A Method for Calculating the Reliability of Welded Metal Bellows for Mechanical Seals

Abstract

:1. Introduction

2. Material and Methods

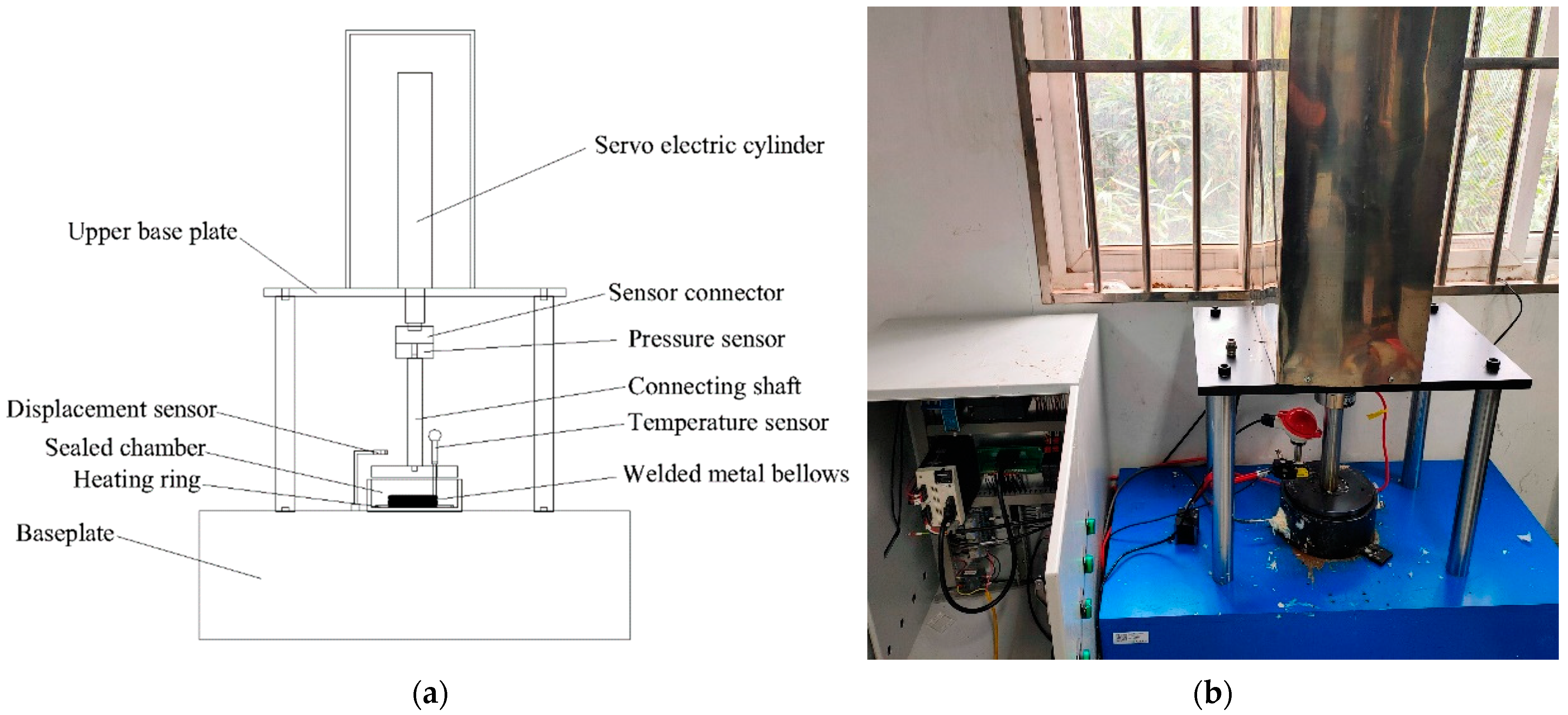

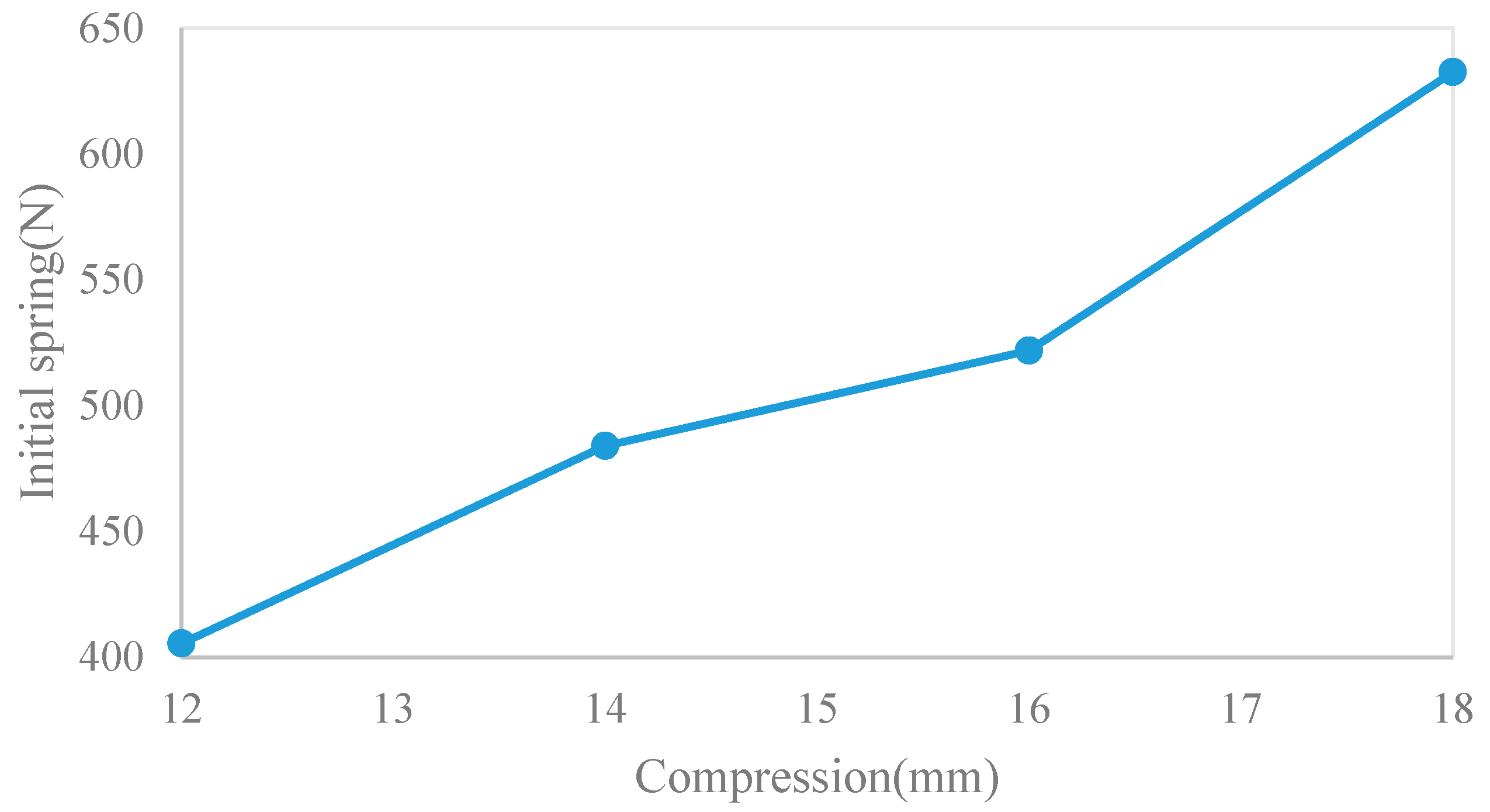

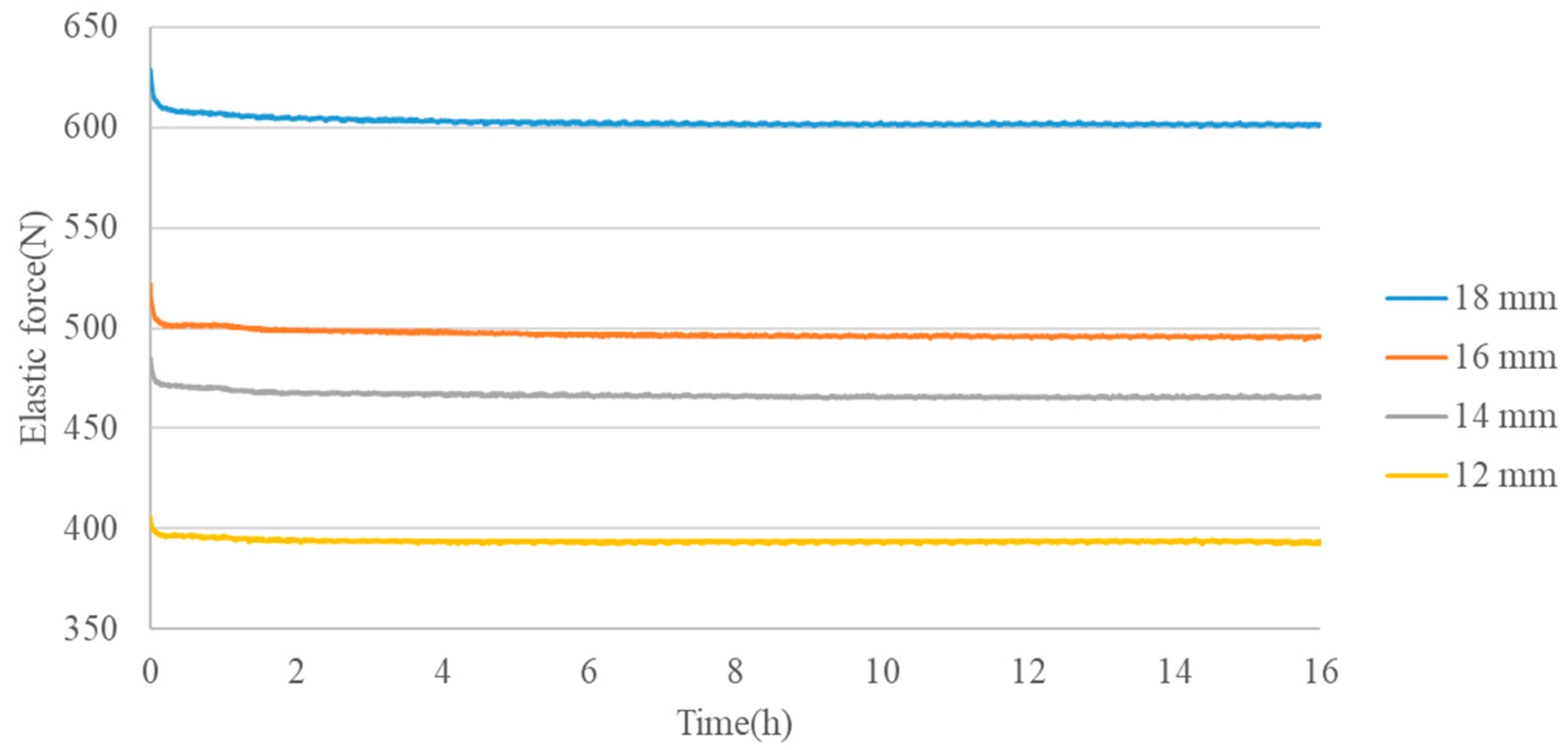

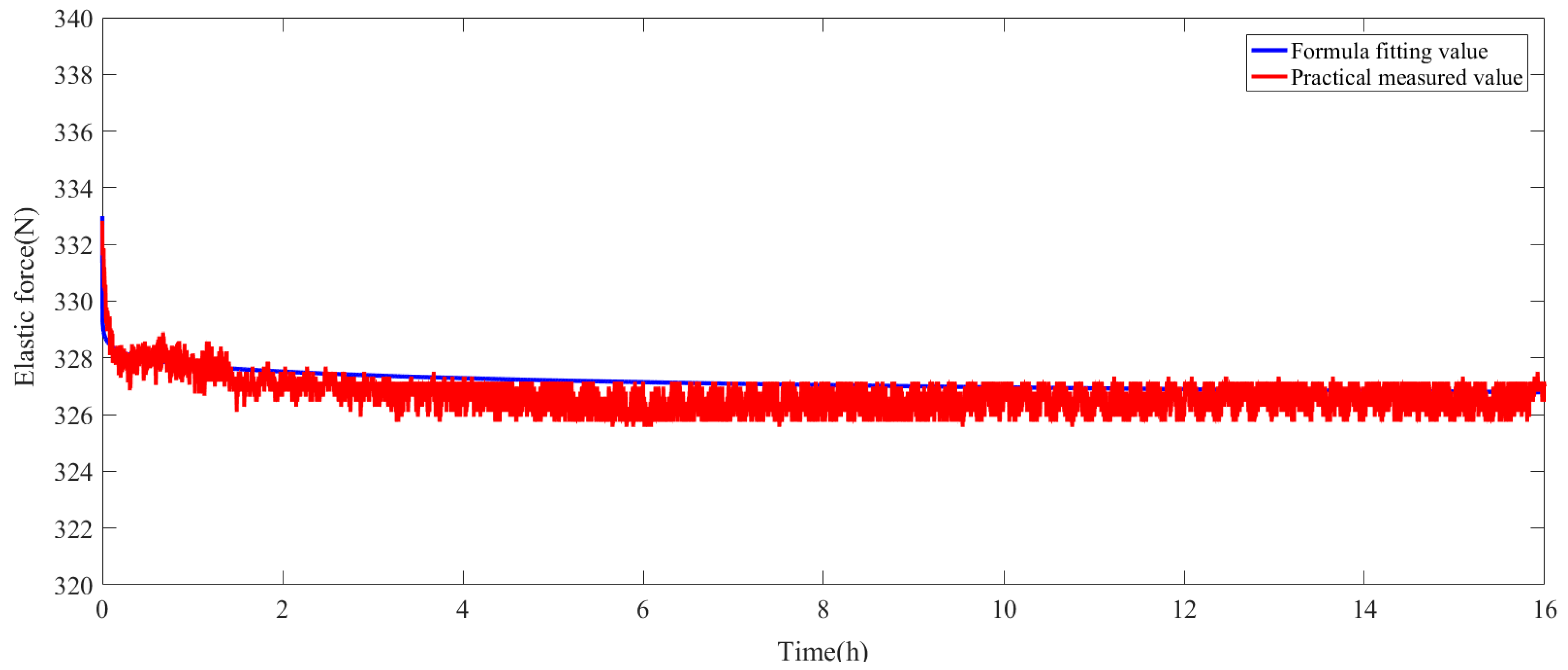

2.1. Stress Relaxation Tests

2.2. Reliability Calculation

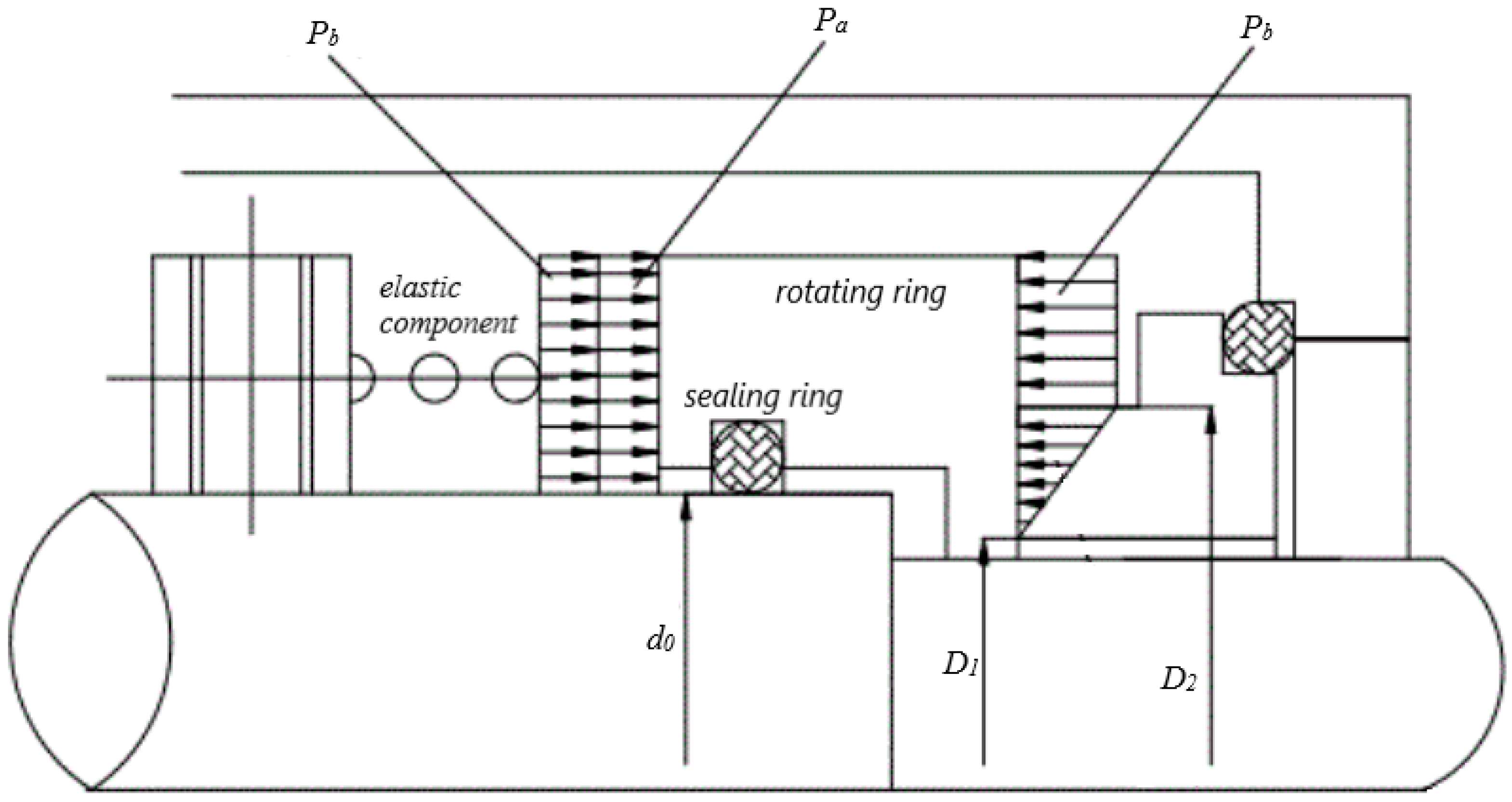

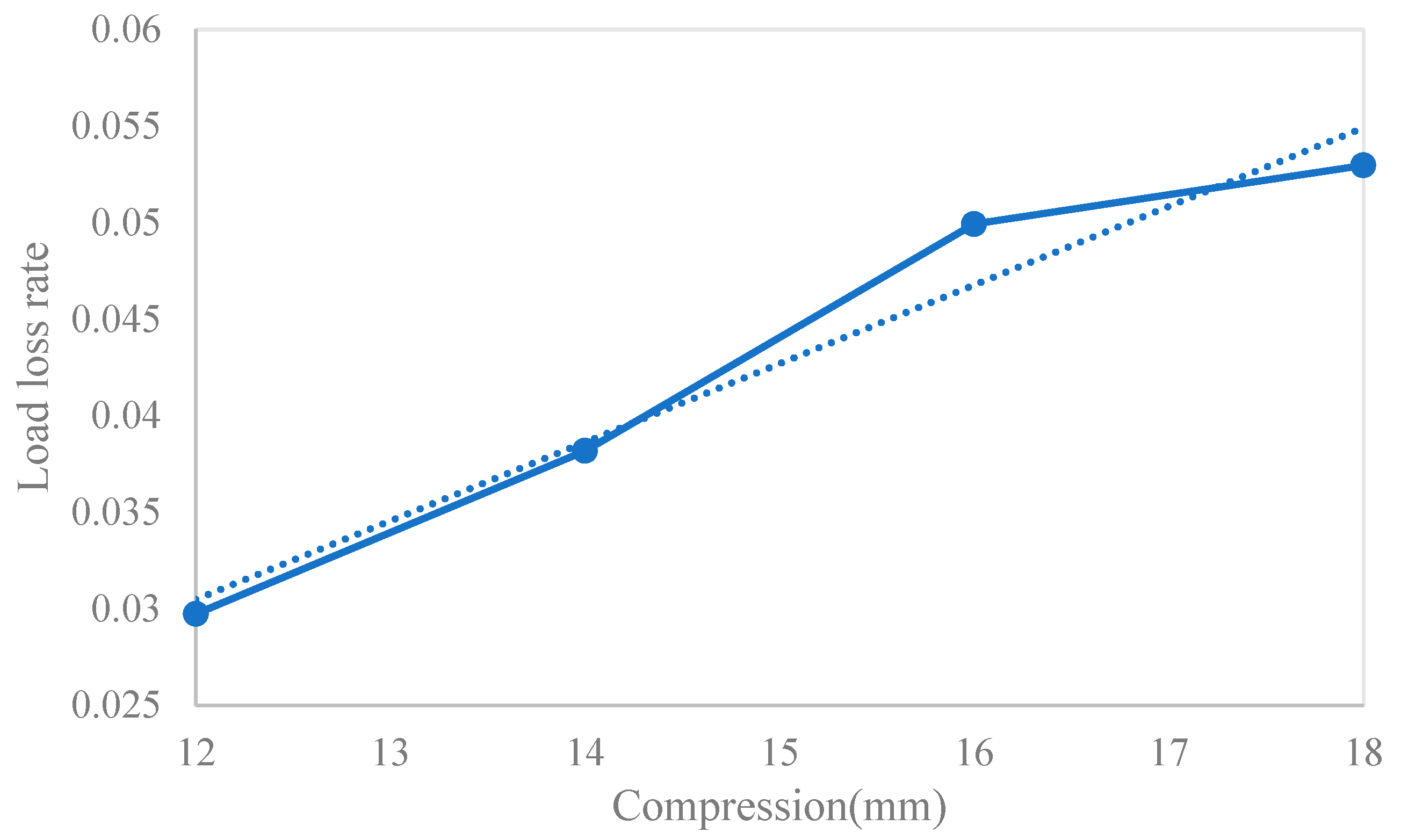

2.2.1. Determination of Elastic Force Loss Range of Welded Metal Bellows

2.2.2. Reliability Calculation Based on the Central Point Method

3. Results and Discussion

4. Conclusions

- The stress relaxation degree of welded metal bellows becomes more significant with the increase in initial displacement load. Based on the stress relaxation test data, the equation of bellows loss is obtained.

- According to the relationship between the seal face pressure of mechanical seal and the axial elasticity of welded metal bellows, it can analyze the elastic force loss range of welded metal bellows under different working conditions.

- The reliability of welded metal bellows under specific working conditions can be obtained quickly by using the central point method, and the results have certain reliability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| F | Residual elastic force |

| t | time |

| P | Initial elastic force |

| D1 | Inner diameter of seal ring contact face |

| D2 | outer diameter of seal ring contact face |

| d0 | axle diameter |

| Pa | pressure on bellows |

| Pb | medium pressure |

| λ | constant |

| Z | Function function |

| β | Reliability index |

| Pf | Reliability probability |

| Pr | Effective probability |

| ΔP | Load loss |

References

- Fei, M. Discussion on the mechanical seal of external moving ring. J. Manag. Technol. SME 2017, 04, 177–178. [Google Scholar]

- Plumridge, J.M.; Ketch, D.P.; Straszewski, C.J. Mechanical seals: The current status of metal bellows sealing. Tribol. Int. 1986, 19, 193–197. [Google Scholar] [CrossRef]

- Tian, X.F. Comparative Analysis of Dynamic characteristics and Fatigue Characteristics of Metal Bellows in Mechanical Seals. Master’s Thesis, Xinjiang University, Urumqi, China, 2018. [Google Scholar]

- Zhou, C. Theoretical Calculation and Experimental Study on Stiffness and Fatigue Life of Bellows in Automobile Exhaust System. Master’s Thesis, Nanjing University of Science and Technology, Nanjing, China, 2018. [Google Scholar]

- Yang, W.J.; Hao, M.M.; Ren, B.J.; Wang, X.Y. Analysis of the Elastic-Loss Feature of welded Metal Bellows for High Temperature Mechanical Seals. J. Lanzhou Univ. Technol. 2016, 4, 46–50. [Google Scholar]

- Wen, Y.Z.; Xue, F.T.; Tian, X.F. Structural and thermal coupling failure analysis of mechanical seal bellows under extreme conditions. Fluid Mach. 2018, 46, 5. [Google Scholar]

- An, Y.S.; Cai, R.L.; Liu, W.D. Study on the mechanism of elastic loss of welded metal bellows: Stress force relaxation. Lubr. Seal. 2002, 1, 7–9. [Google Scholar]

- Kraus, H. Creep Analysis; John Wiley & Sons: Hoboken, NJ, USA, 1980. [Google Scholar]

- Ma, Y.M. Study on mechanism of projectile loss of welded metal bellows based on thin shell theory. Petrochem. Equip. 2020, 19, 17–22. [Google Scholar]

- Li, X.; Yang, B.F.; Zheng, G.Y.; Dai, X.W. Failure analysis of metal bellows mechanical seal for high temperature heavy oil pump. Chem. Mach. 2011, 3, 367–369. [Google Scholar]

- Hao, Z.L.; Luo, J.T.; Chen, L.H.; Cai, Y.; Chen, Y.H.; Cheng, M.Z. Failure mechanism of unequal parameters metal bellows under repeated bending process. Eng. Fail. Anal. 2021, 129, 105671. [Google Scholar] [CrossRef]

- Cao, W.H.; Yu, X.C. Fatigue life reliability analysis of bellows. Chem. Autom. Instrum. 2010, 37, 56–58. [Google Scholar]

- Xie, J.; Chen, Y.L.; Chen, H.J. Probabilistic finite element analysis of structural reliability of metal bellows. Chem. Eng. Equip. 2019, 271, 210–212. [Google Scholar]

- Wang, K. Analysis of Stress Relaxation Characteristics and Service Life Prediction of Spiral Compression Spring. Master’s Thesis, Xi’an University of Technology, Xi’an, China, 2019. [Google Scholar]

- Ding, W.; Ma, Y.M.; Sun, S. Development of the test device for elasticity loss of the welded metal bellows in mechanical seal. Mach. Des. Manuf. Eng. 2016, 45, 63–66. [Google Scholar]

- Chen, W.; Wang, X.; Yan, Y.; Sumigawac, T.; Kitamura, T.; Feng, M.; Xuan, F. Bending stress relaxation of microscale single-crystal copper at room temperature: An in situ SEM study. Eur. J. Mech. -A/Solids 2021, 90, 104377. [Google Scholar] [CrossRef]

- Tang, Y. Analysis of influencing factors of mechanical seal failure. Sci. Technol. Vis. 11 2017, 283, 71. [Google Scholar]

- Zhang, B.R. Cause analysis and improvement of mechanical seal failure of alkali pump. China Equip. Eng. 2021, S2, 114–115. [Google Scholar]

- Zou, X.H.; Wang, J. Analysis of factors affecting performance of mechanical seal’s end-face characteristics. Top. Chem. Mater. Eng. 2018, 1, 233–235. [Google Scholar]

- Freudenthal, A.M. The safety of structures. J. Trans. Am. Soc. Civ. Eng. 1947, 112, 125–159. [Google Scholar] [CrossRef]

- Wu, Z.Y.; Shi, Q.; Guo, Q.Q.; Chen, J.K. Cst-based first order second moment method for probabilistic slope stability analysis. Comput. Geotech. 2017, 85, 51–58. [Google Scholar] [CrossRef]

- Li, J.; Guo, Z.P.; Guo, J.X. Reliability analysis of bolt support in underground roadway based on central point method. Coal Mine Saf. 2019, 50, 243–246, 250. [Google Scholar]

- Yin, X.Y. Effect of Temperature and Stress Acceleration Test on Stress Relaxation Behavior of Spiral Compression Spring. Master’s Thesis, Tianjin University, Tianjin, China, 2012. [Google Scholar]

- GB/T 33509-2017General Specifications for Mechanical Seals, Standardization Administration of the P.R.C: Beijing, China, 2017.

- API 682-2002Pump—Shaft Seal Systems for Centrifugal Pumps and Rotary Pumps Technical Specifications, American Petroleum Institute: Washington, DC, USA, 2014.

- Zhou, J.F.; Gu, B.Q. Reliability evaluation method of mechanical seals based on monte carlo method. Lubr. Eng. 2006, 2, 102–104, 135. [Google Scholar]

| Initial Elastic Force | 405.5 | 484.9 | 521.8 | 632.5 |

|---|---|---|---|---|

| B | −10.33 | −16.51 | −22.05 | −26.71 |

| n | 0.065 | 0.058 | 0.059 | 0.061 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Ma, C.; Sun, J.; Zhang, Y.; Ni, X. A Method for Calculating the Reliability of Welded Metal Bellows for Mechanical Seals. Coatings 2022, 12, 175. https://doi.org/10.3390/coatings12020175

Zhang Z, Ma C, Sun J, Zhang Y, Ni X. A Method for Calculating the Reliability of Welded Metal Bellows for Mechanical Seals. Coatings. 2022; 12(2):175. https://doi.org/10.3390/coatings12020175

Chicago/Turabian StyleZhang, Zhong, Chenbo Ma, Jianjun Sun, Yuyan Zhang, and Xingya Ni. 2022. "A Method for Calculating the Reliability of Welded Metal Bellows for Mechanical Seals" Coatings 12, no. 2: 175. https://doi.org/10.3390/coatings12020175

APA StyleZhang, Z., Ma, C., Sun, J., Zhang, Y., & Ni, X. (2022). A Method for Calculating the Reliability of Welded Metal Bellows for Mechanical Seals. Coatings, 12(2), 175. https://doi.org/10.3390/coatings12020175