The Effect of the Dilution Level on Microstructure and Wear Resistance of Fe-Cr-CV Hardfacing Coatings Deposited by PTA-P

Abstract

1. Introduction

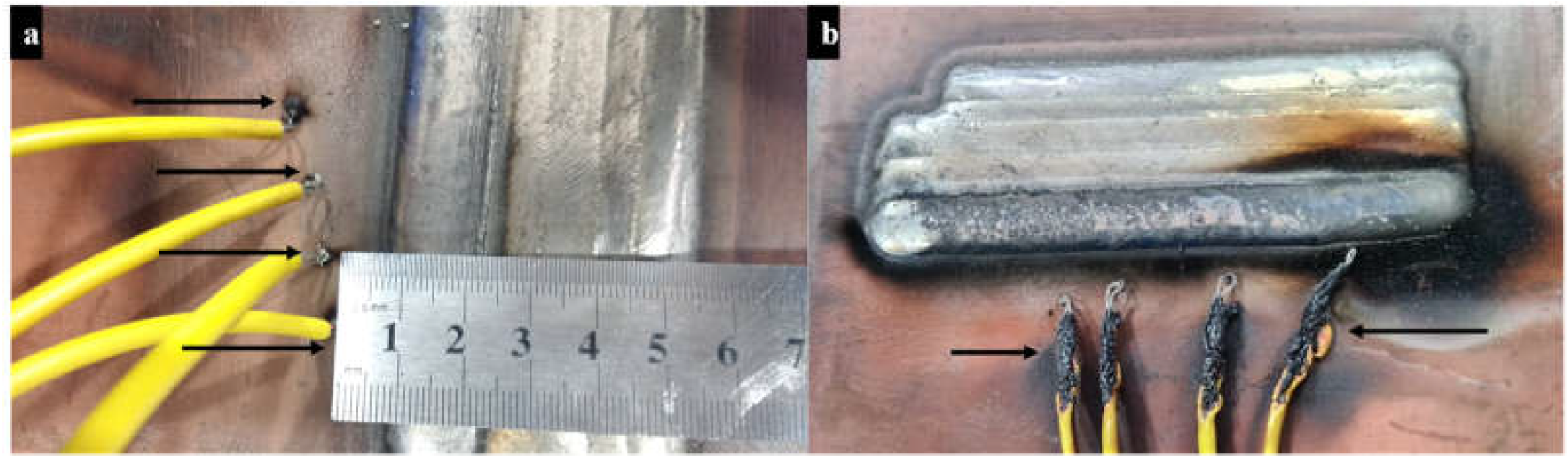

2. Materials and Methods

3. Results

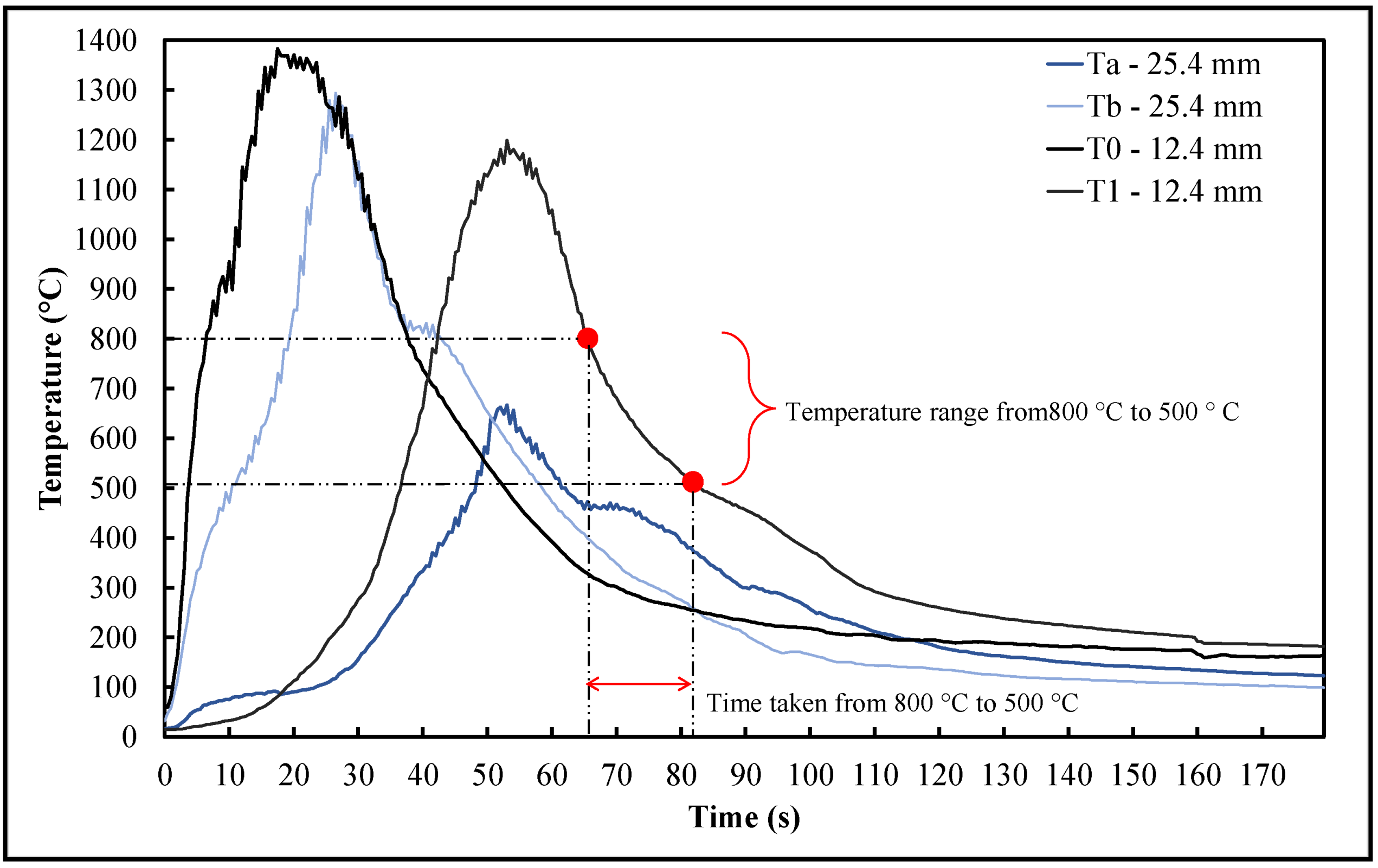

3.1. Cooling Rate

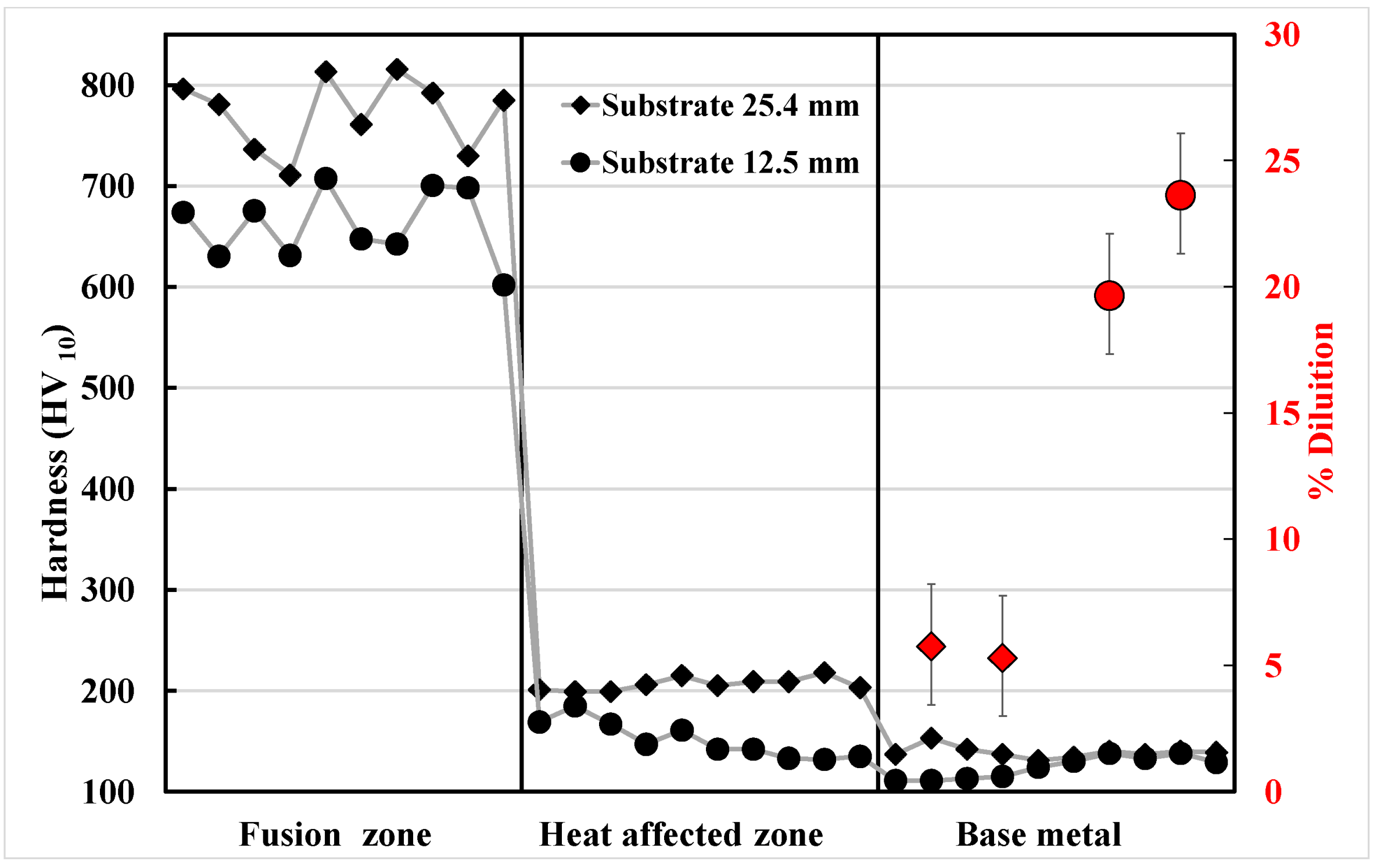

3.2. Dilution

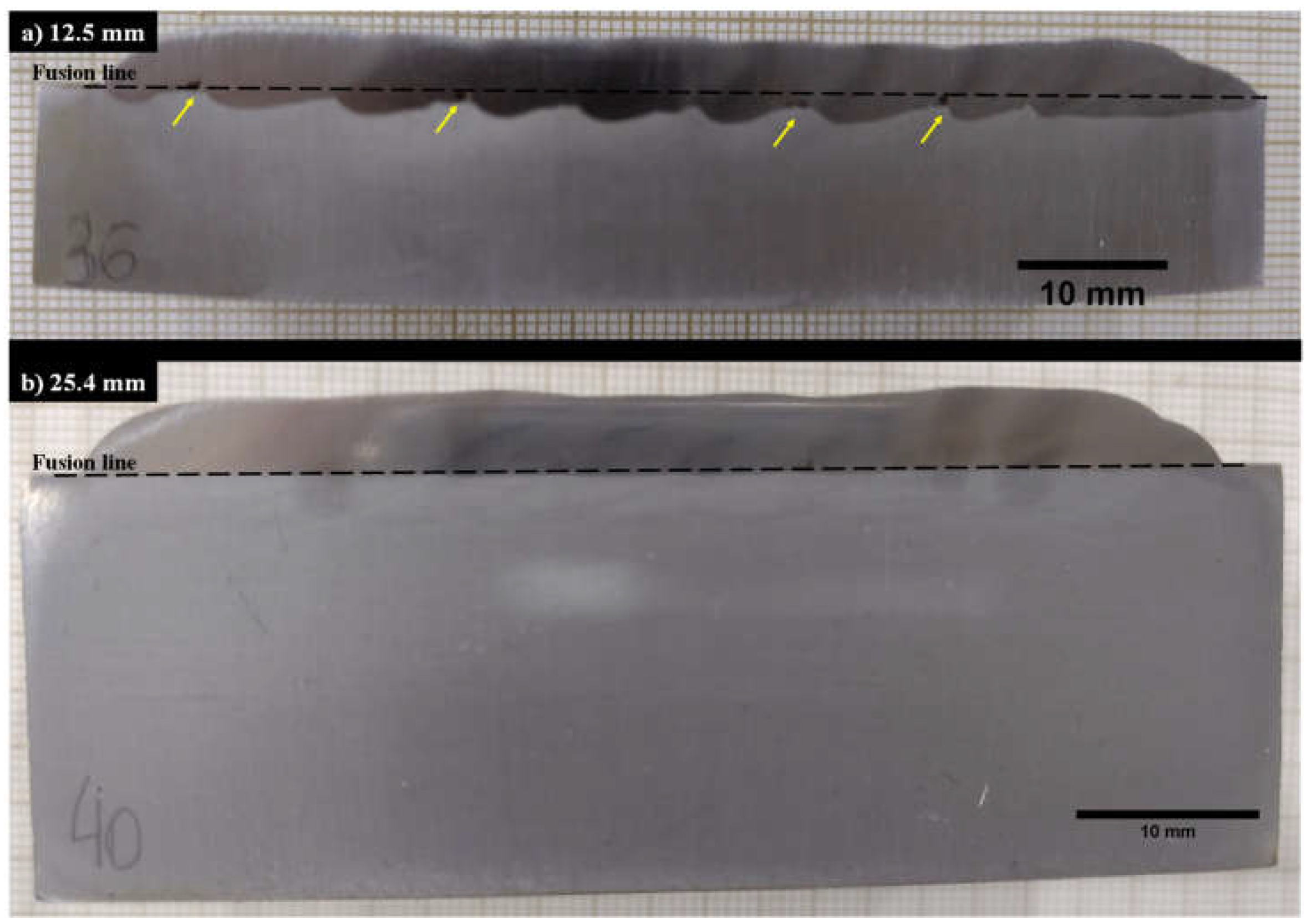

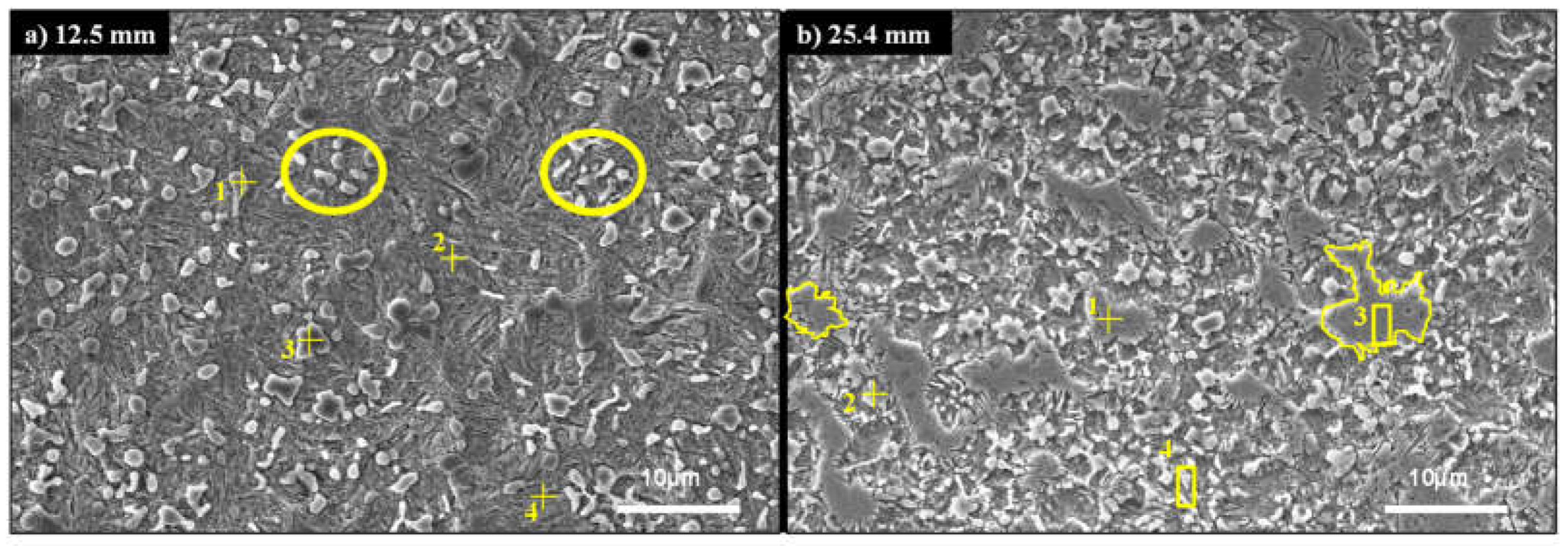

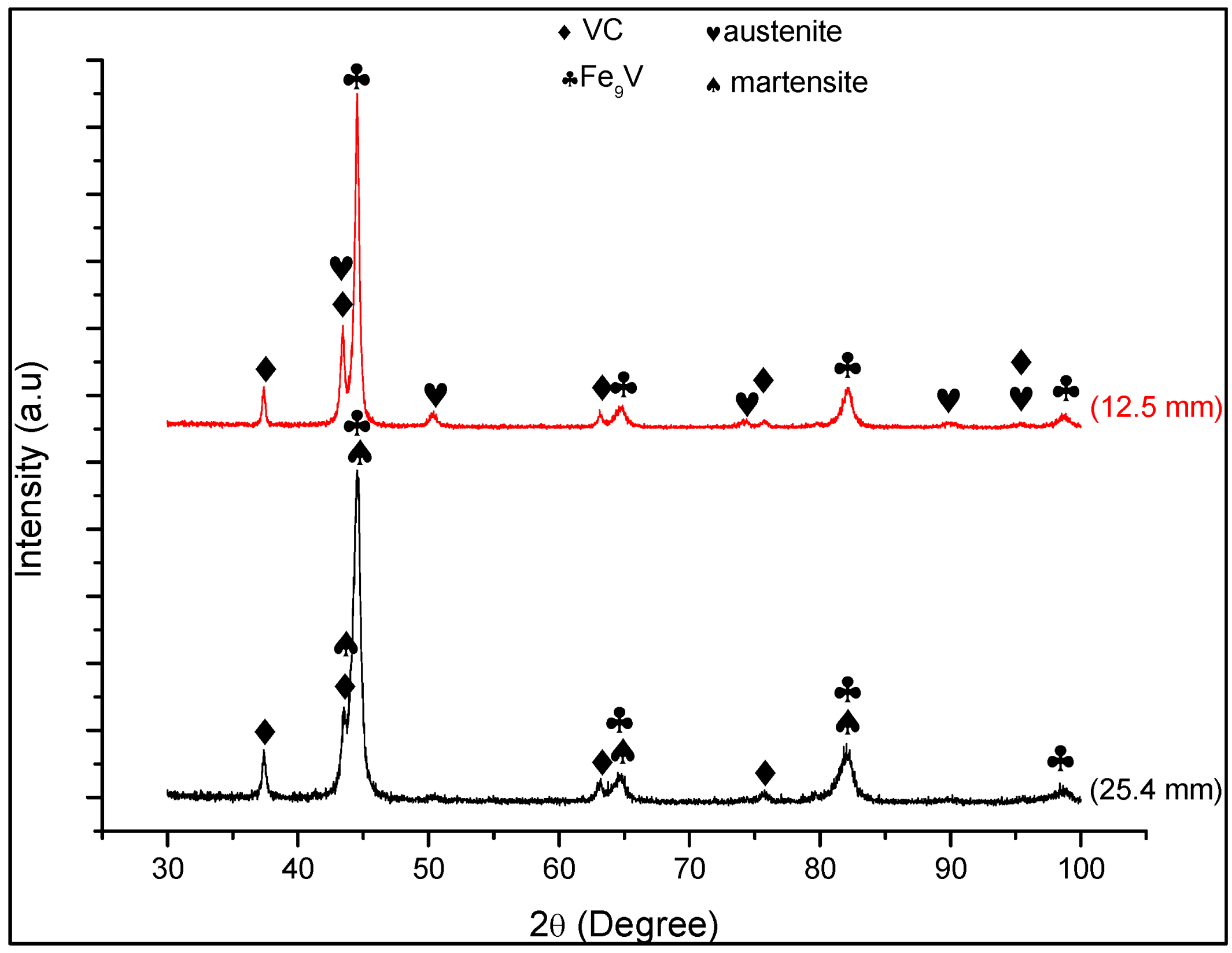

3.3. Microstructure

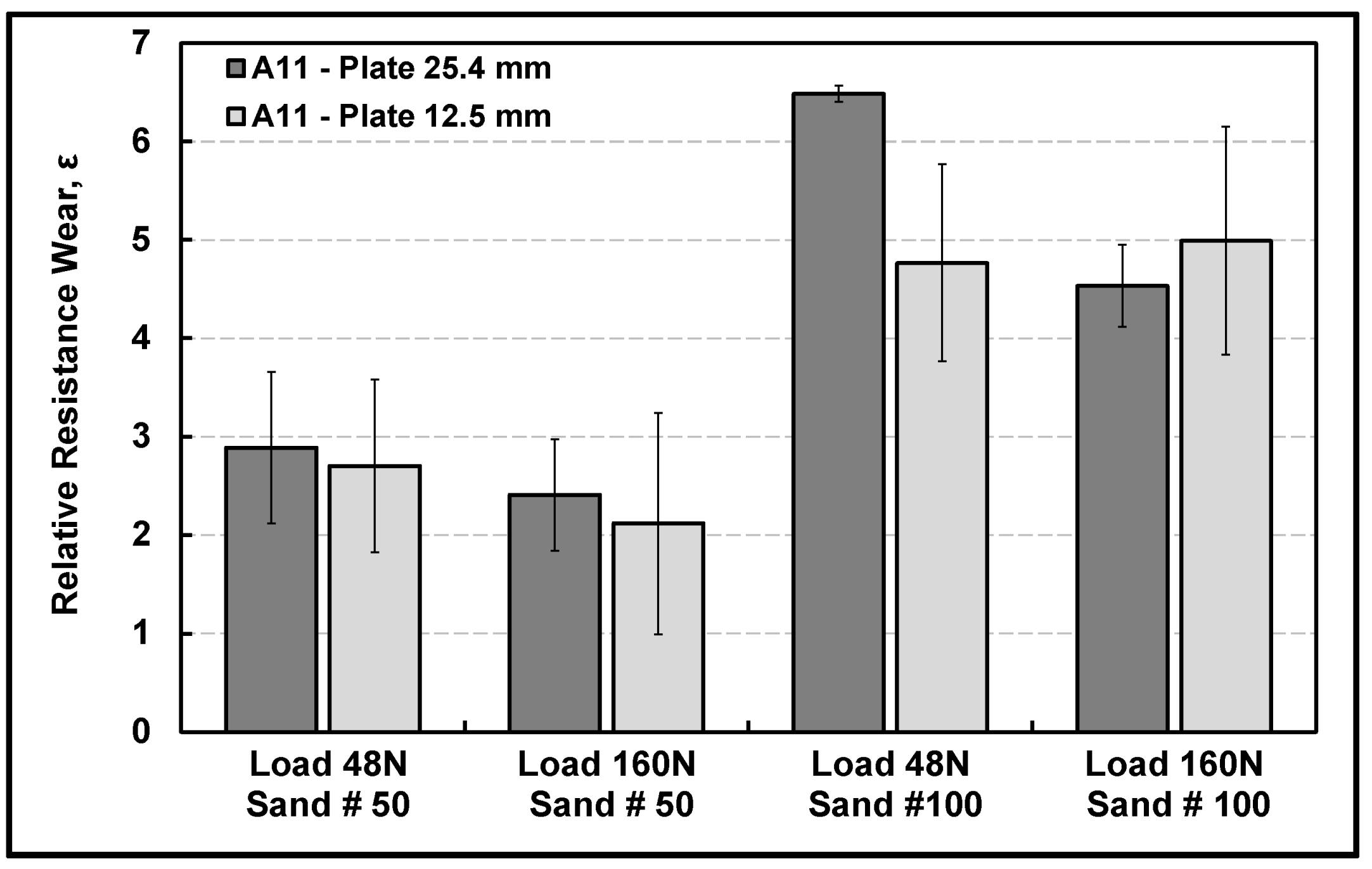

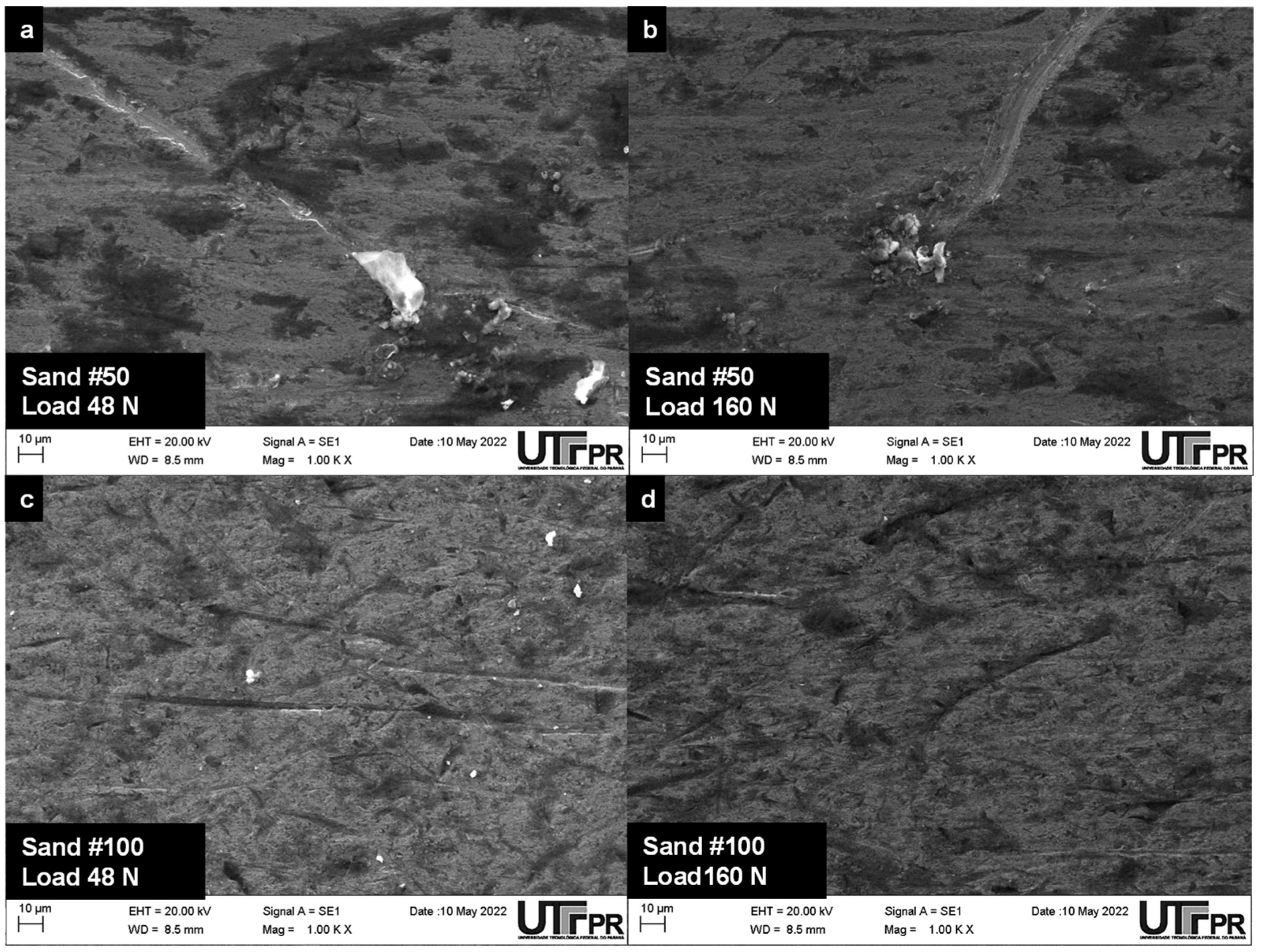

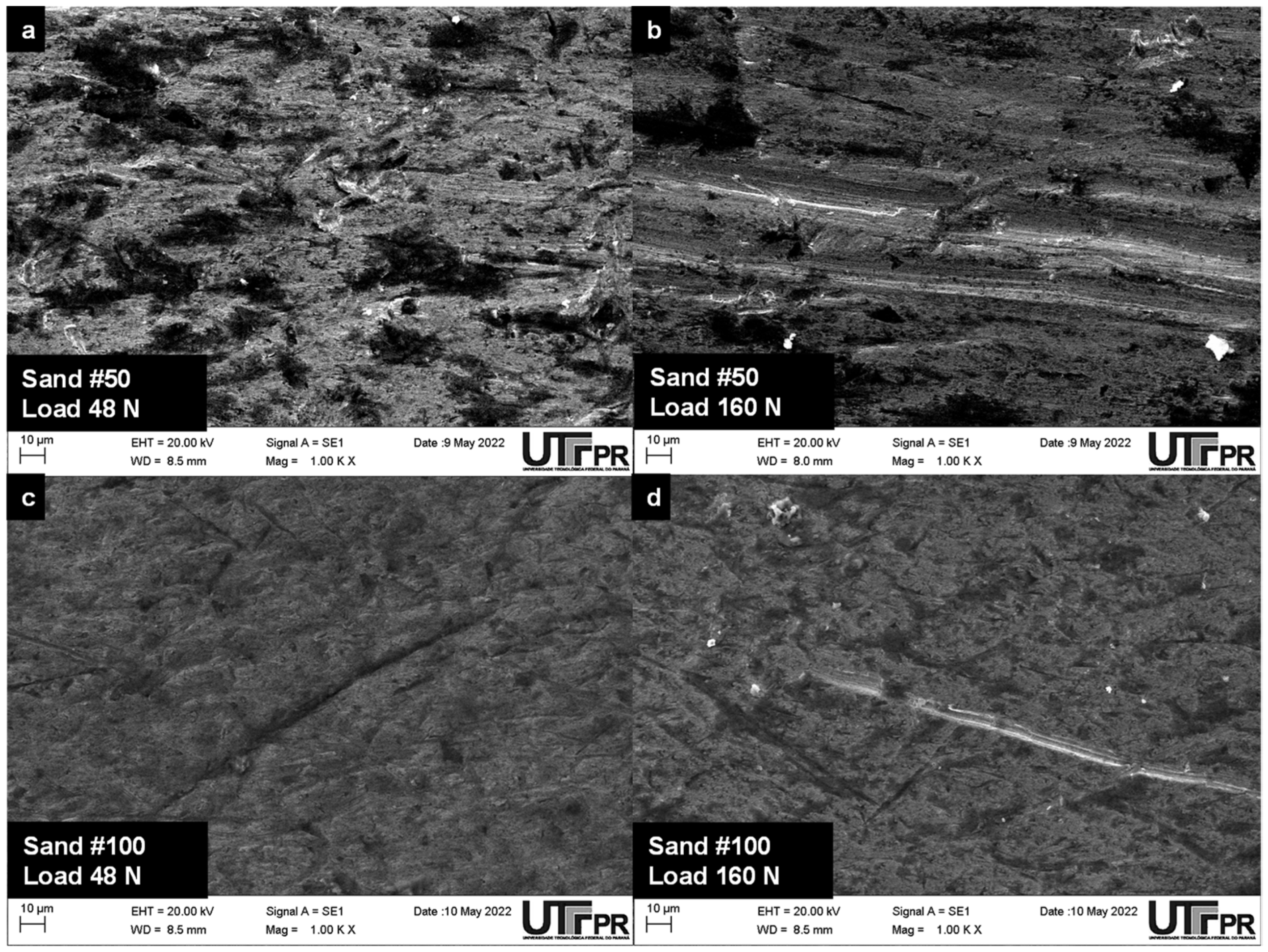

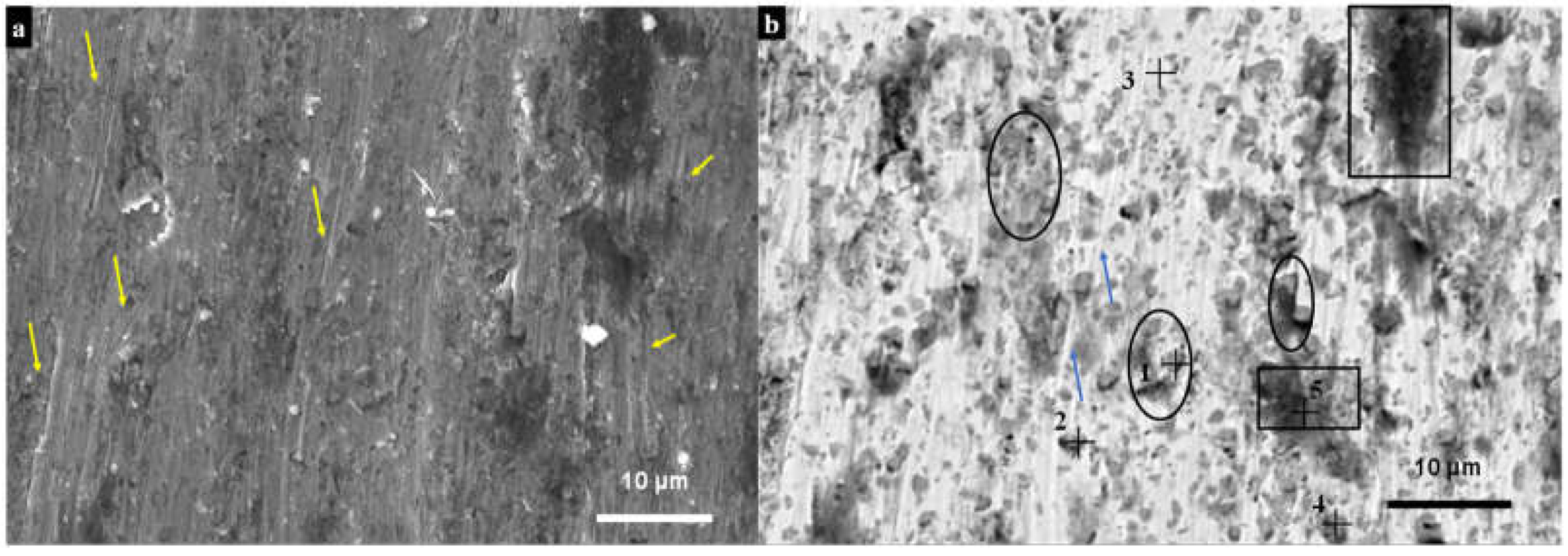

3.4. Wear Rates

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- G40-22; Standard Terminology Relating to Wear and Erosion. Book of Standards; ASTM International: West Conshohocken, PA, USA, 2022; p. 9.

- Holmberg, K.; Kivikytö-Reponen, P.; Härkisaari, P.; Valtonen, K.; Erdemir, A. Global energy consumption due to friction and wear in the mining industry. Tribol. Int. 2017, 115, 116–139. [Google Scholar] [CrossRef]

- Singh, J.; Chatha, S.S.; Sidhu, B.S. Influence of soil conditions on abrasion wear behaviour of tillage implements. Int. J. Latest Trends Eng. Technol. 2018, 258–263. [Google Scholar]

- Miller, B.A.; Shipley, R.J.; Parrington, R.J.; Dennies, D.P. Abrasive Wear Failures. In Failure Analysis and Prevention; Miller, B.A., Shipley, R.J., Parrington, R.J., Dennies, D.P., Eds.; ASM International: West Conshohocken, PA, USA, 2021. [Google Scholar]

- Singh, J.; Chatha, S.S.; Sidhu, B.S. Abrasive wear behavior of newly developed weld overlaid tillage tools in laboratory and in actual field conditions. J. Manuf. Process. 2020, 55, 143–152. [Google Scholar] [CrossRef]

- Hutchings, I.M. Tribology, Friction and Wear of Engineering Materials, 1st ed.; Elsevier Limited: Oxford, UK, 1992. [Google Scholar]

- ÇöMez, N. Effect of Vanadium on Wear and Corrosion Resistance of Fe-C-Cr Hardfacing Coatings. J. Mater. Eng. Perform. 2022, 1–11. [Google Scholar] [CrossRef]

- Ashvinkumar Padhiar, S.; Vincent, S. Effect of hard facing processes on Mild steel A-36 by arc welding. Mater. Today Proc. 2020, 28, 526–531. [Google Scholar] [CrossRef]

- Preedawiphat, P.; Mahayotsanun, N.; Sa-Ngoen, K.; Noipitak, M.; Tuengsook, P.; Sucharitpwatskul, S.; Dohda, K. Mechanical Investigations of ASTM A36 Welded Steels with Stainless Steel Cladding. Coatings 2020, 10, 844. [Google Scholar] [CrossRef]

- Buchely, M.F.; Gutierrez, J.C.; León, L.M.; Toro, A. The effect of microstructure on abrasive wear of hardfacing alloys. Wear 2005, 259, 52–61. [Google Scholar] [CrossRef]

- Balasubramanian, V.; Varahamoorthy, R.; Ramachandran, C.S.; Muralidharan, C. Selection of welding process for hardfacing on carbon steels based on quantitative and qualitative factors. Int. J. Adv. Manuf. Technol. 2009, 40, 887–897. [Google Scholar] [CrossRef]

- Garcia, R.; Canobre, S.; Costa, H. Microabrasion-corrosion resistance of Ni–Cr superalloys deposited by plasma transferred arc (PTA) welding. Tribol. Int. 2020, 143, 106080. [Google Scholar] [CrossRef]

- Deng, D.; Zhang, L.; Niu, T.; Liu, H.; Zhang, H.-C. Microstructures and Wear Performance of PTAW Deposited Ni-Based Coatings with Spherical Tungsten Carbide. Metals 2015, 5, 1984–1996. [Google Scholar] [CrossRef]

- Ferreira, L.d.S.; Graf, K.; Scheid, A. Microstructure and properties of Nickel-based C276 alloy coatings by PTA on AISI 316L and API 5L X70 steel substrates. Mater. Res. 2015, 18, 212–221. [Google Scholar] [CrossRef]

- Keränen, M. Effect of welding parameters of plasma transferred arc welding method on abrasive wear resistance of 12V tool steel deposit. Ph.D. Thesis, Aalto University School of Science and Technology, Espoo, Finland, 2010. [Google Scholar]

- Raghu, D.; Webber, R. PTA proves its worth in high-volume hardfacing jobs. Weld. J. 1996, 75, 34–40. [Google Scholar]

- Mendez, P.F.; Barnes, N.; Bell, K.; Borle, S.D.; Gajapathi, S.S.; Guest, S.D.; Izadi, H.; Gol, A.K.; Wood, G. Welding processes for wear resistant overlays. J. Manuf. Process. 2014, 16, 4–25. [Google Scholar] [CrossRef]

- Pintaude, G. Strategies for the development of wear-resistant coatings: A review. Soldag. Inspeção 2021, 26, e2616. [Google Scholar] [CrossRef]

- Ulutan, M.; Kiliçay, K.; Çelik, O.N.; Er, U. Microstructure and wear behaviour of plasma transferred arc (PTA)-deposited FeCrC composite coatings on AISI 5115 steel. J. Mater. Process. Technol. 2016, 236, 26–34. [Google Scholar] [CrossRef]

- Buytoz, S.; Orhan, A.; Gur, A.K.; Caligulu, U. Microstructural Development of Fe–Cr–C and B4C Powder Alloy Coating on Stainless Steel by Plasma-Transferred Arc Weld Surfacing. Arab. J. Sci. Eng. 2013, 38, 2197–2204. [Google Scholar] [CrossRef]

- Deshmukh, D.D.; Kalyankar, V.D. Recent status of overlay by plasma transferred arc welding technique. Int. J. Mater. Prod. Technol. 2018, 56, 23–83. [Google Scholar] [CrossRef]

- Buchanan, V.; Shipway, P.; McCartney, D. Microstructure and abrasive wear behaviour of shielded metal arc welding hardfacings used in the sugarcane industry. Wear 2007, 263, 99–110. [Google Scholar] [CrossRef]

- Qi, X.; Jia, Z.; Yang, Q.; Yang, Y. Effects of vanadium additive on structure property and tribological performance of high chromium cast iron hardfacing metal. Surf. Coatings Technol. 2011, 205, 5510–5514. [Google Scholar] [CrossRef]

- Wang, X.; Han, F.; Liu, X.; Qu, S.; Zou, Z. Microstructure and wear properties of the Fe–Ti–V–Mo–C hardfacing alloy. Wear 2008, 265, 583–589. [Google Scholar] [CrossRef]

- Aramide, B.; Pityana, S.; Jamiru, T.; Popoola, P.; Sadiku, R. Influence of Vanadium-Chromium Carbide on the Microstructure of Reinforced FeCrV15 Hardfacing during Laser Cladding Deposit. J. Mater. Eng. Perform. 2022, 31, 514–523. [Google Scholar] [CrossRef]

- Günther, K.; Bergmann, J.P. Influencing Microstructure of Vanadium Carbide Reinforced FeCrVC Hardfacing during Gas Metal Arc Welding. Metals 2020, 10, 1345. [Google Scholar] [CrossRef]

- Wei, S.; Zhu, J.; Xu, L. Effects of vanadium and carbon on microstructures and abrasive wear resistance of high speed steel. Tribol. Int. 2006, 39, 641–648. [Google Scholar] [CrossRef]

- Dutra, W.T.; Machado, I.G. Influência do Pré-aquecimento Indutivo Localizado sobre Características Metalúrgicas de Juntas Soldadas. Soldag. Inspeção 2017, 22, 333–342. [Google Scholar] [CrossRef][Green Version]

- Deshmukh, D.D.; Kalyankar, V.D. Deposition Characteristics of Multitrack Overlayby Plasma Transferred Arc Welding on SS316Lwith Co-Cr Based Alloy—Influence of Process Parameters. High Temp. Mater. Process. 2019, 38, 248–263. [Google Scholar] [CrossRef]

- Laurila, J.; Milanti, A.; Nurminen, J.; Kallio, M.; Vuoristo, P. Microstructure and wear behaviour of a vanadium carbide reinforced weld coating. Wear 2013, 307, 142–149. [Google Scholar] [CrossRef]

- Czupryński, A.; Poloczek, T.; Urbańczyk, M.; Spawalnictwa, S.B.-I. Characterization of a new high abrasion and erosion resistance iron-based alloy for pta hardfacing. Int. J. Mod. Manuf. Technol. 2022, 14, 45–54. [Google Scholar] [CrossRef]

- Chen, L.H.; Chang, L.C.; Lui, T.S. The abrasion resistance of high-chromium white cast irons as a linear function of carbide volume fraction. Chukung (J. Chin. Foundrymen’s Assoc.) 1990, 65, 21–25. [Google Scholar]

- Pereplyotchikov, E. Development of high-vanadium alloy for plasma-powder surfacing of knives for cutting of non-metallic materials. Paton Weld. J. 2014, 2014, 128–131. [Google Scholar] [CrossRef][Green Version]

- Kumar, R.; Arya, H.K. Experimental Determination of Cooling Rate and its Effect on Microhardness in Submerged Arc Welding of Mild Steel Plate (Grade c-25 as per IS 1570). J. Mater. Sci. Eng. 2013, 3, 1–4. [Google Scholar] [CrossRef]

- Naksuk, N.; Nakngoenthong, J.; Printrakoon, W.; Yuttawiriya, R. Real-Time Temperature Measurement Using Infrared Thermography Camera and Effects on Tensile Strength and Microhardness of Hot Wire Plasma Arc Welding. Metals 2020, 10, 1046. [Google Scholar] [CrossRef]

- Poorhaydari, K.; Patchett, B.M.; Ivey, D.G. Estimation of cooling rate in the welding of plates with intermediate thickness. Weld. J. 2005, 84, 149S–155S. [Google Scholar]

- Souza, D.; Tavares, A.F.; Costa, H.L.; Osorio, A.G. Efeito da energia de soldagem sobre a microestrutura e resistência à corrosão de revestimentos de Inconel 625 aplicados pelo processo GMAW. Materia 2020, 25, e12633. [Google Scholar] [CrossRef]

- D’Oliveira, A.; Paredes, R.; Santos, R. Pulsed current plasma transferred arc hardfacing. J. Mater. Process. Technol. 2006, 171, 167–174. [Google Scholar] [CrossRef]

- Balasubramanian, V.; Lakshminarayanan, A.K.; Varahamoorthy, R.; Babu, S. Understanding the Parameters Controlling Plasma Transferred Arc Hardfacing Using Response Surface Methodology. Mater. Manuf. Process. 2008, 23, 674–682. [Google Scholar] [CrossRef]

- Tarragó, J.; Coureaux, D.; Torres, Y.; Wu, F.; Al-Dawery, I.; Llanes, L. Implementation of an effective time-saving two-stage methodology for microstructural characterization of cemented carbides. Int. J. Refract. Met. Hard Mater. 2016, 55, 80–86. [Google Scholar] [CrossRef]

- Dong, L.-M.; Qiu, X.-B.; Liu, T.-Y.; Lu, Z.-Y.; Fang, F.; Hu, X.-J. Estimation of cooling rate from 800 °C to 500 °C in the welding of intermediate thickness plates based on FEM simulation. J. Mater. Sci. Eng. 2017, B7, 258–267. [Google Scholar]

- Voort, V.G.F. Metallography, Principles and Practice; ASM International: West Conshohocken, PA, USA, 1999. [Google Scholar]

- G65-16; Measuring Abrasion Using the Dry Sand/Rubber Wheel Apparatus. Annual Book of Standards Volume 0302: Wear and Erosion; Metal Corrosion. Book of Standards; ASTM International: Philadelphia, PA, USA, 2021.

- Macedo, B.P.N.; Trevisan, L.A.; Crespo, G.d.S.; Manera, R.d.S.; Ventrella, V.A.; Gallego, J. Revestimentos duros depositados por soldagem. In XXXVI Consolda—Congresso Nacional de Soldagem; ABS—Associação Brasileira de Soldagem: Sao Paulo, SP, Brazil, 2010. [Google Scholar]

- Modenesi, P.J.; Marques, P.V.; Santos, D.B. Introdução à Metalurgia da Soldagem; Universidade Federal de Minas Gerais: Belo Horizonte, Brazil, 2004; p. 79. [Google Scholar]

- Quintino, L.; Liskevich, O.; Vilarinho, L.; Scotti, A. Heat input in full penetration welds in gas metal arc welding (GMAW). Int. J. Adv. Manuf. Technol. 2013, 68, 2833–2840. [Google Scholar] [CrossRef]

- Maroli, B.; Dizdar, S.; Bengtsson, S. Iron Based Hardfacing Alloys for Abrasive and Impact Wear. In Proceedings of the ITSC2017—International Thermal Spray Conference, Düsseldorf, Germany, 7–9 June 2017. [Google Scholar]

- Takeda, M.; Mitome, M.; Hayakawa, H.; Nishiuchi, S.; Tanabe, T.; Yamamoto, S. Morphology and crystallographic phase of V–C particles formed in Fe–Cr–Ni–V–C alloys. Mater. Sci. Technol. 2013, 29, 672–678. [Google Scholar] [CrossRef]

- Todd, J.A.; Li, P. Microstructure-mechanical property relationships in isothermally transformed vanadium steels. Met. Mater. Trans. A 1986, 17, 1191–1202. [Google Scholar] [CrossRef]

- Pan, X.-L.; Umemoto, M. Precipitation Characteristics and Mechanism of Vanadium Carbides in a V-Microalloyed Medium-Carbon Steel. Acta Met. Sin. Engl. Lett. 2018, 31, 1197–1206. [Google Scholar] [CrossRef]

- Lei, Y.; Wang, X.; Zhu, Q.; Liu, F. Effect of Vanadium on Microstructure and Mechanical Properties of TIG Weld Joint of China Low Activation Martensitic Steel. J. Fusion Energy 2015, 34, 1112–1117. [Google Scholar] [CrossRef]

- Benito, S.; Wulbieter, N.; Pöhl, F.; Theisen, W. Microstructural Analysis of Powder Metallurgy Tool Steels in the Context of Abrasive Wear Behavior: A New Computerized Approach to Stereology. J. Mater. Eng. Perform. 2019, 28, 2919–2936. [Google Scholar] [CrossRef]

- Michalcová, A.; Pečinka, V.; Kačenka, Z.; Šerák, J.; Kubásek, J.; Novák, P.; Vojtěch, D. Microstructure, Mechanical Properties, and Thermal Stability of Carbon-Free High Speed Tool Steel Strengthened by Intermetallics Compared to Vanadis 60 Steel Strengthened by Carbides. Metals 2021, 11, 1901. [Google Scholar] [CrossRef]

- Costa, H.; Ardila, M.; Labiapari, W.; Silva, W.; de Mello, J. Effect of surface topography on the dynamics of the abrasive particles during micro-abrasion. Wear 2015, 324-325, 129–139. [Google Scholar] [CrossRef]

- Grasser, D.; Gallo, S.C.; Pereira, M.; Barnett, M. Experimental investigation of the effect of insert spacing on abrasion wear resistance of a composite. Wear 2022, 494-495, 204277. [Google Scholar] [CrossRef]

- Gates, J. Two-body and three-body abrasion: A critical discussion. Wear 1998, 214, 139–146. [Google Scholar] [CrossRef]

- García, C.; Martín, F.; Herranz, G.; Berges, C.; Romero, A. Effect of adding carbides on dry sliding wear behaviour of steel matrix composites processed by metal injection moulding. Wear 2018, 414-415, 182–193. [Google Scholar] [CrossRef]

- García, C.; Romero, A.; Herranz, G.; Blanco, Y.; Martin, F. Effect of vanadium carbide on dry sliding wear behavior of powder metallurgy AISI M2 high speed steel processed by concentrated solar energy. Mater. Charact. 2016, 121, 175–186. [Google Scholar] [CrossRef]

- Xu, L.; Wei, S.; Xiao, F.; Zhou, H.; Zhang, G.; Li, J. Effects of carbides on abrasive wear properties and failure behaviours of high speed steels with different alloy element content. Wear 2017, 376-377, 968–974. [Google Scholar] [CrossRef]

- De Mello, J.D.B.; Durand-Charre, M.; Mathia, T. Abrasion mechanisms of white cast iron II: Influence of the metallurgical structure of V Cr white cast irons. Mater. Sci. Eng. 1986, 78, 127–134. [Google Scholar] [CrossRef]

| C | Fe | Si | Cr | V | Mn | Ni | |

|---|---|---|---|---|---|---|---|

| A11—Commercial powder | 2.35–2.55 | Bal. | 0.75–1.10 | 4.75–5.75 | 9.15–10.35 | 0.35–0.60 | - |

| Commercial anti-wear steel USI AR 450 | ≥0.25 | Bal. | - | 0.40 | - | 1.50 | 0.20 |

| Parameters | Value |

|---|---|

| Feeding rate (kg/h) | 1.0 |

| Set current (A) | 200 |

| Average current (A) | 193 |

| Torch weaving frequency (Hz) | 3.5 |

| Weaving width (mm) | 3.0 |

| Shielding gas; Ar (L/min) | 12 |

| Plasma and Carrier gas; Ar (L/min) | 2.0 |

| Electrode setback (mm) | 1.5 |

| Travel speed (cm·min−1) | 7 |

| Nozzle to workpiece distance (mm) | 15 |

| Parameter | Value |

|---|---|

| Wheel diameter (mm) | 225 |

| Rotation speed (rpm) | 200 |

| Time (min) | 60 |

| Normal load (N) | 48 e 160 |

| Sand flow | 2 kg·min−1 |

| Sand granulometry # 50 | 0.6 mm up to 0.3 mm |

| Sand granulometry # 100 | 0.3 mm up to 0.15 mm |

| Substrate | Point | Elements Content (wt.%) | ||||||

|---|---|---|---|---|---|---|---|---|

| C | Si | V | Cr | Mn | Fe | Mo | ||

| 12.5 mm | pt1 | 1.96 | 1.32 | 7.42 | 5.63 | 0.58 | 81.52 | 1.56 |

| pt2 | 4.13 | 1.13 | 18.34 | 5.54 | 0.68 | 67.72 | 2.46 | |

| pt3 | 2.01 | 1.29 | 6.36 | 4.38 | 0.75 | 84.08 | 1.15 | |

| pt4 | 1.93 | 1.27 | 4.81 | 4.48 | 0.53 | 86.33 | 0.65 | |

| 25.4 mm | pt1 | 6.71 | 1.16 | 24.58 | 5.55 | - | 59.16 | 2.67 |

| pt2 | 7.59 | 1.32 | 24.99 | 5.77 | 0.61 | 57.22 | 2.50 | |

| pt3 | 7.79 | 1.16 | 18.94 | 5.06 | 0.55 | 64.84 | 1.66 | |

| pt4 | 8.08 | 0.87 | 49.85 | 4.25 | - | 34.66 | 1.89 | |

| Substrate | Volume Fraction, % | Mean Free Distance (λ), µm | Size Particles Area, µm² | |

|---|---|---|---|---|

| Primary Carbides | Coarse Microstructures | |||

| 12.5 mm | 18 | 4.2 ± 0.1 | 1.2 | - |

| 25.4 mm | 38 | 2.2 ± 0.1 | Min. 0.6 Max. 10.3 | Min. 0.6 Max. 33.4 |

| Element Content (wt.%) | |||||||

|---|---|---|---|---|---|---|---|

| C | O | Si | V | Cr | Mn | Fe | |

| shiny particles | 3.72 | 39.54 | 17.63 | 3.80 | 1.46 | - | 21.98 |

| darker spots | 5.62 | 18.57 | 3.02 | 11.45 | 3.14 | 0.38 | 54.58 |

| Point | Elements Content (wt.%) | |||||||

|---|---|---|---|---|---|---|---|---|

| C | O | Si | V | Cr | Mn | Fe | Mo | |

| pt1 | 2.73 | 4.92 | 1.77 | 21.80 | 6.21 | 0.51 | 58.37 | 3.20 |

| pt2 | 1.67 | 11.58 | 3.52 | 12.67 | 4.69 | 0.54 | 61.97 | 1.41 |

| pt3 | 1.37 | 0.97 | 1.70 | 5.14 | 4.61 | 0.75 | 84.23 | 0.88 |

| pt4 | 1.17 | 37.13 | 5.83 | 23.53 | 2.99 | 0.39 | 22.56 | 1.82 |

| pt5 | 1.44 | 36.24 | 12.91 | 7.95 | 2.61 | 0.40 | 29.17 | 1.18 |

| Substrate | Sand | Load, N | Mean Free Distance (λ), µm | Average Width of Grooves L, µm |

|---|---|---|---|---|

| 12.5 mm | #50 | 48 | 4.2 | 5.4 ± 2 |

| 160 | 12.4 ± 1 | |||

| #100 | 48 | 2.7 ± 1 | ||

| 160 | 1.6 ± 1 | |||

| 25.4 mm | #50 | 48 | 2.2 | 2.2 ± 2 |

| 160 | 5.2 ± 3 | |||

| #100 | 48 | 1.5 ± 0.2 | ||

| 160 | 3.9 ± 0.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Passos, T.A.; Costa, H.; Luz, F.K.C.; Pintaude, G. The Effect of the Dilution Level on Microstructure and Wear Resistance of Fe-Cr-CV Hardfacing Coatings Deposited by PTA-P. Coatings 2022, 12, 1835. https://doi.org/10.3390/coatings12121835

Passos TA, Costa H, Luz FKC, Pintaude G. The Effect of the Dilution Level on Microstructure and Wear Resistance of Fe-Cr-CV Hardfacing Coatings Deposited by PTA-P. Coatings. 2022; 12(12):1835. https://doi.org/10.3390/coatings12121835

Chicago/Turabian StylePassos, Thais Andrezza, Henara Costa, Felipe Kevin Correa Luz, and Giuseppe Pintaude. 2022. "The Effect of the Dilution Level on Microstructure and Wear Resistance of Fe-Cr-CV Hardfacing Coatings Deposited by PTA-P" Coatings 12, no. 12: 1835. https://doi.org/10.3390/coatings12121835

APA StylePassos, T. A., Costa, H., Luz, F. K. C., & Pintaude, G. (2022). The Effect of the Dilution Level on Microstructure and Wear Resistance of Fe-Cr-CV Hardfacing Coatings Deposited by PTA-P. Coatings, 12(12), 1835. https://doi.org/10.3390/coatings12121835