In Situ Deposition of Amorphous Al2O3-GAP Ceramic Coating with Excellent Microstructure Stability and Uniformity via Atmospheric Plasma Spraying

Abstract

:1. Introduction

- High-temperature calcination for solid-phase reaction (direct heat treatment at 1673~1873 K or step-by-step heating cycle calcination at 1173~1773 K), roughened the surface of the spray powder and resulted in the agglomeration effect of powder, which brought some negative effects on the powder sphericity and fluidity [24]. The step-by-step heating cycle calcination process was very cumbersome, which was difficult to control powder quality and reliability. Moreover, the time and cost were greatly increased;

- The plasma spheroidization process of the powder needed to be carried out to remove the unfavorable factors caused by high-temperature solid-phase reaction;

- Al2O3/YAG powders obtained by high-temperature solid-phase reaction may lead to gun blockage in the long-term plasma spraying process, which would be adverse to the uniformity of coating preparation.

2. Experimental Procedure

2.1. Feedstock Preparation and Coating Deposition

2.2. Microstructure and Property Characterization

3. Results and Discussion

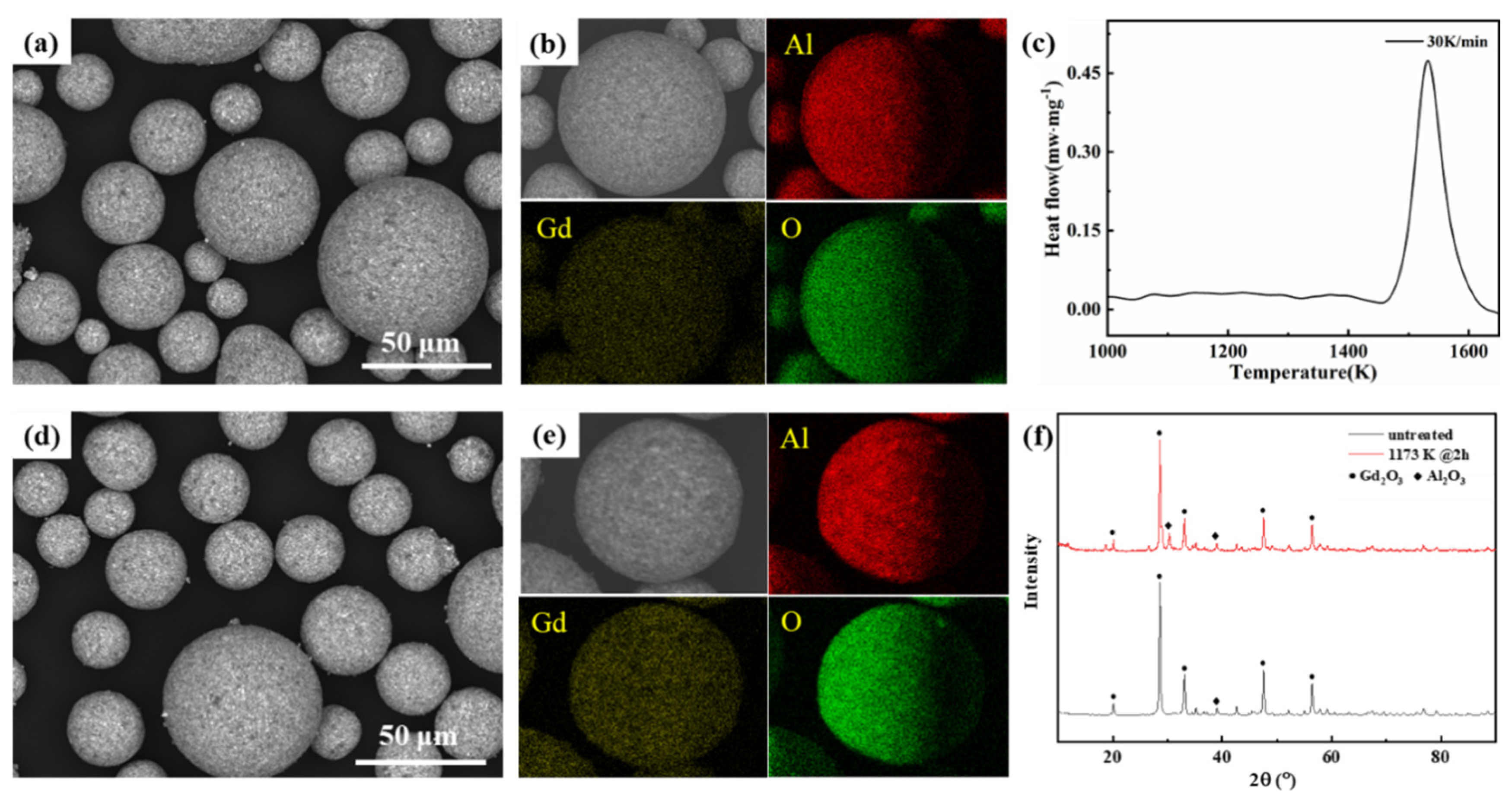

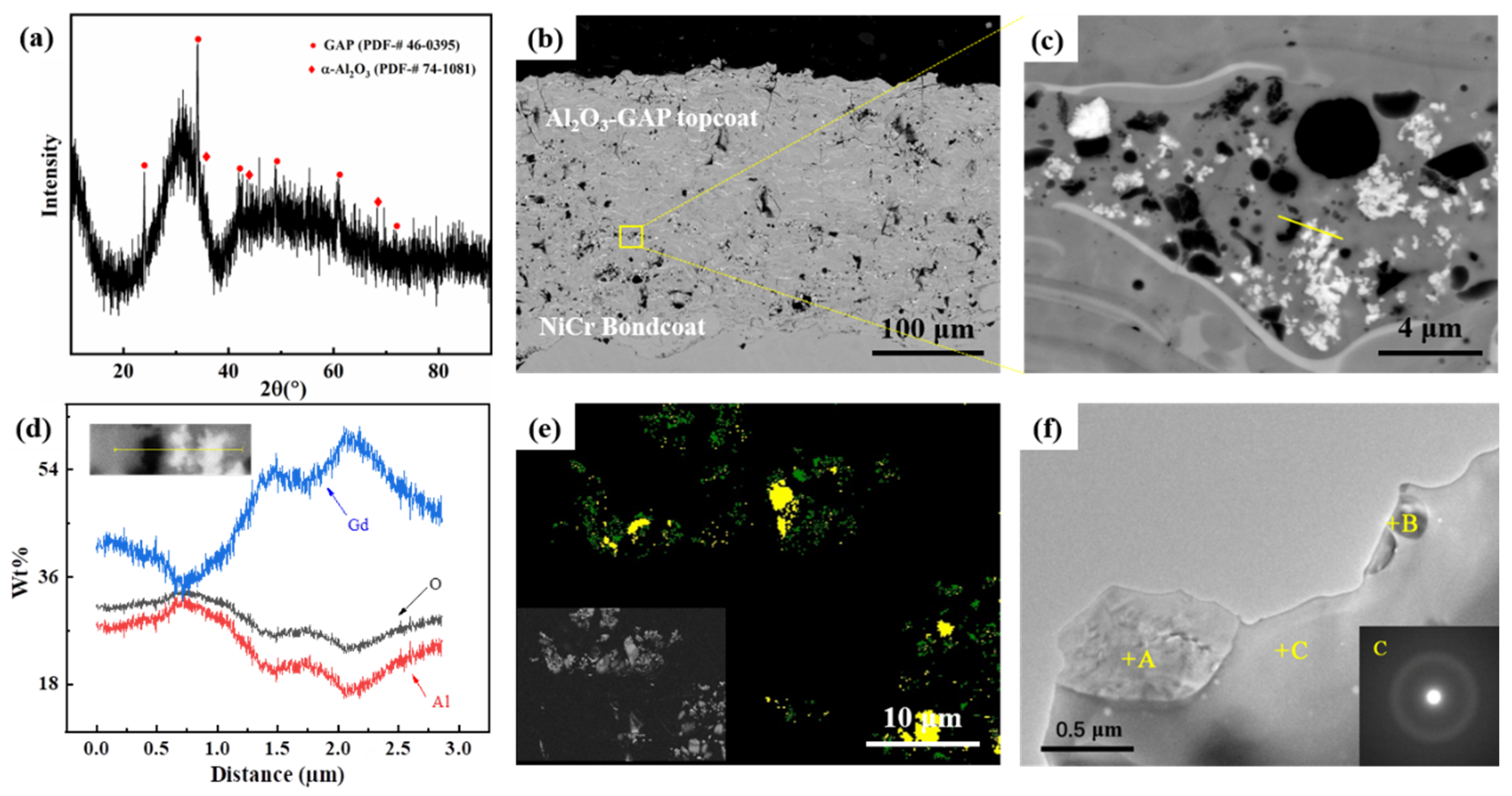

3.1. Structural Characterization

3.2. Thermal Stability Analysis

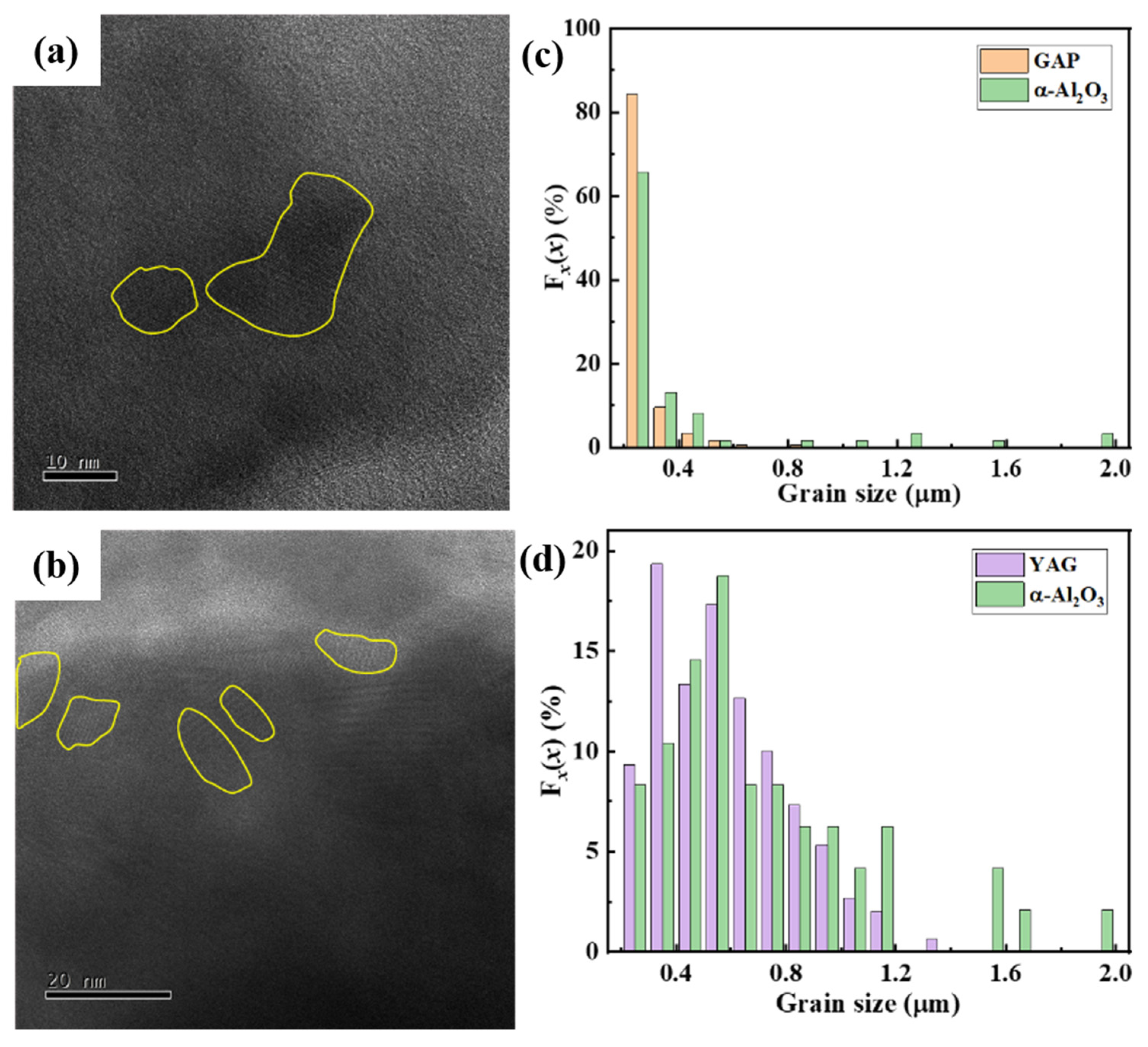

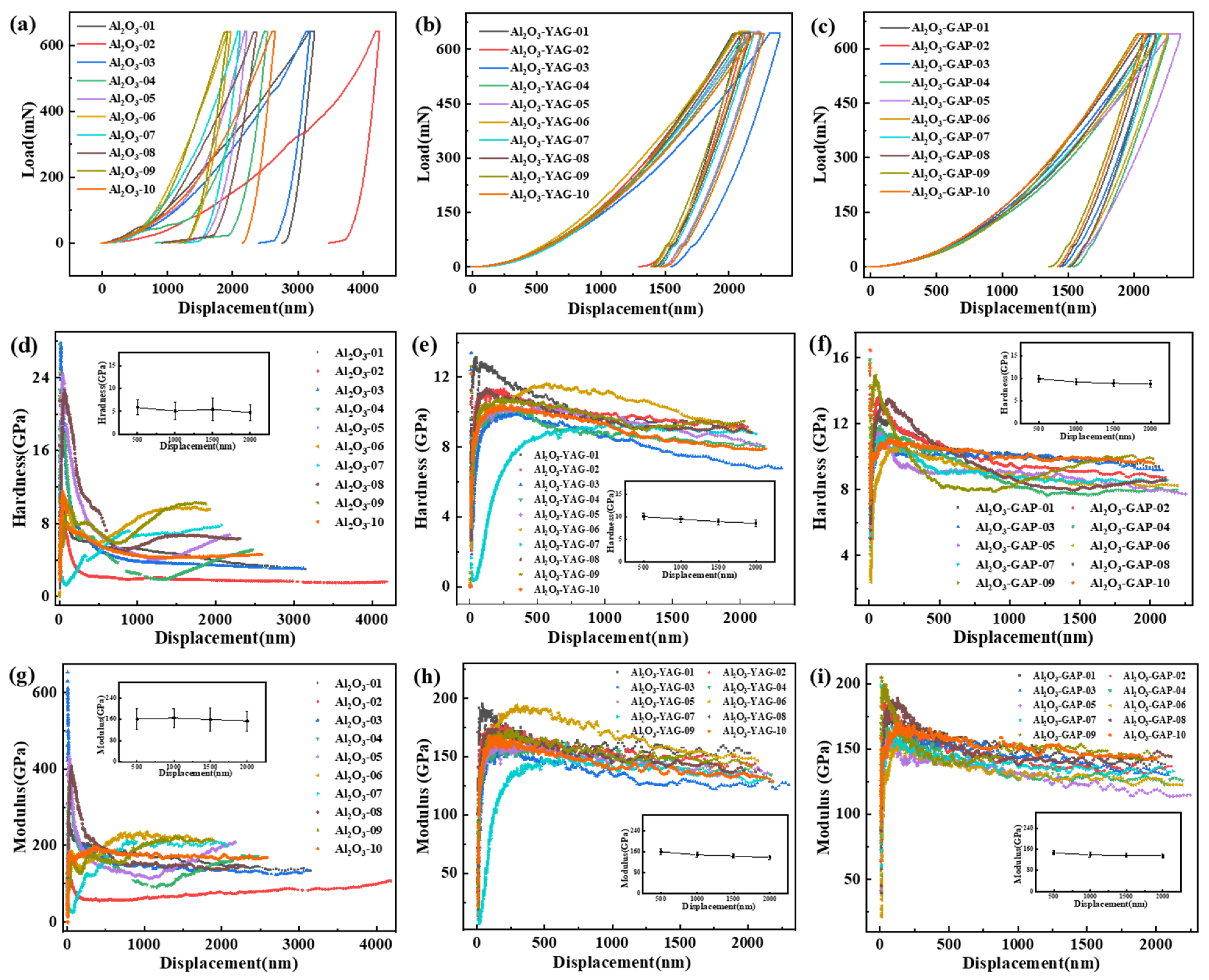

3.3. Microstructure and Mechanical Property Uniformity

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Fouvry, S.; Paulin, C. An effective friction energy density approach to predict solid lubricant friction endurance: Application to fretting wear. Wear 2014, 319, 211–226. [Google Scholar] [CrossRef]

- Wang, Y.A.; Li, J.X.; Yan, Y.; Qiao, L.J. Effect of pv factor on sliding friction and wear of copper-impregnated metallized carbon. Wear 2012, 289, 119–123. [Google Scholar] [CrossRef]

- Padture, N.P. Advanced structural ceramics in aerospace propulsion. Nat. Mater. 2016, 15, 804–809. [Google Scholar] [CrossRef] [PubMed]

- Padture, N.P.; Gell, M.; Jordan, E.H. Thermal Barrier Coatings for Gas-Turbine Engine Applications. Science 2002, 296, 280–284. [Google Scholar] [CrossRef] [PubMed]

- Hou, G.L.; An, Y.L.; Zhao, X.Q.; Zhou, H.D.; Chen, J.M. Effect of alumina dispersion on oxidation behavior as well as friction and wear behavior of HVOF-sprayed CoCrAlYTaCSi coating at elevated temperature up to 1000 degrees C. Acta Mater. 2015, 95, 164–175. [Google Scholar] [CrossRef]

- Zum Gahr, K.-H. Modeling and microstructural modification of alumina ceramic for improved tribological properties. Wear 1996, 200, 215–224. [Google Scholar] [CrossRef]

- Rao, K.P.; Ram, G.D.J.; Stucker, B.E. Improvement in corrosion resistance of friction stir welded aluminum alloys with micro arc oxidation coatings. Scr. Mater. 2008, 58, 998–1001. [Google Scholar] [CrossRef]

- Cheng, J.P.; Liu, T.; Zhang, J.; Wang, B.B.; Ying, J.; Liu, F.; Zhang, X.B. Influence of phase and morphology on thermal conductivity of alumina particle/silicone rubber composites. Appl. Phys. A 2014, 117, 1985–1992. [Google Scholar] [CrossRef]

- Hao, S.; Li, C.-J.; Yang, G.-J. Influence of Deposition Temperature on the Microstructures and Properties of Plasma-Sprayed Al2O3 Coatings. J. Therm. Spray Technol. 2011, 20, 160–169. [Google Scholar] [CrossRef]

- Dong, S.; Song, B.; Hansz, B.; Liao, H.; Coddet, C. Study on the Mechanism of Adhesion Improvement Using Dry-Ice Blasting for Plasma-Sprayed Al2O3 Coatings. J. Therm. Spray Technol. 2013, 22, 213–220. [Google Scholar] [CrossRef]

- Yin, Z.; Tao, S.; Zhou, X.; Ding, C. Microstructure and mechanical properties of Al2O3-Al composite coatings deposited by plasma spraying. Appl. Surf. Sci. 2008, 254, 1636–1643. [Google Scholar] [CrossRef]

- Wang, H.; Li, Y.; Zhu, T.; Sang, S.; Wang, Q. Microstructures and mechanical properties of Al2O3-C refractories with addition of microcrystalline graphite. Ceram. Int. 2014, 40, 11139–11148. [Google Scholar] [CrossRef]

- Chen, Y.; Samant, A.; Balani, K.; Dahotre, N.B.; Agarwal, A. Effect of laser melting on plasma-sprayed aluminum oxide coatings reinforced with carbon nanotubes. Appl. Phys. A 2009, 94, 861–870. [Google Scholar] [CrossRef]

- Yan, Y.; Han, Y.; Huang, J. Formation of Al2O3-ZrO2 composite coating on zirconium by micro-arc oxidation. Scr. Mater. 2008, 59, 203–206. [Google Scholar] [CrossRef]

- Saremi, M.; Valefi, Z. Thermal and mechanical properties of nano-YSZ-Alumina functionally graded coatings deposited by nano-agglomerated powder plasma spraying. Ceram. Int. 2014, 40, 13453–13459. [Google Scholar] [CrossRef]

- Goberman, D.; Sohn, Y.H.; Shaw, L.; Jordan, E.; Gell, M. Microstructure development of Al2O3-13wt.%TiO2 plasma sprayed coatings derived from nanocrystalline powders. Acta Mater. 2002, 50, 1141–1152. [Google Scholar] [CrossRef]

- Yang, K.; Feng, J.; Zhou, X.; Tao, S. In-situ formed γ-Al2O3 nanocrystals repaired and toughened Al2O3 coating prepared by plasma spraying. Surf. Coat. Technol. 2012, 206, 3082–3087. [Google Scholar] [CrossRef]

- Yang, K.; Zhou, X.; Zhao, H.; Tao, S. Microstructure and mechanical properties of Al2O3-Cr2O3 composite coatings produced by atmospheric plasma spraying. Surf. Coat. Technol. 2011, 206, 1362–1371. [Google Scholar] [CrossRef]

- Tao, S.; Yin, Z.; Zhou, X.; Ding, C. Sliding wear characteristics of plasma-sprayed Al2O3 and Cr2O3 coatings against copper alloy under severe conditions. Tribol. Int. 2010, 43, 69–75. [Google Scholar] [CrossRef]

- Yang, K.; Feng, J.; Rong, J.; Liu, C.; Tao, S.; Ding, C. In situ Formed α-Al2O3 Nanocrystals Repaired the Preexisting Microcracks in Plasma-Sprayed Al2O3 Coating via Stress-Induced Phase Transformation. J. Therm. Spray Technol. 2015, 25, 518–525. [Google Scholar] [CrossRef]

- Yang, K.; Rong, J.; Feng, J.; Zhuang, Y.; Tao, S.; Ding, C. In-situ fabrication of amorphous/eutectic Al2O3-YAG ceramic composite coating via atmospheric plasma spraying. J. Eur. Ceram. Soc. 2016, 36, 4261–4267. [Google Scholar] [CrossRef]

- Rong, J.; Yang, K.; Zhuang, Y.; Zhong, X.; Zhao, H.; Ni, J.; Tao, S.; Wang, L.; Ding, C. Non-isothermal crystallization kinetics of Al2O3-YAG amorphous ceramic coating deposited via plasma spraying. J. Am. Ceram. Soc. 2018, 101, 2888–2900. [Google Scholar] [CrossRef]

- Yang, K.; Rong, J.; Zhuang, Y.; Ni, J.; Yang, J.; Tao, S.; Shao, F.; Ding, C. Microstructure and High PV Wear Behavior of Novel Amorphous Al2O3-YAG Ceramic Coating Fabricated by Atmospheric Plasma Spraying. J. Therm. Spray Technol. 2019, 28, 803–825. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, K.; Rong, J.; Zhuang, Y.; Ai, Y.; Zhong, X.; Sheng, J.; Yang, H.; Ding, C. Study on Process Optimization of Sprayable Powders and Deposition Performance of Amorphous Al2O3-YAG Coatings. Coatings 2020, 10, 1158. [Google Scholar] [CrossRef]

- Henniche, A.; Ouyang, J.-H.; Ma, Y.-H.; Wang, Z.-G.; Wang, Y.-J.; Liu, Z.-G. Microstructure and mechanical properties of ceramics obtained from chemically co-precipitated Al2O3-GdAlO3 nano-powders with eutectic composition. Ceram. Int. 2017, 43, 6996–7001. [Google Scholar] [CrossRef]

- Waku, Y.; Nakagawa, N.; Wakamoto, T.; Ohtsubo, H.; Shimizu, K.; Kohtoku, Y. A ductile ceramic eutectic composite with high strength at 1873 K. Nature 1997, 389, 49–52. [Google Scholar] [CrossRef]

- Waku, Y. A New Ceramic Eutectic Composite with High Strength at 1873 K. Adv. Mater. 1998, 10, 615–617. [Google Scholar] [CrossRef]

- Voorhees, P.W. The theory of Ostwald ripening. J. Stat. Phys. 1985, 38, 231–252. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.-R.; Gao, Y.-L.; Ye, Y.-F.; Min, G.-H.; Chen, Y.; Teng, X.-Y. Crystallization kinetics of an amorphous Zr-Cu-Ni alloy: Calculation of the activation energy. J. Alloys Compd. 2003, 353, 200–206. [Google Scholar] [CrossRef]

- Tang, L.; Peng, K.; Wu, Y.; Zhang, W. Effect of ion bombardment on the crystallization kinetics of FeSiNbBCu amorphous alloys. J. Alloys Compd. 2017, 695, 2136–2141. [Google Scholar] [CrossRef]

- Fan, H.F.; Yan, H.J.; Zhang, Y.; Liu, Z.L.; Liang, G.F. Crystallization kinetics of electroless Ni-P and Ni-P-Cg composite coating on titanium. Chin. J. Inorg. Chem. 2008, 24, 403–408. [Google Scholar]

- Shi, H.Y.; Deng, J.; Zhang, Y.Q.; Dong, J. Preparation of amerphous alloys in cobalt with lanthanum, cerium by electrodeposition and its crystallization kinetics. J. Inorg. Mater. 2002, 17, 1124–1128. [Google Scholar]

- Fang, Y.; Peng, G.; Ghafari, M.; Feng, T. Thermodynamic properties and crystallization kinetics of the Co90Sc10 amorphous alloy. Intermetallics 2018, 96, 58–62. [Google Scholar] [CrossRef]

- Salam, M.N.A.-E.; Shaaban, E.R.; Benabdallah, F.; Hussein, A.M.A.; Mohamed, M. Experimental and theoretical studies of glass and crystallization kinetics of semiconducting As40Se40Ag20 chalcogenide glass. Phys. B Condens. Matter 2021, 608, 412745. [Google Scholar] [CrossRef]

- Tan, L.M.; Yang, K.; Yuan, J.H.; Zhao, H.Y.; Tao, S.Y.; Ding, C.X. Kinetics of non-isothermal crystallization of Fe-Cr-Mo-B-C-P amorphous alloy coatings. Chin. Surf. Eng. 2019, 32, 141–150. [Google Scholar]

- Yu, J.K.; Qiao, Q.; Niu, D.Y.; Jia, Q.H.; Wang, D.D.; Liu, R.H. Determination of activation energy for crystallizations in Ni-Cu-P amorphous alloys. Phase Transit. 2012, 85, 761–767. [Google Scholar] [CrossRef]

- Mansouri, M.; Bidhendi, H.R.A.; Akhavan, S. Non-isothermal kinetics study of primary crystallization in amorphous Al86Ni10Zr2 MM2 alloy. J. Non-Cryst. Solids 2017, 468, 1–4. [Google Scholar] [CrossRef]

- Liu, K.T.; Duh, J.G. Isothermal and non-isothermal crystallization kinetics in amorphous Ni45.6Ti49.3Al5.1 thin films. J. Non-Cryst. Solids 2008, 354, 3159–3165. [Google Scholar] [CrossRef]

- Ercenk, E.; Sen, U.; Yilmaz, S. The effect of SiC addition on the crystallization kinetics of atmospheric plasma-sprayed basalt-based coatings. Ceram. Int. 2012, 38, 6549–6556. [Google Scholar] [CrossRef]

- Bayrak, G.; Yilmaz, S. Crystallization kinetics of plasma sprayed basalt coatings. Ceram. Int. 2006, 32, 441–446. [Google Scholar] [CrossRef]

- Pan, W.; Li, R.T. Crystallization kinetics of the aluminum silicate glass fiber. Mater. Sci. Eng. A 1999, 271, 298–305. [Google Scholar] [CrossRef]

- Lopes, A.A.S.; Soares, R.S.; Lima, M.M.A.; Monteiro, R.C.C. Glass transition and crystallization kinetics of a barium borosilicate glass by a non-isothermal method. J. Appl. Phys. 2014, 115, 043516. [Google Scholar] [CrossRef] [Green Version]

- Tseng, J.-Y.; Chen, Y.-T.; Chang, Z.G.; Wu, C.W.; Yang, L.C. Crystallization Behavior and Thermal Analysis of CoFeB Thin Films. J. Nanomater. 2015, 2015, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Wu, J.; Pan, Y.; Liu, H.; Pi, J. Activation energy, viscosity and fragility of Cu-Zr-Ti-In bulk metallic glasses. Mater. Sci. Technol. 2014, 30, 670–675. [Google Scholar] [CrossRef]

- Han, X.; Ding, F.; Qin, Y.; Wu, D.; Xing, H.; Shi, Y.; Song, K.; Cao, C. Compositional dependence of crystallization kinetics in Zr-Ni-Al metallic glasses. Vacuum 2018, 151, 30–38. [Google Scholar] [CrossRef]

- Deng, J.; Shi, H.Y.; Zhang, Y.Q. Study of the crystallization kinetics of titanium-contained alloy amorphous coatings by brush plating (II). Acta Phys. Chim. Sin. 1997, 13, 283–287. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, K.; Li, Q. Comparative study of non-isothermal crystallization kinetics between Fe80P13C7 bulk metallic glass and melt-spun glassy ribbon. J. Alloys Compd. 2012, 540, 6–15. [Google Scholar] [CrossRef]

- Górecki, C.; Górecki, T. Effect of electrolytical hydrogenation on the thermal stability and crystallization kinetics of metallic glass Fe79Si9B12. J. Phys. Conf. Ser. 2011, 289, 012022. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Y.; Feng, T.; Sun, Y.; Dong, J.; Gao, W. Effect of pores on the micromechanics of plasma-sprayed Cr3C2-NiCr coating in the nanoindentation testing. Int. J. Mod. Phys. B 2017, 31, 012022. [Google Scholar] [CrossRef]

| Parameters | NiCr Bondcoat | Al2O3-GAP Topcoat |

|---|---|---|

| Arc current, A | 600 | 650 |

| Primary plasma gas (Ar), slpm | 57 | 49 |

| Secondary plasma gas (H2), slpm | 7.5–8.0 | 8.5–9.0 |

| Carrier gas (Ar), slpm | 3.5 | 4.0 |

| Powder feed rate, g/min | 10 | 30 |

| Power, kW | 40–45 | 45–50 |

| Stand-off distance, mm | 120 | 110 |

| Angle of Repose | Carr Index * | Hausner Ratio * | |

|---|---|---|---|

| Al2O3/YAG powders 24] | 46.5° | 26% | 1.35 |

| Al2O3/Gd2O3 powders | 30.0° | 8% | 1.09 |

| Amorphous Coatings | Tg (K) | Tc1 (K) | ΔT (K) | Tp1 (K) | Ec (kJ/mol) | Ec/RTg | β (K/min) |

|---|---|---|---|---|---|---|---|

| Al2O3-YAG [22] | 1166.0 | 1198.4 | 29.3 | 1215.5 | 807.8 | 83.3 | 20 |

| Al2O3-GAP | 1155.1 | 1179.2 | 17.4 | 1215.0 | 847.6 | 88.3 | 20 |

| Displacement (nm) | Al2O3 Hardness (GPa) | Al2O3 Modulus (GPa) | Al2O3-YAG Hardness (GPa) | Al2O3-YAG Modulus (GPa) | Al2O3-GAP Hardness (GPa) | Al2O3-GAP Modulus (GPa) |

|---|---|---|---|---|---|---|

| 500–1000 | 5.16 ± 1.35 | 157.24 ± 41.90 | 9.85 ± 0.68 | 154.78 ± 9.90 | 9.54 ± 0.68 | 144.36 ± 6.78 |

| 1000–1500 | 5.22 ± 2.38 | 157.04 ± 47.02 | 9.24 ± 0.64 | 146.66 ± 8.77 | 9.02 ± 0.69 | 138.74 ± 8.39 |

| 1500–2000 | 5.61 ± 2.63 | 161.84 ± 41.30 | 8.80 ± 0.66 | 141.29 ± 8.17 | 8.90 ± 0.70 | 134.97 ± 8.09 |

| 500–2000 | 5.22 ± 1.87 | 158.64 ± 41.89 | 9.46 ± 0.63 | 149.71 ± 8.98 | 9.25 ± 0.57 | 140.77 ± 7.10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiang, L.; Zhang, X.; Ai, Y.; Zhuang, Y.; Sheng, J.; Ni, J.; Yang, K. In Situ Deposition of Amorphous Al2O3-GAP Ceramic Coating with Excellent Microstructure Stability and Uniformity via Atmospheric Plasma Spraying. Coatings 2022, 12, 119. https://doi.org/10.3390/coatings12020119

Qiang L, Zhang X, Ai Y, Zhuang Y, Sheng J, Ni J, Yang K. In Situ Deposition of Amorphous Al2O3-GAP Ceramic Coating with Excellent Microstructure Stability and Uniformity via Atmospheric Plasma Spraying. Coatings. 2022; 12(2):119. https://doi.org/10.3390/coatings12020119

Chicago/Turabian StyleQiang, Linya, Xiaozhen Zhang, Yizhaotong Ai, Yin Zhuang, Jing Sheng, Jinxing Ni, and Kai Yang. 2022. "In Situ Deposition of Amorphous Al2O3-GAP Ceramic Coating with Excellent Microstructure Stability and Uniformity via Atmospheric Plasma Spraying" Coatings 12, no. 2: 119. https://doi.org/10.3390/coatings12020119

APA StyleQiang, L., Zhang, X., Ai, Y., Zhuang, Y., Sheng, J., Ni, J., & Yang, K. (2022). In Situ Deposition of Amorphous Al2O3-GAP Ceramic Coating with Excellent Microstructure Stability and Uniformity via Atmospheric Plasma Spraying. Coatings, 12(2), 119. https://doi.org/10.3390/coatings12020119