Abstract

In this work, the influence of the technological parameters of the detonation method on the formation of metal oxide compounds on the basis of titanium was investigated. The aim of the work was to investigate the method of the effective control of the phase composition and microstructure of titanium-based coatings during detonation spraying. The main parameters that varied in detonation spraying were the volume of filling the detonation barrel with explosive mixture and the oxygen/fuel ratio. The mechanism of formation of the gradient structure of coatings based on metal oxide compounds depending on the technological parameters of detonation spraying was considered. The structural-phase states and tribological properties of detonation coatings were investigated by the following methods: X-ray phase analysis (XRD), scanning electron microscopy (SEM), energy dispersive spectroscopy (EDX-mapping), profilometry, and the test for wear-resistance according to the “ball-disk” scheme. It is shown that the phase composition of coatings may significantly change relative to the initial titanium powder during the detonation spraying due to the interaction of particles of powders with components of the gas atmosphere. Varying the spraying parameters may control the chemical reaction and provide conditions for the synthesis of the desired phases in the coatings (titanium oxide TiO2 and Ti2O3).

1. Introduction

Titanium (Ti) is a silver–gray metal, paramagnetic, non-corrosive (after oxidation), with a high melting point, known for its light weight and strength [1,2]. Due to these properties, titanium has found applications in various industries, in particular, in the aviation, automotive, marine, medical, chemical, and energy industries [3,4].

Modern materials from titanium and its alloys for structural and functional purposes should have high values of wear resistance, fatigue strength, and corrosion resistance. At present, this is achieved by such technological methods as protective coating, the modification of the physical and chemical properties of part surface layers by methods of modification, and processing methods combining surface modification and coating applications [5].

There are many methods for obtaining Ti-based coatings, such as plasma spraying, laser deposition, magnetron sputtering, high-speed sputtering, electrodeposition, or detonation spraying [6,7]. Most of them are characterized by extreme temperature changes, phase transitions, and/or the rapid kinetic deposition on the surface of the workpiece. This often leads to the formation of amorphous-crystalline structures with a high degree of defectiveness, with low cohesion and adhesion due to the mismatch between the physical and chemical properties of coatings compared to metal substrates. Among them, the most promising is detonation spraying, which is carried out with the help of a special detonation gun filled with an explosive gas mixture [8]. The essence of the detonation spraying method is very simple: sprayed powder particles are placed into a water-cooled tube (barrel) filled with an explosive gas mixture, and then the detonation is excited in the gas. Interacting with detonation products, the particles are heated and accelerated in the direction of the sprayed surface of the part, when they collide and form a dense and well adhered coating [9,10]. Each shot sputters 1–8 μm of coating thickness over an area roughly equal to the diameter of the barrel [11]. Obviously, the nature of detonation spraying—interaction with gaseous products of an exothermic chemical reaction—is close to flame spraying. However, in contrast to it, there is no strong heating of the part, which is related to the pulse character of the detonation spraying process [12].

One of the most perspective ways to improve the service properties of materials is the creation of surface layers with gradients in composition, structure, and properties [13]. The functionally graded material (FGM) differs from isotropic materials by the presence of gradient structure and properties (hardness, density, and thermal conductivity). These gradients are created by special processes and quantitatively controlled in order to significantly improve the properties of the final product [14]. The application of special, in particular, combined coatings on part surfaces often gives essentially better protection of the part surface. Industrial technologies for obtaining multilayer and adaptive coatings (with some properties varying in thickness) are of particular importance [15]. Technologies of laser cladding, arc cladding, gas-thermal spraying, etc., are successfully applied for the formation of a gradient of properties on the surface. The application of functionally graded coatings (FGC) allows one to combine high adhesive and cohesive properties with high surface hardness, wear, and corrosion resistance, thus creating products with unique characteristics. The structure of graded material in the simplest case is characterized by the anisotropic distribution of one component in the volume of the other in the two-phase system. In FGC spraying, the composition of the sprayed material changes layer by layer, due to which the properties change layer by layer [16,17]. From the point of view of cost of FGC production, relatively simple methods of plasma and gas-dynamic spraying are the most attractive. The gradient of properties in the coating applied by one method is created by changing the composition of the sprayed powder or the spraying conditions [18,19]. Detonation spraying, accompanied by chemical reactions, is a method of obtaining coatings, the structure, and the phase composition, which can vary within a wide range, and layered structures can be obtained that cannot be achieved by other methods [20].

The aim of the work is to study the influence of the technological parameters of detonation spraying on the formation of the microstructure and phase composition of titanium-based coatings. The research will focus on the development of a method for obtaining coatings with a gradient structure in which the titanium oxide/titanium ratio changes smoothly along the thickness of the coating and the content of titanium oxide compounds increases to the surface of the coatings. The results of this work will be recommended for use in the technology of obtaining composite coatings based on metals and ceramics by thermal spraying methods.

2. Materials and Methods

2.1. Materials

Technical titanium of BT1-0 grade was used as a substrate material. The composition of technical titanium of BT1-0 grade is given in Table 1. The samples were ground (using SiC paper with grain size from 100 to 2000). Before coating, the substrates were sandblasted with aluminum oxide with granularity of 100–200 µm and processed in an ultrasonic bath.

Table 1.

Chemical composition of technical titanium BT1-0 (weight percent).

The spherical titanium powder (CL42Ti) (Concept Laser, Lichtenfels, Germany) with a diameter of 15–45 μm, whose chemical composition corresponds to ASTM F67 and ASTM B348 standards, and whose phase composition consists of α-Ti, was used as a starting material.

2.2. Spraying Methods and Characteristics

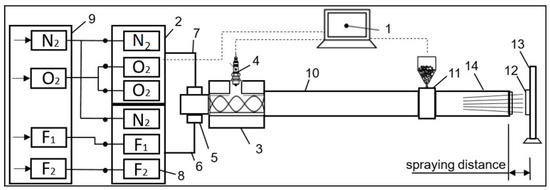

Coatings on the basis of titanium (Ti) were applied on a substrate VT1-0 by means of the detonation complex CCDS2000 (Computer Controlled Detonation Spraying, manufactured by LLC INOX, Novosibirsk, Russia) in the Research Center “Surface Engineering and Tribology” of Sarsen Amanzholov EKU. Detonation set consists of a detonation gun, powder dispensers, a gauge panel, a control unit, a cooling system, and a system of manipulation with both the gun and the part [21]. A schematic diagram of the detonation spraying process is shown in Figure 1.

Figure 1.

The CCDS2000 setup schematic diagram: 1—controlling computer; 2—distribution company; 3—mixing chamber; 4—spark plug; 5—barrel damper; 6—fuel line; 7—oxygen line; 8—gas valves; 9—gas distribution unit; 10—barrel indicated part; 11—powder feeder; 12—workpiece; 13—manipulator; and 14—the barrel muzzle, F1—acetylene, F2—propane–butane, O2—oxygen and N2—nitrogen.

Fuel–oxygen mixtures based on acetylene and propane were chosen as combustible mixtures for experiments. In the CCDS2000 setup, the volume of the explosive mixture in the detonation gun barrel and the oxygen/fuel ratio are controlled and can be varied. This allows varying the degree of thermal and chemical effects of detonation products on the particles of the sprayed powder. When obtaining titanium (Ti)-based coatings, the ratio of the O2/C2H2 mixture and the degree to which the barrel was filled with fuel–oxygen mixture varied. At O2/C2H2 mixture ratio = 1.026, acetylene + propane + oxygen was used as a fuel, and at O2/C2H2 mixture ratio = 1.856, the coating was obtained without propane (WP); in particular, acetylene + oxygen was used as a fuel (Table 2). As the amount of explosive mixture increases, the temperature at which the particles are heated as they move inside the barrel increases.

Table 2.

Technological parameters for obtaining Ti coatings.

On the basis of preliminary experiments according to Table 2, we developed a regime for obtaining coatings with a gradient structure, in which the ratio of titanium oxide/titanium changes smoothly along the thickness of the coating and the content of titanium oxide compounds increases to the surface of the coatings. Technological conditions for obtaining coatings with a gradient structure are shown in Table 3.

Table 3.

Technological parameters for obtaining coatings with a gradient structure.

The phase composition of titanium-based coatings was studied using an X-ray diffractometer X’PertPRO (Philips Corporation, Amsterdam, the Netherlands) with Cu-Kα radiation (λ = 1.5405 Å), voltage 40 kV and current 30 mA. The diffractograms were interpreted using the HighScore program, and measurements were taken in the range of 2θ equal to 20–90°, with a step of 0.02° and a counting time of 0.5 s/step. The coating structure was analyzed by scanning electron microscopy (SEM) using the microscope “Tescan Mira 3 LMU” (Tescan, Brno, Czech Republic). Electron backscattering (BSE) and element-distribution methods by X-ray energy dispersive spectroscopy (EDS), attached to the Tescan Mira 3 LMU scanning electron microscope (SEM), were used to obtain a transverse contrast image for the distribution of elements, respectively. Sliding wear resistance was evaluated by tribometer TRB3 (Anton Paar Srl, Peseux, Switzerland) using a standard-procedure “ball-disk” (international standards ASTM G 133-95 and ASTM G99), whereas counter-body, they used a ball-disk with a diameter of 6.0 mm, SiC coated steel, a load of 6 N, a linear speed 15 cm/s, a radius of curvature 5 mm, and a friction path 100 m [22]. The surface roughness of the titanium-based coatings (Ra) was estimated by means of the profilometer model 130 (JSC “Plant Proton”, Moscow, Russia). Using data of the obtained profile lines by arithmetic calculations, the coefficient of friction, volume, and rate of wear were defined. The microhardness of samples was measured according to GOST 9450-76 (ASTM E384-11) on the microtesting device Metolab 502 (METOLAB, Moscow, Russia), at loads on an indenter P = 1 N and an exposure time of 10 s [23,24].

3. Results and Discussion

Table 4 shows the roughness values of detonation coatings with a homogeneous and gradient structure. The Ra values (arithmetic mean deviation of the profile) of the coatings obtained with the volume of filling of the detonation borehole 48% and 64% without and with propane were in the range from 3.76 μm to 4.64 μm. The roughness of the BT1-0 substrate after sandblasting showed values of Ra = 5.39 μm. The coating that has a gradient structure has a higher roughness value Ra = 4.97 μm. This is due to a gradual change in the structure and composition of the coatings across the cross section of the sample from the metal phase to the metal oxide compound phase (Figures 6–8). As the volume of filling the detonation bore with the fuel–oxygen mixture increases, the explosion energy (temperature) increases; the titanium powder particles melt; and, as a result of interaction with oxygen, a matrix of oxide compounds is formed in which titanium powder particles become conglomerates (Figure 4). The absence of propane as a detonating gas in the spraying process promotes the formation of oxide compounds, and the conglomeration of titanium powder particles is reduced (Figure 5). Thus, in the case of detonation spraying of titanium, two types of structure arise: the structure due to incomplete consolidation of solid particles into the coating, and the structure associated with the course of chemical reactions and localized in the areas of coatings formed by reaction products. Due to the difference in structures, pores can form and the roughness of the coatings increases [25].

Table 4.

Roughness values of coatings.

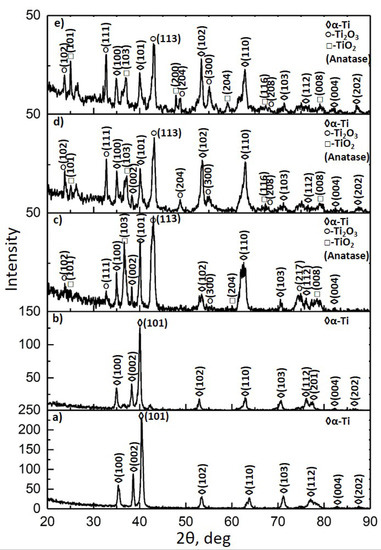

The phase composition of the titanium (Ti) powder is shown in Figure 2a. On the diffractogram, the peaks appearing at about 35°, 38°, and 40° were identified as Ti crystal planes corresponding to (100), (002), and (101) [26]. The following phases were recorded in the coatings Ti, TiO2 (anatase), and Ti2O3. In the coatings, the intensity of the Ti diffraction peaks decreased compared to the original powder. The decrease in the intensity of Ti diffraction peaks is related to its oxidation process. As the fill volume of the detonation gun barrel increases (Ti2 and Ti3), the temperature during sputtering increases; as a result, the titanium powder is oxidized and titanium oxide phases are formed (Figure 2c–e).

Figure 2.

X-ray diffractograms of powder (a) and detonation coatings: Ti1 (b), Ti2 (c), Ti3 (d), and gradient (e).

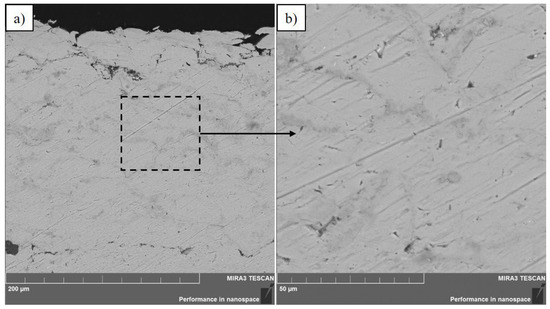

The study of the microstructure of the detonation coating cross section showed the formation of a layered structure with a thickness of 100–300 µm (Figure 3, Figure 4, Figure 5 and Figure 6). On the microstructure of the sample cross section at the coating–substrate interface, no delamination and shearing of the coatings is observed. A homogeneous coating structure is observed in the T1 sample (Figure 3). According to the results of the X-ray phase analysis, the coating consists of titanium. Based on these results, it can be said that the reaction behavior of titanium can be controlled by detonation spraying.

Figure 3.

Cross-sectional microstructure of Ti1 coating. Microstructure of ×1000 (a) and ×3000 (b).

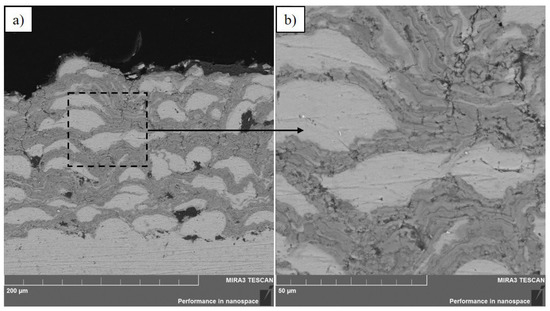

Figure 4 shows the cross-sectional microstructure of the Ti2 coating. Judging by the contrast, the particles are very similar to the typical structure of the substrate and have a dense structure, and the dark areas are a non-compact structure with some irregularly shaped micropores. These dense dark bands were formed as a result of the oxidation of Ti powder particles caused by changes in the technological parameters of detonation spraying. As we know, the layered structure is a typical microstructure for detonation-sprayed coatings not achievable by other methods [27]. When the volume of explosive mixture is increased up to 64%, pores appear in the coating in the zones formed by interaction products. Unmelted titanium powder particles form conglomerates in the coating.

Figure 4.

Cross-sectional microstructure of Ti2 coating. Microstructure of ×1000 (a) and ×3000 (b).

Figure 5 shows the cross-sectional microstructure of the Ti3 coating. The microstructure of the coatings changes when switching to the mode with O2/C2H2 ratio = 1.856 (mode without propane). The layered structure of the coatings contains fewer conglomerates of titanium powder particles. It follows from the obtained data that the content of titanium oxide compounds in the composition of the coatings increases with increasing volume of the explosive mixture and the O2/C2H2 ratio, i.e., with increasing particle temperature. This statement agrees well with the results of the X-ray phase analysis (Figure 2d).

Figure 5.

Cross-sectional microstructure of Ti3 coating. Microstructure of ×1000 (a) and ×3000 (b).

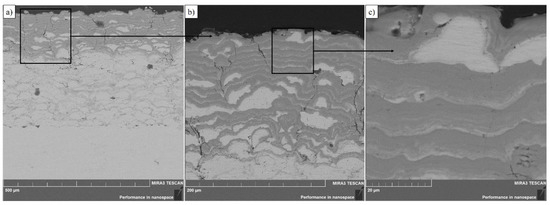

Figure 6 shows the cross-sectional microstructure of the coatings that has a gradient structure in which the ratio of titanium to titanium oxides decreases to the surface layers of the coatings. The technological mode of obtaining the gradient structure of the coatings was determined on the basis of the T1–T3 results. In the case of the interaction of titanium with an explosive mixture, the characteristic structural elements of detonation coatings are alternating layers with different chemical and phase compositions. It is worth noting that a promising direction in the synthesis of wear-resistant coatings is the creation of gradient compositions whose high functional characteristics are determined by the composition, application conditions, and structural state.

Figure 6.

Microstructure of the cross section of the coating with gradient structure. Microstructure of ×250 (a), ×3000 (b), and ×5000 (c).

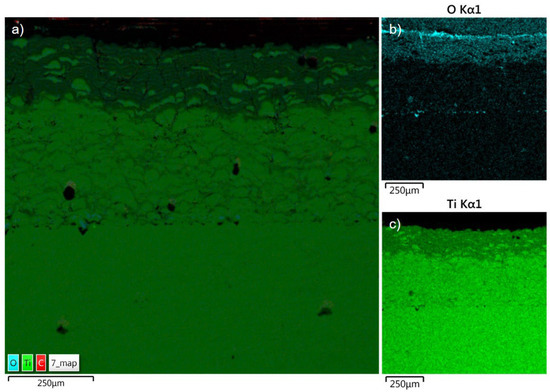

Figure 7 shows the results of the EDS cross-sectional analysis of the coatings. The surface layers of the coatings contain large amounts of oxygen. These results agree with the previously obtained X-ray diffraction analysis data. The gradient distribution of the coating elements can be clearly seen in Figure 6 and Figure 8.

Figure 7.

EDS analysis by light of the cross section of the coating having a gradient structure: (a) microphotograph, (b) O, and (c) Ti.

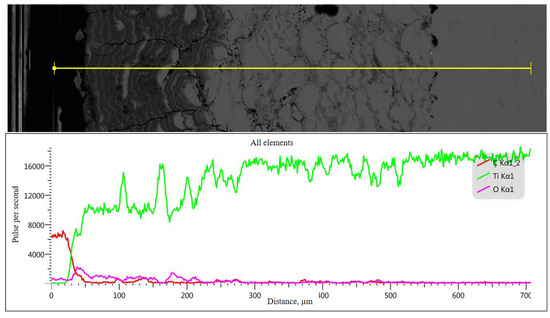

EDS analysis along the gradient-structured coating line showed that the light, curved bands consisted mainly of Ti, while the dark regions consisted mainly of Ti and O. Examination of the microstructure showed that the shape of the white, curved bands differed from that of the microstructure of the original Ti particles, demonstrating that significant plastic deformation and oxidation of the Ti powder particles occurred during the formation of the Ti coating. A small number of pores and cracks are observed at the interface between the white, curved strips and the gray matrix. In [28,29], it is reported that the coatings obtained by detonation spraying have a wave-like porous structure.

Figure 8.

EDS analysis along the cross-sectional line of the coating that has a gradient structure.

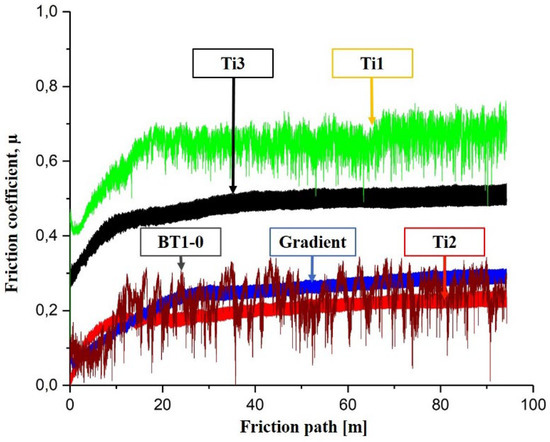

Tribological tests of the coatings obtained under different regimes of detonation spraying were carried out. The tribological characteristics of the titanium-based coatings were evaluated by the intensity and volume of wear, as well as the friction coefficient. Figure 9 shows the results of the tribological tests of the coatings. The results of the tribological tests of the coatings showed that the propane content during detonation spraying significantly affects the wear resistance of the coatings. So, as the detonation gas propane content decreases, the microhardness value increases four times, and the reason for the change in the values of the tribological parameters is most likely the heterogeneity of the coating surface structure (Table 4).

Figure 9.

Results of tribological tests of coatings obtained by detonation spraying.

Table 5 presents data on the phase structure and mechanical and tribological characteristics of the detonation coatings. Table 5 clearly shows the change in the hardness and the tribological properties of the coatings. It can be argued that the application of the obtained coatings can provide sufficiently good physical-mechanical and operational properties for products made of titanium.

Table 5.

Experimental data on the phase composition and mechanical and tribological characteristics of the coating.

4. Conclusions

By varying the technological parameters of detonation spraying, it is possible to obtain coatings of metal oxide compounds with a gradient structure using chemical reactions occurring during spraying. It is shown that the phase composition of coatings can significantly change relative to the initial titanium powder during detonation spraying due to the interaction of powder particles with the gaseous components of the spraying atmosphere. By varying the spraying parameters, it is possible to control the reaction behavior of titanium and create conditions for the synthesis of titanium oxide compounds. Under spraying conditions at O2/C2H2 ratios equal to 1.026, the Ti phase in the coatings was preserved and the elemental composition coincided with the initial powder. The content of the titanium oxide compounds in the composition of the coatings increased when the volume of the explosive mixture was increased to 64% and the O2/C2H2 ratio = 1.856, i.e., when the temperature of the particles was increased. It has been established that for the formation of strengthening phases, such as titanium oxides, the necessary condition is the minimization or complete absence of propane content as a detonating gas in the process of spraying. It was determined that in the absence of propane in the explosive mixture of acetylene/oxygen, the microhardness of the coating increased 3–4 times.

Author Contributions

A.K. and Z.S. designed the experiments; K.T. and D.B. performed the experiments; Y.K., M.Y. and S.A. analyzed the data; A.K., D.B., M.M. and Z.S. wrote, reviewed, and edited the paper. All authors have read and agreed to the published version of the manuscript.

Funding

This research has been funded by the Science Committee of the Ministry of Education and Science of the Republic of Kazakhstan (Grant No. AP08857800).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare that there is no conflict of interest regarding the publication of this manuscript.

References

- Zhao, W.; Liu, C.; Dong, L.; Wang, Y. Effects of arc spray process parameters on corrosion resistance of Ti coatings. J. Therm. Spray Technol. 2009, 18, 702–707. [Google Scholar] [CrossRef]

- Kim, K.; Kuroda, S.; Watanabe, M.; Huang, R.; Fukanuma, H.; Katanoda, H. Comparison of oxidation and microstructure of warm-sprayed and cold-sprayed titanium coatings. J. Therm. Spray Technol. 2012, 21, 550–560. [Google Scholar] [CrossRef]

- Rakhadilov, B.; Baizhan, D. Creation of Bioceramic Coatings on the Surface of Ti–6Al–4V Alloy by Plasma Electrolytic Oxidation Followed by Gas Detonation Spraying. Coatings 2021, 11, 1433. [Google Scholar] [CrossRef]

- Dinu, M.; Pana, I.; Scripca, P.; Sandu, I.G.; Vitelaru, C.; Vladescu, A. Improvement of CoCr Alloy Characteristics by Ti-Based Carbonitride Coatings Used in Orthopedic Applications. Coatings 2020, 10, 495. [Google Scholar] [CrossRef]

- Roman’kov, S.E.; Sagdoldina, Z.B.; Kaloshkin, S.D.; Kaevitser, E.V. Fabrication of Ti-Al composite coatings by the mechanical alloying method. Phys. Met. Metallogr. 2008, 106, 67–75. [Google Scholar] [CrossRef]

- Rakhadilov, B.K.; Baizhan, D.R.; Sagdoldina, Z.B.; Buitkenov, D.B.; Maulet, M. Phase composition and structure of composite Ti/HA coatings synthesized by detonation spraying. AIP Conf. Proc. 2020, 2297, 020022. [Google Scholar] [CrossRef]

- Manivasagam, V.K.; Popat, K.C. In vitro investigation of hemocompatibility of hydrothermally treated titanium and titanium alloy surfaces. ACS Omega 2020, 5, 8108–8120. [Google Scholar] [CrossRef]

- Rakhadilov, B.K.; Sagdoldina, Z.B.; Baizhan, D.R.; Zhurerova, L.G.; Yeskermessov, D.K.; Kalitova, A.A.; Smaiylova, M. Obtaining of hydroxyapatite coatings on A titanium substrate by detonation-gas spraying. Eurasian Phys. Tech. J. 2021, 18, 30–36. [Google Scholar] [CrossRef]

- Biasetto, L.; Elsayed, H. Sphene silicate ceramic coatings on cpTi substrates: Process upgrade. Surf. Coat. Technol. 2017, 321, 416–424. [Google Scholar] [CrossRef]

- Kim, K.; Watanabe, M.; Kawakita, J.; Kuroda, S. Grain refinement in a single titanium powder particle impacted at high velocity. Scr. Mater. 2008, 59, 768–771. [Google Scholar] [CrossRef]

- Rakhadilov, B.; Buitkenov, D.; Idrisheva, Z.; Zhamanbayeva, M.; Pazylbek, S.; Baizhan, D. Effect of Pulsed-Plasma Treatment on the Structural-Phase Composition and Tribological Properties of Detonation Coatings Based on Ti–Si–C. Coatings 2021, 11, 795. [Google Scholar] [CrossRef]

- Rakhadilov, B.; Kakimzhanov, D.; Baizhan, D.; Muslimanova, G.; Pazylbek, S.; Zhurerova, L. Comparative Study of Structures and Properties of Detonation Coatings with α-Al2O3 and γ-Al2O3 Main Phases. Coatings 2021, 11, 1566. [Google Scholar] [CrossRef]

- Klyui, N.I.; Chornyi, V.S.; Zatovsky, I.V.; Tsabiy, L.I.; Buryanov, A.A.; Protsenko, V.V.; Gryshkov, O. Properties of gas detonation ceramic coatings and their effect on the osseointegration of titanium implants for bone defect replacement. Ceram. Int. 2021, 47, 25425–25439. [Google Scholar] [CrossRef]

- Łatka, L.; Pawłowski, L.; Winnicki, M.; Sokołowski, P.; Małachowska, A.; Kozerski, S. Review of functionally graded thermal sprayed coatings. Appl. Sci. 2020, 10, 5153. [Google Scholar] [CrossRef]

- Rakhadilov, B.; Maulet, M.; Abilev, M.; Sagdoldina, Z.; Kozhanova, R. Structure and Tribological Properties of Ni–Cr–Al-Based Gradient Coating Prepared by Detonation Spraying. Coatings 2021, 11, 218. [Google Scholar] [CrossRef]

- Rakhadilov, B.; Tyurin, Y.; Kakimzhanov, D.; Baizhan, D.; Kolisnichenko, O.; Zhurerova, L. Deposition of duplex Cr3 C2-NiCr coatings on steel using a combined technique of gas detonation spraying and pulse-plasma treatment. High Temp. Mater. Process. 2021, 25, 25–37. [Google Scholar] [CrossRef]

- Mamaeva, A.; Kenzhegulov, A.; Panichkin, A.; Alibekov, Z.; Wieleba, W. Effect of Magnetron Sputtering Deposition Conditions on the Mechanical and Tribological Properties of Wear-Resistant Titanium Carbonitride Coatings. Coatings 2022, 12, 193. [Google Scholar] [CrossRef]

- Kawakita, J.; Kuroda, S.; Fukushima, T.; Kodama, T. Corrosion resistance of HastelloyC coatings formed by an improved HVOF thermal spraying process. Mater. Trans. 2003, 44, 253–258. [Google Scholar] [CrossRef]

- Kenzhegulov, A.; Mamaeva, A.; Panichkin, A.; Alibekov, Z.; Kshibekova, B.; Bakhytuly, N.; Wieleba, W. Comparative Study of Tribological and Corrosion Characteristics of TiCN, TiCrCN, and TiZrCN Coatings. Coatings 2022, 12, 564. [Google Scholar] [CrossRef]

- Rahmani, R.; Antonov, M.; Kollo, L. Wear resistance of (Diamond-Ni)-Ti6Al4V gradient materials prepared by combined selective laser melting and spark plasma sintering techniques. Adv. Tribol. 2019, 2019, 5415897. [Google Scholar] [CrossRef]

- Baizhan, D.R.; Rakhadilov, B.K.; Zhurerova, L.G.; Torebek, K. Preparation of bio-ceramic composite coatings on Ti6Al4V titanium alloy by gas-detonation spraying. Bull. Karaganda Univ. 2022, 1, 89–98. [Google Scholar] [CrossRef]

- Rahadilov, B.K.; Zhurerova, L.G.; Sagdoldina, Z.B.; Kenesbekov, A.B.; Bayatanova, L.B. Morphological changes in the dislocation structure of structural steel 20GL after electrolytic-plasma hardening of the surface. J. Surf. Investig. 2021, 15, 408–413. [Google Scholar] [CrossRef]

- Popova, N.A.; Zhurerova, L.G.; Nikonenko, E.L.; Skakov, M.K. Effect of plasma electrolytic nitrocarburizing on phase composition of 0.3C-1Mn-1Si-fe steel. Inorg. Mater. Appl. Res. 2017, 8, 130–135. [Google Scholar] [CrossRef]

- Rakhadilov, B.; Skakov, M.; Miniyzov, A.; Kenesbekov, A. Hydrogen and deuterium storage in tungsten when irradiation with plasma beam. In Proceedings of the METAL 2018—27th International Conference on Metallurgy and Materials, Conference Proceedings, Brno, Czech Republic, 23–25 May 2018; pp. 1216–1221. [Google Scholar]

- Tu, R.; Min, R.; Yang, M.; Yuan, Y.; Zheng, L.; Li, Q.; Ji, B.; Zhang, S.; Yang, M.; Shi, J. Overcoming the Dilemma between Low Electrical Resistance and High Corrosion Resistance Using a Ta/(Ta,Ti)N/TiN/Ti Multilayer for Proton Exchange Membrane Fuel Cells. Coatings 2022, 12, 689. [Google Scholar] [CrossRef]

- Chen, L.; Komasa, S.; Hashimoto, Y.; Hontsu, S.; Okazaki, J. Vitro and in vivo osteogenic activity of titanium implants coated by pulsed laser deposition with a thin film of fluoridated hydroxyapatite. Int. J. Mol. Sci. 2018, 19, 1127. [Google Scholar] [CrossRef]

- Buitkenov, D.; Rakhadilov, B.; Erbolatuly, D.; Sagdoldina, Z. Reserach of the mechanic-tribological characteristics of Ti3SiC2/TiC coatings after annealing. Eurasian J. Phys. Funct. Mater. 2020, 4, 86–89. [Google Scholar] [CrossRef]

- Ulianitsky, V.Y.; Batraev, I.S.; Shtertser, A.A.; Dudina, D.V.; Bulina, N.V.; Smurov, I. Detonation spraying behaviour of refractory metals: Case studies for Mo and Ta-based powders. Adv. Powder Technol. 2018, 29, 1859–1864. [Google Scholar] [CrossRef]

- Rakhadilov, B.K.; Sagdoldina, Z.B.; Kylyshkanov, M.K.; Buitkenov, D.B. Method of Obtaining a Wear-Resistant Coating. KZ Utility Model Patent No. 6659; Application No. 03.08.21, 11 December 2021. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).