Improving the Efficiency of Air Plasma Spraying of Titanium Nitride Powder

Abstract

:1. Introduction

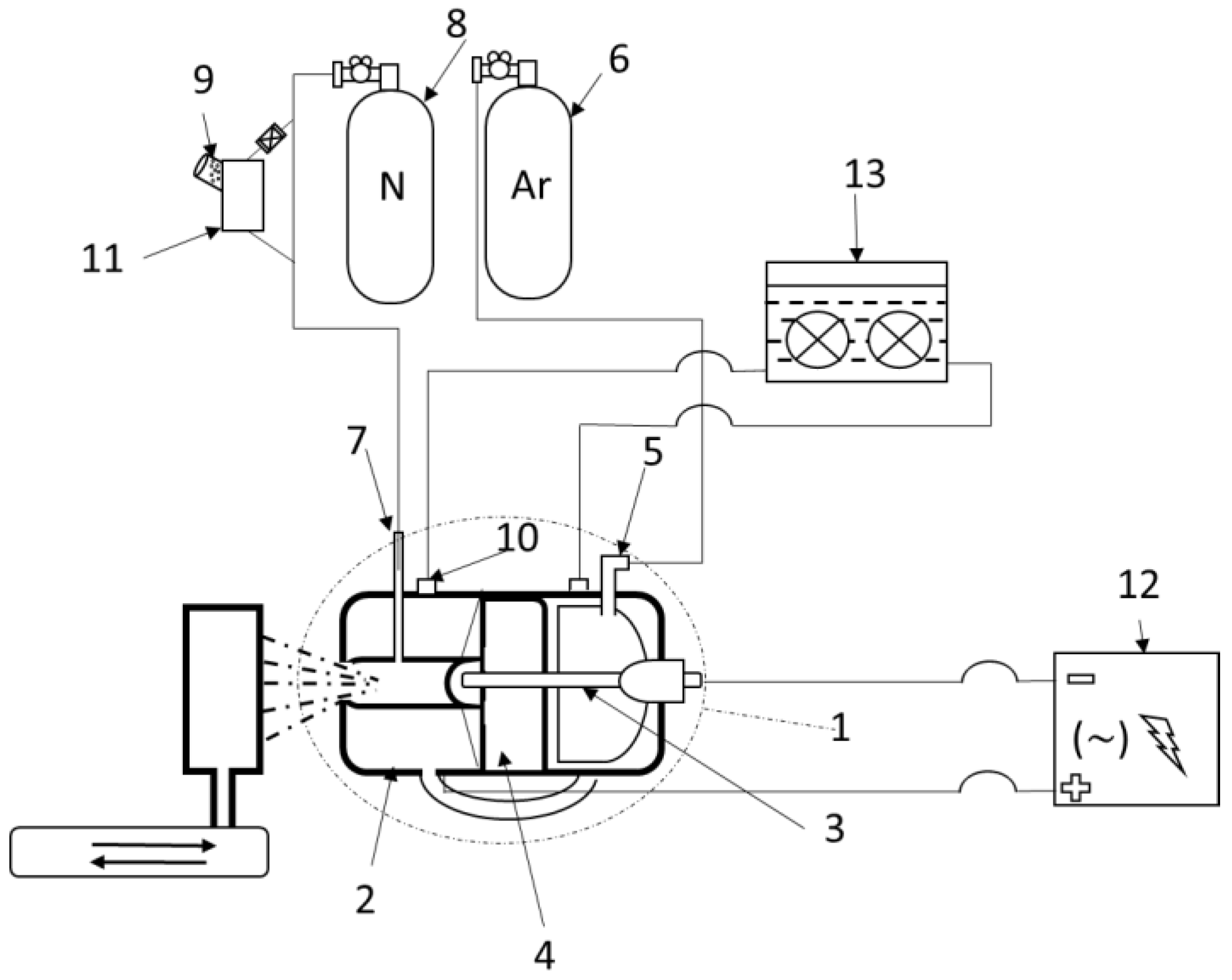

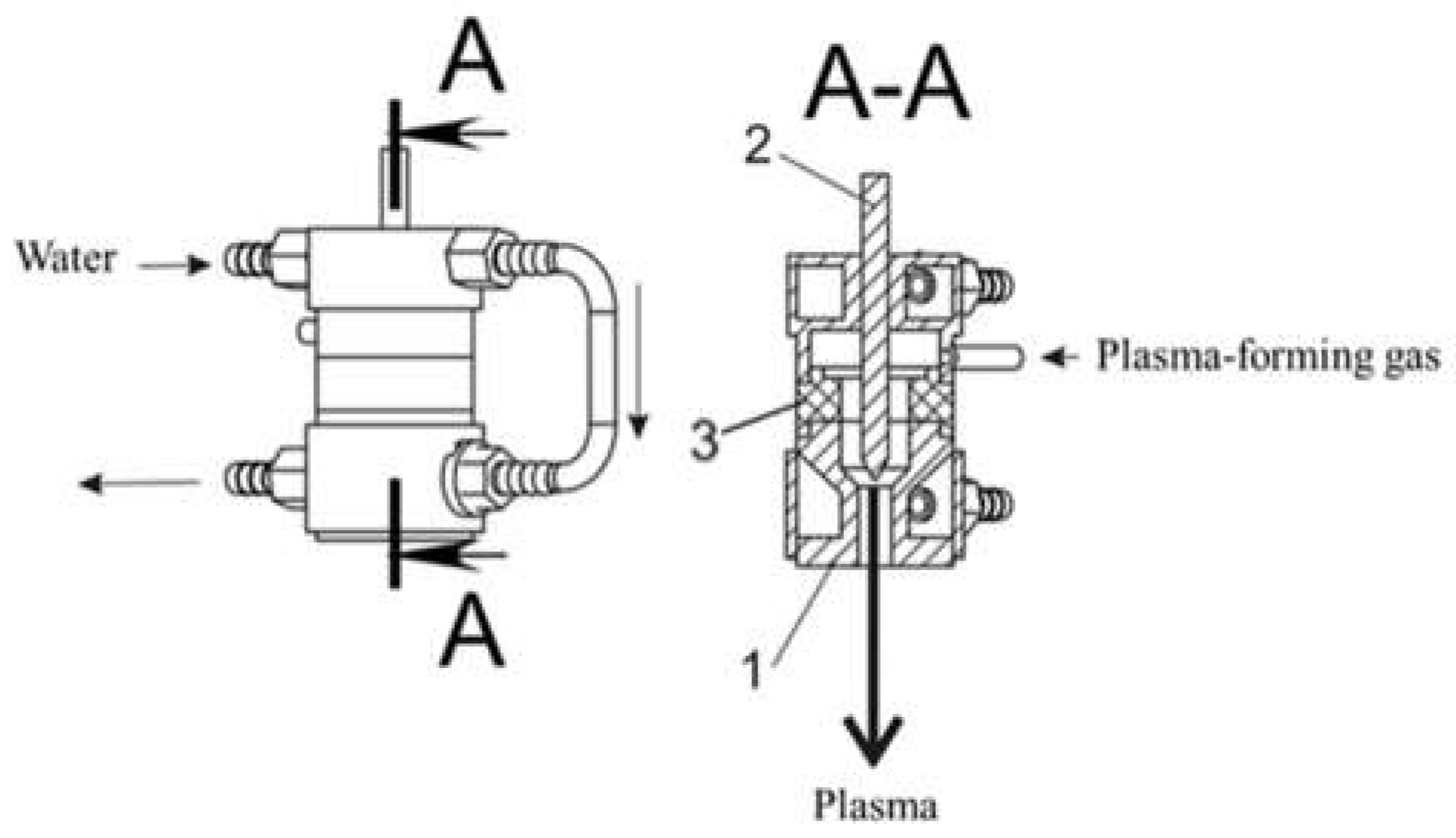

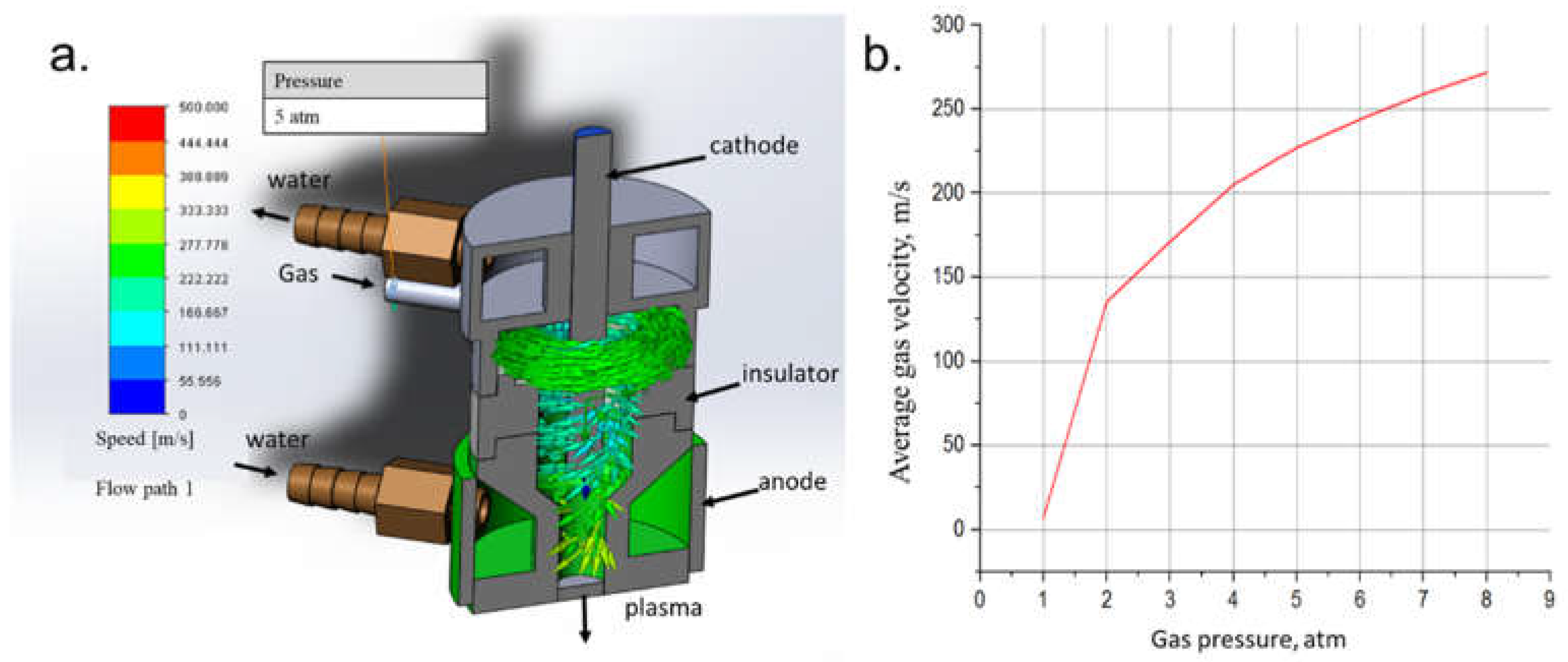

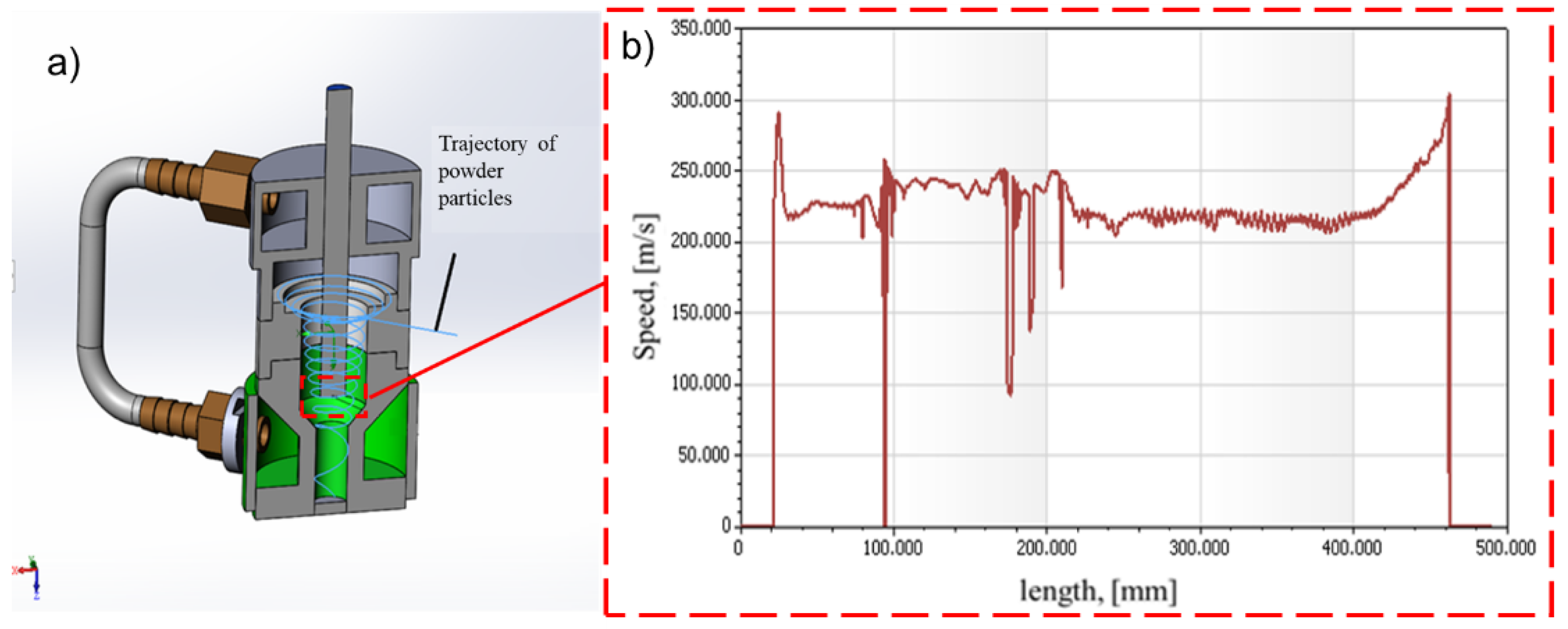

2. Technology and Methods

3. Results and Discussion

4. Conclusions

- The possibility of TiN powder deposition on the steel surface by the APS method is shown. Powder of titanium nitride fraction of 5 microns is fed through an annular slit in the air-plasma jet and is sprayed on the preheated surface (up to 250 °C) with a plasma jet. The particle length of TiN powder in the plasmatron is up to 500 mm, in the plasma zone (nozzle area) it is about 150 mm, and the speed in the plasmatron nozzle area is ≈220 m/s;

- The optimum regime of APS for deposition of TiN powder was determined: the current is 250 A, the voltage is 68 V, the gas flow rate is 34 L/min, the spraying distance is 150 mm. To reduce the oxidation of TiN powder in the APS process, a method of creating a nitrogen environment at the outlet of the nozzle-anode, nitrogen flow rate 3 bar was used;

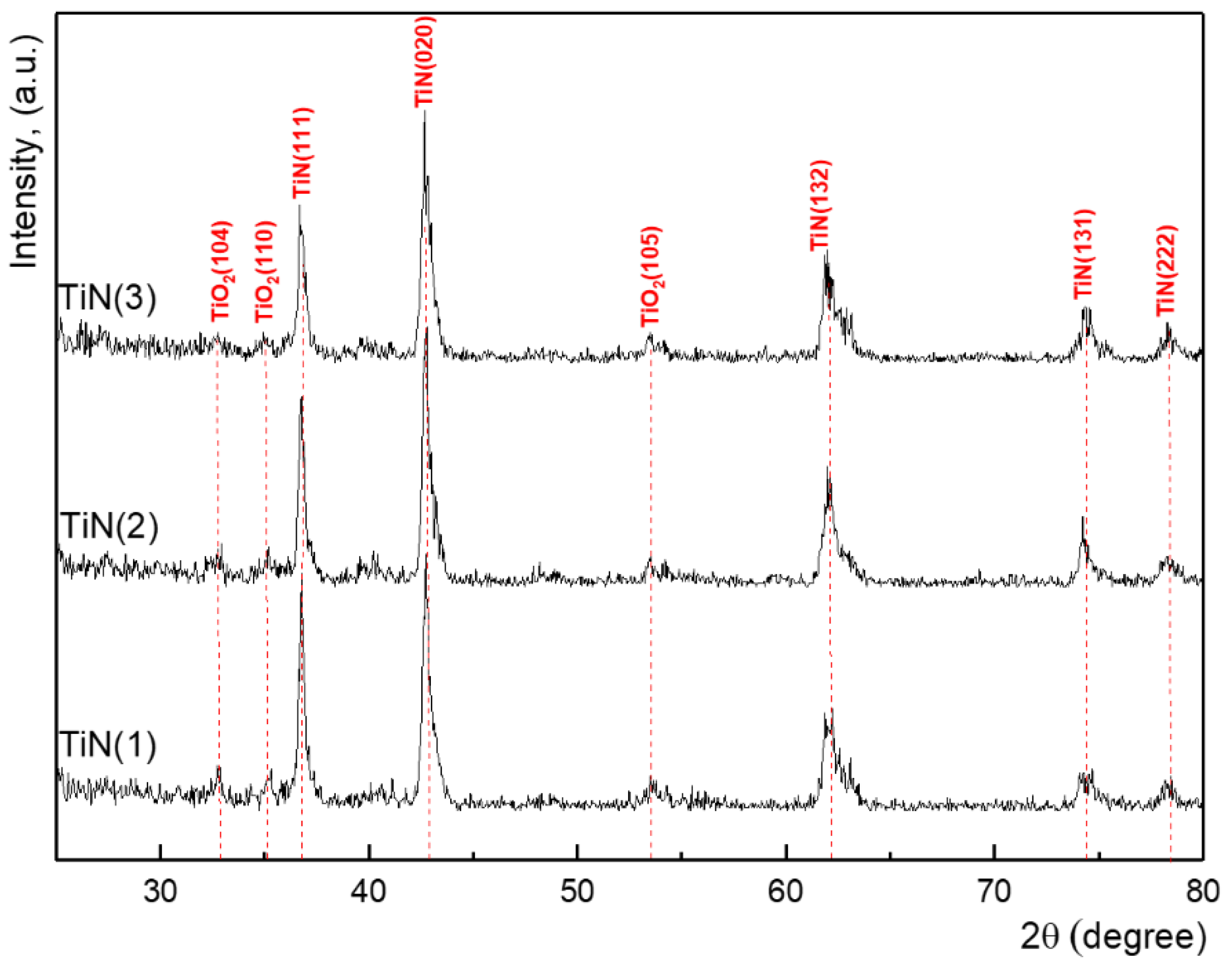

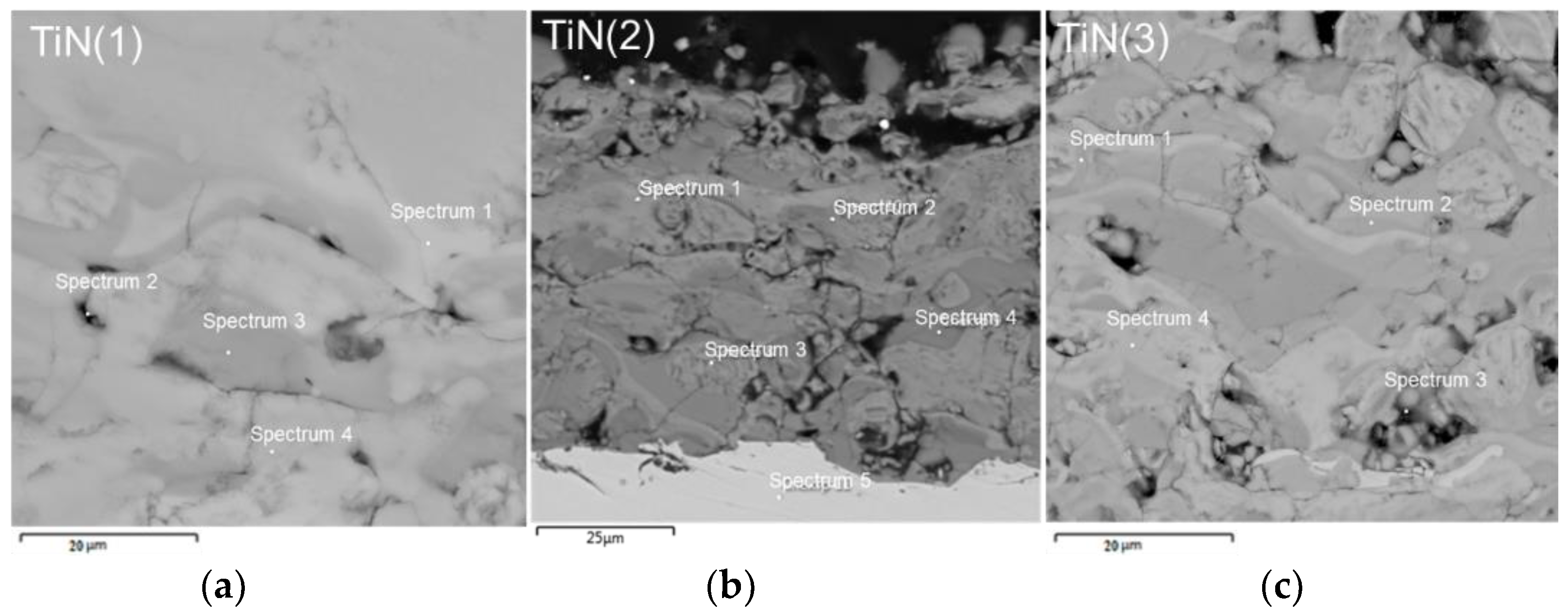

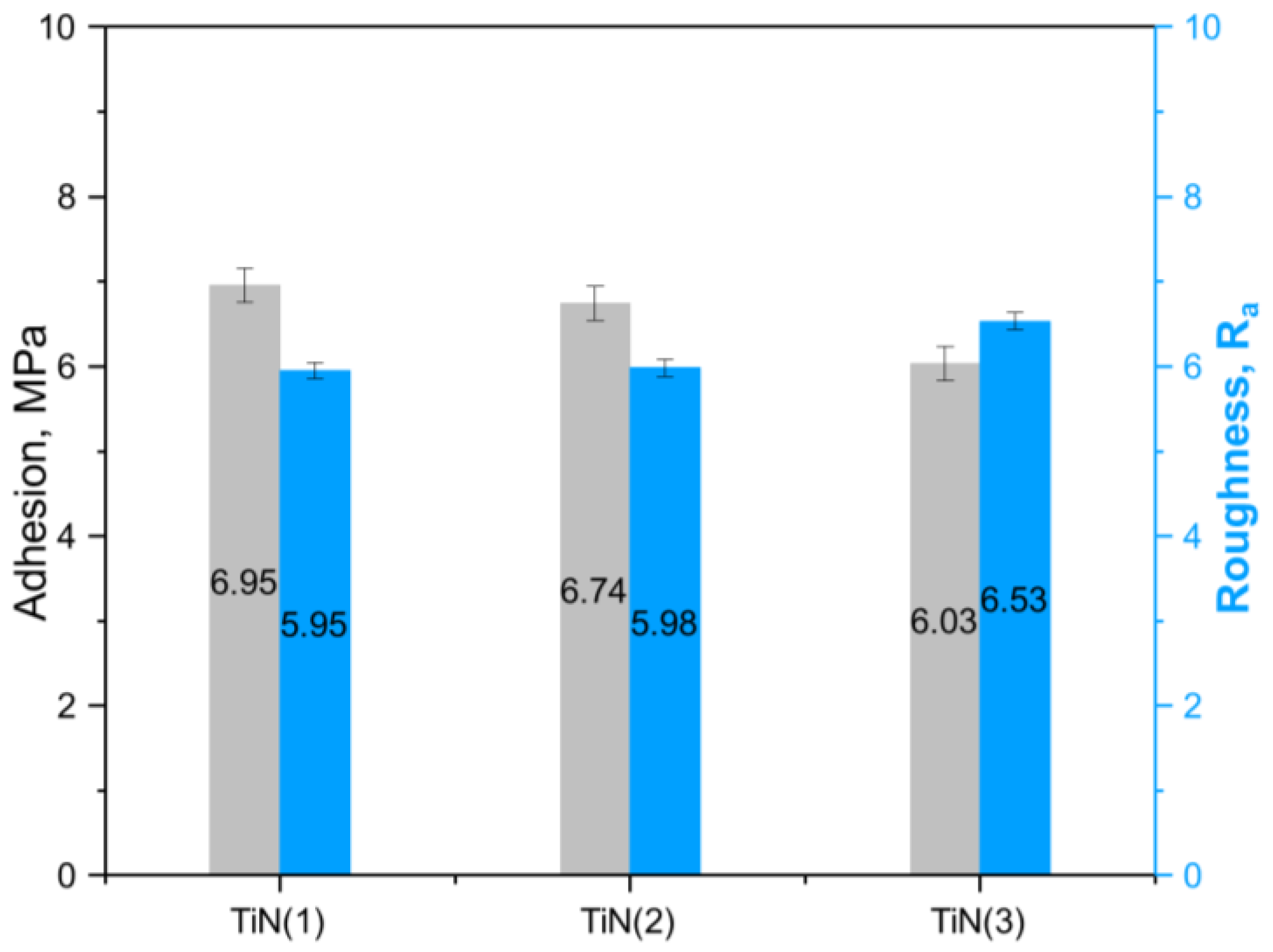

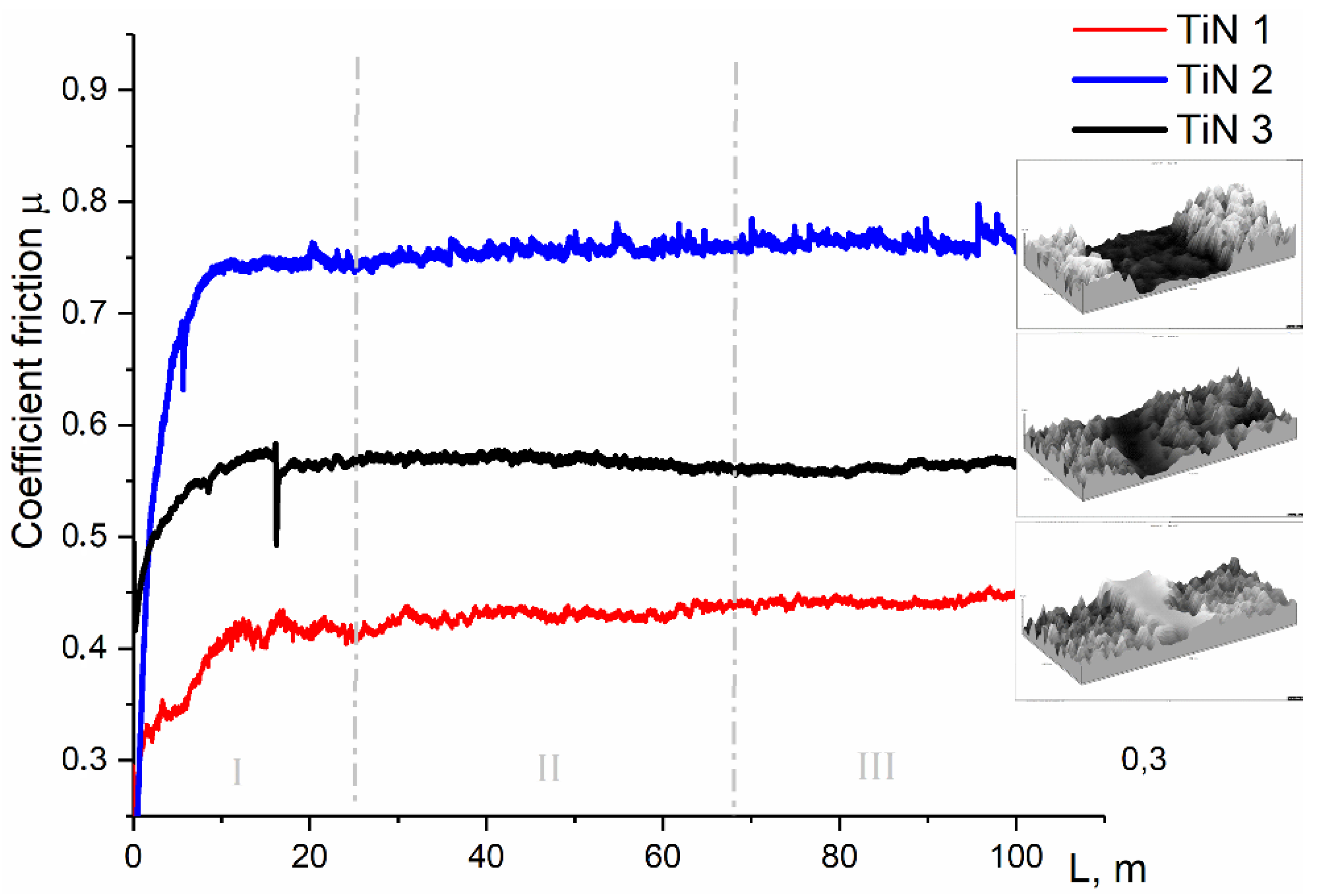

- Microstructure of coatings is a lamellar structure with the presence of a small number of defects (cracks, pores) regardless of the application mode. The main coating phase is TiN. Increasing the spraying current causes the formation of a porous coating structure with a developed surface topography and leads to the deterioration of mechanical and tribological properties of the coatings.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kobayashi, A. Formation of TiN coatings by gas tunnel type plasma reactive spraying. Surf. Coat. Technol. 2000, 132, 152–157. [Google Scholar] [CrossRef]

- Zou, D.L.; Yan, D.R.; He, J.N.; Li, X.Z.; Dong, Y.C.; Zhang, J.X. Reactive Plasma sprayed TiN coating and its thermal stability. J. Iron Steel Res. Int. 2007, 14, 71–75. [Google Scholar] [CrossRef]

- Shinde, S.V.; Sampath, S. Factors governing segmentation crack characteristics in air plasma sprayed ceramics. J. Eur. Ceram. Soc. 2022, 42, 1077–1087. [Google Scholar] [CrossRef]

- Li, G.; Zhang, L.; Cai, F.; Yang, Y.; Wang, Q.; Zhang, S. Characterization and corrosion behaviors of TiN/TiAlN multilayer coatings by ion source enhanced hybrid arc ion plating. Surf. Coat. Technol. 2019, 366, 355–365. [Google Scholar] [CrossRef]

- Xian, G.; Xiong, J.; Fan, H.; Jiang, F.; Guo, Z.; Zhao, H.; Liu, Y. Investigations on microstructure, mechanical and tribological properties of TiN coatings deposited on three different tool materials. Int. J. Refract. Met. Hard Mater. 2022, 102, 105700. [Google Scholar] [CrossRef]

- Rakhadilov, B.; Kenesbekov, A.; Skakov, M.; Miniyzov, A. Hydrogen and deuterium storage in tungsten when irradiation with Plasma beam. In Proceedings of the METAL 2018-27th International Conference on Metallurgy and Materials, Brno, Czech, 23–25 May 2018; pp. 1216–1221. [Google Scholar]

- Rahadilov, B.K.; Zhurerova, L.G.; Sagdoldina, Z.B.; Kenesbekov, A.B.; Bayatanova, L.B. Morphological Changes in the Dislocation Structure of Structural Steel 20GL after Electrolytic-Plasma Hardening of the Surface. J. Surf. Investig. X-Ray Synchrotron Neutron Tech. 2021, 15, 408–413. [Google Scholar] [CrossRef]

- Sharma, A.; Pathak, D.; Sharma, D.P.; Nunzi, J.M. Recent advances in bulkheterojunction solar cells: A Review. Eur. Phys. J. Appl. Phys. 2022. [Google Scholar] [CrossRef]

- Liu, K.; Chen, X.; Du, K.; Wang, Y.; Du, J.; Wang, X.; Ming, W. LC/8YSZ TBCs Thermal Cycling Life and Failure Mechanism under Extreme Temperature Gradients. Coatings 2021, 11, 1051. [Google Scholar] [CrossRef]

- Liu, K.; Bai, Y.; Li, J.; Ma, J.; Du, J.; Cao, Y.; Li, X. Structure-property relationship and design of plasma-sprayed La2Ce2O7/8YSZ composite coatings for gas turbine blades. Ceram. Int. 2018, 44, 13662–13673. [Google Scholar] [CrossRef]

- Lee, S.Y.; Chung, J.W.; Kim, K.B.; Han, J.G.; Kim, S.S. Duplex plasma surface treatment process on mild steel and high alloyed tool steel. Surf. Coat. Technol. 1996, 86, 325–331. [Google Scholar] [CrossRef]

- Schönjahn, C.; Bamford, M.; Donohue, L.; Lewis, D.; Forder, S.; Münz, W.-D. The interface between TiAlN hard coatings and steel substrates generated by high energetic Cr+ bombardment. Surf. Coat. Technol. 2000, 125, 66–70. [Google Scholar] [CrossRef]

- Stoiber, M.; Perlot, S.; Mitterer, C.; Beschliesser, M.; Lugmair, C.; Kullmer, R. PACVD TiN/Ti–B–N multilayers: From micro-to nano-scale. Surf. Coat. Technol. 2004, 177, 348–354. [Google Scholar] [CrossRef]

- Motte, P.; Proust, M.; Torres, J.; Gobil, Y.; Morand, Y.; Palleau, J.; Juhel, M. TiN-CVD process optimization for integration with Cu-CVD. Microelectron. Eng. 2000, 50, 369–374. [Google Scholar] [CrossRef]

- Kobayashi, A. New applied technology of plasma heat sources. Weld. Int. 1990, 4, 276–282. [Google Scholar] [CrossRef]

- Rickerby, D.S.; Burneet, P.J. The wear and corrosion resistance of hard PVD coatings. Surf. Coat. Technol. 1987, 33, 191–211. [Google Scholar] [CrossRef]

- Lang, F.; Yu, Z. The corrosion resistance and wear resistance of thick TiN coatings deposited by arc ion plating. Surf. Coat. Technol. 2001, 145, 80–87. [Google Scholar] [CrossRef]

- Murthy, J.K.N.; Rao, D.S.; Venkataraman, B. Effect of grinding on the erosion behaviour of a WC–Co–Cr coating deposited by HVOF and detonation gun spray processes. Wear 2001, 249, 592–600. [Google Scholar] [CrossRef]

- Zhang, X.; Li, F.; Li, Y.; Lu, Q.; Li, Z.; Lu, H.; Qi, X. Comparison on multi-angle erosion behavior and mechanism of Cr3C2-NiCr coatings sprayed by SPS and HVOF. Surf. Coat. Technol. 2020, 403, 126366. [Google Scholar] [CrossRef]

- Sagdoldina, Z.; Rakhadilov, B.; Kurbanbekov, S.; Kozhanova, R.; Kengesbekov, A. Effect of irradiation with Si+ ions on phase transformations in Ti–Al system during thermal annealing. Coatings 2021, 11, 205. [Google Scholar] [CrossRef]

- Feng, W.R.; Yan, D.R.; He, J.N.; Zhang, G.L.; Chen, G.L.; Gu, W.C.; Yang, S.Z. Microhardness and toughness of the TiN coating prepared by reactive plasma spraying. Appl. Surf. Sci. 2005, 243, 204–213. [Google Scholar] [CrossRef]

- Feng, W.; Yan, D.; He, J.; Li, X.; Dong, Y. Reactive plasma sprayed TiN coating and its tribological properties. Wear 2005, 258, 806–811. [Google Scholar] [CrossRef]

- Galvanetto, E.; Galliano, F.P.; Borgioli, F.; Bardi, U.; Lavacchi, A. XRD and XPS study on reactive plasma sprayed titanium–titanium nitride coatings. Thin Solid Film. 2001, 384, 223–229. [Google Scholar] [CrossRef]

- Luo, L.; Chen, Y.; Zhou, M.; Shan, X.; Lu, J.; Zhao, X. Progress update on extending the durability of air plasma sprayed thermal barrier coatings. Ceram. Int. 2022, 48, 18021–18034. [Google Scholar] [CrossRef]

- Rakhadilov, B.K.; Kenesbekov, A.B.; Kowalevski, P.; Ocheredko, Y.A.; Sagdoldina, Z.B. Development of air-plasma technology for hardening cutting tools by applying wear-resistant coatings. News Natl. Acad. Sci. Repub. Kazakhstan Ser. Geol. Tech. Sci. 2020, 3, 54–62. [Google Scholar] [CrossRef]

- Basha, G.M.T.; Srikanth, A.; Venkateshwarlu, B. A critical review on nano structured coatings for alumina-titania (Al2O3-TiO2) deposited by air plasma spraying process (APS). Mater. Today Proc. 2020, 22, 1554–1562. [Google Scholar] [CrossRef]

- Ocheredko Igor Alexandrovich, Rakhadilov Bauyrzhan Korabaevich, Tuyakbaev Bauyrzhan Toleubekovich, Kenesbekov Aidar Bakytbekuly. Plasmatron for spraying, KZ For Invention Patent No. 34334. Available online: https://kzpatents. com/?page=ipc (accessed on 29 May 2020).

- Kornienko, E.; Lapushkina, E.J.; I Kuzmin, V.; Vaschenko, S.P.; Gulyaev, I.; Kartaev, E.V.; Sergachev, D.S.; Kashapov, N.; Sharifullin, S.; Fayrushin, I. Air plasma sprayed coatings of self-fluxing powder materials. J. Phys. Conf. Ser. 2014, 567, 012010. [Google Scholar] [CrossRef]

- Doudkin, M.; Kim, A.; Kim, V. Application of fem method for modeling and strength analysis of feed elements of vibroscreen. In Proceedings of the International Conference on Computer Aided Engineering, Cairo, Egypt, 18–19 December 2018; pp. 155–162. [Google Scholar]

- Doudkin, M.; Kim, A.; Kim, V.; Mlynczak, M.; Kustarev, G. Computer modeling application for analysis of stress-strain state of vibroscreen feed elements by finite elements method. In Proceedings of the International Conference on Computational and Information Technologies in Science, Engineering and Education, Hong Kong, China, 14–16 June 2018; pp. 82–96. [Google Scholar]

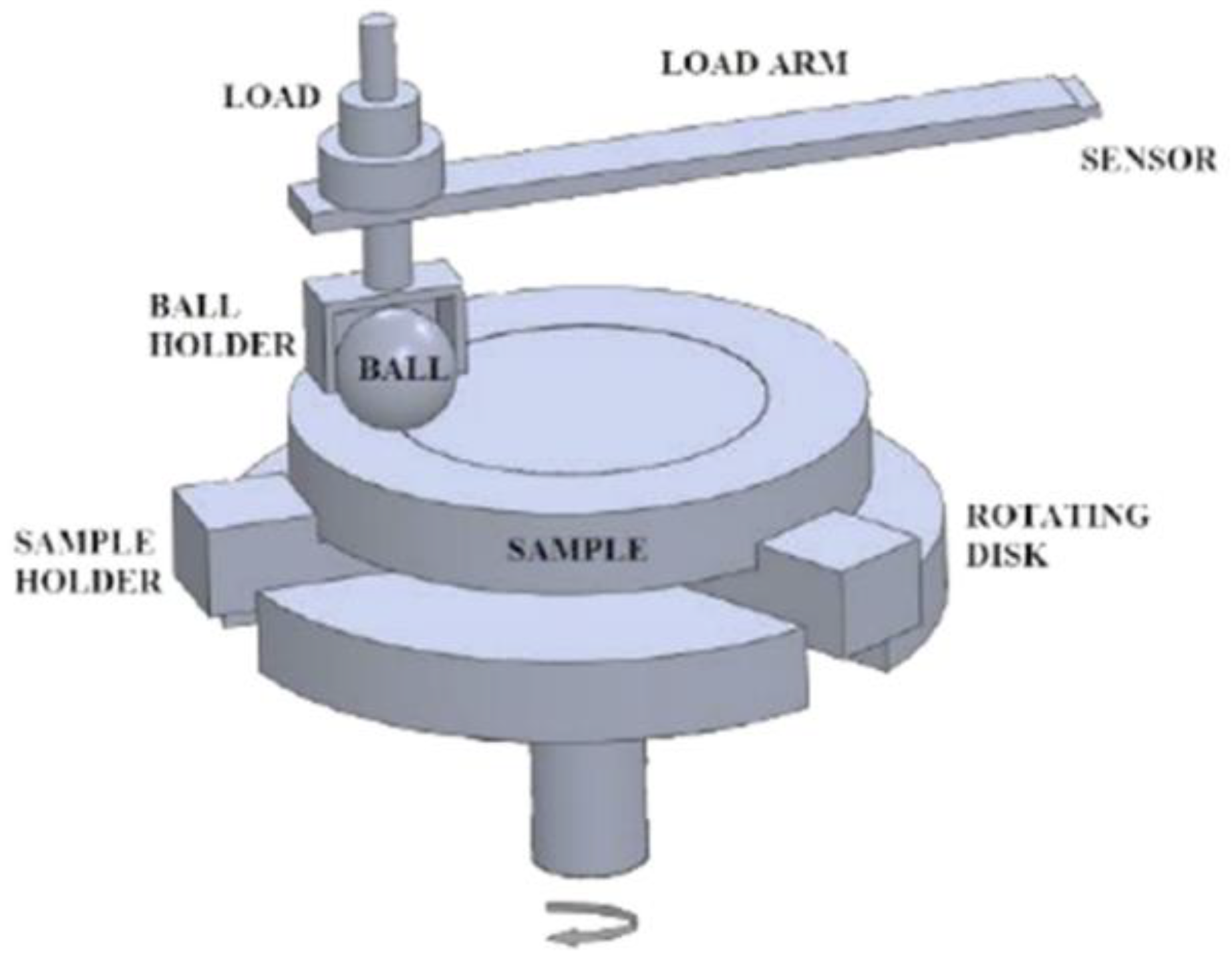

- American Society for Testing and Materials. ASTM G99-17: Standard Test Method for Wear Testing with a Ball-on-Disk Apparatus; ASTM: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Beake, B.D.; Fox-Rabinovich, G.S.; Veldhuis, S.C.; Goodes, S.R. Coating optimisation for high speed machining with advanced nanomechanical test methods. Surf. Coat. Technol. 2009, 203, 1919–1925. [Google Scholar] [CrossRef]

- Beake, B.D. The influence of the H/E ratio on wear resistance of coating systems–Insights from small-scale testing. Surf. Coat. Technol. 2022, 442, 128272. [Google Scholar] [CrossRef]

| Sample | Spraying Distance, mm | Ar Gas Flow Rate, L/min | Gas Flow Rate N, bar | Current, A | Processing Time, s | Thickness of Coatings, μm | Voltages, V |

|---|---|---|---|---|---|---|---|

| TiN(1) | 150 | 34 | 3 | 250 | 60 | ~70 | 68 |

| TiN(2) | 150 | 37 | 3 | 350 | 60 | ||

| TiN(3) | 150 | 40 | 3 | 450 | 60 |

| Sample | Spectrum | N | Ti | Fe | O | Ni | Cr | Total, % |

|---|---|---|---|---|---|---|---|---|

| TiN(1) | Spectrum 1 | 10.14 | 61.17 | - | 28.69 | - | - | 100.00 |

| Spectrum 2 | 37.65 | 63.35 | - | 27.70 | - | - | 100.00 | |

| Spectrum 3 | - | 63.64 | - | 36.37 | - | - | 100.00 | |

| Spectrum 4 | 31.53 | 68.47 | - | - | - | - | 100.00 | |

| TiN(2) | Spectrum 1 | 30.89 | 67.62 | - | 1.49 | - | - | 100.00 |

| Spectrum 2 | 0.85 | 65.02 | - | 34.13 | - | - | 100.00 | |

| Spectrum 3 | 29.59 | 69.14 | - | 1.27 | - | - | 100.00 | |

| Spectrum 4 | - | 61.79 | - | 37.21 | - | - | 100.00 | |

| Spectrum 5 | - | 0.6 | 71.50 | 1.40 | 8.70 | 17.70 | 100.00 | |

| TiN(3) | Spectrum 1 | 32.18 | 67.82 | - | - | - | - | 100.00 |

| Spectrum 2 | - | 73.22 | - | 26.78 | - | - | 100.00 | |

| Spectrum 3 | 27.35 | 67.82 | 1.54 | 3.29 | - | - | 100.00 | |

| Spectrum 4 | 28.47 | 48.12 | - | 23.41 | - | - | 100.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kengesbekov, A.; Rakhadilov, B.; Sagdoldina, Z.; Buitkenov, D.; Dosymov, Y.; Kylyshkanov, M. Improving the Efficiency of Air Plasma Spraying of Titanium Nitride Powder. Coatings 2022, 12, 1644. https://doi.org/10.3390/coatings12111644

Kengesbekov A, Rakhadilov B, Sagdoldina Z, Buitkenov D, Dosymov Y, Kylyshkanov M. Improving the Efficiency of Air Plasma Spraying of Titanium Nitride Powder. Coatings. 2022; 12(11):1644. https://doi.org/10.3390/coatings12111644

Chicago/Turabian StyleKengesbekov, Aidar, Bauyrzhan Rakhadilov, Zhuldyz Sagdoldina, Dastan Buitkenov, Yelmurat Dosymov, and Manarbek Kylyshkanov. 2022. "Improving the Efficiency of Air Plasma Spraying of Titanium Nitride Powder" Coatings 12, no. 11: 1644. https://doi.org/10.3390/coatings12111644

APA StyleKengesbekov, A., Rakhadilov, B., Sagdoldina, Z., Buitkenov, D., Dosymov, Y., & Kylyshkanov, M. (2022). Improving the Efficiency of Air Plasma Spraying of Titanium Nitride Powder. Coatings, 12(11), 1644. https://doi.org/10.3390/coatings12111644