Enhancing the Raveling Resistance of Polyurethane Mixture: From the Perspective of Polyurethane Adhesive

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

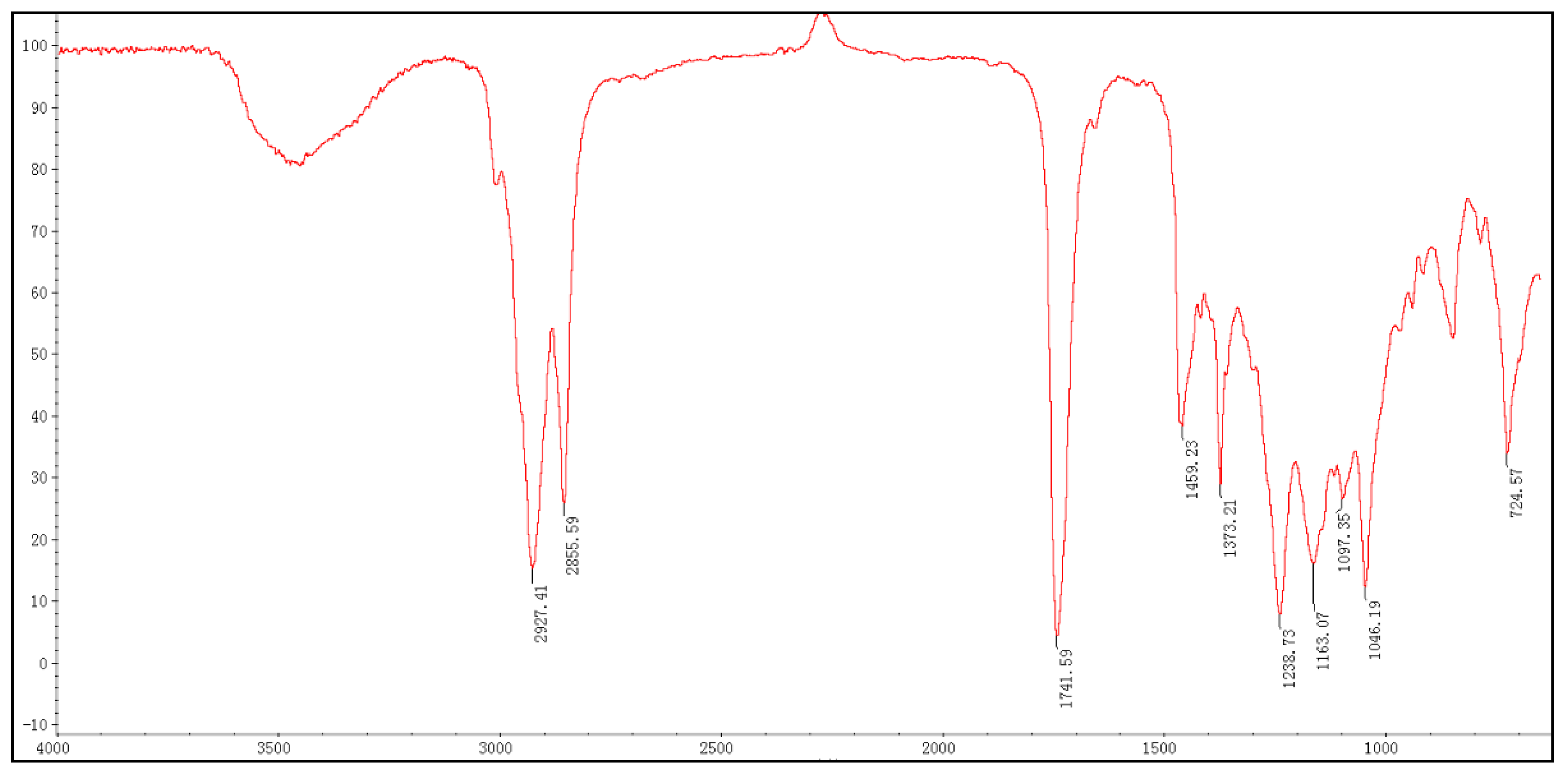

2.2.1. Fourier Transform Infrared Spectroscopy Test

2.2.2. Direct Tensile Test

2.2.3. Crosslink Density Test

2.2.4. Wear Test

2.2.5. Samples Preparation

2.2.6. Orthogonal Experimental Design

3. Results and Discussion

3.1. Determination of Polyol and Its Portion

3.1.1. Preliminary Determination of Hydroxyl Component

3.1.2. The Blending Ratio of Hydroxyl Component (A) and an Isocyanate Component (B)

3.2. Results of the Orthogonal Experiment

3.3. Crosslink Density and Elastic Modulus

3.4. The Relationship between Raveling Resistance and Curing Conditions and Tensile Strength

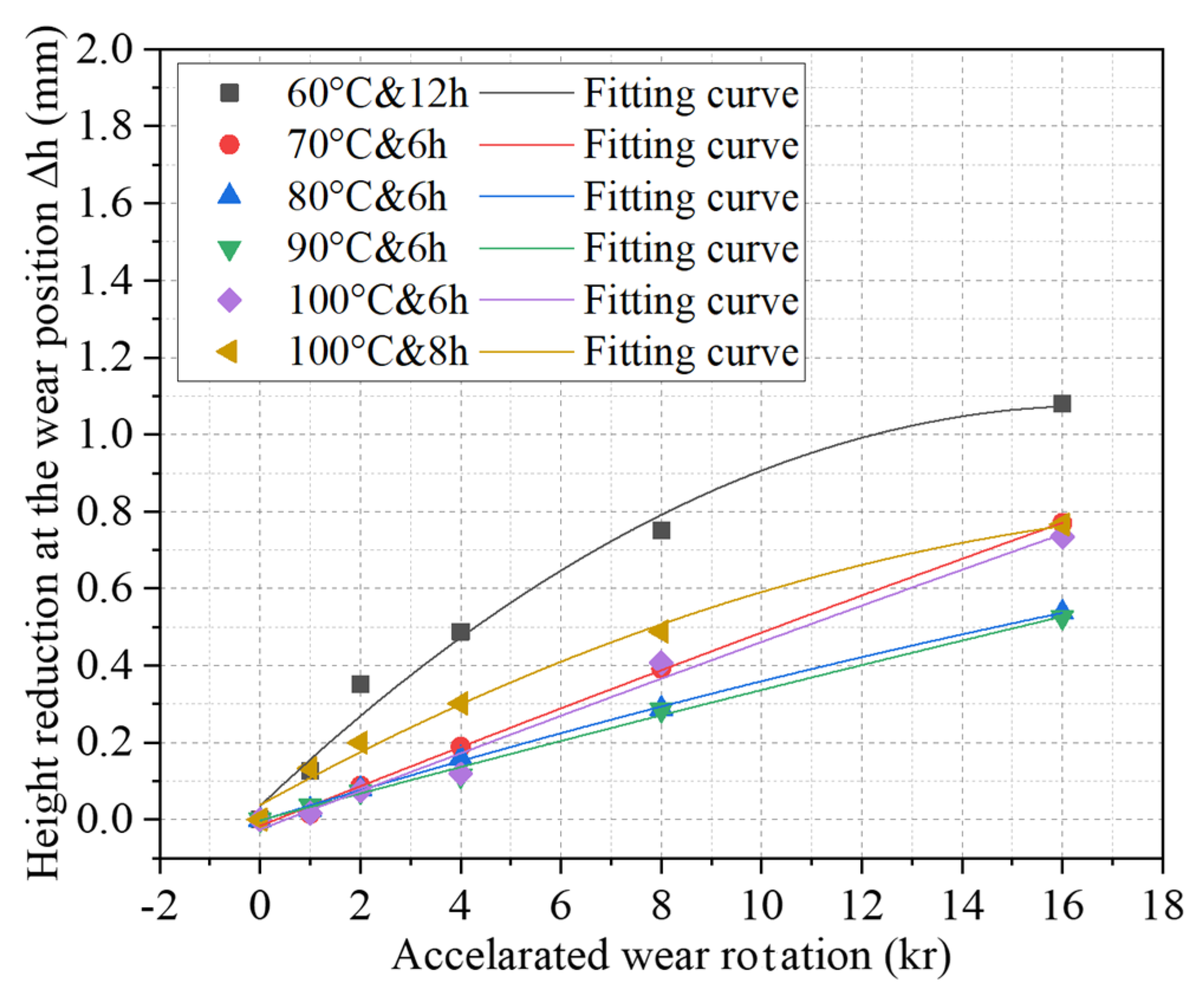

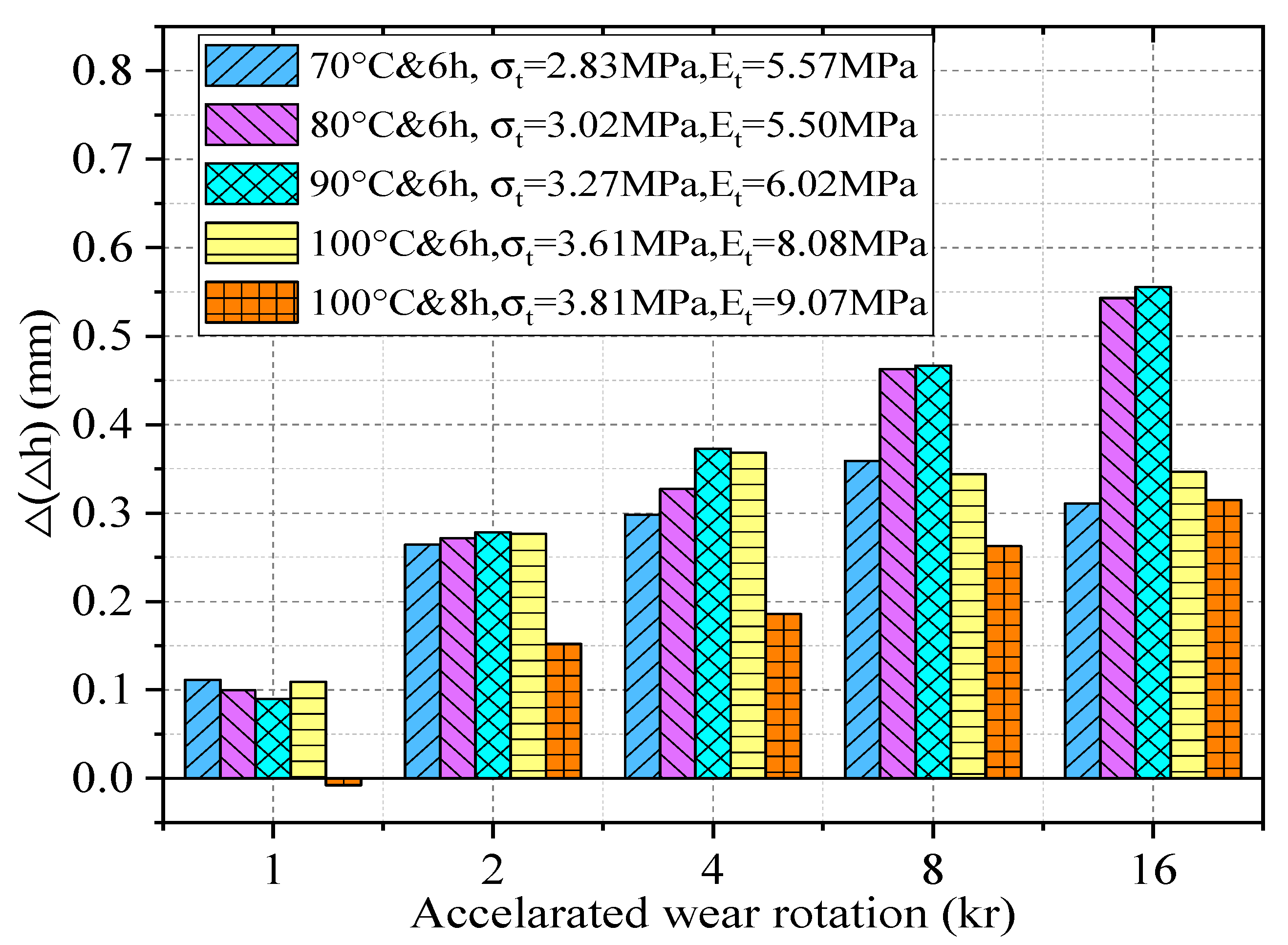

3.4.1. Curing Conditions

3.4.2. Tensile Strength

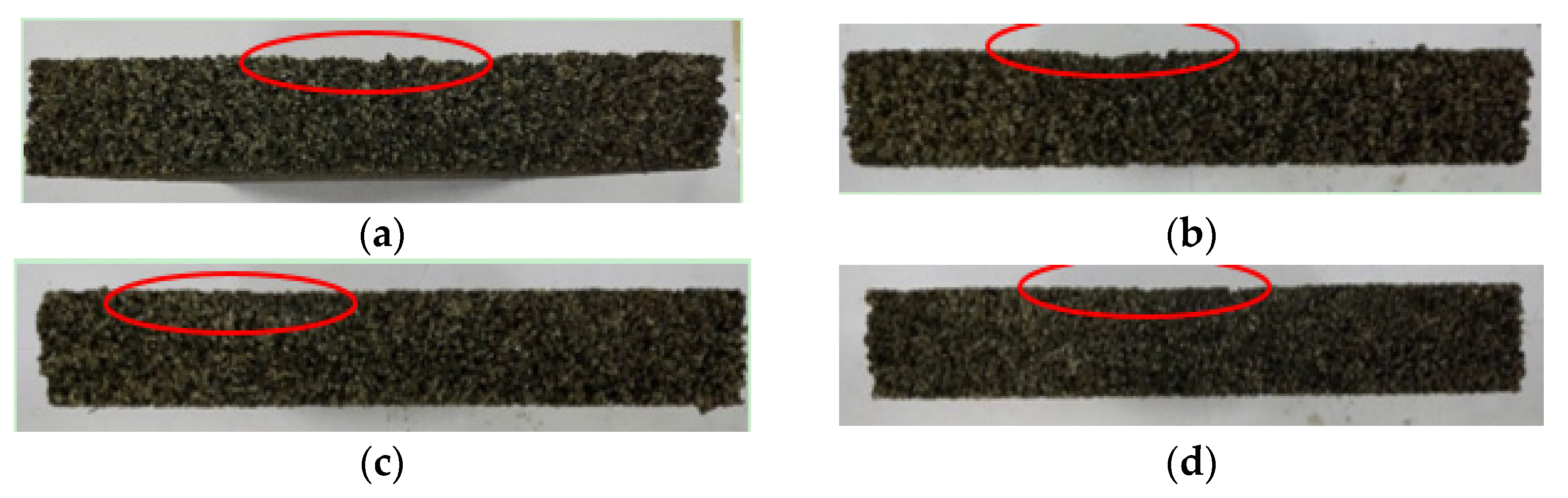

3.4.3. Specimens after Abrasion

4. Conclusions

- (1).

- The mass percentage in the polyol liquid was 31.58% for the hydroxyl component. When the ratios of the isocyanate component to the hydroxyl component were 1:3.2, 1:6.3, and 1:9.5, the isocyanate component was excessive. It was helpful to improve the crosslink density and the tensile strength.

- (2).

- The ranking of the significance of the influence factors, from high to low, was first the curing temperature, then the curing time, and finally the blending ratio; within the ranges of the blending ratio, curing temperature, and curing time selected in this experiment, the appropriate blending ratio was 10:2, and the curing time was 6 h.

- (3).

- For the polyurethane mixture involved in this study to have a high raveling resistance, if a crosslinking agent or a new polyurethane adhesive is added, the tensile strength and tensile elastic modulus should be in the range of 3.02 to 3.27 MPa and 5.50 to 6.02 MPa, respectively; when using FS2 polyurethane adhesive directly, the suitable curing conditions for the mixture are 90 °C and 6 h or 80 °C and 6 h.

Author Contributions

Funding

Conflicts of Interest

References

- Li, F.; Zhang, X.; Wang, L.; Zhai, R. The preparation process, service performances and interaction mechanisms of crumb rubber modified asphalt (CRMA) by wet process: A comprehensive review. Constr. Build. Mater. 2022, 354, 129168. [Google Scholar] [CrossRef]

- Li, J.; Xiao, F.; Amirkhanian, S. Storage, fatigue and low temperature characteristics of plasma treated rubberized binders. Constr. Build. Mater. 2019, 209, 454–462. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, T.; Pei, J.; Amirkhanian, S.; Xiao, F.; Ye, Q.; Fan, Z. Low Temperature and Fatigue Characteristics of Treated Crumb Rubber Modified Asphalt after a Long Term Aging Procedure. J. Clean Prod. 2019, 234, 1262–1274. [Google Scholar] [CrossRef]

- Sebaaly, P.E.; Gopal, V.T.; Epps, J.A. Low Temperature Properties of Crumb Rubber Modified Binders. Road Mater. Pavement Des. 2011, 4, 29–49. [Google Scholar] [CrossRef]

- Xu, H.; McIntyre, A.; Adhikari, T.; Hesp, S.; Marks, P.; Tabib, S. Quality and Durability of Warm Rubberized Asphalt Cement in Ontario, Canada. Transp. Res. Rec. J. Transp. Res. Board 2013, 2370, 26–32. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, J.; Yu, B.; Zhang, J.; Pei, J. Evaluation and optimization of asphalt binder and mixture modified with high activated crumb rubber content. Constr. Build. Mater. 2022, 314, 125676. [Google Scholar] [CrossRef]

- Attia, M. Enhancing the performance of crumb rubber-modified binders through varying the interaction conditions. Int. J. Pavement Eng. 2009, 10, 423–434. [Google Scholar] [CrossRef]

- Gong, Z.; Zhang, L.; Wu, J.; Xiu, Z.; Wang, L.; Miao, Y. Review of regulation techniques of asphalt pavement high temperature for climate change adaptation. J. Infrastruct. Preserv. Resil. 2022, 3, 9. [Google Scholar] [CrossRef]

- Lei, Y.; Wang, H.; Fini, E.H.; You, Z.; Yang, X.; Gao, J.; Dong, S.; Jiang, G. Evaluation of the effect of bio-oil on the high-temperature performance of rubber modified asphalt. Constr. Build. Mater. 2018, 191, 692–701. [Google Scholar] [CrossRef]

- Liu, H.Y.; Chen, Z.J.; Wang, W.; Wang, H.N.; Hao, P.W. Investigation of the rheological modification mechanism of crumb rubber modified asphalt (CRMA) containing TOR additive. Constr. Build. Mater. 2014, 67, 225–233. [Google Scholar] [CrossRef]

- Wang, H.; Dang, Z.; Li, L.; You, Z. Analysis on fatigue crack growth laws for crumb rubber modified (CRM) asphalt mixture. Constr. Build. Mater. 2013, 47, 1342–1349. [Google Scholar] [CrossRef]

- Wang, H.N.; Zhang, C.; Li, L.; You, Z.P.; Diab, A. Characterization of Low Temperature Crack Resistance of Crumb Rubber Modified Asphalt Mixtures Using Semi-Circular Bending Tests. J. Test. Eval. 2016, 44, 847–855. [Google Scholar] [CrossRef]

- Cao, D.W.; Zhang, Y.J.; Xia, L.; Li, Y.F.; Zhang, H.Y. Study on the Properties of Waterborne Polyurethane Modified Emulsified Asphalt. In Proceedings of the Transportation Research Congress 2016 (TRC), Beijing, China, 6–8 June 2016; pp. 207–215. [Google Scholar]

- Chen, B.; Dong, F.Q.; Yu, X.; Zheng, C.J. Evaluation of Properties and Micro-Characteristics of Waste Polyurethane/Styrene-Butadiene-Styrene Composite Modified Asphalt. Polymers 2021, 13, 2249. [Google Scholar] [CrossRef] [PubMed]

- Jin, X.; Guo, N.S.; You, Z.P.; Wang, L.; Wen, Y.K.; Tan, Y.Q. Rheological properties and micro-characteristics of polyurethane composite modified asphalt. Constr. Build. Mater. 2020, 234, 16. [Google Scholar] [CrossRef]

- Yu, R.E.; Zhu, X.J.; Zhou, X.; Kou, Y.F.; Zhang, M.R.; Fang, C.Q. Rheological properties and storage stability of asphalt modified with nanoscale polyurethane emulsion. Pet. Sci. Technol. 2018, 36, 85–90. [Google Scholar] [CrossRef]

- Wang, D.; Schacht, A.; Leng, Z.; Leng, C.; Kollmann, J.; Oeser, M. Effects of material composition on mechanical and acoustic performance of poroelastic road surface (PERS). Constr. Build. Mater. 2017, 135, 352–360. [Google Scholar] [CrossRef]

- Sandberg, U.; Gucbert, L. Pooelastic road surface (PERS): A review of 30 Years of R and D work. In Proceedings of the Inter-Noise and Noise-Con Congress and Conference Proceedings, InterNoise11, Osaka, Japan, 4–7 September 2011; pp. 3014–3021. [Google Scholar]

- Zhang, K.; Kevern, J. Review of porous asphalt pavements in cold regions: The state of practice and case study repository in design, construction, and maintenance. J. Infrastruct. Preserv. Resil. 2021, 2, 4. [Google Scholar] [CrossRef]

- Luc, G.; Ulf, S. PERSUADE Final Teachnical Report. In Proceedings of the Seventh framework programme of the European Community, Brussels, Belgium, 7 January 2016. [Google Scholar]

- Kazuyuki, K. Present Status of Porous Elastic Rubber Surface (PERS) in Japan. In Proceedings of the Inter-Noise and Noise-Con Congress and Conference Proceedings, InterNoise11, Osaka, Japan, 4–7 September 2011; pp. 3147–3153. [Google Scholar]

- Ulf, S.; Luc, G. PERSUADE—A European project for exceptional noise reduction by means of poroelastic road surfaces. In Proceedings of the Inter-Noise and Noise-Con Congress and Conference Proceedings, InterNoise11a, Osaka, Japan, 4–7 September 2011; pp. 2979–2989. [Google Scholar]

- Goubert, L.; Sandberg, U.; Biligiri, K.P. State-of-the-Art Regarding Poroelastic Road Surfaces. In Proceedings of the Transportation Research Board (TRB) 89th Annual Meeting, Washington, DC, USA, 10–14 January 2020; p. 152. [Google Scholar]

- Sandberg, U.; Kalman, B. The poroelastic road surfaceeresults of an experiment in Stockholm. In Proceedings of the Forum Acusticum: 4th European Congress on Acustics, Budapest, Hungary, 29 August–2 September 2005; pp. 834–840. [Google Scholar]

- Hitoshi, F.; Yoshifumi, A.; Kouji, H. Performace of the Porous Elastic Road Surface (PERS) as Low Noise Pavement. In Proceedings of the Inter-Noise and Noise-Con Congress and Conference Proceedings, InterNoise11, Osaka, Japan, 4–7 September 2011; pp. 2960–2966. [Google Scholar]

- Biligiri, K.P.; Kalman, B.; Samuelsson, A. Understanding the fundamental material properties of low-noise poroelastic road surfaces. Int. J. Pavement Eng. 2013, 14, 12–23. [Google Scholar] [CrossRef]

- Ejsmont, J.; Goubert, L.; Ronowski, G.; Świeczko-Żurek, B. Ultra Low Noise Poroelastic Road Surfaces. Coatings 2016, 6, 18. [Google Scholar] [CrossRef] [Green Version]

- Srirangam, S.K.; Anupam, K.; Casey, D.; Liu, X.; Kasbergen, C.; Scarpas, A. Evaluation of Structural Performance of Poroelastic Road Surfacing Pavement Subjected to Rolling–Truck Tire Loads. Transp. Res. Rec. J. Transp. Res. Board 2016, 2591, 42–56. [Google Scholar] [CrossRef]

- Wang, D.; Liu, P.; Leng, Z.; Leng, C.; Lu, G.; Buch, M.; Oeser, M. Suitability of PoroElastic Road Surface (PERS) for urban roads in cold regions: Mechanical and functional performance assessment. J. Clean Prod. 2017, 165, 1340–1350. [Google Scholar] [CrossRef]

- Hong, B.; Lu, G.; Li, T.; Lin, J.; Wang, D.; Liang, D.; Oeser, M. Gene-editable materials for future transportation infrastructure: A review for polyurethane-based pavement. J. Infrastruct. Preserv. Resil. 2021, 2, 27. [Google Scholar] [CrossRef]

- Hong, B.; Lu, G.; Gao, J.; Dong, S.; Wang, D. Green tunnel pavement: Polyurethane ultra-thin friction course and its performance characterization. J. Clean. Prod. 2021, 289, 125131. [Google Scholar] [CrossRef]

- Mohammad Asib, A.S.; Rahman, R.; Romero, P.; Hoepfner, M.P.; Mamun, A. Physicochemical characterization of short and long-term aged asphalt mixtures for low-temperature performance. Constr. Build. Mater. 2022, 319, 126038. [Google Scholar] [CrossRef]

- Zhang, H.; Duan, H.; Luo, H.; Shi, C. Synthesis, characterization and utilization of zinc oxide/expanded vermiculite composite for bitumen modification. Fuel 2021, 306, 121731. [Google Scholar] [CrossRef]

- Sekkar, V.; Narayanaswamy, K.; Scariah, K.J.; Nair, P.R.; Sastri, K.S.; Ang, H.G. Evaluation by various experimental approaches of the crosslink density of urethane networks based on hydroxyl-terminated polybutadiene. J. Appl. Polym. Sci. 2007, 103, 3129–3133. [Google Scholar] [CrossRef]

- Venkataraman, S.; Alex, A.S.; Kumar, V.; Bandyopadhyay, G.G. Theoretical Evaluation of Crosslink Density of Chain Extended Polyurethane Networks Based on Hydroxyl Terminated Polybutadiene and Butanediol and Comparison with Experimental Data. J. Energetic Mater. 2018, 36, 38–47. [Google Scholar]

- Jutrzenka Trzebiatowska, P.; Santamaria Echart, A.; Calvo Correas, T.; Eceiza, A.; Datta, J. The changes of crosslink density of polyurethanes synthesised with using recycled component. Chemical structure and mechanical properties investigations. Prog. Org. Coat. 2018, 115, 41–48. [Google Scholar] [CrossRef]

- Ren, R.; Han, K.; Zhao, P.; Shi, J.; Zhao, L.; Gao, D.; Zhang, Z.; Yang, Z. Identification of asphalt fingerprints based on ATR-FTIR spectroscopy and principal component-linear discriminant analysis. Constr. Build. Mater. 2019, 198, 662–668. [Google Scholar] [CrossRef]

- Xiao, D.; Le, T.T.G.; Doan, T.T.; Le, B.T. Coal identification based on a deep network and reflectance spectroscopy. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2022, 270, 120859. [Google Scholar] [CrossRef]

- Dong, Z. Study on Accelerated Polishing Test and the Regularity of Skid Resistance Degradation of Asphalt Pavement Material. Master’s Thesis, Chang’an University, Xi’an, China, 2011. [Google Scholar]

| Level | 1 | 2 | 3 | |

|---|---|---|---|---|

| Factor | ||||

| Blending ratio A | 10:2 (5:1) | 10:2.5 (4:1) | 10:3 | |

| Curing temperature B (°C) | 60 | 80 | 100 | |

| Curing time C (h) | 4 | 6 | 8 | |

| NO. | Mass of Centrifuge Tube (g) | Mass of Component A (g) | Total Mass after Centrifugation (g) | Percentage (%) |

|---|---|---|---|---|

| 1 | 68.2 | 99.9 | 135.6 | 32.53 |

| 2 | 62.7 | 98.9 | 130.7 | 31.24 |

| 3 | 67.1 | 99.9 | 136.5 | 30.53 |

| 4 | 67.2 | 99.9 | 135.1 | 32.03 |

| No. | Blending Factor A | Curing Temperature B (°C) | Curing Time C (h) | Tensile Strength (MPa) |

|---|---|---|---|---|

| 1 | 10:2 | 60 | 4 | 2.37 |

| 2 | 10:2 | 80 | 6 | 3.02 |

| 3 | 10:2 | 100 | 8 | 3.81 |

| 4 | 10:2.5 | 60 | 6 | 2.11 |

| 5 | 10:2.5 | 80 | 8 | 2.54 |

| 6 | 10:2.5 | 100 | 4 | 2.60 |

| 7 | 10:3 | 60 | 8 | 1.45 |

| 8 | 10:3 | 80 | 4 | 1.60 |

| 9 | 10:3 | 100 | 4 | 4.68 |

| Factor | A | B | C | |

|---|---|---|---|---|

| Level | ||||

| 1 | 3.067 | 1.977 | 2.190 | |

| 2 | 2.417 | 2.387 | 3.267 | |

| 3 | 2.573 | 3.693 | 2.600 | |

| Sample range | 0.650 | 1.716 | 0.836 | |

| No. | Blending Ratio | Curing Temperature (°C) | Curing Time (h) | Tensile Strength (MPa) | Elongation at Break (%) |

|---|---|---|---|---|---|

| 1 | 10:2 | 60 | 12 | 2.69 | 56.4 |

| 2 | 10:2 | 70 | 6 | 2.83 | 60.0 |

| 3 | 10:2 | 80 | 6 | 3.02 | 58.0 |

| 4 | 10:2 | 90 | 6 | 3.27 | 50.8 |

| 5 | 10:2 | 100 | 6 | 3.61 | 51.9 |

| 6 | 10:2 | 100 | 8 | 3.81 | 35.1 |

| No | Blending Ratio | Curing Temperature (°C) | Curing Time (h) | Elastic Modulus (MPa) | Crosslink Density (mol·m−3) |

|---|---|---|---|---|---|

| 1 | 10:2 | 60 | 12 | 4.58 | 620.36 |

| 2 | 10:2 | 70 | 6 | 5.57 | 754.45 |

| 3 | 10:2 | 80 | 6 | 5.50 | 745.97 |

| 4 | 10:2 | 90 | 6 | 6.02 | 815.41 |

| 5 | 10:2 | 100 | 6 | 8.08 | 1094.43 |

| 6 | 10:2 | 100 | 8 | 9.07 | 1228.53 |

| Curing Condition | 60 °C & 12 h | 70 °C & 6 h | 80 °C & 6 h | 90 °C & 6 h | 100 °C & 6 h | 100 °C & 8 h | |

|---|---|---|---|---|---|---|---|

| Parameters | A | 0.03528 | −0.01467 | −0.00297 | −0.00206 | −0.02537 | 0.03773 |

| B | 0.12414 | 0.05188 | 0.04036 | 0.03515 | 0.04987 | 0.07204 | |

| C | −0.00371 | −0.00016 | −0.00041 | −0.00013 | −0.00012 | −0.00167 | |

| R2 | 0.98656 | 0.99836 | 0.99892 | 0.99635 | 0.98735 | 0.99204 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, J.; Wang, H.; Chen, J.; Tang, B. Enhancing the Raveling Resistance of Polyurethane Mixture: From the Perspective of Polyurethane Adhesive. Coatings 2022, 12, 1950. https://doi.org/10.3390/coatings12121950

Gao J, Wang H, Chen J, Tang B. Enhancing the Raveling Resistance of Polyurethane Mixture: From the Perspective of Polyurethane Adhesive. Coatings. 2022; 12(12):1950. https://doi.org/10.3390/coatings12121950

Chicago/Turabian StyleGao, Junfeng, Hainian Wang, Jiakang Chen, and Boming Tang. 2022. "Enhancing the Raveling Resistance of Polyurethane Mixture: From the Perspective of Polyurethane Adhesive" Coatings 12, no. 12: 1950. https://doi.org/10.3390/coatings12121950

APA StyleGao, J., Wang, H., Chen, J., & Tang, B. (2022). Enhancing the Raveling Resistance of Polyurethane Mixture: From the Perspective of Polyurethane Adhesive. Coatings, 12(12), 1950. https://doi.org/10.3390/coatings12121950