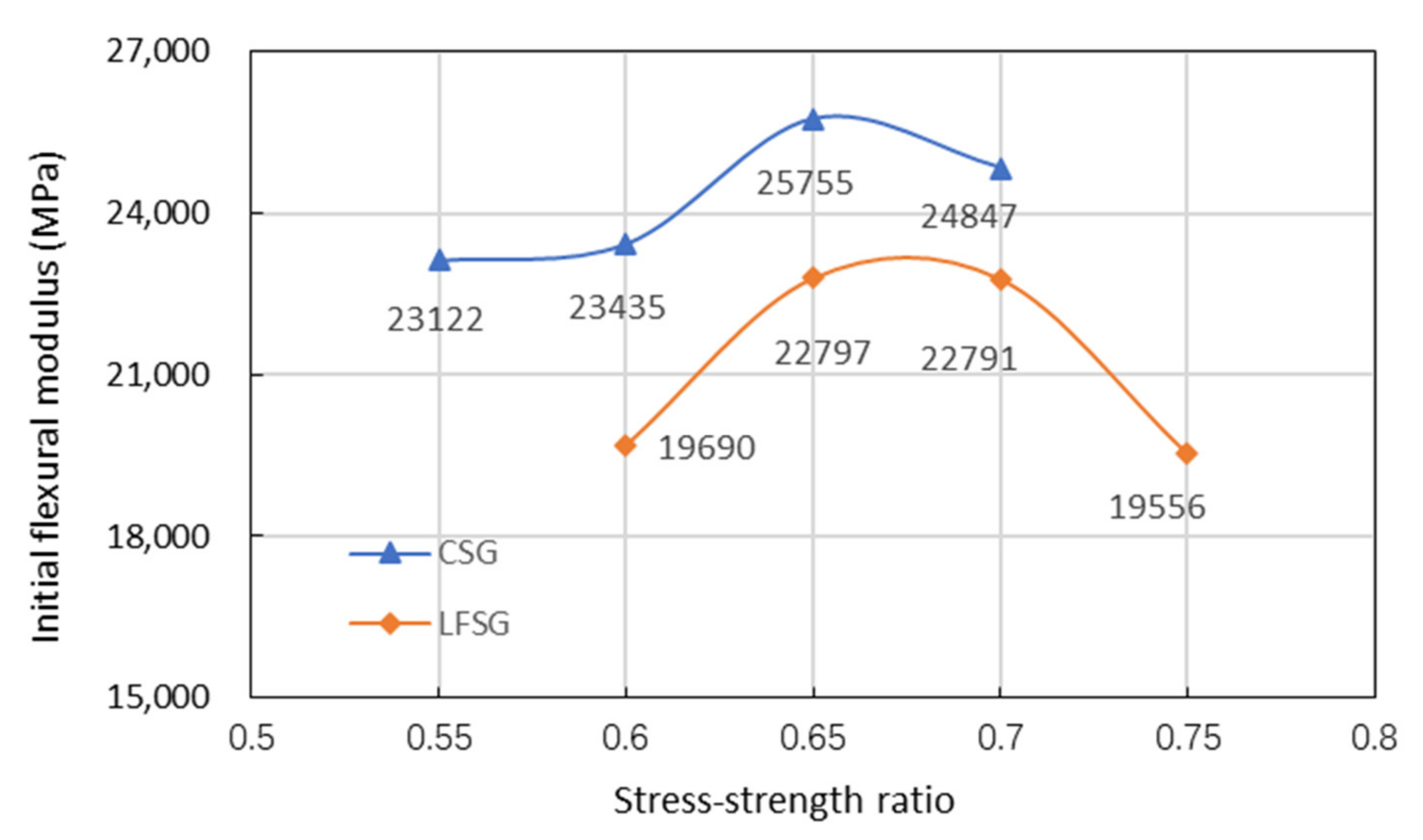

3.1. Dynamic Modulus of LFSG and CSG

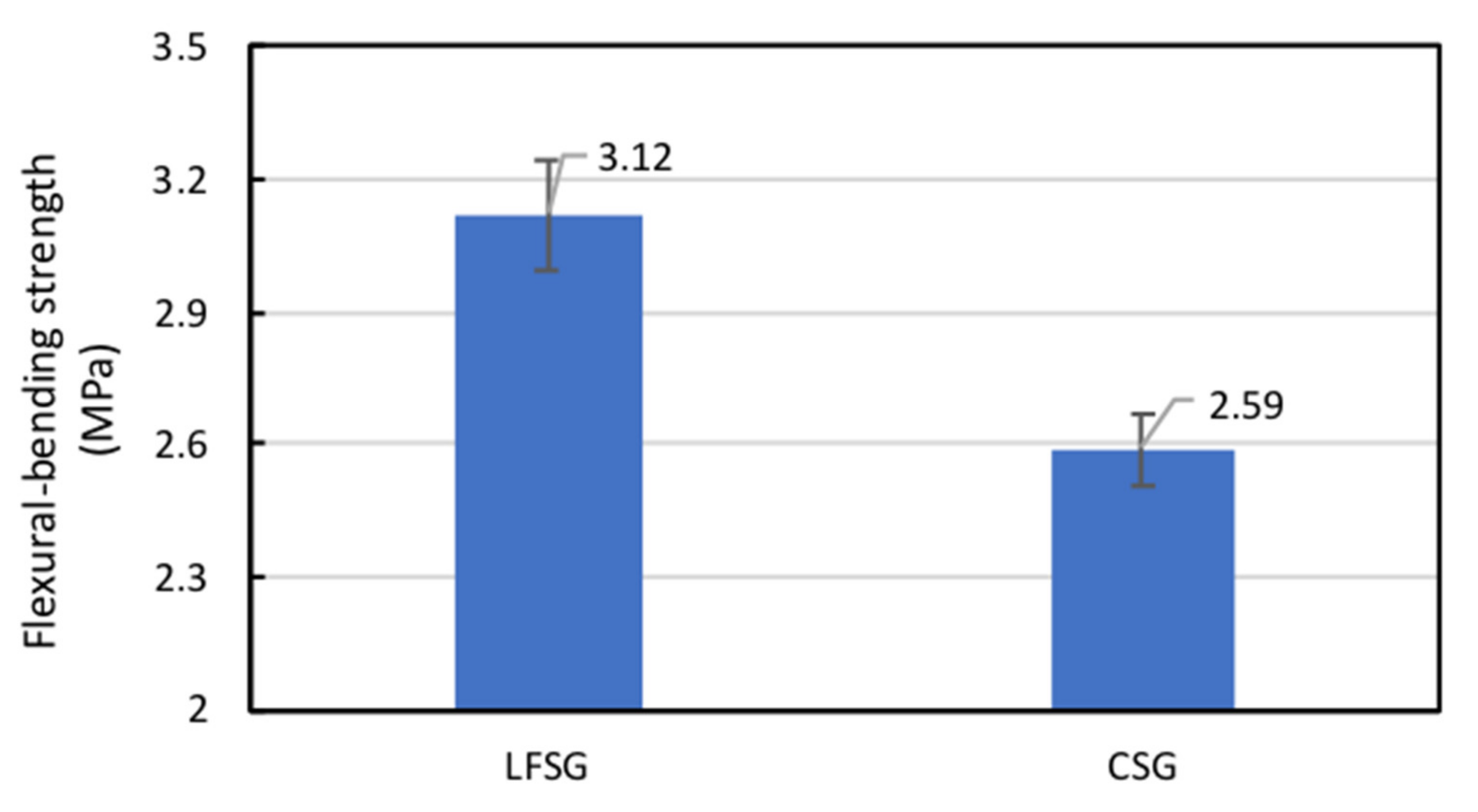

3.2. Flexural-bending Strength of LFSG and CSG

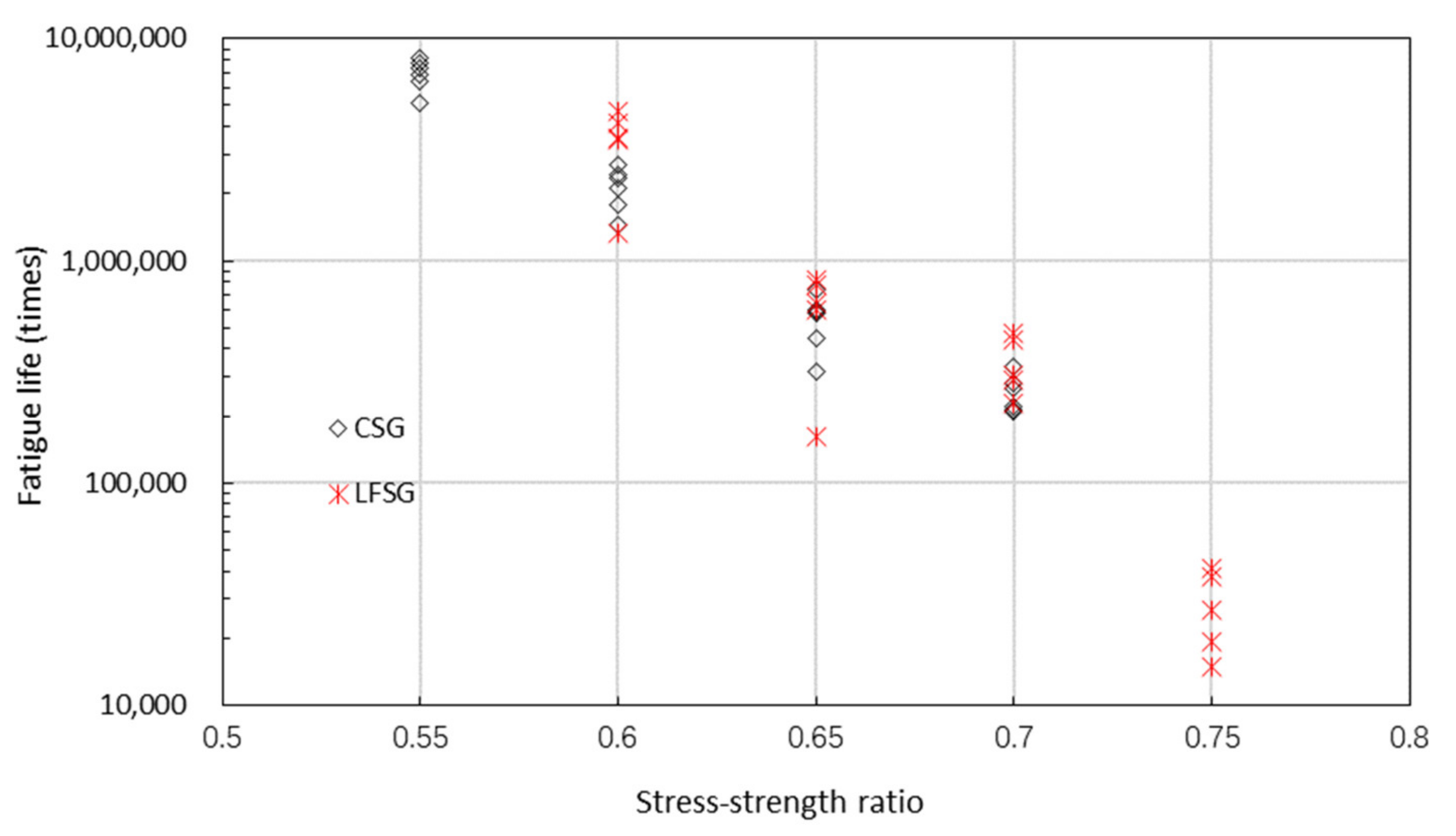

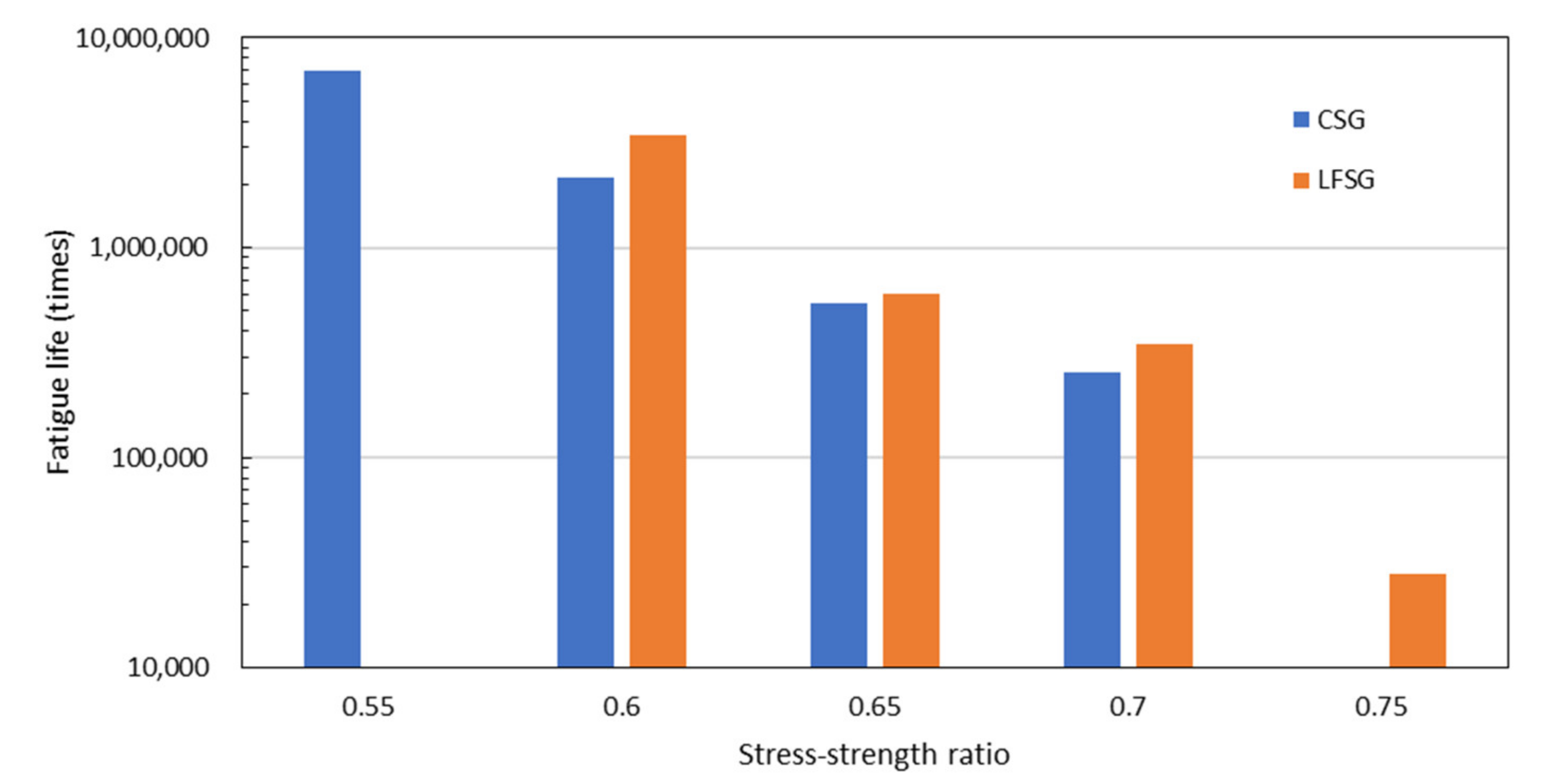

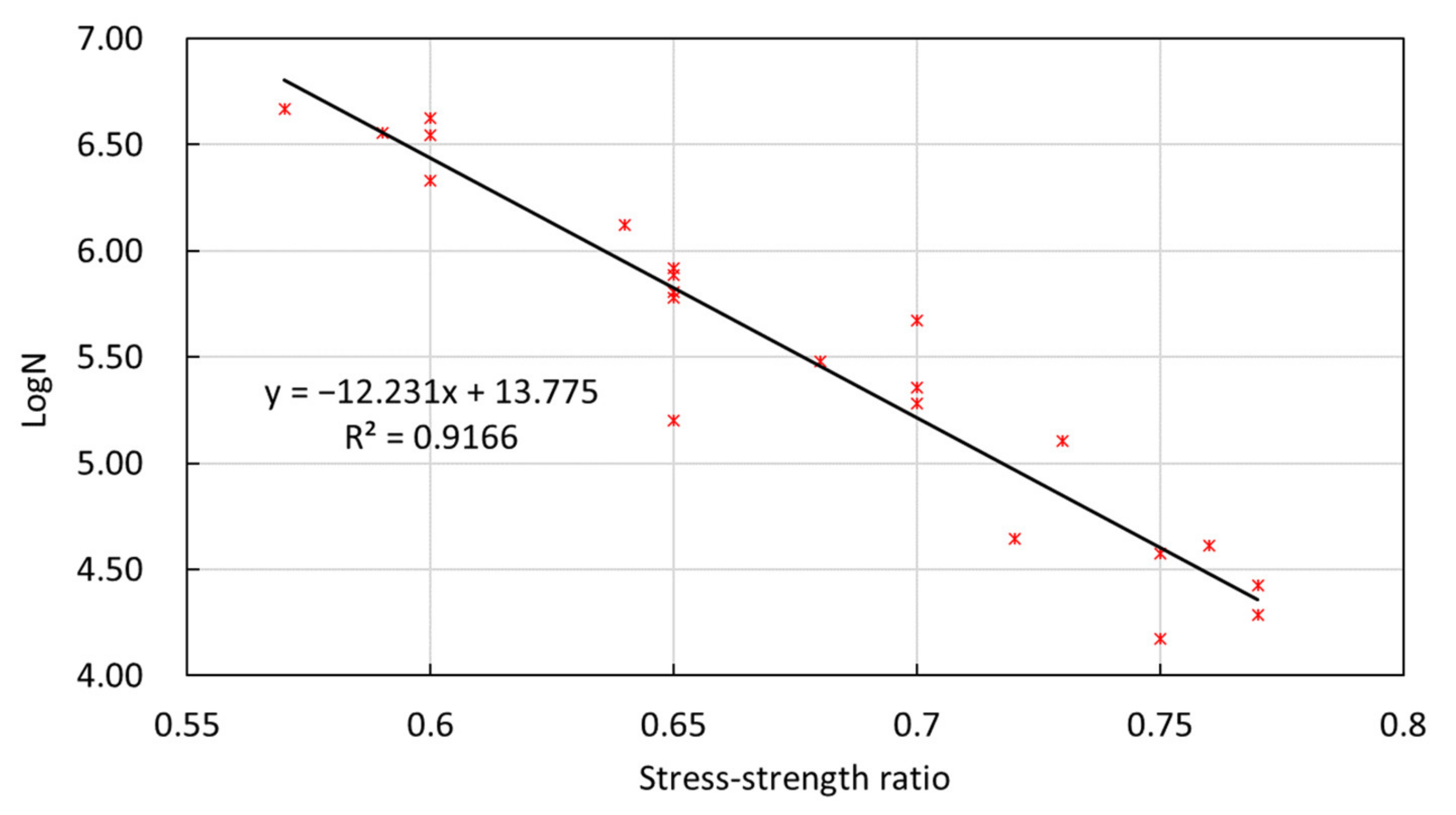

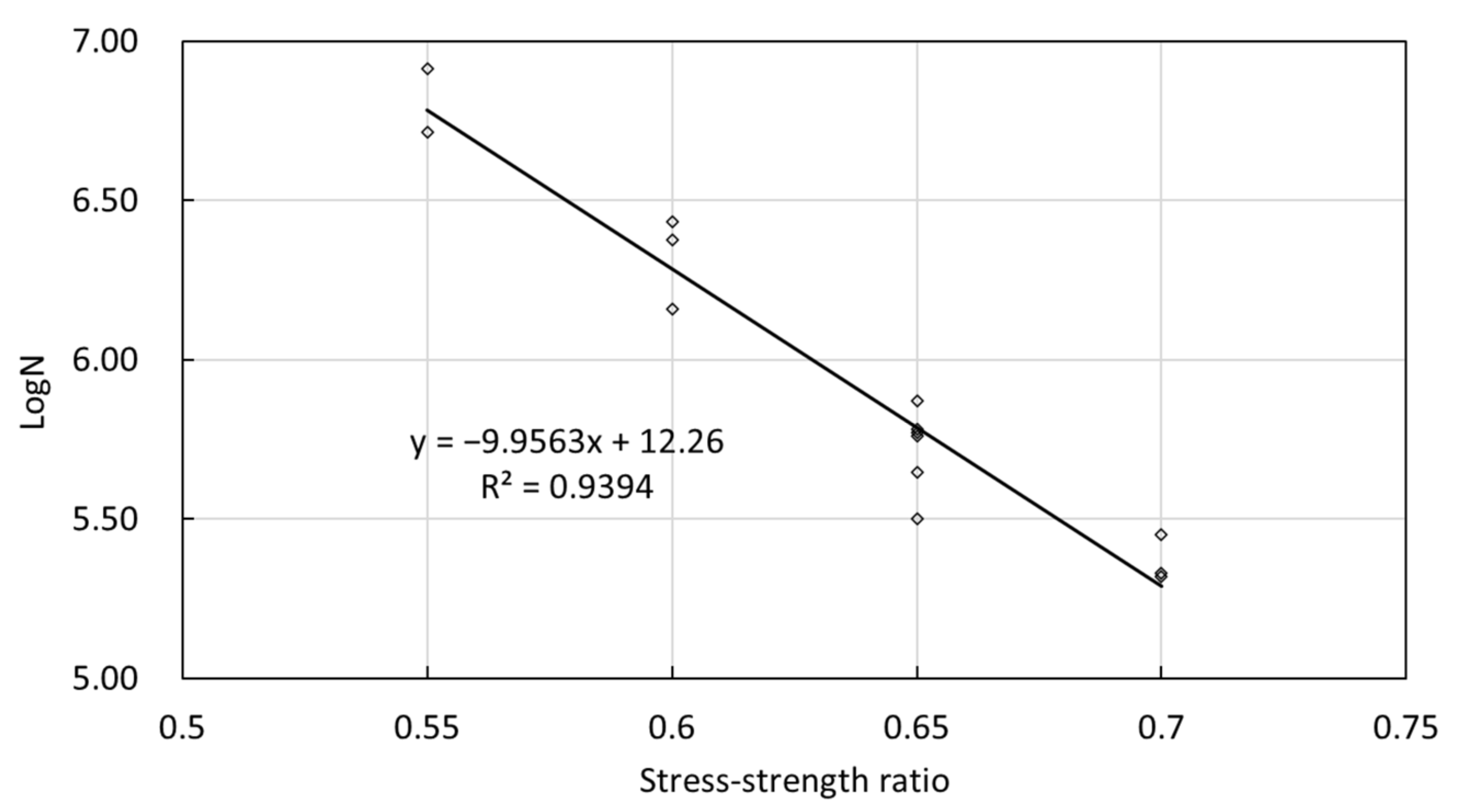

3.3. Fatigue Behavior of CSG and LSFG

3.4. Analysis on Fatigue Damage of Semi-rigid Road Base Materials

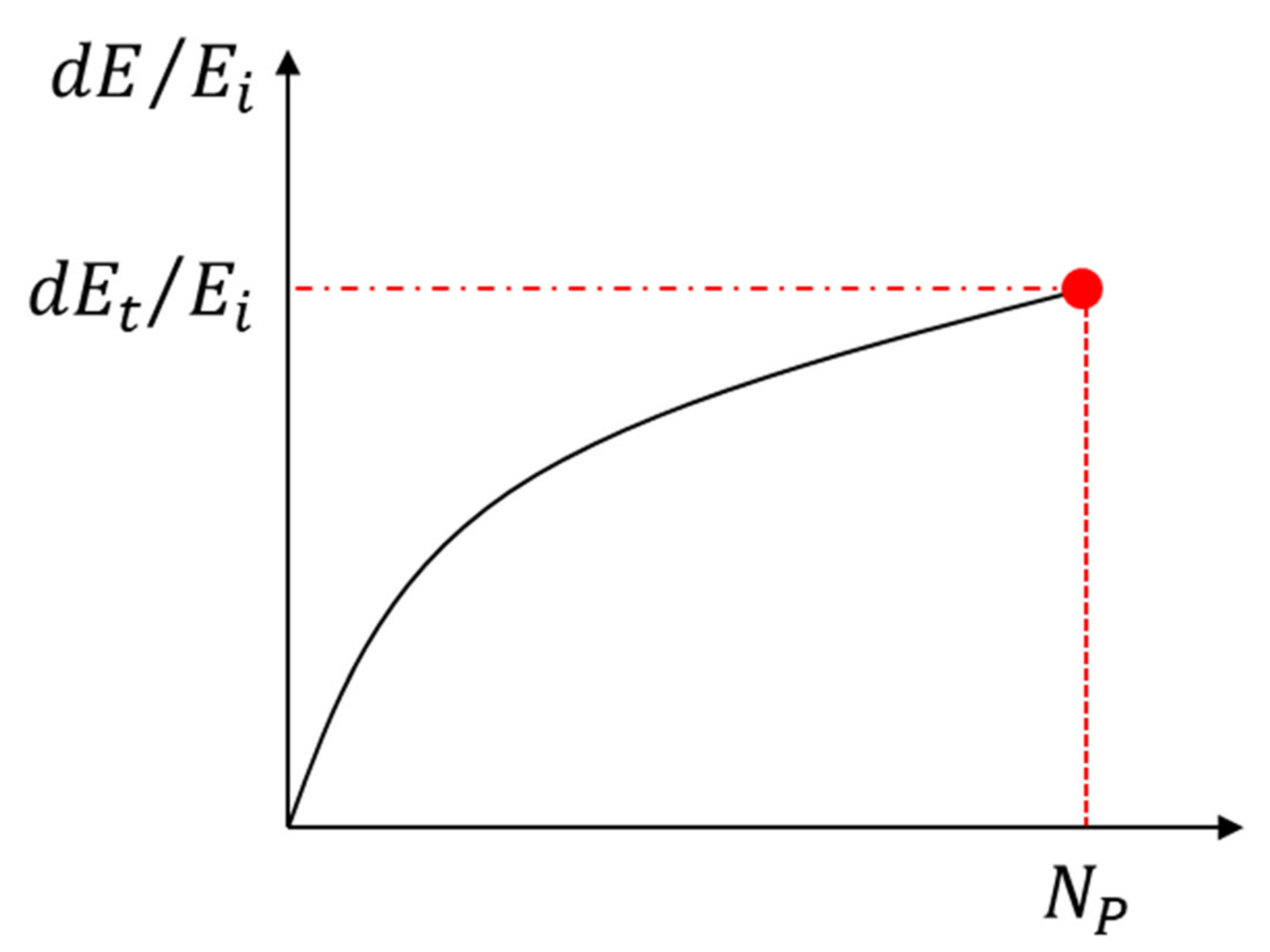

3.4.1. Introduction of Fatigue Damage Model

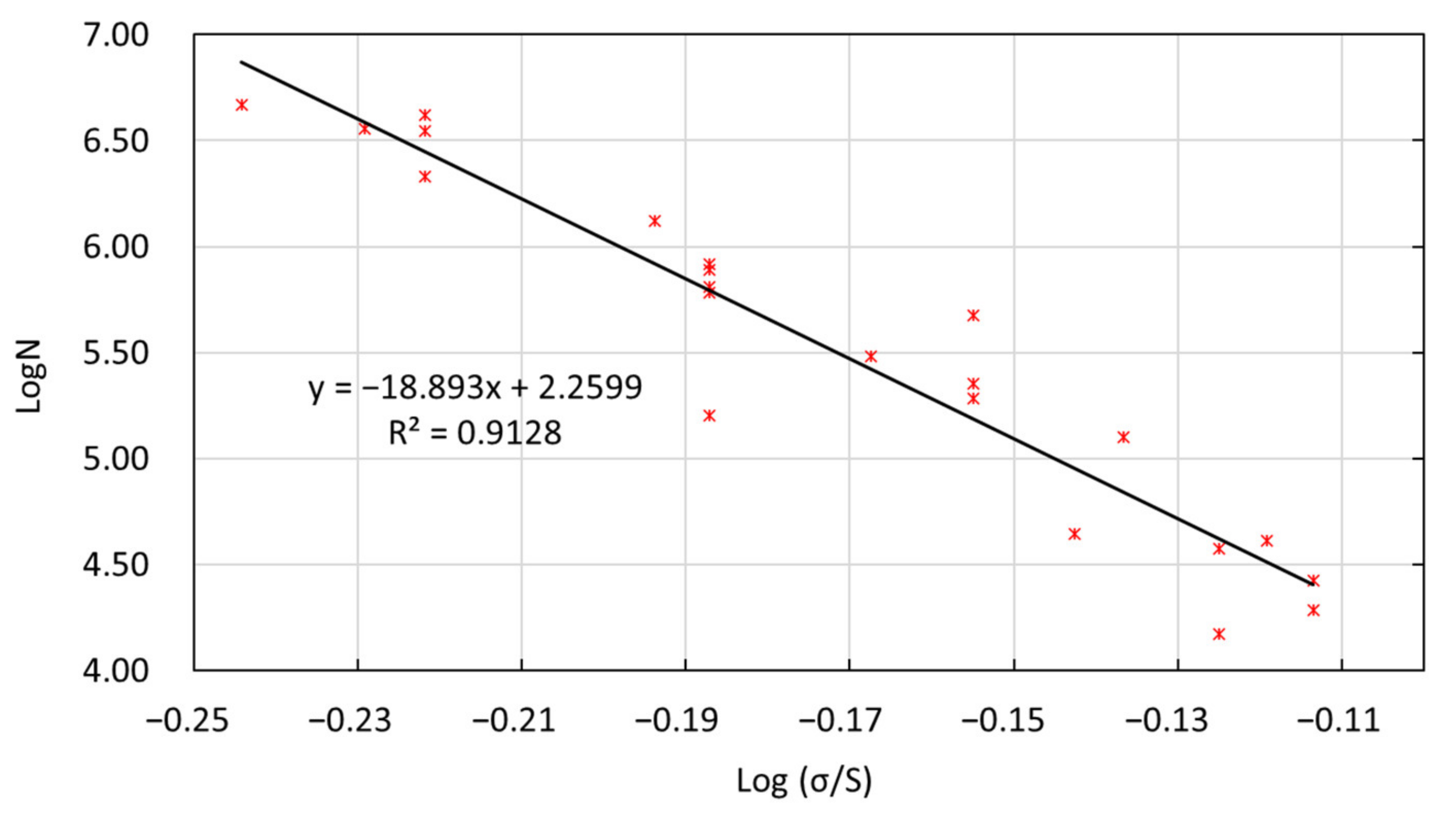

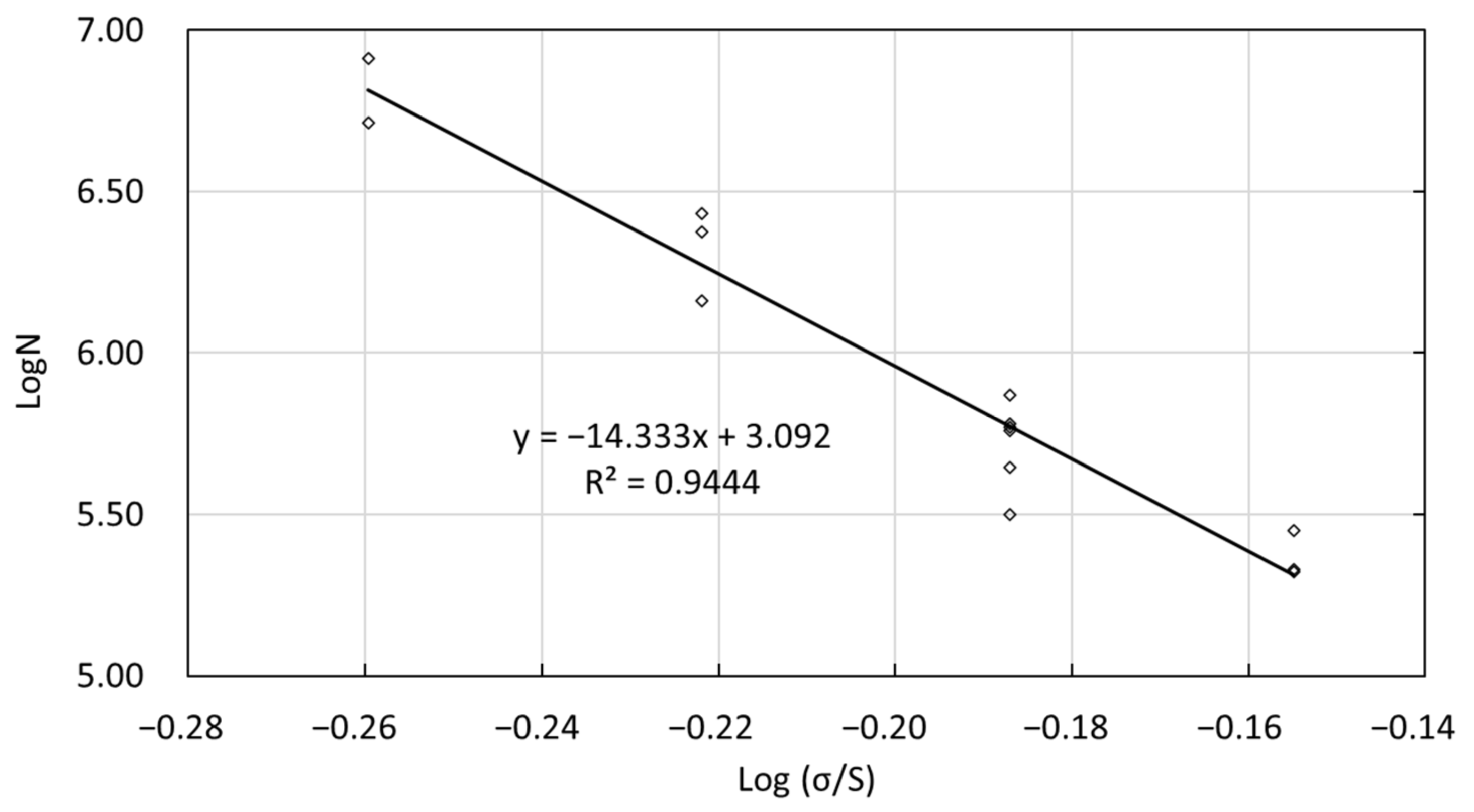

3.4.2. Fatigue Damage Model Construction

3.5. Analysis on Attenuation of Bending Modulus of Semi-Rigid Road Base Materials

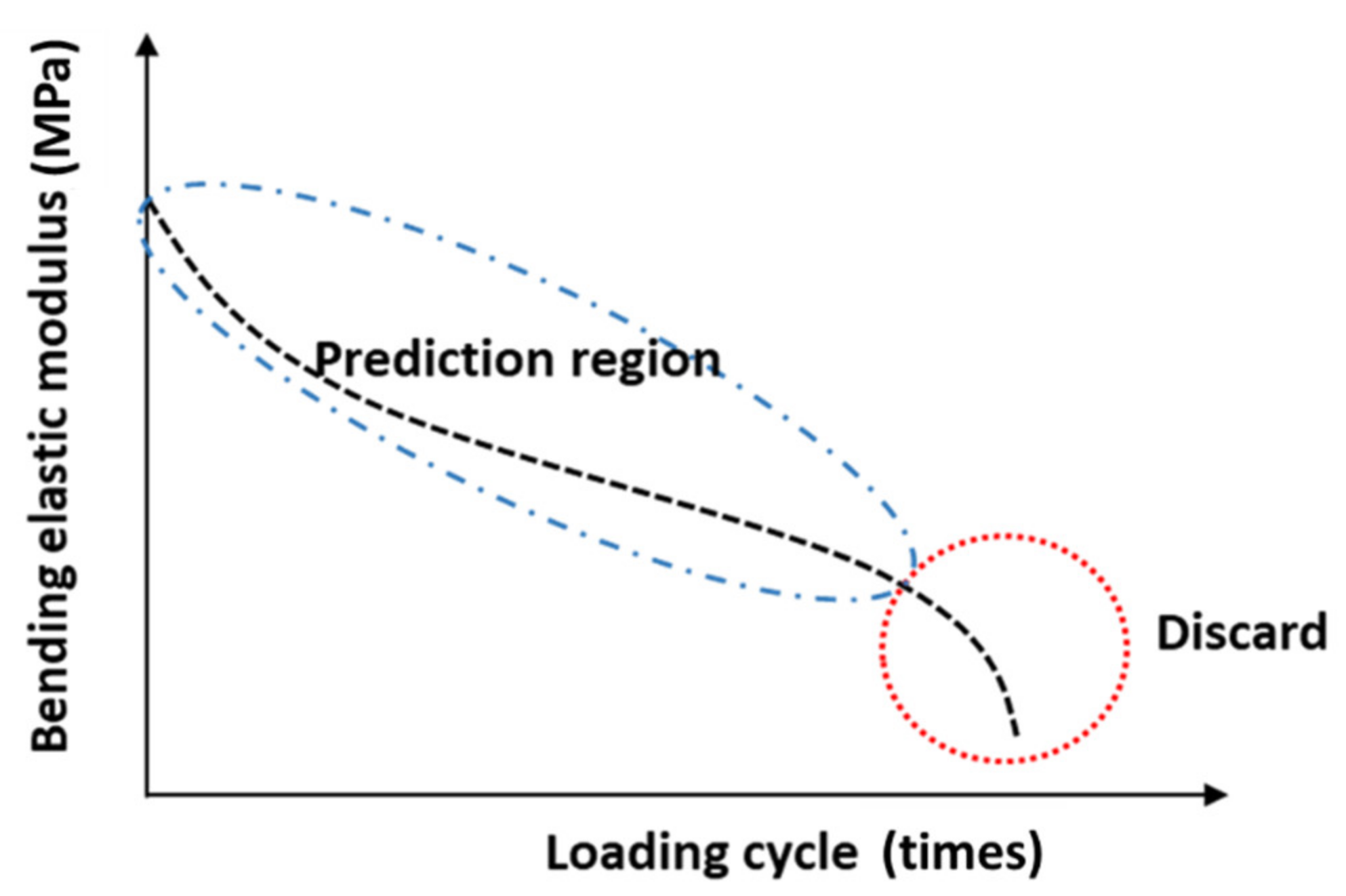

3.5.1. Introduction of Modulus Degradation Model

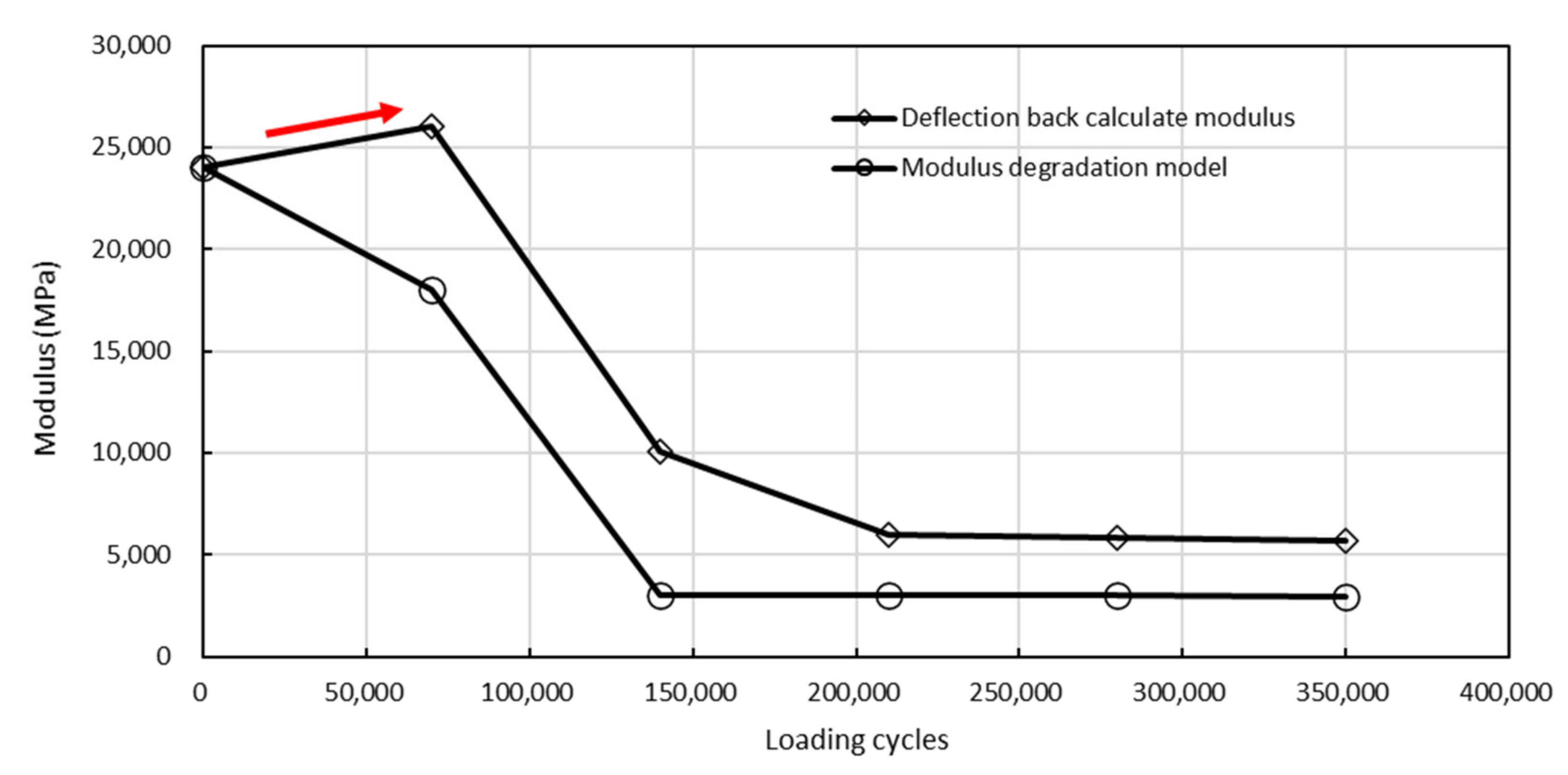

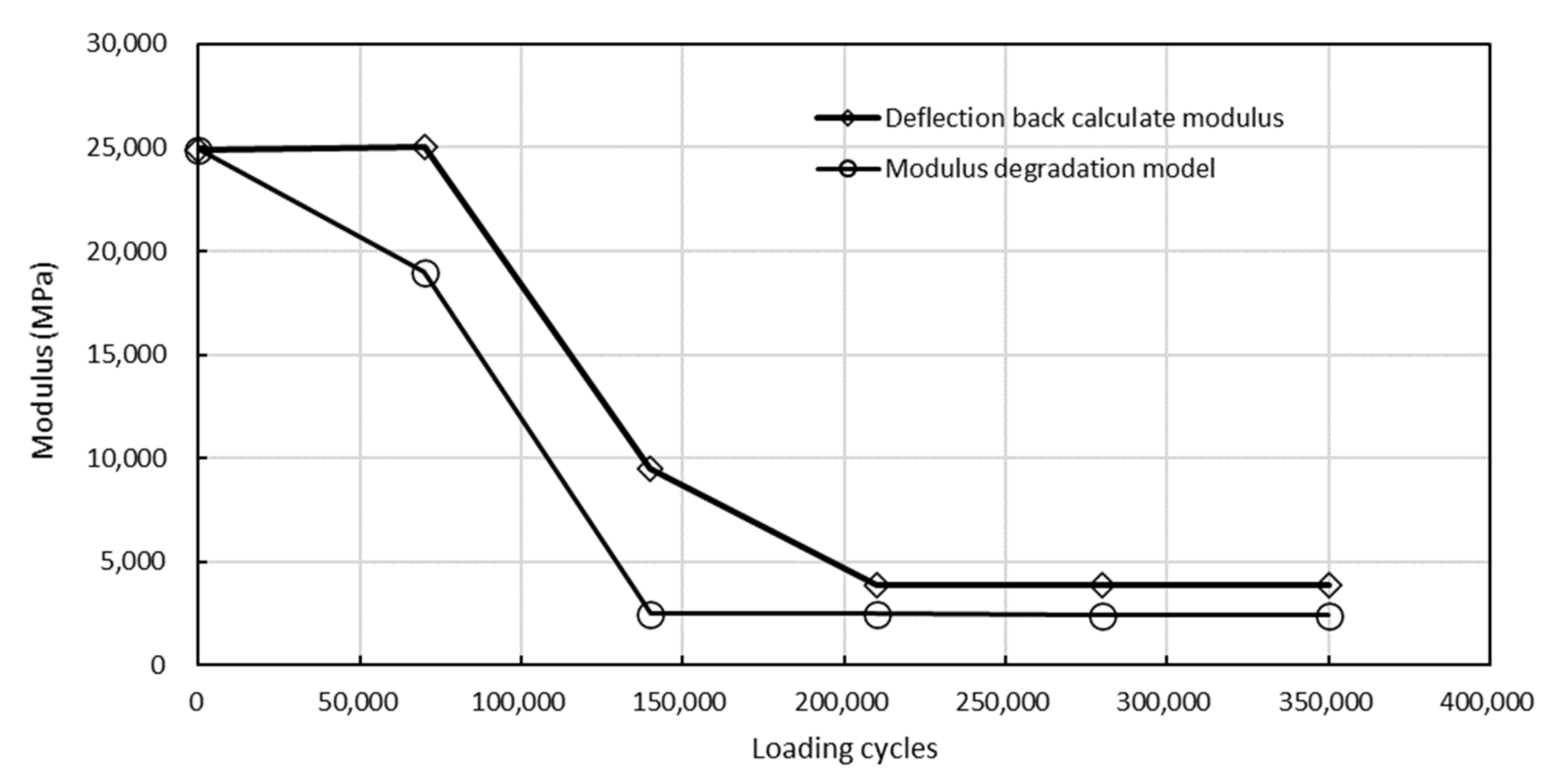

3.5.2. Modulus Attenuation Model Construction

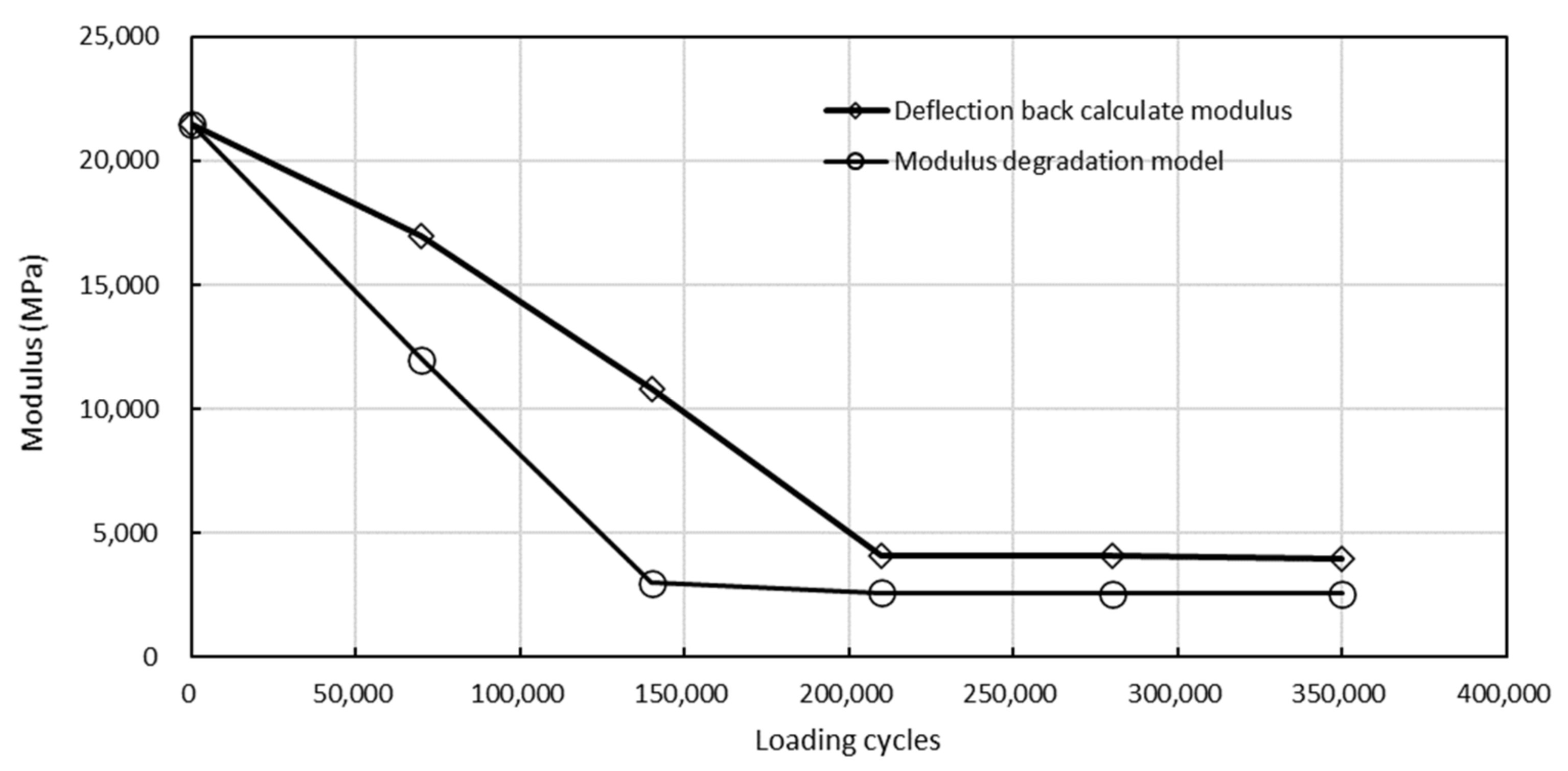

3.5.3. Modulus Attenuation Model Verification

4. Conclusions

- From the dynamic compression test, the LFSG had a 59% higher dynamic modulus than that of the CSG. The load frequency had less influence on the dynamic modulus of these two semi-rigid road base materials;

- The LFSG obtained a 19.7% higher flexural-bending strength than that of the CSG, which indicated its higher bearing capacity as a road base course material. The LFSG had the potential to resist flexural tensile failure as a road base course;

- The fatigue life of LFSG and CSG decreased with the increase of stress ratio. It is indicated that a higher traffic loading will accelerate the fatigue deterioration of the semi-rigid base course. Slightly higher fatigue life of LFSG indicated its better fatigue resistance than that of the CSG;

- A fatigue damage model was established by S-N curve. This model can be used to predict the fatigue life of CSG and LFSG materials under different stress–strength ratios; and

- A modulus degradation model was developed based on the incremental-recursive mechanics. This model can not only be used to predict the fatigue deterioration of semi-rigid materials under different stress levels, but is also able to calculate the current bending elastic modulus based on the initial modulus value.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, J.Z.; Li, P.Z.; Liang, M.; Jiang, H.G.; Yao, Z.Y.; Zhang, X.M.; Yu, S. Utilization of red mud as an alternative mineral filler in asphalt mastics to replace natural limestone powder. Constr. Build. Mater. 2020, 237, 117821. [Google Scholar] [CrossRef]

- Zhang, J.Z.; Sun, C.J.; Li, P.Z.; Liang, M.; Jiang, H.G.; Yao, Z. Experimental study on rheological properties and moisture susceptibility of asphalt mastic containing red mud waste as a filler substitute. Constr. Build. Mater. 2019, 211, 159–166. [Google Scholar] [CrossRef]

- Zhang, J.Z.; Sun, H.; Jiang, H.G.; Xu, X.B.; Liang, M.; Hou, Y.; Yao, Z. Experimental assessment of reclaimed bitumen and RAP asphalt mixtures incorporating a developed rejuvenator. Constr. Build. Mater. 2019, 215, 660–669. [Google Scholar] [CrossRef]

- Li, S.L.; Wu, G.M.; Wu, H.S. Study on acoustic emission characteristics of a semirigid base of dense skeleton type during complete uniaxial compression tests. Adv. Mater. Sci. Eng. 2016, 6, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Xuan, D.X.; Houben, L.J.M.; Molenaar, A.A.A.; Shui, Z.H. Mechanical properties of cement-treated aggregate material-A review. Mater. Design 2012, 33, 496–502. [Google Scholar] [CrossRef]

- Huang, B.; Dong, Q.; He, W. Laboratory evaluation of reclaimed asphalt pavement used as unbound base material. In Proceedings of the 87th Annual Meeting of Transportation Research Board 2008, National Research Council, Washington, DC, USA, 13–17 January 2008. [Google Scholar]

- Xuan, D.X.; Molenaar, A.A.A.; Houben, L.J.M. Shrinkage cracking of cement treated demolition waste as a road base. Mater. Struct. 2016, 49, 631–640. [Google Scholar] [CrossRef]

- Fallon, E.; McNally, C.; Gibney, A. Evaluation of fatigue resistance in asphalt surface layers containing reclaimed asphalt. Constr. Build. Mater. 2016, 128, 77–87. [Google Scholar] [CrossRef]

- Moghaddam, T.B.; Karim, M.R.; Abdelaziz, M. A review on fatigue and rutting performance of asphalt mixes. Sci. Res. Essays 2011, 6, 670–682. [Google Scholar] [CrossRef]

- Underwood, B.S.; Guido, Z.; Gudipudi, P.; Feinberg, Y. Increased costs to US pavement infrastructure from future temperature rise. Nat. Clim. Change 2017, 7, 704–710. [Google Scholar] [CrossRef]

- Micaelo, R.; Pereira, A.; Quaresma, L.; Cidade, M.T. Fatigue resistance of asphalt binders: Assessment of the analysis methods in strain-controlled tests. Constr. Build. Mater. 2015, 98, 703–712. [Google Scholar] [CrossRef]

- Sheng, Y.P.; Li, H.B.; Zhao, H.S.; Chang, M.F. Effect on mechanical behavior of asphalt pavement structure based on semi-rigid base modulus attenuation. J. Hebei University of Tech. 2016, 45, 101–107. [Google Scholar]

- Sheng, Y.P.; Chen, S.F.; Wang, D.; Wang, L.B. Pore water pressure characteristics of semi-rigid base for cement concrete pavement. J. Transp. Eng. 2012, 12, 6–12. [Google Scholar]

- Wang, Y.Q.; Tan, Y.Q.; Guo, M.; Liu, Z.Y.; Wang, X.L. Study on the dynamic compressive resilient modulus and frost resistance of semi-rigid base materials. Road Mater. Pavement 2017, 18, 259–269. [Google Scholar] [CrossRef]

- Yao, K.; Chen, Q.; Xiao, H.; Liu, Y.; Lee, F.H. Small-strain shear modulus of cement-treated marine clay. J. Mater. Civil Eng. 2020, 32, 04020114. [Google Scholar] [CrossRef]

- Yao, K.; Li, N.; Chen, D.H.; Liu, Y. Generalized hyperbolic formula capturing curing period effect on strength and stiffness of cemented clay. Constr. Build. Mater. 2019, 199, 63–71. [Google Scholar] [CrossRef]

- Yao, K.; Chen, Q.; Ho, J.; Xiao, H.; Lee, F.H. Strain-dependent shear stiffness of cement-treated marine clay. J. Mater. Civil Eng. 2018, 30, 04018255. [Google Scholar] [CrossRef]

- Zhou, H.; Sha, A.M. Analysis on the influence of material composition on semi-rigid base fatigue property. J. Wuhan University of Tech. 2012, 34, 41–45. [Google Scholar] [CrossRef]

- Sha, A.M.; Jia, K.; Li, X.G. Fatigue performances of semi-rigid base course materials. J. Transp. Eng. 2009, 9, 29–33. [Google Scholar] [CrossRef] [Green Version]

- Standard, No. JTG E30-2005; Test Methods of Cement and Concrete for Highway Engineering. Renmin Communication Press: Beijing, China, 2005.

- Standard, No. JTG E51-2009; Test Methods of Materials Stabilized with Inorganic Binders for Highway Engineering. Renmin Communication Press: Beijing, China, 2009.

- Standard No. JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Renmin Communication Press: Beijing, China, 2011.

- Standard, No. JTG D50-2017; Specifications for Design of Highway Asphalt Pavement. Renmin Communication Press: Beijing, China.

- Ozer, H. Prediction of pavement fatigue cracking at an accelerated testing section using asphalt mixture performance tests. Int. J. Pavement Eng. 2018, 9, 264–278. [Google Scholar] [CrossRef]

- Lv, S.T.; Xia, C.D.; Liu, H.F.; You, L.Y.; Qu, F.T.; Zhong, W.L.; Yang, Y.; Washko, S. Strength and fatigue performance for cement-treated aggregate base materials. Int. J. Pavement Eng. 2019, 22, 690–699. [Google Scholar] [CrossRef]

- Ma, Y. The bending fatigue performance of cement-stabilized aggregate reinforced with polypropylene filament fiber. Constr. Build. Mater. 2015, 83, 230–236. [Google Scholar] [CrossRef]

- Zhang, J.P.; Cu, S.C.; Cai, J.; Pei, J.Z.; Jia, Y.S. Life-cycle reliability evaluation of semi-rigid materials based on modulus degradation model. KSCE J. Civ. Eng. 2018, 22, 2043–2054. [Google Scholar] [CrossRef]

- Xue, J.; Jiang, Y. Analysis on the fatigue properties of vertical vibration compacted lime-fly ash-stabilized macadam. Constr. Build. Mater. 2017, 155, 531–541. [Google Scholar] [CrossRef]

- ARA, Inc. ERES Consultants Division, Guide for Mechanistic-Empirical design of new and rehabilitated pavement structure; NCHRP 1-37A Final Report; ARA, Inc.: Villa Park, IL, USA, 2004. [Google Scholar]

- ARA, Inc. ERES Division. Guide for Mechanistic-Empirical Design of New and Rehabilitated Pavement Structures 2003; ARA, Inc.: Villa Park, IL, USA, 2003. [Google Scholar]

- Kachanov, L.M. Mechanics of Elastic Stability; Martinus Nijhoff Publishers: Leiden, The Netherlands, 1986. [Google Scholar]

- Li, S.L.; Wu, G.M.; Wu, H.S. Acoustic emission characteristics of semi-rigid bases with three moisture conditions during bending tests. Road Mater. Pavement 2019, 20, 187–198. [Google Scholar] [CrossRef]

- Naser, M.Z.; Alavi, A.H. Error Metrics and Performance Fitness Indicators for Artificial Intelligence and Machine Learning in Engineering and Sciences. Archit. Struc. Constr. 2021, 1–19. [Google Scholar] [CrossRef]

| Inspection Items | Test Results | Technical Requirement | ||

|---|---|---|---|---|

| Fineness (%) | Qualified | ≤10 | ||

| Water quantity for standard consistence (%) | 28 | Actual measurement | ||

| Stability (Standardized Approach) | Qualified | ≤5 mm | ||

| Setting Time (min) | Initial setting | 210 | ≥45 min | |

| Final setting | 280 | ≤12 h | ||

| Cement mortar strength (MPa) | Compressive strength | 3 d | 18.9 | ≥16.0 |

| 28 d | 43.1 | ≥42.5 | ||

| Bending Strength | 3 d | 4.5 | ≥3.5 | |

| 28 d | 8.23 | ≥6.5 | ||

| Inspection Items | Test Results | Test Method |

|---|---|---|

| CaO content (%) | 52.6 | T 0811-1994 |

| MgO content (%) | 3.79 | T 0812-1994 |

| CaO + MgO content (%) | 56.4 | T 0813-1994d |

| Inspection Items | Test Results | Technical Requirement | |

|---|---|---|---|

| Loss on ignition (%) | 3.32 | ≤20 | |

| Passing rate (%) | 0.3 mm | 99.20 | ≥90 |

| 0.075 mm | 72.30 | ≥70 | |

| Chemical component (%) | SiO2 | 56.62 | ∑ > 70 |

| Fe2O3 | 7.05 | ||

| Al2O3 | 27.40 | ||

| Inspection Items | Test Result | Technical Requirement | |

|---|---|---|---|

| Fine Aggregate | Coarse Aggregate | ||

| Specific gravity (g/cm3) | 2.73 | 2.73 | ≥2.6 |

| Water absorption (%) | 0.75 | 0.38 | ≤2.0 |

| LA Abrasion loss (%) | - | 17.60 | ≤28 |

| Crushing value (%) | - | 14.30 | ≤26 |

| Sieve Pit (mm) | 31.5 | 26.5 | 19 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.075 |

|---|---|---|---|---|---|---|---|---|---|

| Composed gradation | 100.0 | 97.2 | 68.1 | 33.5 | 15.6 | 10.2 | 8.1 | 6.1 | 2.2 |

| Lower limit | 100 | 95 | 48 | 24 | 11 | 6 | 2 | 0 | 0 |

| Upper limit | 100 | 100 | 68 | 34 | 21 | 16 | 12 | 6 | 3 |

| Sieve Pit (mm) | 31.5 | 19 | 9.5 | 4.75 | 2.36 | 0.6 | 0.075 |

|---|---|---|---|---|---|---|---|

| Composed gradation | 100.0 | 81.1 | 50.5 | 26.4 | 17.6 | 9.0 | 3.1 |

| Lower limit | 100 | 68 | 38 | 22 | 16 | 8 | 0 |

| Upper limit | 100 | 86 | 58 | 32 | 28 | 15 | 3 |

| Stabilized Aggregate | Mixture Ratio (by Weight) | Moisture Content (%) | Maximum Dry Density (g/m3) | 7d Compressive Strength (MPa) |

|---|---|---|---|---|

| LFSG | lime: fly ash: aggregate = 6: 12: 82 | 6.20 | 2.13 | 0.95 |

| CSG | cement: aggregate = 4.5: 100 | 5.30 | 2.33 | 6.70 |

| Quadratic Sum | Degree of Freedom | Standard Deviation | Statistics F | Confidence Interval Fα (1, 20) α = 0.01 | |

|---|---|---|---|---|---|

| Regression | 12.40 | 1 | |||

| Residue | 1.12 | 20 | 0.24 | 219.75 | 8.10 |

| Sum | 13.53 | 21 | Significant |

| Quadratic Sum | Degree of Freedom | Standard Deviation | Statistics F | Confidence Interval Fα (1, 12) α = 0.01 | |

|---|---|---|---|---|---|

| Regression | 3.19 | 1 | |||

| Residue | 0.21 | 12 | 0.13 | 185.97 | 9.33 |

| Sum | 3.39 | 13 | Significant |

| Quadratic Sum | Degree of Freedom | Standard Deviation | Statistics F | Confidence Interval Fα (1, 20) α = 0.01 | |

|---|---|---|---|---|---|

| Regression | 19.16 | 1 | |||

| Residue | 5.63 | 20 | 0.53 | 68.09 | 8.10 |

| Sum | 13.53 | 21 | Significant |

| Quadratic Sum | Degree of Freedom | Standard Deviation | Statistics F | Confidence Interval Fα (1, 12) α = 0.01 | |

|---|---|---|---|---|---|

| Regression | 3.20 | 1 | |||

| Residue | 0.19 | 12 | 0.13 | 203.64 | 9.33 |

| Sum | 3.39 | 13 | Significant |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, L.; Yu, S.; Zhu, Y.; Zhang, X.; Wu, W.; Sun, Q.; Chen, T.; Wang, X.; Wei, J. Assessment of Modulus Attenuation of Cement and Lime-Fly Ash Semi-Rigid Road Base Materials. Coatings 2022, 12, 216. https://doi.org/10.3390/coatings12020216

Chen L, Yu S, Zhu Y, Zhang X, Wu W, Sun Q, Chen T, Wang X, Wei J. Assessment of Modulus Attenuation of Cement and Lime-Fly Ash Semi-Rigid Road Base Materials. Coatings. 2022; 12(2):216. https://doi.org/10.3390/coatings12020216

Chicago/Turabian StyleChen, Luchuan, Sixin Yu, Ying Zhu, Xiaomeng Zhang, Wenjuan Wu, Qiang Sun, Tingting Chen, Xiaoyan Wang, and Jincheng Wei. 2022. "Assessment of Modulus Attenuation of Cement and Lime-Fly Ash Semi-Rigid Road Base Materials" Coatings 12, no. 2: 216. https://doi.org/10.3390/coatings12020216

APA StyleChen, L., Yu, S., Zhu, Y., Zhang, X., Wu, W., Sun, Q., Chen, T., Wang, X., & Wei, J. (2022). Assessment of Modulus Attenuation of Cement and Lime-Fly Ash Semi-Rigid Road Base Materials. Coatings, 12(2), 216. https://doi.org/10.3390/coatings12020216